Pneumatic tire for traveling on off road

A technology for pneumatic tires and roads, which is applied to off-road vehicle tires, tire parts, tire treads/tread patterns, etc., and can solve problems such as air leakage resistance and wear, sufficient traction performance, and small air leakage effects. problems, to achieve the effect of improving air leakage resistance, improving traction performance, and ensuring traction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

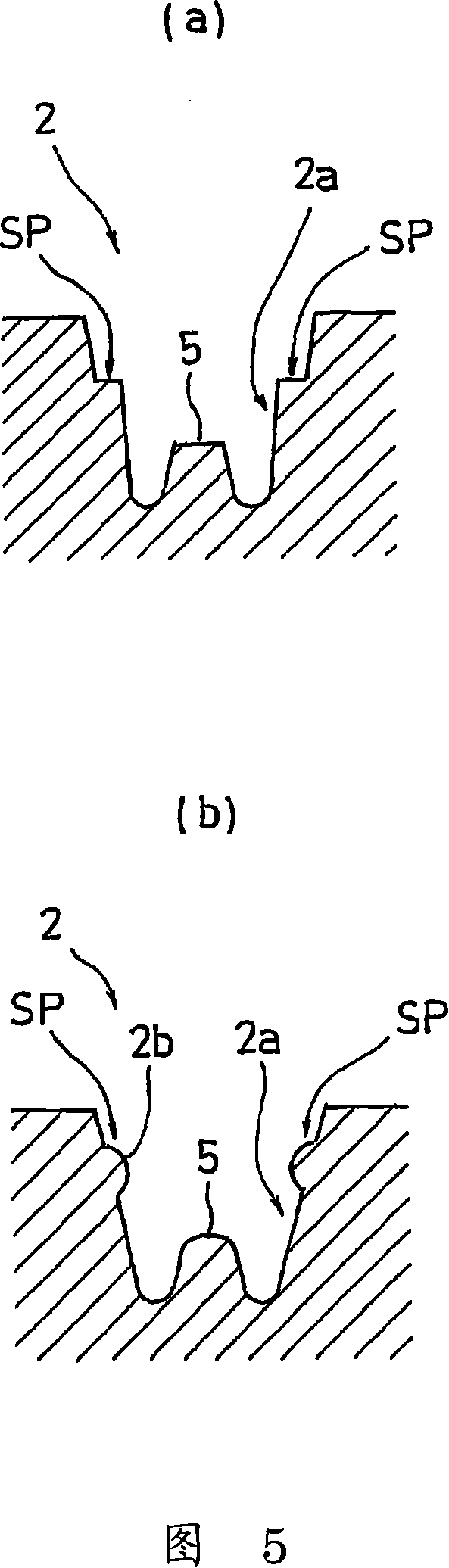

[0040] Next, other embodiments of the present invention will be described.

[0041] (1) In the above embodiment, an example having a tread pattern formed with the blocks shown in FIG. 1 was shown, but the blocks are not limited to this shape, and may be approximately square, rectangular, parallelogram, or rhombus. , polygon, etc. any pattern block shape.

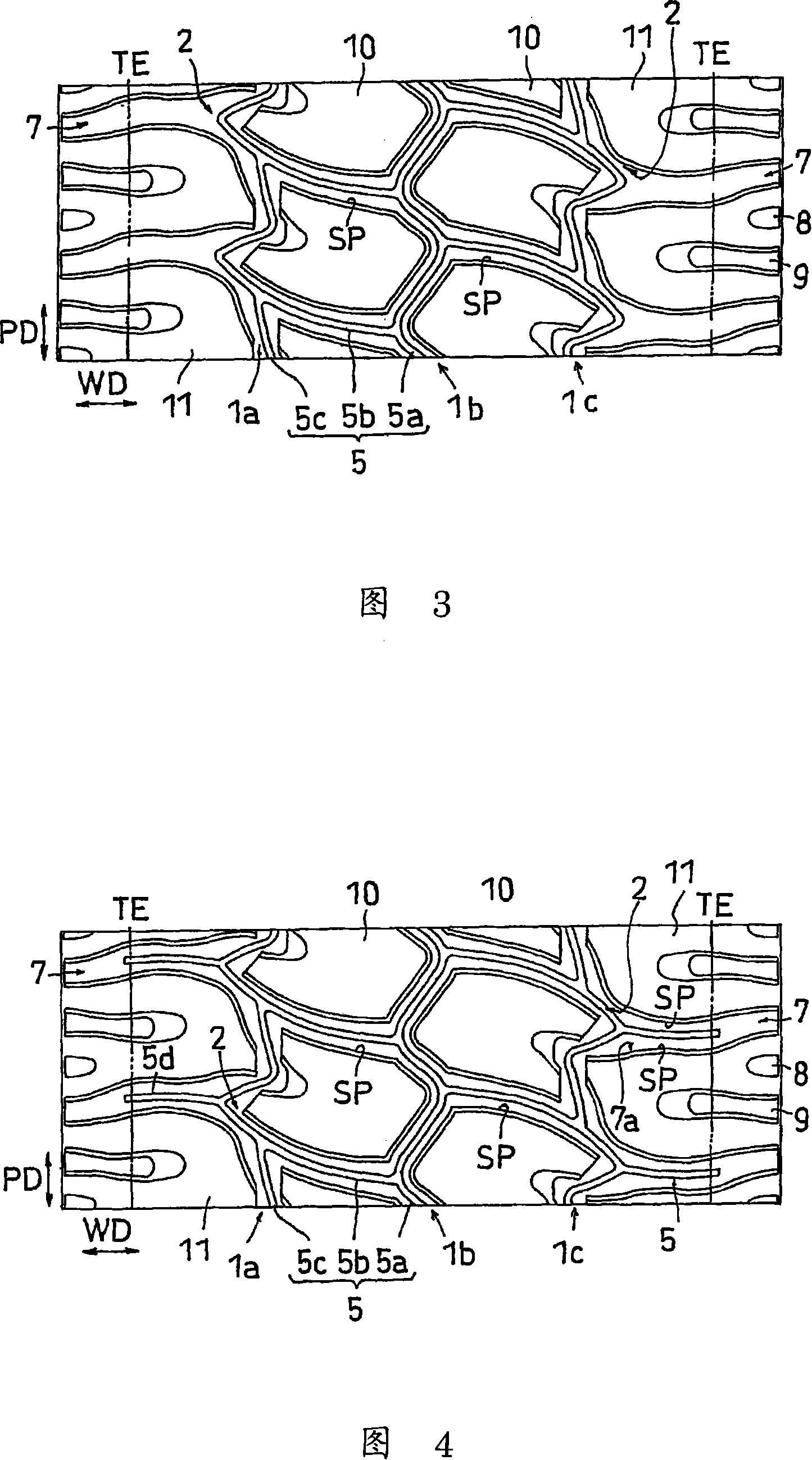

[0042] (2) In the above-mentioned embodiment, the example in which a continuous convex line is provided on the entire groove bottom of the horizontal groove arranged between the three vertical grooves and the vertical groove arranged on the most central side is shown, but as shown in FIG. As shown in 3, in the present invention, it is preferable to provide protruding lines 5c at the bottoms of the longitudinal grooves 1a and 1c on both sides, so that continuous protruding lines 5 having approximately the same height are provided around the block 10. In this case, the step portions SP may also be formed on the groove wall surf...

Embodiment 1

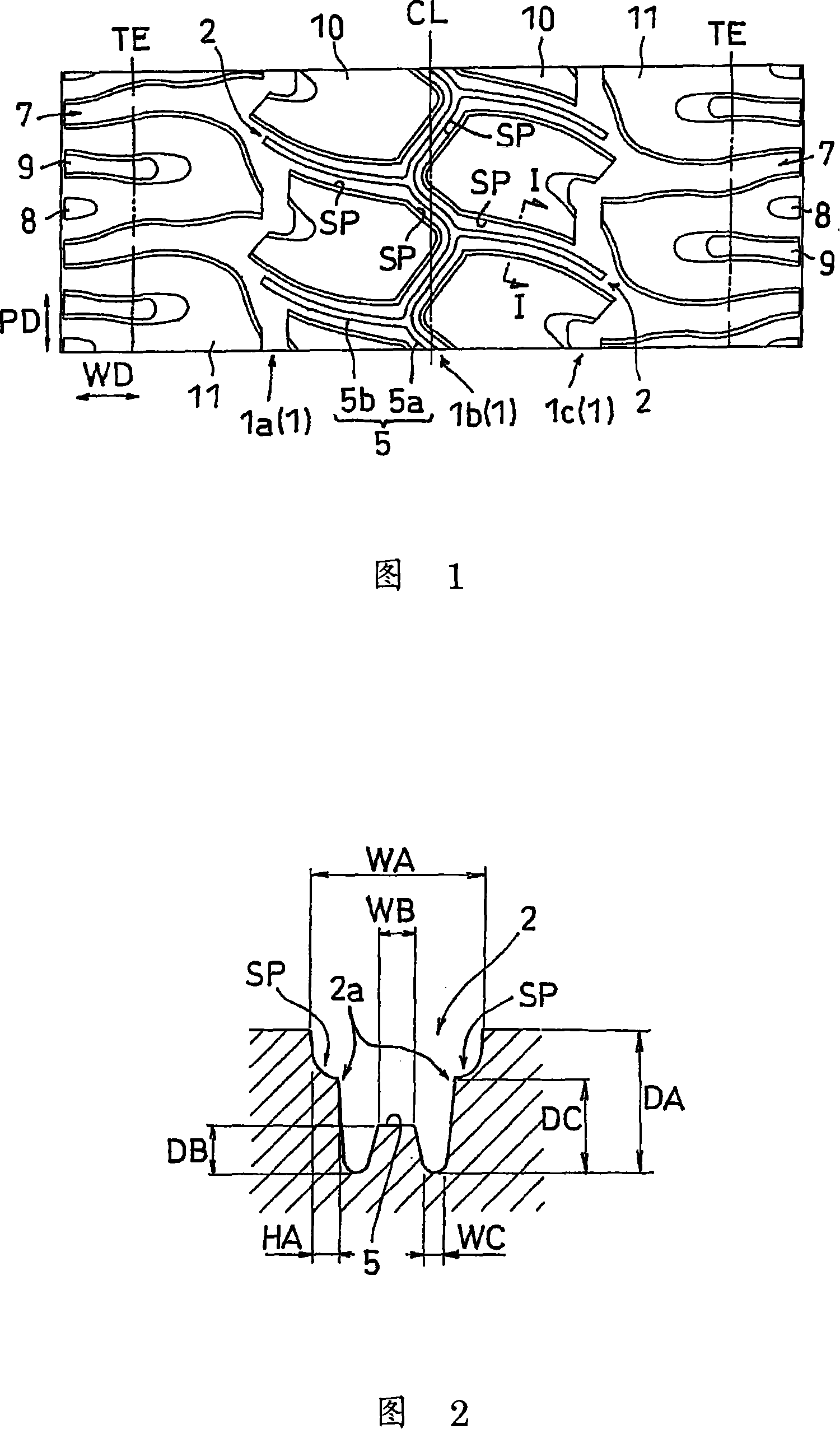

[0058] In the tread pattern shown in FIG. 1 and FIG. 2, the depth DA of the longitudinal groove 1 and the lateral groove 2 is set to 12.5 mm, the groove width WA is set to 14 mm, the height HA of the step portion is set to 2 mm, and the width WB of the rib 5 is set. is 3mm, height DB is 4mm, interval W C is 1.5mm, and a radial tire with a specification of 35×12.50R 15LT is manufactured. The tires were used for each performance evaluation described above, and the evaluation results are shown in Table 1.

Embodiment 2

[0060] As shown in FIG. 3 , a radial tire was manufactured in the same manner as in Example 1, except that the ridge 5 c having the same shape and size was further set. The tires were used for each performance evaluation described above, and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com