Bicycle tire tube and manufacture method thereof

A manufacturing method and bicycle technology, applied to bicycle tires, bicycles, two-wheeled bicycles, etc., can solve the problems of difficult production, complicated operation, and trouble, and achieve the effect of convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

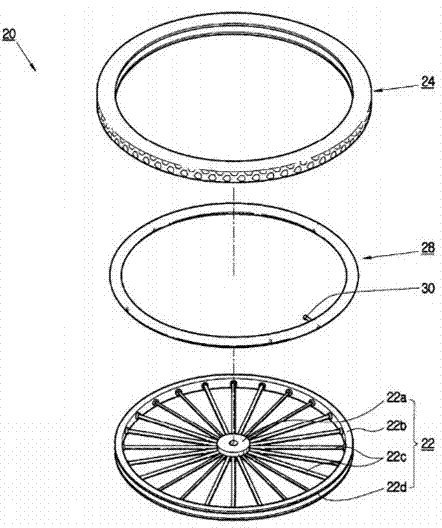

[0027] Specific embodiments will be described in detail below with reference to the description and drawings of the present invention.

[0028] The invention is capable of many modifications and assumes various forms. Specific embodiments are presented on the drawings in detail. However, this does not set limits to the initial form of the present invention, and it should be understood that all changes, equivalents, and substitutes are included in the idea and technical scope of the present invention. Similar reference signs are used for similar structural elements in describing the respective drawings. Terms such as first and second can be used to describe various structural elements, but the above-mentioned structural elements cannot be limited by the above-mentioned terms. The above terms are used only for purposes of distinguishing one structural element from another structural element. For example: without departing from the scope of rights of the present invention, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com