Patents

Literature

114results about How to "Safe and reliable support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

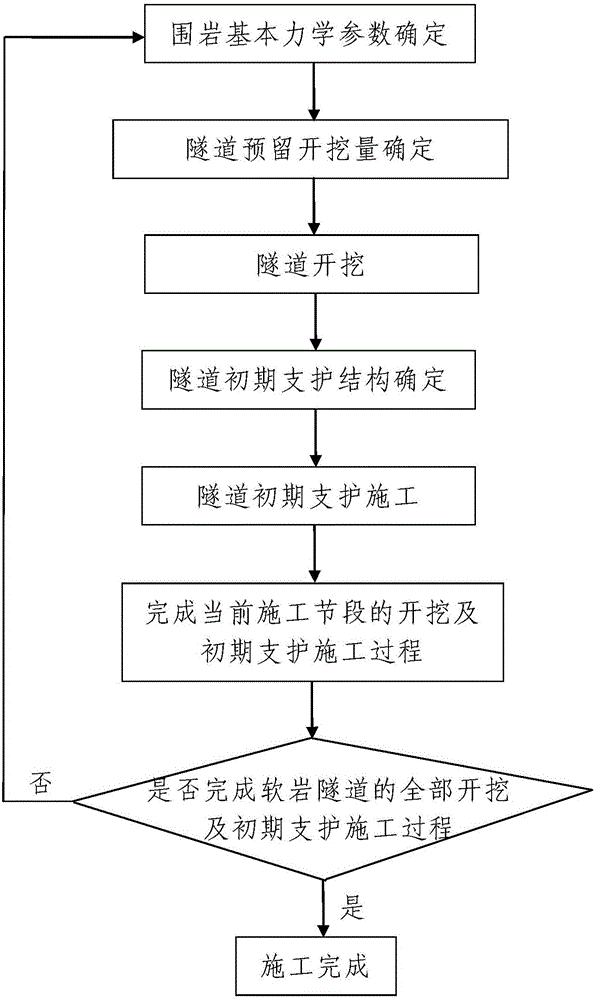

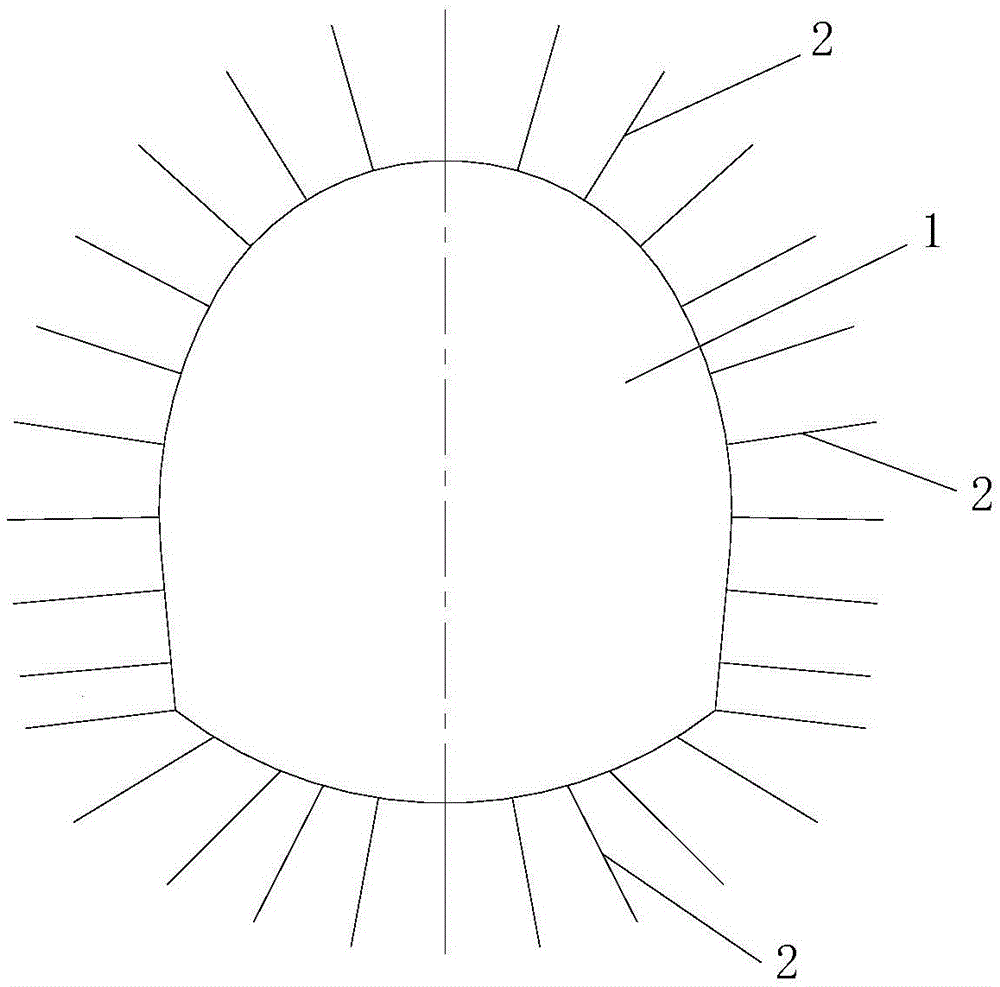

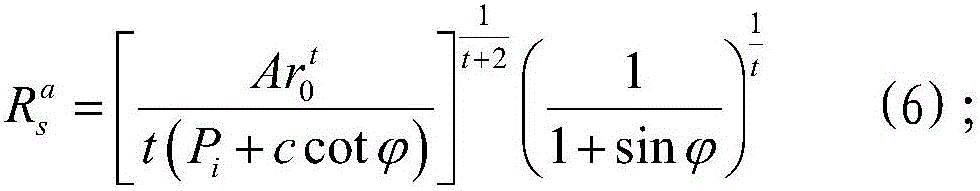

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

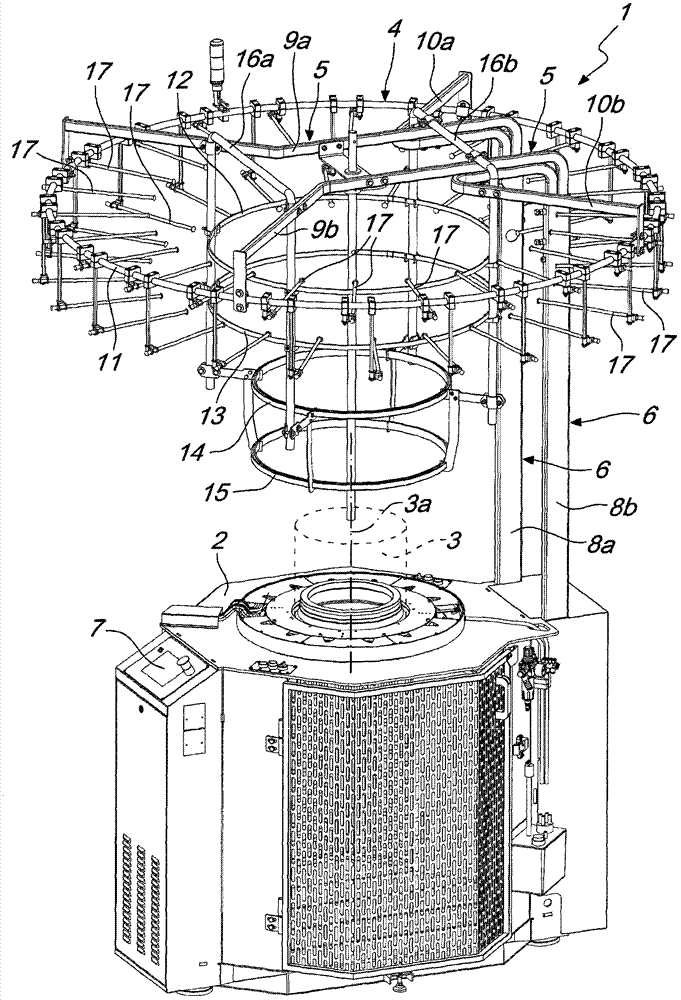

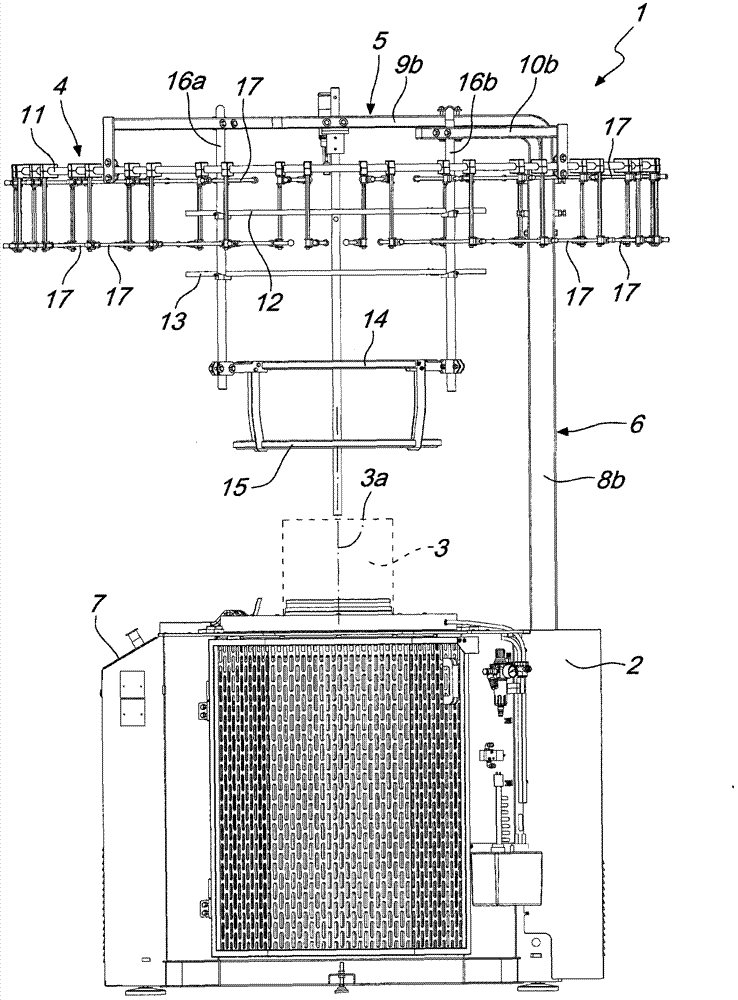

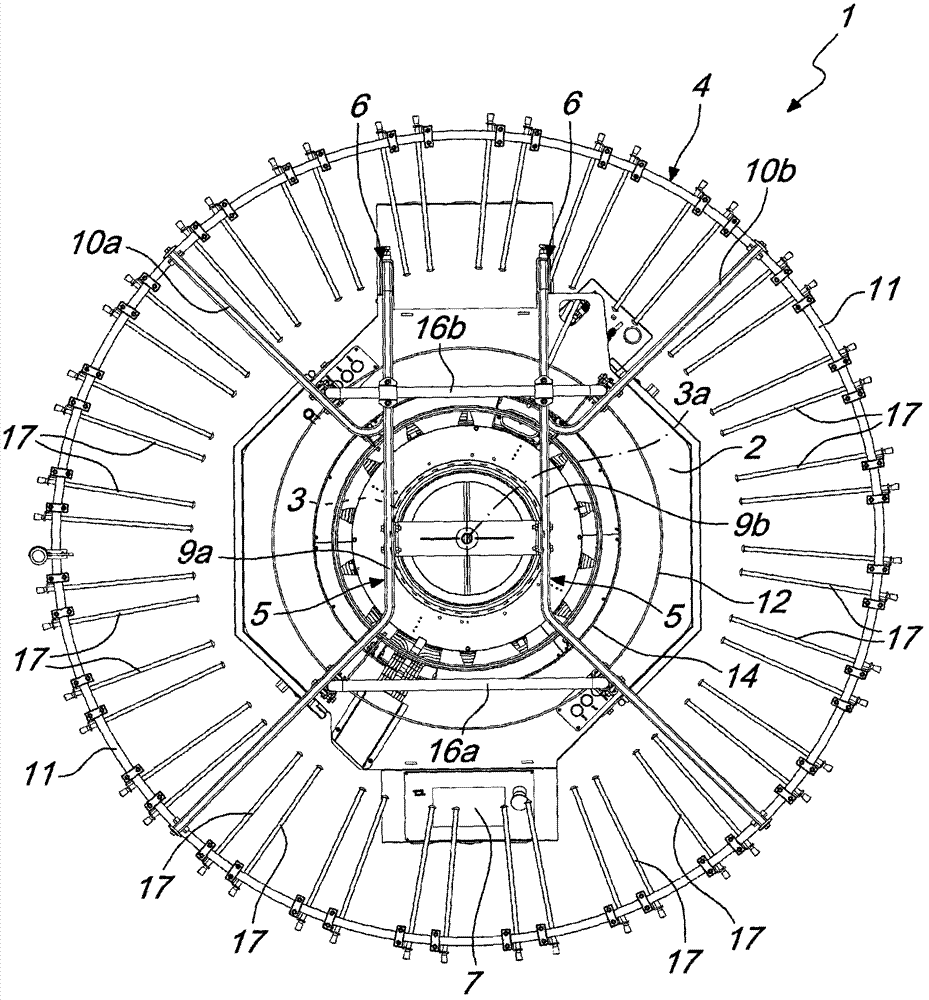

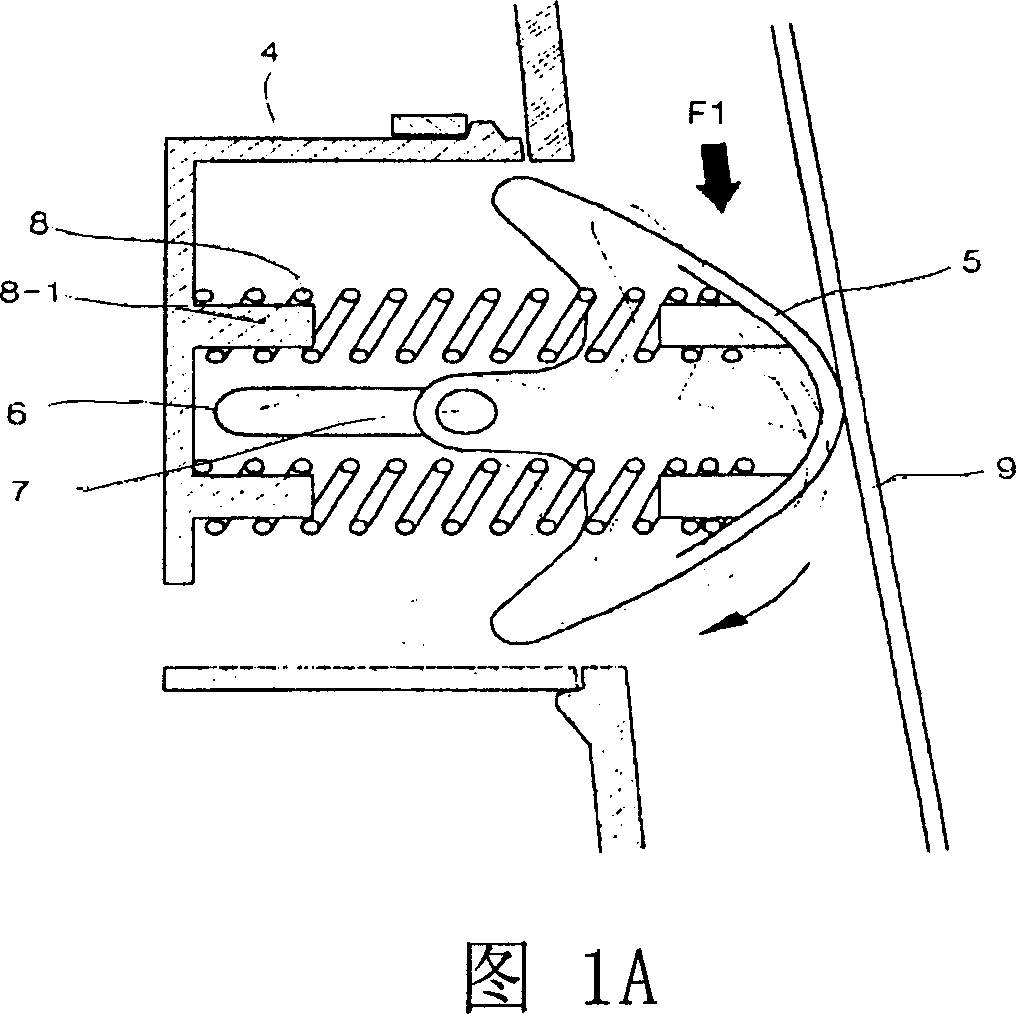

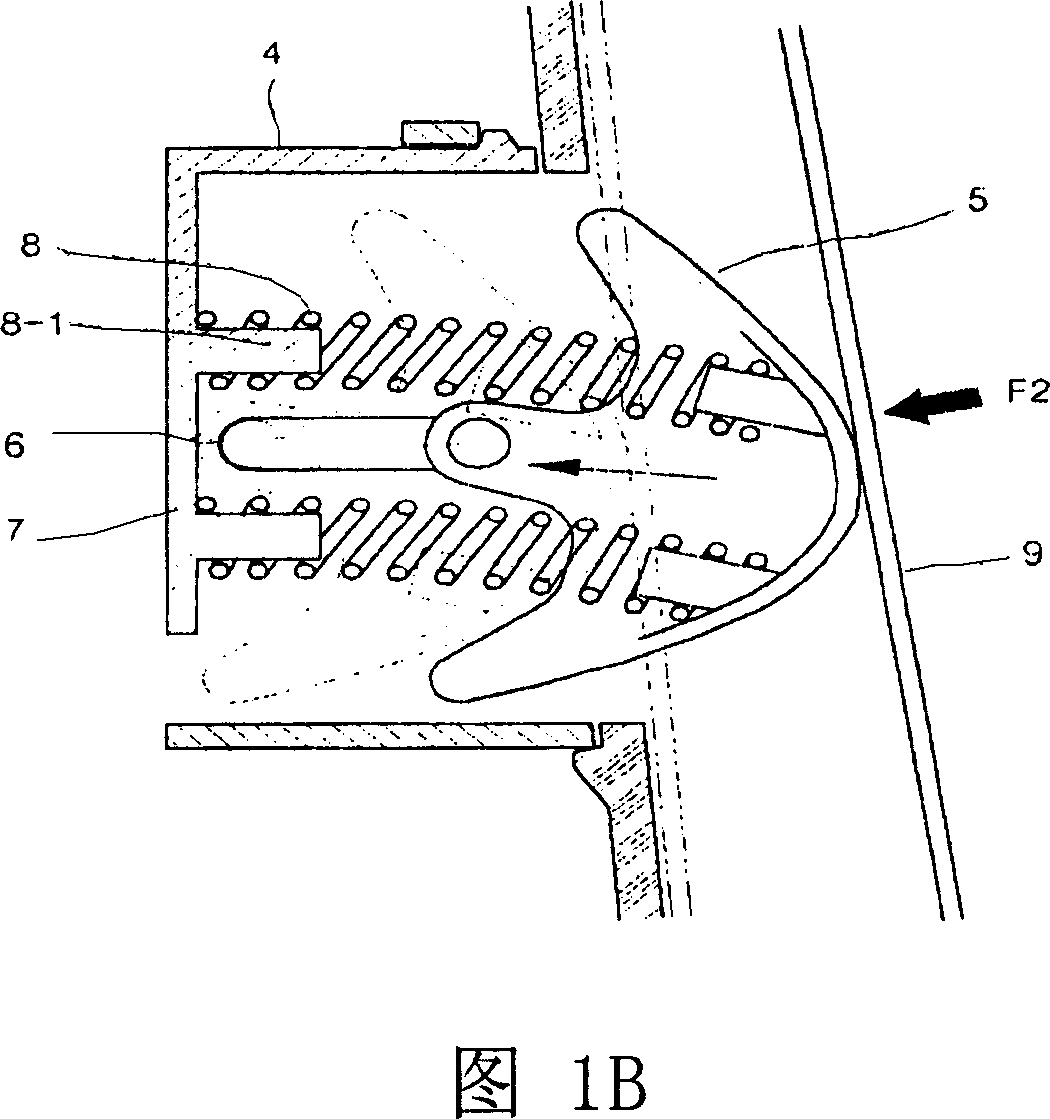

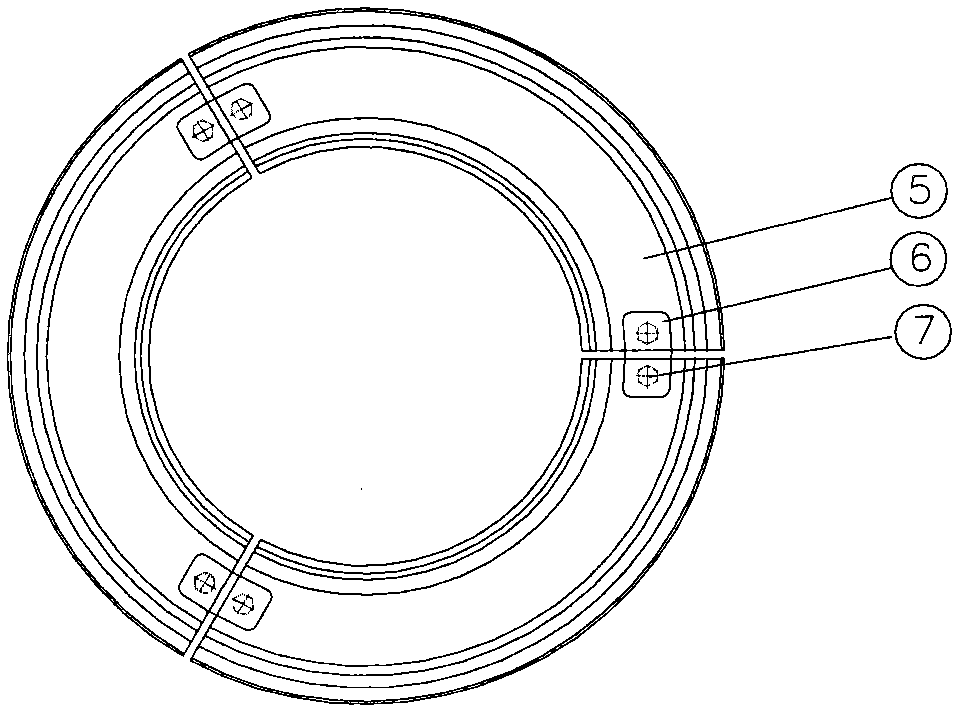

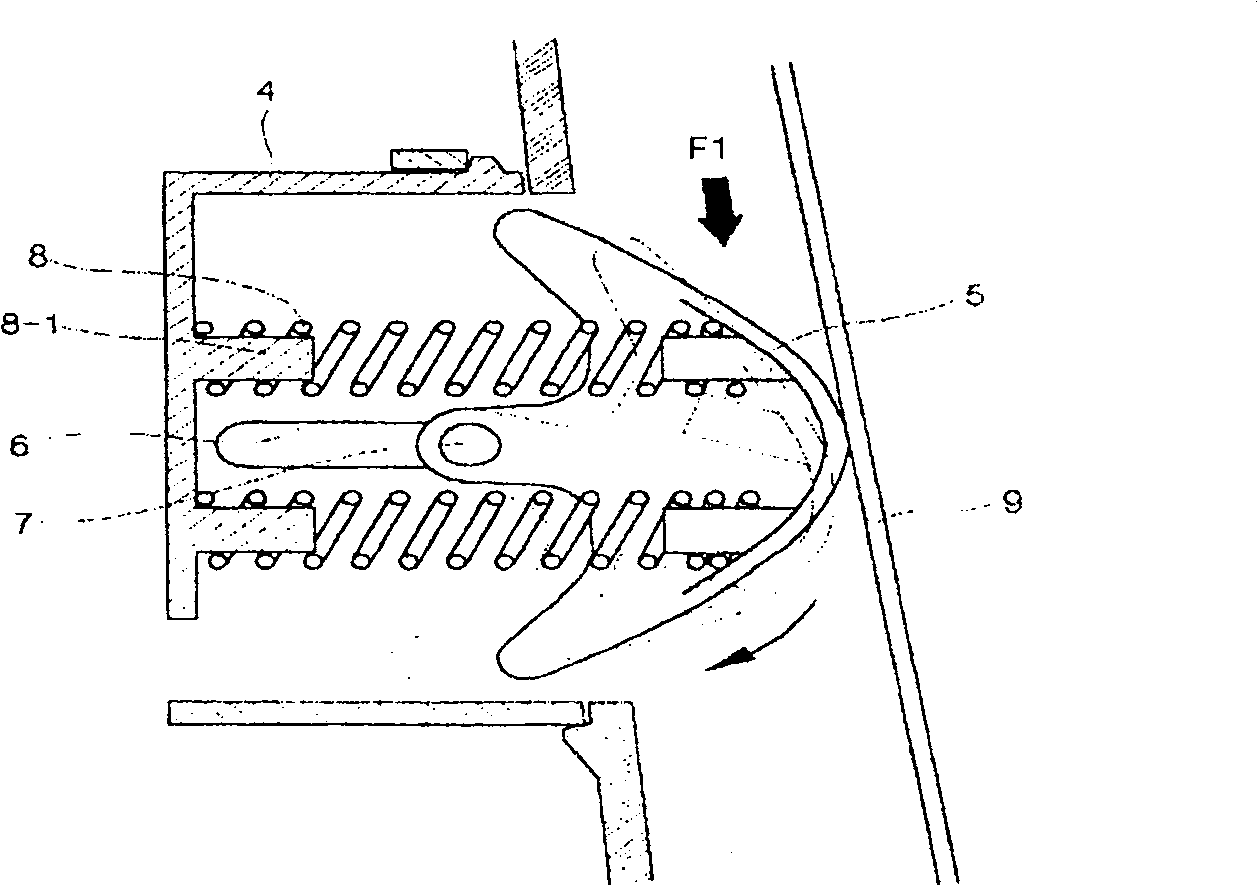

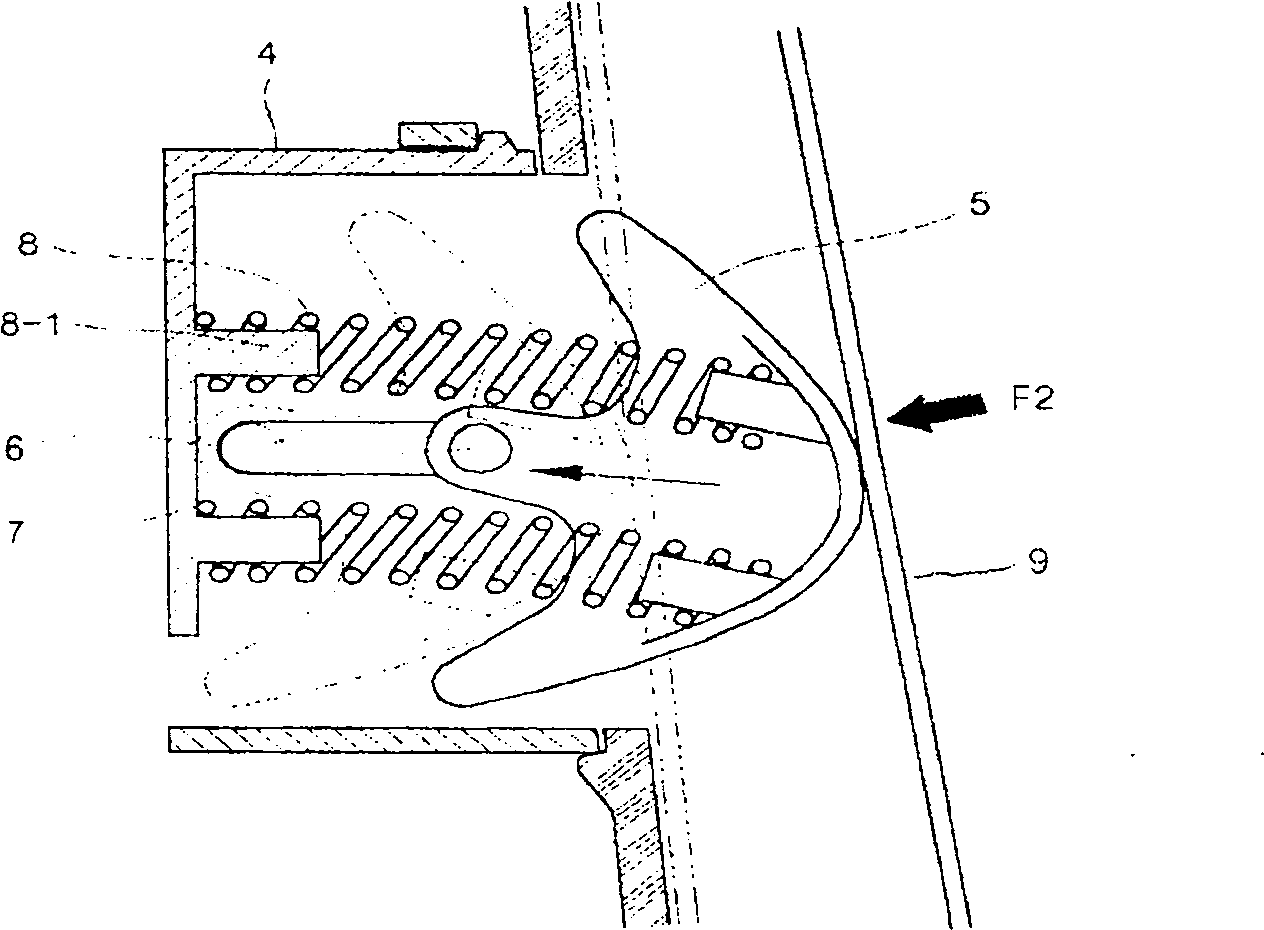

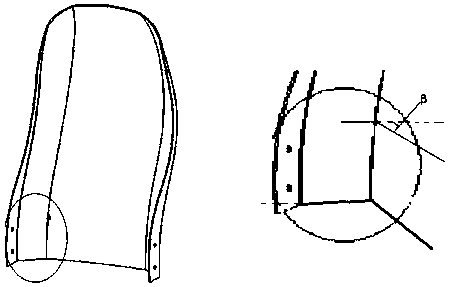

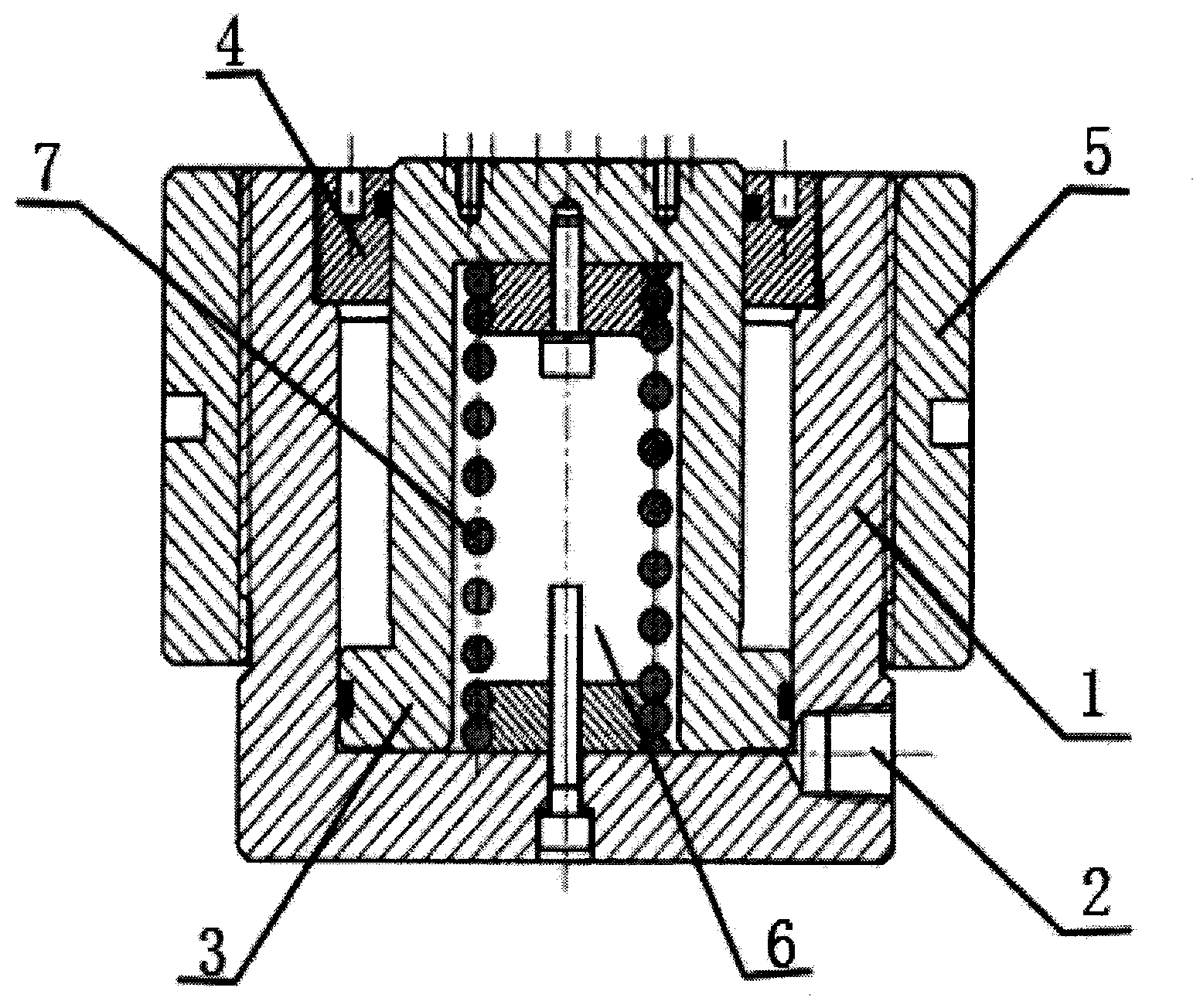

Accessible circular knitting machine with improved spinning head

ActiveCN102733062ANo hindranceSafe and reliable supportCircular knitting machinesYarnBiomedical engineering

The present invention relates to an accessible circular knitting machine (1) with an improved spinning head, comprising bottom legs supporting needle cylinders (3), wherein the needle cylinders are arranged to enable the axes (3a) to be perpendicular to each other and actuated to rotate about the axes (3a) thereof relative to the bottom legs (2), the bottom legs (2) also support a yarn guide carrier (4) arranged above the needle cylinders (3), the yarn guide carrier (4) is supported by an arm (5), the arm extends out from the top of a column (6) vertically rising from the areas of the bottom legs (2) in a manner of suspension arm, and the areas are spaced broadwise relative to the needle cylinders (3).

Owner:SANTONI SPA

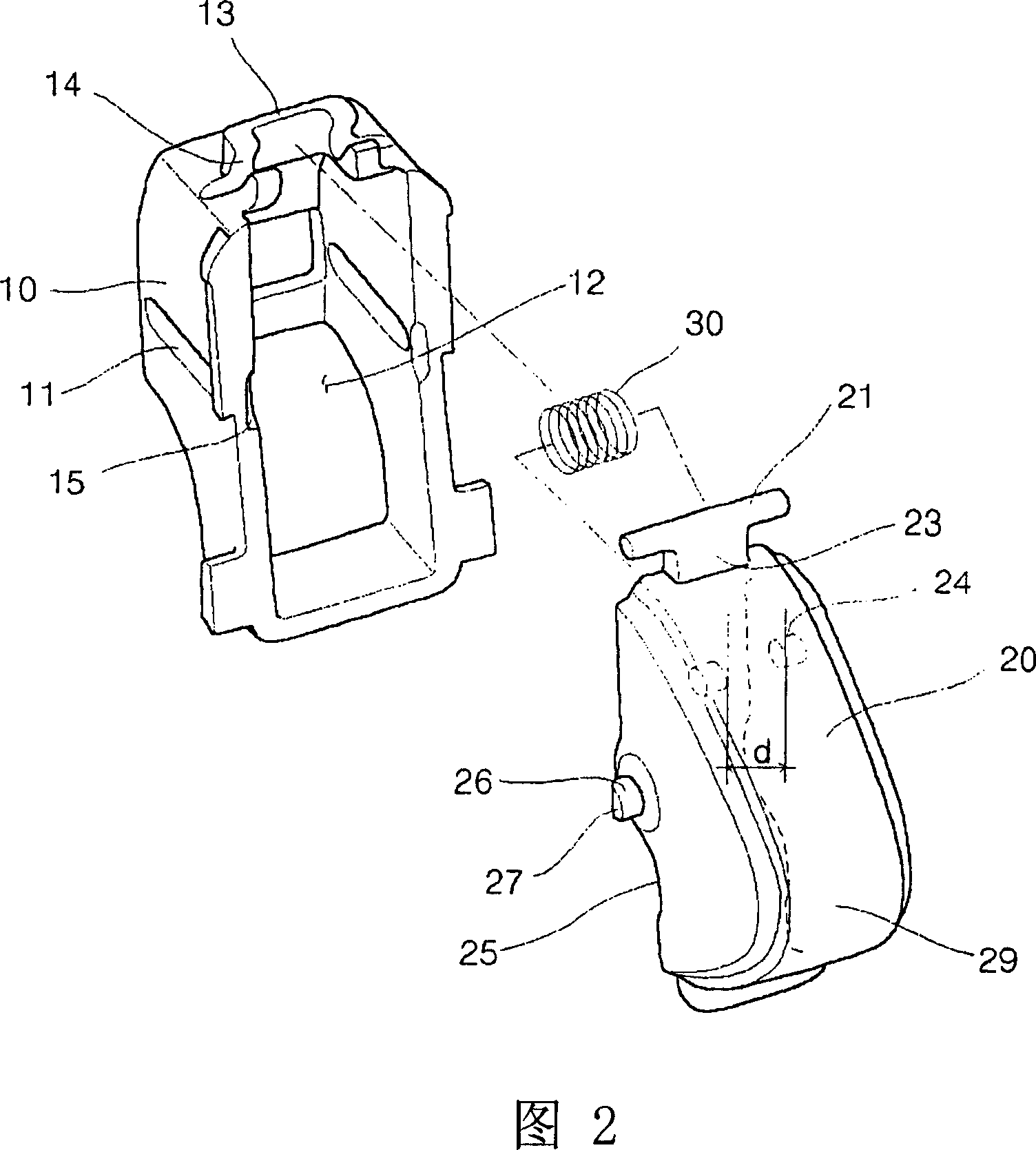

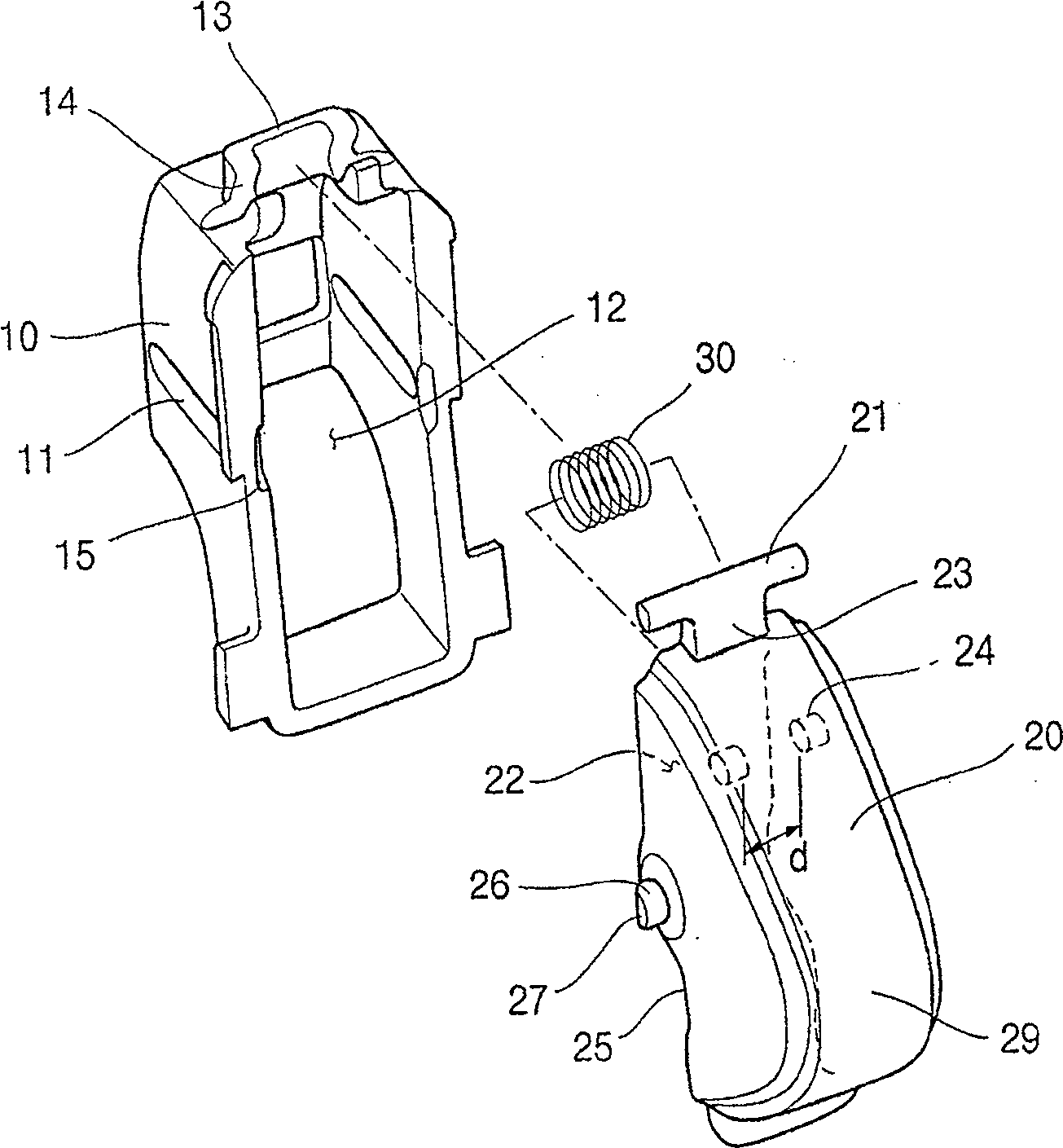

Cup holder for a vehicle

ActiveCN1939770APrevent disengagementSafe and reliable supportVehicle arrangementsPassenger spaceEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD +1

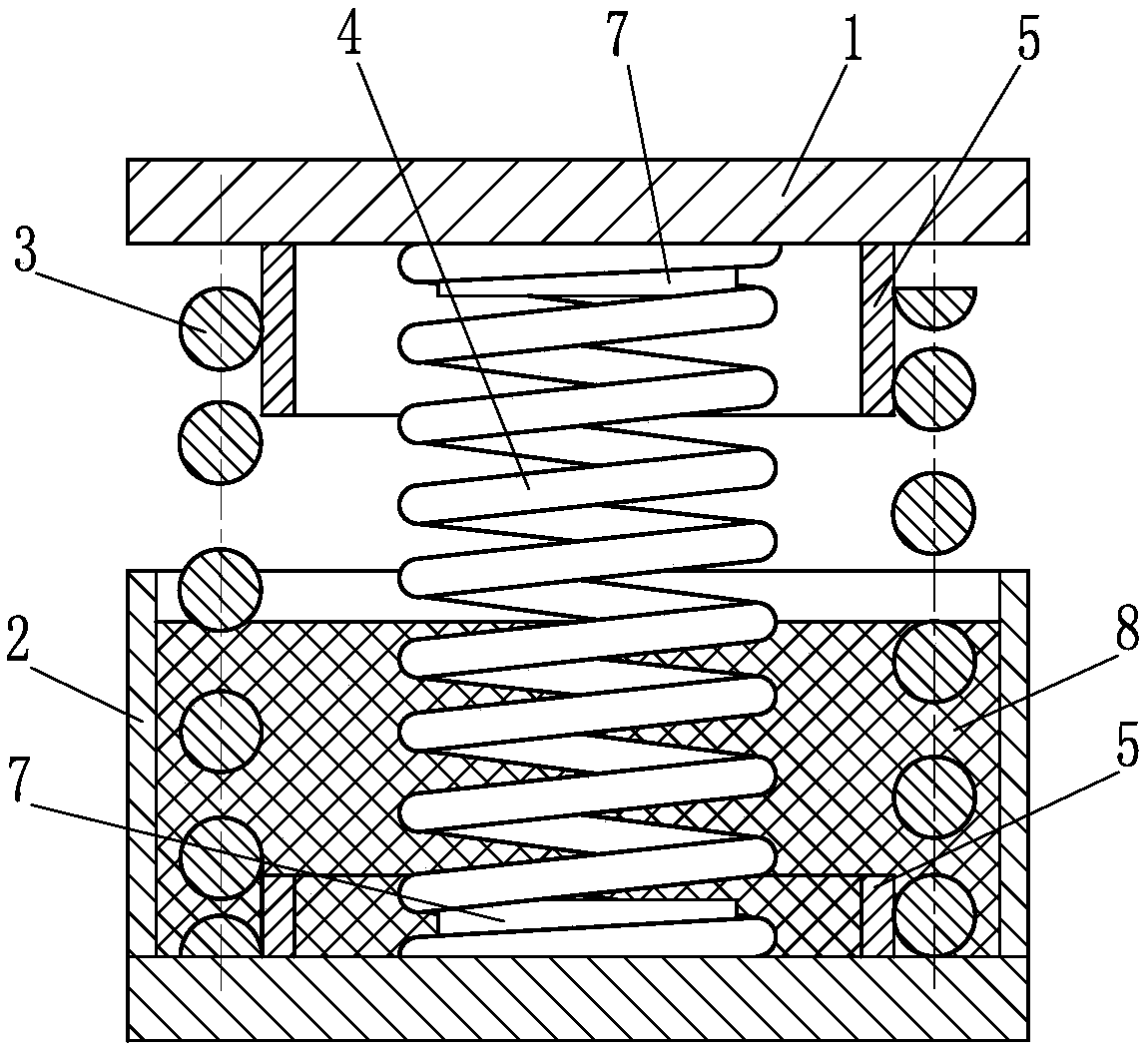

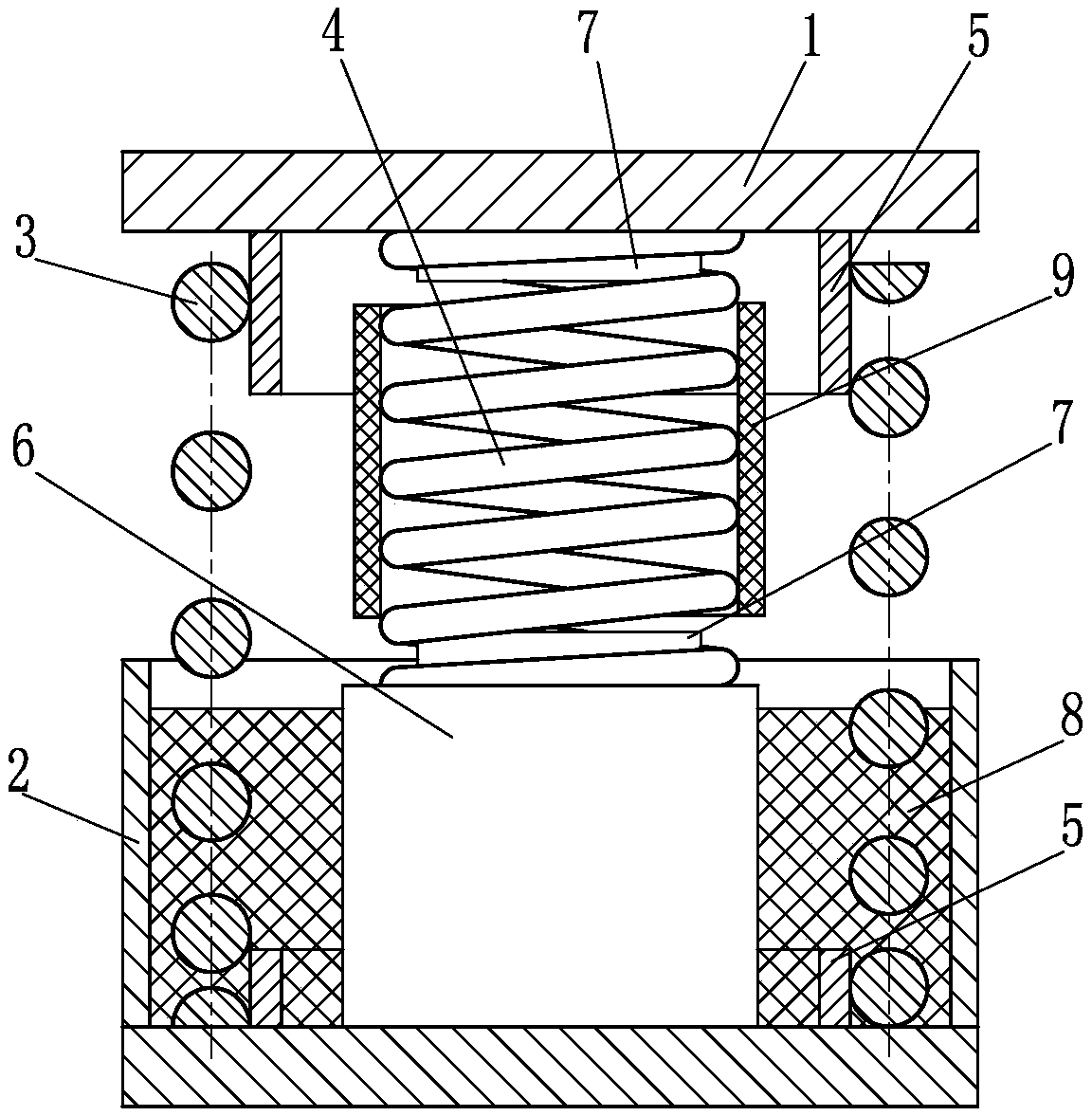

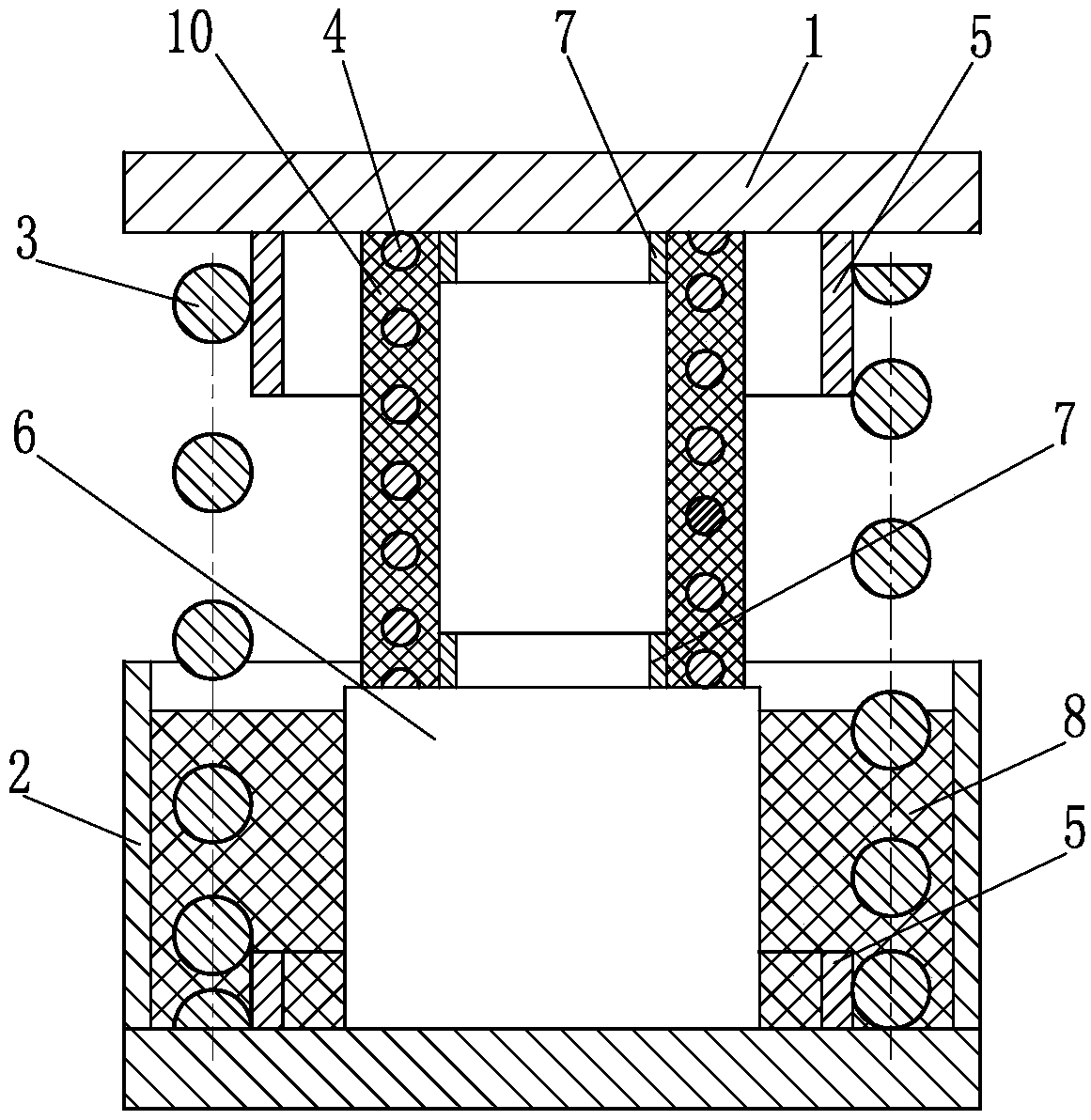

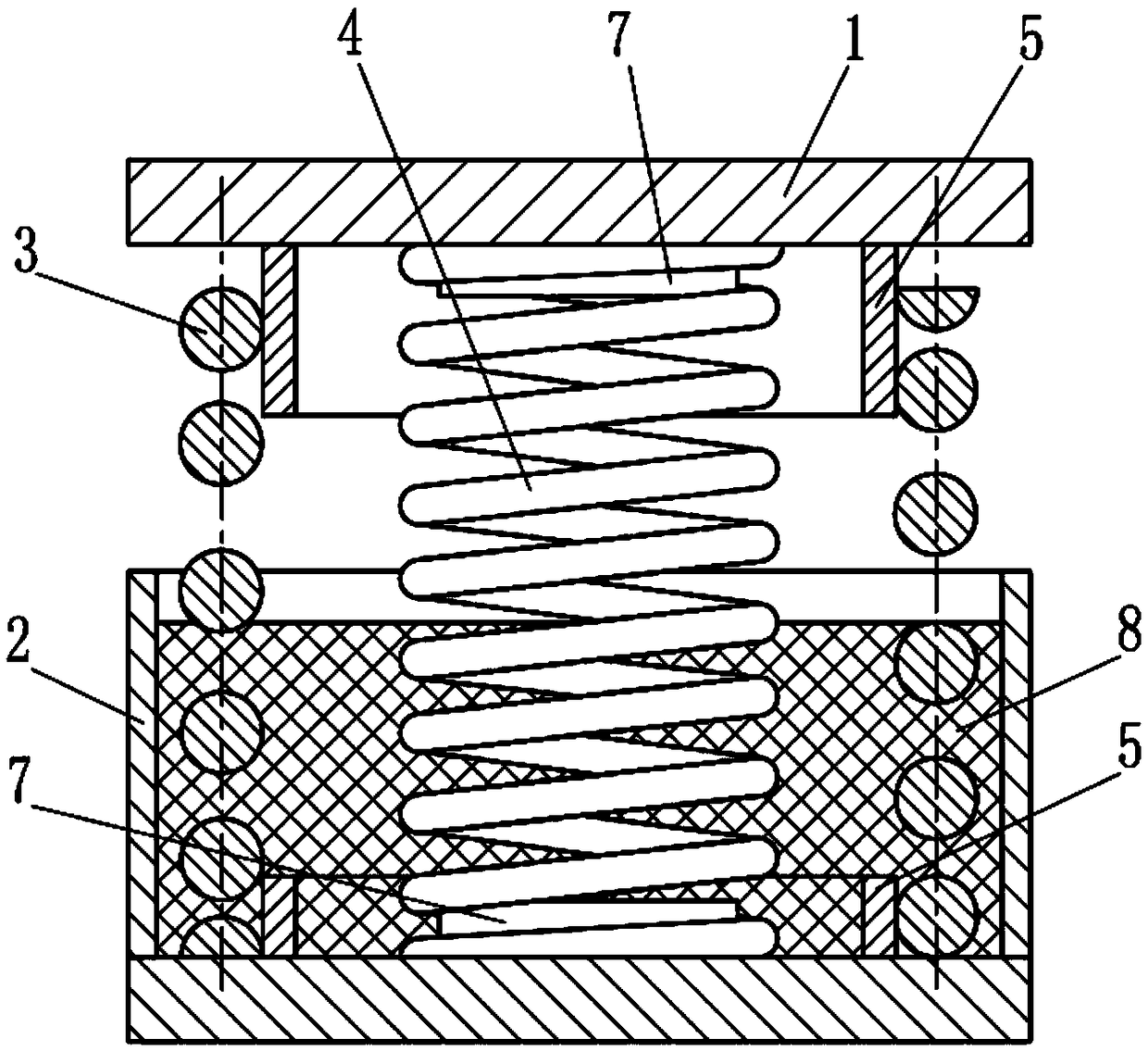

Non-linear combined spring vibration isolator

InactiveCN109098046AConvenient height adjustment and leveling operationLarge amount of compressionRailway tracksVibration controlEngineering

The invention belongs to the technical field of vibration and noise reduction of rail transit, in particular to a steel spring vibration isolator which can provide nonlinear elastic bearing capacity.The invention solves the problems of poor vibration control effect and low leveling construction efficiency of the floating ballast bed system under the condition of varying dynamic load. At least oneof that static load support spr and the combined support spring respectively comprises a helical steel spring, A static load bearing spring and a combined bearing spring are arranged in parallel or the combined bearing spring is sleeved outside the static load bearing spring, and the static bearing spring supports the upper shell, at least a part of the combined bearing spring is provided with asolid damping structure, or the lower shell is provided with a damping material, and the combined bearing spring is at least partially arranged in the damping material; The invention has the advantages of simple structure, strong adaptability to dynamic load change and good vibration isolation performance, and can be widely applied to complex vibration isolation engineering where dynamic load is easy to change.

Owner:GERB QINGDAO VIBRATION CONTROL +1

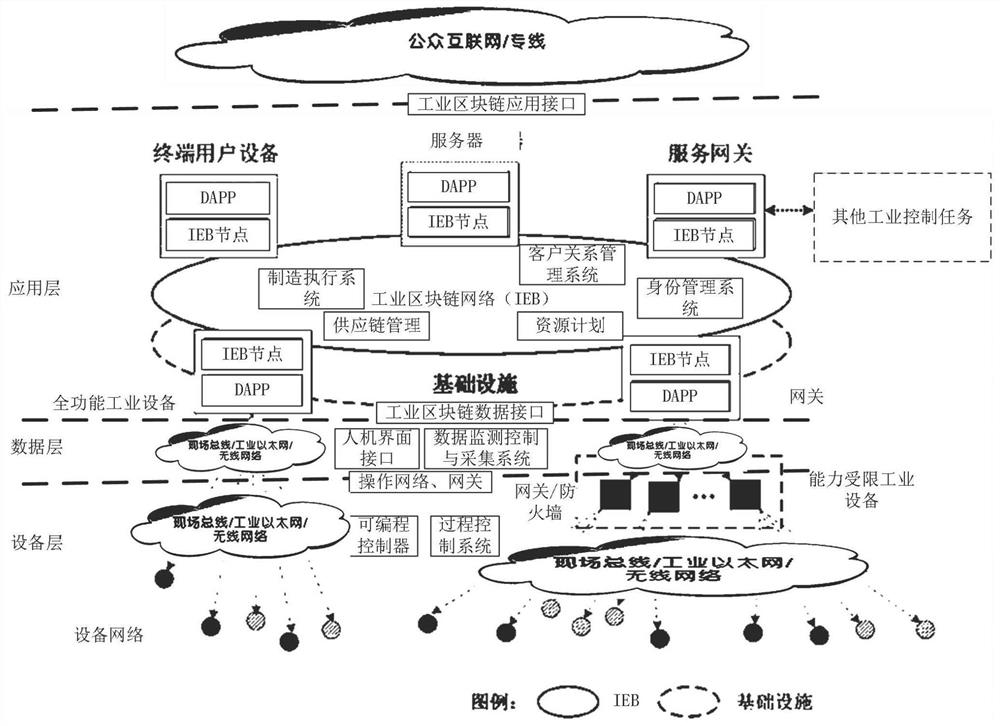

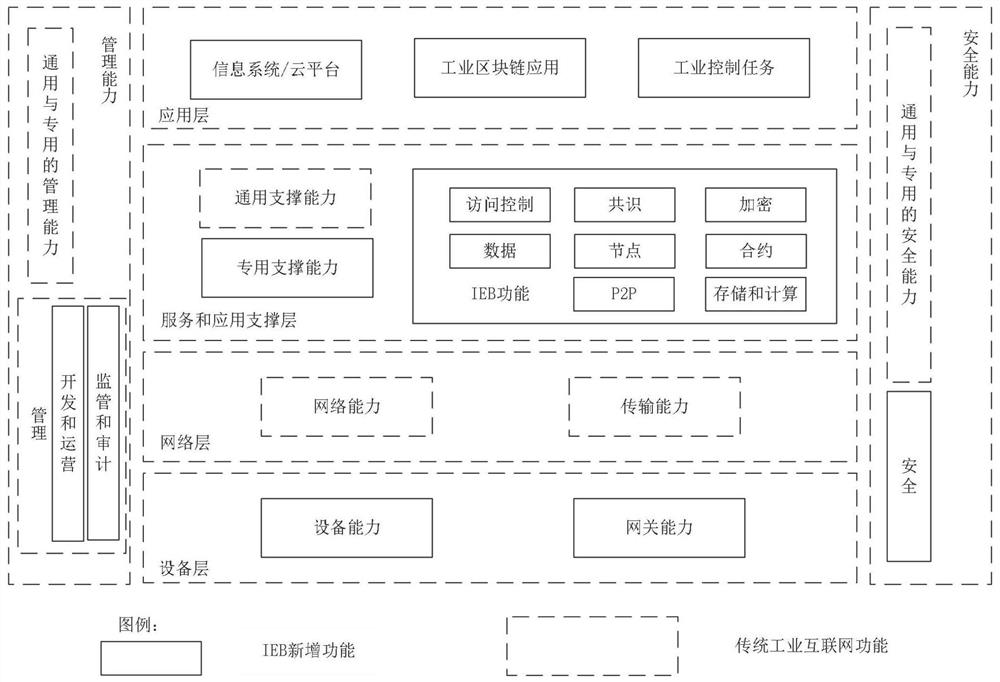

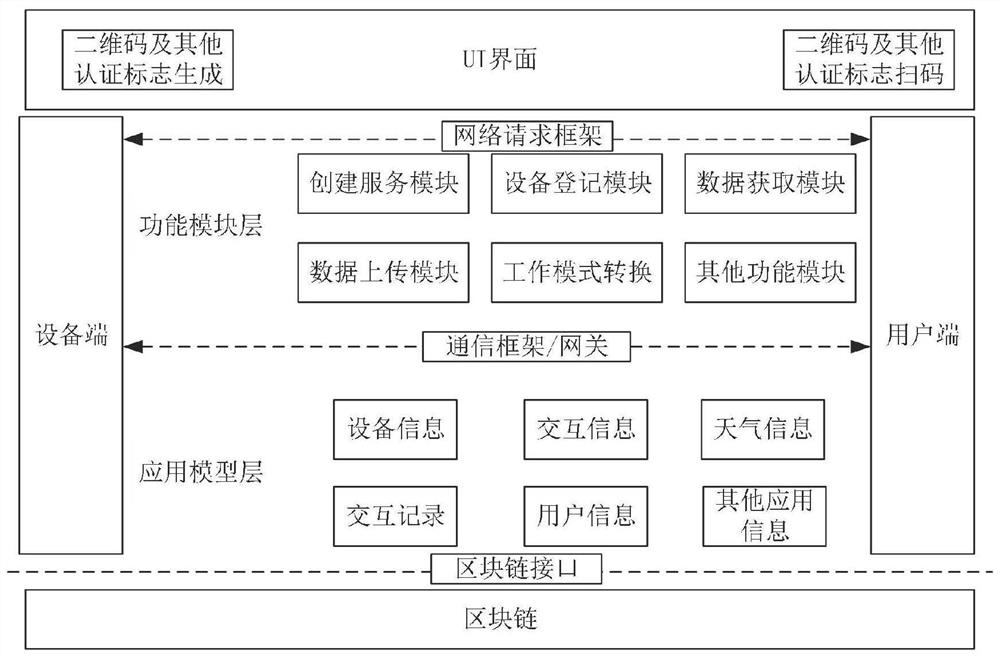

Blockchain construction method for distributed identity authentication in industrial field

ActiveCN112417037ASafe and reliable supportIndustrial Manufacturing Efficiency ImprovementData processing applicationsDatabase distribution/replicationDigital identityEngineering

The invention discloses a blockchain construction method for distributed identity authentication in the industrial field, and the method comprises the steps: recording an identity authentication auditing identifier of an industrial entity at an authentication institution end into an identifier analysis system; carrying out authentication and credit endorsement of the industrial entity digital identity by an authentication authority (e.g., government, enterprise, etc.), with the authentication and endorsement being done prior to the industrial entity chaining; allocating a blockchain address ofeach industrial entity in an industrial network based on an identifier recorded by the industrial entity at an authentication mechanism end, registering the industrial entity on a blockchain according to a specific address, and preparing to perform an uplink operation, thereby protecting the digital identity of the industrial entity from being influenced by other equipment; after chaining, carrying out credible authentication of industrial entity digital identity information based on a digital identity authentication system of the block chain; the digital identity authentication system basedon the block chain guarantees the authenticity of digital identity information and provides credible authentication service.

Owner:HANGZHOU YUNXIANG NETWORK TECH

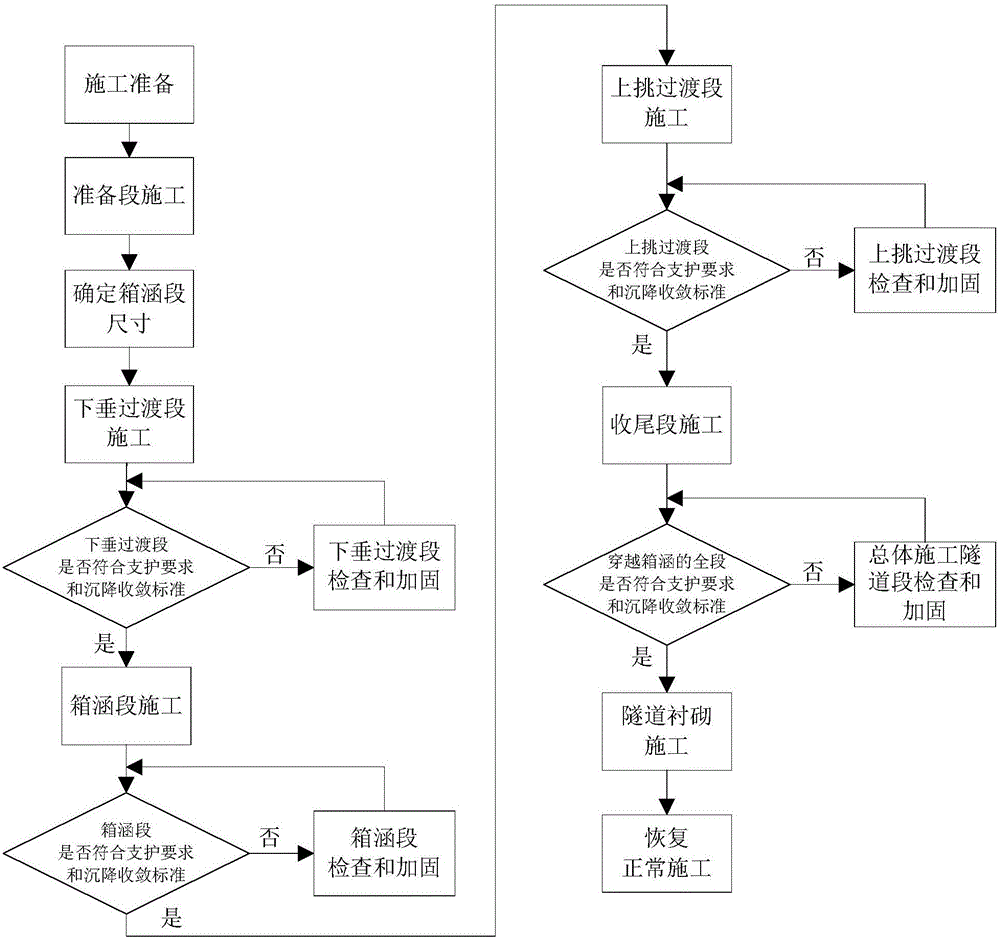

Construction method for shallow depth bored tunnel to penetrate through box culvert

ActiveCN106761779AImprove anti-settlingFast convergenceDesign optimisation/simulationTunnelsUltimate tensile strengthCulvert

The invention discloses a construction method for a shallow depth bored tunnel to penetrate through a box culvert. The method comprises the following steps of construction preparation, construction of a preparation section, determination of the size of a box culvert section, construction of a sagging transitional section, construction of the box culvert section, construction of an upward-tilting transitional section, construction of an ending section, inspection of the supporting strength, and restoration of normal excavation of the constructed tunnel. The transition sections of the tunnel are short, the bottom of the tunnel is unchanged in excavation depth, only the shape of the section of the tunnel is changed, the influence of the existing box culvert on tunnel construction is ingeniously avoided, and the construction progress is guaranteed on the premise that the construction safety is guaranteed.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

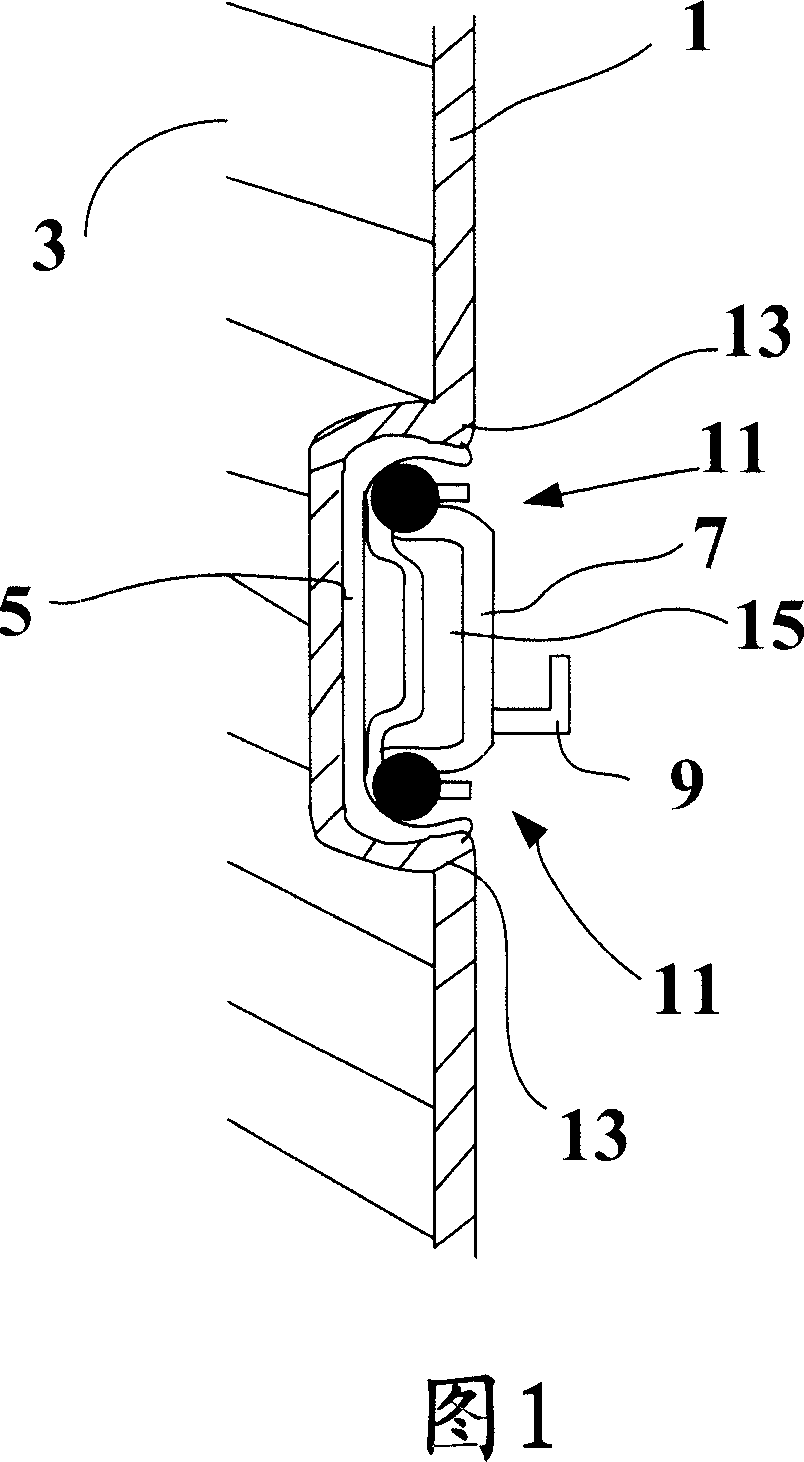

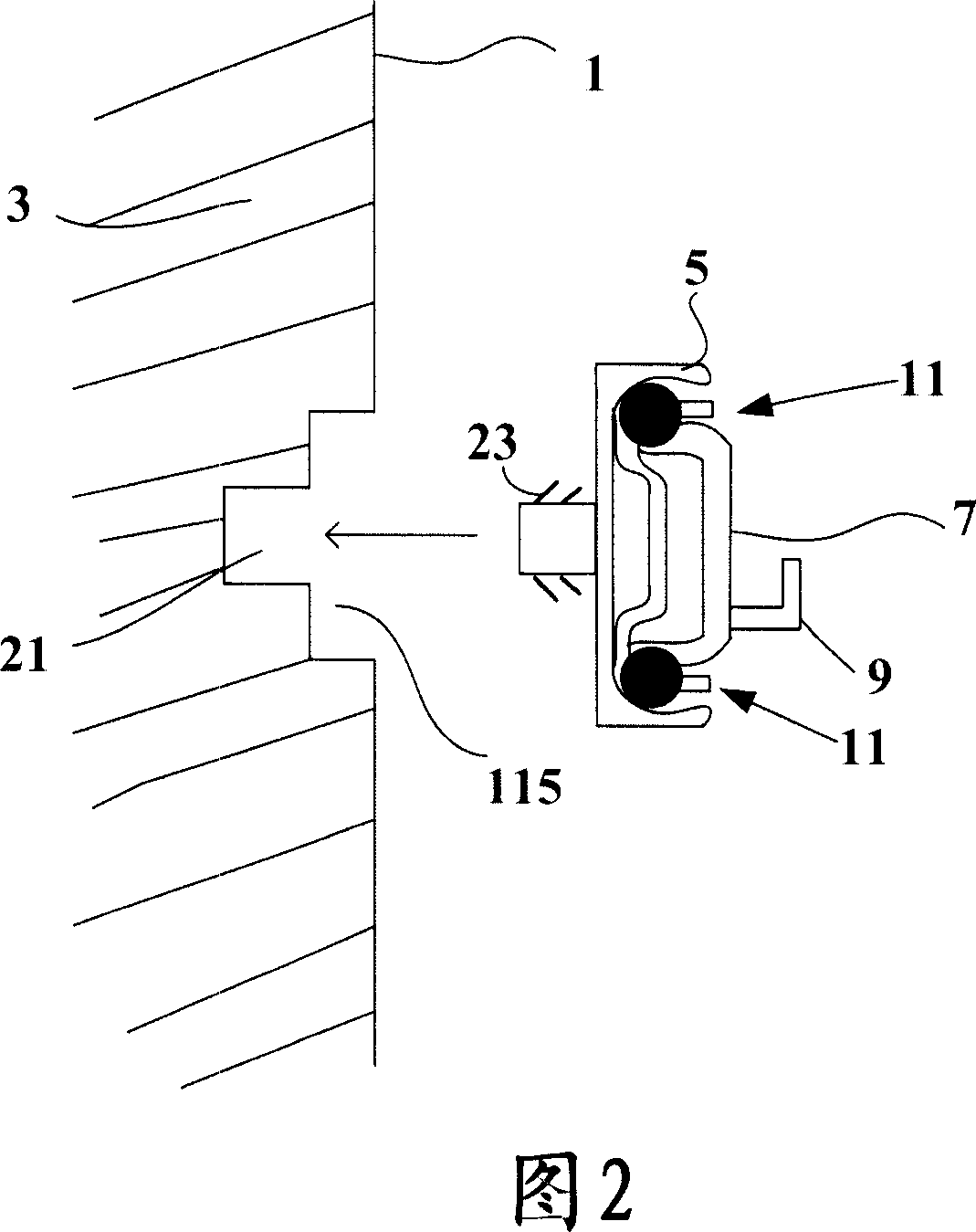

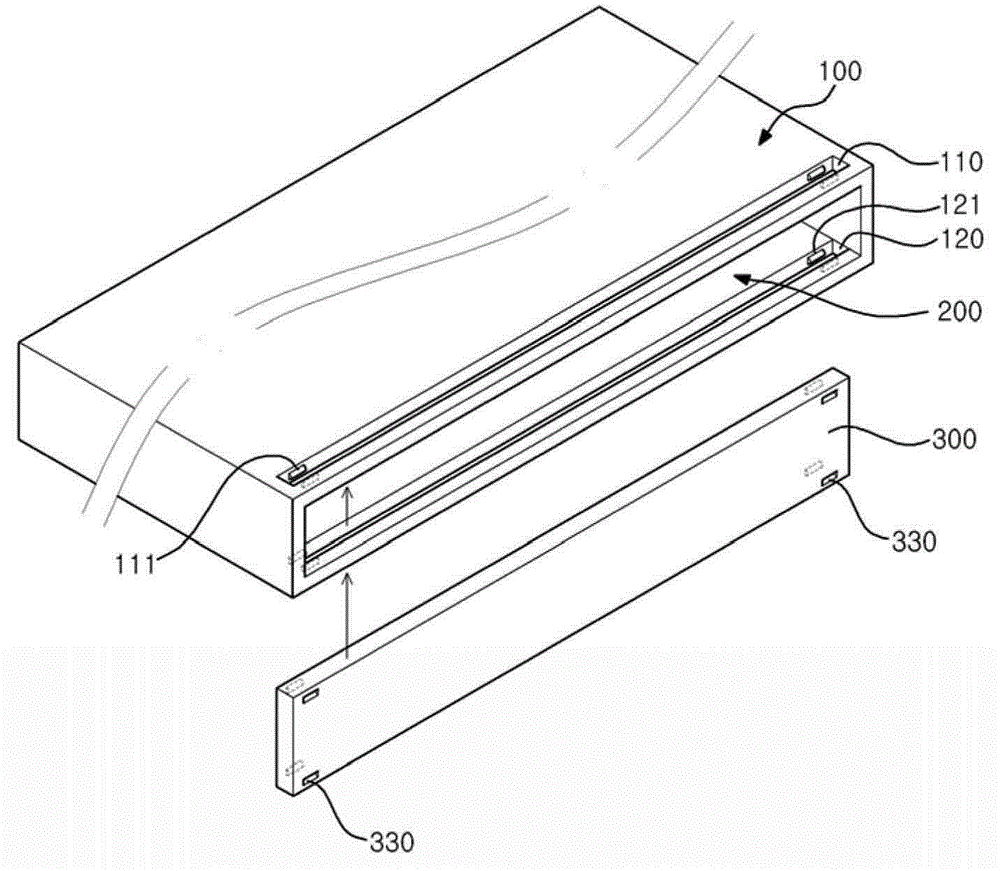

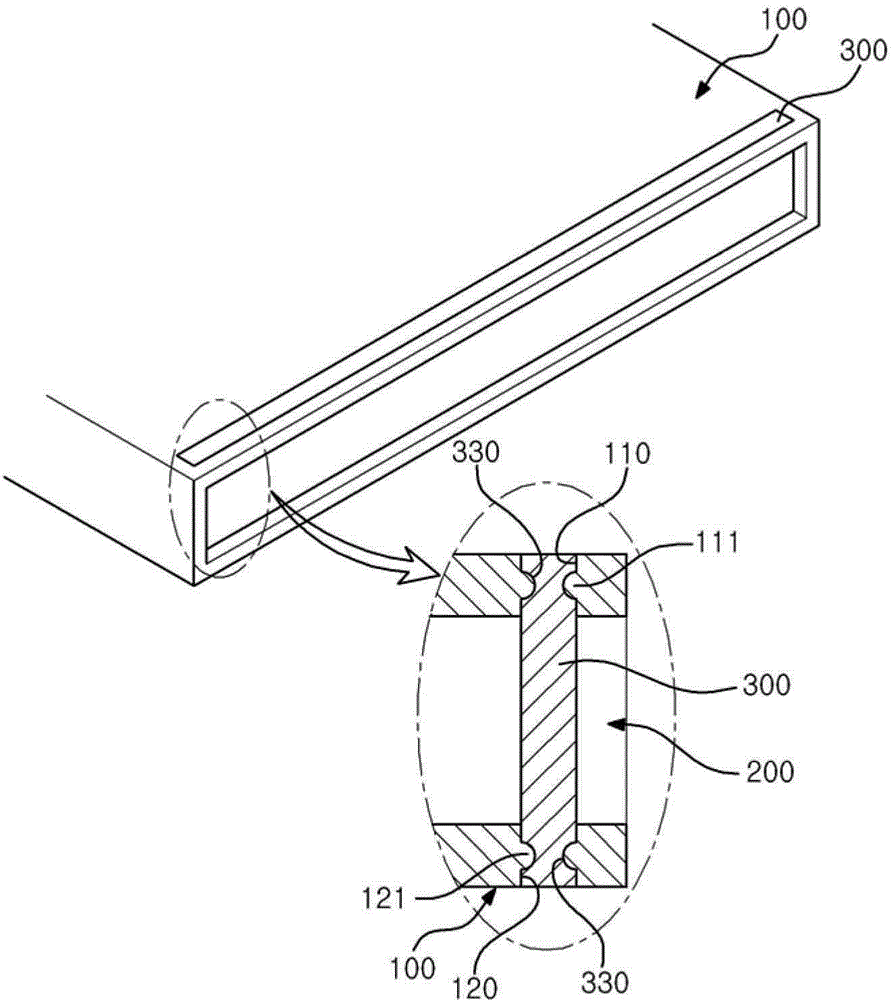

Fastening system and method for fixing elements on the lining of refrigerators and/or freezers

InactiveCN1954184AEnsure retentionSave spaceLighting and heating apparatusDomestic articlesPlastic materialsThermal insulation

Disclosed is a method for producing a fastening system for fixing elements on the plastic lining (1) of a refrigerator and / or freezer wall that is thermally insulated by means of foam. According to the inventive method, the lining is deep-drawn from a plastic material with a receiving contour (15) which is embodied so as to partly correspond to the outer contour of the element that is to be fixed such that the element that is to be fixed can be accommodated by the receiving contour, and the element that is to be fixed can be placed therein. Alternatively, the element that is to be fixed is inserted into a deep-drawing die, and the lining is deep-drawn from plastic material so as to at least partly mold the element that is to be fixed in order to form a receiving contour in the plastic lining for the element that is to be fixed. In both instances, a thermal insulation made of foam (3) is then foamed onto the rear face of the plastic lining.

Owner:LIEBHERR HAUSGERATE OCHSENHAUSEN

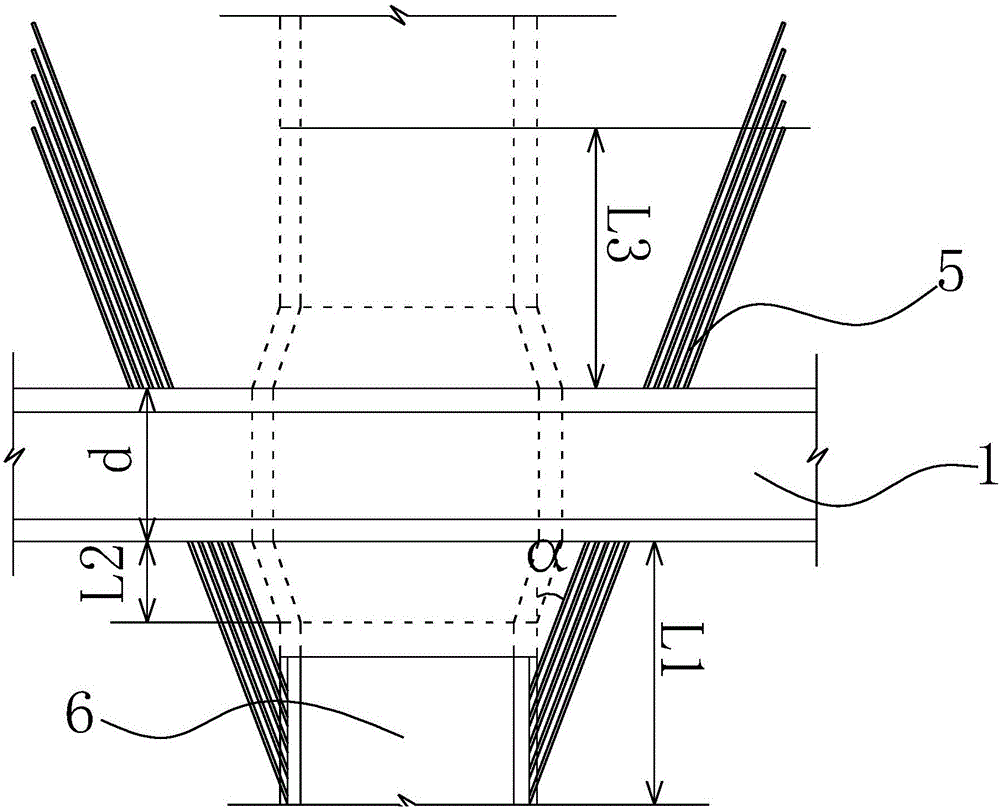

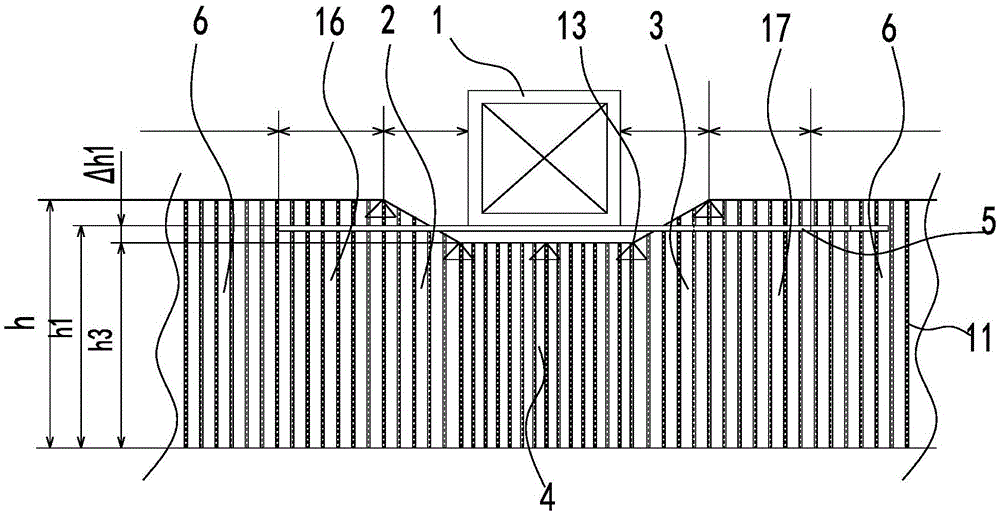

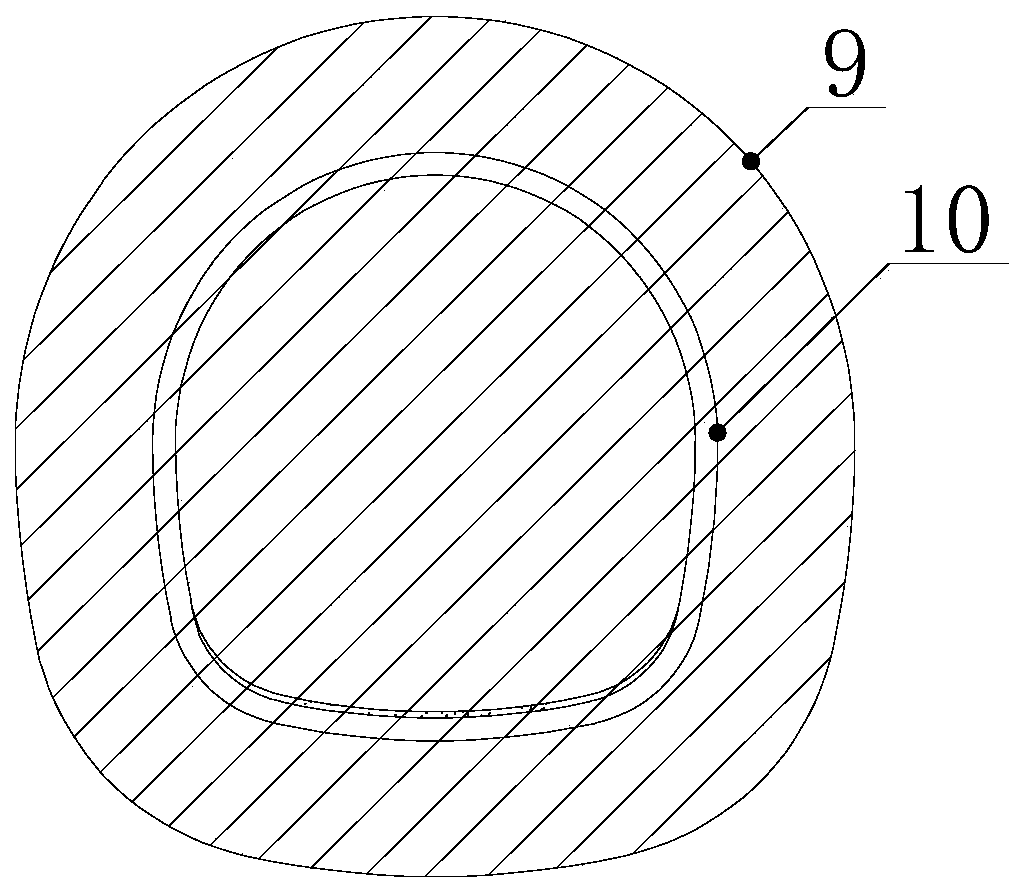

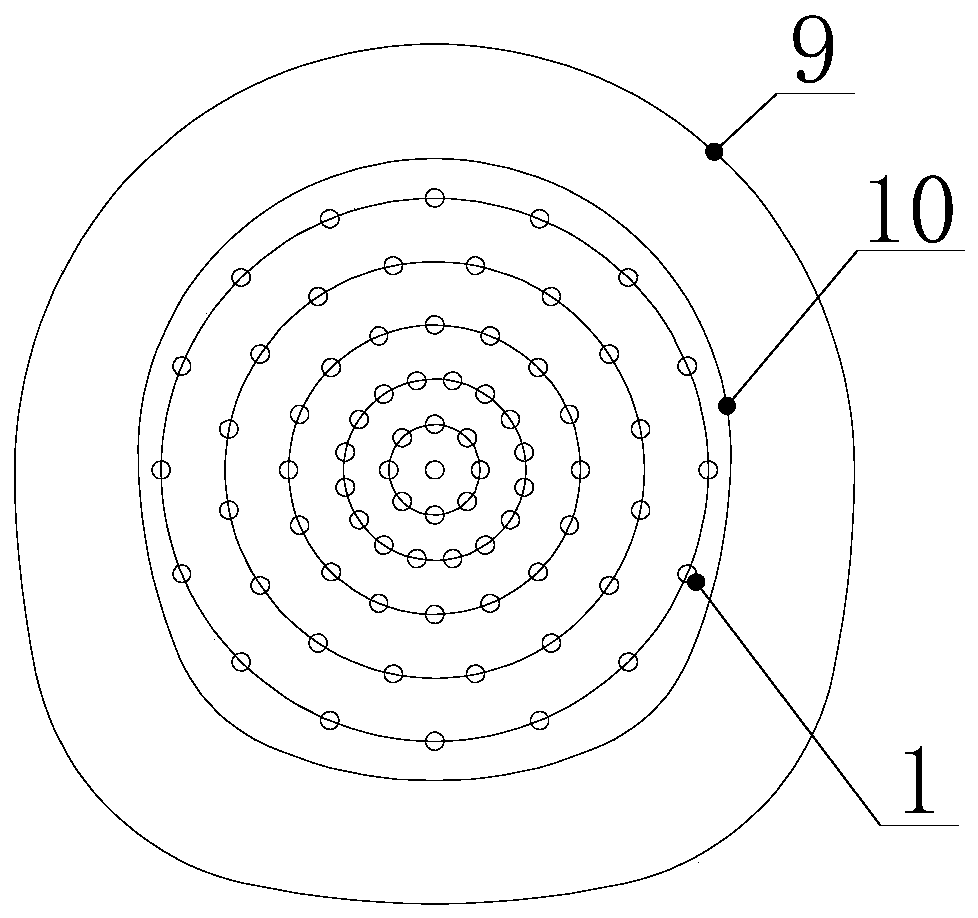

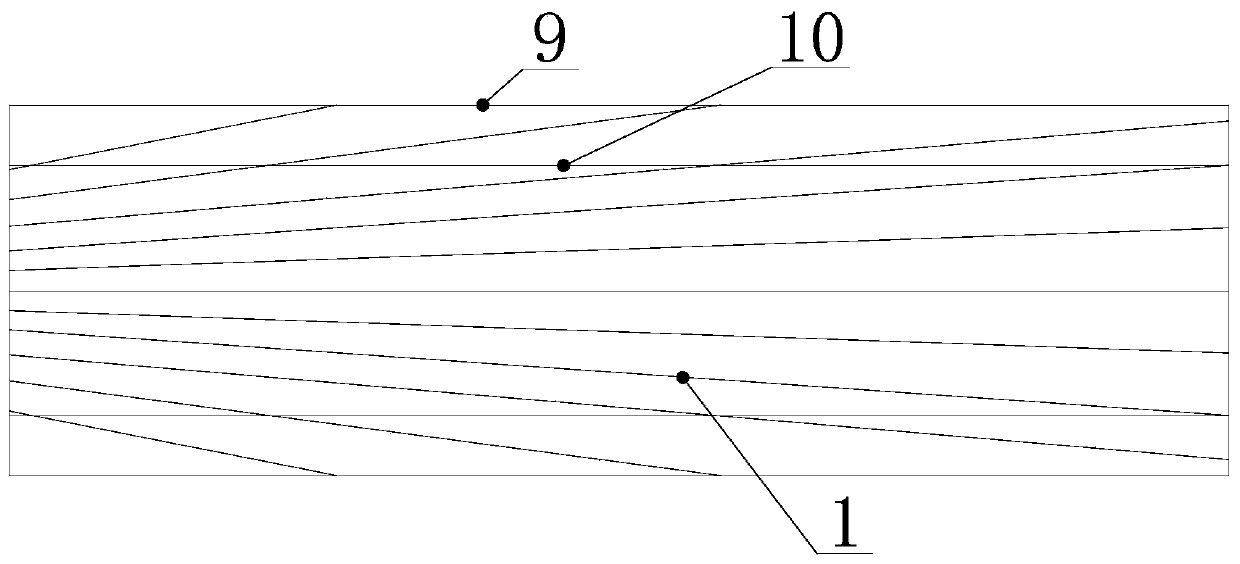

Dense net type advanced supporting system of bored tunnel and construction method

PendingCN111502696ASettlement controlLow costUnderground chambersTunnel liningGeotechnical engineeringPipe

The invention discloses a dense net type advanced supporting system of a bored tunnel and a construction method applying the system for carrying out supporting. The system comprises a grouting sleevevalve pipe and a pipe shed, the grouting sleeve valve pipe is adopted for grouting, then, a subsequently-excavated front tunnel face and surrounding rock thereof are subjected to reinforcing, the dense net type pipe shed is driven for serving as supporting, through the pipe shed, the surrounding rock on the excavated section top is subjected to supporting, an advanced small guide pipe is driven into a pipe shed gap, through the advanced small guide pipe, the rock soil strength nearby the inner side face of the tunnel is reinforced, the system is more suitable for underground excavation construction work of a sandy cobble stratum, the dense net type pipe shed is added, grouting is carried out, the self framework effect of the sandy cobble stratum is effectively used, compared with previoussandy cobble stratum underground excavation engineering, the stratum settlement is effectively controlled, happening of excavating oversquare condition is limited, meanwhile, during construction, theexcavating length is not limited, engineering cost is saved, construction and surrounding building safety is ensured, and the forceful guarantee is provided for urban underground excavation engineering safety construction.

Owner:GUANGZHOU METRO DESIGN & RES INST

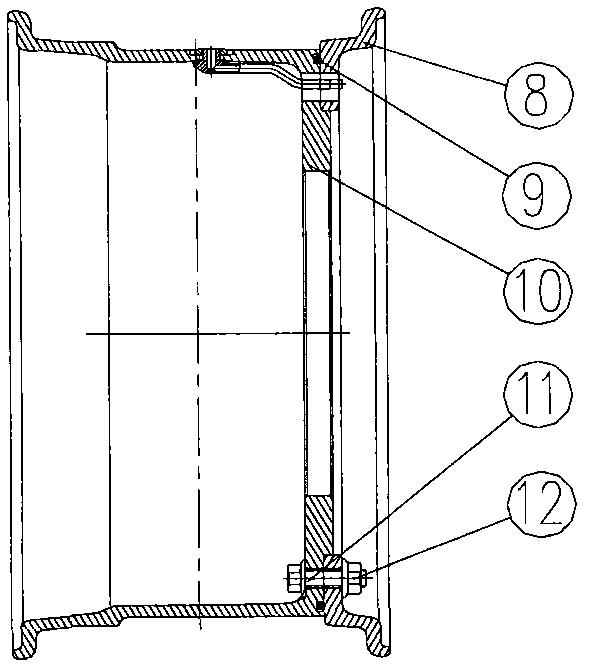

Safety wheel with oppositely-opened type aluminum-alloy wheel rim with large offset distance for special vehicle

The invention relates to a safety wheel and particularly relates to a safety wheel with an oppositely-opened type aluminum-alloy wheel rim with large offset distance for a special vehicle. The problems that a traditional wheel has large weight and is also inconvenient to assemble are solved. The safety wheel with the oppositely-opened type aluminum-alloy wheel rim with the large offset distance for the special vehicle comprises a tubeless tyre, a hard supporting body and an oppositely-opened type aluminum-alloy wheel rim with large offset distance, wherein the structure of the hard supporting body is the structure of a supporting body which is a three-section type detachable structure, and the offset distance of the wheel is not smaller than 90mm. The material of the hard supporting body is hard nylon. Compared with a steel wheel rim with the same specification, the weight of the safety wheel is reduced by more than 50 percent; compared with a rubber supporting body with the same specification, the weight of the hard supporting body is reduced by about 55 percent, so that the weight of an entire wheel assembly is greatly decreased; and the safety wheel with the oppositely-opened type aluminum-alloy wheel rim with the large offset distance for the special vehicle is beneficial to enhancing the operating and controlling performance of a vehicle and lowering the energy loss of the vehicle. The safe running mileage can be obviously enhanced. The assembling process is simple, the assembly and the disassembly of the wheel assembly can be carried out without exclusive tyre pressing and installing equipment, the assembling process is simplified, the assembling time is shortened, and the cost of logistic guarantee is also lowered.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

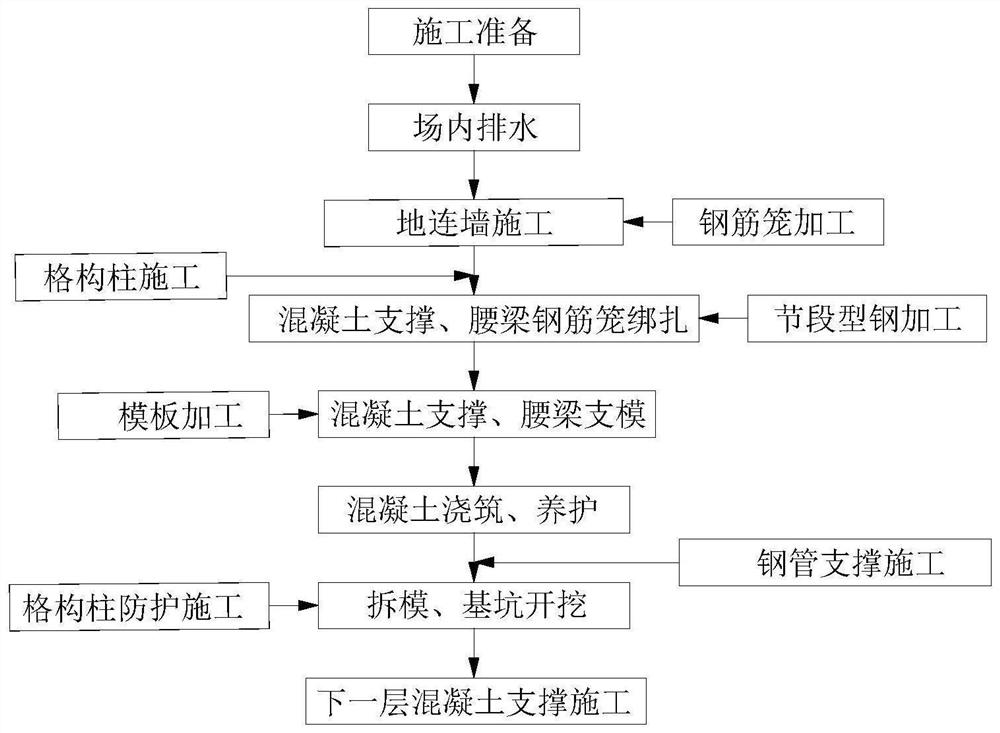

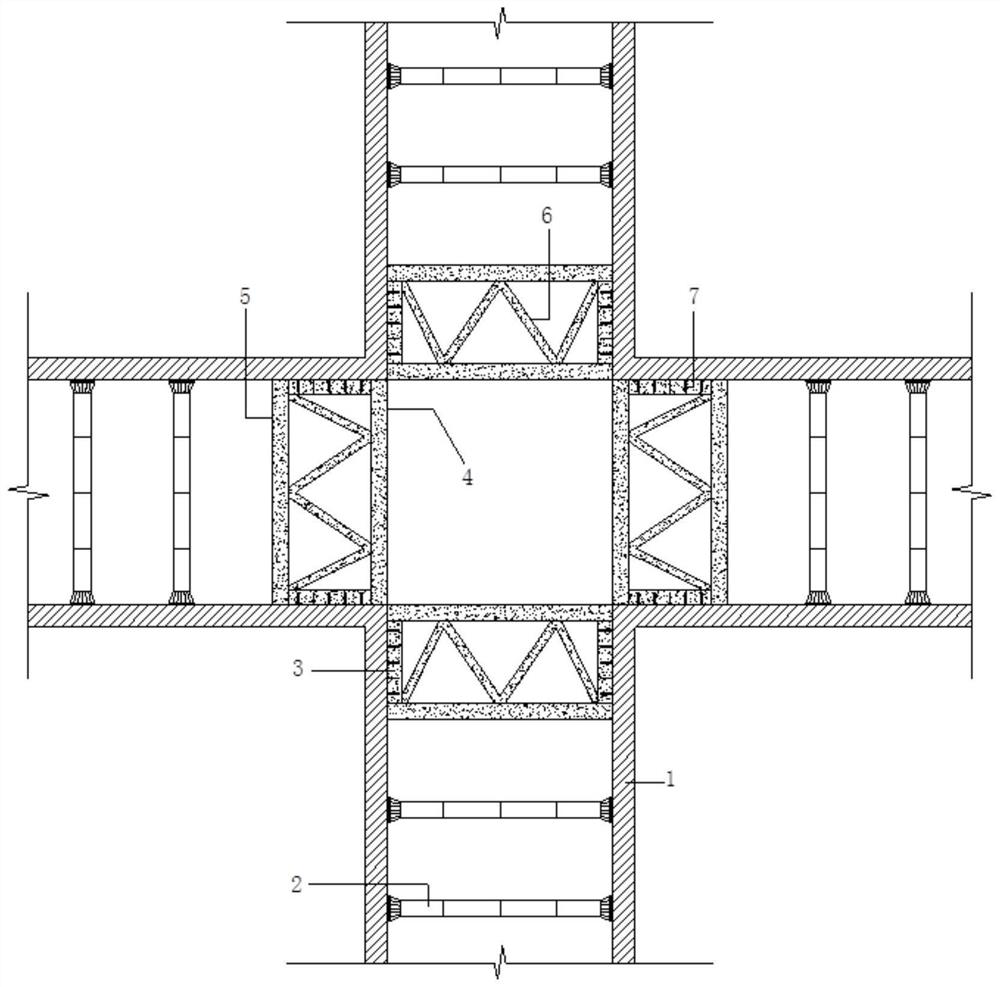

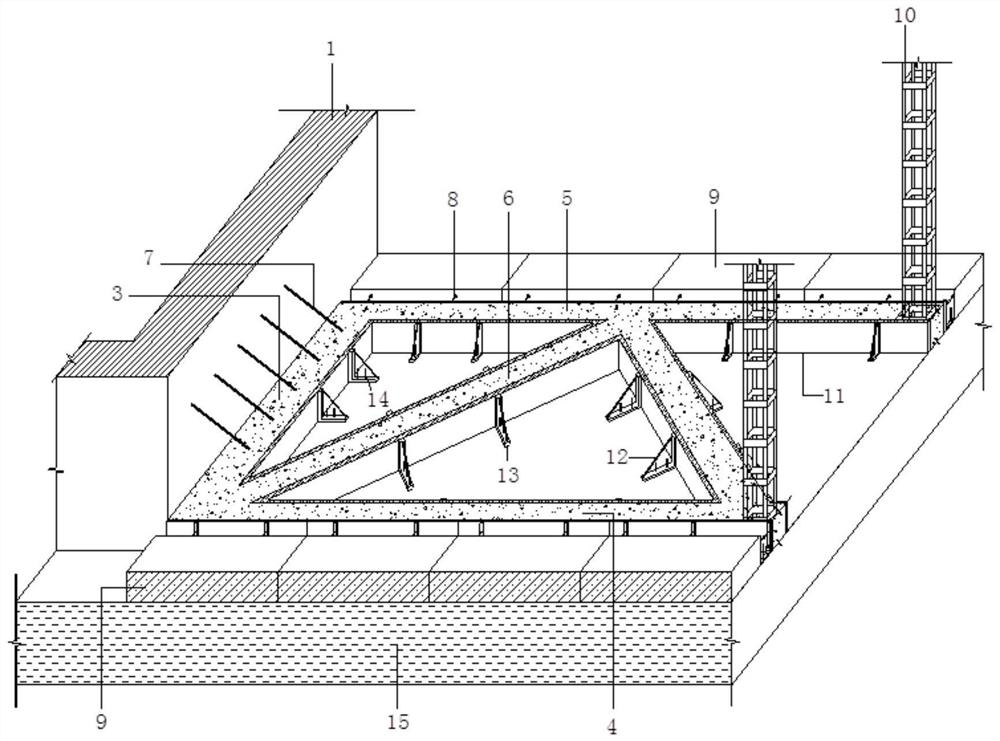

Subway transfer station deep foundation pit excavation support construction method

InactiveCN112813991AEnsure safetyEnsure stabilityExcavationsReinforced concreteArchitectural engineering

The invention discloses a subway transfer station deep foundation pit excavation support construction method. A diaphragm wall enclosure structure is adopted, concrete supports and steel pipe combined supports are arranged, the inner side concrete supports form annular reinforced concrete supports, concrete support formworks adopt prefabricated reverse pressing block reverse pressing easy-to-dismantle formwork systems and shaped formwork systems, built-in segmental steel of waist beams and the diaphragm wall enclosure structure are combined in an anchoring-hanging mode to form a whole, and latticed columns adopt flexible anti-collision construction protection devices. The construction method comprises the steps of (1) construction preparation, (2) drainage in a field, (3) diaphragm wall construction, (4) concrete support and waist beam reinforcement cage binding, (5) concrete support and waist beam formwork erection, (6) concrete pouring and maintenance, (7) formwork removal and foundation pit excavation, and (8) construction of the next layer of concrete supports. According to the subway transfer station deep foundation pit excavation support construction method, the overall safety and stability of a foundation pit are guaranteed, the construction speed is greatly increased, and obvious social benefits and economic benefits are achieved.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

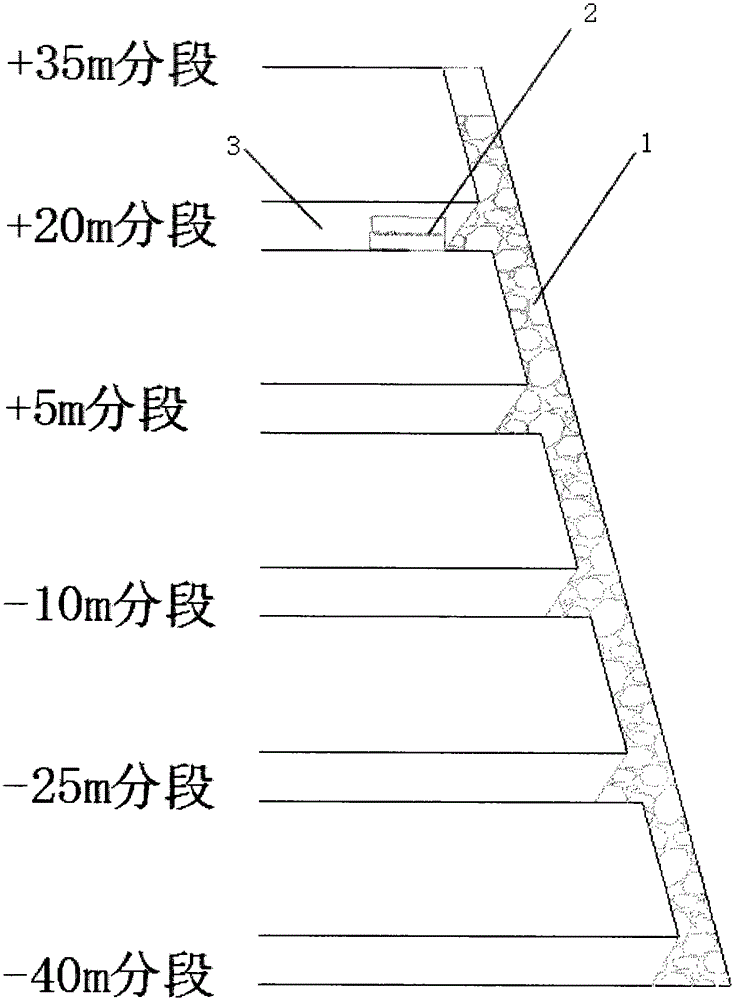

Convenient segmented support method for mine slant chute

ActiveCN106337687ASafe and reliable supportNo progressUnderground chambersMaterial fill-upMedicineSlag

The invention relates to a convenient segmented support method for a mine slant chute comprising following steps: (1) the stability of a wall of the slant chute is calculated and analyzed to determine a support form according to the actual construction situation; (2) a chute link lane is dug every 15 meters downwards from the mouth of the well in the slant chute; (3) the slant chute is filled with backfill slag until the distance between the surface of the backfill slag and the well mouth is 2 meters, then wood boards are laid on the upper surface of the backfill slag inside the well and construction workers perform support construction operation sanding on the wood boards; (4) slag removal is performed in a next segmented chute link lane until the slag level inside the chute decreases by 2 meters; (5) construction workers perform the next support construction operation; (6) step (4) and (5) are repeated until the construction work is completed. The support method of the invention has the following beneficial effects: (1) the slant chute is filled with slag, slag is discharged by several times, support is performed by several times and the support circulation are continued until the slag surface level decreases to the completion of the slant chute support; (2) the safety factor is high.

Owner:CHINA HUAYE GROUP

Cup holder for a vehicle

ActiveCN100526120CPrevent disengagementSafe and reliable supportPassenger spaceVehicle arrangementsEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD +1

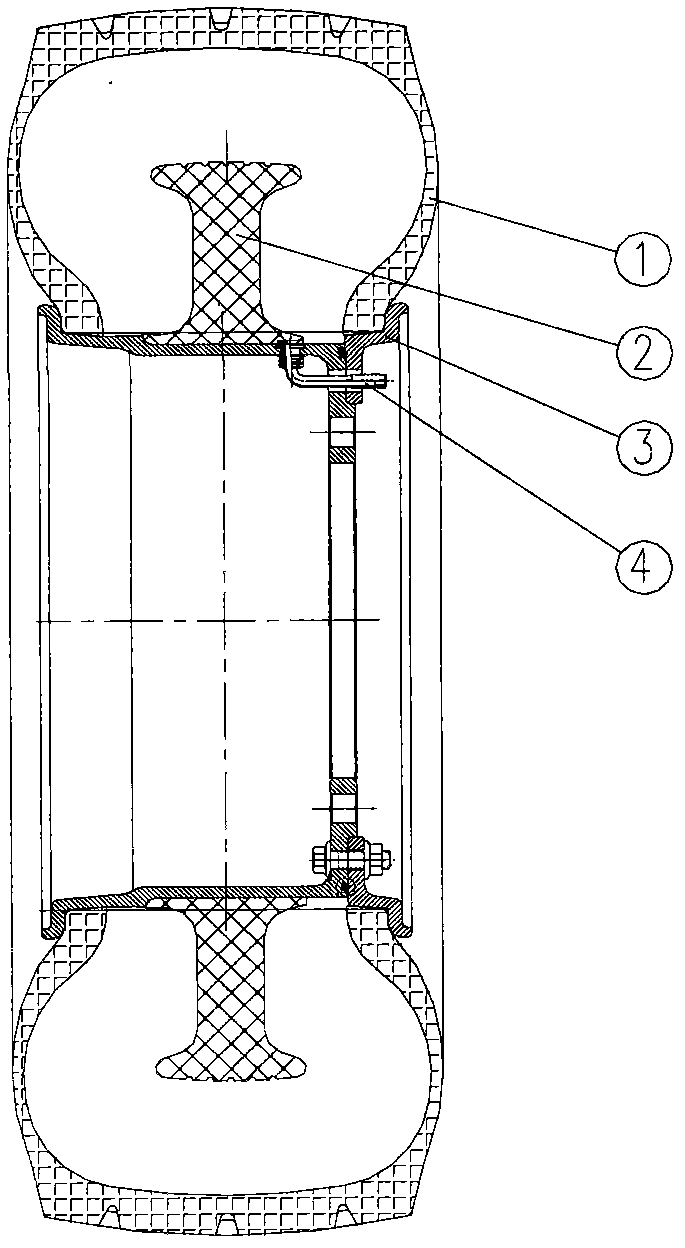

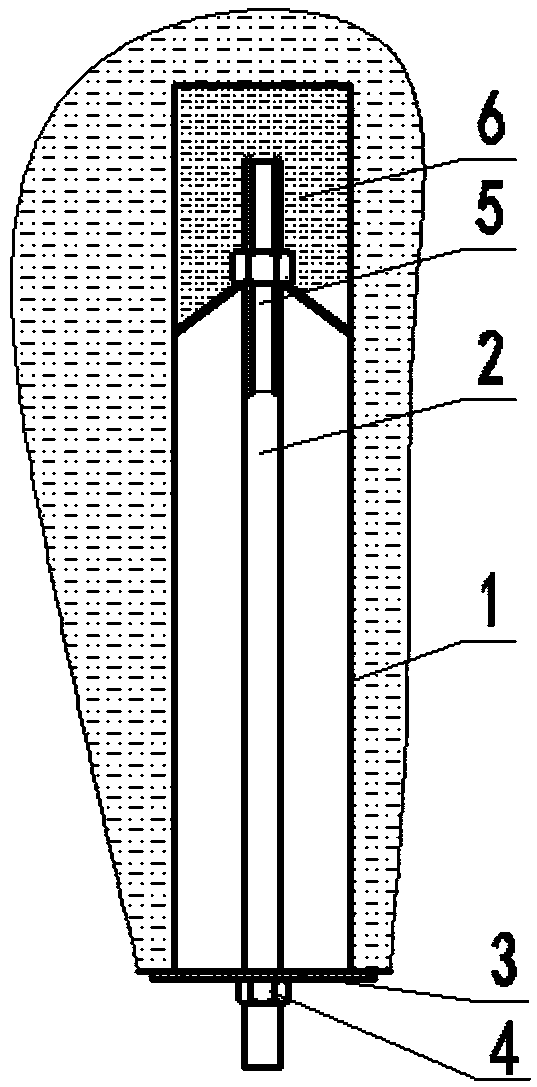

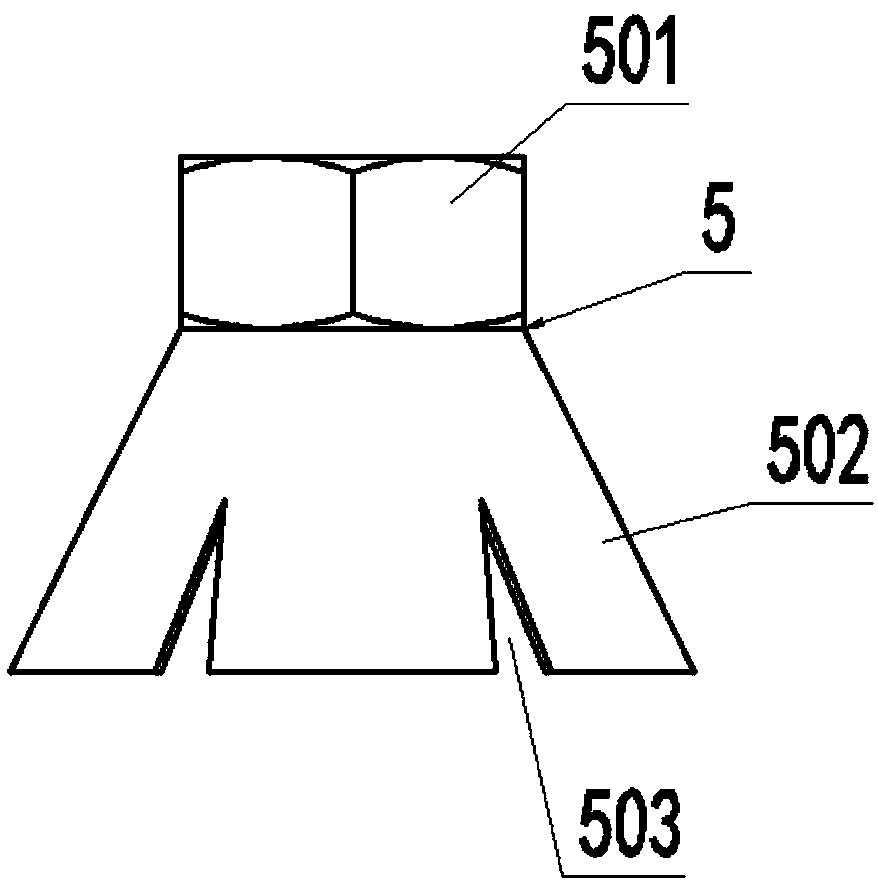

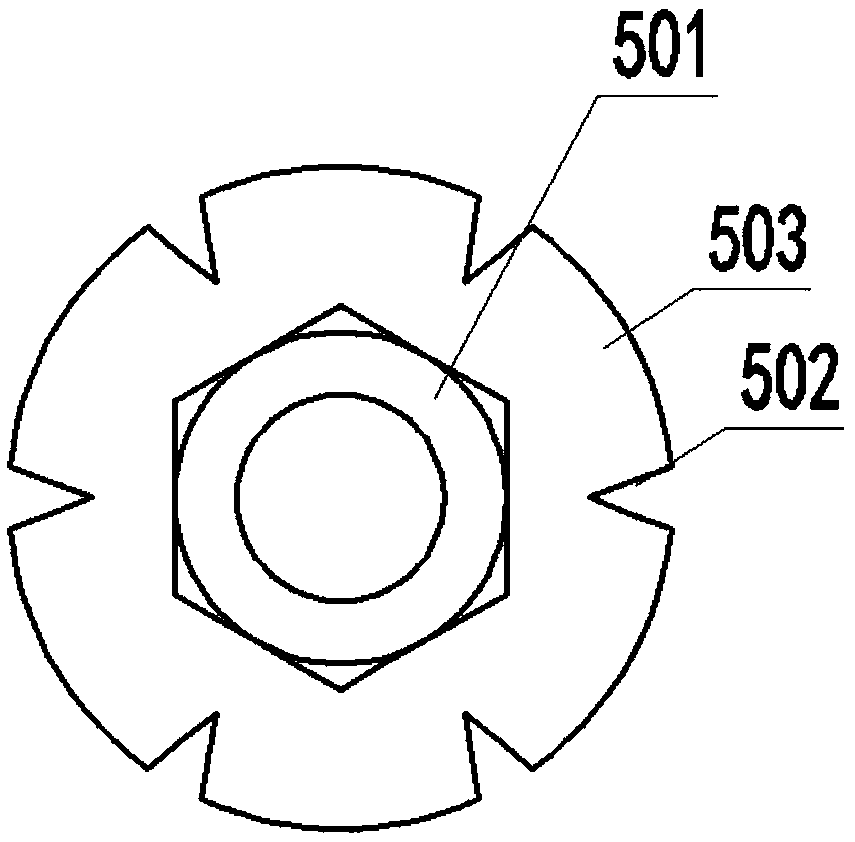

Anchor rod structure based on phosphorus-magnesium anchoring agent

The invention provides an anchor rod structure based on a phosphorus-magnesium anchoring agent and a support system of the anchor rod structure. The anchor rod structure comprises a rod body, the anchoring agent, a tray, a lock nut and a self-locking ring, wherein an anchor eye is formed in tunnel surrounding rock mass, the self-locking ring is mounted on the anchor rod body, one end of the rod body extends into the anchor eye, the other end of the rod body penetrates through the tray to be screwed with the lock nut, the tray is enabled to be tightly attached to the anchor eye rock surface, and an anchorage section from the bottom of the anchor eye to the self-locking ring is filled with the anchoring agent; the support system is formed by connecting multiple anchor rod structures. With the adoption of the technical scheme, the self-locking ring is arranged on the rod body, so that when the anchoring agent is promoted to move, the loss caused by leakage of the anchoring agent is effectively avoided; the phosphorus-magnesium anchoring agent is one fast-hardening and uniformly-stirred anchoring agent with early strength, under the pushing action of the self-locking ring, a gap between the rod body and the anchor eye can be uniformly and densely filled with the anchoring agent, therefore, adhesion of the rod body and the rock mass is tighter, bearing capacity and support effect ofthe anchor rod are improved, and potential safety hazard is eliminated.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

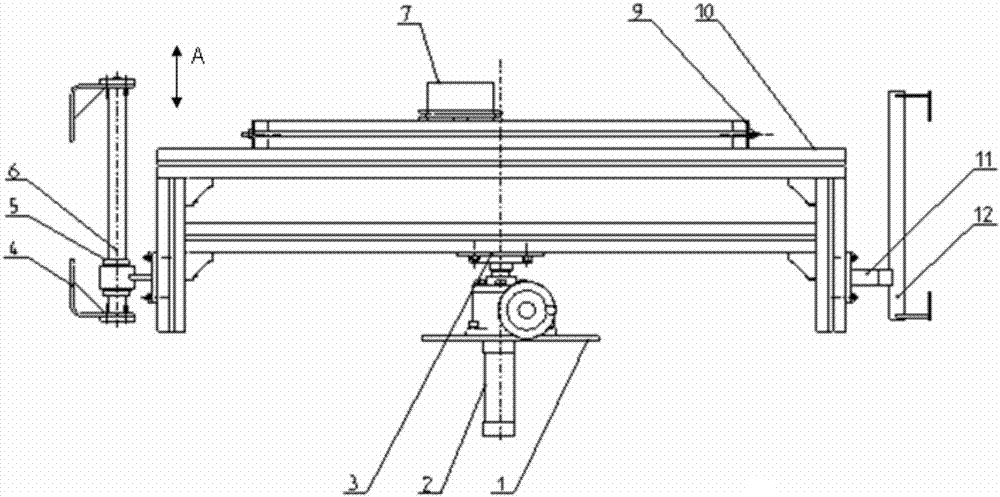

Novel three-dimensional degree-of-freedom burner support device

ActiveCN106855253ASafe and reliable supportMeet heating needsContinuous combustion chamberCombustorThermal fatigue

The invention provides a novel three-dimensional degree-of-freedom burner support device. The novel three-dimensional degree-of-freedom burner support device comprises a lift base plate, a lift, a supporting plate, a first guide mechanism, a second guide mechanism, a burner lifting frame, a burner bracket and a burner. The supporting plate is fixedly connected with an output shaft of the lift; the burner lifting frame is fixedly connected with the supporting plate and fixedly provided with a pair of slide rails which are mutually parallel in the horizontal direction; the first guide mechanism and the second guide mechanism are fixed to the two opposite ends of the burner lifting frame respectively; the burner bracket is fixed on the slide rails in a sliding mode and fixedly provided with a pair of moving guide rails which are perpendicular to the slide rails in the horizontal direction; the burner is installed on the moving guide rails in a sliding mode. According to the novel three-dimensional degree-of-freedom burner support device, stable moving and safe supporting of the burner assembly in three dimensions are achieved, and the heating requirements for internal combustion engine heated part thermal fatigue tests of different cylinder numbers, cylinder diameters and volume power are met.

Owner:CHINA NORTH ENGINE INST TIANJIN

Floating slab ballast bed with weak correlation between frequency and load

PendingCN109056425AReasonable amount of compressionConvenient height adjustment and leveling operationBallastwayCouplingElastic vibration

The invention belongs to the technical field of vibration and noise reduction of rail transit, A floating slab ballast bed for isolating vibrations generated during operation of a rail vehicle is disclosed, comprising a floating plate and an elastic vibration isolation device, the elastic vibration isolation device is placed in an installation reserved space or a coupling sleeve arranged on the floating plate, The elastic vibration isolation device includes an upper housing, a lower housing, and an elastic element disposed between the upper housing and the lower housing, the elastic element including a static support spring and a combined support spring. As that system frequency of the float slab ballast bed with weak correlation between the frequency and the load does not change obviouslywith the change of the load, the correlation between the system frequency and the load is weak, and the float slab ballast bed has the characteristics of simple structure, strong adaptability to dynamic load variation, good vibration isolation performance and the like, and can be widely applied to vibration isolation engineering of various rail transit.

Owner:GUANGZHOU METRO DESIGN & RES INST +1

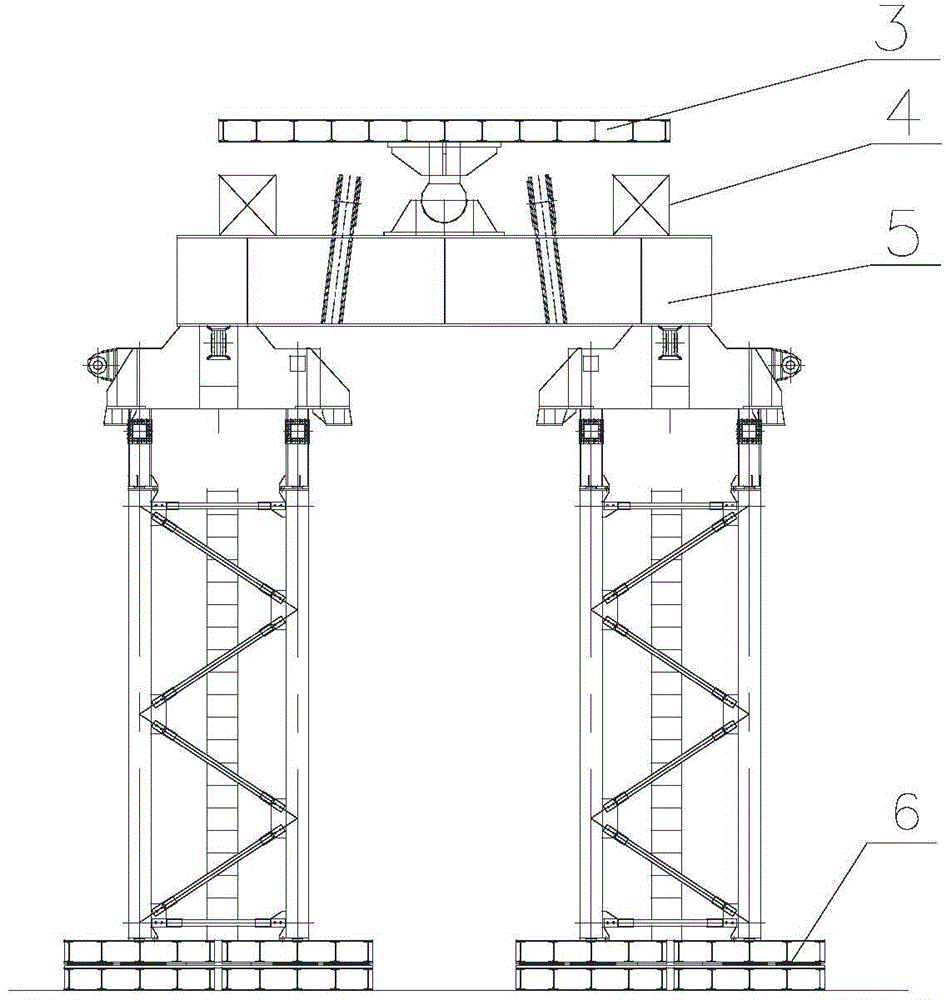

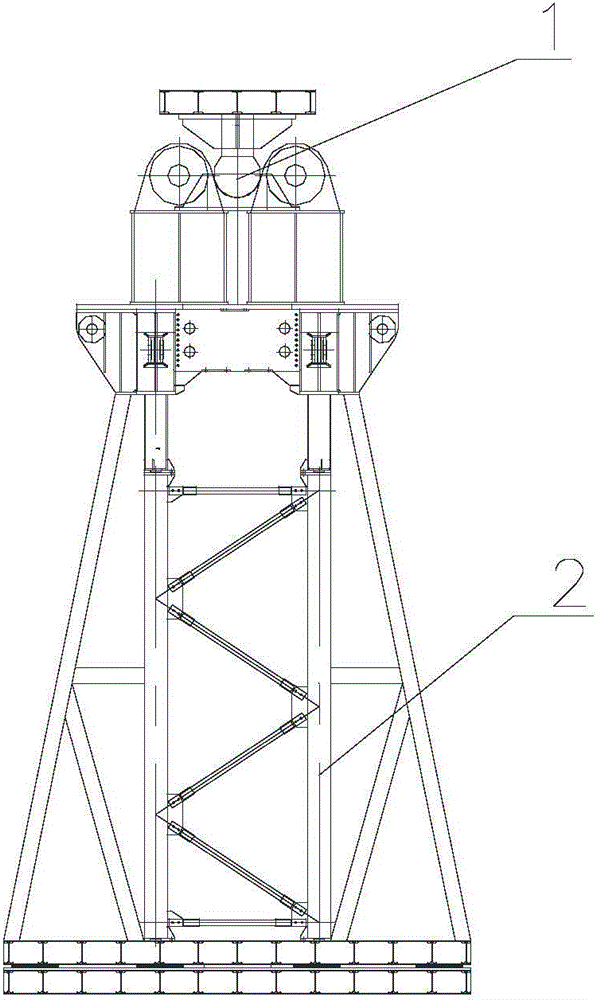

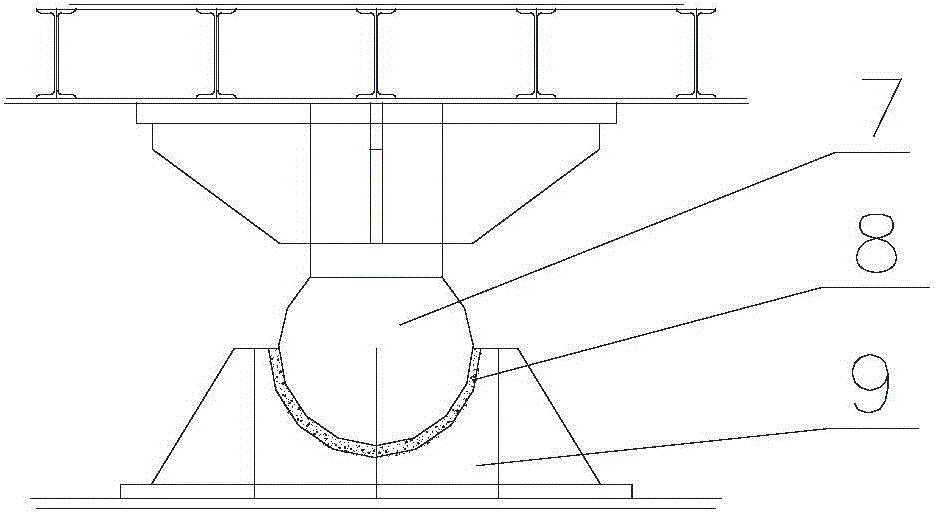

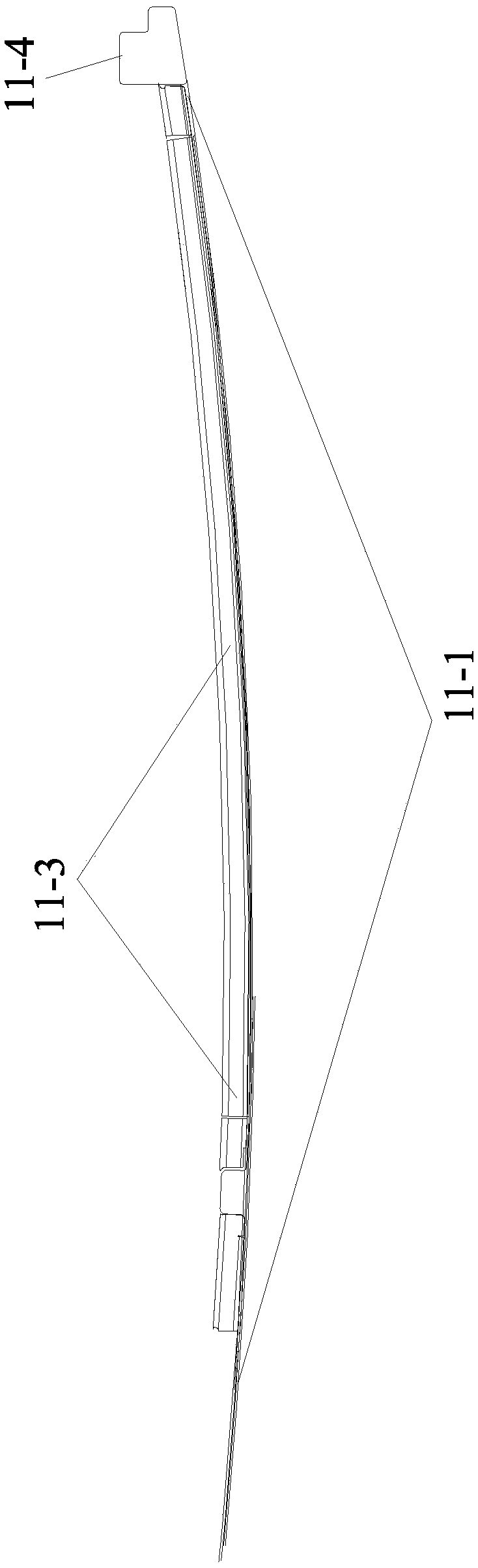

Compliant support frame and installation method of compliant support frame to large floating crane boom

The invention discloses a compliant support frame and an installation method of the compliant support frame to a large floating crane boom. The compliant support frame comprises a joist, a spherical hinge device, a support beam, a support frame body and a base, wherein the top of the support frame body is fixedly connected to a whole through a connection beam; the upper surface of the joist is used for supporting the head of the large floating crane boom, the lower surface of the joist is fixedly connected with the spherical hinge device, and the spherical groove seat of the spherical hinge device is welded on the support beam; the base is in a split structure, and comprises an upper base and a lower base which are placed in a stacking manner, a planar slide layer is further arranged between the upper base and the lower base, and capable of compliantly following the large floating crane boom to slightly rotate in various directions along the horizontal plane under the impacts of seawater tides and ocean currents with a hull, so as to protect the various members of the boom from being damaged by the impacts. According to the installation method disclosed by the invention, main installation project amount is carried out on the land instead of the sea; the compliant support frame is low in installation difficulty, high in efficiency, short in period, low in cost, safe, and suitable for all-weather working.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

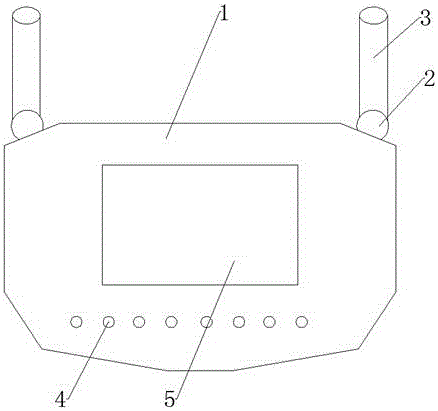

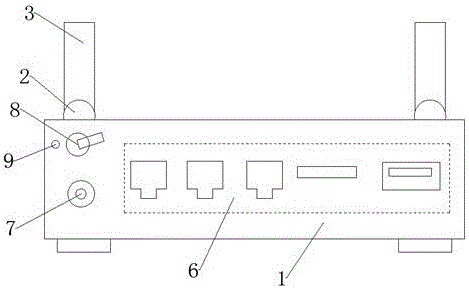

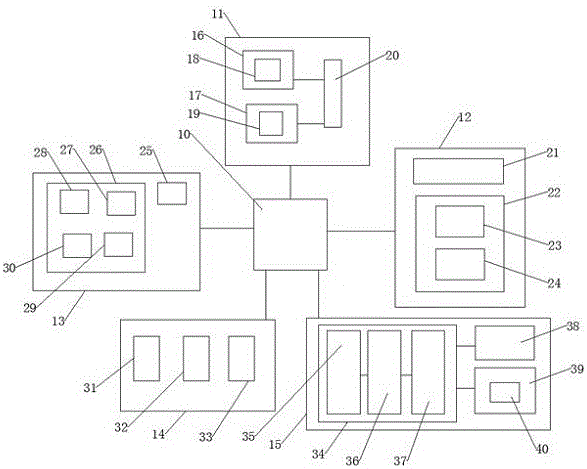

Novel network safety firewall wireless router

InactiveCN106685840ASafe and reliable supportImprove securityData switching networksWireless routerToggle switch

The invention discloses a novel network safety firewall wireless router, and the wireless router comprises a case. The case is provided with a universal shaft, and the universal shaft is connected with a wireless transmitting antenna. The case is also provided with a plurality of LED indicator lights, and the upper ends of the LED indicator lights are provided with a display. The rear surface of the case is provided with an external interface and a power interface. The upper end of the power interface is provided with a toggle switch, and the left end of the toggle switch is provided with a phosphor dot. The interior of the case is provided with a main controller, and the main controller is connected with a firewall module, a data storage module, a network communication module, an interface module and a power module. The main controller is used in the wireless router through combining with the technology of network safety firewall, and enables the wireless router in use to be able to provide safe and reliable network support, thereby greatly improving the safety of the wireless router and guaranteeing the reliability when a user uses a network. Therefore, the wireless router is worthy of being popularized.

Owner:合肥海亚信息科技有限公司

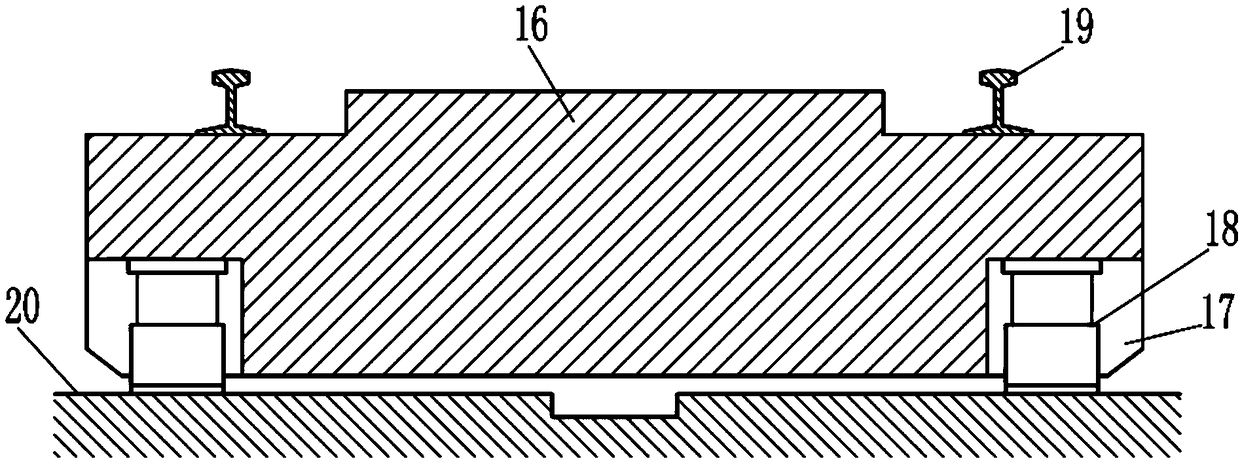

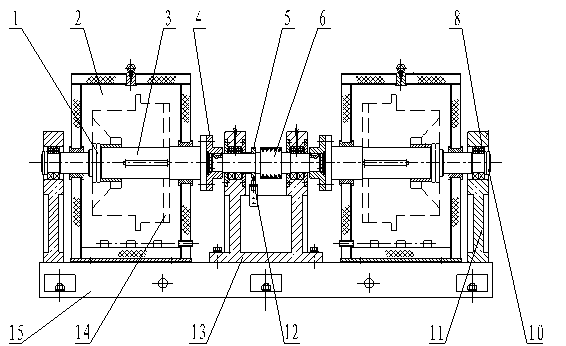

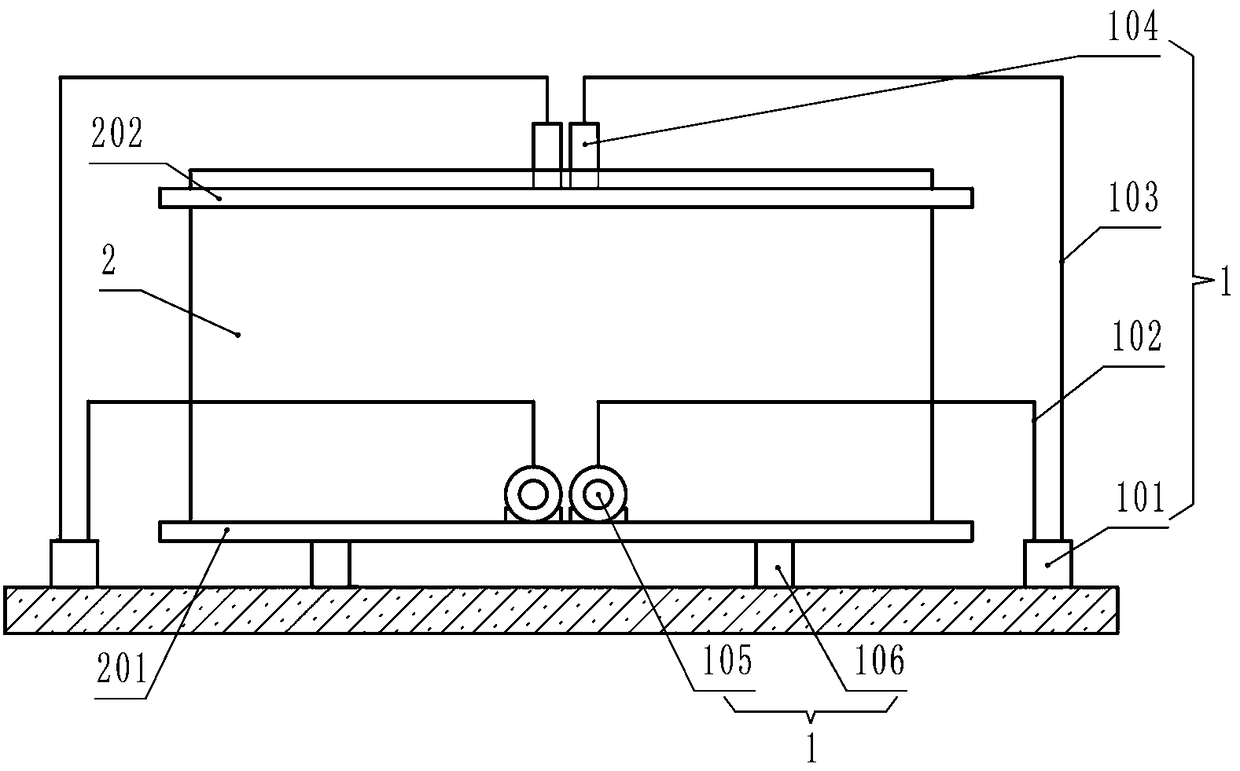

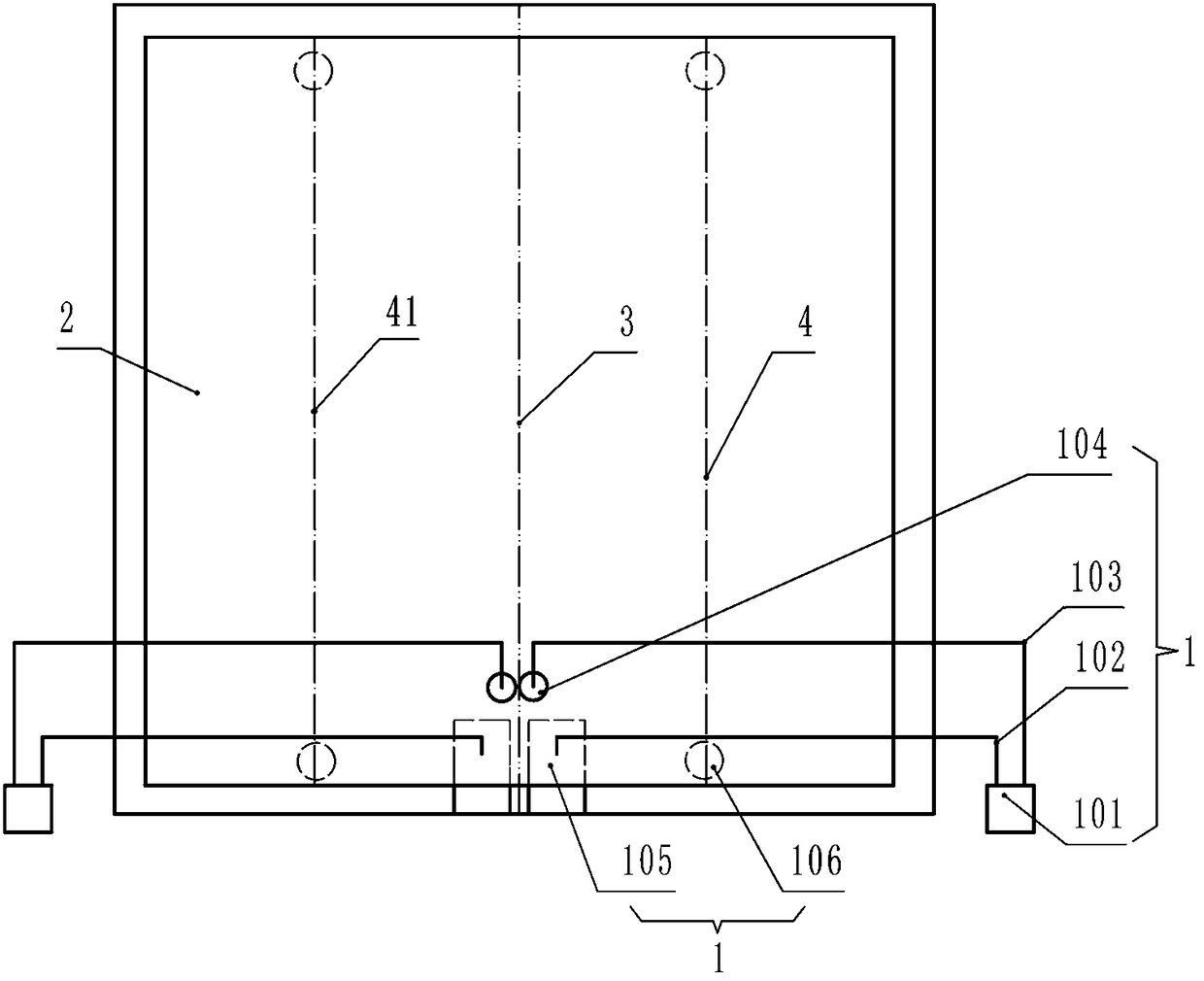

Direct-current motor armature commutator dynamic pressure overspeed testing machine

InactiveCN103376202AReasonable supportStable supportMachine part testingDynamo-electric machine testingSupport pointDevice failure

The invention discloses a direct-current motor armature commutator dynamic pressure overspeed testing machine, and relates to devices for dynamic pressure overspeed tests after armature commutators of various direct-current motors of railway locomotives are assembled. The direct-current motor armature commutator dynamic pressure overspeed testing machine is mainly used for solving the problems that an existing vertical type overspeed machine is unstable in rotation, high in shock, high in equipment failure rate and low in efficiency when commutator high-speed overspeed experiments are carried out. According to the direct-current motor armature commutator dynamic pressure overspeed testing machine, a power output shaft is fixed on a double-support base through a bearing, the two ends of the power output shaft are connected with spigots of dummy shafts through flanges respectively, the other ends of the dummy shafts are fixed on double dummy shaft supporting points through bearings, constant-temperature overspeed boxes are symmetrically arranged on the two sides, in the axial direction, of the power output shaft, and the dummy shafts are arranged in the constant-temperature overspeed boxes respectively. The direct-current motor armature commutator dynamic pressure overspeed testing machine is convenient to operate, stable in shafting supporting and low in equipment failure rate, and can carry out overspeed tests on two commutators at the same time or one commutator.

Owner:襄阳中车电机技术有限公司

Gob-side entry retaining method for pouring spacing concrete walls in tunnel of advanced highwall

InactiveCN102606171AHigh strengthReduce workloadUnderground chambersTunnel liningArchitectural engineeringRock bolt

The invention discloses a gob-side entry retaining method for pouring spacing concrete walls in a tunnel of an advanced highwall. A plurality of flexible formworks which are arranged at intervals are hung in a return air laneway of the advanced highwall by single bodies or anchor rods, concrete is poured into the flexible formworks via a concrete pump, a spacing concrete wall is formed and clings to a roof, then the flexible formworks are hung in space intervals of the spacing concrete wall by a lagging work surface, the concrete is pumped into the flexible formworks, so that a closed concrete continuous wall is formed, and finally a gob-side entry is formed. The spacing concrete wall is poured in the advanced highwall to realize gob-side entry retaining, requirements of ventilation, recovery and construction are met, supporting is safe and reliable, and recovery is not affected. The method is suitable for crushing the roof to realize gob-side entry retaining during recovery, and is widely used for industries of coal mines, metallurgical mines and the like.

Owner:王晓利

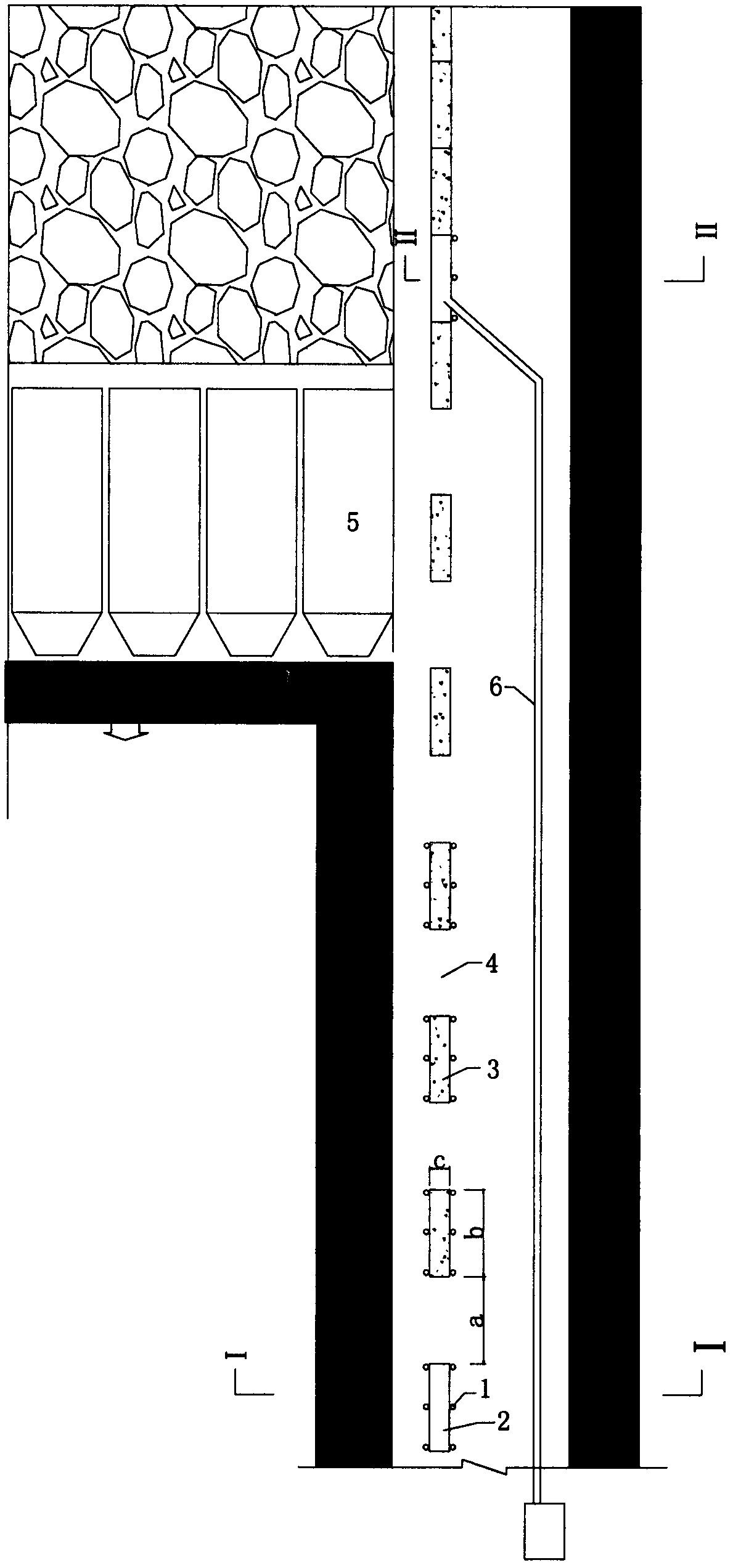

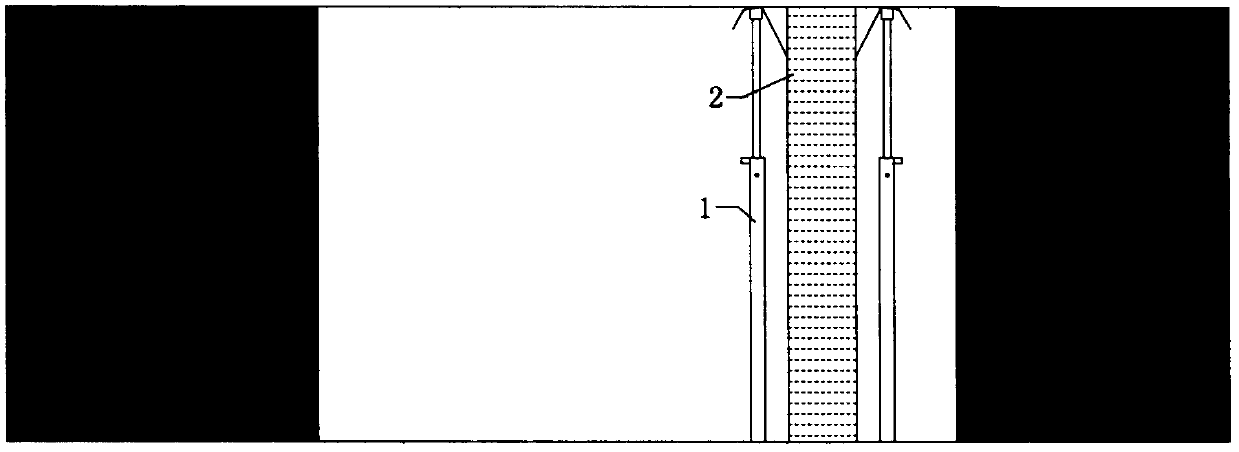

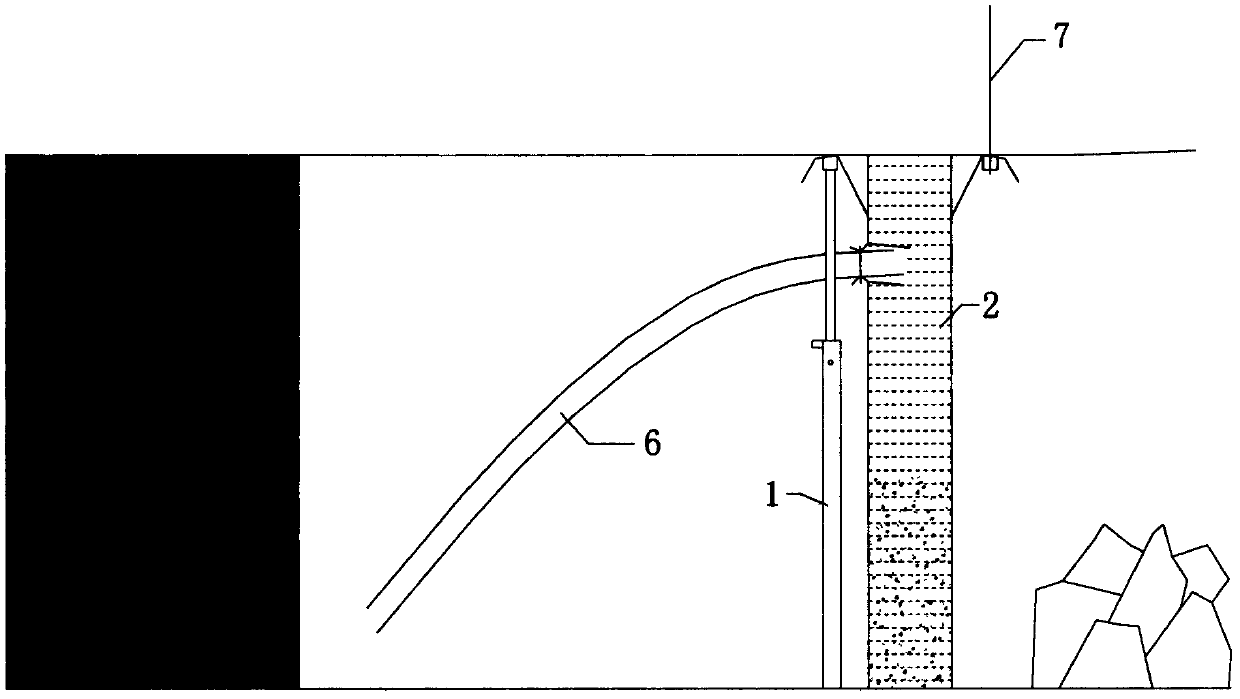

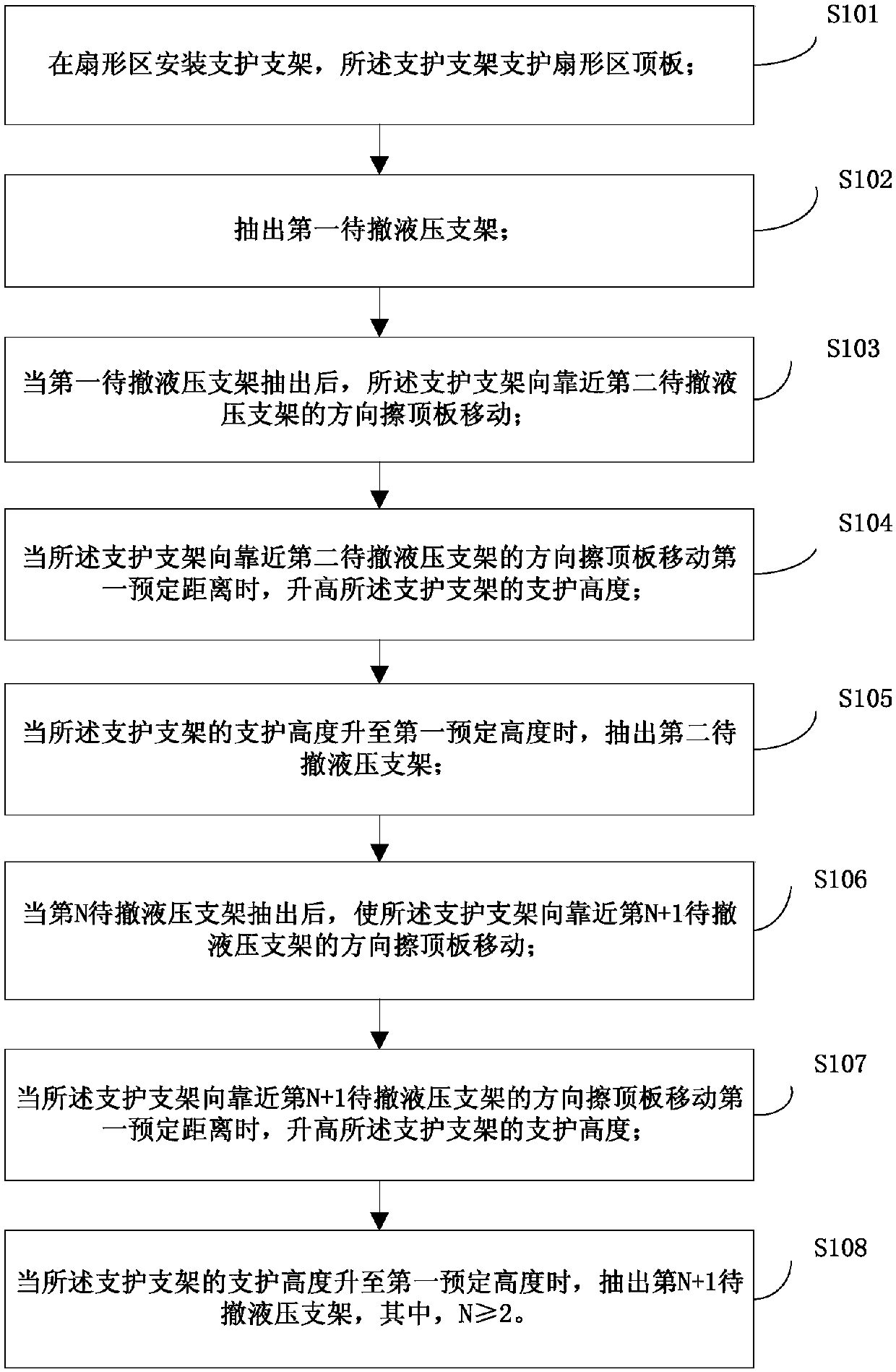

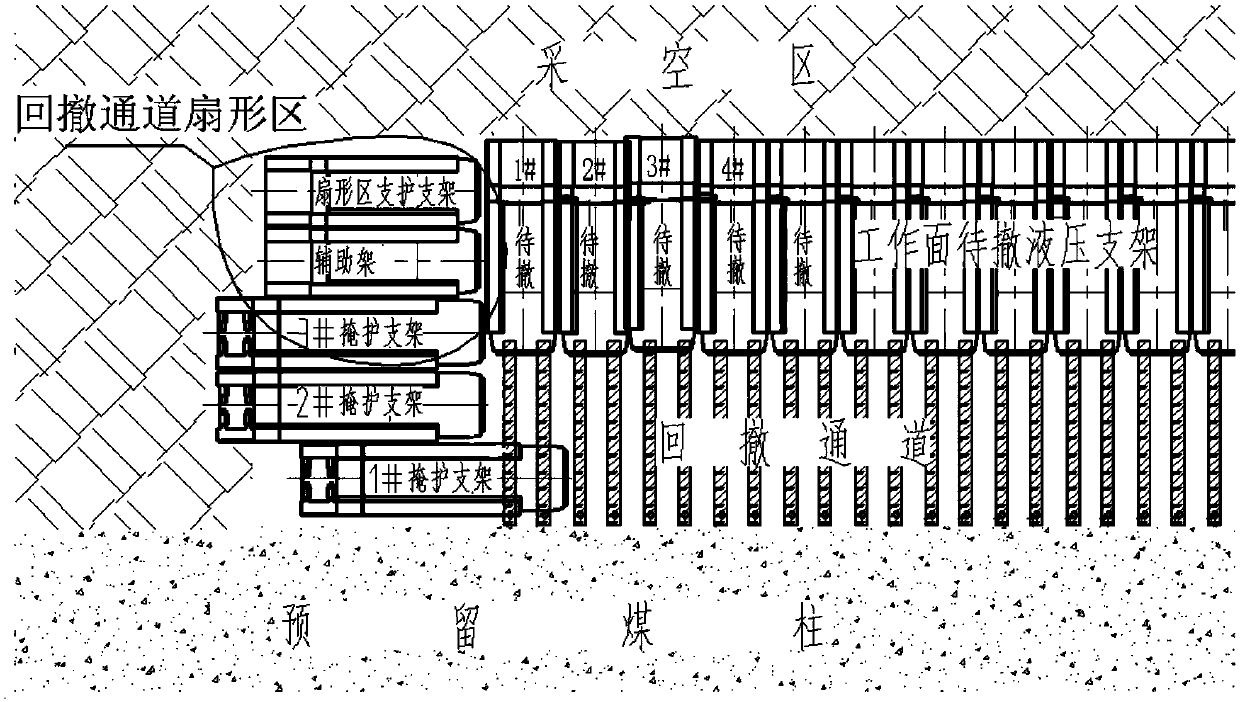

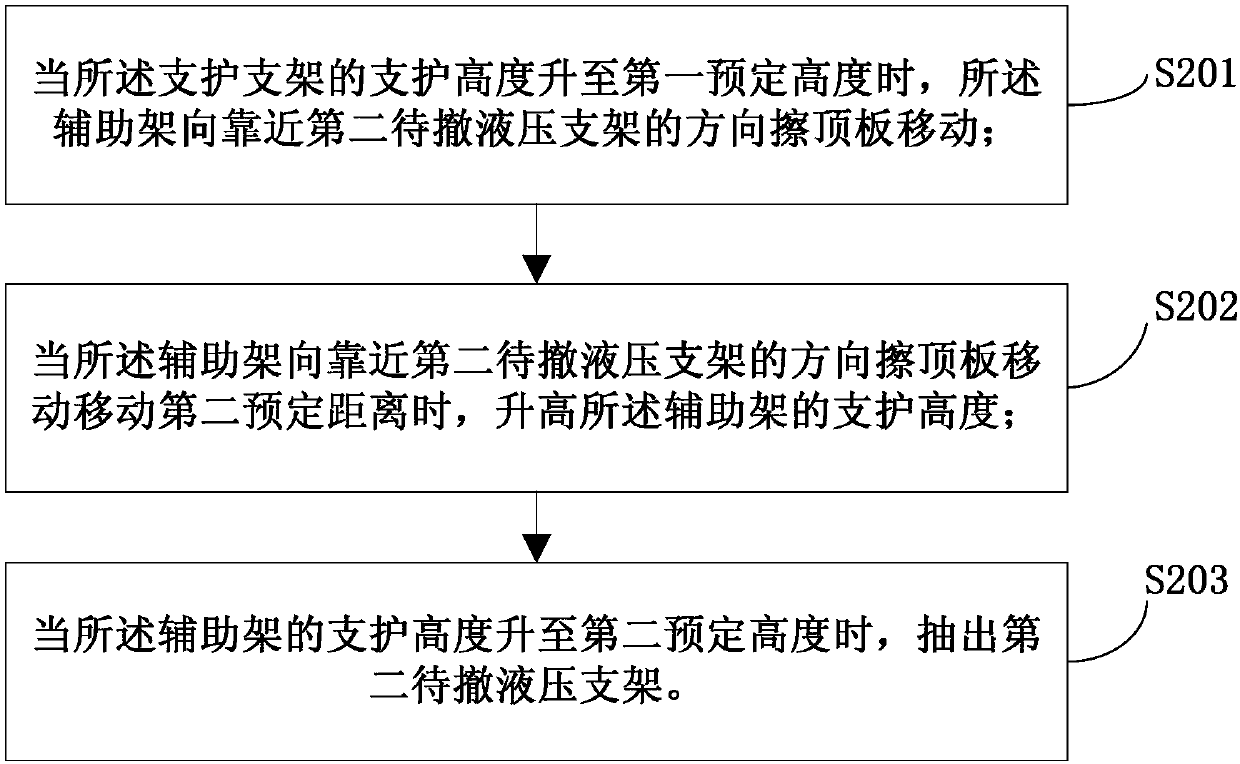

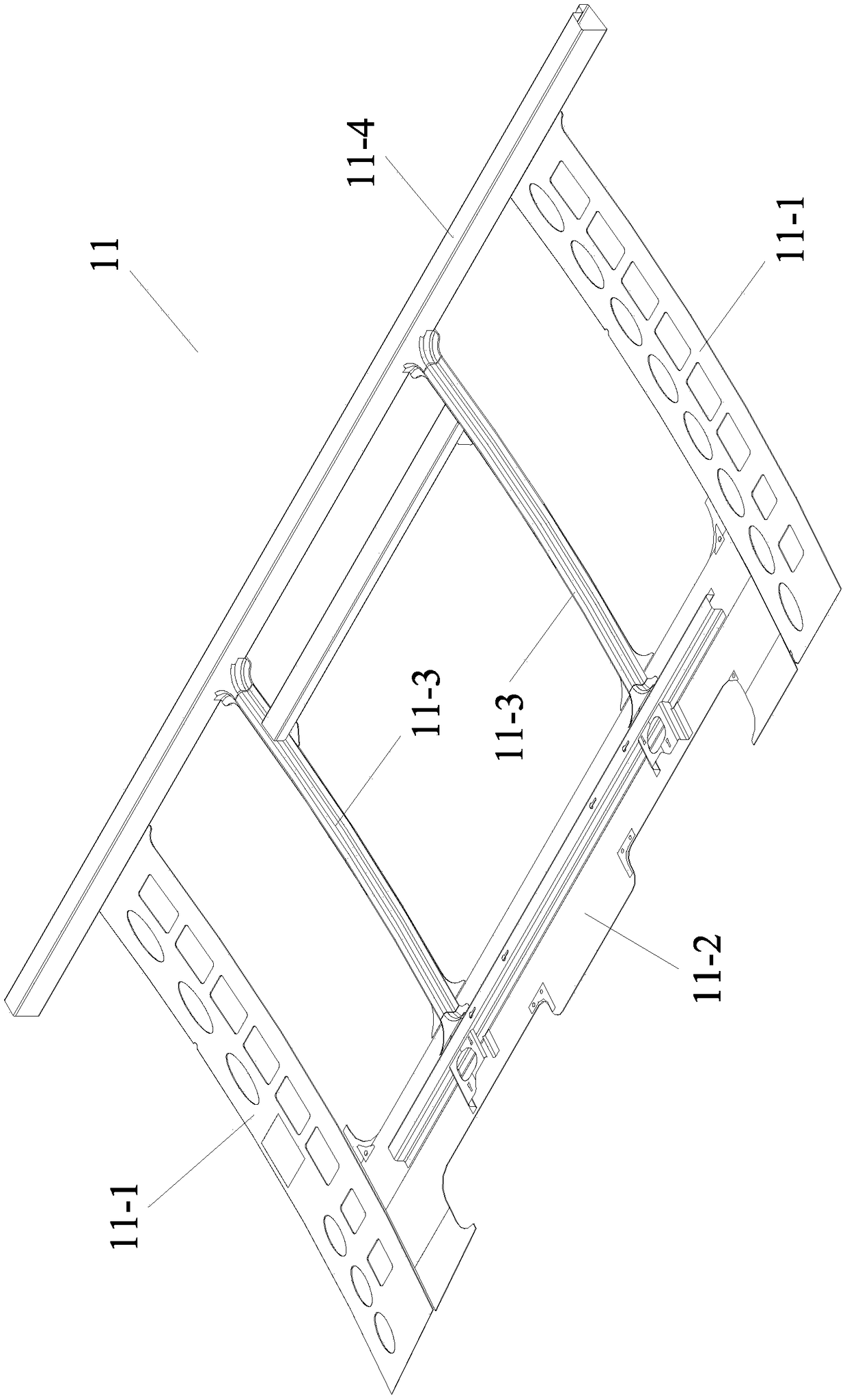

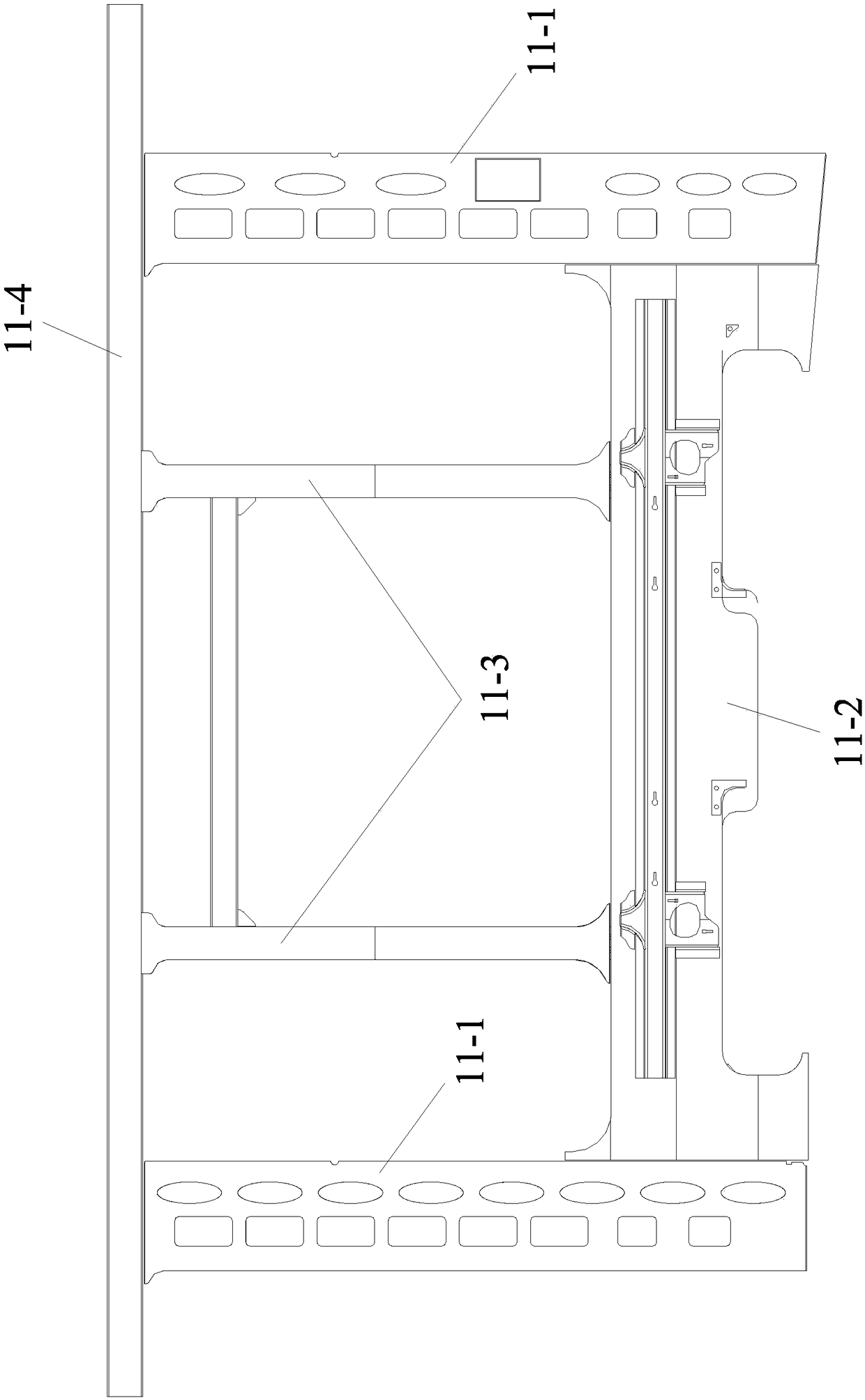

Retracement method for fan section of fully-mechanized coal mining retracement working face

The embodiment of the invention discloses a retracement method for a fan section of a fully-mechanized coal mining retracement working face. The retracement method comprises the steps that a supporting support is mounted in the fan section, wherein the supporting support supports a fan section top plate; a first hydraulic support to be retraced is drawn out; after the first hydraulic support to beretracted is drawn out, the supporting support moves in the direction close to a second hydraulic support to be retraced by rubbing the top plate; when the supporting support moves in the direction close to the second hydraulic support to be retraced by rubbing the top plate for a first preset distance, the supporting height of the supporting support is increased; when the supporting height of the supporting support is increased to first preset height, the second hydraulic support to be retraced is drawn out. According to the retracement method, the retracement efficiency can be improved, andthe retracement cost can be reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

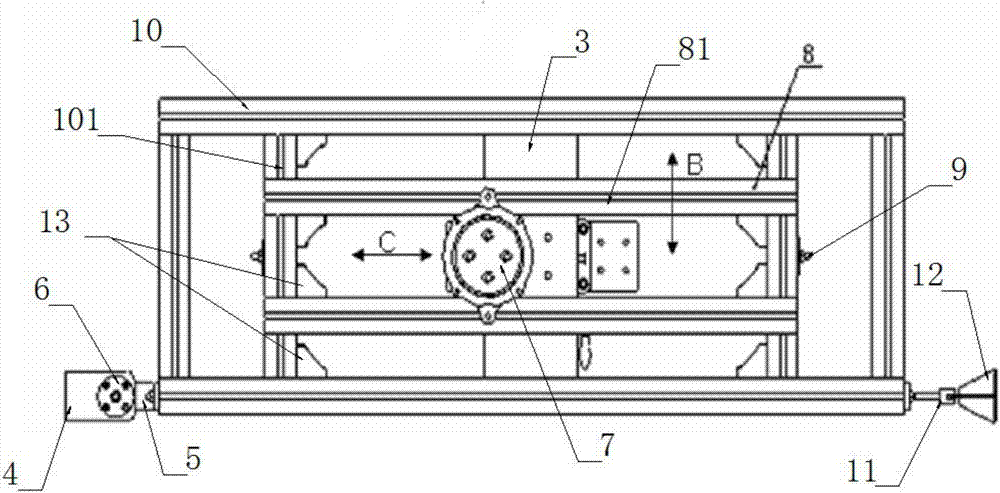

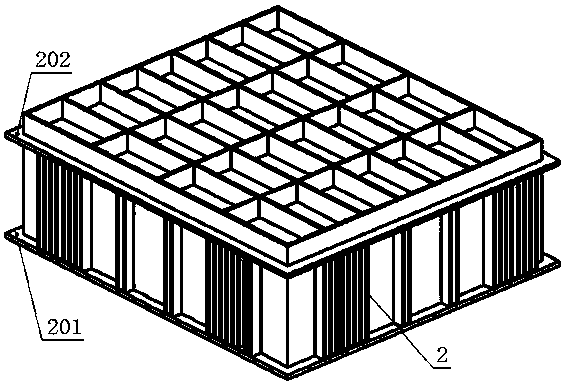

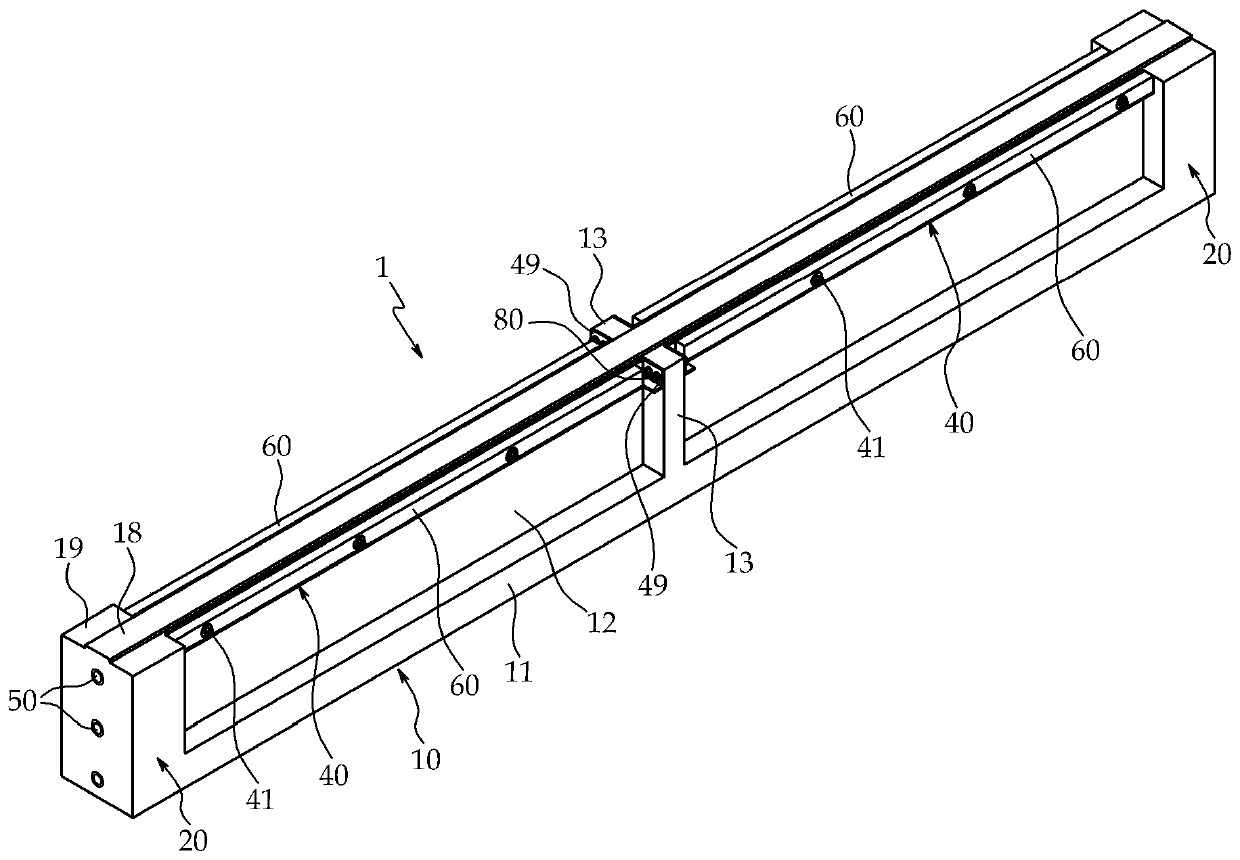

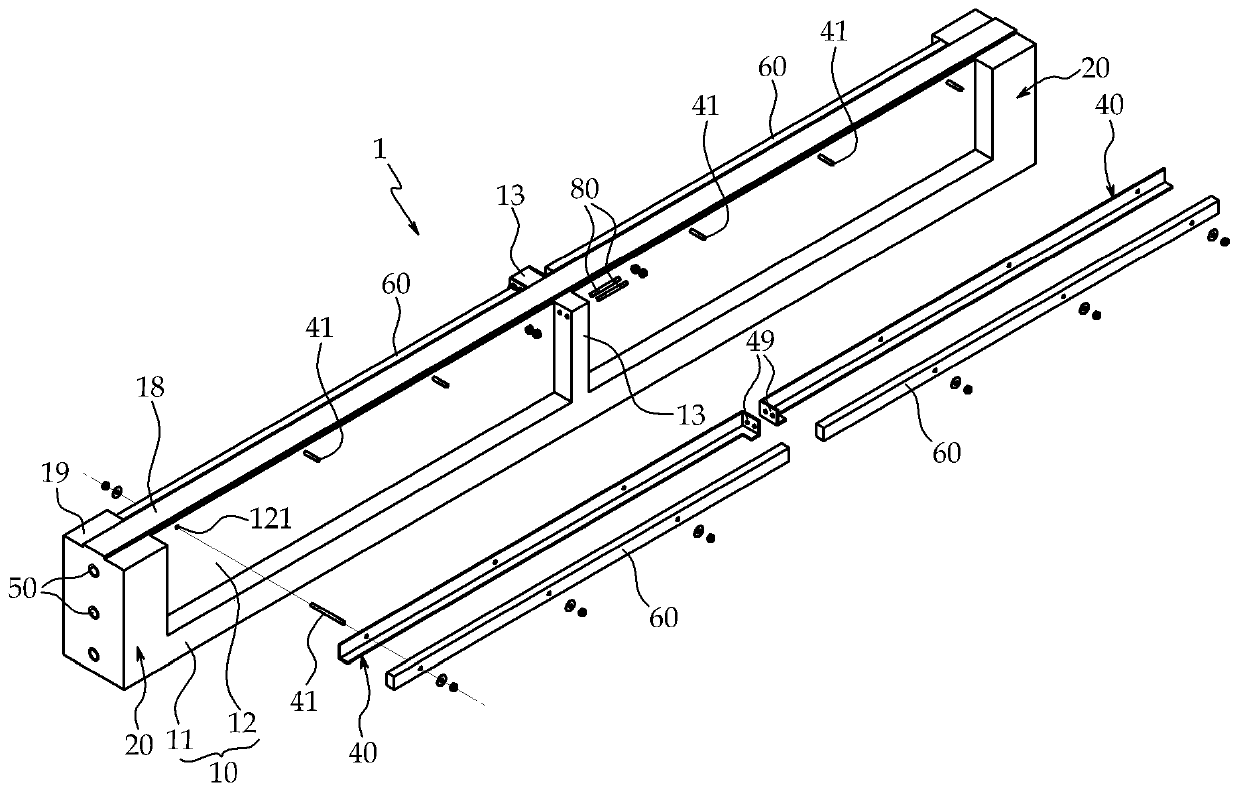

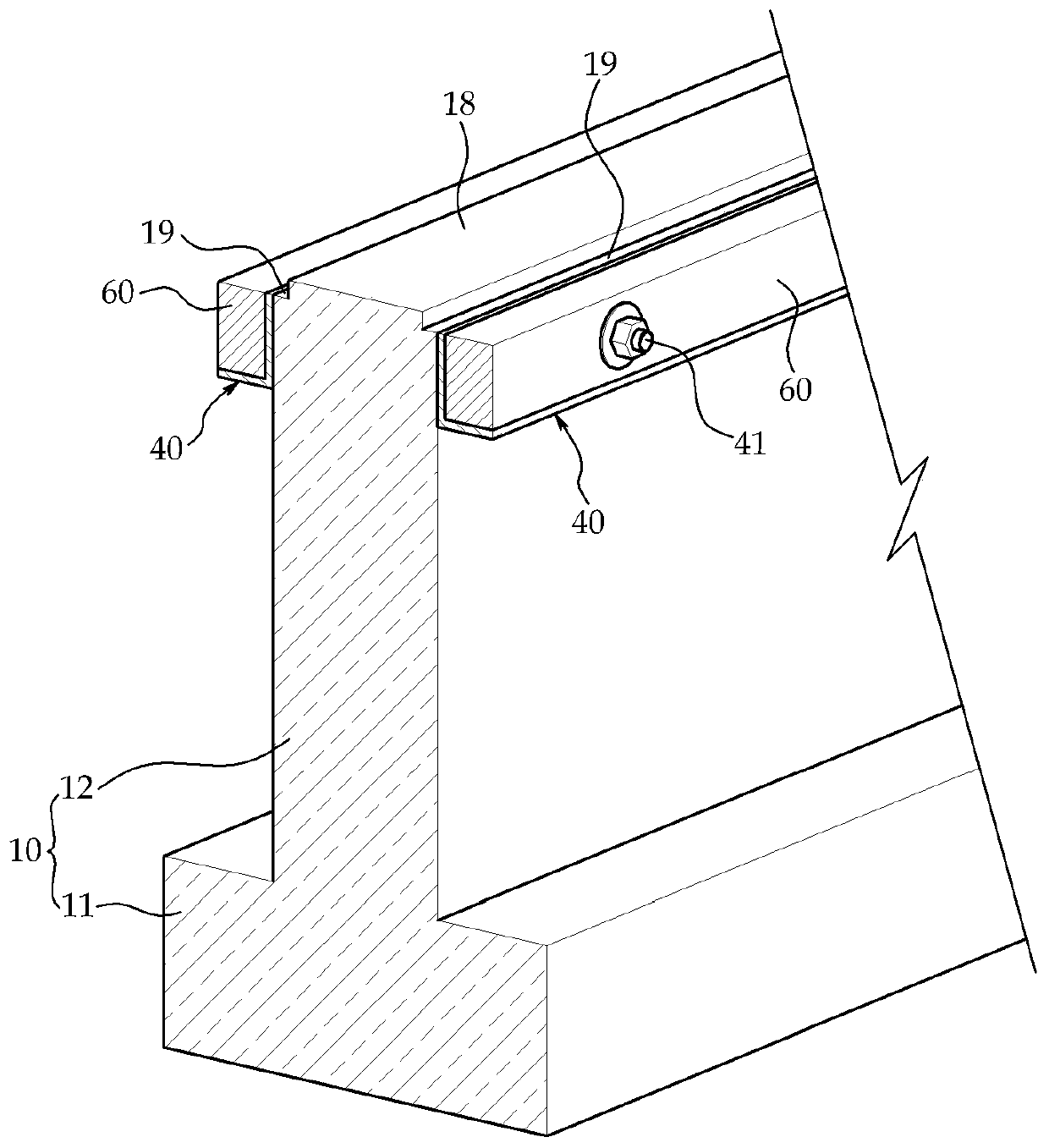

General type assembly welding and positioning device used for various side wall frameworks

ActiveCN109454382ASafe and reliable supportQuickly Locate PairsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCushion

The invention discloses a general type assembly welding and positioning device used for various side wall frameworks, and relates to the technical field of railway vehicle side wall framework welding.The general type assembly welding and positioning device comprises a plurality of foundation T-shaped slot guide rails, a plurality of height adjustable foundation beds, a table board, four pressingmechanisms, a plurality of ball head mechanisms, a plurality of pivotal shafts, a plurality of upper positioning blocks, a plurality of lower positioning blocks, a plurality of cushion blocks and twothree-sided right-angled positioning blocks. The height adjustable foundation beds, the ball head mechanisms and the pivotal shafts are matched, so that the supporting end surface of the table board has different angles, and therefore, side wall frameworks of different structures can be supported; the height adjustable foundation beds are matched with the foundation T-shaped slot guide rails, so that production cost is reduced, and support for side wall frameworks of various structures can be safely and reliably realized; and the upper and lower positioning blocks are matched, so that quick positioning and assembly for the side wall frameworks of various structures is realized. The device is convenient in dismounting, is simple in operation, is strong in generality, reduces workload of anoperator, reduces the production cost, and improves production efficiency.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Bridge pier VSR (vibration stress relief) method for steel structural bridge

ActiveCN108130414AVibration aging treatment time is smallNo damage to surface qualityStress reliefMultiple resonance

The invention discloses a bridge pier VSR (vibration stress relief) method for a steel structural bridge and relates to the technical field of stress relief treatment of steel structure parts. A bridge pier of the steel structural bridge is a high-rigidity and heavy large structural part, and stress relief treatment is difficult to perform with existing thermal stress relief, natural stress relief, ultrasonic impact stress relief and VSR methods. According to the method, the bridge pier is supported by a support pad, multiple sets of VSR equipment are used, multiple vibration exciters are adjacently fixed on a lower frame beam of the bridge pier, multiple vibration testers are adjacently fixed on an upper frame beam of the bridge pier, then, multiple vibration exciters are controlled by use of multiple controllers, co-frequency sub-resonance vibration is performed on multiple resonance peaks of the bridge pier for several hours, the purpose of effectively relieving the residual stressis achieved, the average relief rate of the residual stress reaches 43%, the problem of difficulty in relieving the residual stress of the bridge pier is solved, and the method can be applied to steelstructural bridges.

Owner:NANNING SHENHUA VSR TECH RES INST +1

Intrinsic safety type driving and anchoring integrated machine for underground coal mine anaerobic tunneling face

InactiveCN106545339ATransportation safetySafe and reliable supportSlitting machinesCutting machinesTime conditionIntrinsic safety

The invention provides an intrinsic safety type driving and anchoring integrated machine for an underground coal mine anaerobic tunneling face, and belongs to the technical field of coal mining equipment. The integrated machine comprises a cutting mechanism, a caterpillar band walking mechanism, support equipment, a safety protection monitoring device, a safety working bin and a safety escaping device; and the cutting mechanism is arranged at the most front end of the integrated machine, a jumbolter is arranged subsequently to serve as the support equipment, the caterpillar band walking mechanism drives the integrated machine to move ahead, and a worker can visually watch the position and the working condition of the integrated machine and observe the real-time condition outside the bin through an operation platform in the safety working bin. Meanwhile, in order to handle emergency events, the worker can be rapidly evacuated to the safety zone through the safety escaping device. When the integrated machine is used, the underground worker can safely do a series of tunneling work such as transportation and support under the anaerobic working condition.

Owner:UNIV OF SCI & TECH BEIJING

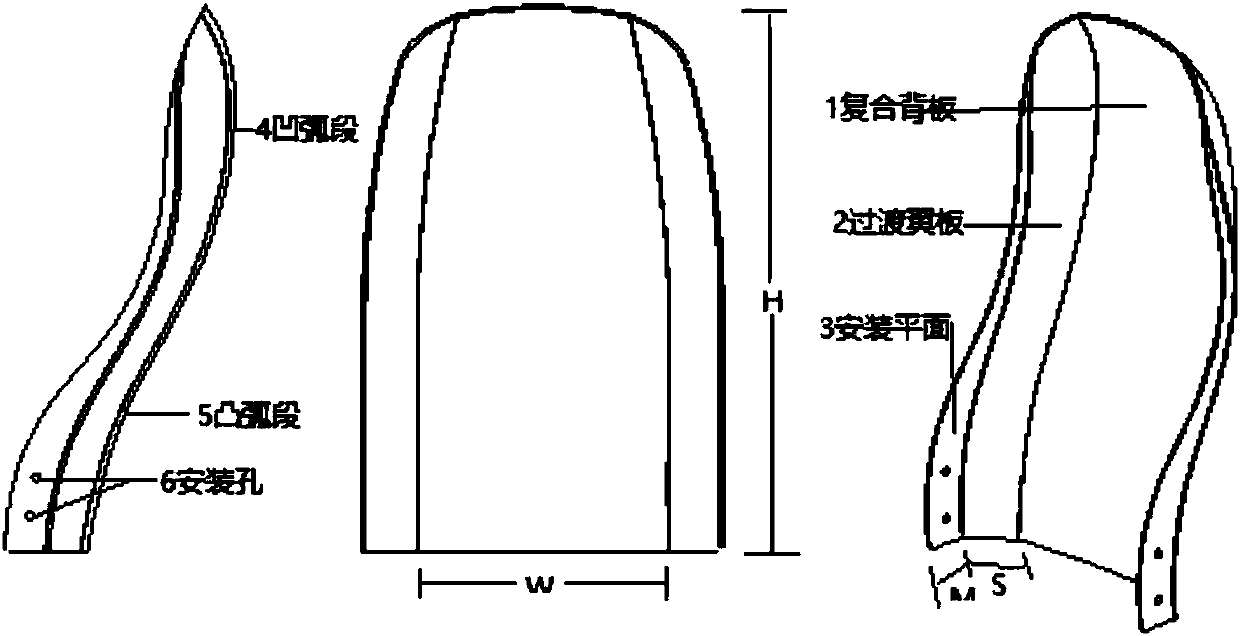

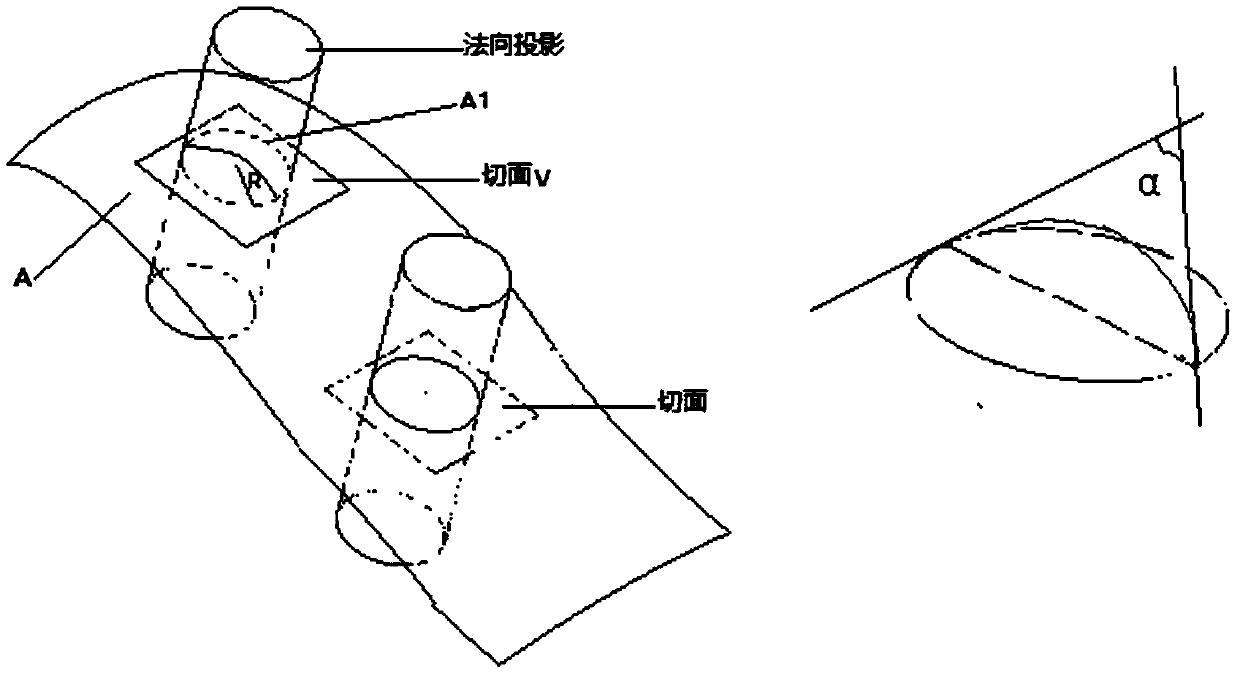

Seat backrest framework made of composite material

The invention discloses a modeling structure of a seat backrest framework adopting continuous glass fiber reinforced composite material plates. The modeling structure defines a composite back plate ofwhich the seat composite material backrest framework should be divided into a passenger supporting area, a transition wing plate of a transition connecting area and a mounting plane. The mounting hole parameters of a mounting plane are provided. The trepanning process parameters of the seat backrest framework of the continuous glass fiber reinforced composite material plates are adopted. According to the perforating process, the perforating diameter range, the range of the distances between holes, the range of the distances between the holes and the edge of the framework and the selection range of the thickness of the framework and the thickness of a plate are specified, so that the composite framework adopting the perforating process can be in conventional bolt connection with a metal piece. The better connection strength can be achieved.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

Hybrid psc girder having reverse t-shaped cross section and method for constructing slab using same

ActiveCN110392758AReduce the amount of materialImprove stabilityFloorsBridge erection/assemblyEngineeringOut of plane

One aspect of the present invention presents a hybrid PSC girder having a reverse T-shaped cross section, the girder comprising: a lower flange; a web which is vertically formed upward from the widthwise central part of the lower flange and includes, at an upper part, a plurality of coupling holes formed therethrough or formed in a predetermined depth at an uniform interval in the longitudinal direction; a central body part having a reverse T-shaped cross section, which comprises reinforcing partition walls protruding from both sides of the web in a predetermined thickness to resist out-of-plane deformation; end partition walls formed at both lengthwise ends of the central body part in a predetermined length and having a box-type cross section; and reinforcing beams made of steel, having apredetermined length, and coupled in the lengthwise direction to opposite side surfaces of the upper part of the web between the reinforcing partition walls and the end partition walls by using coupling fasteners inserted into the coupling holes.

Owner:(株)知胜建设咨询公司 +1

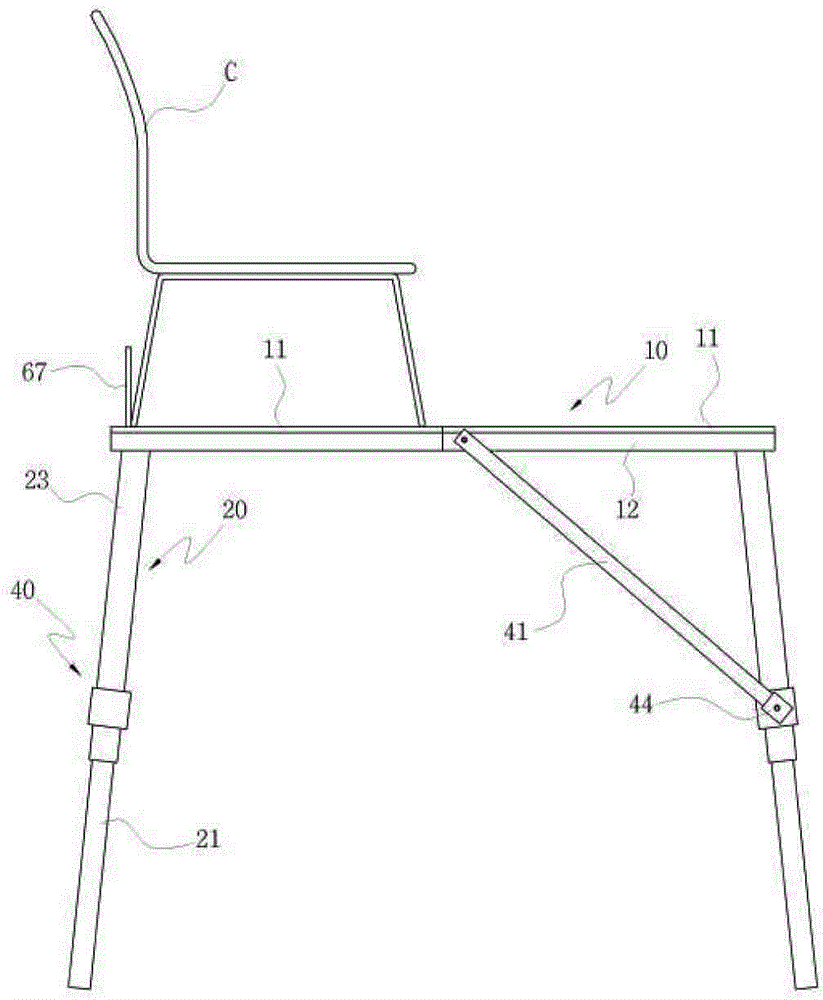

Sitting stage for fishing

The invention provides a seating stage for fishing, comprising an upper plate, and a plurality of support columns. The upper plate provides a space for the user to sit and for placing a space for containing a chair for the user to sit and also provides a space for placing a plurality of fishing rods; besides, the part of the upper plate can be folded and expanded according to the need; the integral appearance is made of the carbon fiber comprising a first carbon fiber layer, a polyurethane foam layer and a second carbon fiber layer; the plurality of support columns constitute a double-tube type, wherein a plurality of length regulation holes horizontally go through the inner tube; and the fixing holes horizontally go through the outer tube so as to communicate with the length regulation holes. Because the sitting stage for fishing is easy to store and solid, when the user sits or stands on the sitting stage, the sitting stage can be fully supported and the manufacture cost is low.

Owner:KANGWON IND

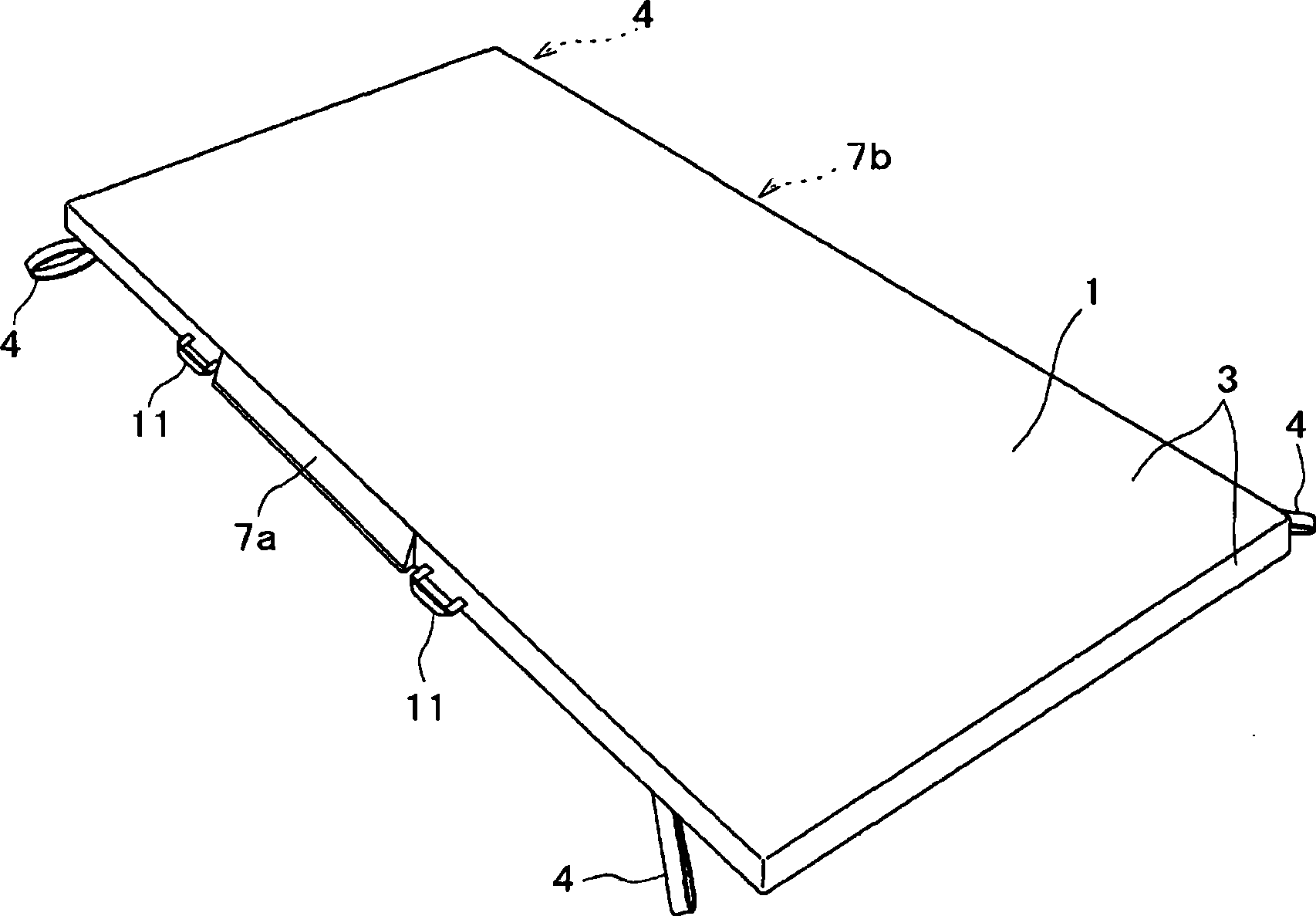

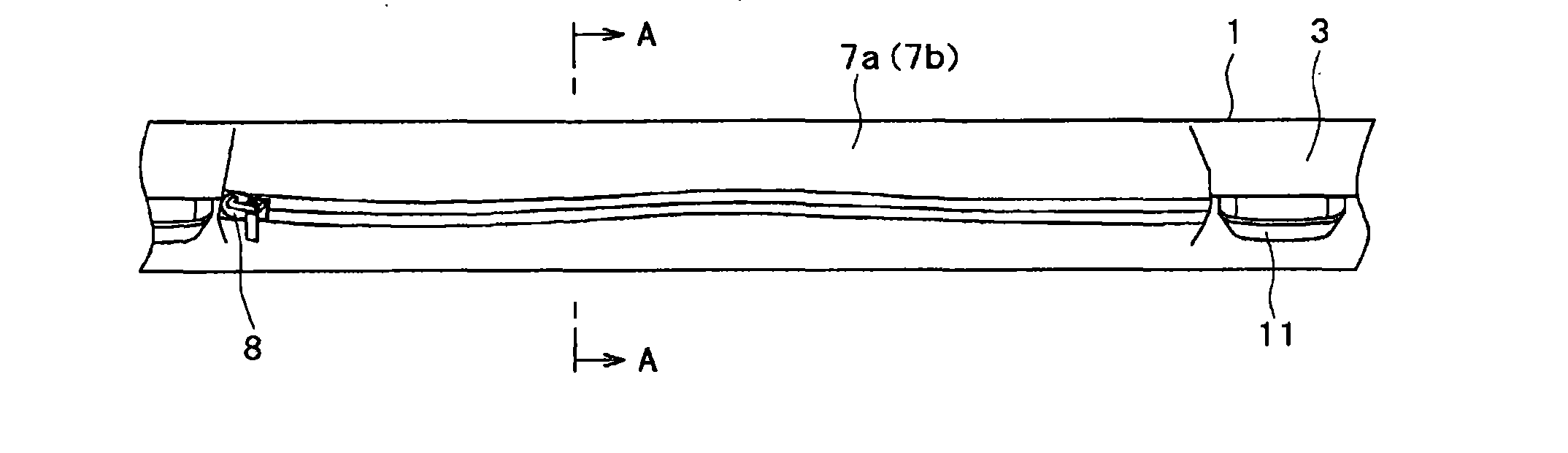

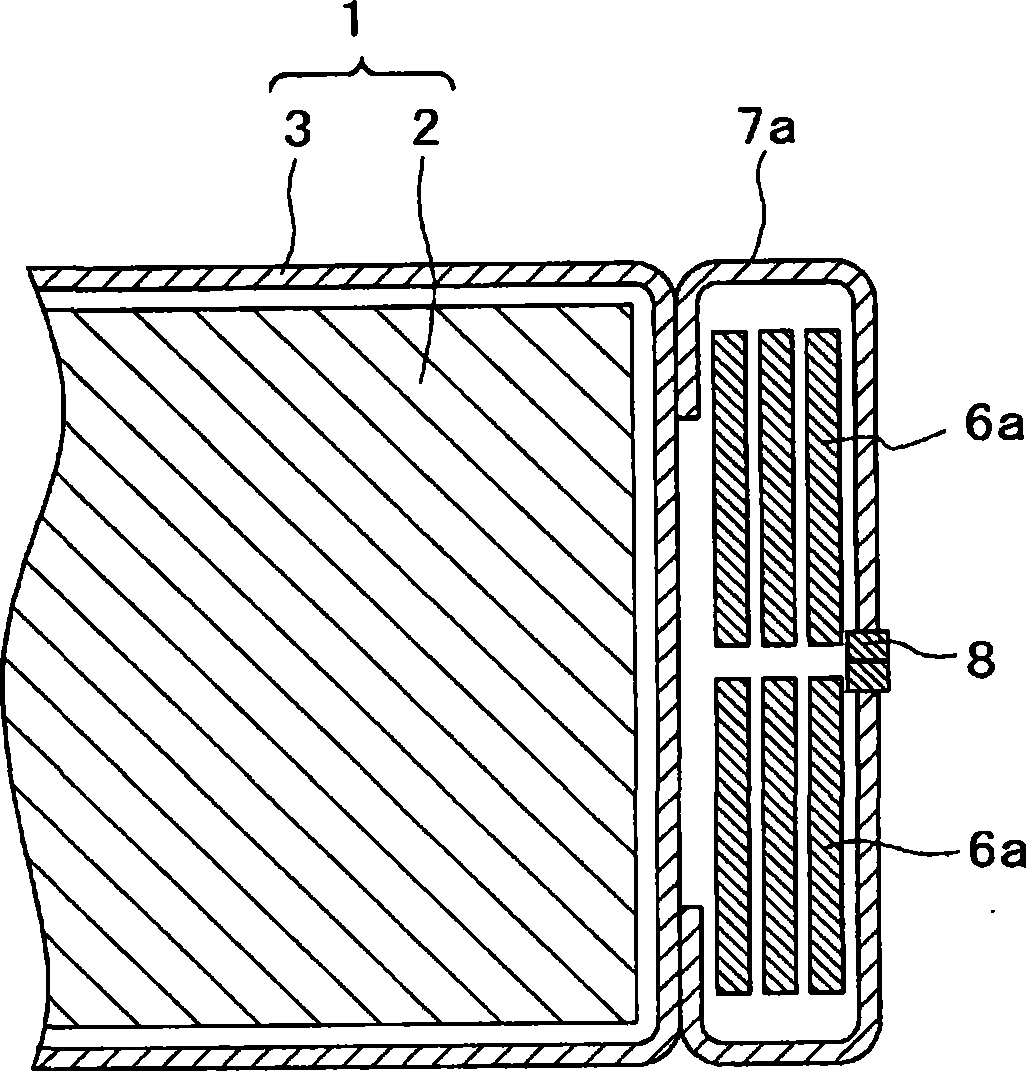

Mattress

InactiveCN101378715ASafe deliverySafe and reliable supportStuffed mattressesStretcherEngineeringGrippers

A mattress that at disaster strike, can be used as a stretcher, and that when not used as a stretcher, can find ordinary mattress uses. There is provided mattress (1) having stuffing covered by a covering material, wherein on covering material (3), not only are grippers (4) fixed at corner side edge portions of the mattress but also one end portion of each of multiple fixing belts is fixed to both longitudinal side edges, and wherein there are disposed storage parts (7a,7b) for storing of the fixing belts, the fixing belts at the other end portions having fastening members fixed thereto.

Owner:PARAMOUNT BED CO LTD

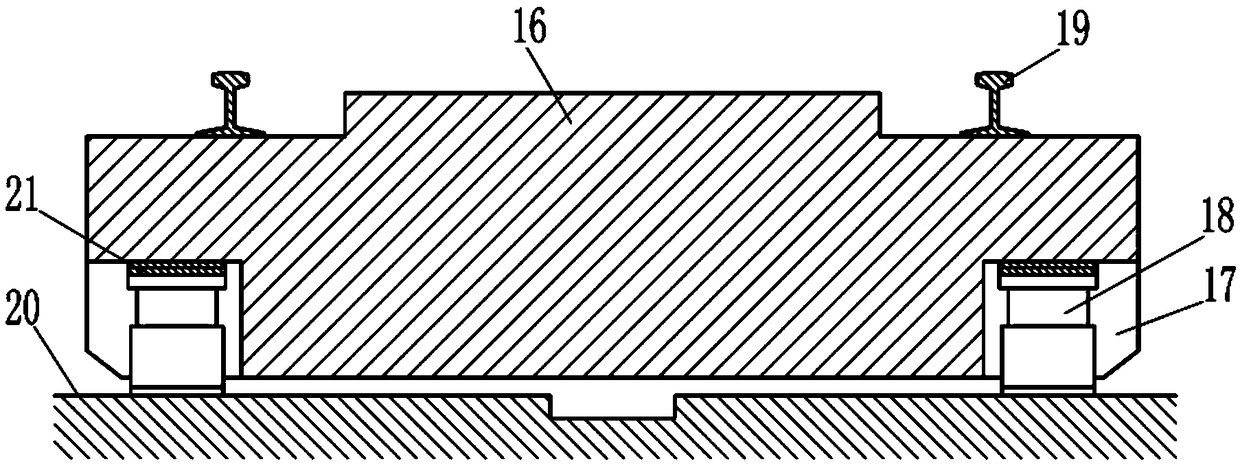

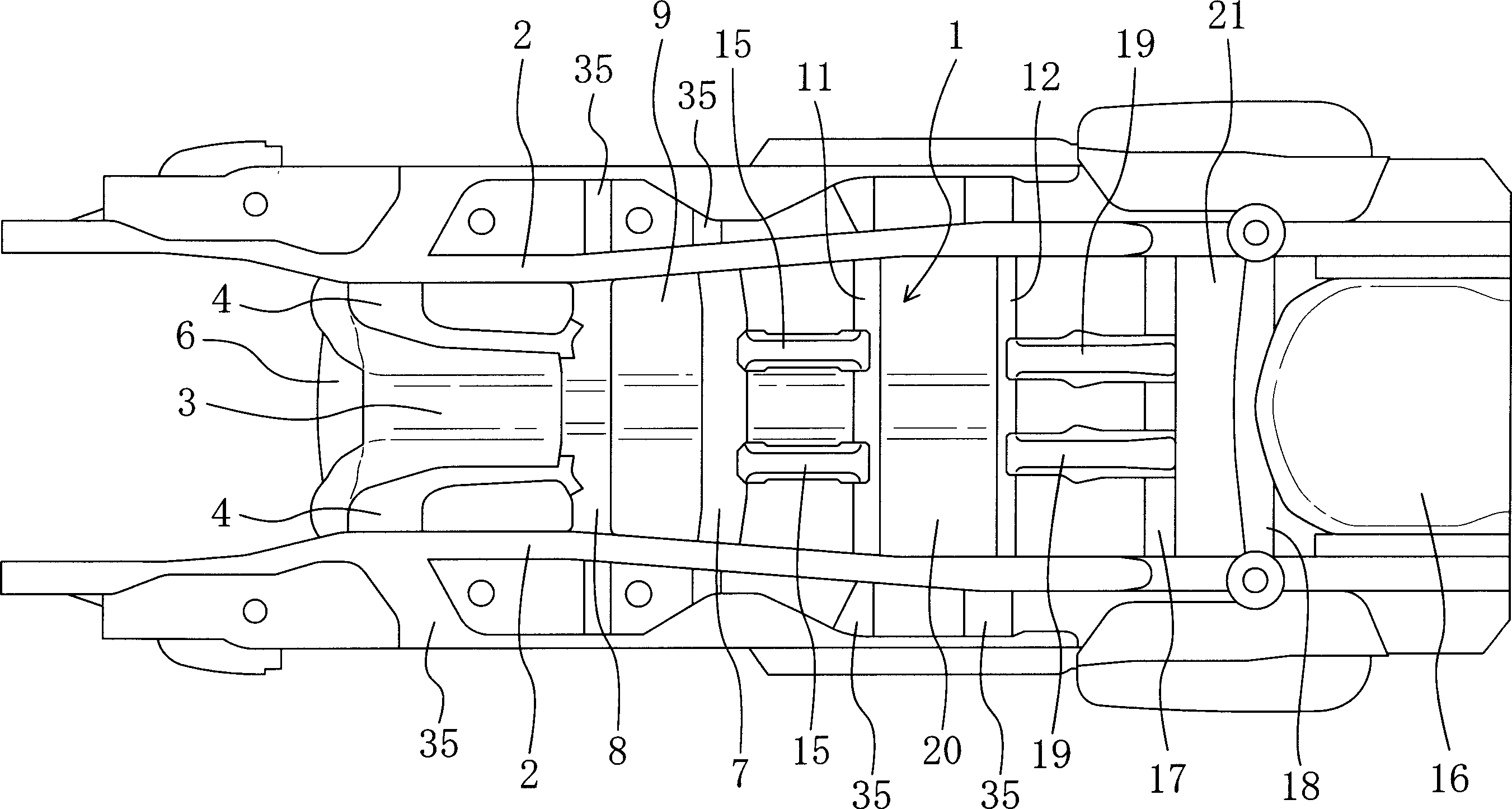

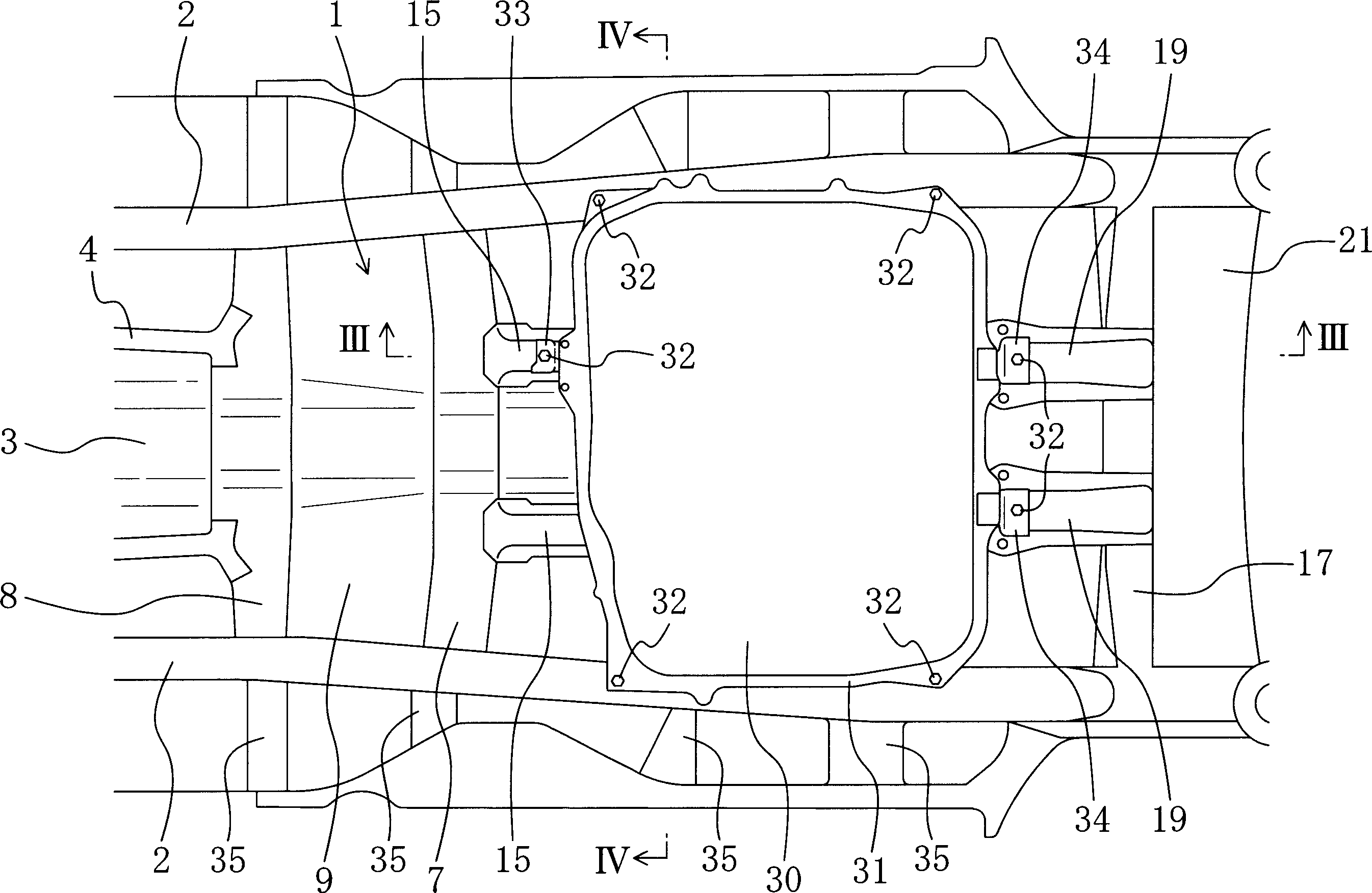

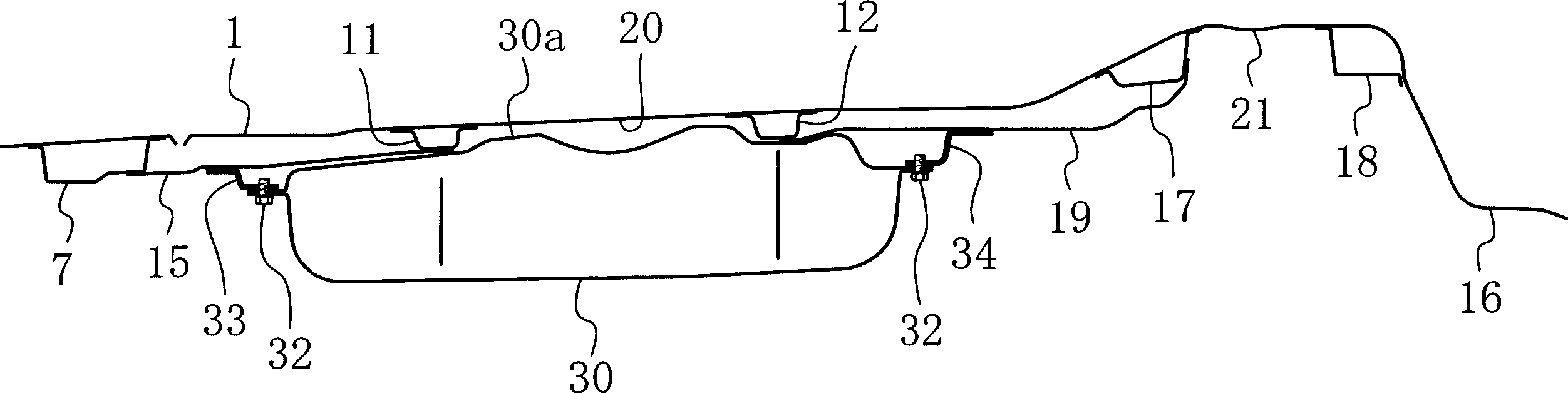

Support structure of vehicle fuel cell

The invention discloses a vehicle fuel tank supporting structure. A pair of longitudinal brackets (15, 19) extending along the front-to-rear direction are arranged on the central channel (3) sandwiching the central part of the vehicle width direction of the base plate (1), so as to connect the joint under the base plate (1) and along the base plate (1) A plurality of horizontal frames (7, 11, 12, 17) provided between the vehicle body underframes (2) extending forward and backward on both sides in the vehicle width direction of ) are connected front and rear. At least one of the pair of longitudinal supports (15, 19) supports the center portion of the fuel tank (30) in the vehicle width direction. Therefore, in the support structure of the fuel tank (30) provided under the floor (1) of the vehicle, the fuel tank (30) can be reliably supported without providing a horizontal frame only for supporting the fuel tank (30).

Owner:MAZDA MOTOR CORP

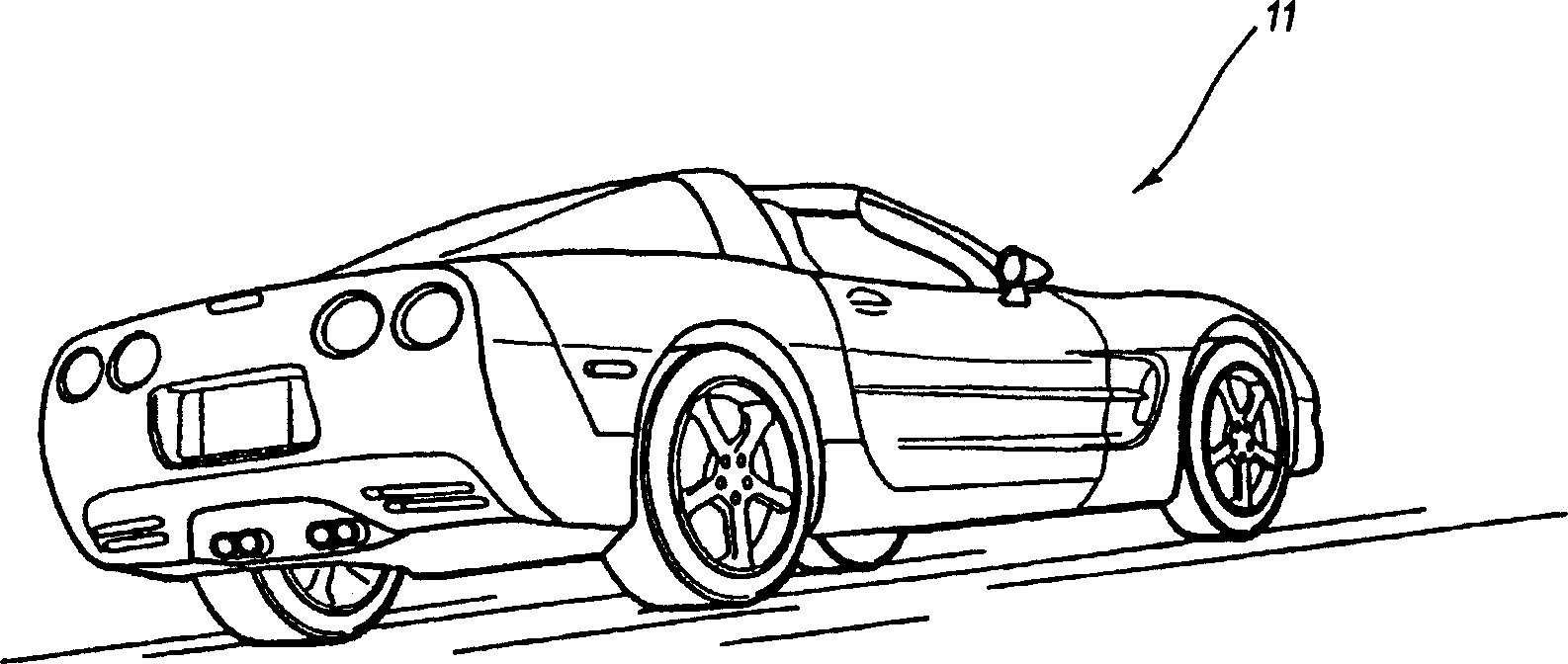

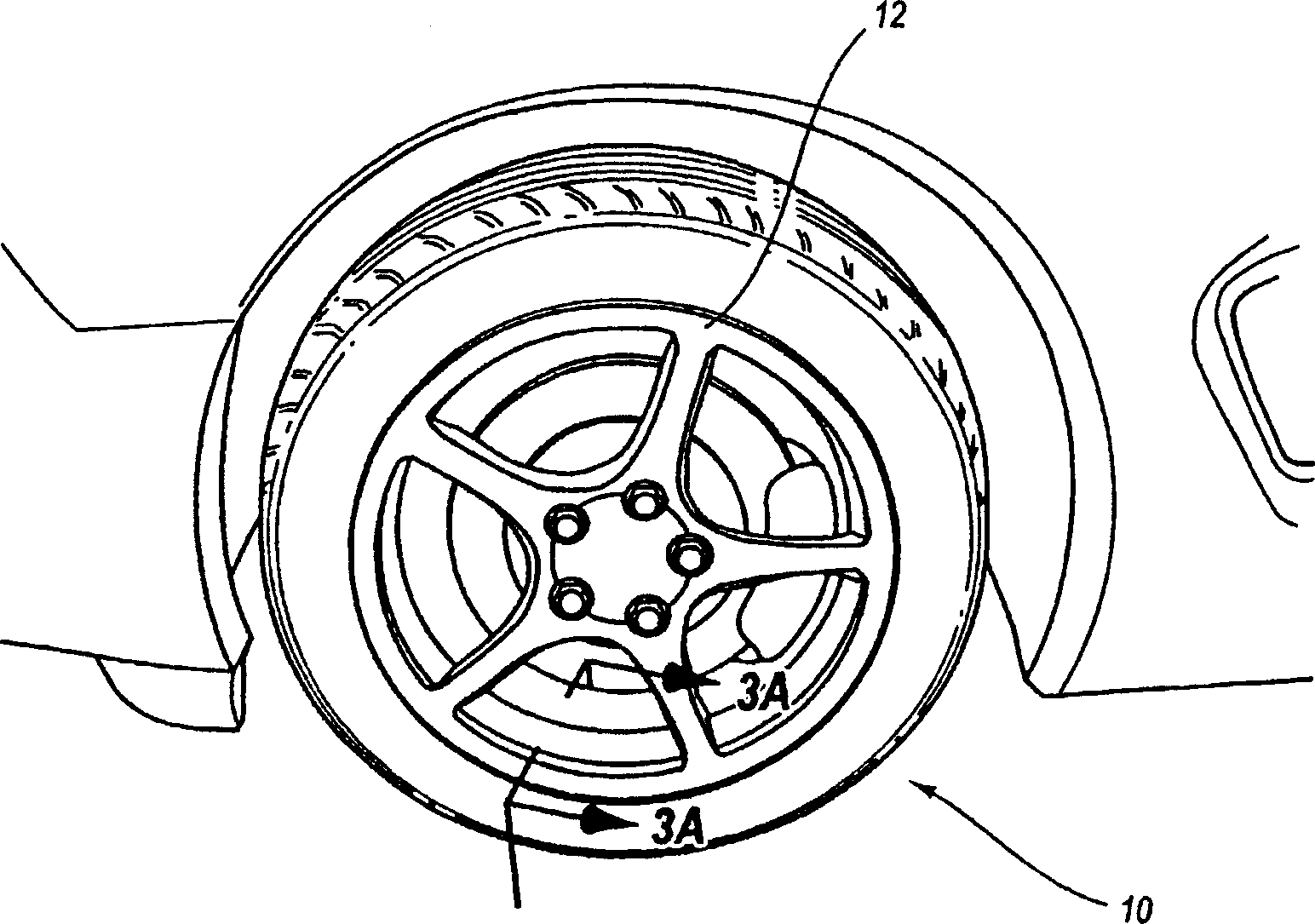

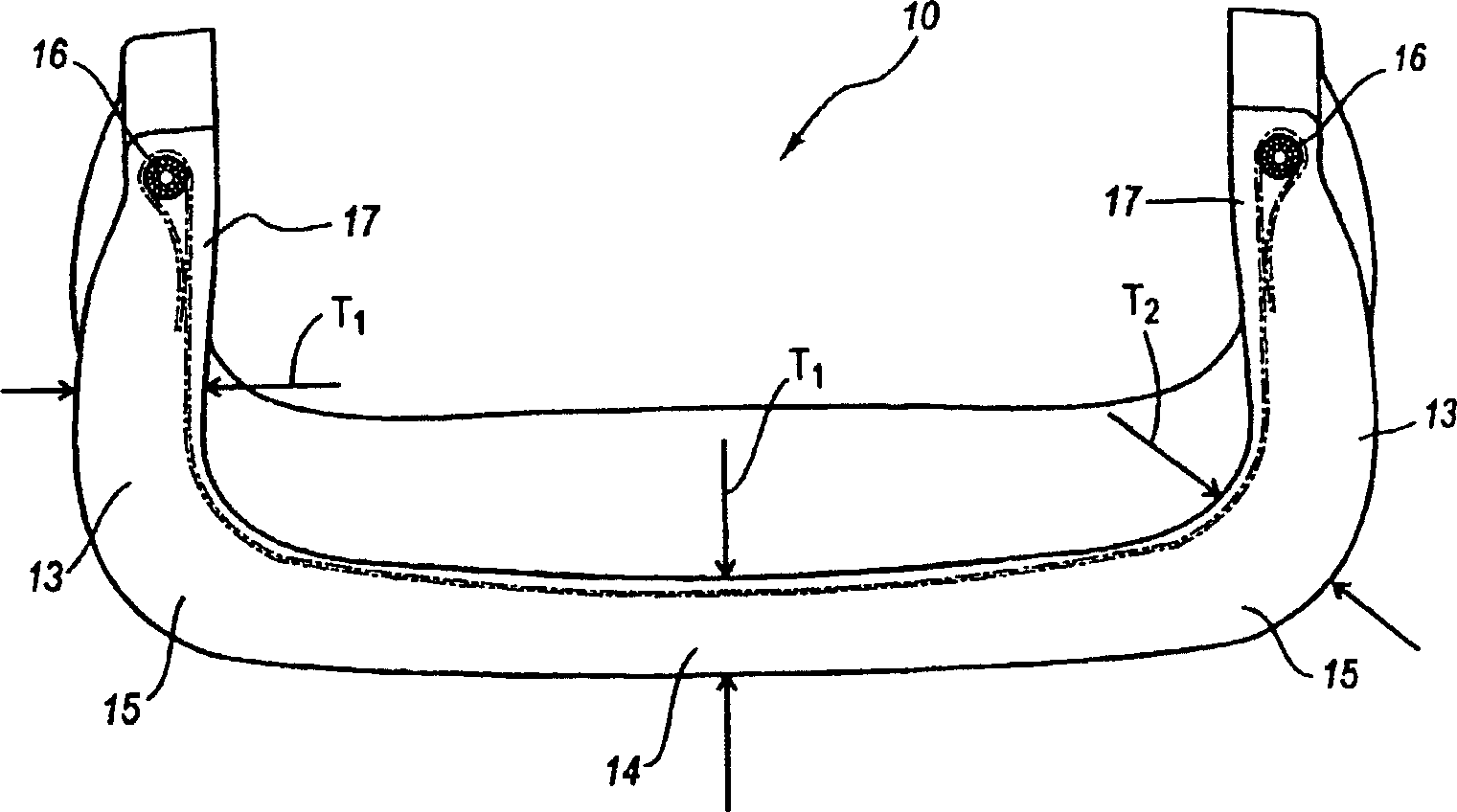

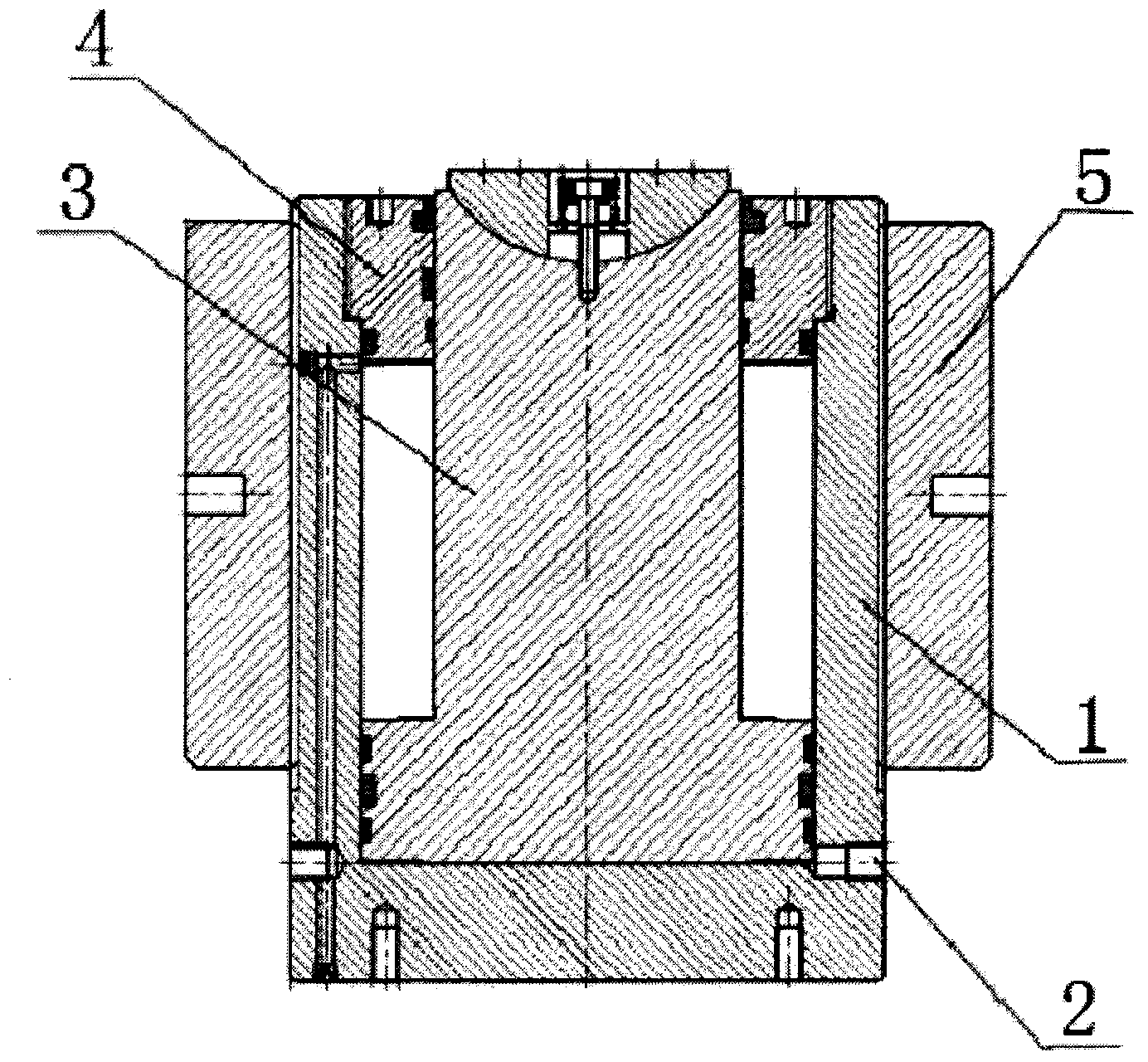

Elastomeric tire with arch shaped shoulders

InactiveCN1906045ASafe and reliable supportIncreasing the thicknessWithout cord reinforcementNon-inflatable tyresElastomerSpin casting

An elastomeric tire with arch shaped shoulders for mounting onto a rim that is manufactured by spin casting or molding methods that includes an annular cavity that is centered under the tire tread having equal thicknesses of side walls and an area under the tread whose slope outwardly into shoulder that the side walls upper ends intersect that have greater thickness and which side walls lower ends include beads that are each spaced a selected distance from the surfaces of the side wall ends that slope upwardly from inner to outer surfaces and with the tire preferably including plies that extend across the tire having ends that wrap around the beads and belts fitted around the tire circumference, above the plies, and including porous spacers fitted between the layers of plies and belts to pass a flow of the elastomeric material therethrough during tire formation.

Owner:理查德·A·施泰因克

Mechanical self-locking hydraulic jack

InactiveCN103663246ASafe and reliable supportExtended service lifeLifting devicesSelf lockingCylinder block

The invention discloses a mechanical self-locking hydraulic jack. A locking nut is movably connected to the outer wall of a cylinder block of a traditional jack in a screwed mode through threads, and under the jacking action of the jack, the locking nut is matched to go up and down along the thread on the outer wall of the cylinder block so as to achieve the supporting function. The mechanical self-locking hydraulic jack is simple and compact in structure, firm and stable in connection, convenient, rapid and safe to use and operate, and suitable for meeting the requirement for the double actions of jacking and supporting on various occasions.

Owner:李志华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com