Patents

Literature

50results about How to "Address is challenge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

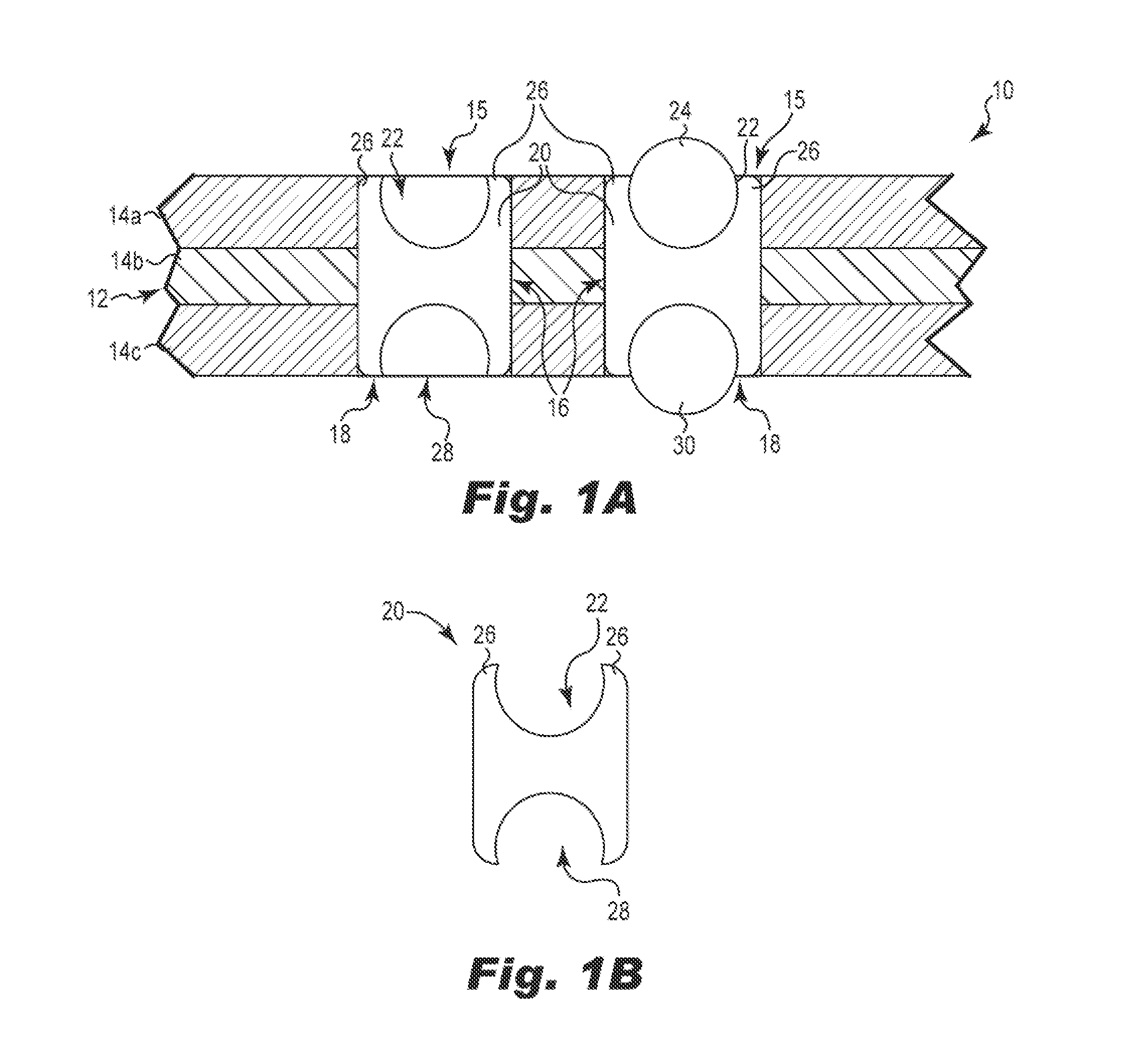

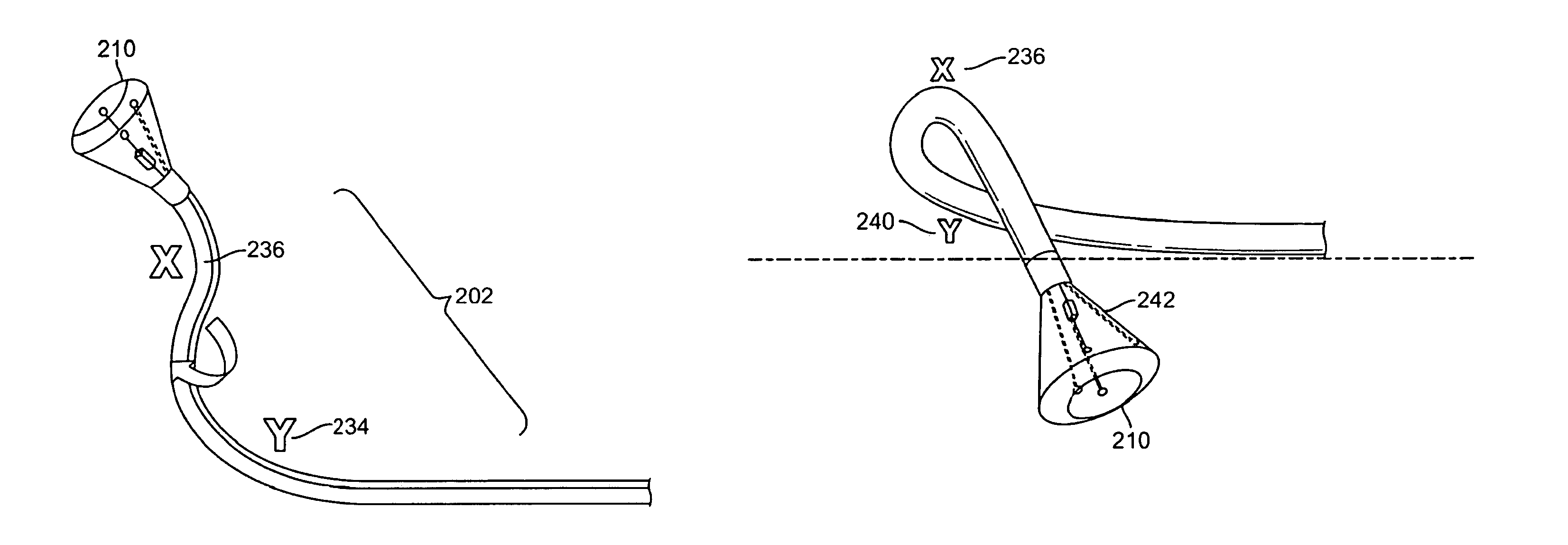

Complex shape steerable tissue visualization and manipulation catheter

ActiveUS20080275300A1Available spaceLong period of timeEndoscopesSurgical instrument detailsBiomedical engineeringCatheter device

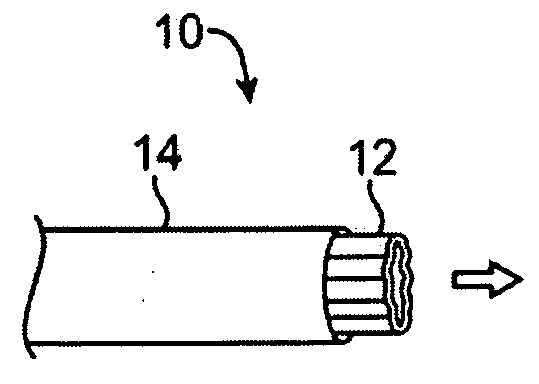

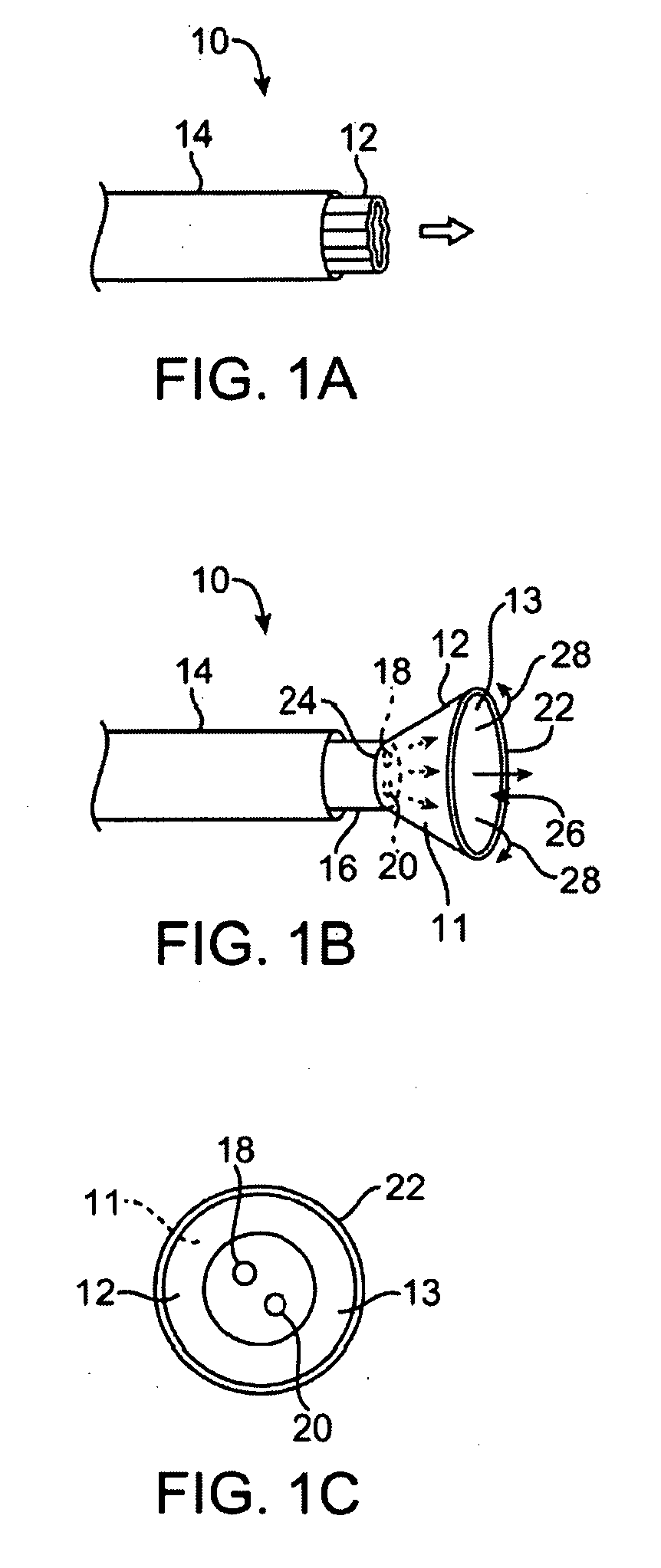

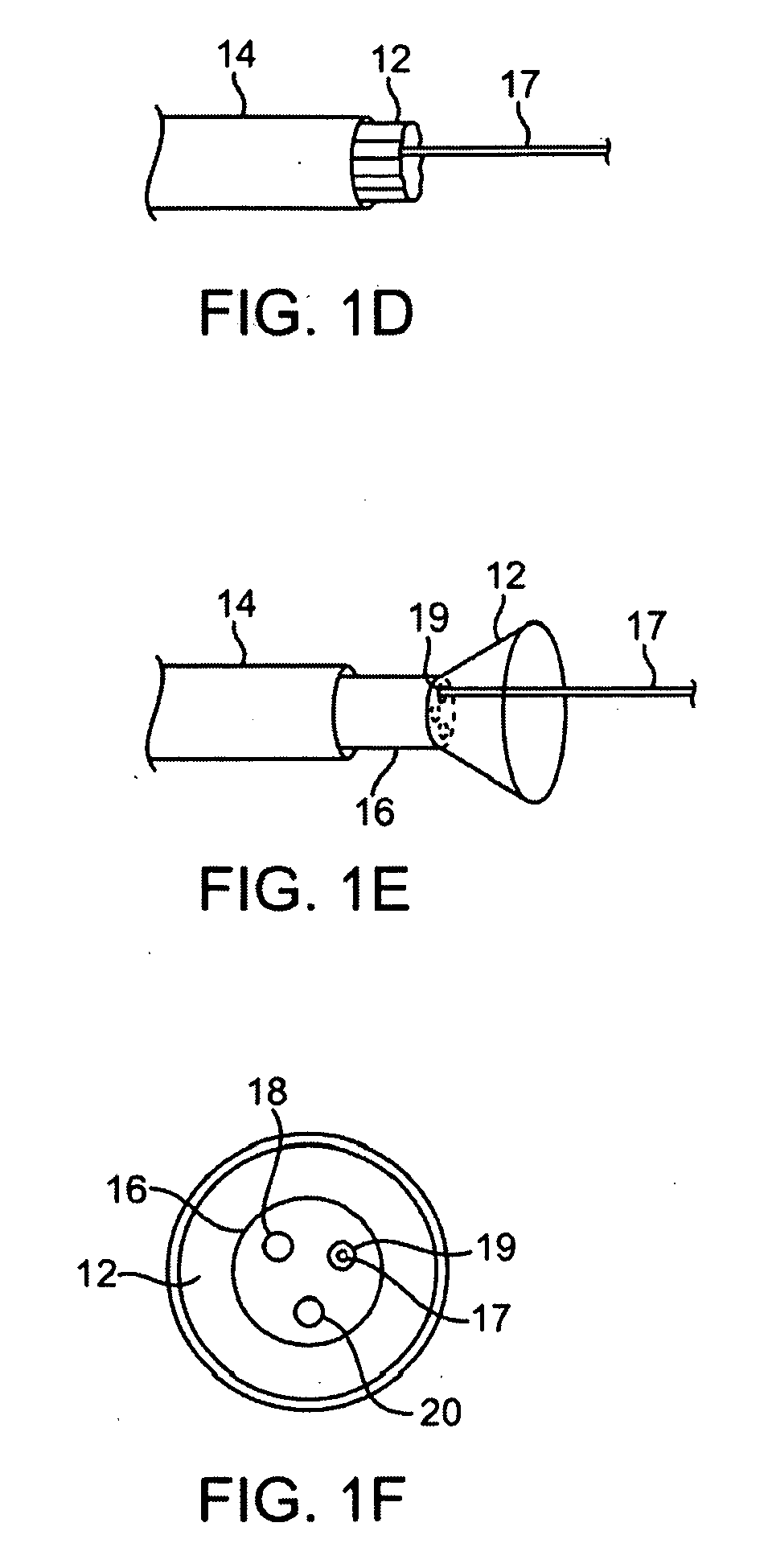

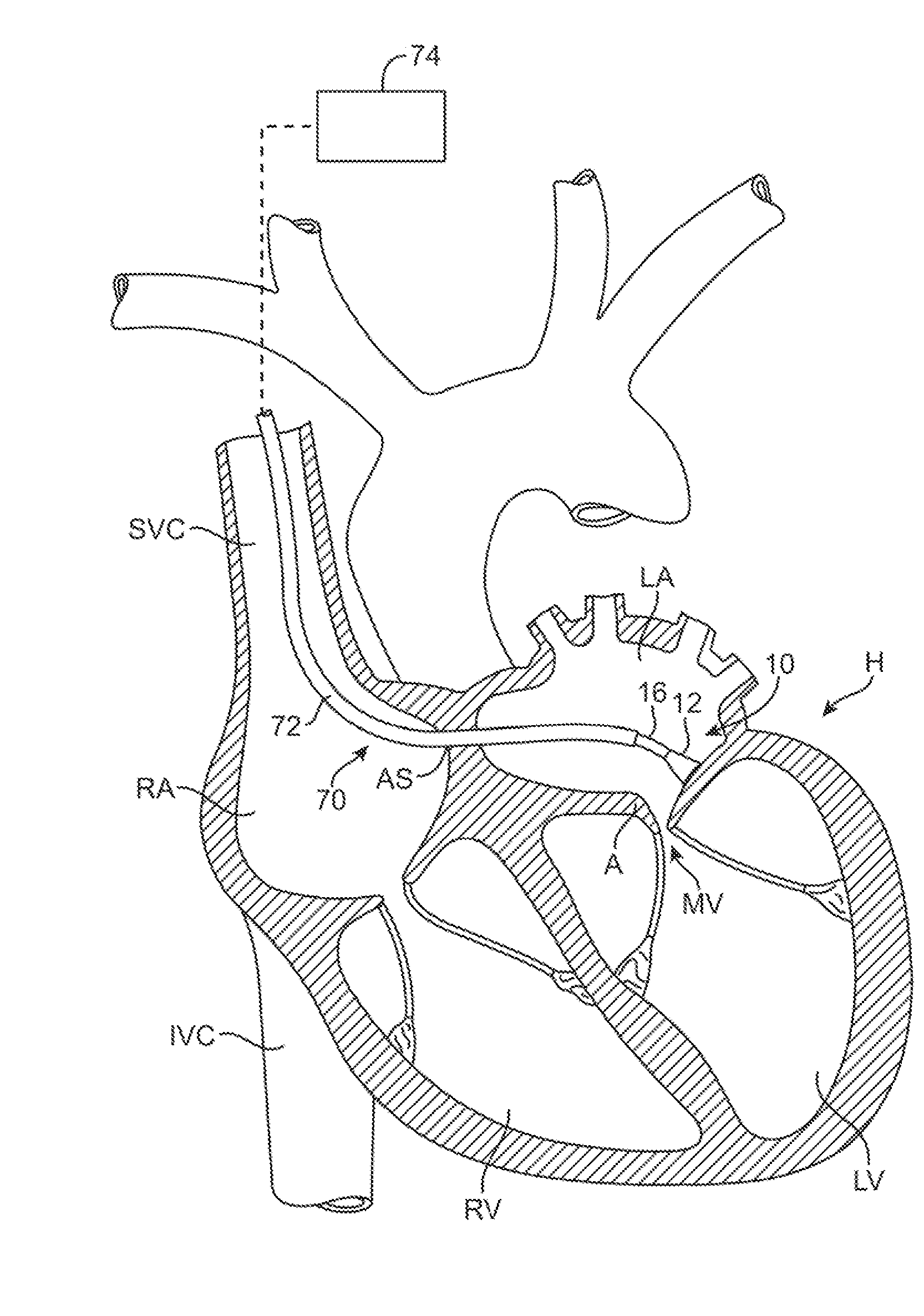

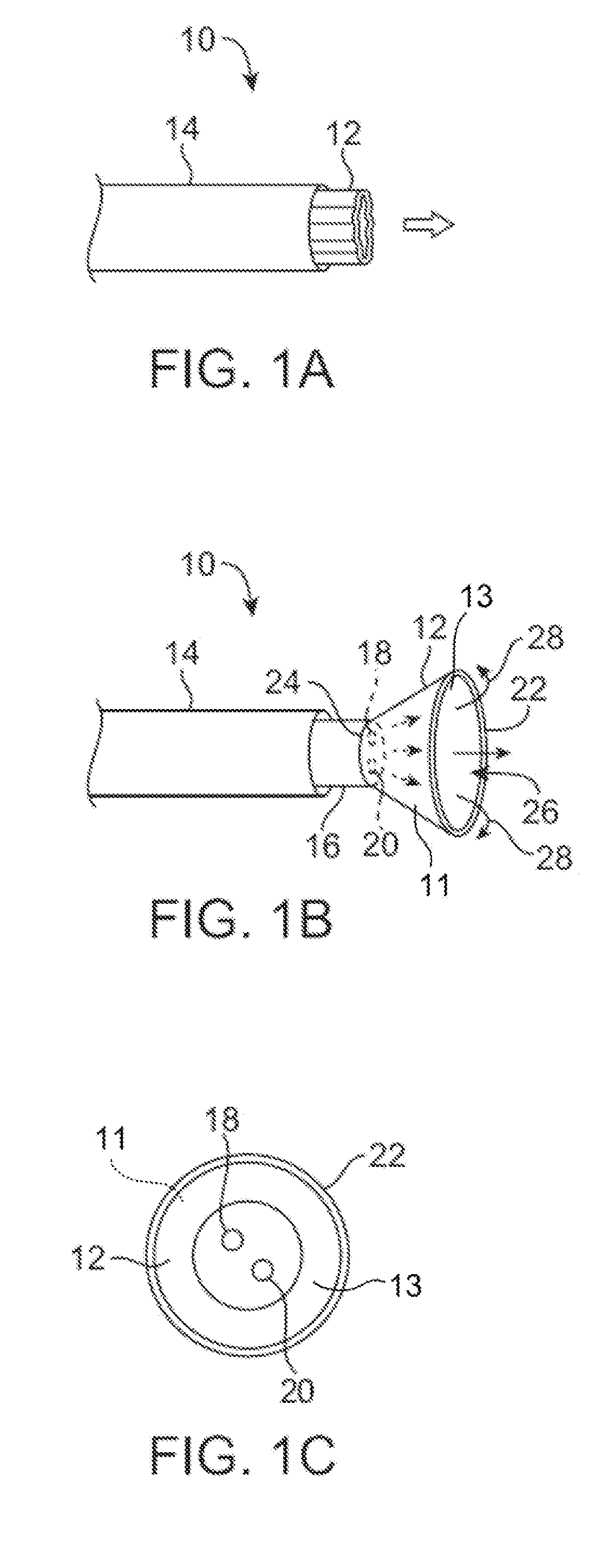

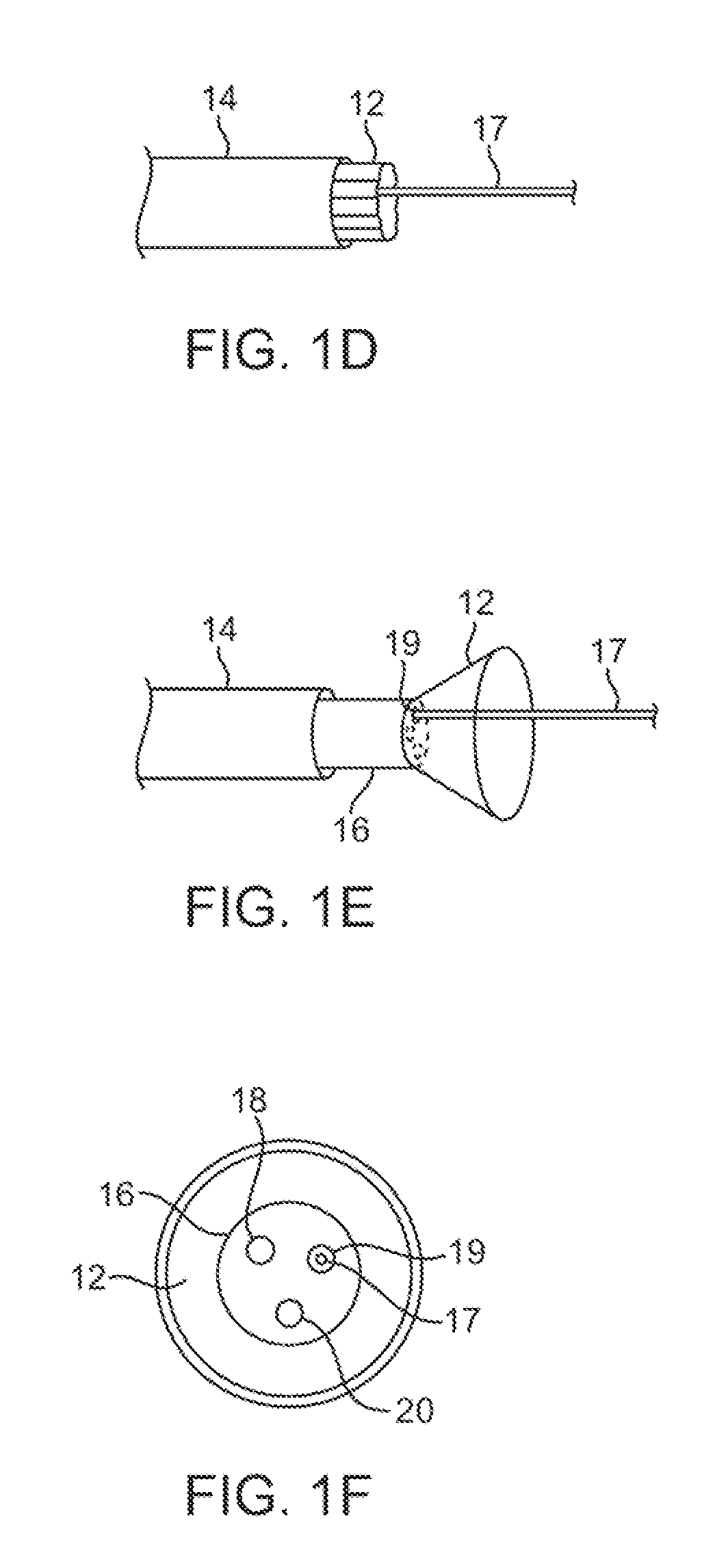

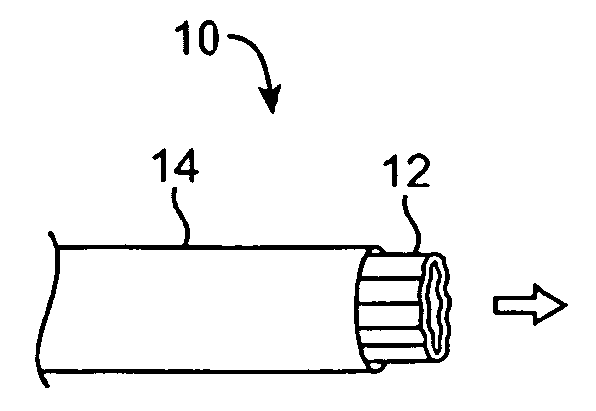

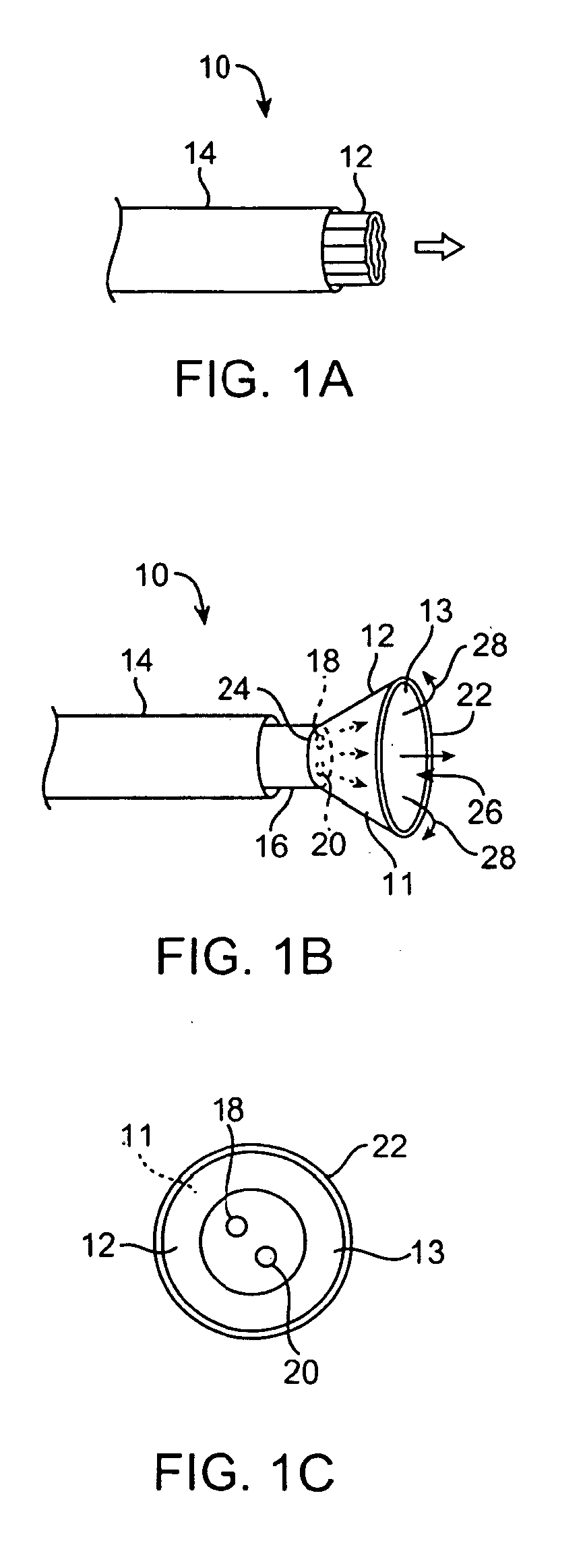

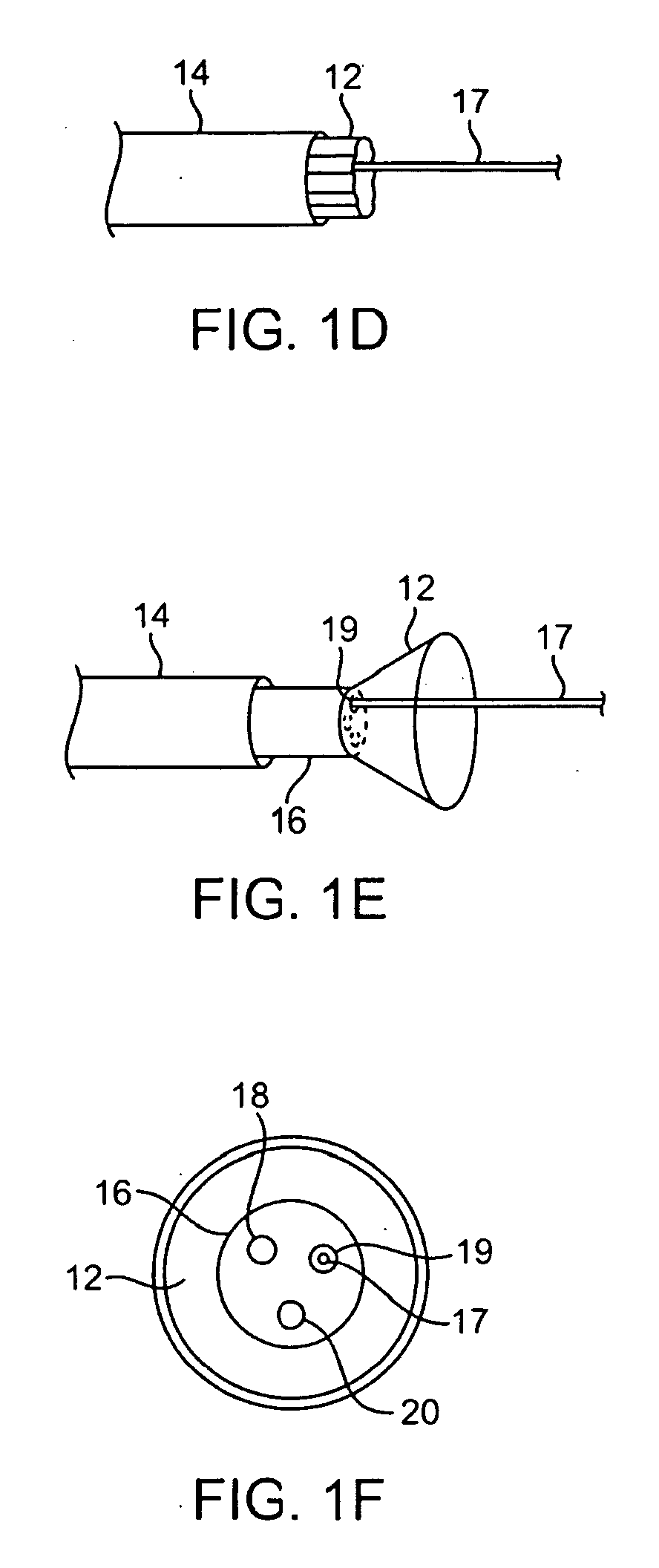

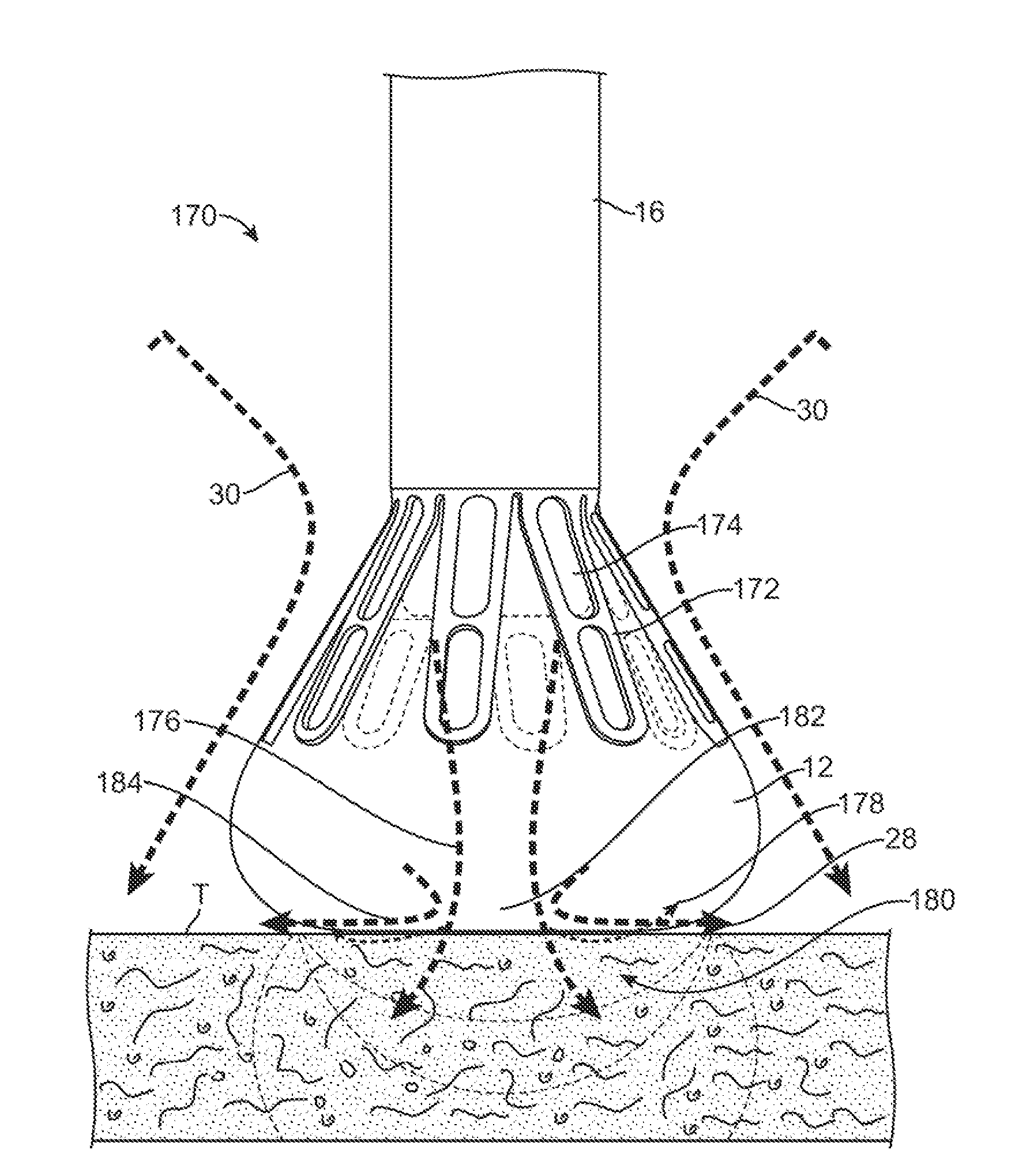

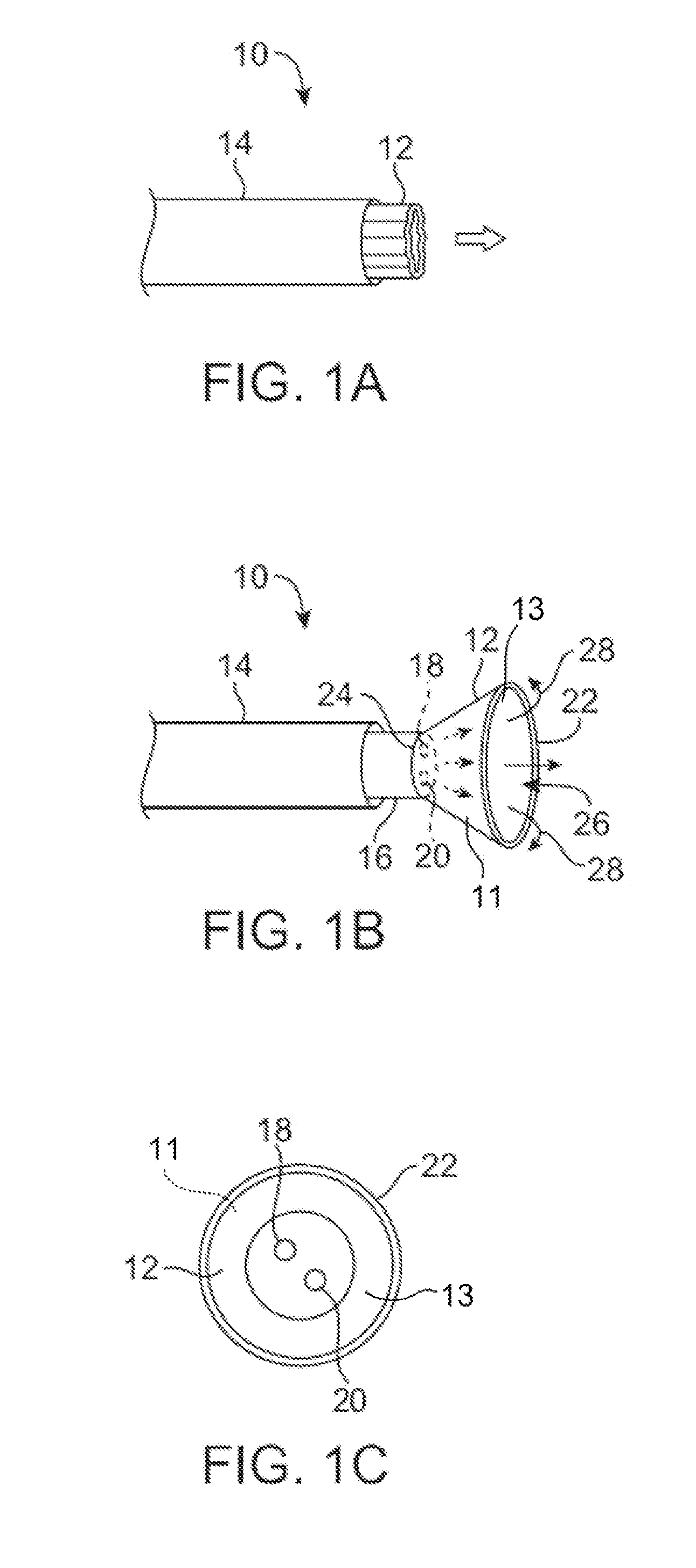

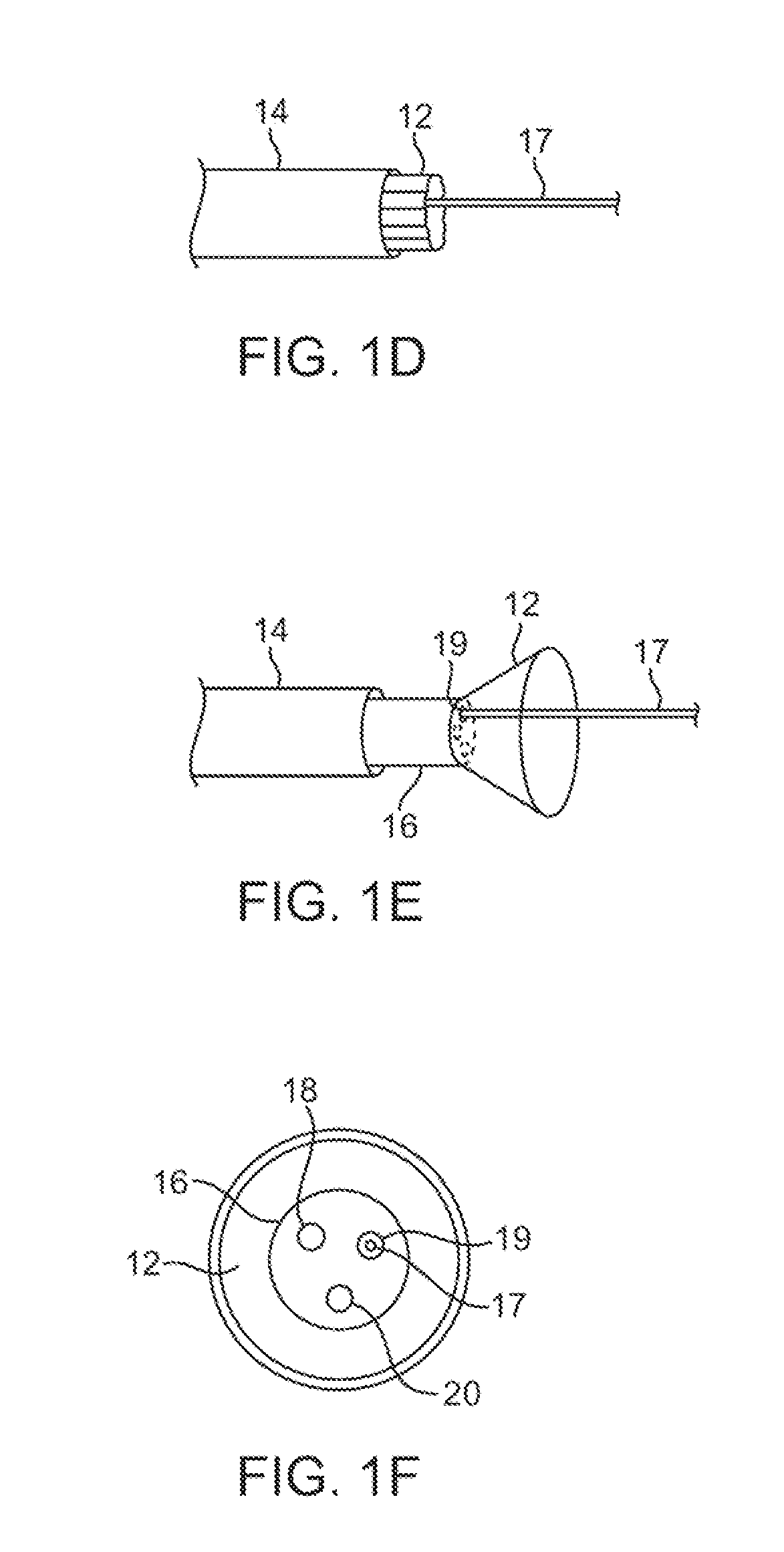

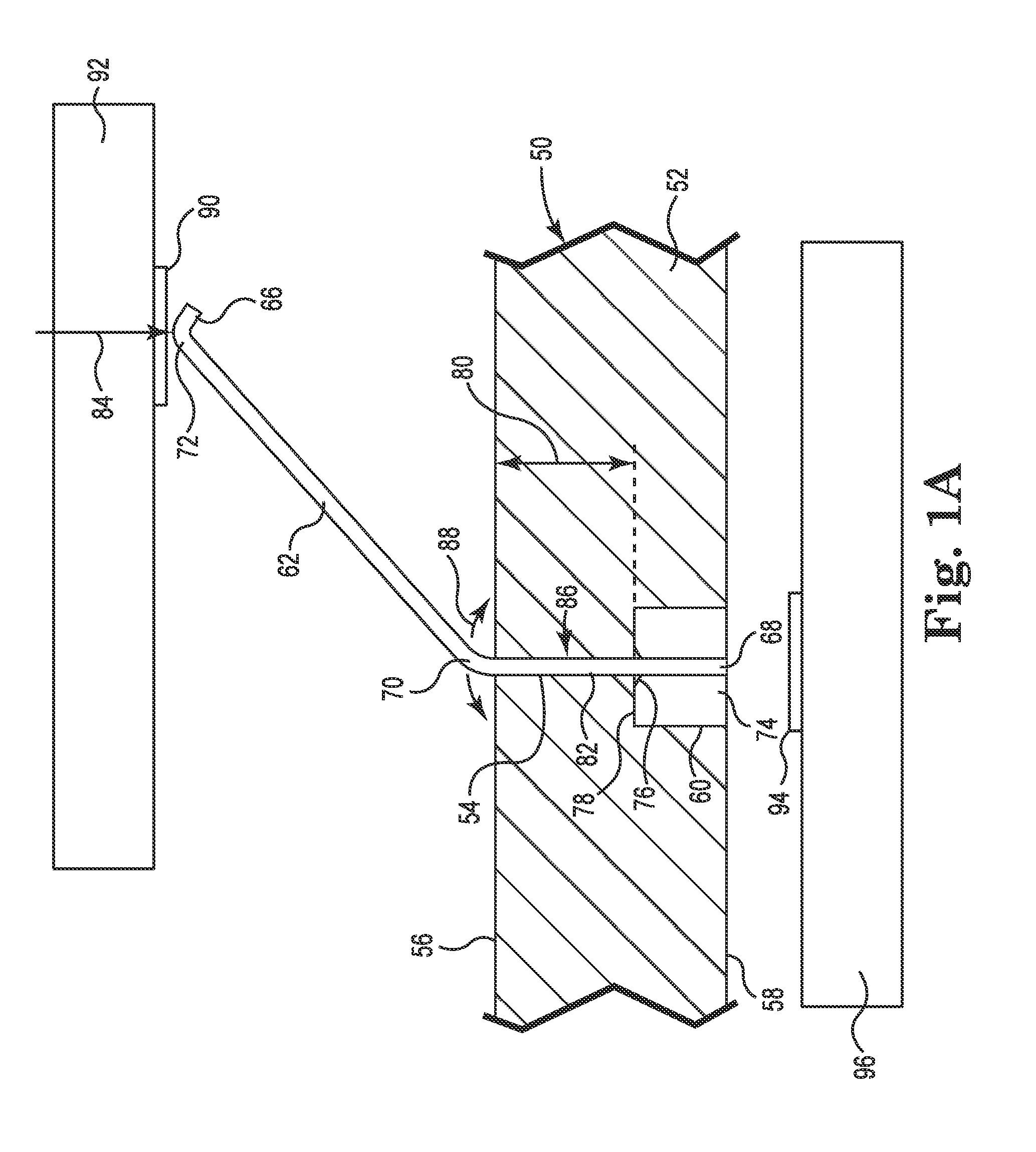

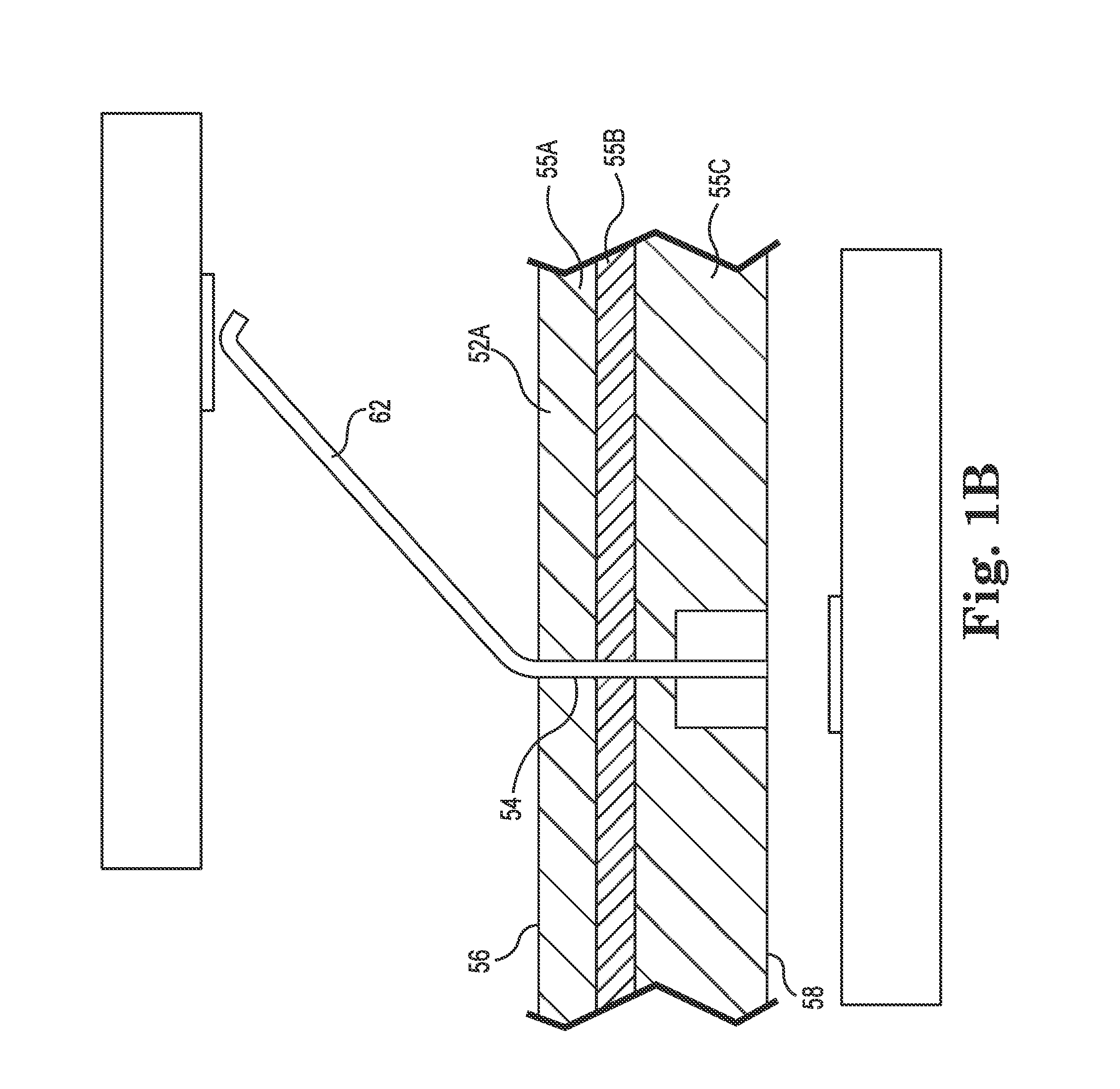

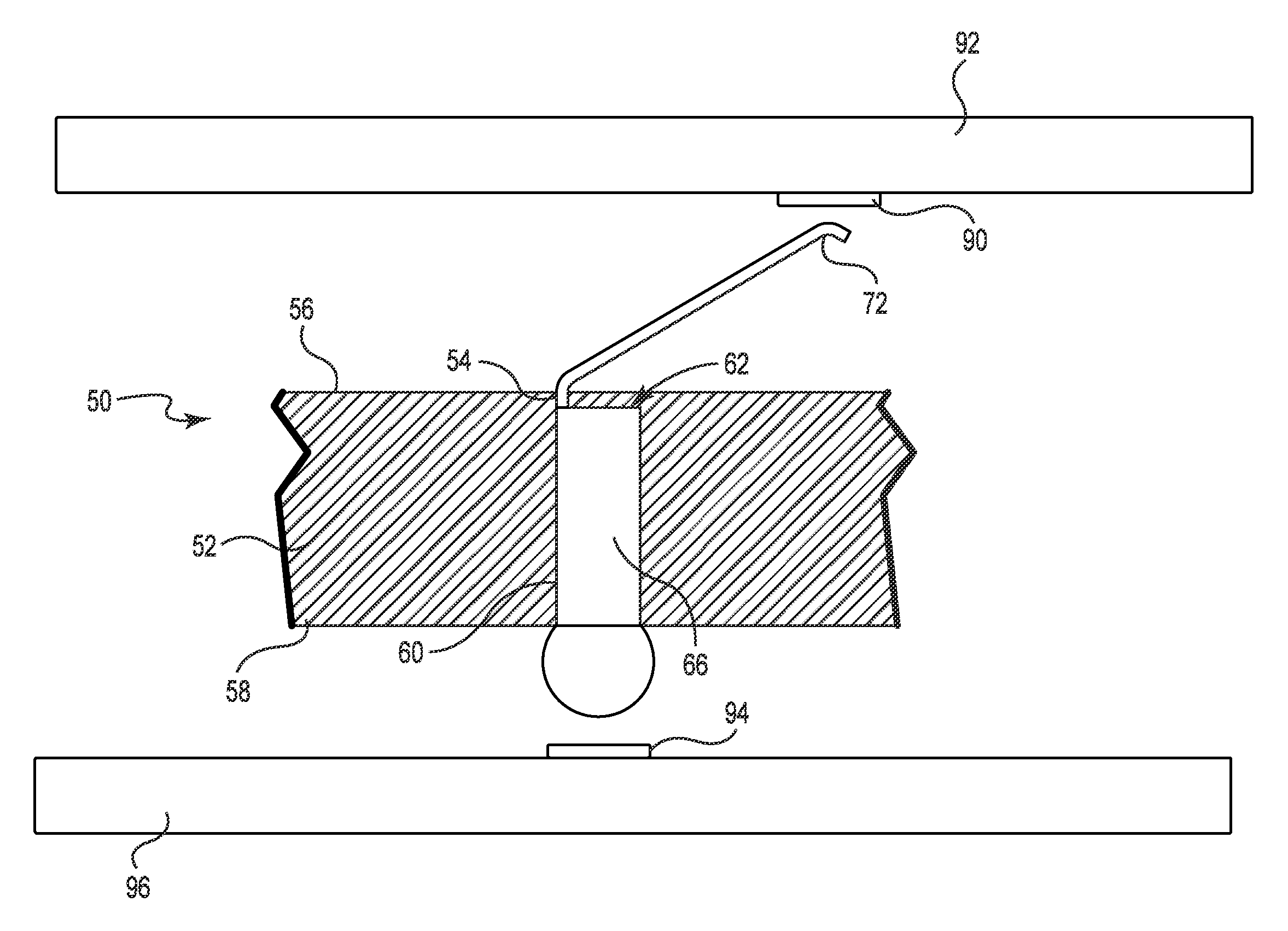

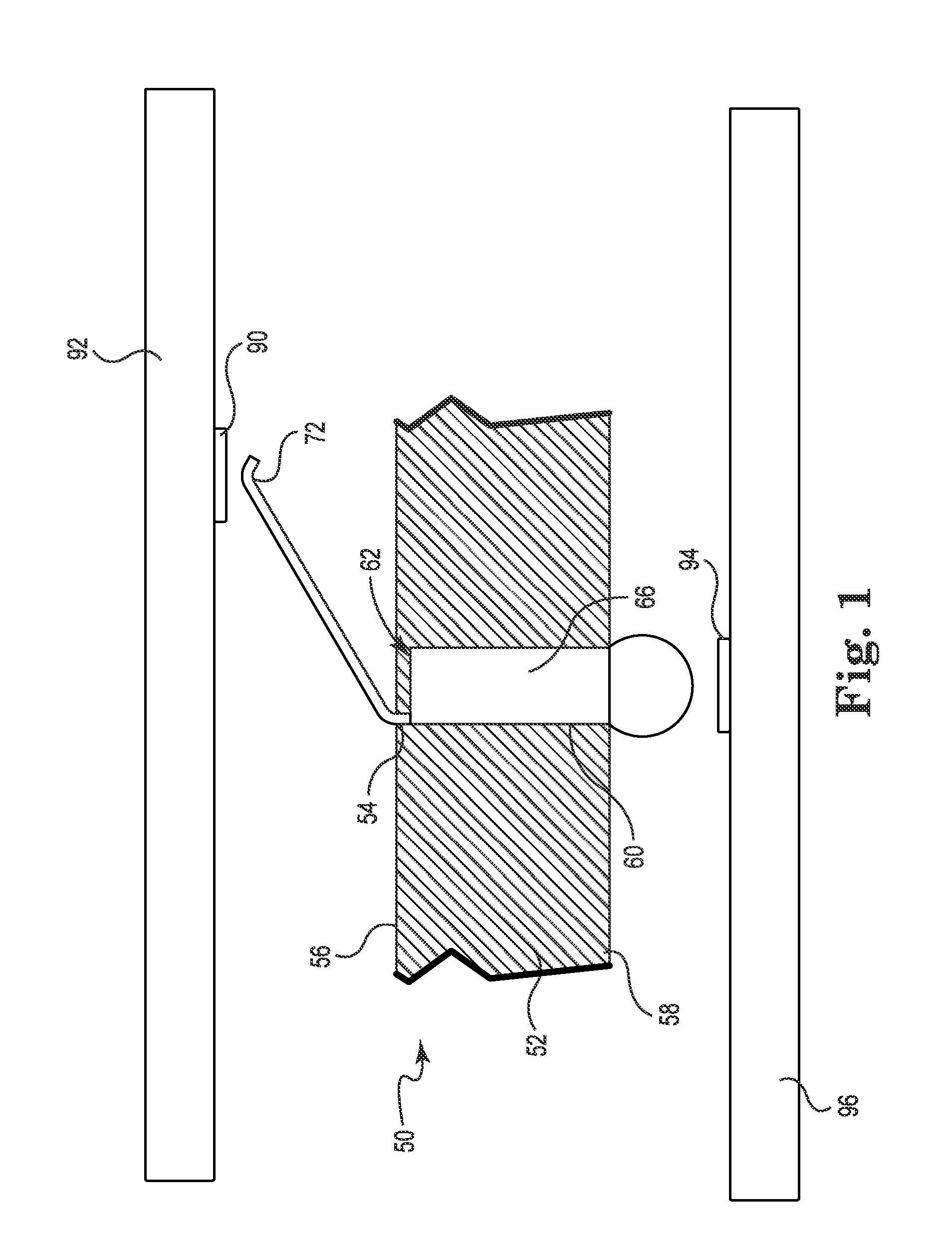

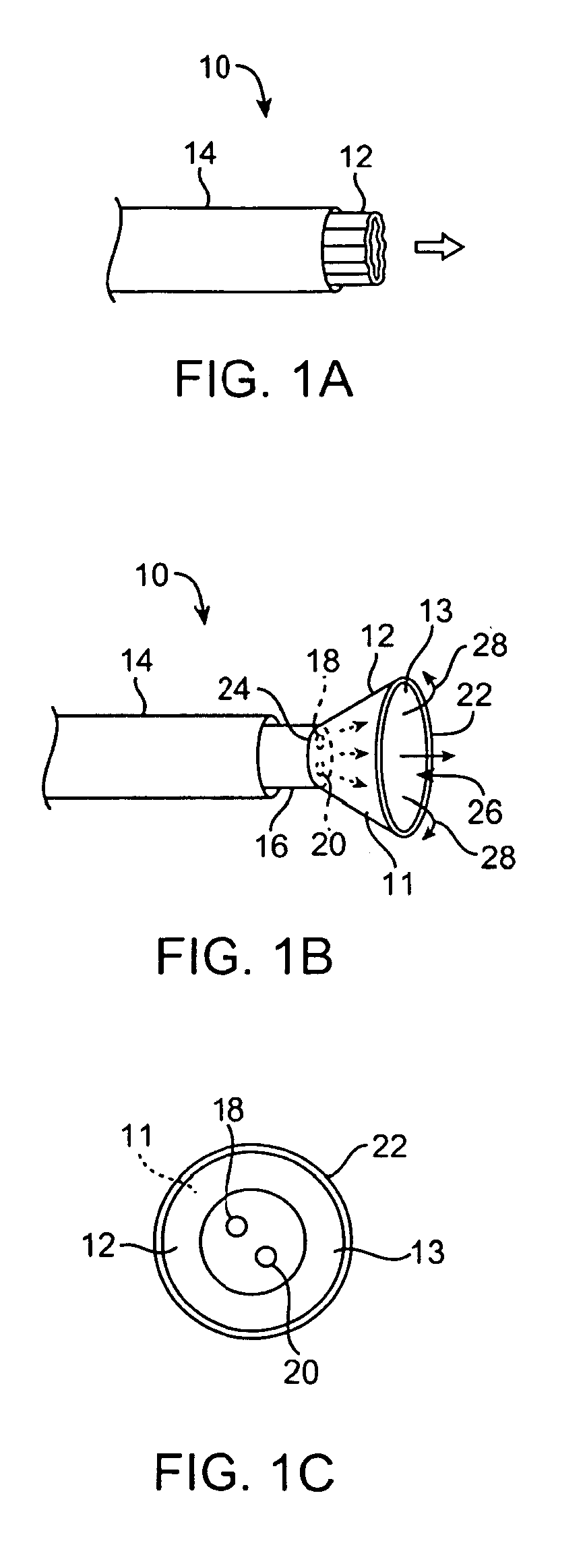

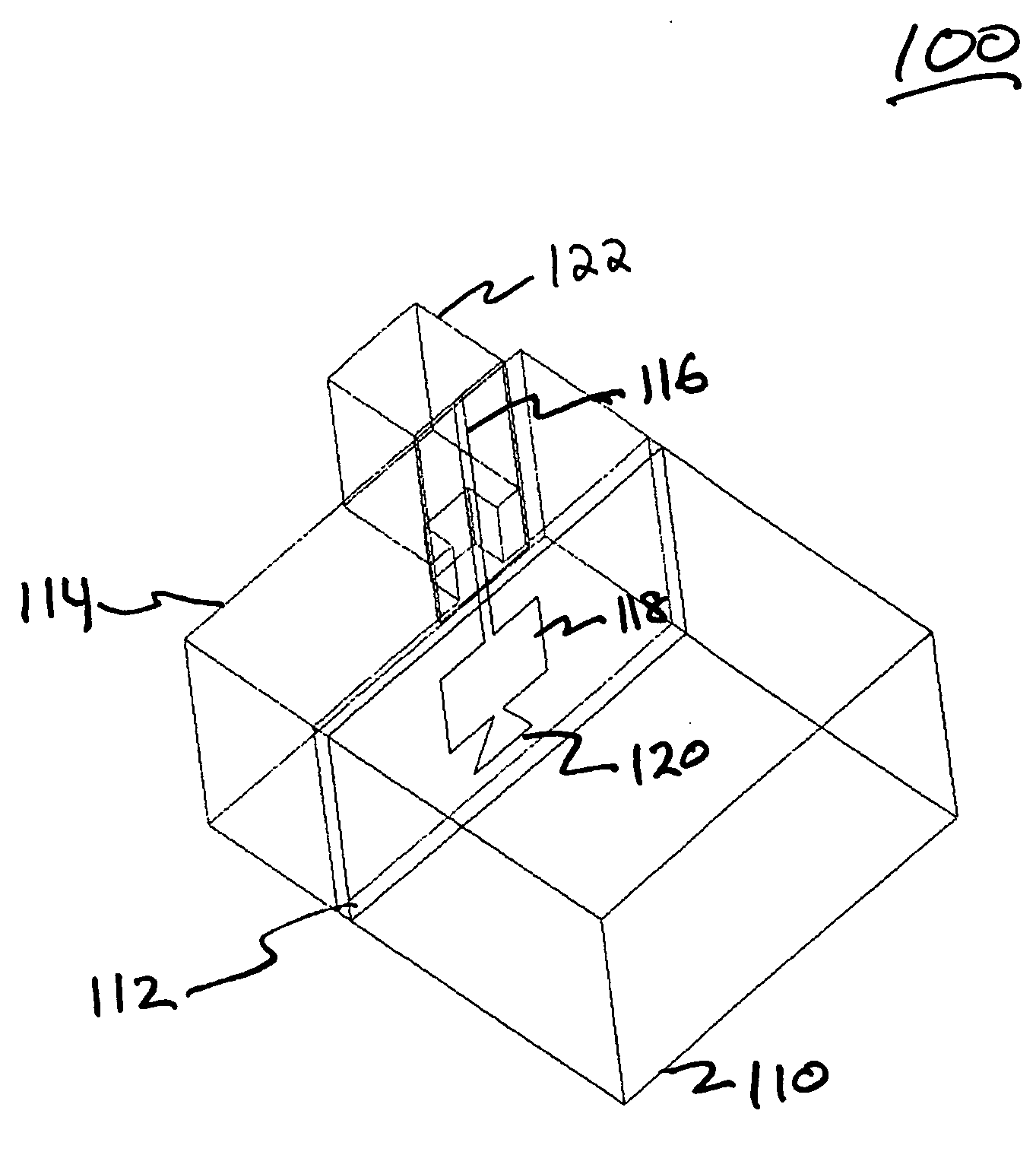

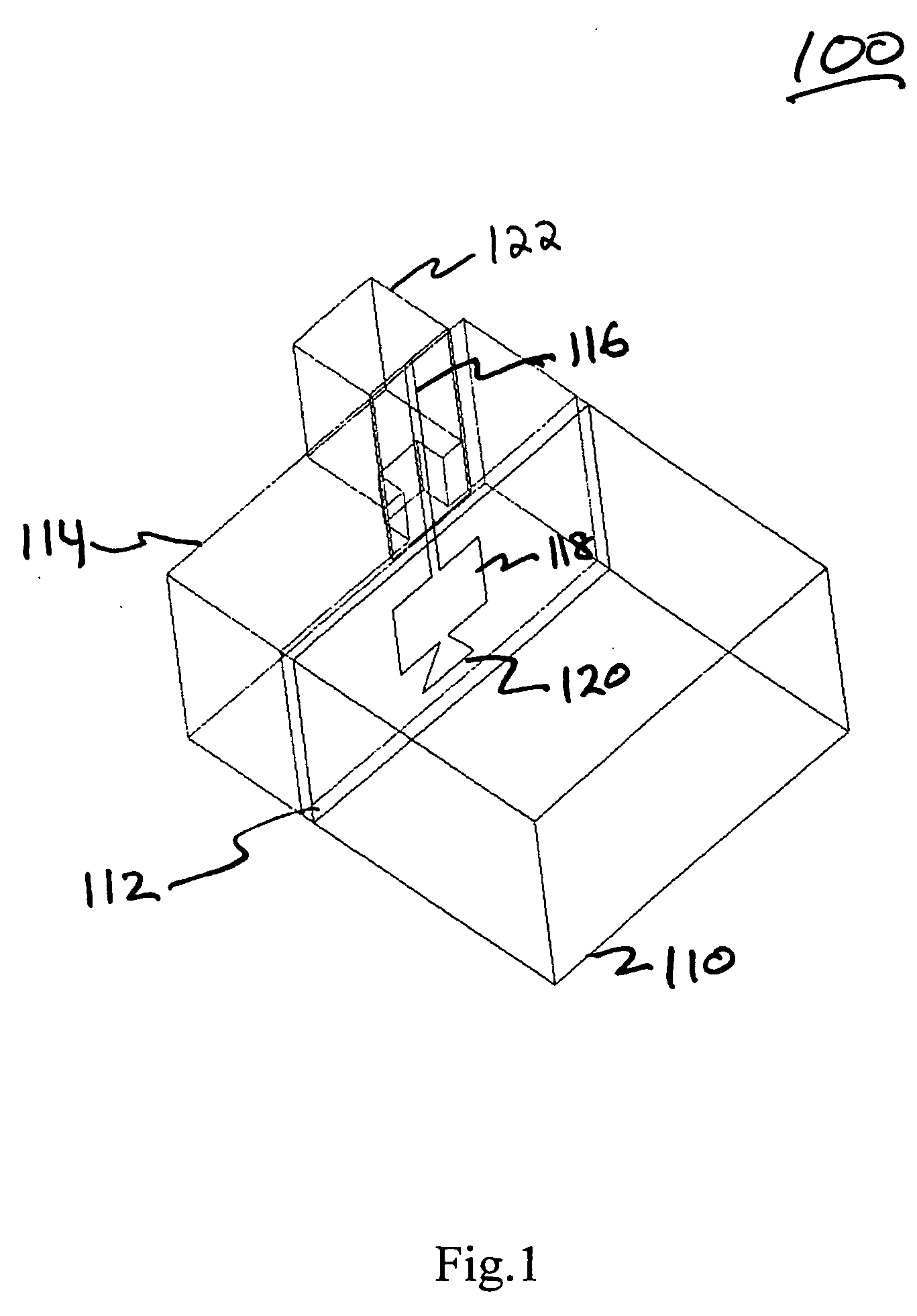

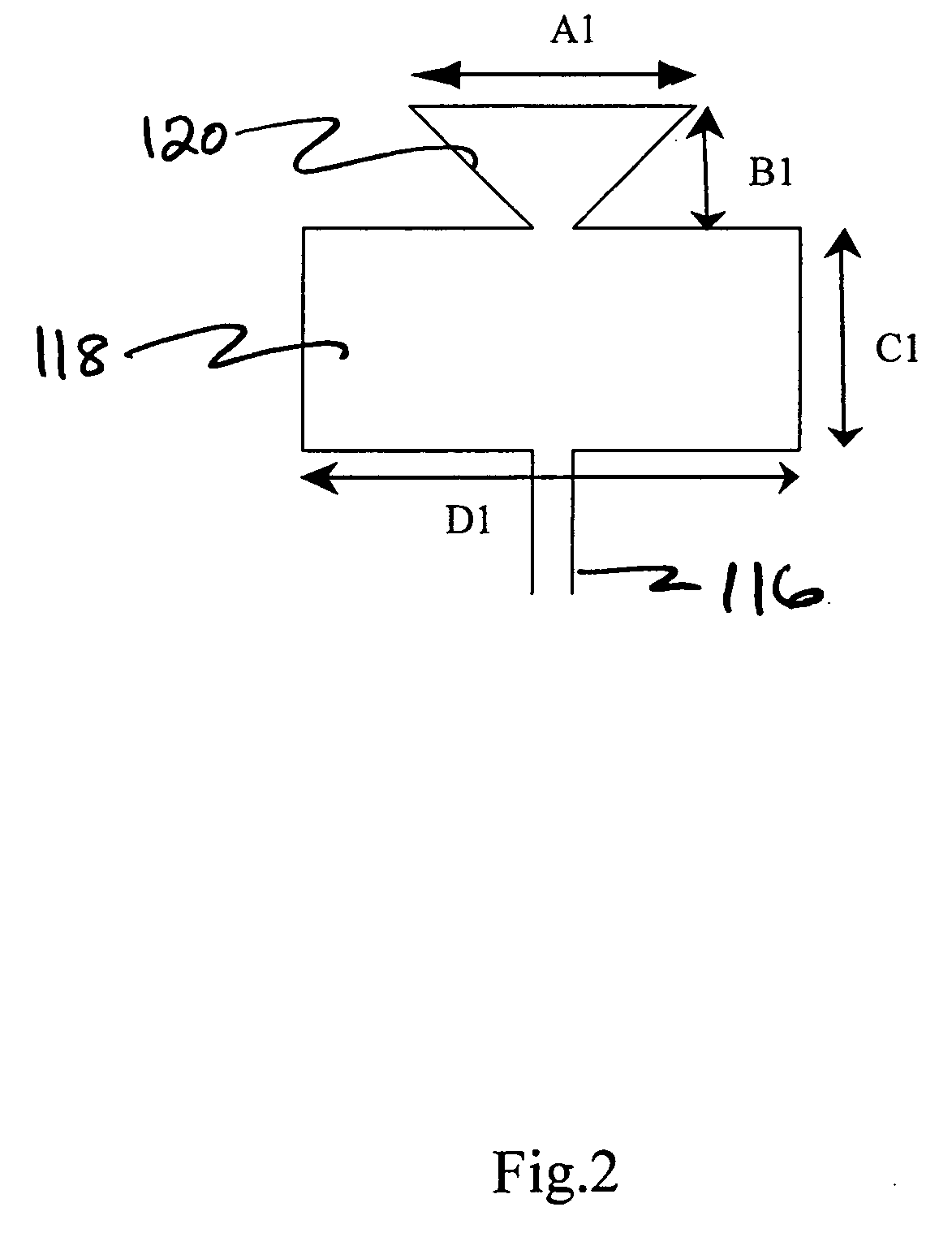

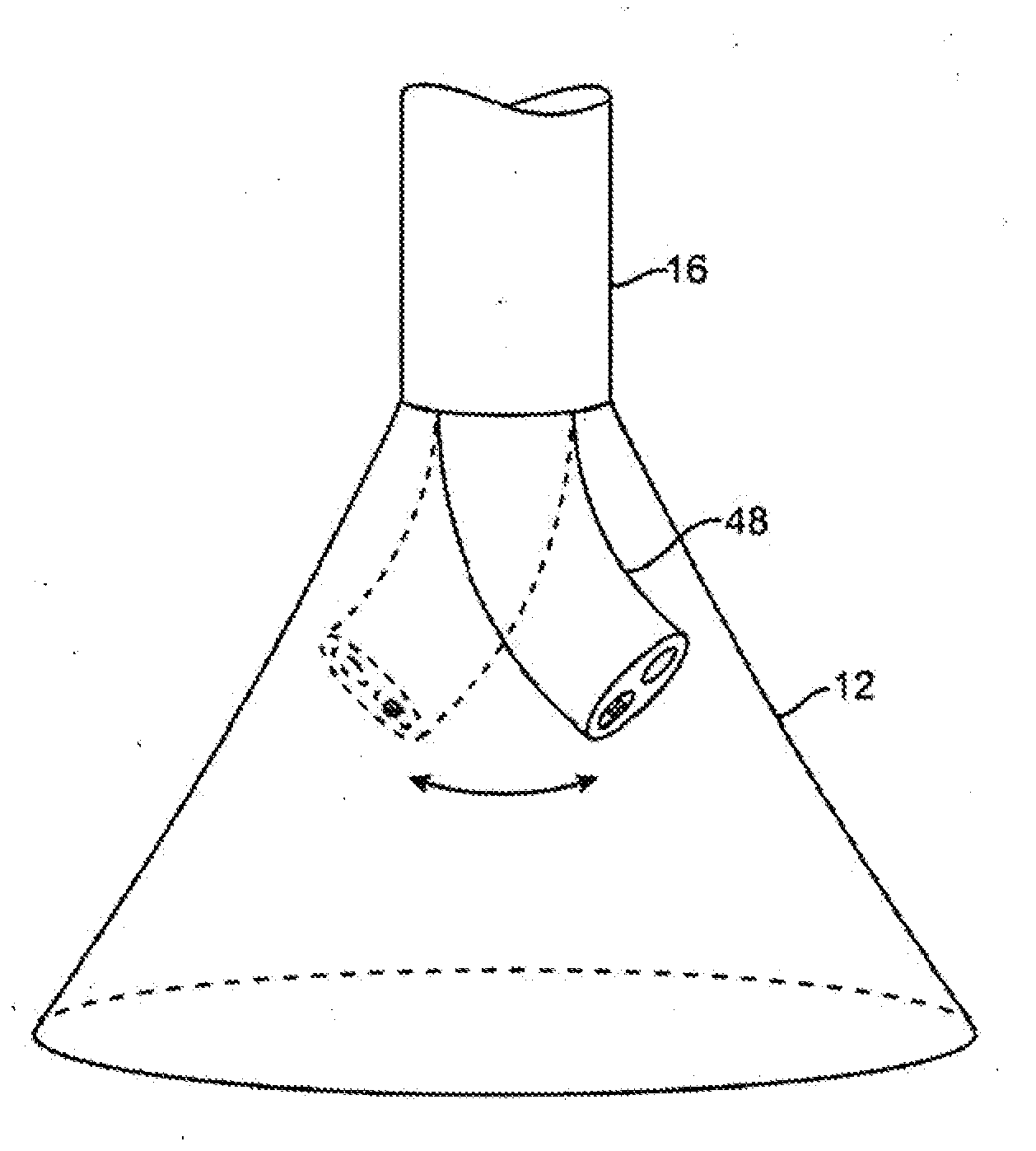

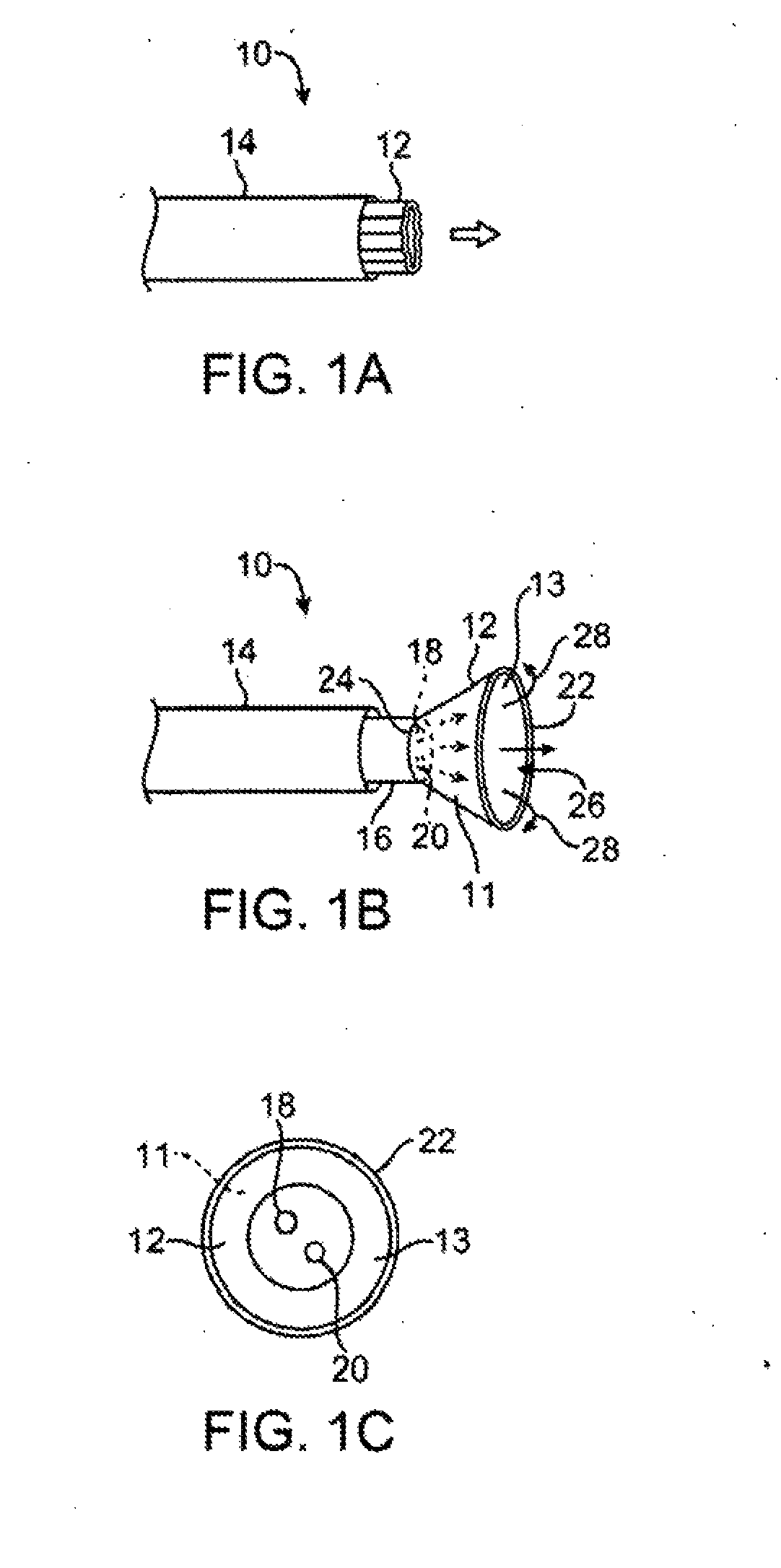

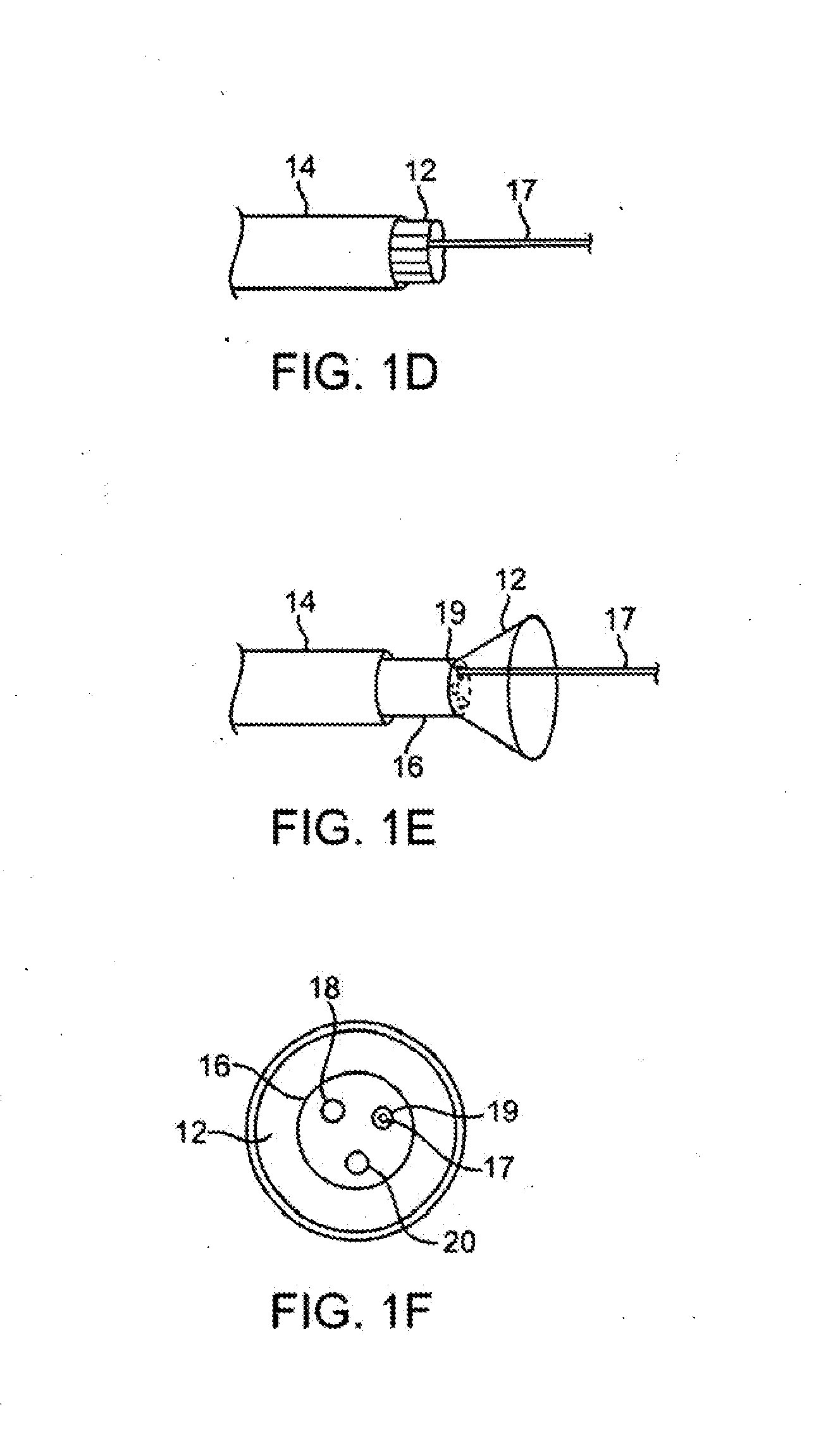

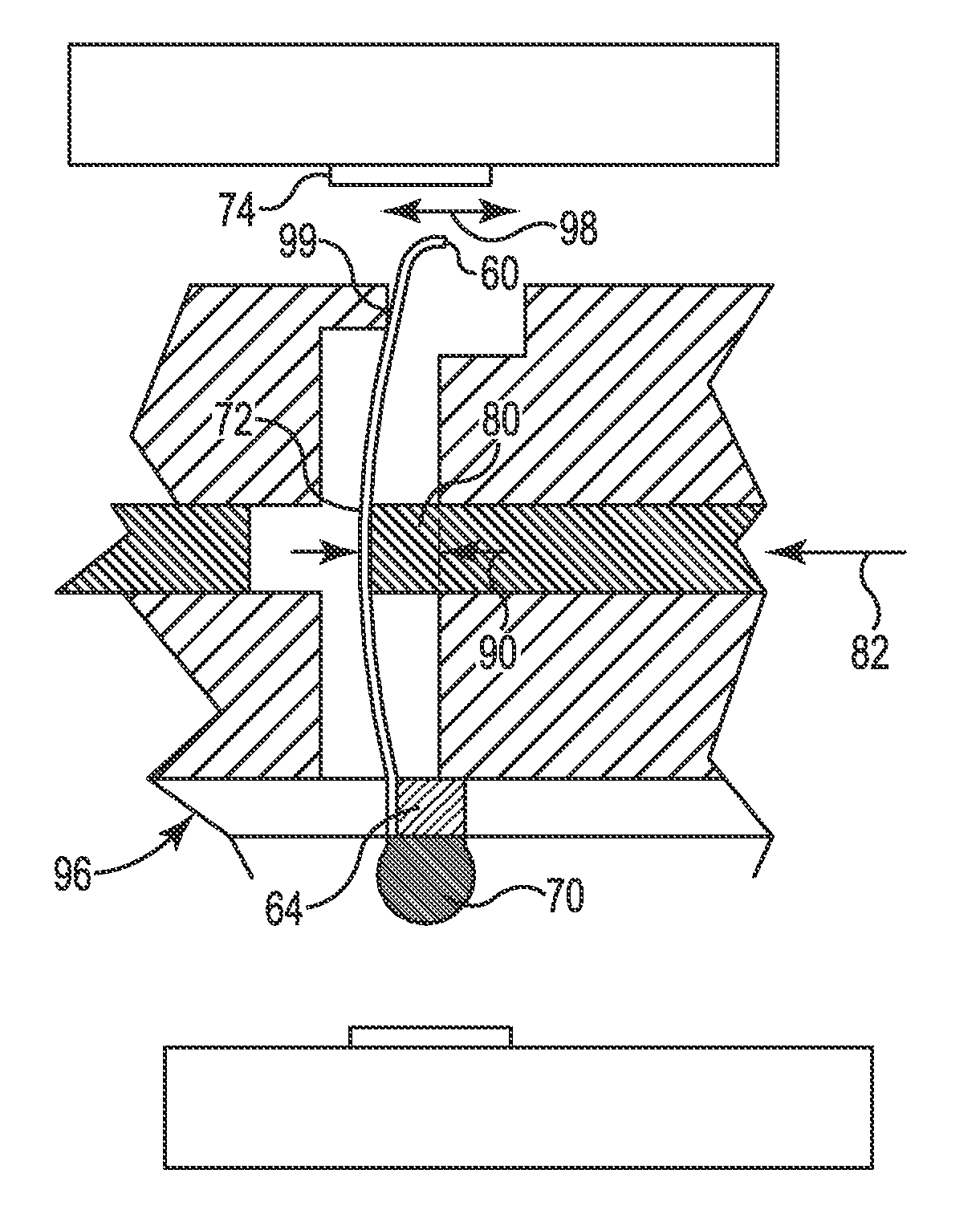

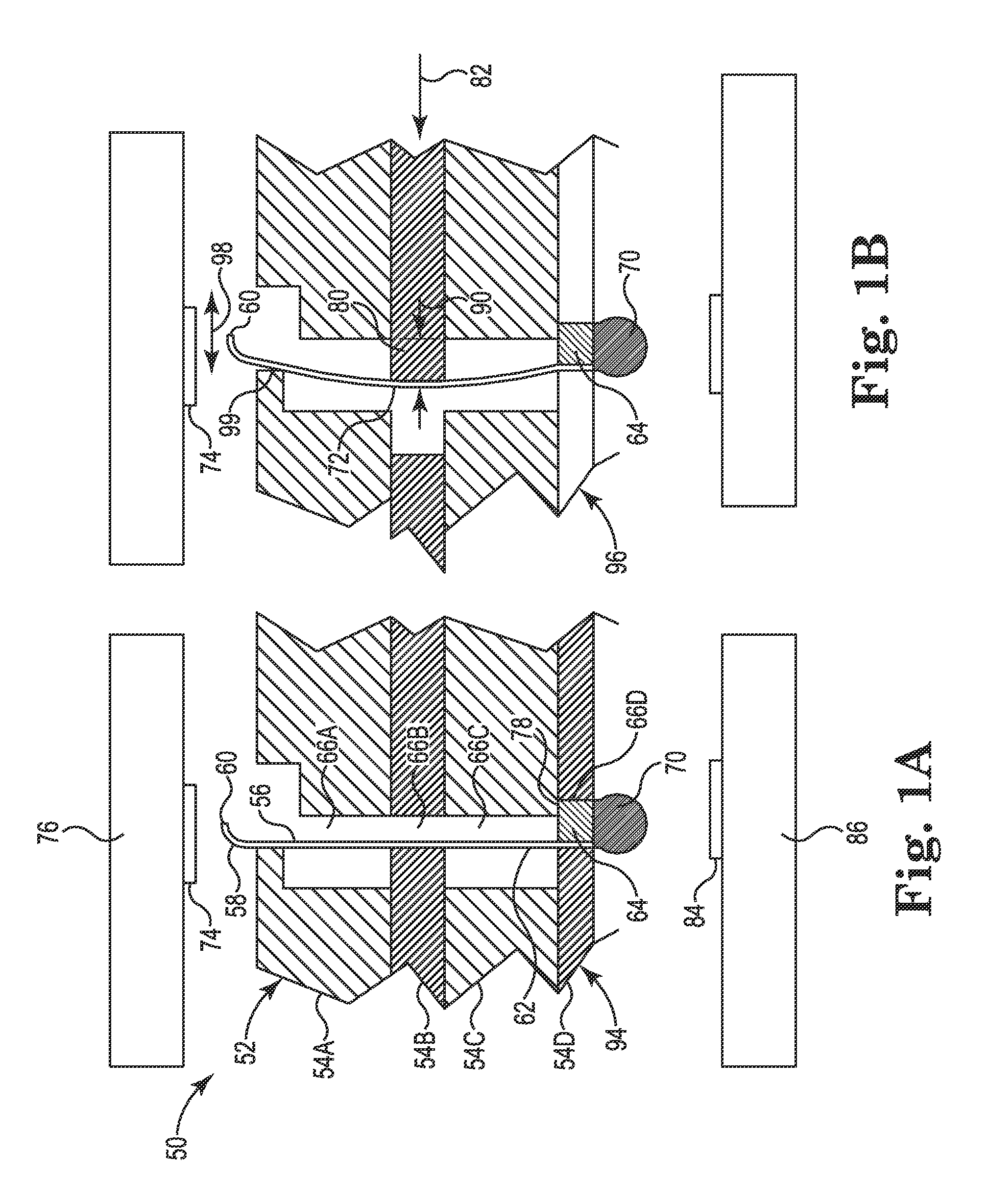

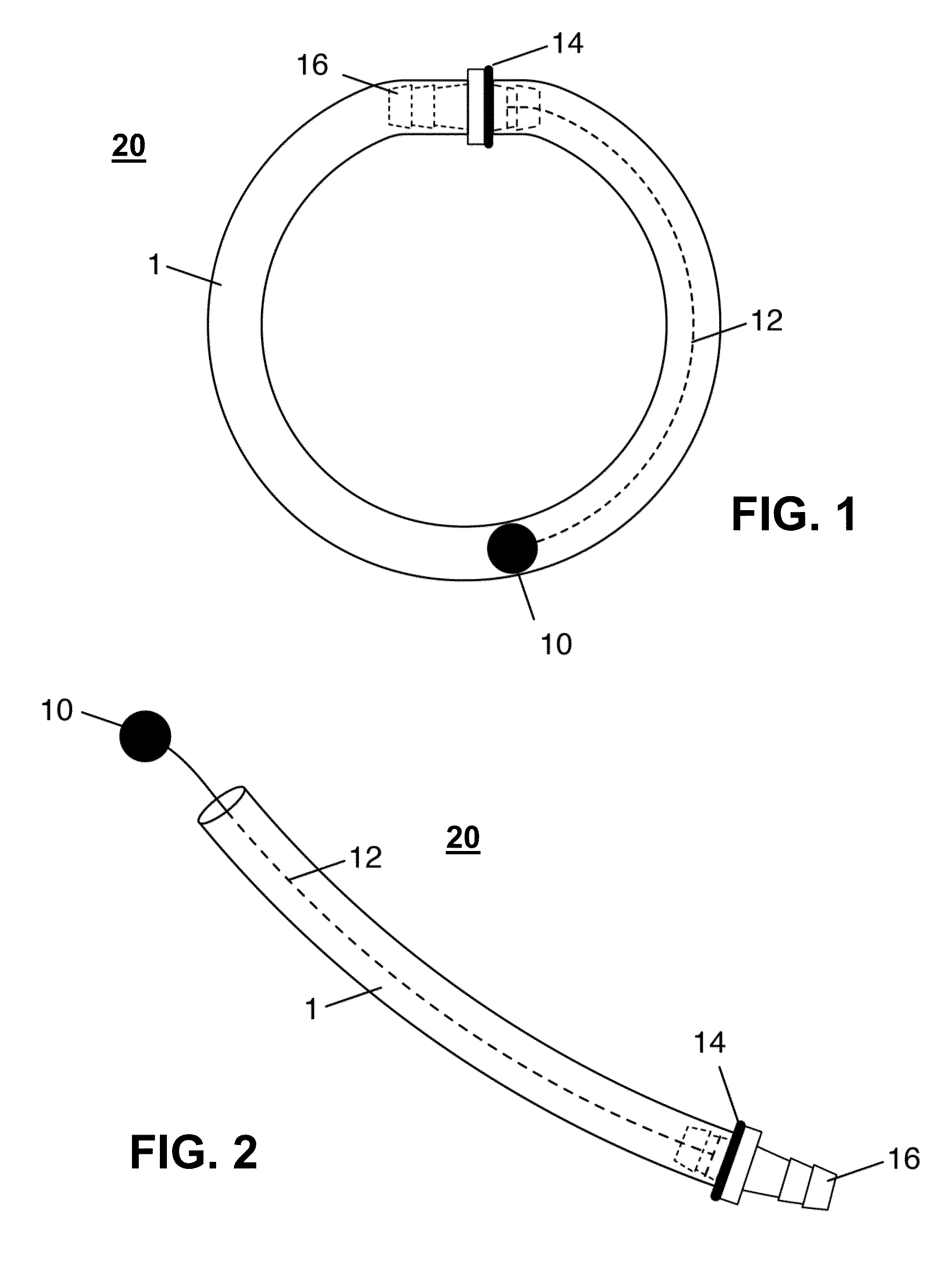

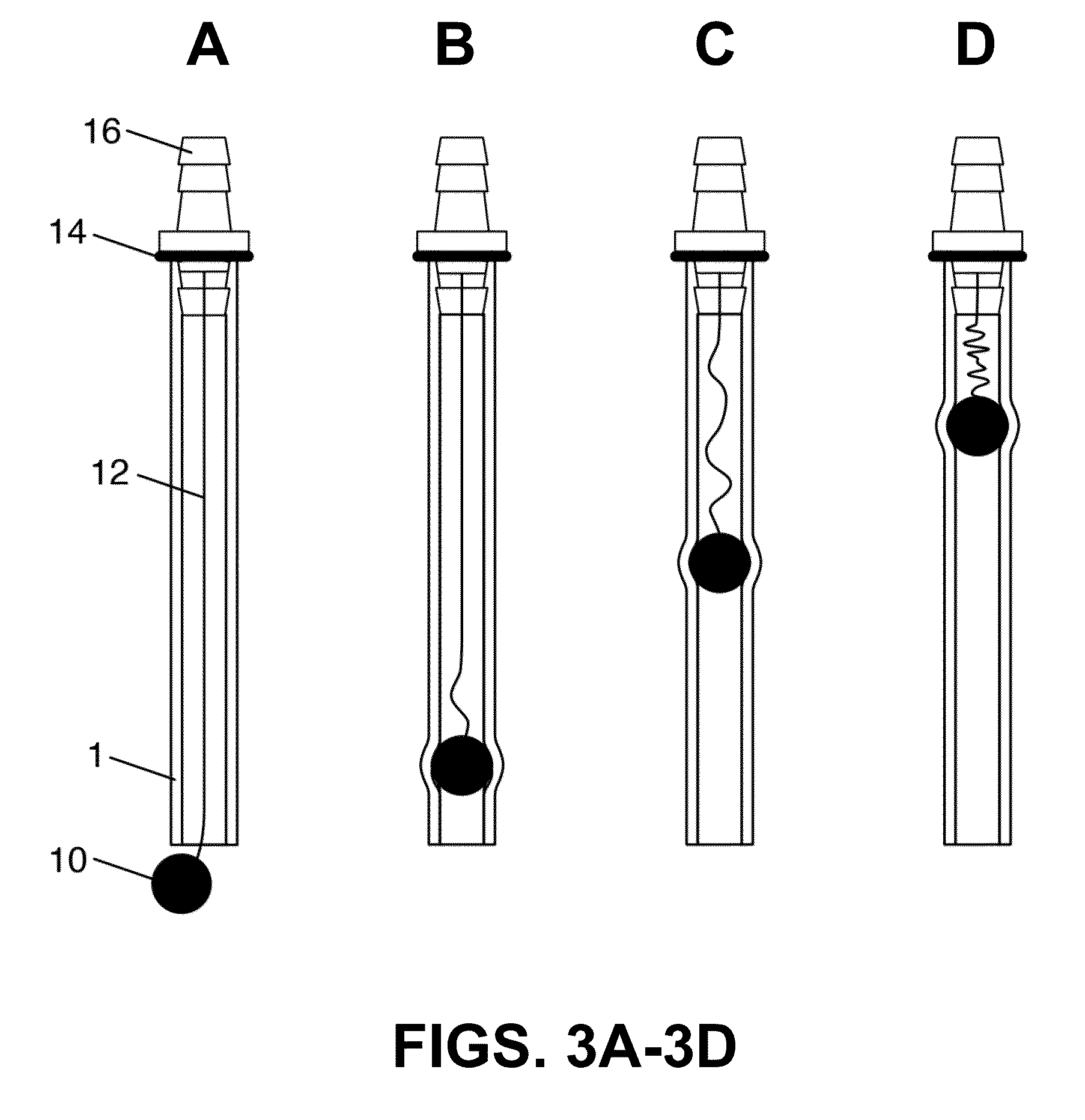

Complex shape steerable tissue visualization and manipulation catheters and their methods of use of disclosed herein. The deployment catheter may be articulated utilizing various steering mechanisms to adjust a position of a visualization hood or membrane through which underlying tissue may be visualized.

Owner:INTUITIVE SURGICAL OPERATIONS INC

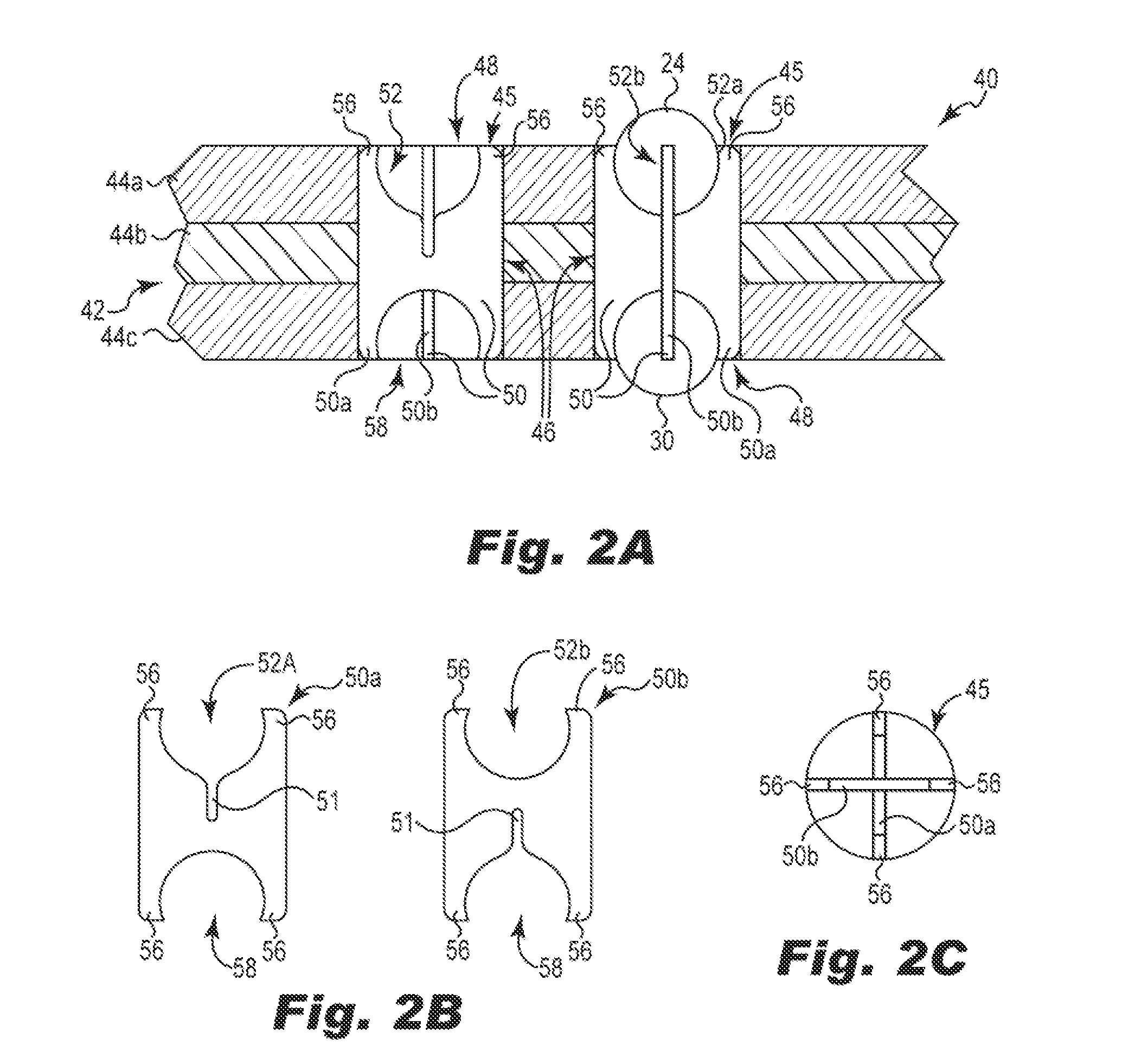

Visual electrode ablation systems

ActiveUS20090030412A1Improve sealingReduce saline dischargeEndoscopesSurgical instruments for heatingPower flowBody fluid

Visual electrode ablation systems are described herein which include a deployment catheter and an attached imaging hood deployable into an expanded configuration. In use, the imaging hood is placed against or adjacent to a region of tissue to be imaged in a body lumen that is normally filled with an opaque bodily fluid such as blood. A translucent or transparent fluid, such as saline, can be pumped into the imaging hood until the fluid displaces any blood, thereby leaving a clear region of tissue to be imaged via an imaging element in the deployment catheter. An electric current may be passed through the fluid such that it passes directly to the tissue region being imaged and the electrical energy is conducted through the fluid without the need for a separate ablation probe or instrument to ablate the tissue being viewed.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Complex shape steerable tissue visualization and manipulation catheter

ActiveUS20080281293A1Difficult to reachIncrease contactSurgeryLaproscopesSacroiliac jointCatheter device

Complex steerable catheter visualization and tissue manipulation systems and their methods of use are disclosed herein. The deployment catheter is articulated using various steering mechanisms. Tissue visualization is accomplished from the visualization hood at the distal end of the deployment catheter, the hood having an ability to expand and other features to facilitate visualization and articulation at the tissue surface.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Visual electrode ablation systems

Owner:INTUITIVE SURGICAL OPERATIONS INC

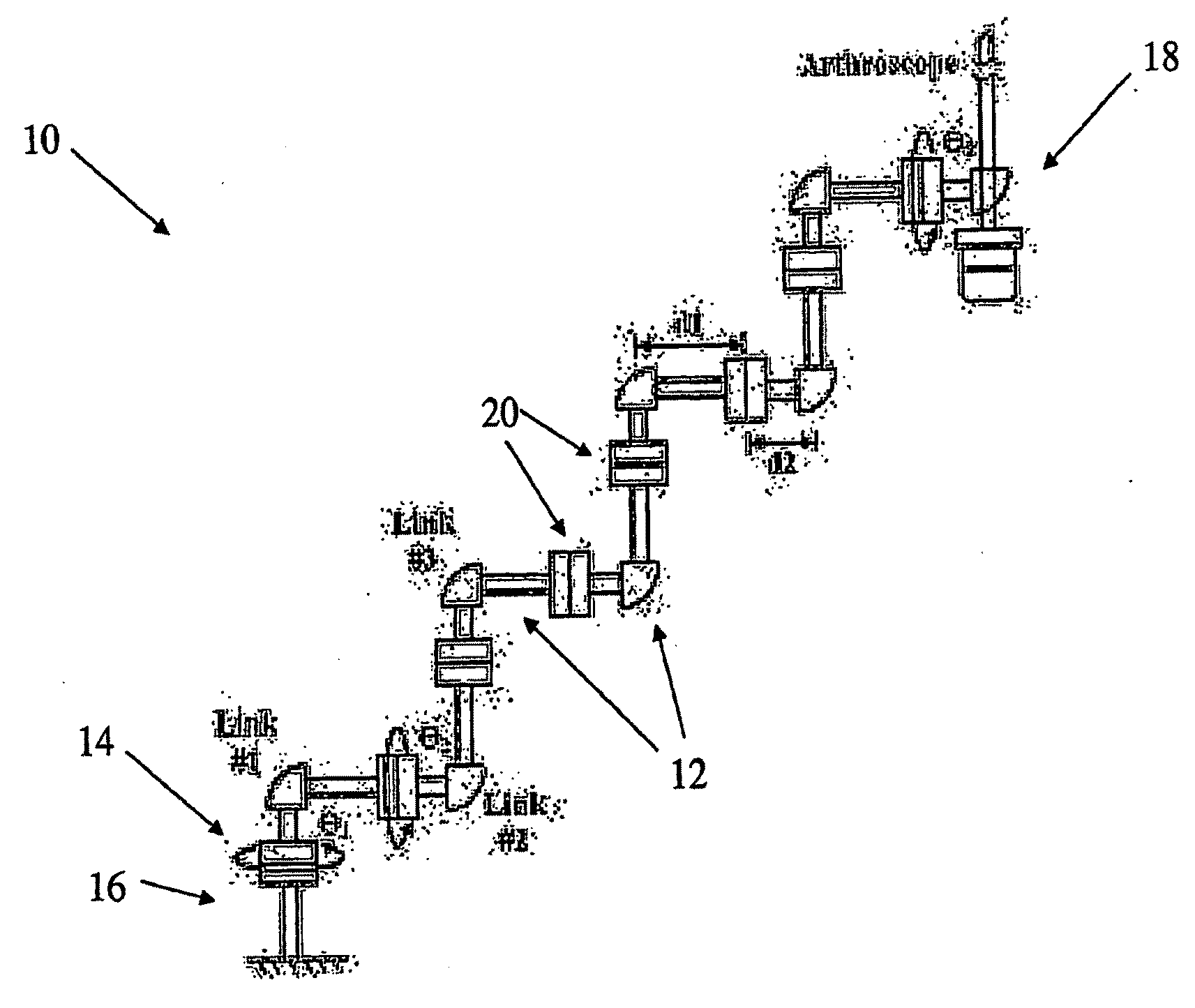

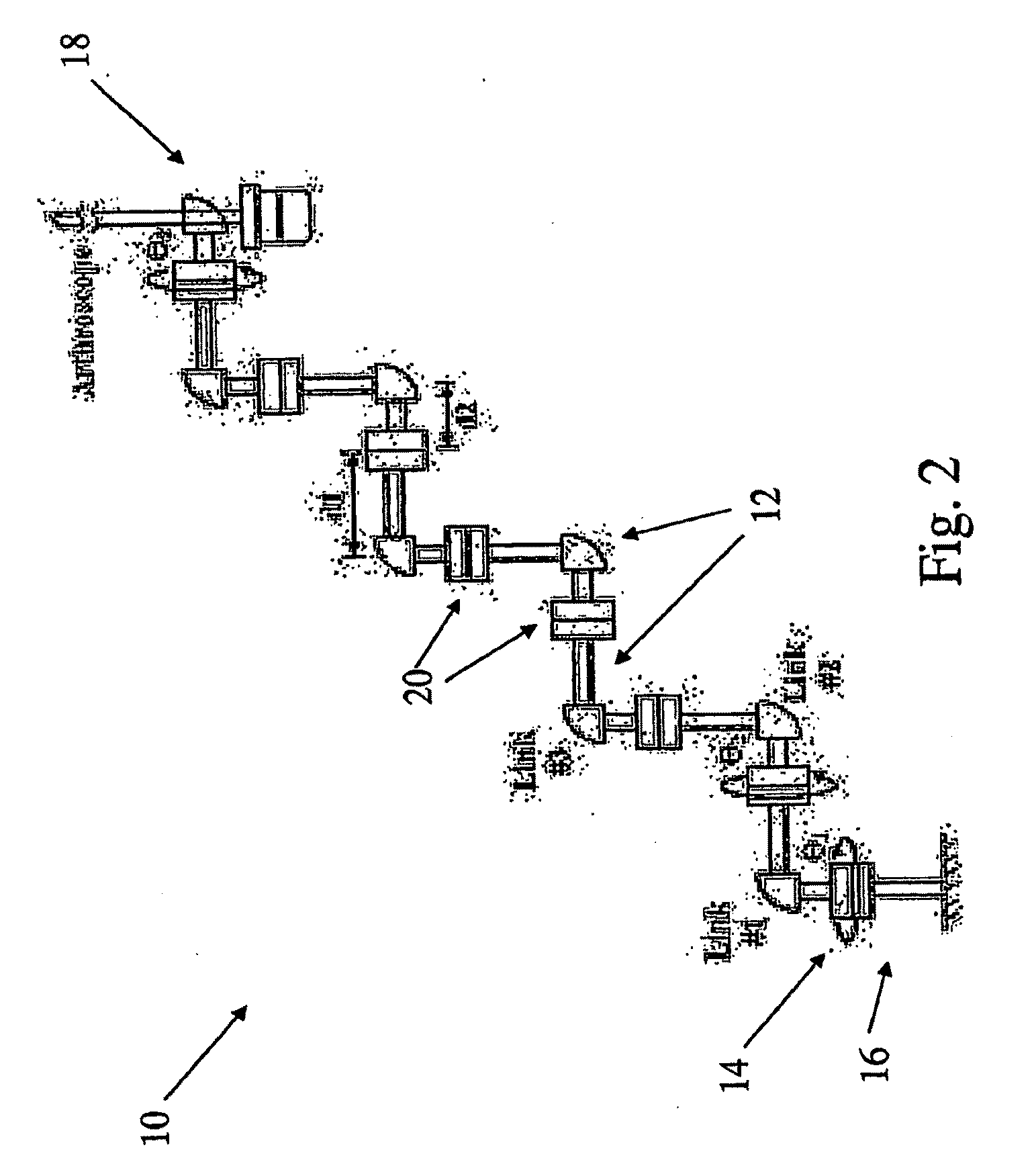

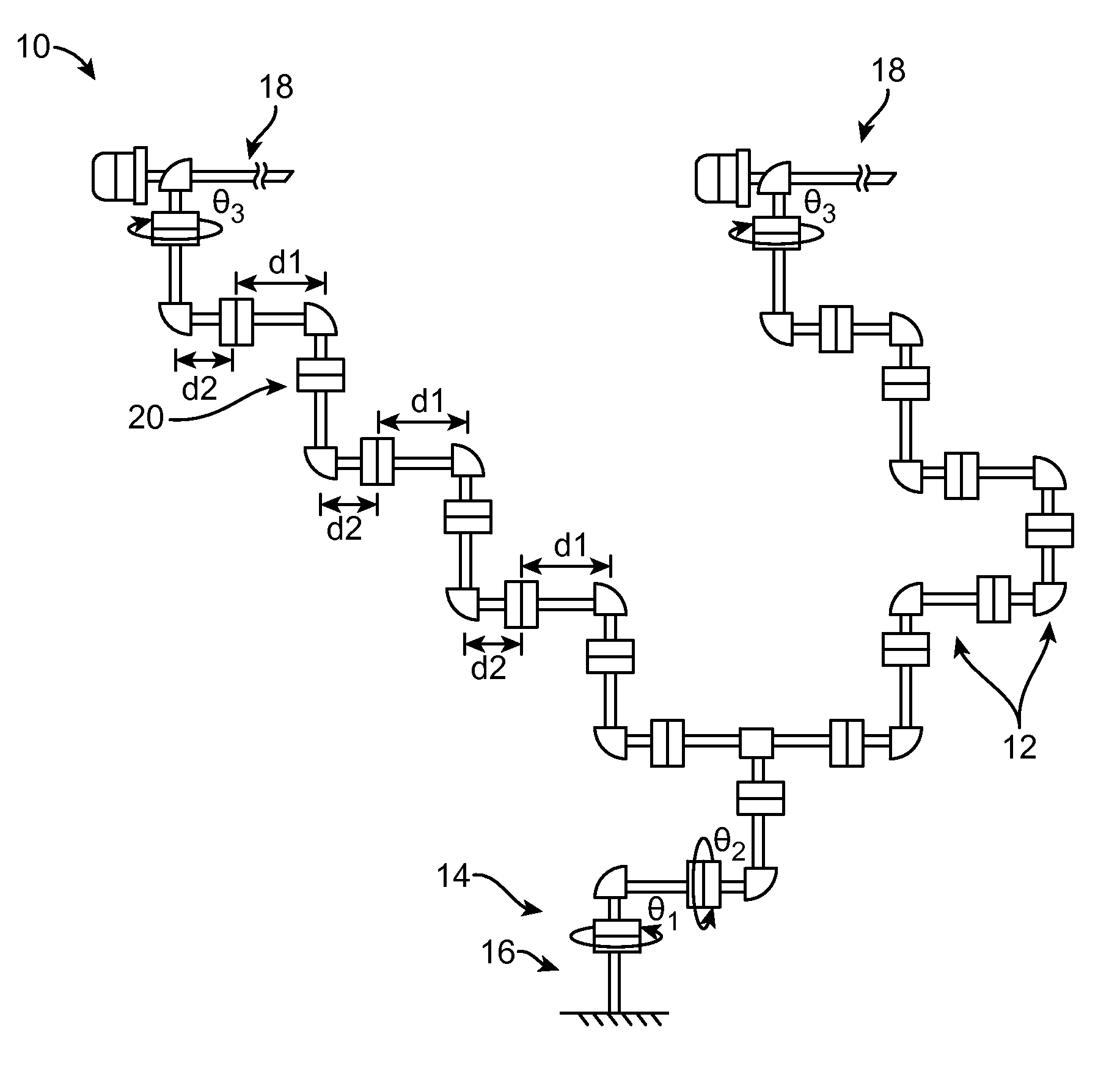

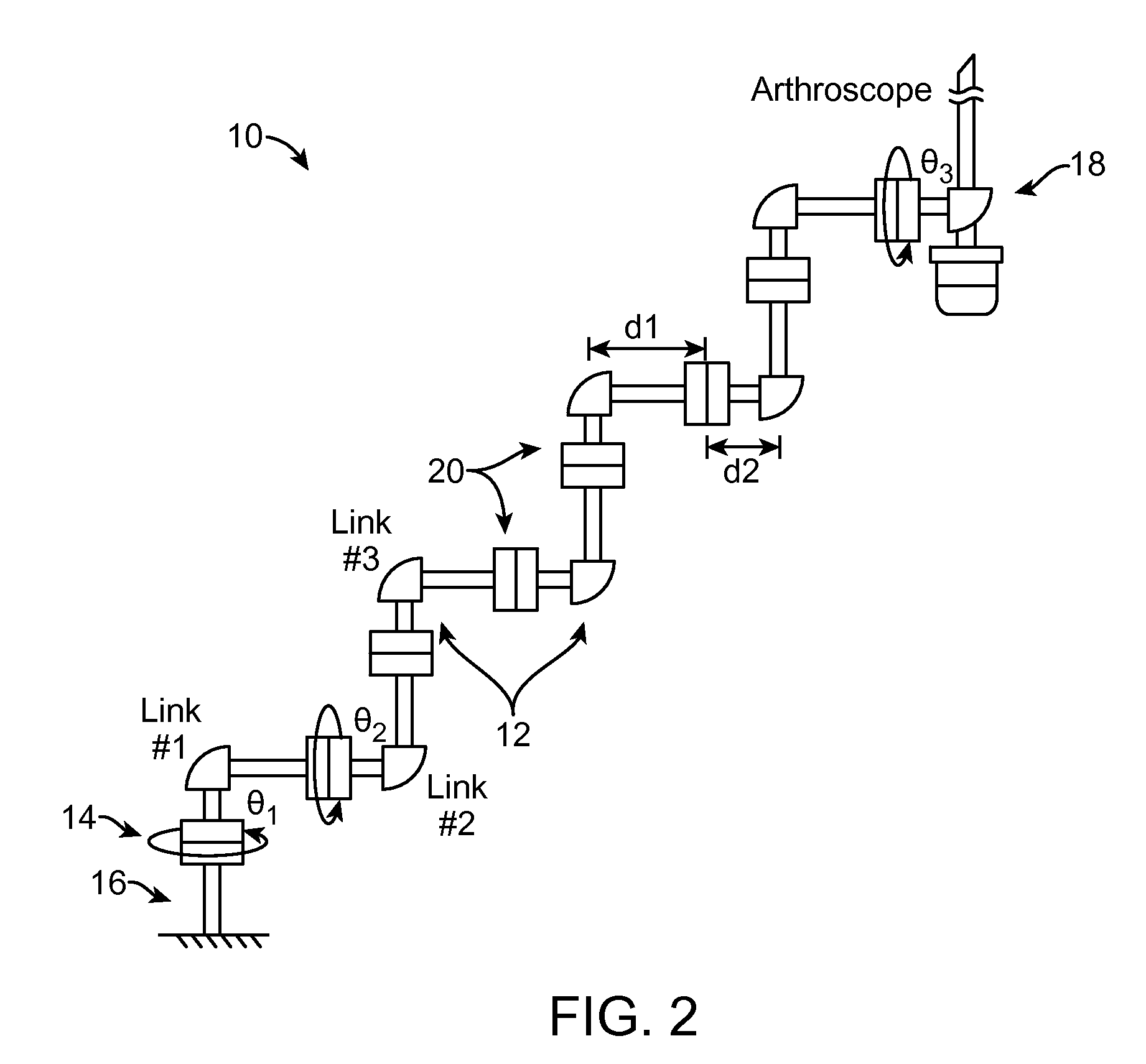

Method, Apparatus, And System For Computer-Aided Tracking, Navigation And Motion Teaching

ActiveUS20100299101A1Improve flexibilityRange be very expensiveProgramme-controlled manipulatorDiagnosticsComputer-aidedMovement tracking

Methods, apparatuses, and systems for computer-aided tracking, navigation, and motion tracking. In one embodiment, a system for determining a spatial position, including a tracking device and a processor. The tracking devices has a working end, a reference end, a plurality of links connecting the working end to the reference end, wherein each link has at least one degree of freedom relative to an adjacent link, and a plurality of sensors measuring the orientation of the links in a plurality of degrees of freedom, wherein X is a minimum number of degrees of freedom about which information is required to define the spatial position. The processor receives information from the sensors and determine the spatial position of the working end of the tracking device relative to the reference end of the tracking device based on information from the sensors measuring Y degrees of freedom, wherein Y is greater than X.

Owner:CARNEGIE MELLON UNIV

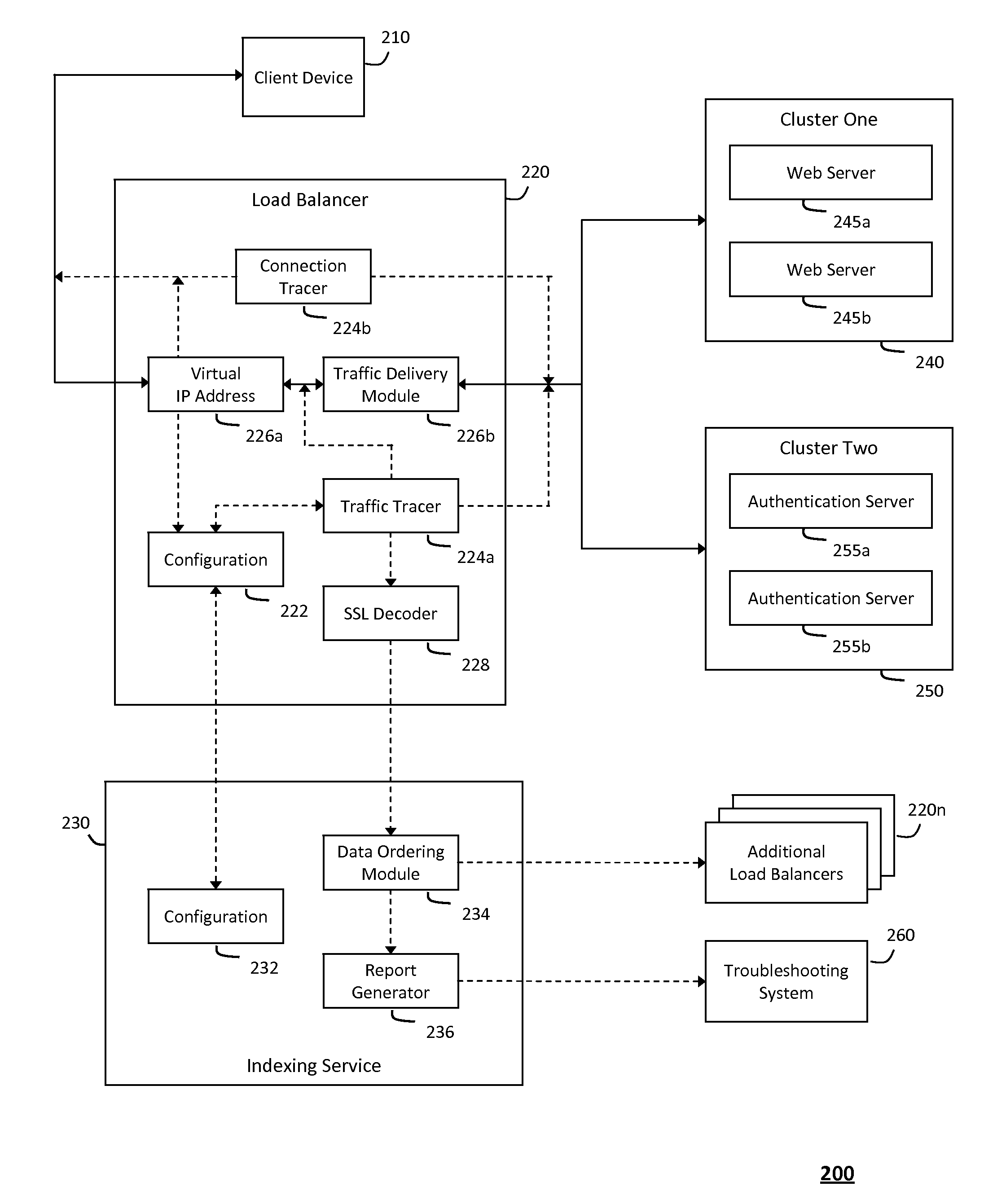

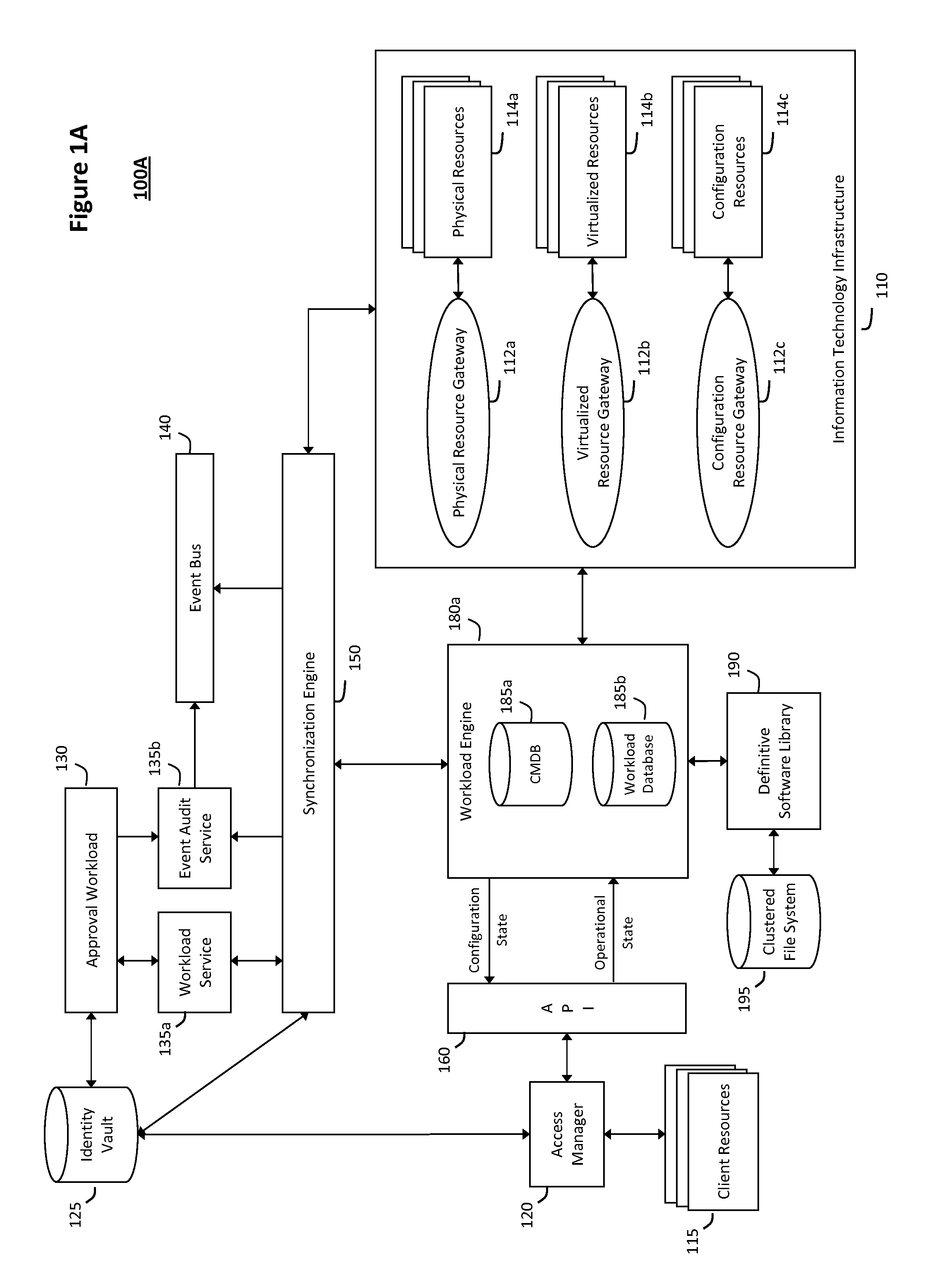

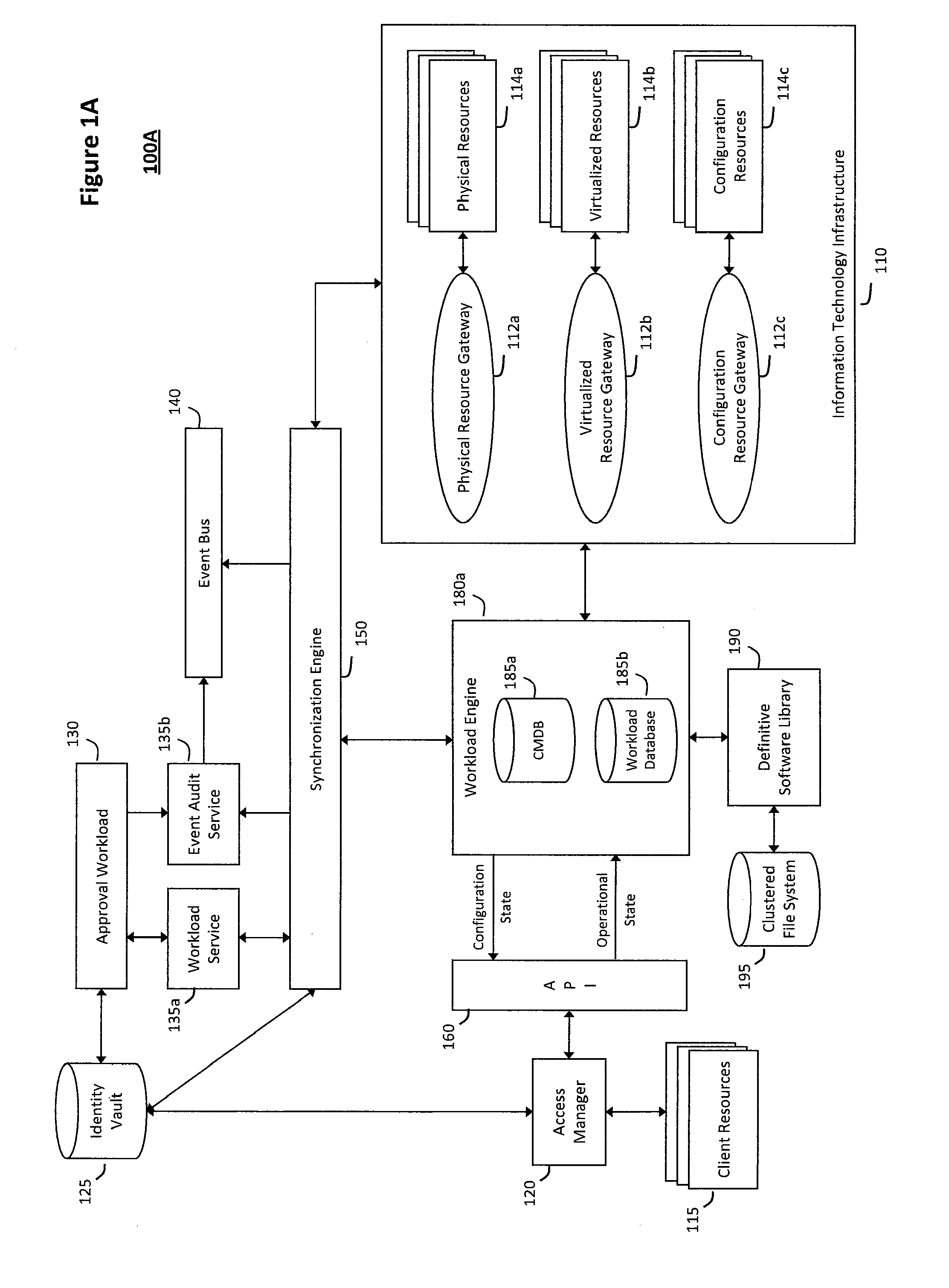

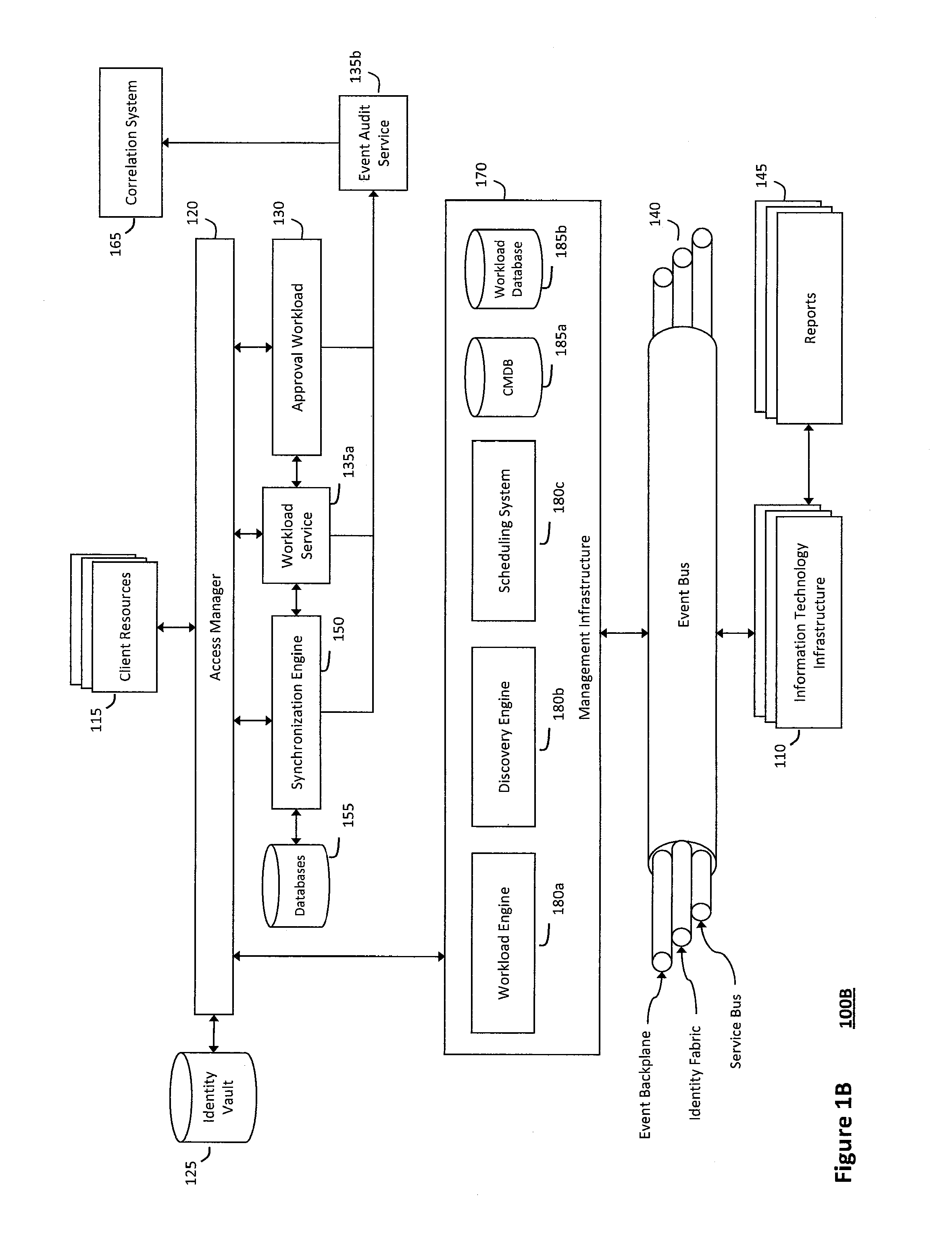

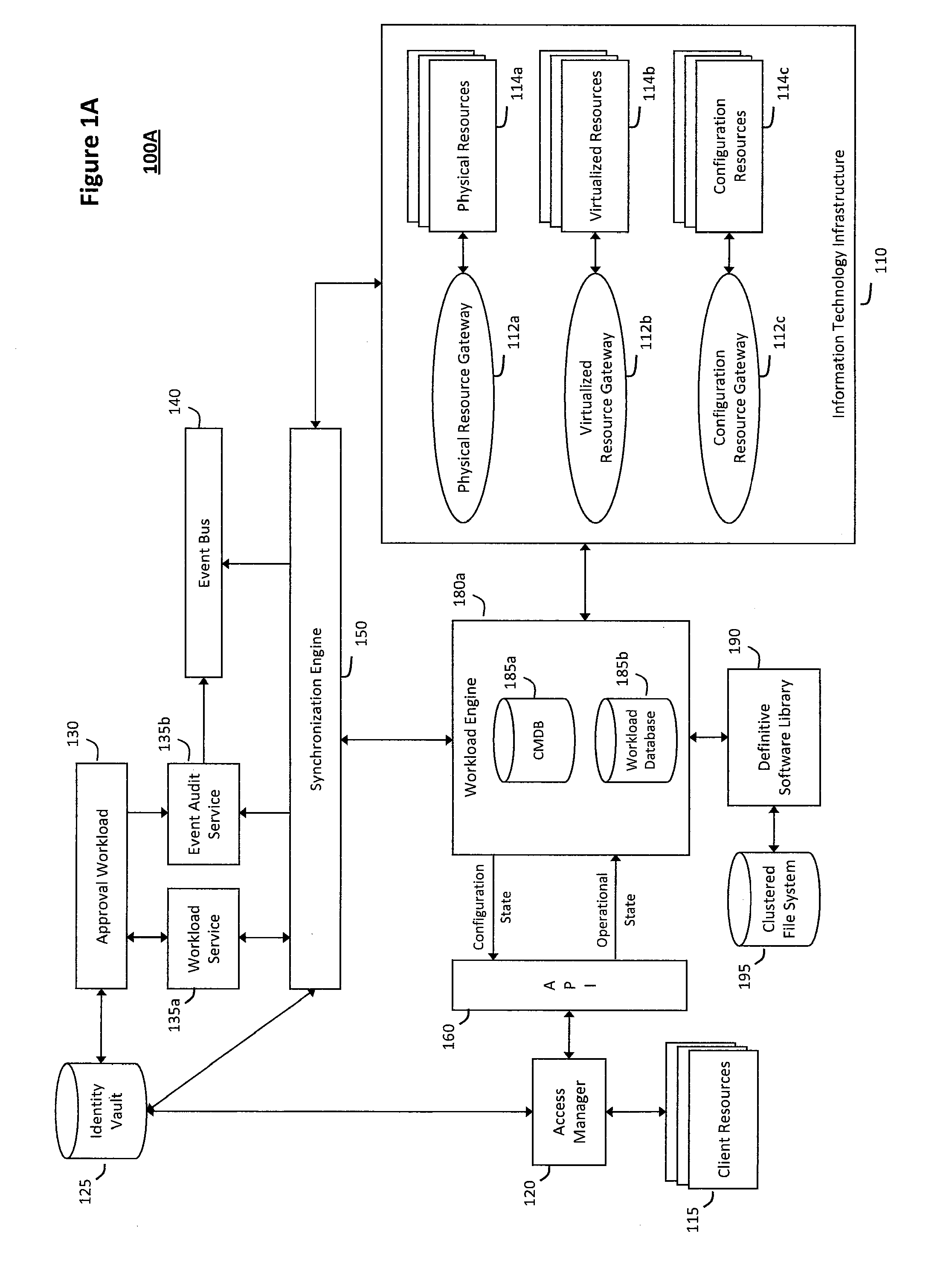

System and method for providing load balancer visibility in an intelligent workload management system

InactiveUS20120066487A1Enable agilityEnable flexibilityDigital computer detailsProgram controlVisibilityLoad Shedding

The system and method for providing load balancer visibility in an intelligent workload management system described herein may expand a role or function associated with a load balancer beyond handling incoming and outgoing data center traffic into supporting governance, risk, and compliance concerns that may be managed in an intelligent workload management system. In particular, the load balancer may establish external connections with destination resources in response to client devices establishing internal connections with the load balancer and then attach connection tracers to monitor the internal connections and the external connections. The connection tracers may then detect incoming traffic and outgoing traffic that the internal and external connections pass through the load balancer, and traffic tracers may collect data from the incoming traffic and the outgoing traffic, which the workload management system may use to manage the data center.

Owner:MICRO FOCUS SOFTWARE INC

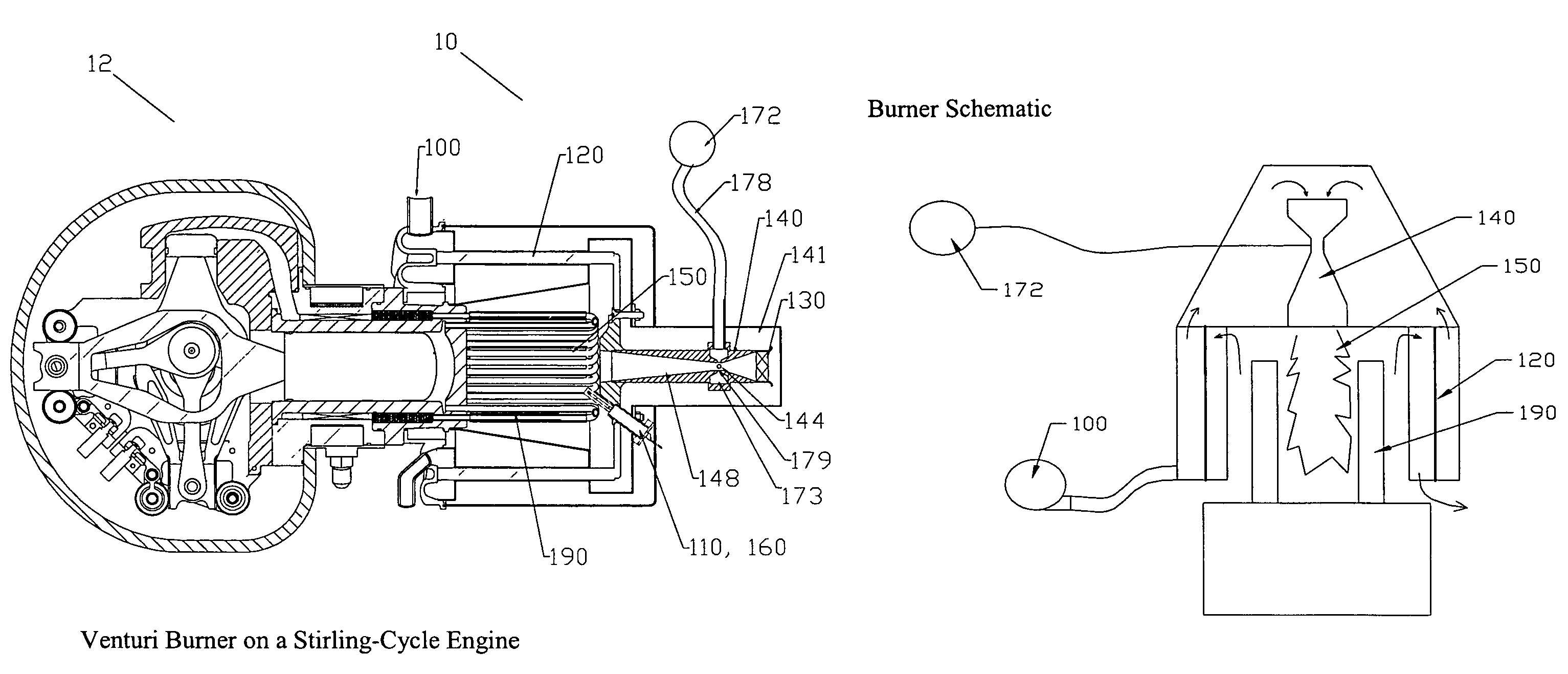

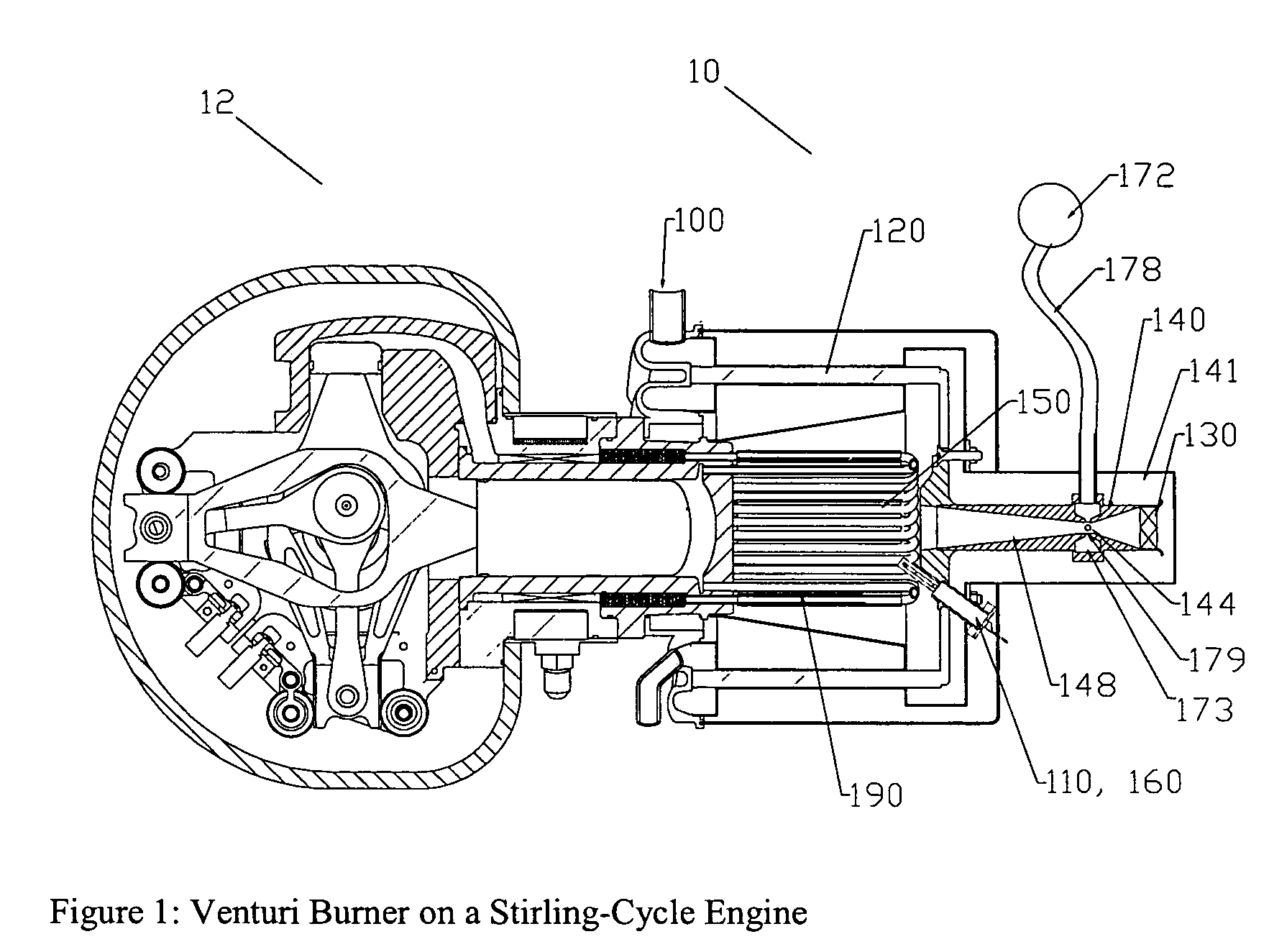

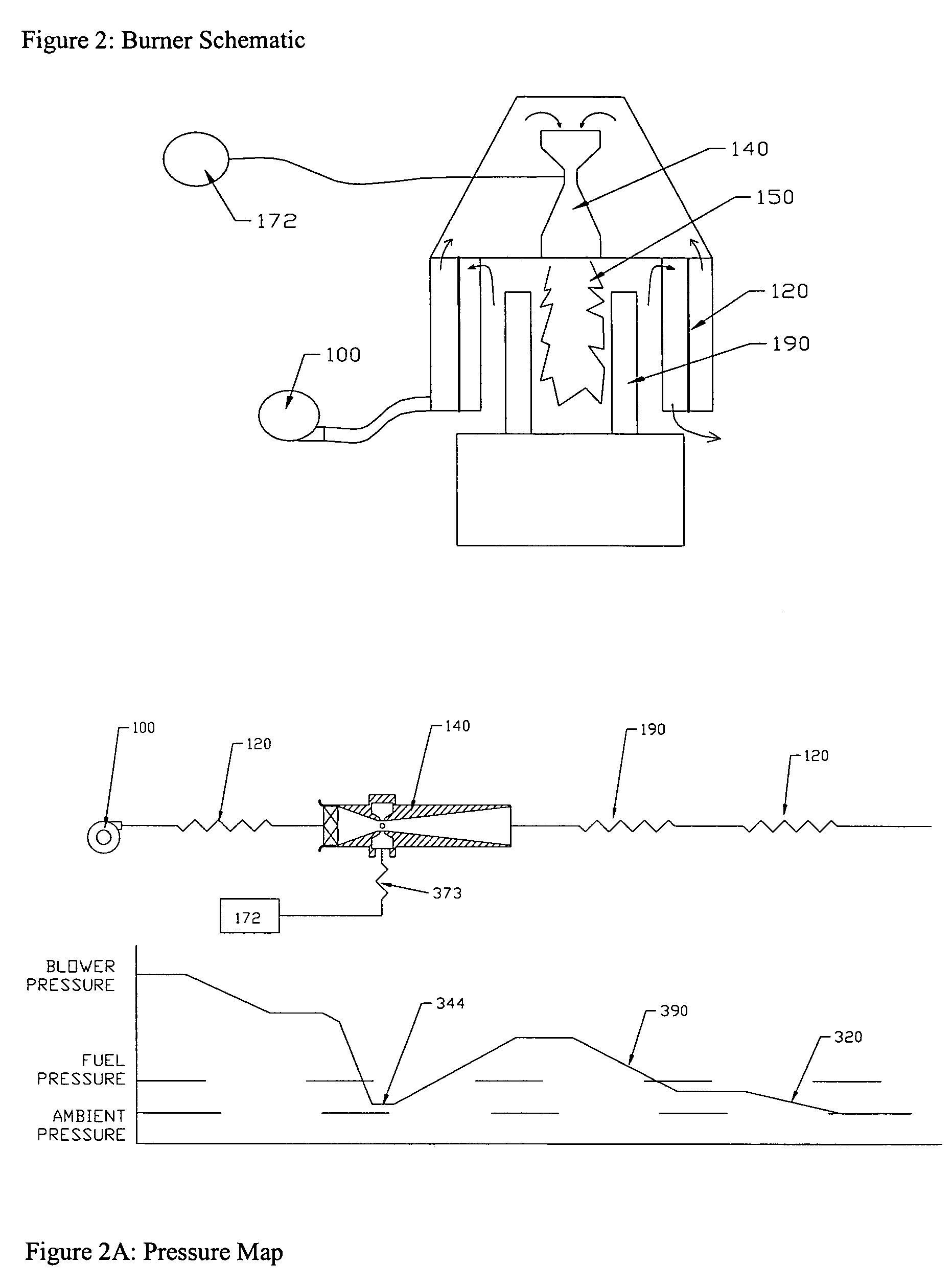

Gaseous fuel burner

ActiveUS7934926B2Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

Owner:NEW POWER CONCEPTS

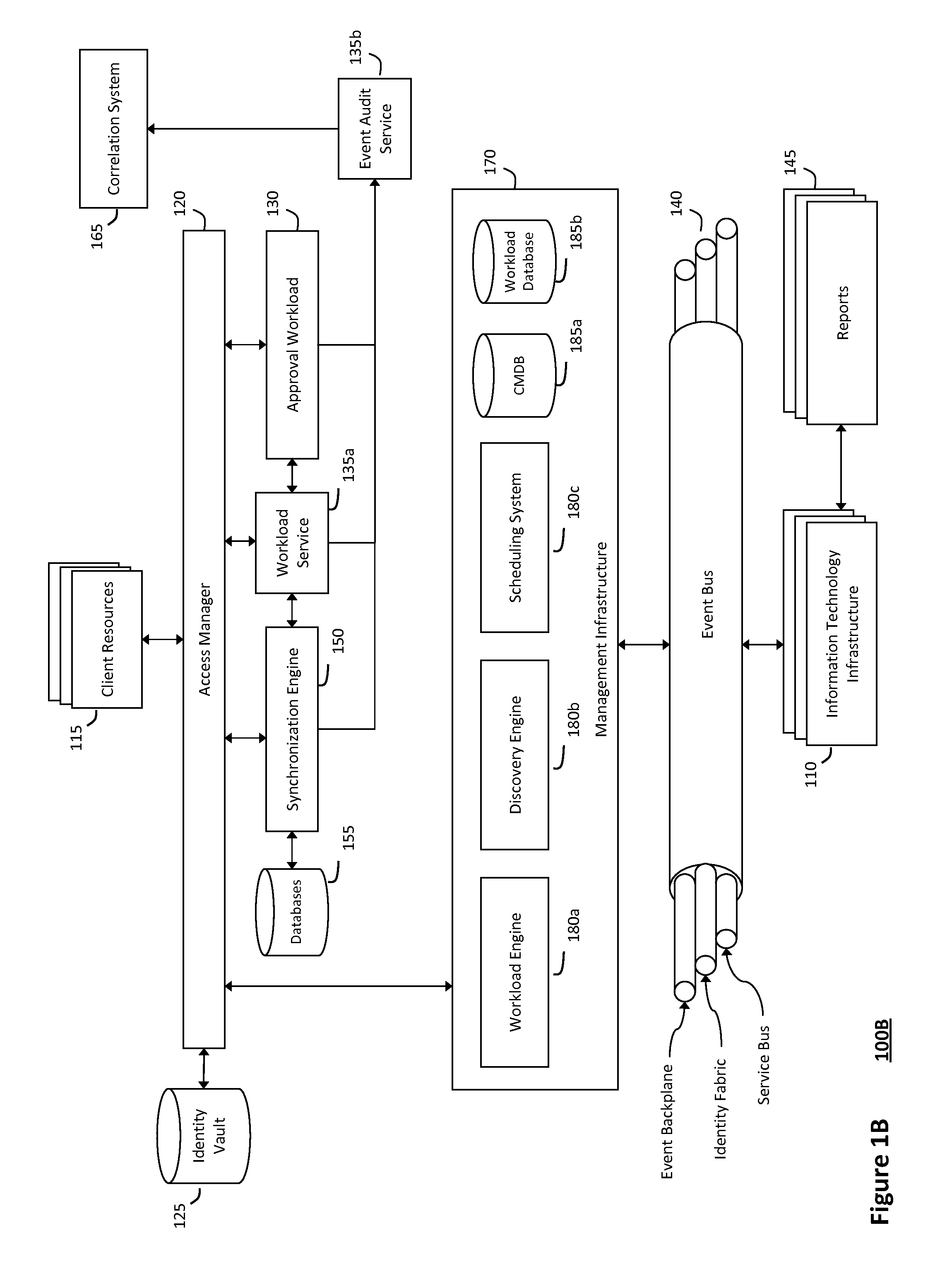

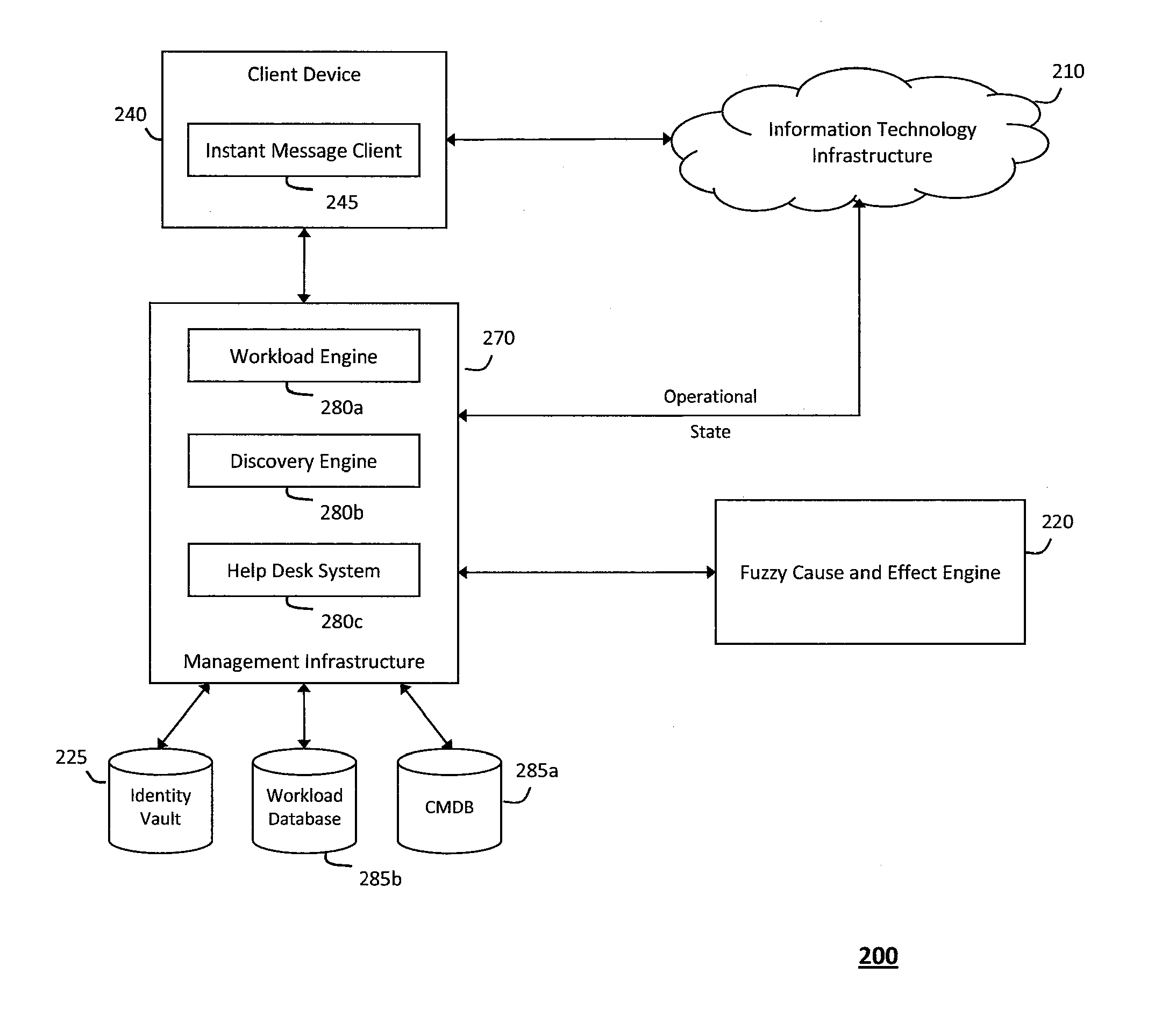

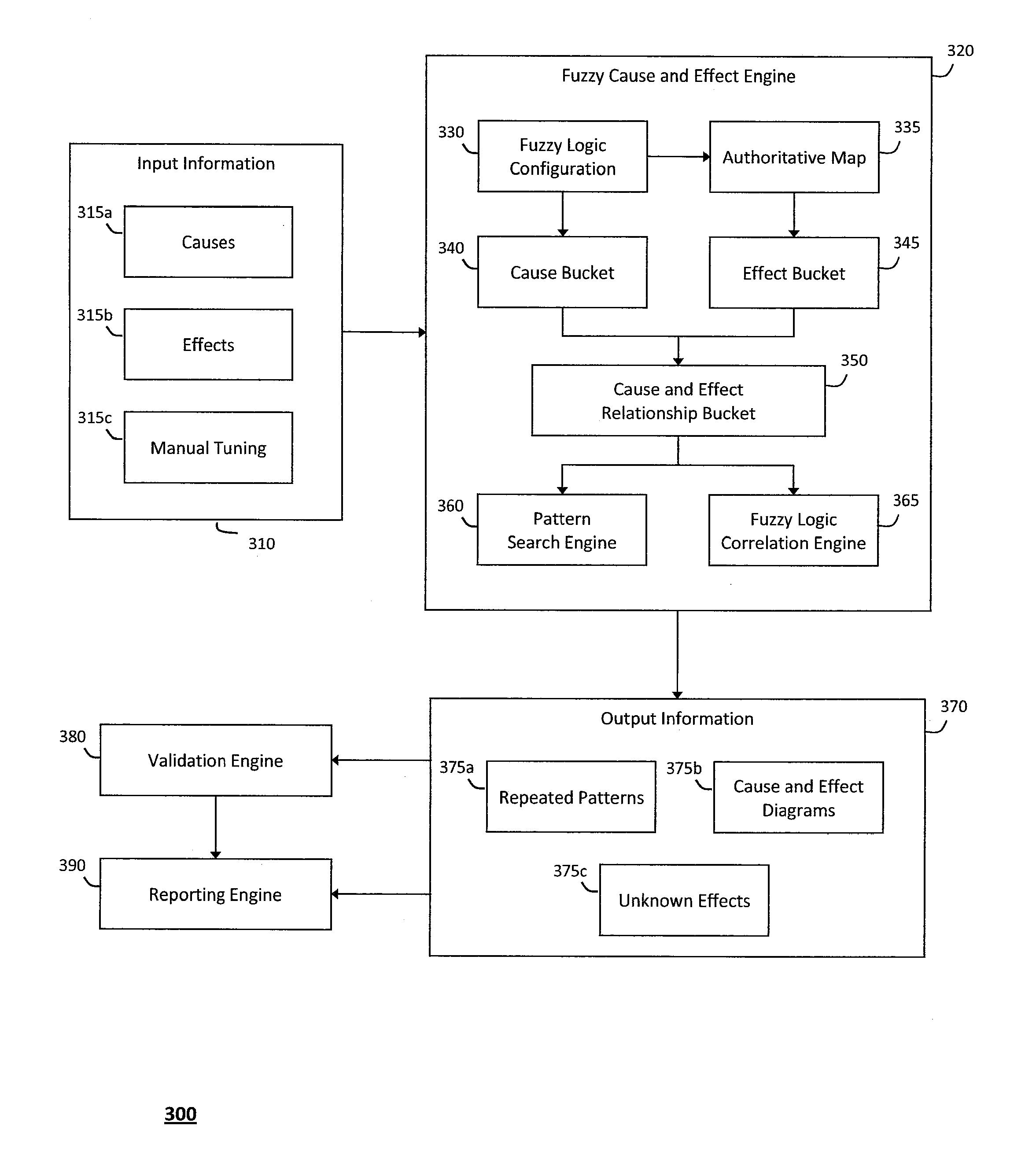

System and method for determining fuzzy cause and effect relationships in an intelligent workload management system

InactiveUS20120130936A1Determine relationshipEnable agilityFuzzy logic based systemsKnowledge representationKnowledge sourcesPotential effect

The system and method for determining fuzzy cause and effect relationships in an intelligent workload management system described herein may combine potential causes and effects captured from various different sources associated with an information technology infrastructure with substantially instantaneous feedback mechanisms and other knowledge sources. As such, fuzzy correlation logic may then be applied to the combined information to determine potential cause and effect relationships and thereby diagnose problems and otherwise manage interactions that occur in the infrastructure. For example, information describing potential causes and potential effects associated with an operational state of the infrastructure may be captured and combined, and any patterns among the information that describes the multiple potential causes and effects may then be identified. As such, fuzzy logic may the be applied to any such patterns to determine possible relationships among the potential causes and the potential effects associated with the infrastructure operational state.

Owner:MICRO FOCUS SOFTWARE INC

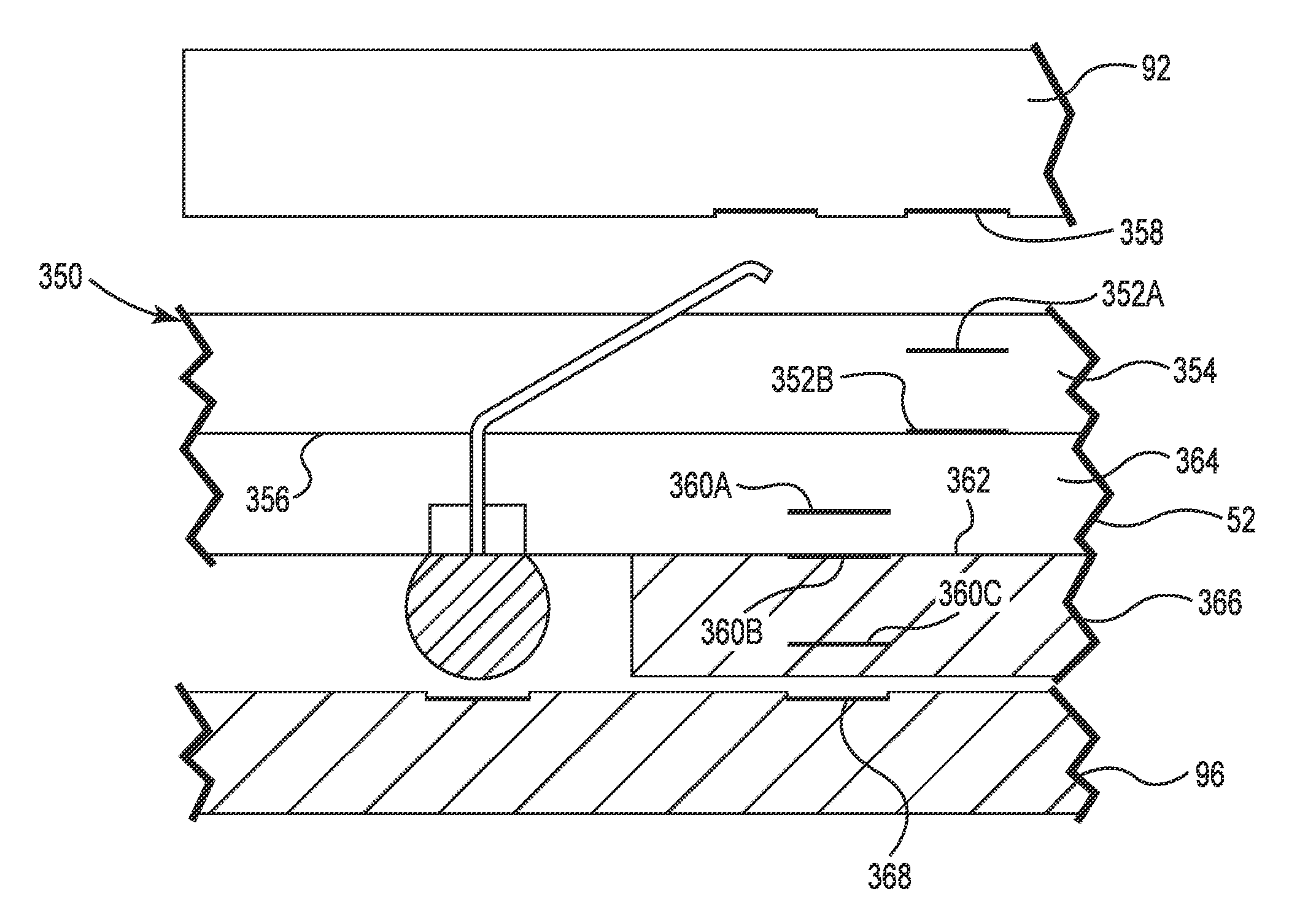

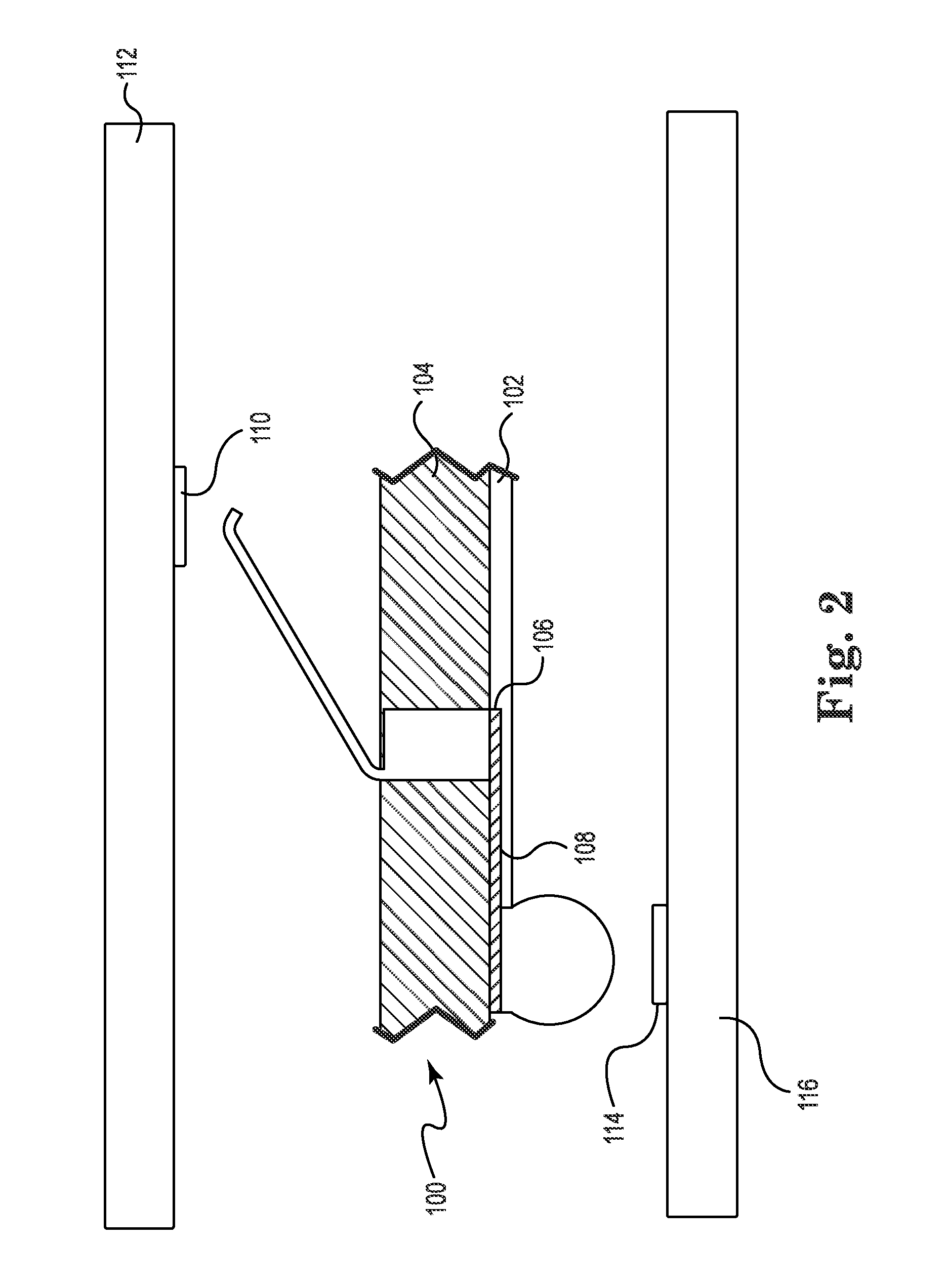

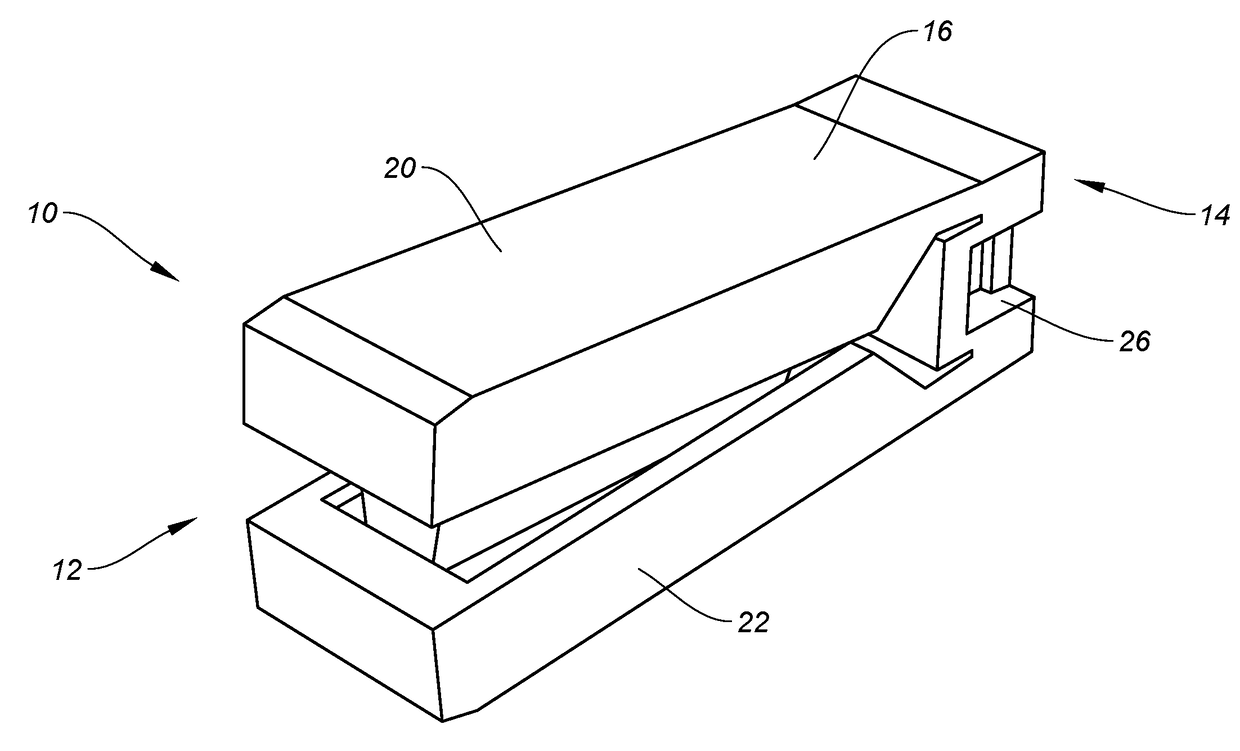

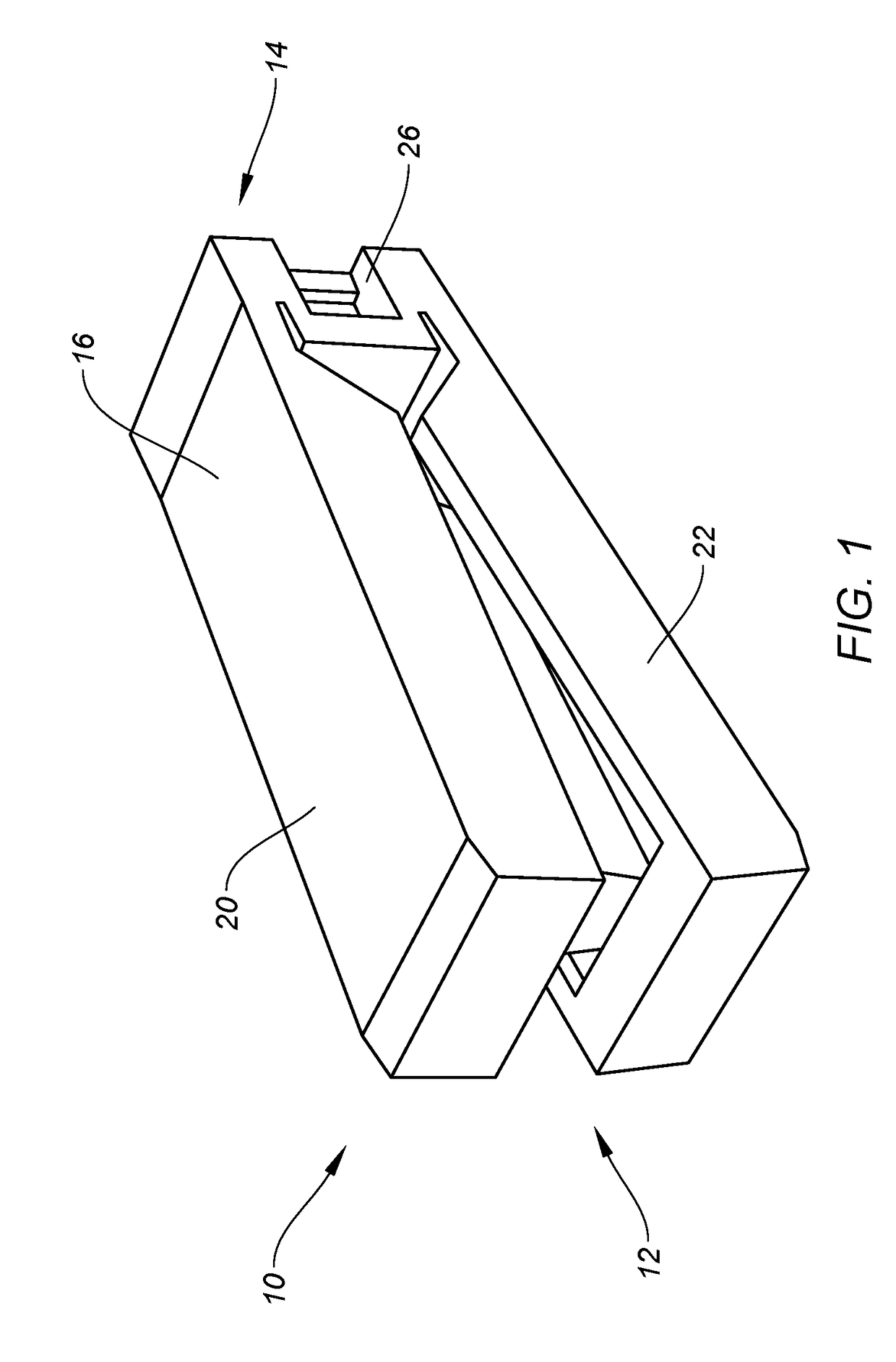

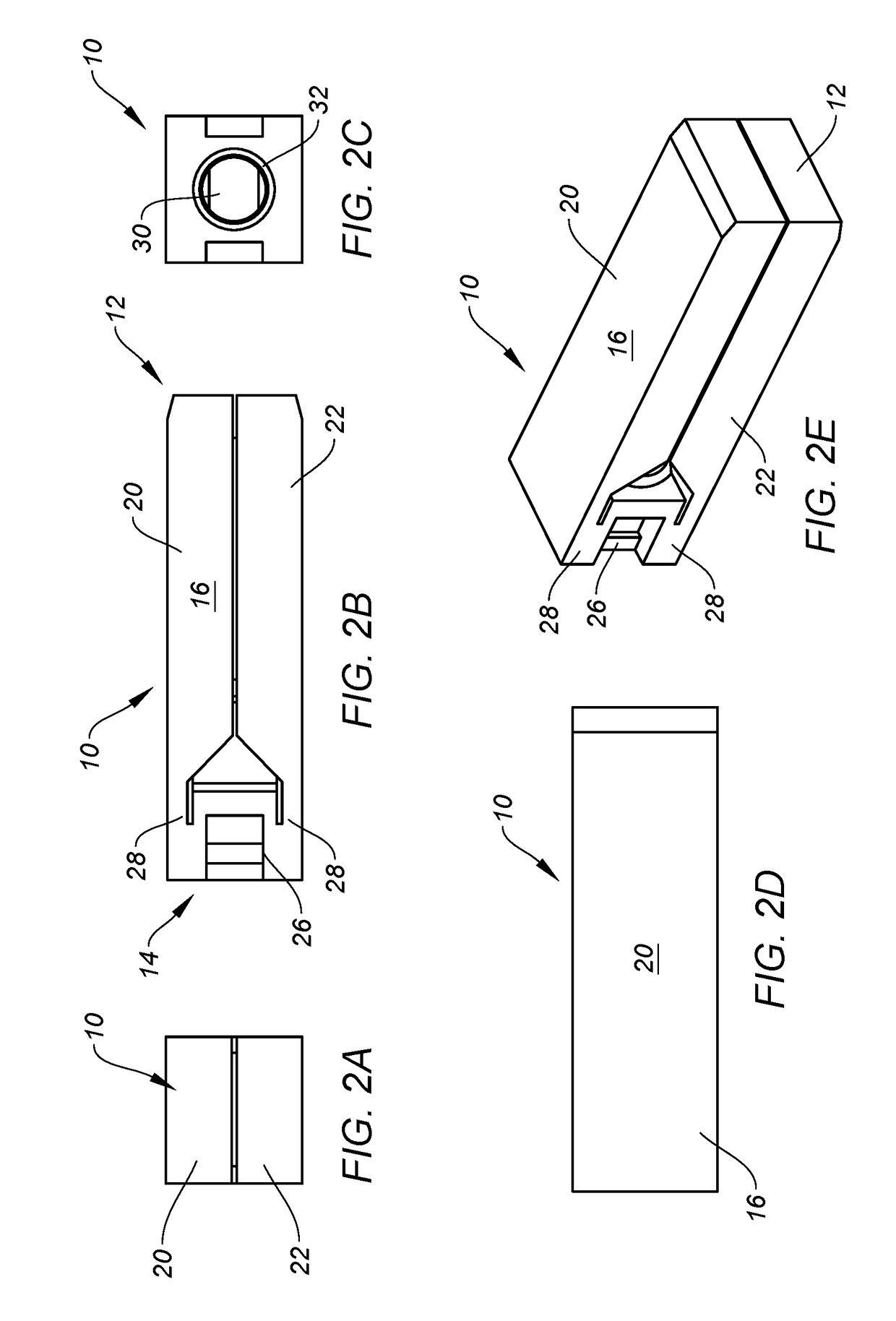

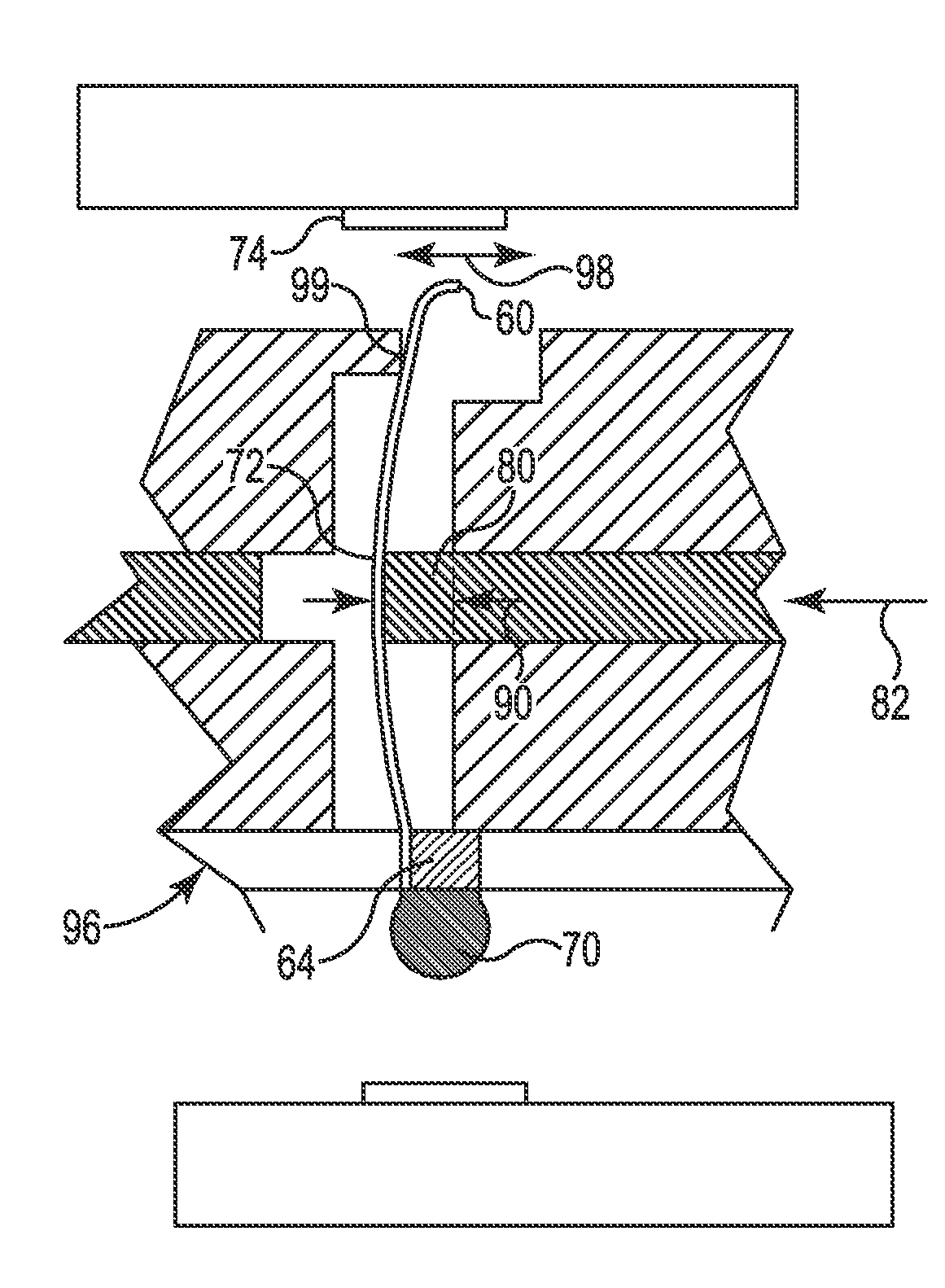

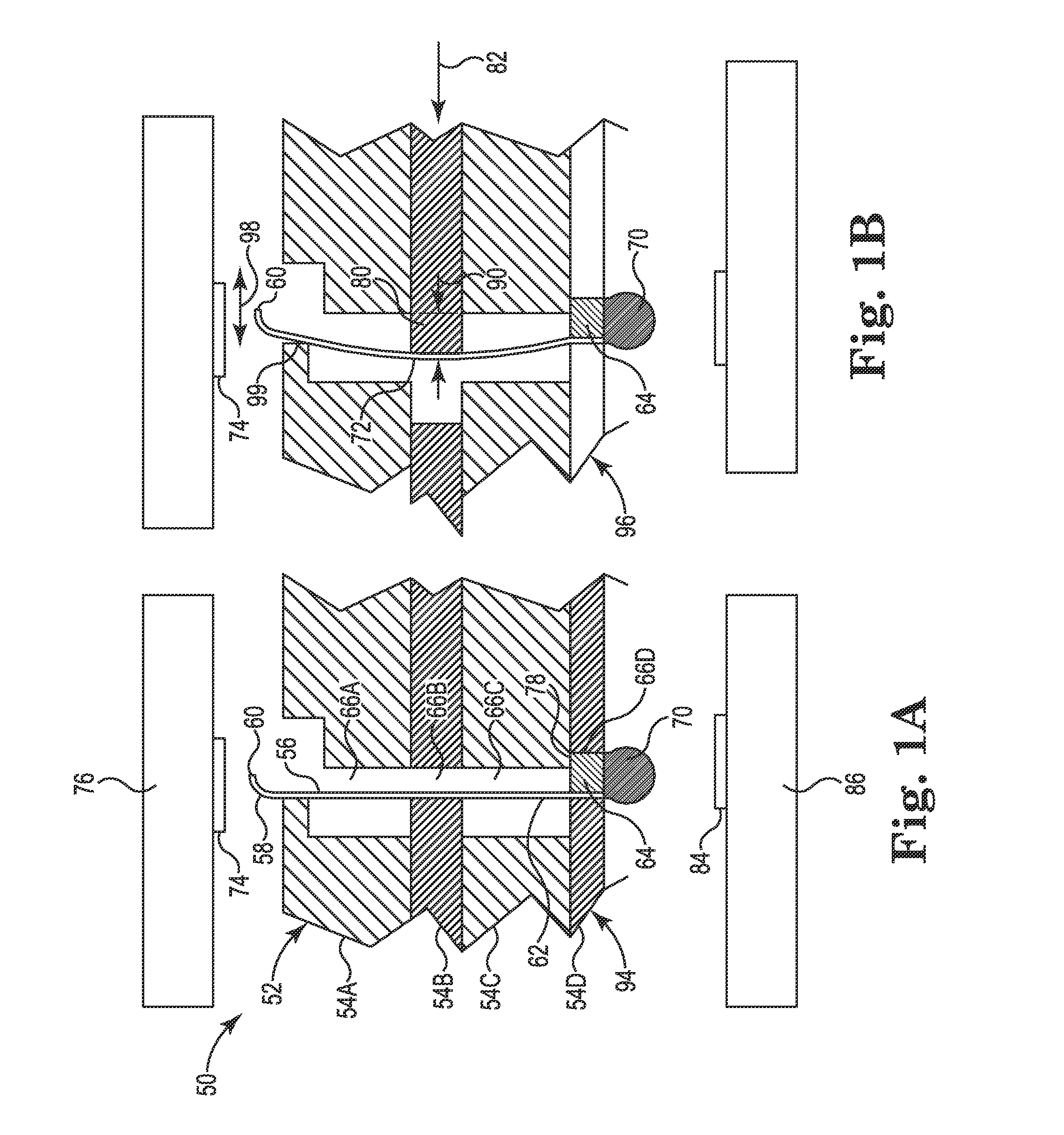

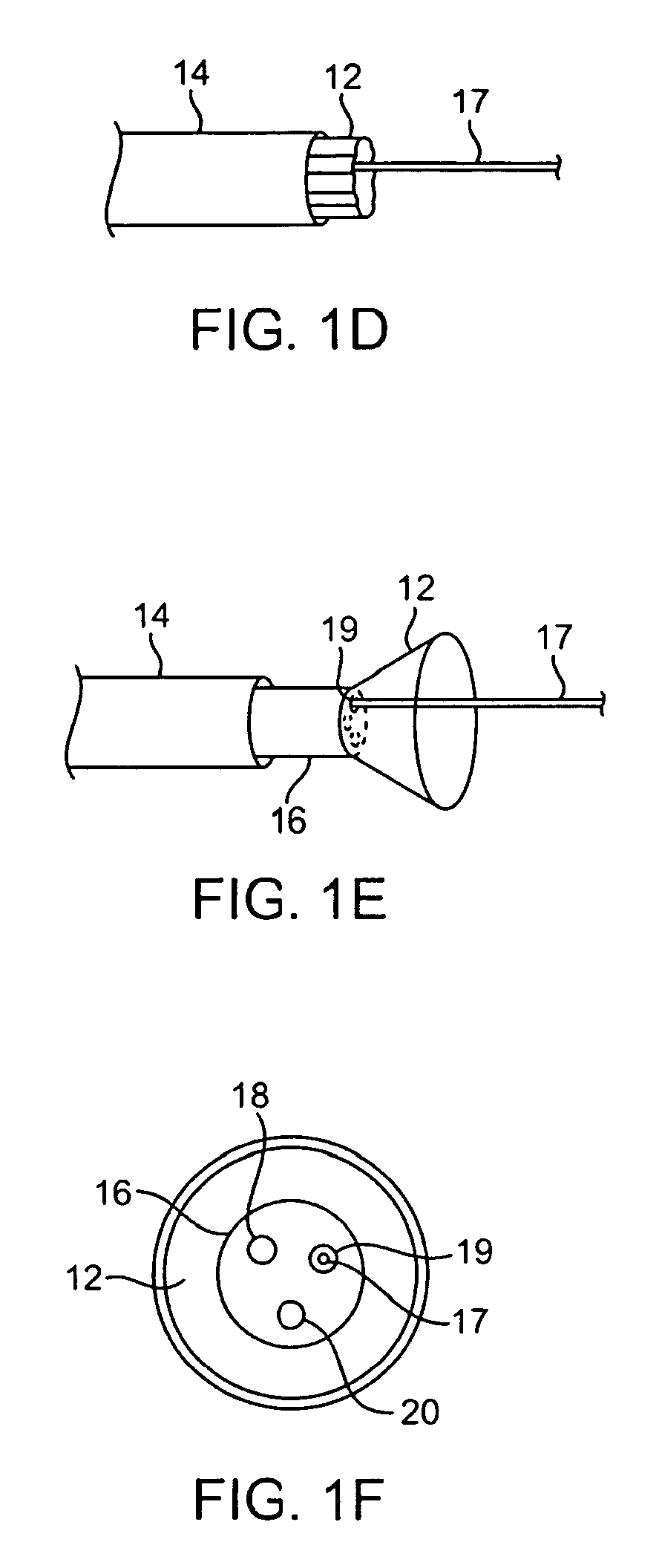

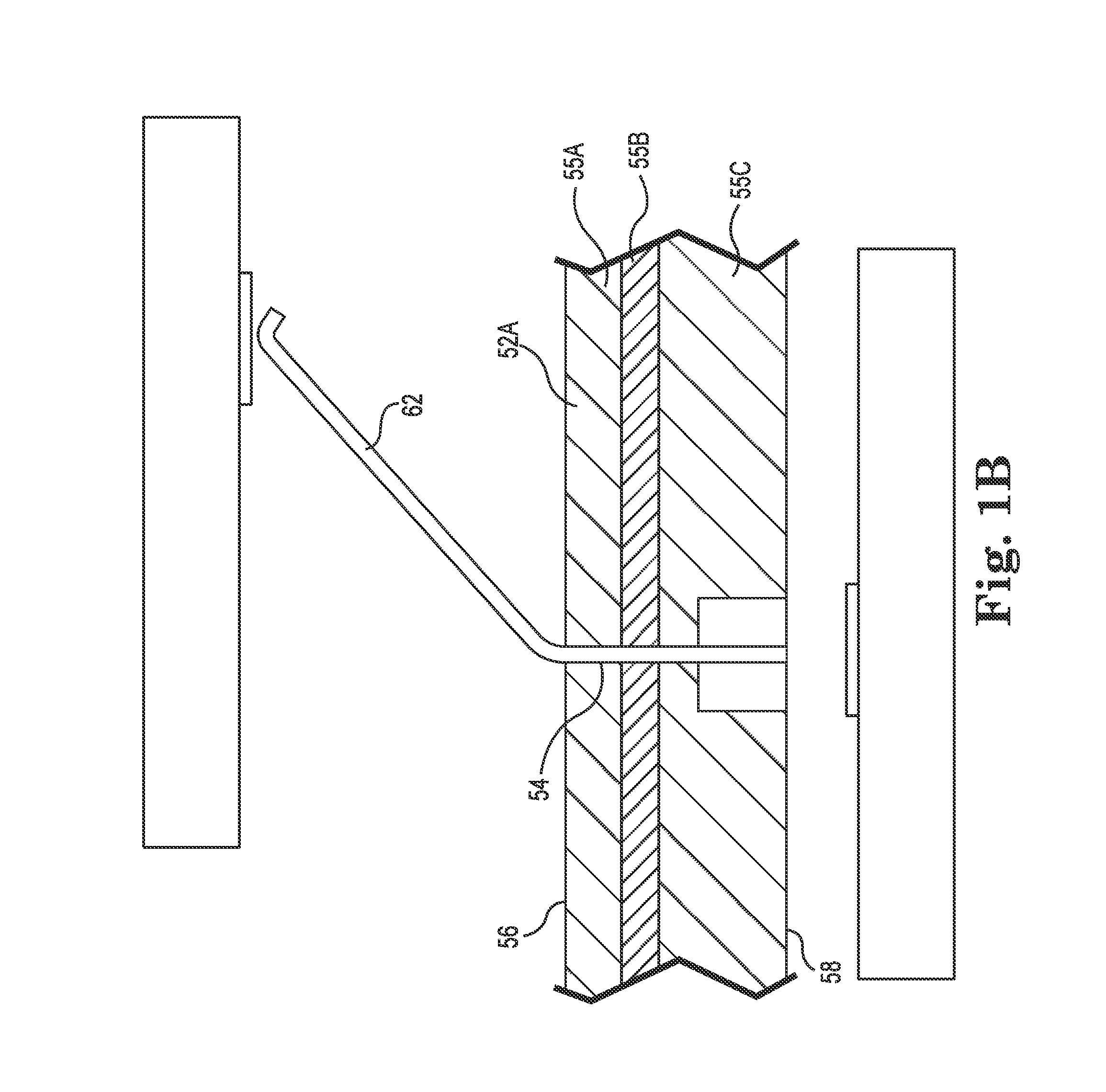

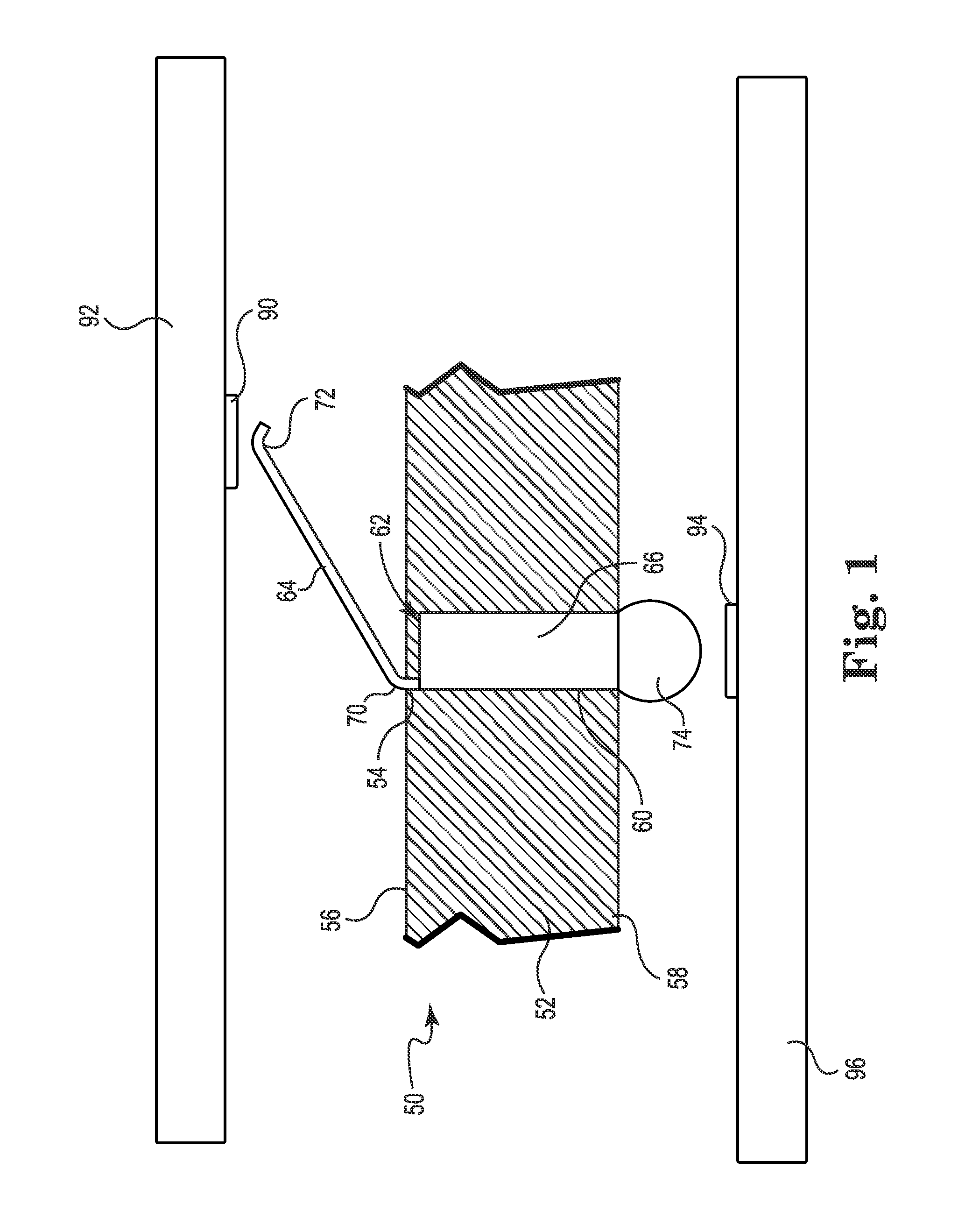

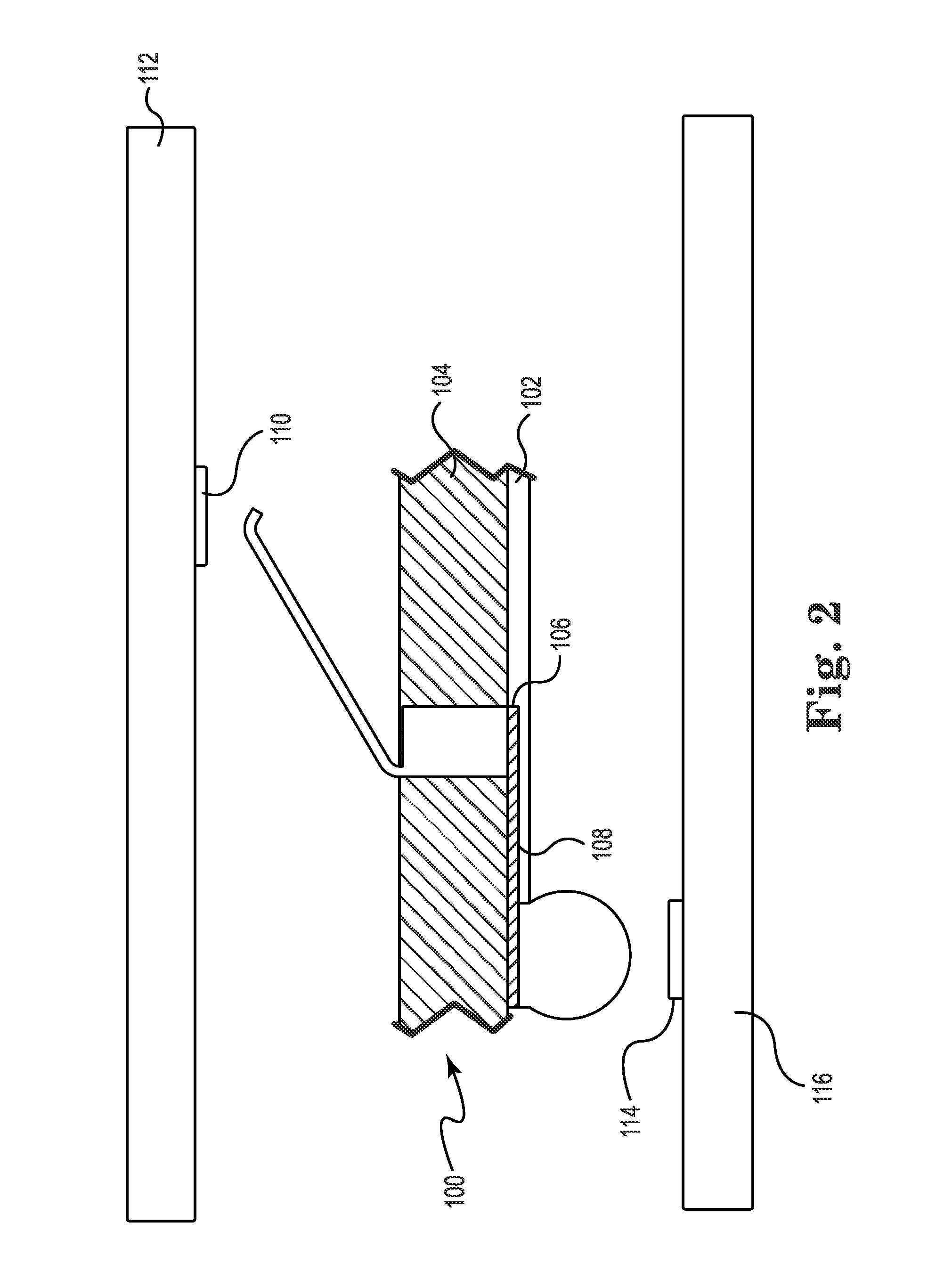

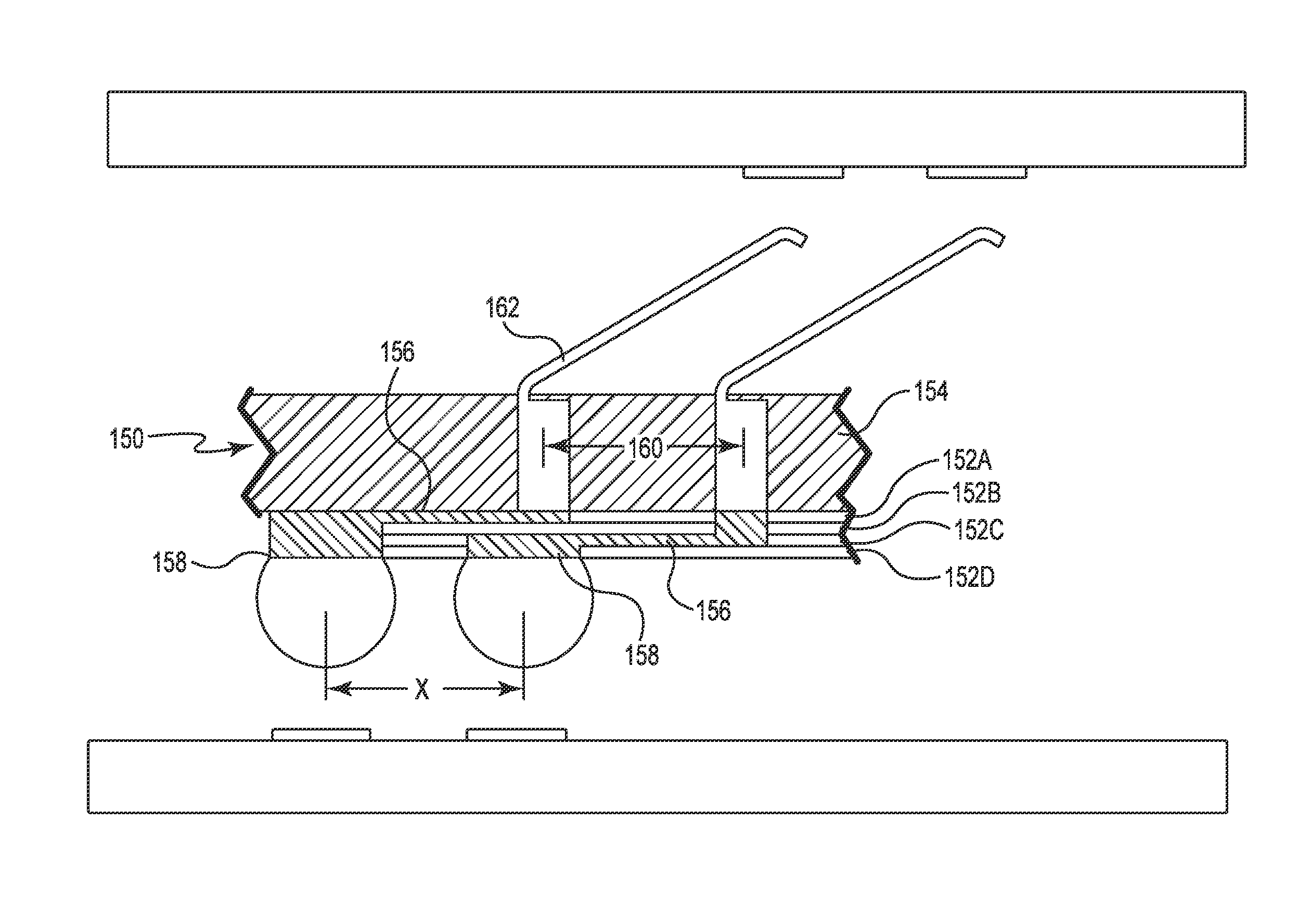

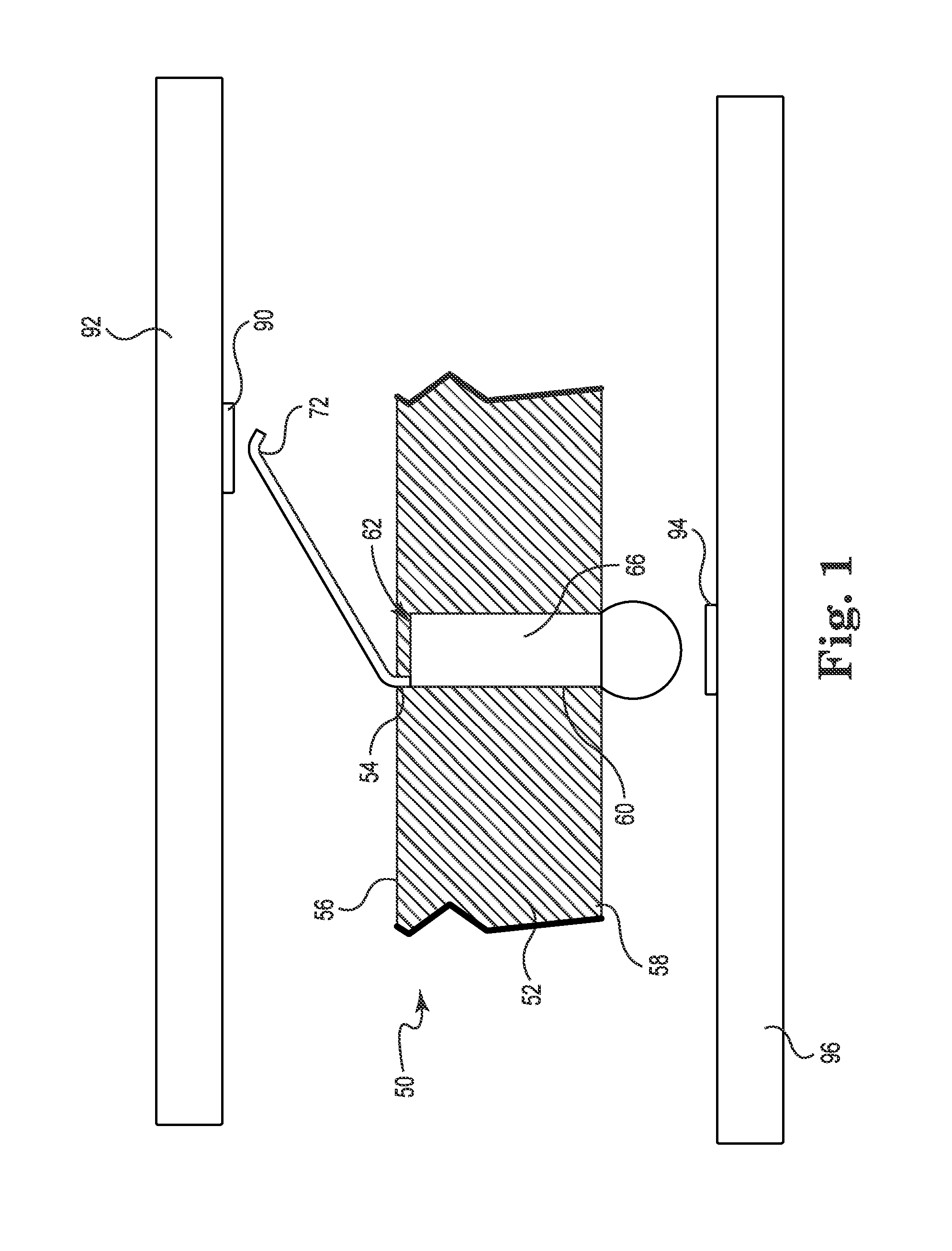

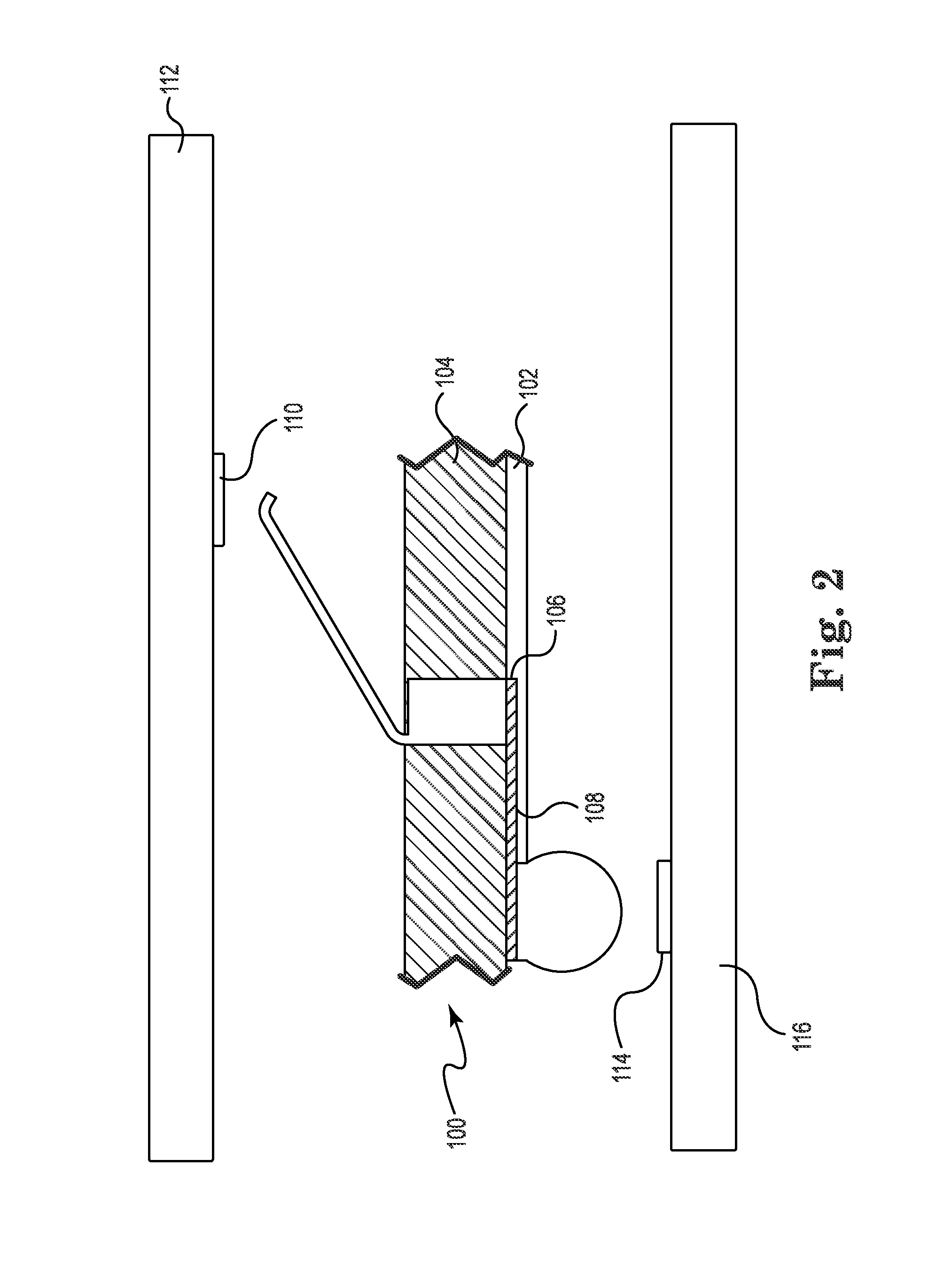

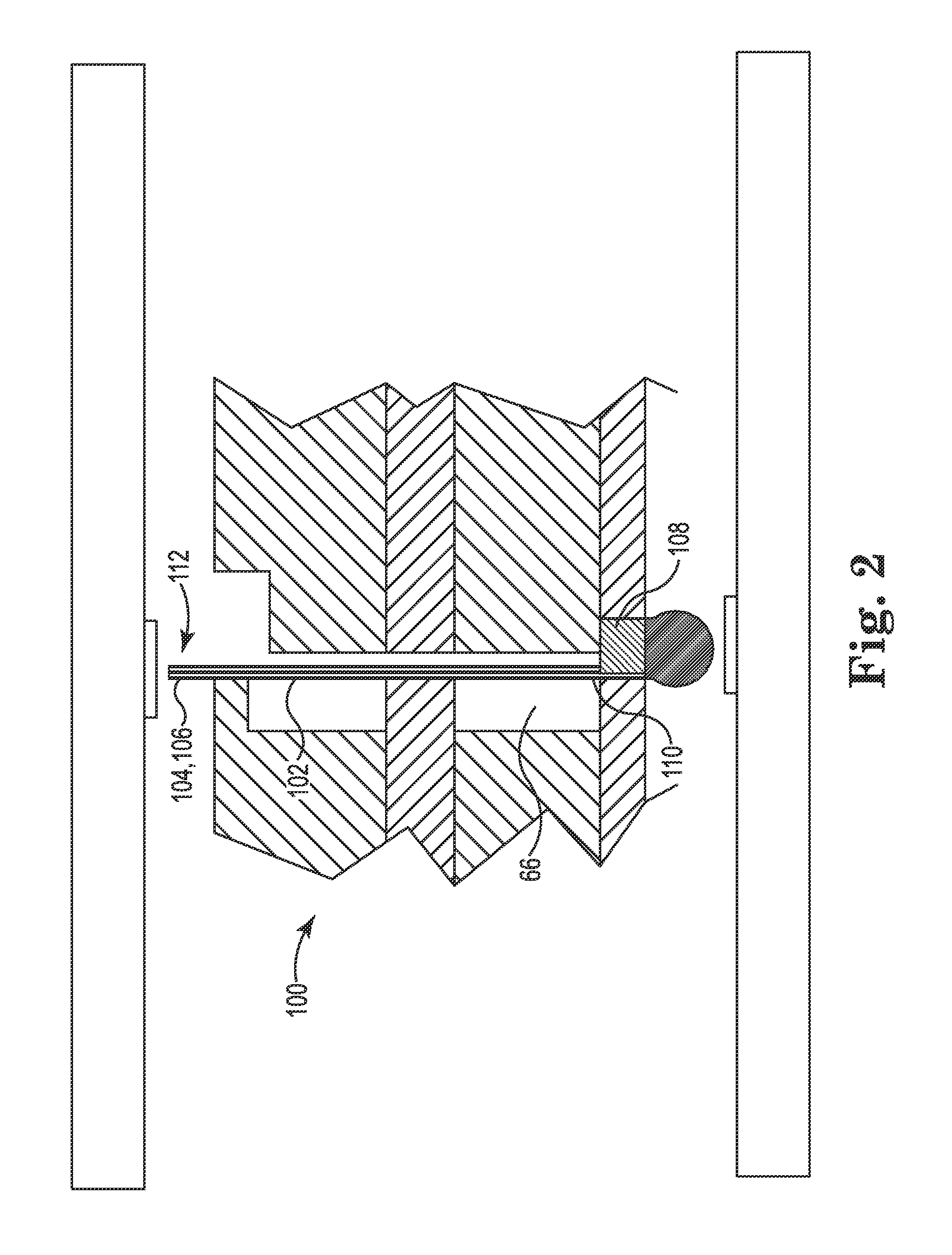

Electrical interconnect IC device socket

ActiveUS20130206468A1Firmly connectedAddress is challengeLine/current collector detailsElectrically conductive connectionsSurface mountingSolder ball

A surface mount electrical interconnect is disclosed that provides an interface between a PCB and solder balls of a BGA device. The electrical interconnect includes a socket substrate and a plurality of electrically conductive contact members. The socket substrate has a first layer with a plurality of openings configured to receive solder balls of the BGA device and has a second layer with a plurality of slots defined therethrough that correspond to the plurality of openings. The contact members may be disposed in the openings in the first layer and through the plurality of slots of the second layer of the socket substrate. The contact members can be configured to engage a top portion, a center diameter, and a lower portion of the solder ball of the BGA device. Each contact member electrically couples a solder ball on the BGA device to the PCB.

Owner:HSIO TECH

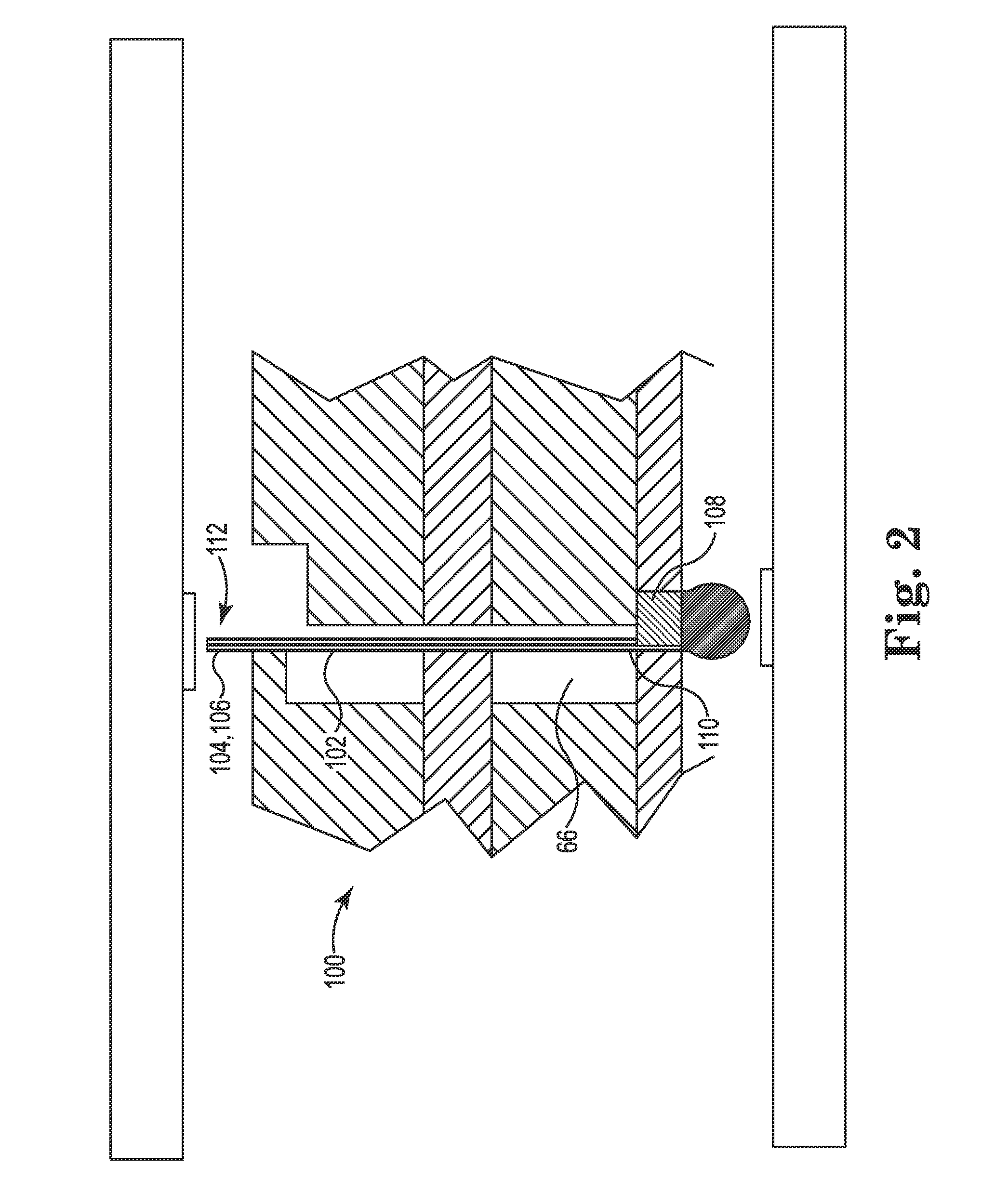

High performance surface mount electrical interconnect

ActiveUS20120055701A1Improve the substrateReduce complexityPrinted electric component incorporationFixed connectionsEngineeringMechanical engineering

An interconnect assembly including a substrate with a plurality of through holes extending from a first surface to a second surface. A plurality of discrete contact member are located in the plurality of through holes. The contact members include proximal ends that are accessible from the second surface, distal ends extending above the first surface, and intermediate portions engaged with an engagement region of the substrate located between the first surface and the recesses. Retention members are coupled with at least a portion of the proximal ends to retain the contact members in the through holes. The retention members can be made from a variety of materials with different levels of conductivity, ranging from highly conductive to non-conductive.

Owner:HSIO TECH

Semiconductor socket

ActiveUS20120051016A1Improve electrical performanceImprove intelligenceElectrically conductive connectionsPrinted circuit aspectsConductive materialsDielectric layer

A semiconductor socket including a substrate with a plurality of through holes extending from a first surface to a second surface. A plurality of discrete contact members are located in the plurality of the through holes. The plurality of contact members each include a proximal end accessible from the second surface, and a distal end extending above the first surface. At least one dielectric layer is bonded to the second surface of the substrate with recesses corresponding to target circuit geometry. A conductive material deposited in at least a portion of the recesses to form conductive traces redistributing terminal pitch of the proximal ends of the contact members.

Owner:HSIO TECH

Expandable, angularly adjustable intervertebral cages

ActiveUS20170367843A1Easy to insertStabilize spineJoint implantsSpinal implantsIntervertebral spaceReduced size

The embodiments provide various interbody fusion spacers, or cages, for insertion between adjacent vertebrae. These intervertebral cages can restore and maintain intervertebral height of the spinal segment to be treated, and stabilize the spine by restoring sagittal balance and alignment. The cages may have a first, insertion configuration characterized by a reduced size at each of their insertion ends to facilitate insertion through a narrow access passage and into the intervertebral space. The cages may be expanded to a second, expanded size once implanted. In their second configuration, the cages are able to maintain the proper disc height and stabilize the spine by restoring sagittal balance and alignment. The intervertebral cages are configured to be able to adjust the angle of lordosis, and can accommodate larger lodortic angles in their second, expanded configuration. Further, these cages may promote fusion to further enhance spine stability by immobilizing the adjacent vertebral bodies.

Owner:EIT EMERGING IMPLANT TECH GMBH

High performance electrical connector with translated insulator contact positioning

ActiveUS20140220797A1Reliable flexural propertyReduce complexityContact member cases/bases manufactureCoupling device detailsDistal portionProximal point

An electrical interconnect including a substrate with at least two adjacent layers configured to translate relative to each other between a nominal position and a translated position. A plurality of through holes are formed through the layers from a first surface of the substrate to a second surface of the substrate in both the nominal position and the translated position. At least one contact member is positioned in the through holes with distal portions accessible from the first surface and a proximal portions positioned near the second surface. The proximal portion of the contact members are secured to the substrate near the second surface with a conductive structure. The two adjacent layers of the substrate are translated from the nominal position to the translated position to elastically deform the contact members within the through holes and to displace the distal portions of the contact members toward the conductive structures, respectively.

Owner:HSIO TECH

Complex shape steerable tissue visualization and manipulation catheter

Complex steerable catheter visualization and tissue manipulation systems and their methods of use are disclosed herein. The deployment catheter is articulated using various steering mechanisms. Tissue visualization is accomplished from the visualization hood at the distal end of the deployment catheter, the hood having an ability to expand and other features to facilitate visualization and articulation at the tissue surface.

Owner:INTUITIVE SURGICAL OPERATIONS INC

High performance surface mount electrical interconnect

ActiveUS8955215B2Reduce complexityFirmly connectedCoupling device connectionsPrinted circuit assemblingEngineeringMechanical engineering

A method of forming an interconnect assembly including forming a substrate with a plurality of through holes extending from a first major surface to a second major surface. A plurality of recesses are formed in the second major surface of the substrate that at least partially overlap with the plurality of through holes. The recesses have a cross-sectional area greater than a cross-sectional area of the through holes. At least one discrete contact member is inserted in a plurality of the through holes. The contact members include proximal ends extending into the recesses, distal ends extending above the first major surface, and intermediate portions engaged with an engagement region of the substrate located between the first major surface and the recesses. Retention members at least partially deposited in the recesses bond to the proximal ends to retain the contact members in the through holes.

Owner:HSIO TECH

Method, apparatus, and system for computer-aided tracking, navigation and motion teaching

ActiveUS9082319B2Reduce difficultyEasy to useDiagnosticsSurgical instrument supportDegrees of freedomComputer-aided

Methods, apparatuses, and systems for computer-aided tracking, navigation, and motion tracking. In one embodiment, a system for determining a spatial position, including a tracking device and a processor. The tracking devices has a working end, a reference end, a plurality of links connecting the working end to the reference end, wherein each link has at least one degree of freedom relative to an adjacent link, and a plurality of sensors measuring the orientation of the links in a plurality of degrees of freedom, wherein X is a minimum number of degrees of freedom about which information is required to define the spatial position. The processor receives information from the sensors and determine the spatial position of the working end of the tracking device relative to the reference end of the tracking device based on information from the sensors measuring Y degrees of freedom, wherein Y is greater than X.

Owner:CARNEGIE MELLON UNIV

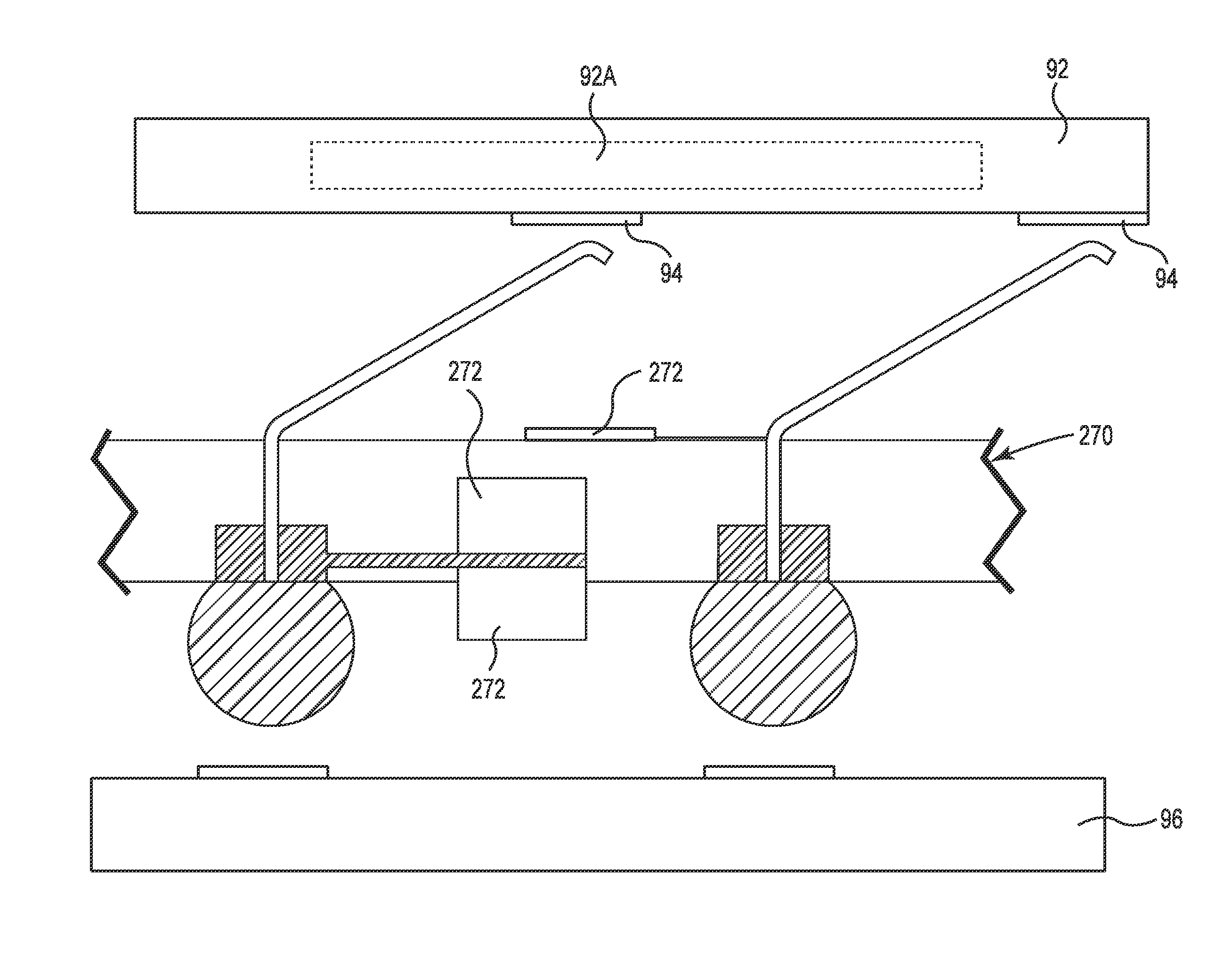

Apparatus and method for waveguide to microstrip transition having a reduced scale backshort

ActiveUS20060255875A1Reduce problem sizeAddress is challengeMultiple-port networksOne-port networksResonanceAcoustics

Methods and apparatuses are directed to a transition between a waveguide and a microstrip. One embodiment features an open-ended waveguide having an exposed side at a distal end, a substrate coupled to the open-ended waveguide at a proximate end, a resonator coupled to the substrate, a microstrip line electromagnetically coupled to the resonator, and a backshort coupled to the substrate. Another embodiment features receiving an electromagnetic wave, collecting an incident portion of the received electromagnetic wave, generating first wave having a resonance at a predetermined frequency using the incident portion of the received electromagnetic wave, reflecting a portion of the received electromagnetic wave off of a reduced scale backshort, back towards a collector, generating a second wave having a resonance at a predetermined frequency using the reflected portion of the received electromagnetic wave, and combining the first wave and the second wave in phase.

Owner:FURUNO ELECTRIC CO LTD

System and method for determining fuzzy cause and effect relationships in an intelligent workload management system

InactiveUS8620851B2Enable agilityEnable flexibilityFuzzy logic based systemsKnowledge representationKnowledge sourcesPotential effect

The system and method for determining fuzzy cause and effect relationships in an intelligent workload management system described herein may combine potential causes and effects captured from various different sources associated with an information technology infrastructure with substantially instantaneous feedback mechanisms and other knowledge sources. As such, fuzzy correlation logic may then be applied to the combined information to determine potential cause and effect relationships and thereby diagnose problems and otherwise manage interactions that occur in the infrastructure. For example, information describing potential causes and potential effects associated with an operational state of the infrastructure may be captured and combined, and any patterns among the information that describes the multiple potential causes and effects may then be identified. As such, fuzzy logic may the be applied to any such patterns to determine possible relationships among the potential causes and the potential effects associated with the infrastructure operational state.

Owner:MICRO FOCUS SOFTWARE INC

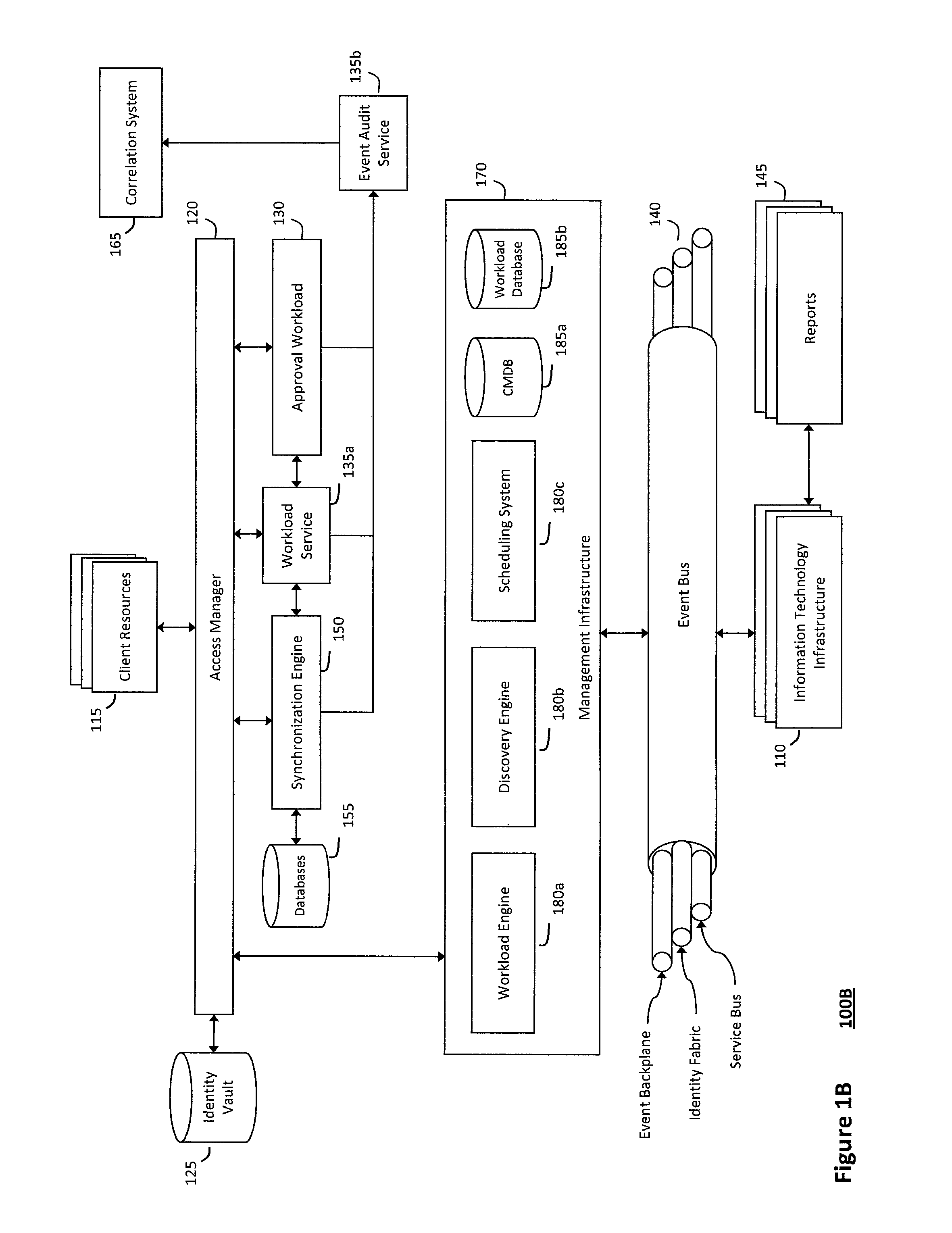

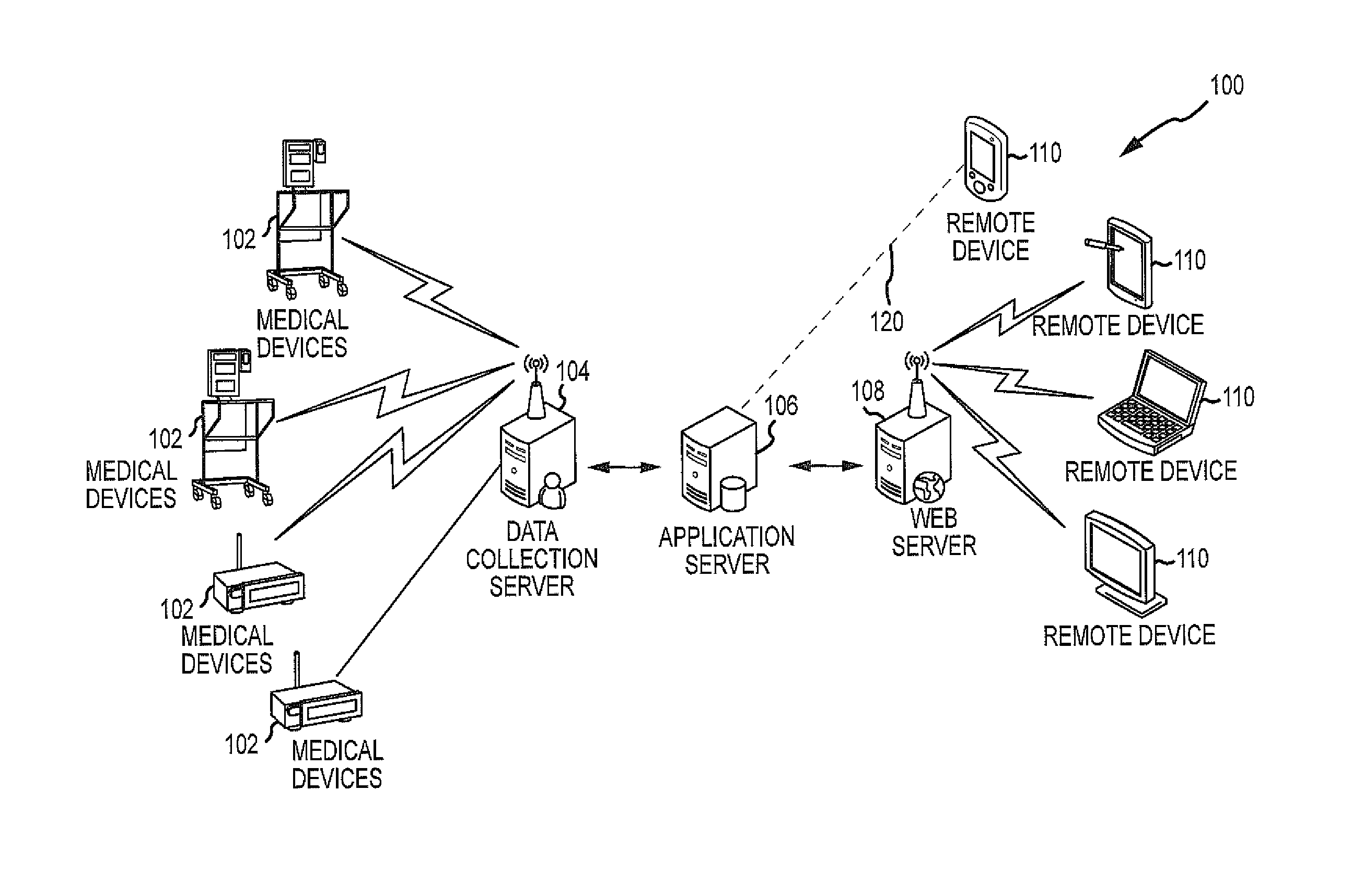

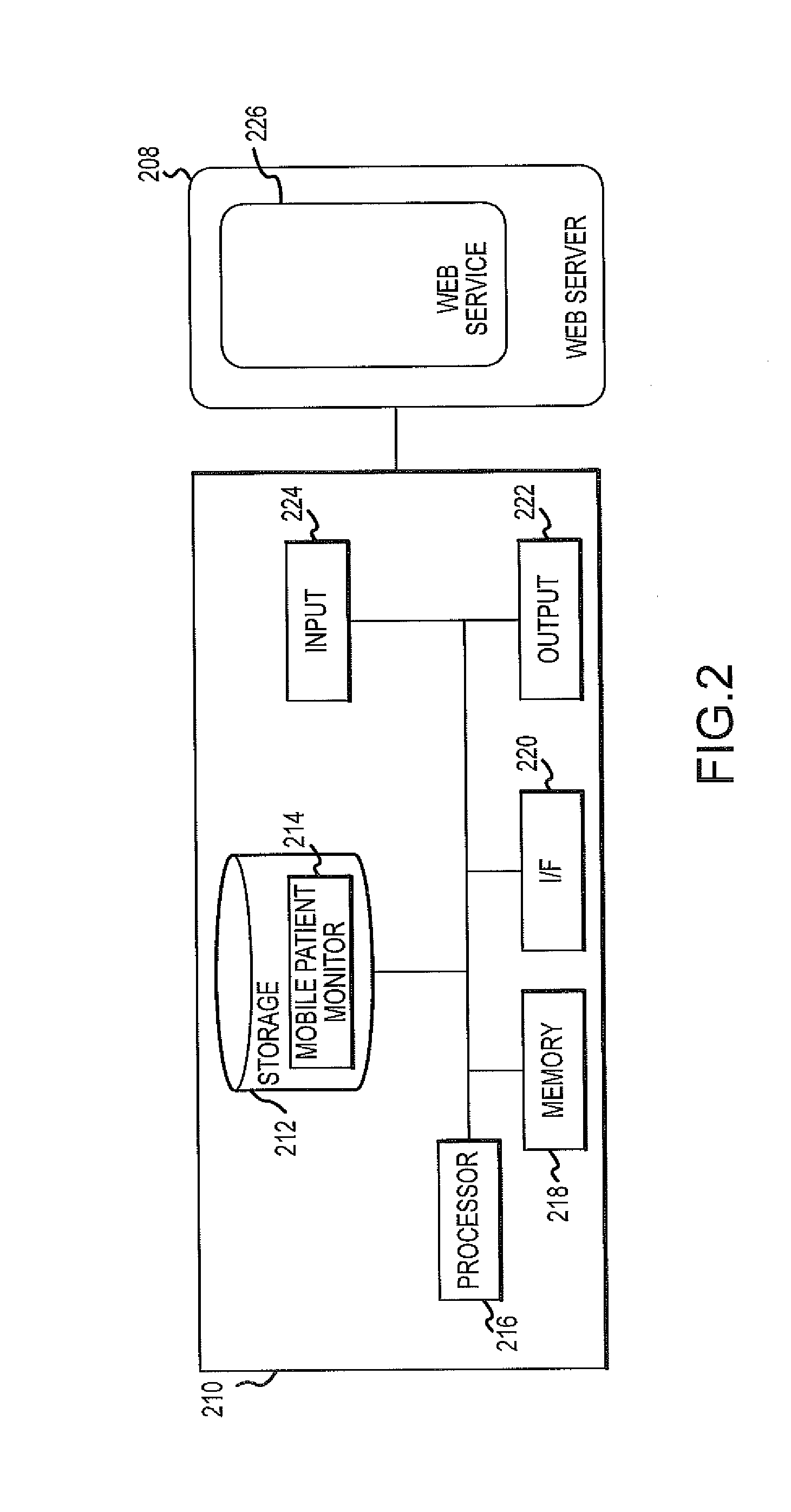

System, method, and software for automating physiologic displays and alerts with trending heuristics

ActiveUS20140085080A1Disadvantages can be reduced eliminatedImproved alerting scenarioSensorsMedical equipmentHeuristicSmoothing operator

A method for automating physiologic alerts and derived parameters with trending heuristics includes receiving at a mobile patient monitor interface, a first input expression indicative of a first parameter source for first patient parameters from a first medical device from a user. The method further includes receiving, at the mobile patient monitor interface, a second input expression indicative of a second parameter source for second patient parameters from a second medical device from a user. The method further includes applying, at the mobile patient monitor interface, a smoothing operator to the first input expression and the second input expression. The method further includes evaluating, at the mobile patient monitor interface, a complex expression of the first patient parameters and the second patient parameters based on the smoothing operator to initiate display of at least one parameter, derived parameter, trend, or alert on a remote device.

Owner:NELLCOR PURITAN BENNETT LLC

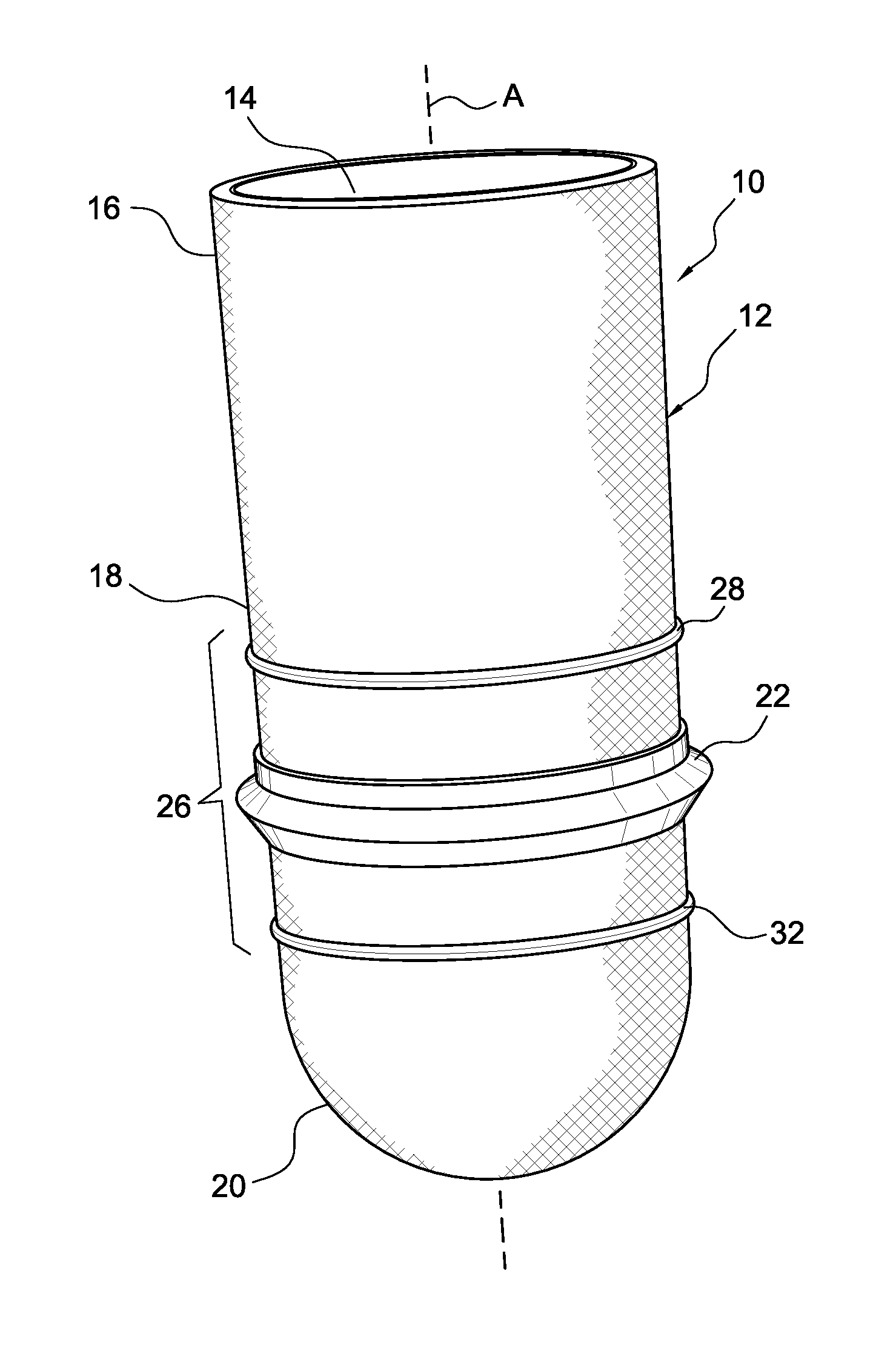

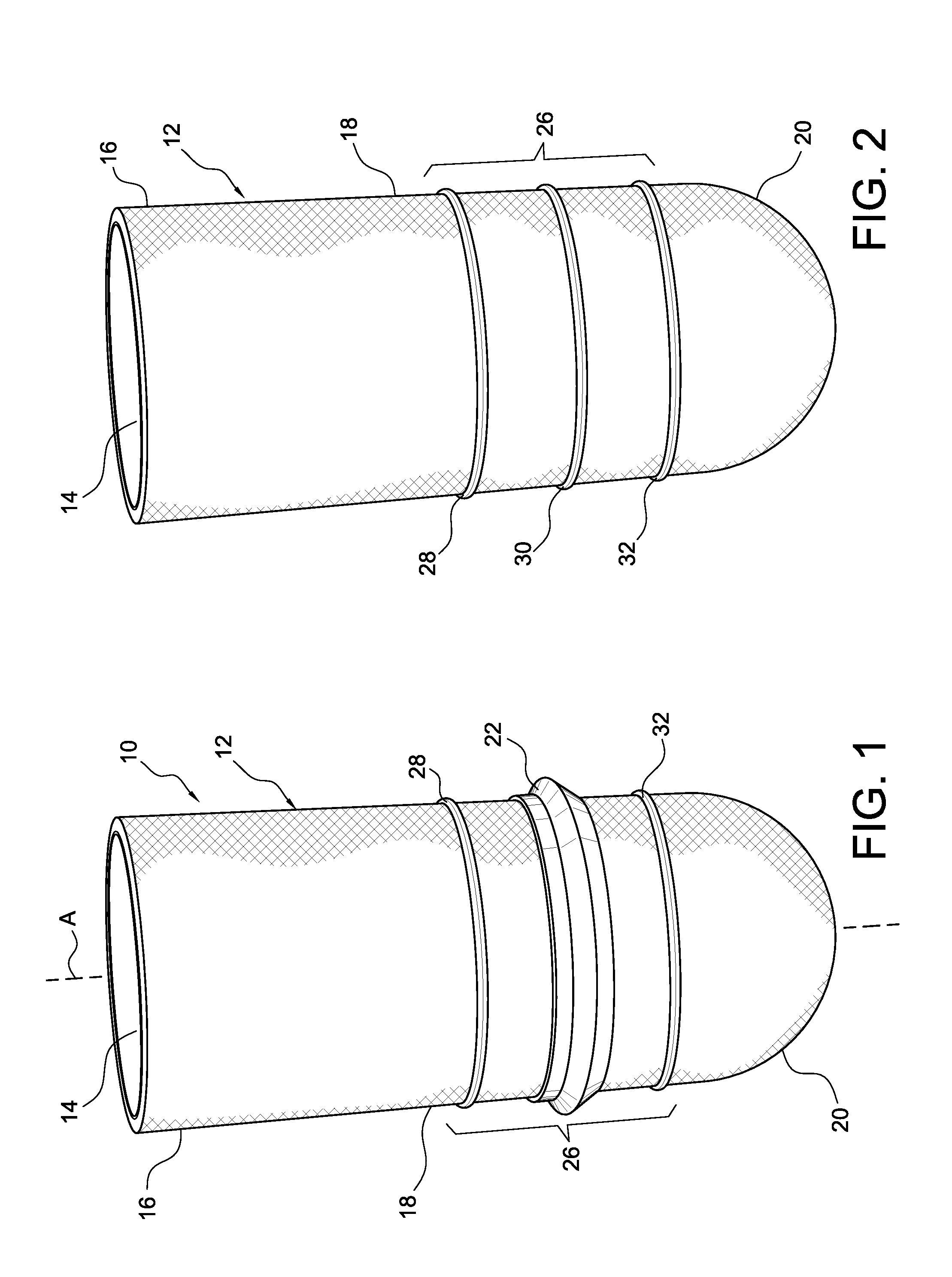

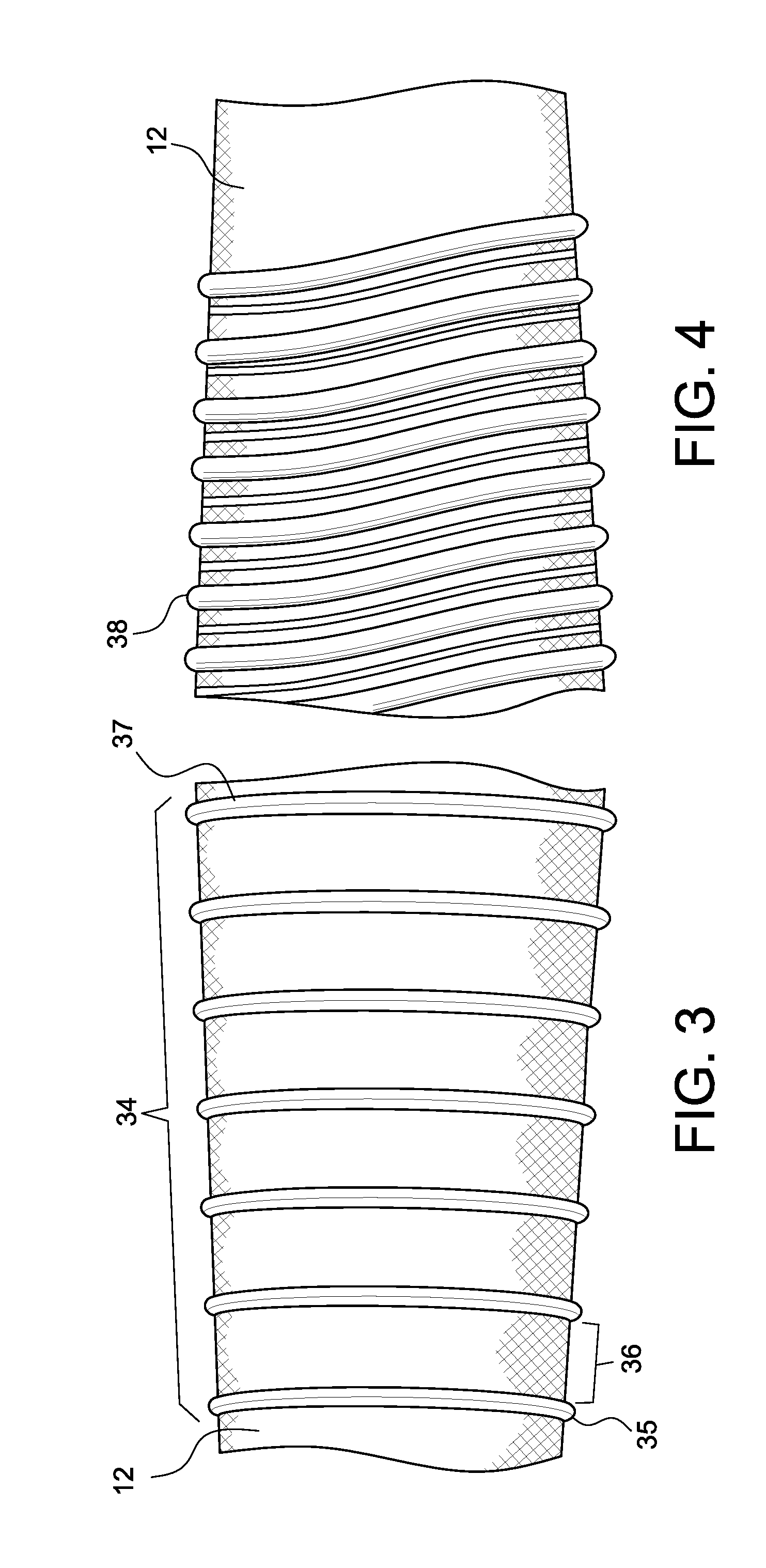

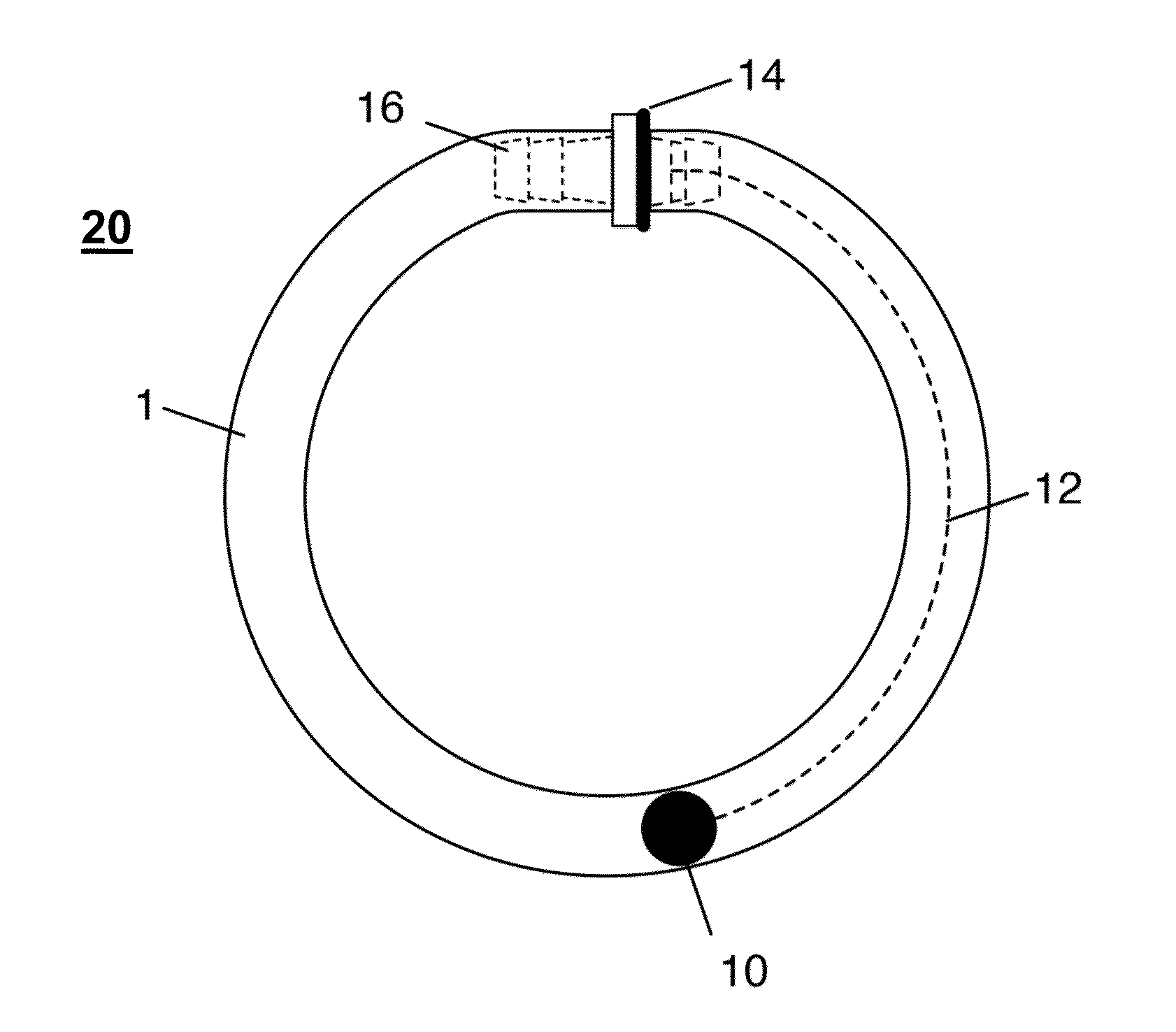

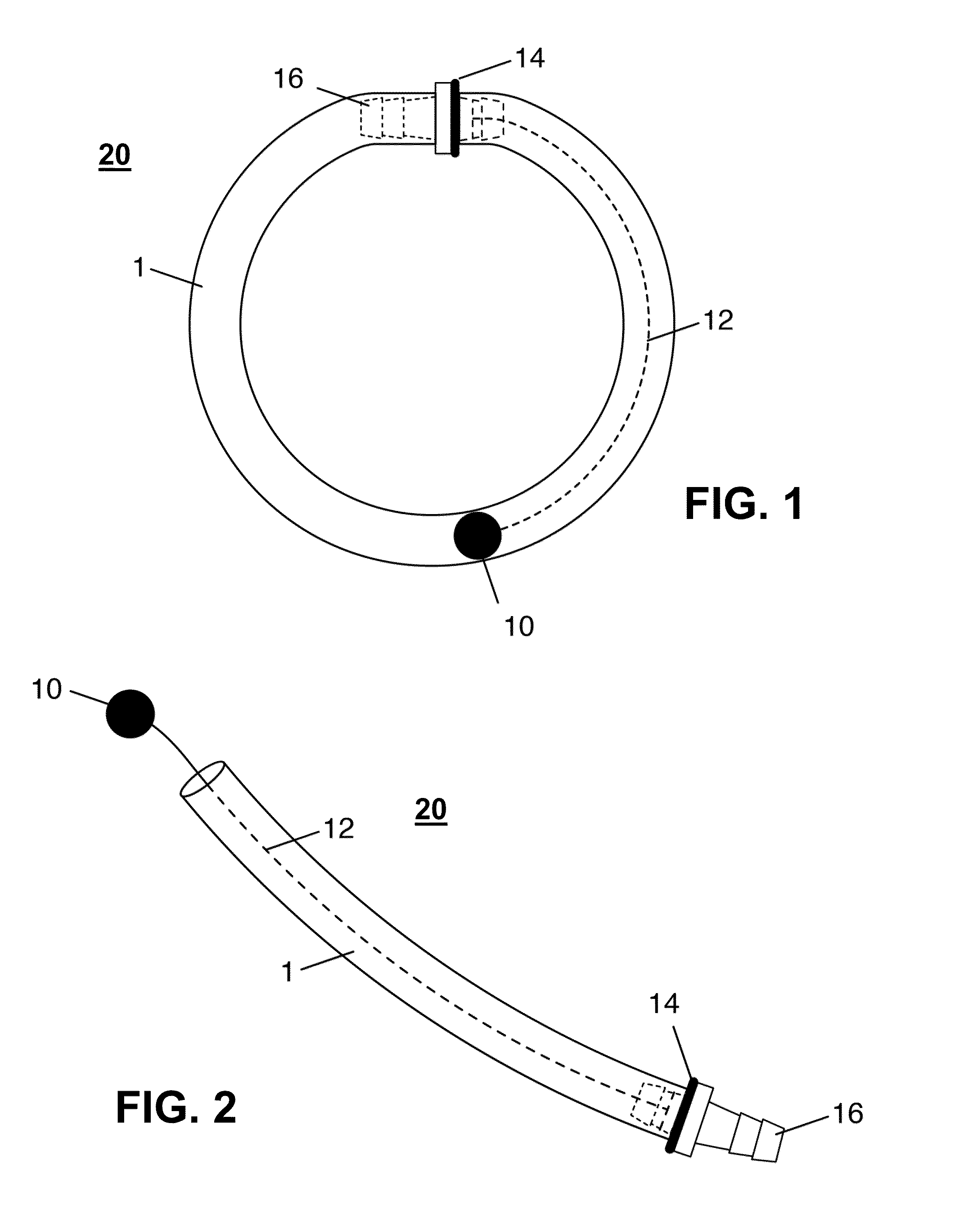

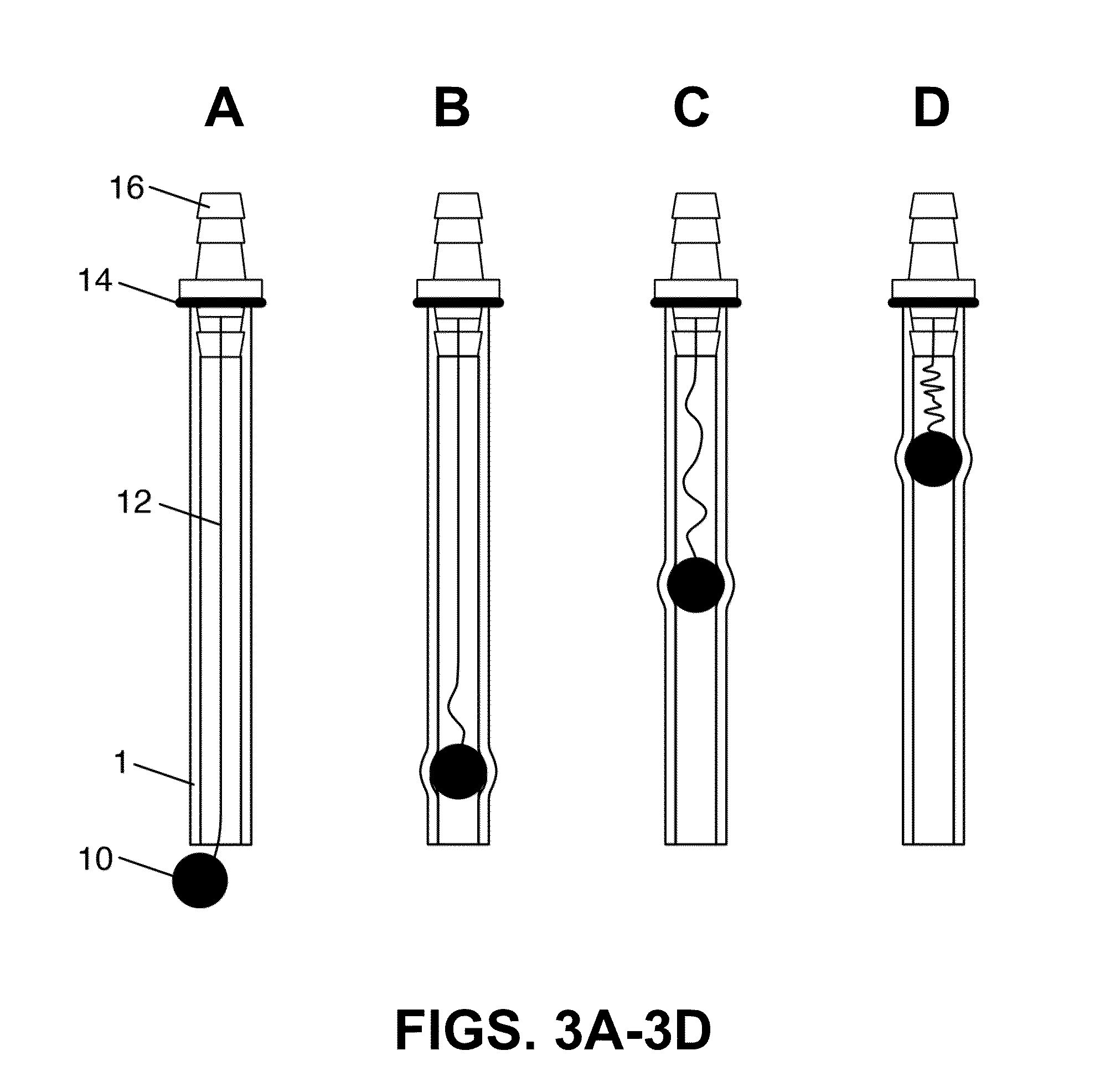

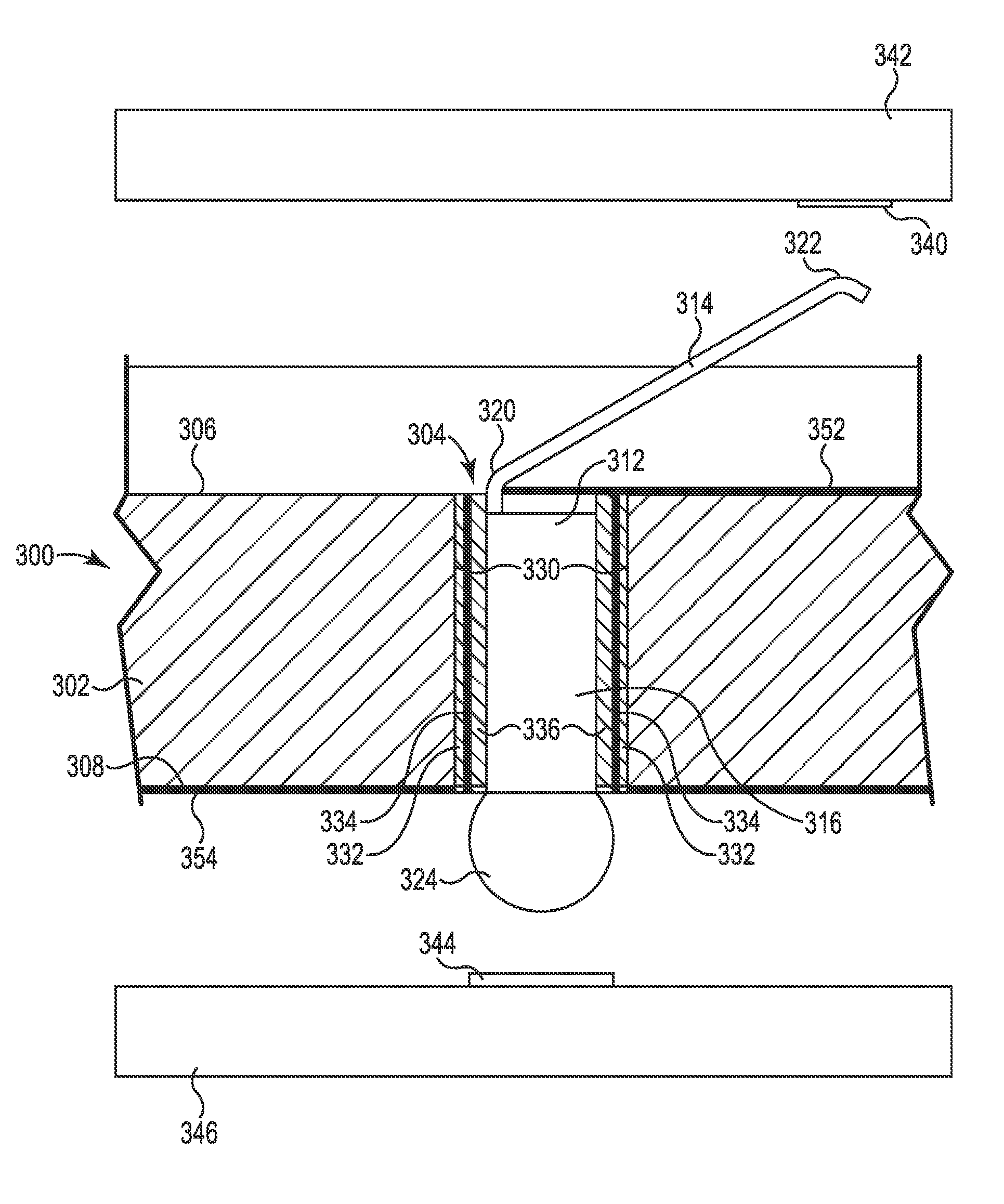

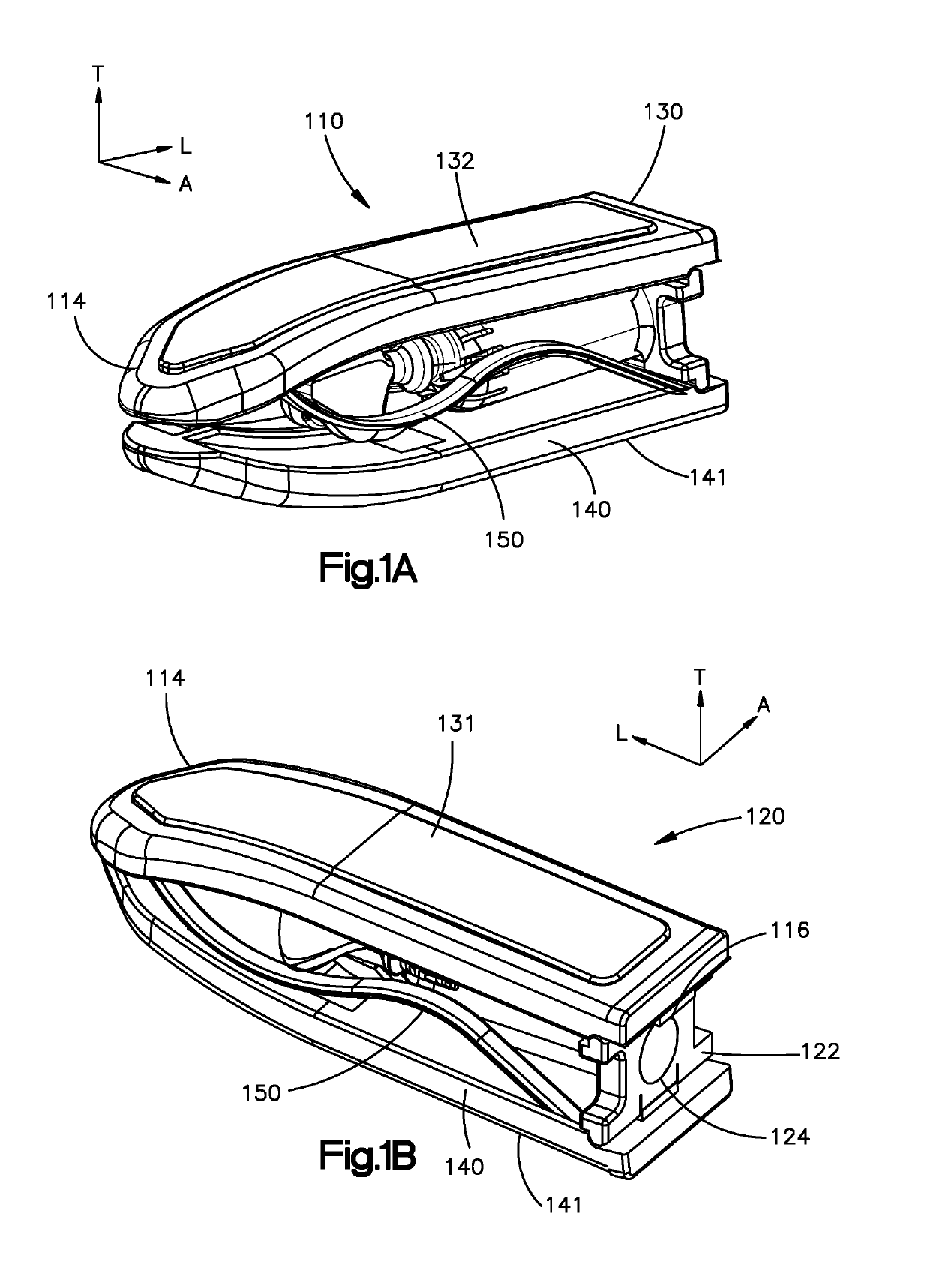

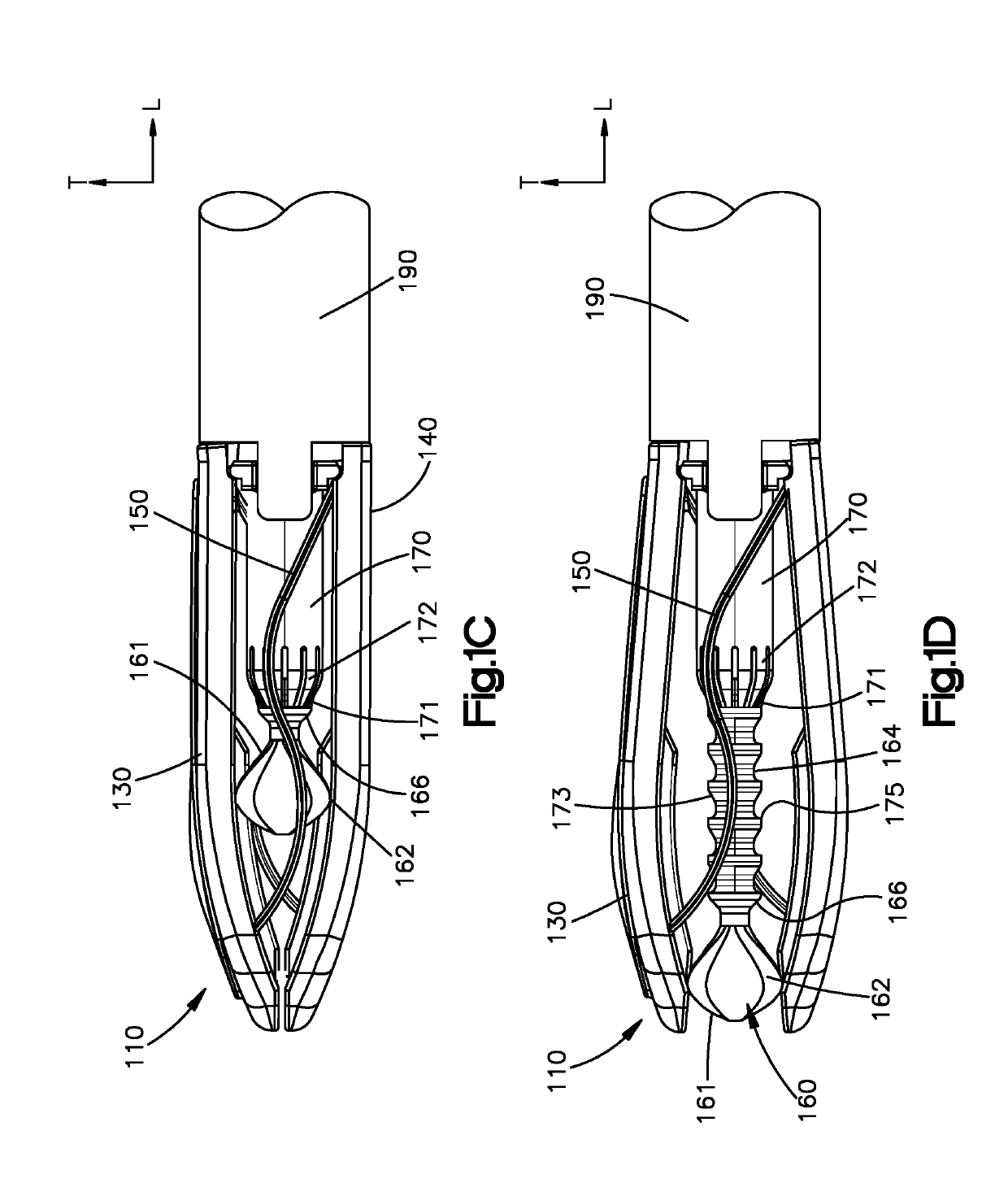

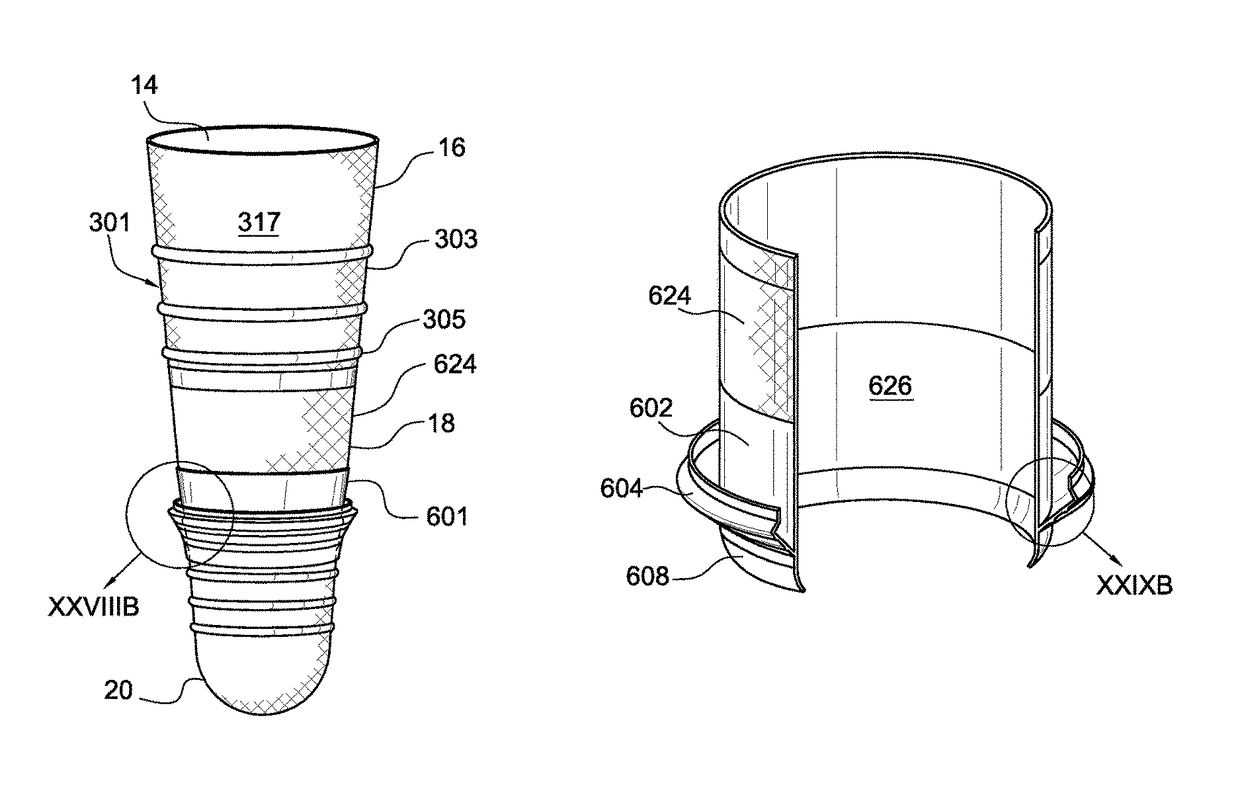

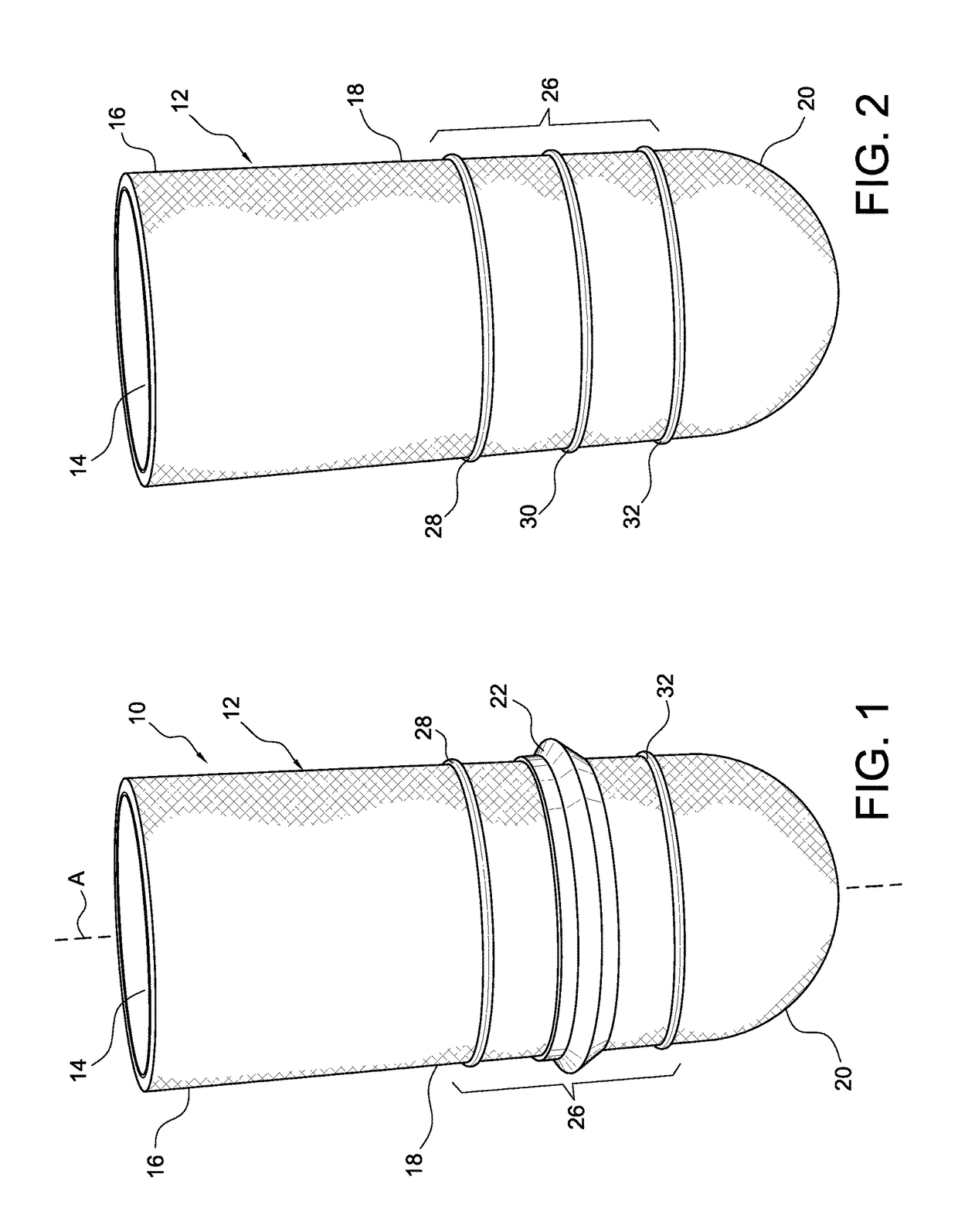

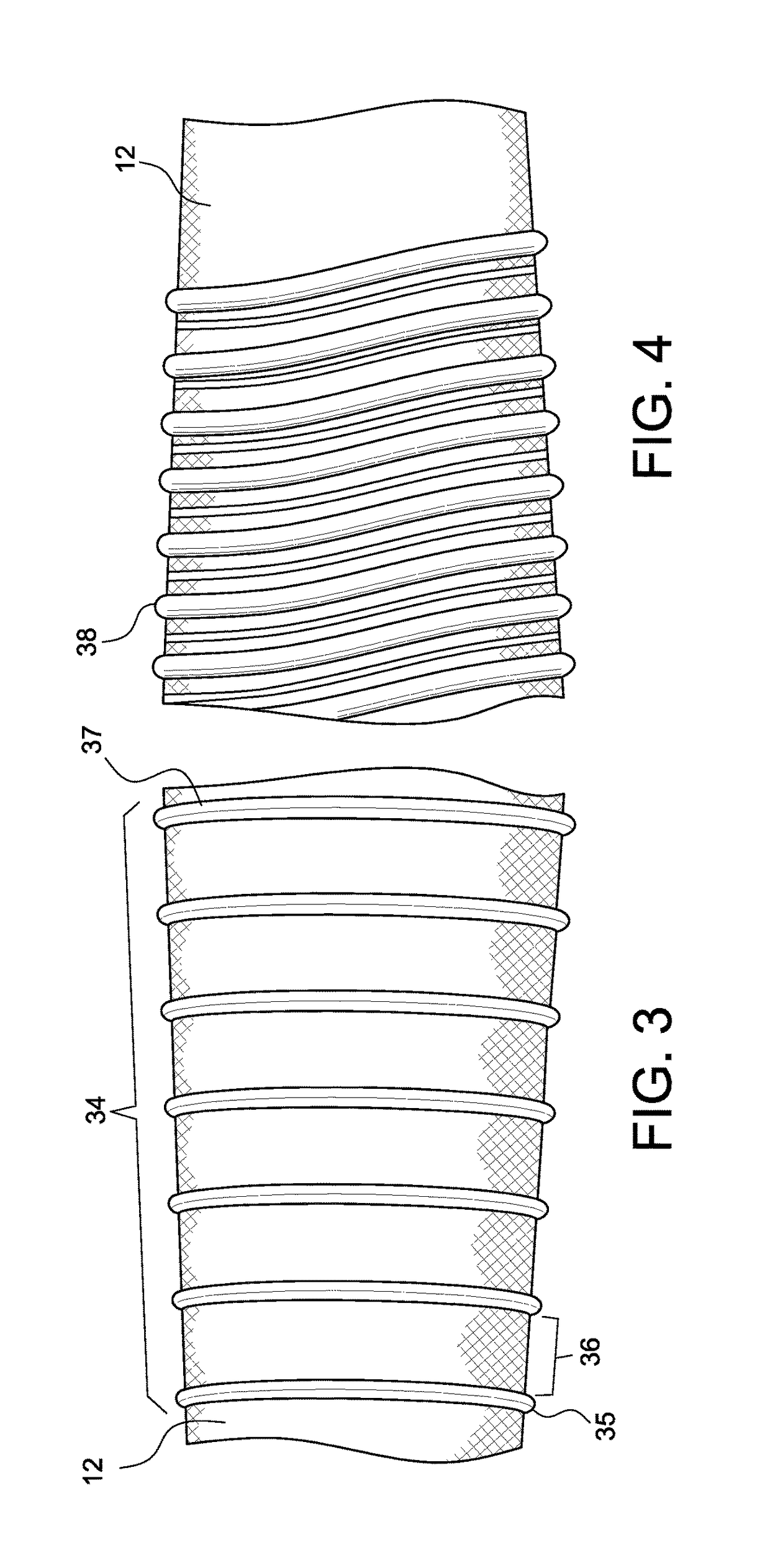

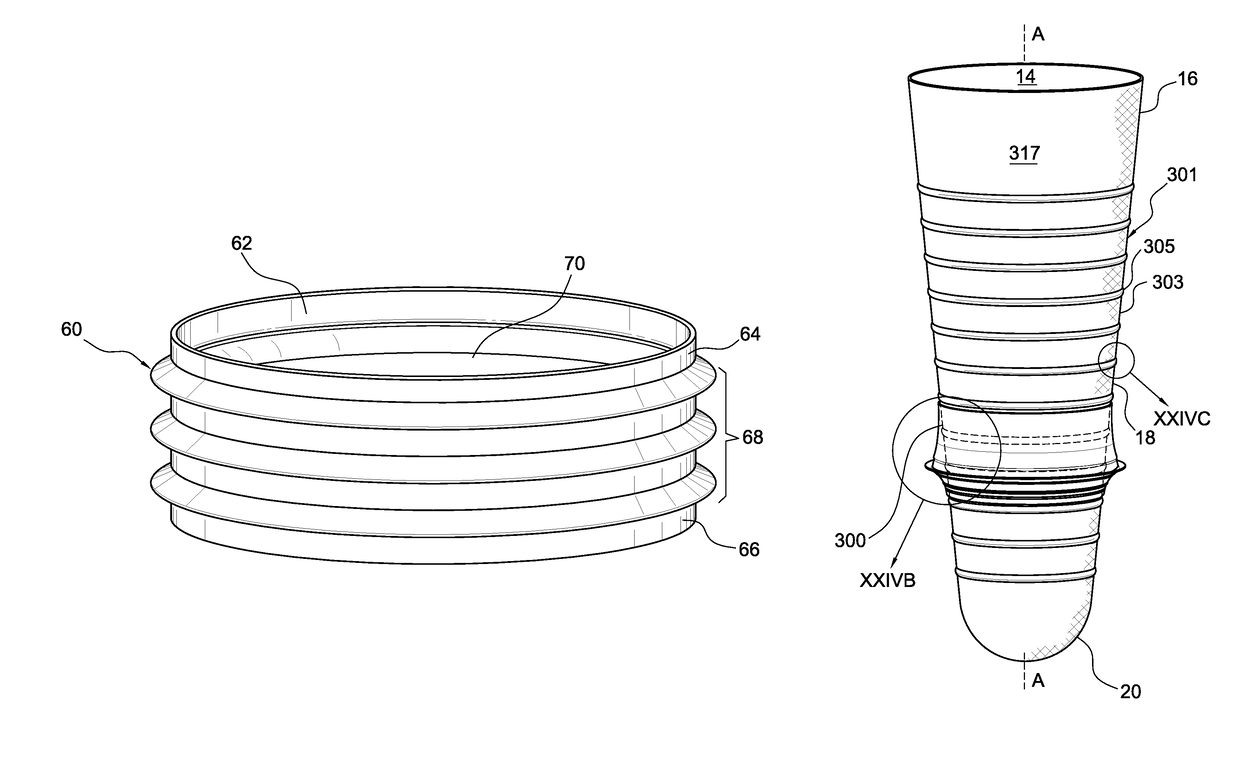

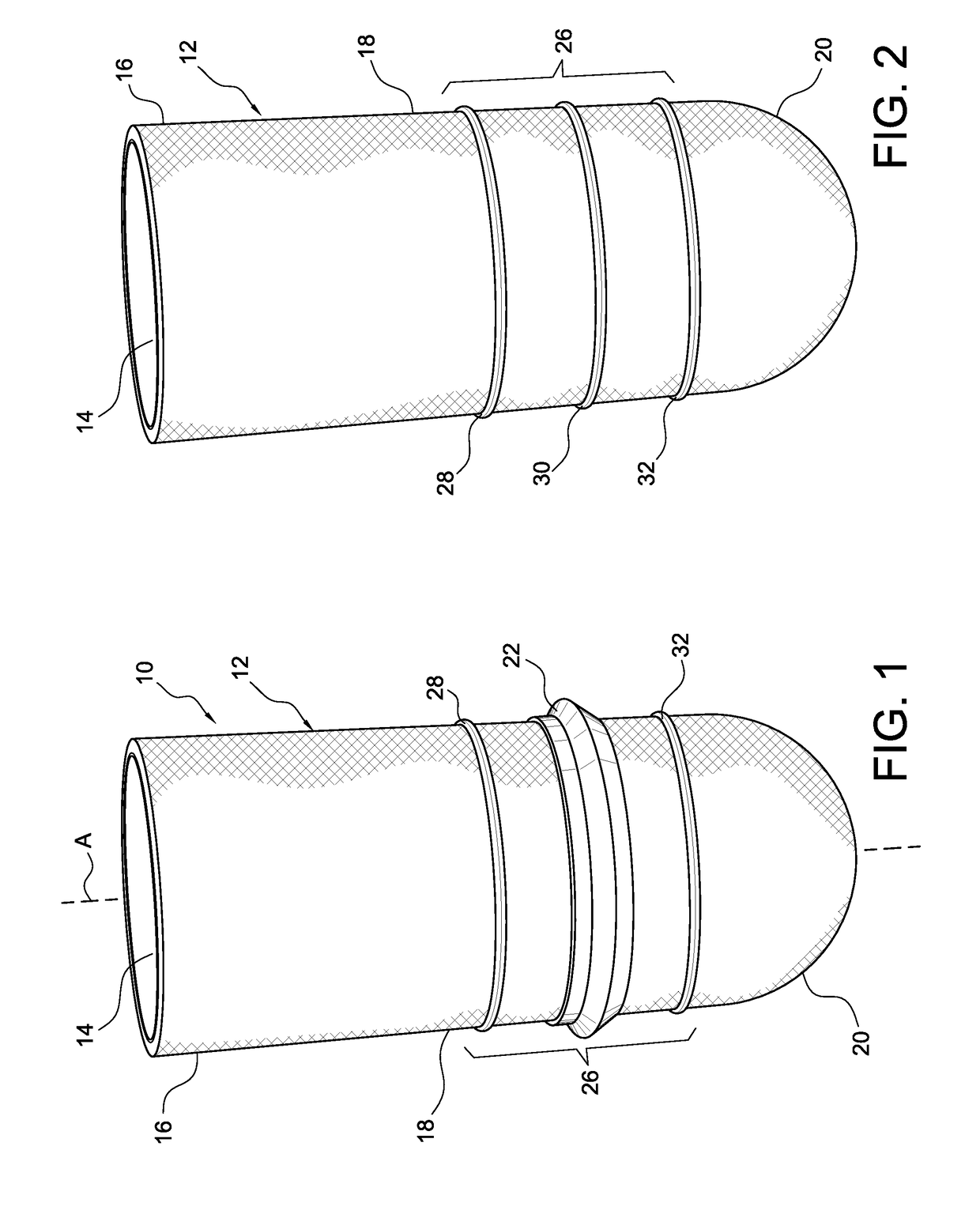

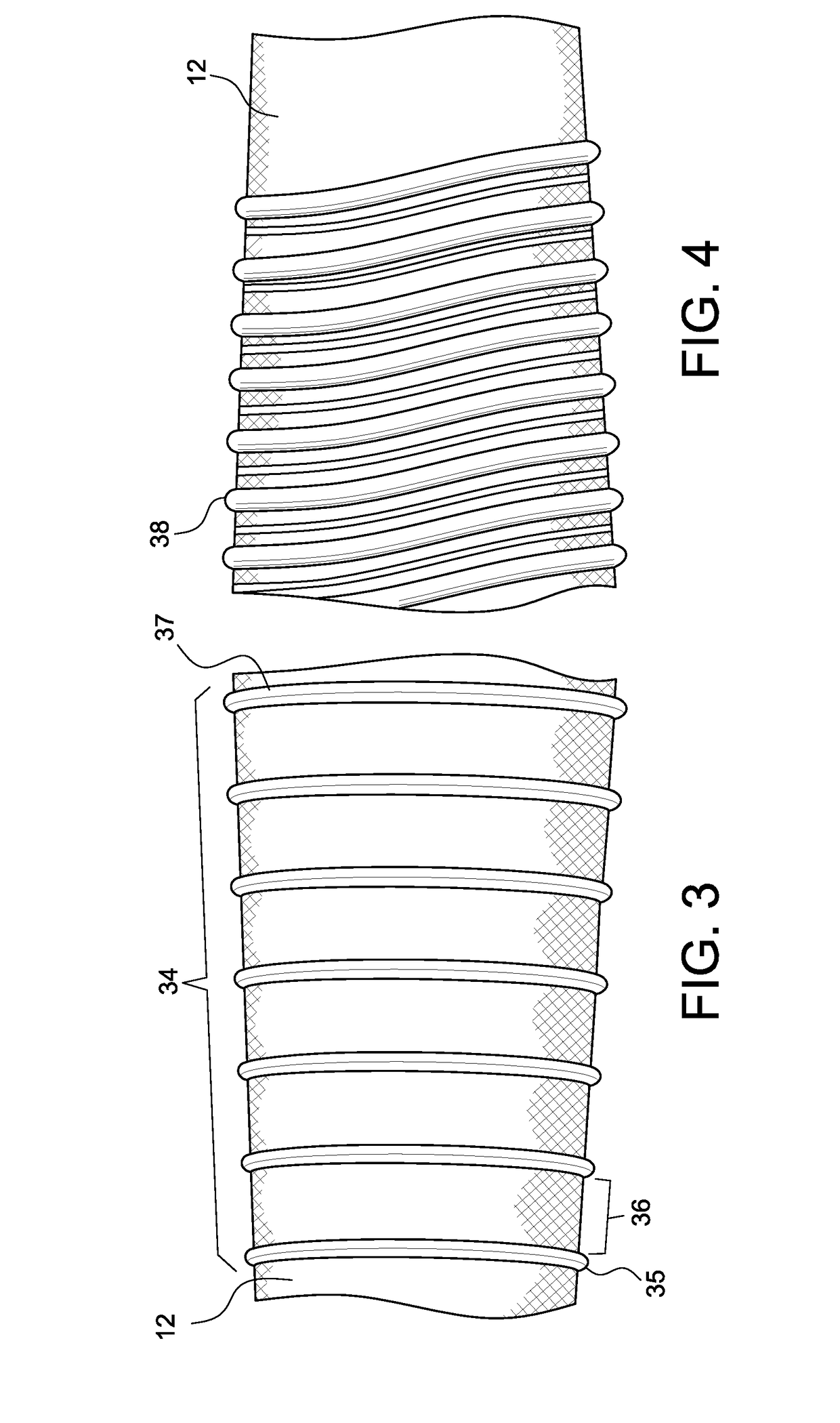

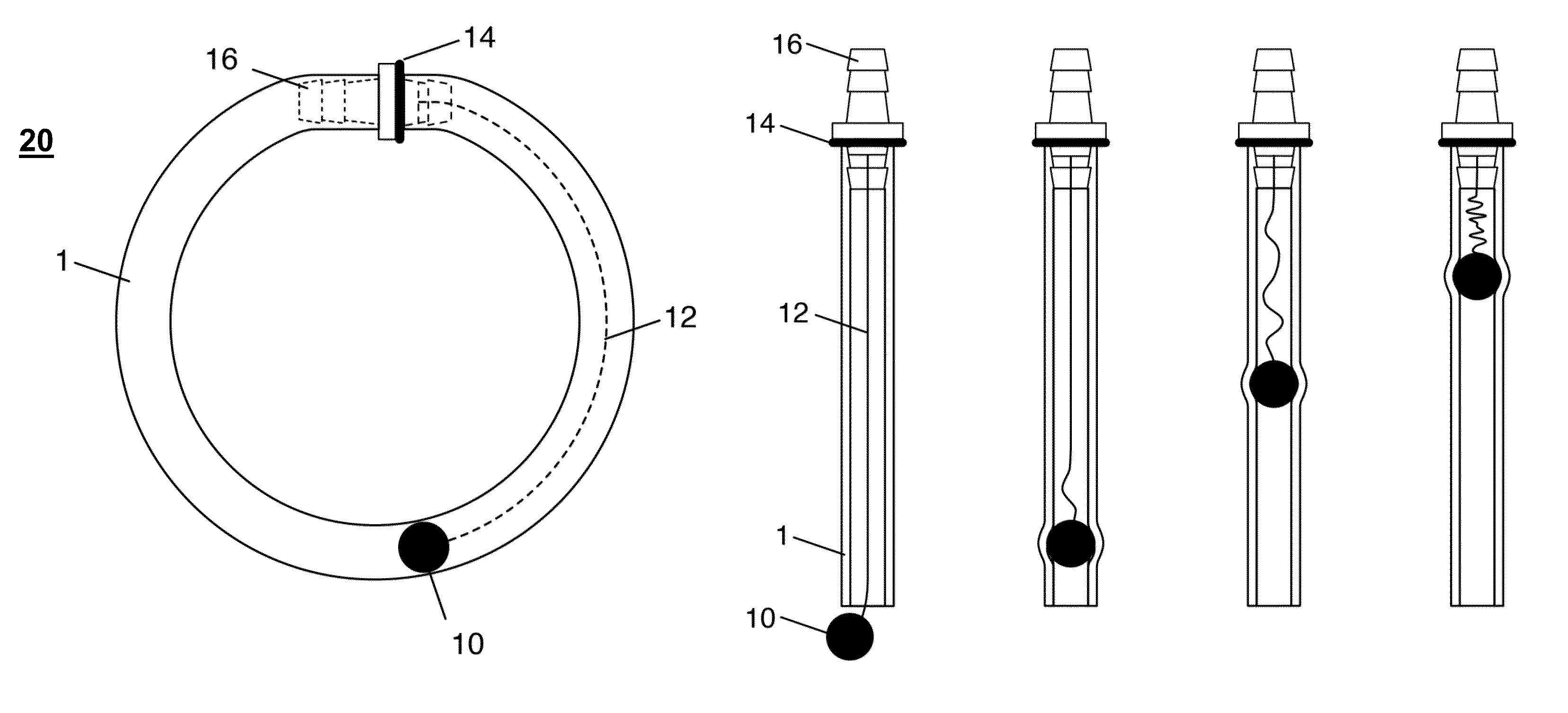

Adjustable seal system, seal component and method for using the same

ActiveUS20150142133A1Address is challengeFlexibility in placementProsthesisEngineeringProsthetic socket

An adjustable seal system, seal component for use in the system, and method are provided for forming a sealing interface between a residual limb and a prosthetic socket. The seal component is selectively placed over the outer surface of a suspension liner including a plurality of seal bands, which the seal component may removably and securely engage.

Owner:OSSUR HF

Device for storing and dispensing fluids

ActiveUS20110127293A1Efficient filling and refillingPrevents and/or slows backflow of the fluid within the containerTravelling carriersPower operated devicesBiomedical engineering

Owner:PASCATORE AMANDA R

Semiconductor socket with direct selective metalization

ActiveUS20150279768A1Improve electrical performanceImprove intelligenceContact member manufacturingSemiconductor/solid-state device detailsEngineeringConductive materials

A semiconductor socket including a substrate with a plurality of through holes extending from a first surface to a second surface. A conductive structure is disposed within the through holes A plurality of discrete contact members are located in the plurality of the through holes, within the conductive structure. The plurality of contact members each include a proximal end accessible from the second surface, and a distal end extending above the first surface. The conductive structure can be electrically coupled to circuit geometry. At least one dielectric layer is bonded to the second surface of the substrate with recesses corresponding to desired circuit geometry. A conductive material deposited in at least a portion of the recesses to form conductive traces redistributing terminal pitch of the proximal ends of the contact members.

Owner:HSIO TECH

Angularly Adjustable Intervertebral Cages With Integrated Ratchet Assembly

ActiveUS20190274836A1Easy to insertStabilize spineBone implantJoint implantsIntervertebral spacesReduced size

The embodiments provide various interbody fusion spacers, or cages, for insertion between adjacent vertebrae. The cages may have integrated ratchet assemblies that allow the cage to change size and angle as needed, with little effort. The cages may have a first, insertion configuration characterized by a reduced size to facilitate insertion through a narrow access passage and into the intervertebral space. The cages may be inserted in a first, reduced size and then expanded to a second, larger size once implanted. In their second configuration, the cages are able to maintain the proper disc height and stabilize the spine by restoring sagittal balance and alignment. Additionally, the intervertebral cages are configured to be able to adjust the angle of lordosis, and can accommodate larger lordotic angles in their second, expanded configuration. Further, these cages may promote fusion to further enhance spine stability by immobilizing the adjacent vertebral bodies.

Owner:EIT EMERGING IMPLANT TECH GMBH

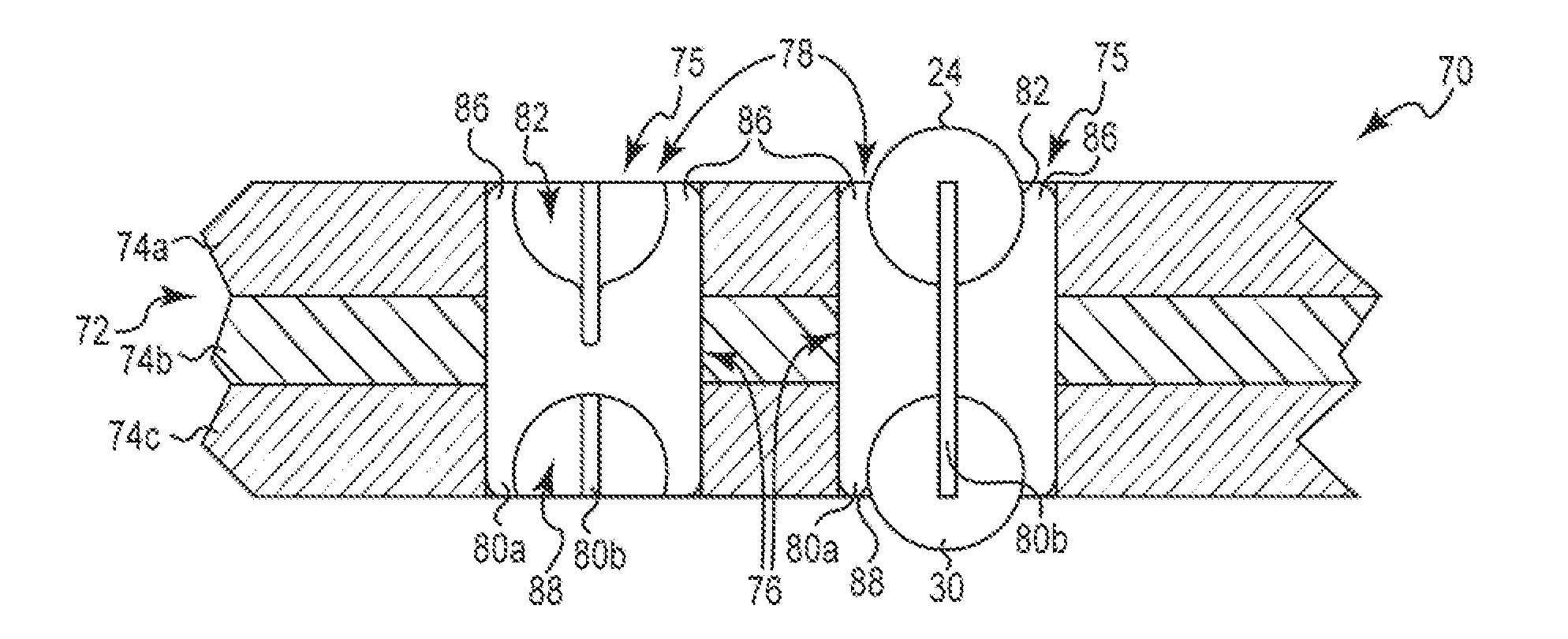

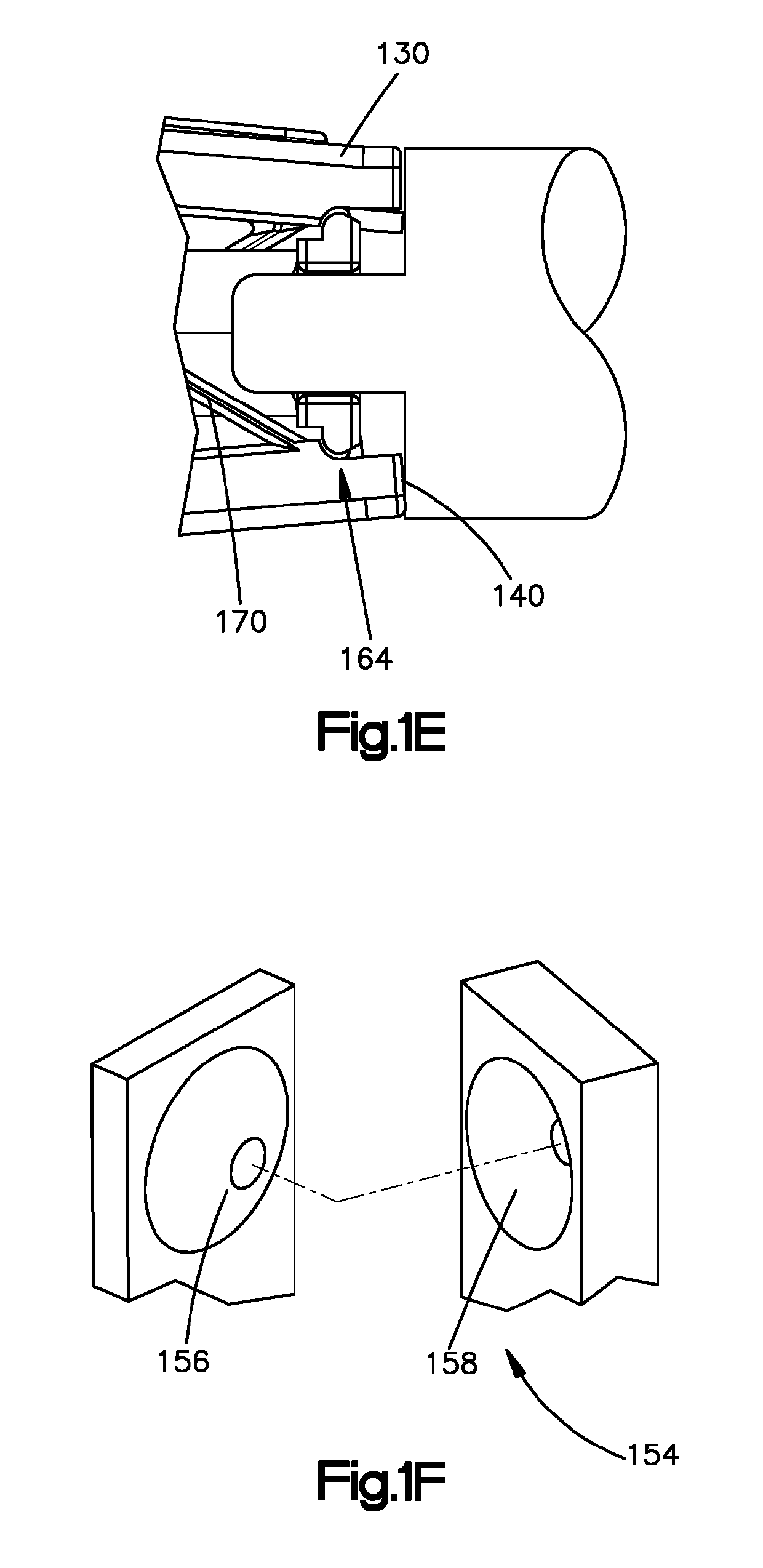

Complex Shape Steerable Tissue Visualization And Manipulation Catheter

PendingUS20150366440A1Address is challengeMinimize fluid leakageEndoscopesCatheterCatheterMedical treatment

A medical manipulation assembly comprises a sheath steerable in response to rotational movement of a sheath steering mechanism. The assembly also comprises a catheter extendable through the sheath. The catheter is steerable in response to rotational movement of a catheter steering mechanism. The sheath and catheter are independently steerable. The assembly also comprises a set of control wires. At least one of the sheath or the catheter includes a plurality of lumens with at least two of the plurality of lumens each sized for passage of one of the control wires of the set of control wires. The steerable catheter includes a working channel sized to receive a visualization instrument therethrough.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Adjustable seal system, seal component and method for using the same

ActiveUS9603726B2Address is challengeFlexibility in placementJoint implantsEngineeringProsthetic socket

An adjustable seal system, seal component for use in the system, and method are provided for forming a sealing interface between a residual limb and a prosthetic socket. The seal component is selectively placed over the outer surface of a suspension liner including a plurality of seal bands, which the seal component may removably and securely engage.

Owner:OSSUR HF

Adjustable seal system, seal component and method for using the same

ActiveUS9707106B2Address is challengeFlexibility in placementJoint implantsProsthetic socketMechanical engineering

An adjustable seal system, seal component for use in the system, and method are provided for forming a sealing interface between a residual limb and a prosthetic socket. The seal component is selectively placed over the outer surface of a suspension liner including a plurality of seal bands, which the seal component may removably and securely engage.

Owner:OSSUR HF

Method of forming a semiconductor socket

ActiveUS9320144B2Reduce complexityFirmly connectedPrinted circuit assemblingElectrically conductive connectionsConductive materialsEngineering

Owner:HSIO TECH

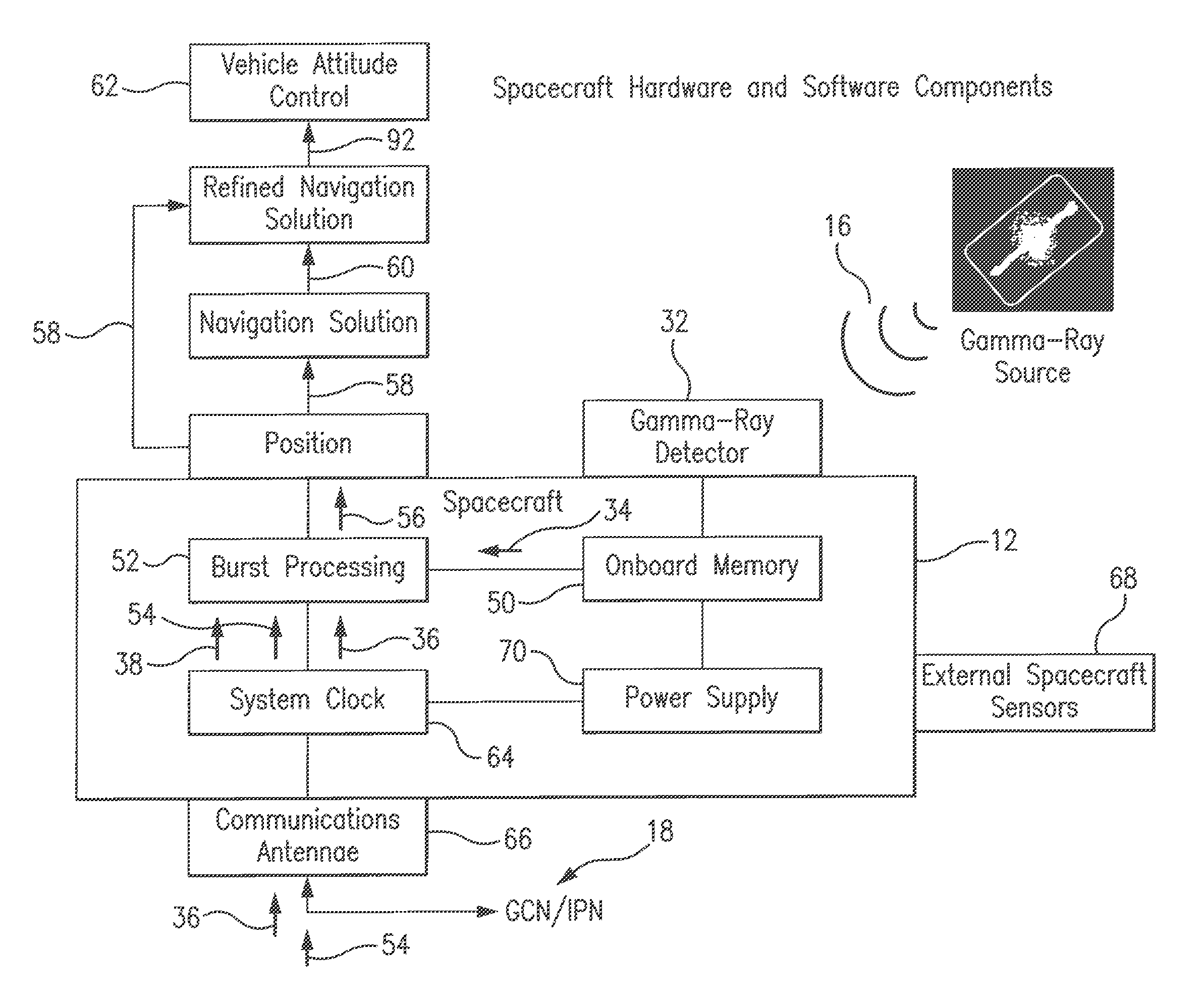

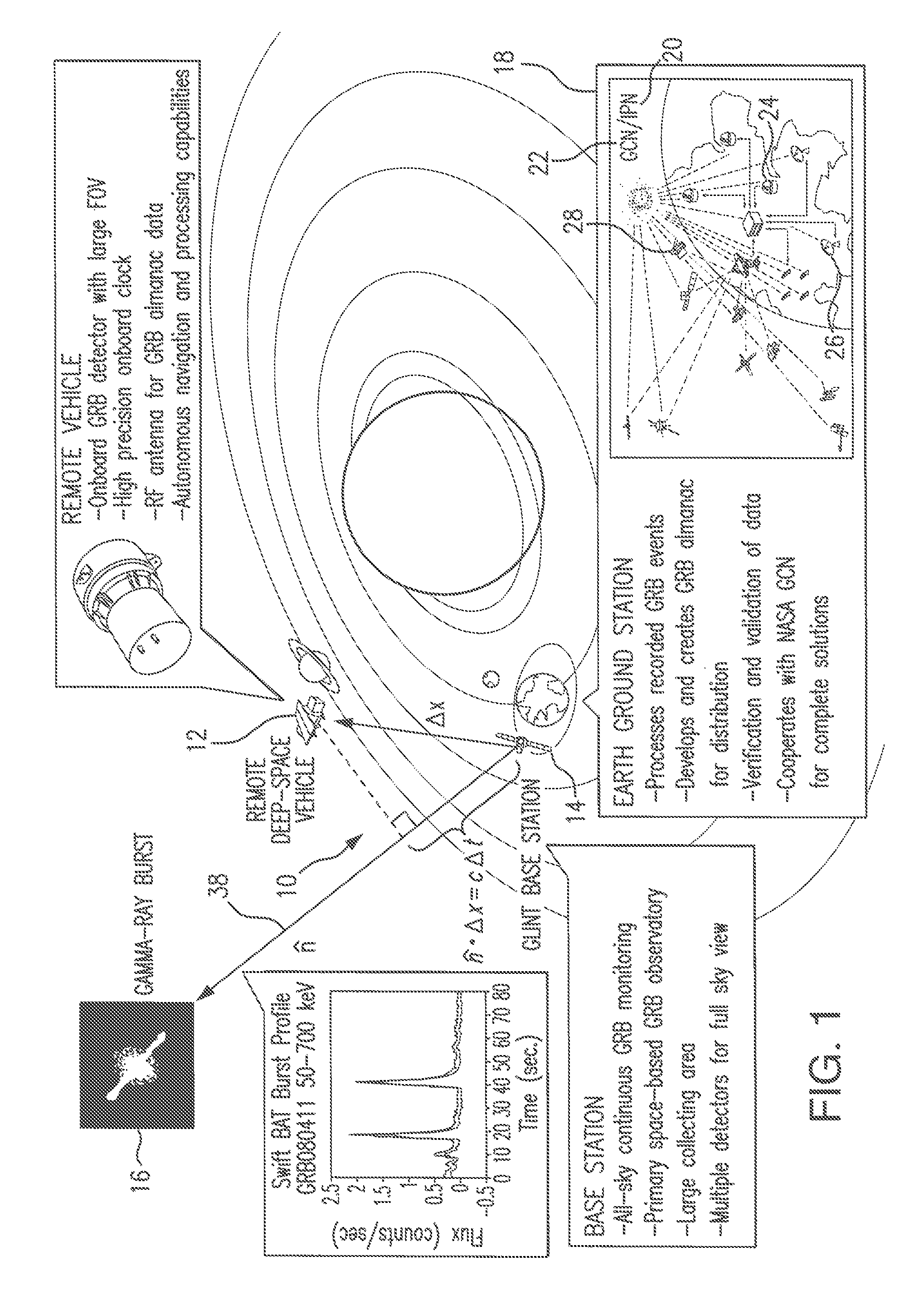

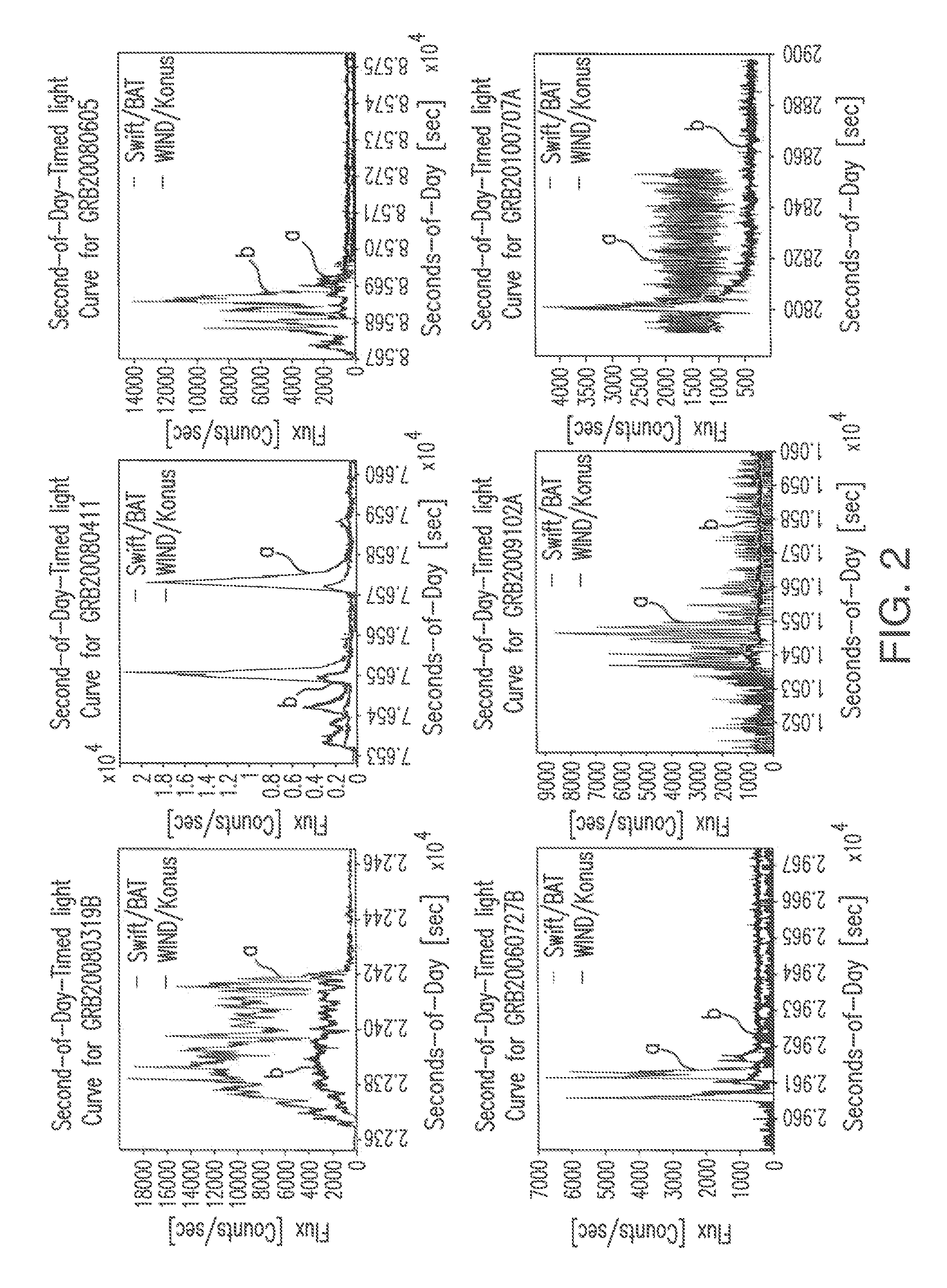

Method and system for gamma-ray localization induced spacecraft navigation using celestial gamma-ray sources

ActiveUS9140556B1Accurate calculationHigh positioning accuracyPosition fixationNavigation by astronomical meansHigh energyTime alignment

Owner:ASTER LABS

Method of making an electronic interconnect

ActiveUS9318862B2Reliable flexural propertyReduce complexityContact member cases/bases manufactureCoupling contact membersDistal portionProximal point

An electrical interconnect including a substrate with at least two adjacent layers configured to translate relative to each other between a nominal position and a translated position. A plurality of through holes are formed through the layers from a first surface of the substrate to a second surface of the substrate in both the nominal position and the translated position. At least one contact member is positioned in the through holes with distal portions accessible from the first surface and a proximal portions positioned near the second surface. The proximal portion of the contact members are secured to the substrate near the second surface with a conductive structure. The two adjacent layers of the substrate are translated from the nominal position to the translated position to elastically deform the contact members within the through holes and to displace the distal portions of the contact members toward the conductive structures, respectively.

Owner:HSIO TECH

Dispenser with movable dispensing component anchored by a filament

ActiveUS8708194B2Efficient filling and refillingPrevents and/or slows backflow of the fluid within the containerTravelling sacksTravelling carriersBiomedical engineeringEngineering

Owner:PASCATORE AMANDA R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com