Tire installing machine suitable for bicycle wheel

A bicycle and tire-loading technology, which is applied to bicycle tires, bicycles, two-wheeled bicycles, etc., can solve the problems of high physical strength, low installation efficiency, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

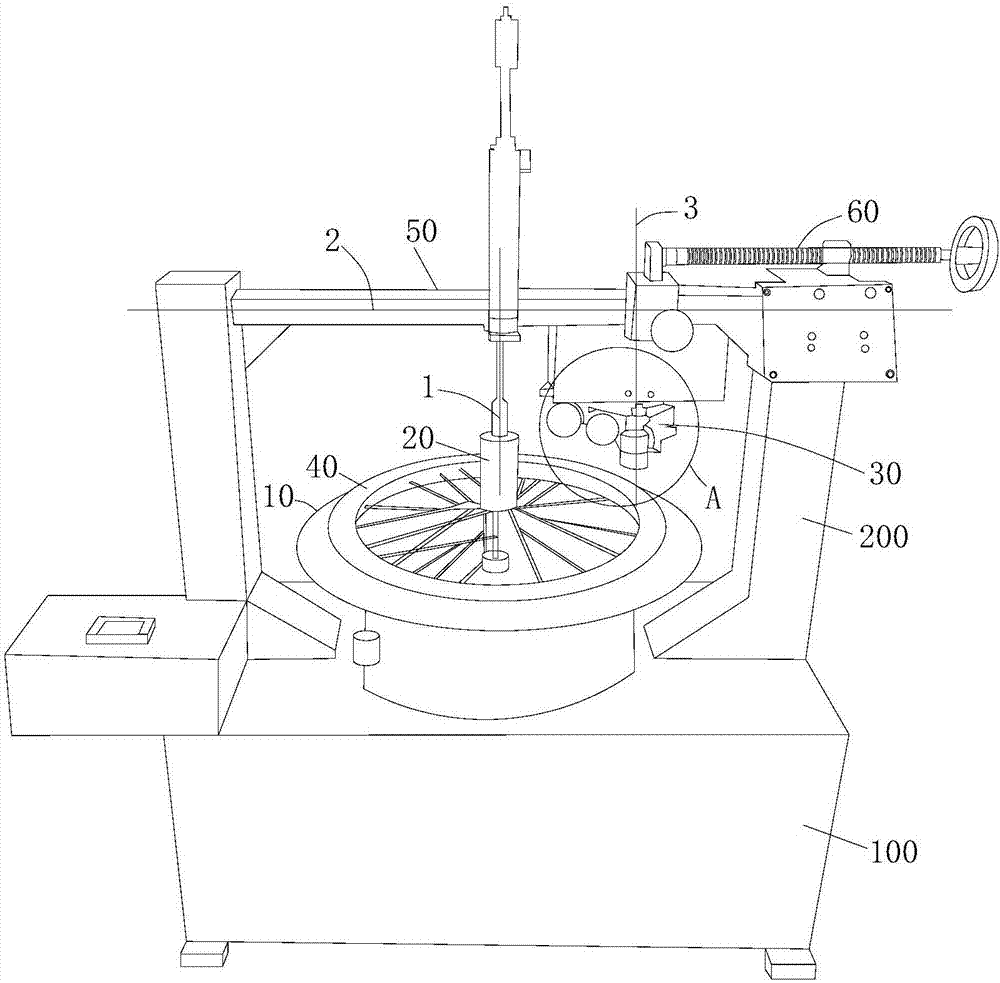

[0036] A preferred embodiment, the tire loading machine also includes: a beam rail 50 connected to the wheel expanding device 30, the wheel expanding device 30 moves on the beam rail 50 and can be fixed in multiple positions , the length direction of the beam track 30 is the same as the extension direction of the horizontal axis 2 .

[0037] Preferably, the tire fitting machine also includes a radius adjusting device 60 useful for making the wheel expanding device 30 move on the beam rail 50 and be fixed in multiple positions, the radius adjusting device 60 is compatible with the wheel expanding device 30 connections. Along the length direction of the beam track, a track groove is provided on the beam track. The wheel expanding device moves horizontally within the length range of the track groove to adjust the horizontal distance of the wheel expanding device. That is, the distance from the second vertical axis 3 to the first vertical axis 1 .

[0038] Further, the expandin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com