Safety wheel with oppositely-opened type aluminum-alloy wheel rim with large offset distance for special vehicle

A special vehicle, split-type technology, applied in the direction of rims, vehicle parts, tire parts, etc., can solve the problems of maintenance support performance limitations, high mobility requirements, and bad driving conditions, so as to shorten assembly time and improve safe driving Mileage and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

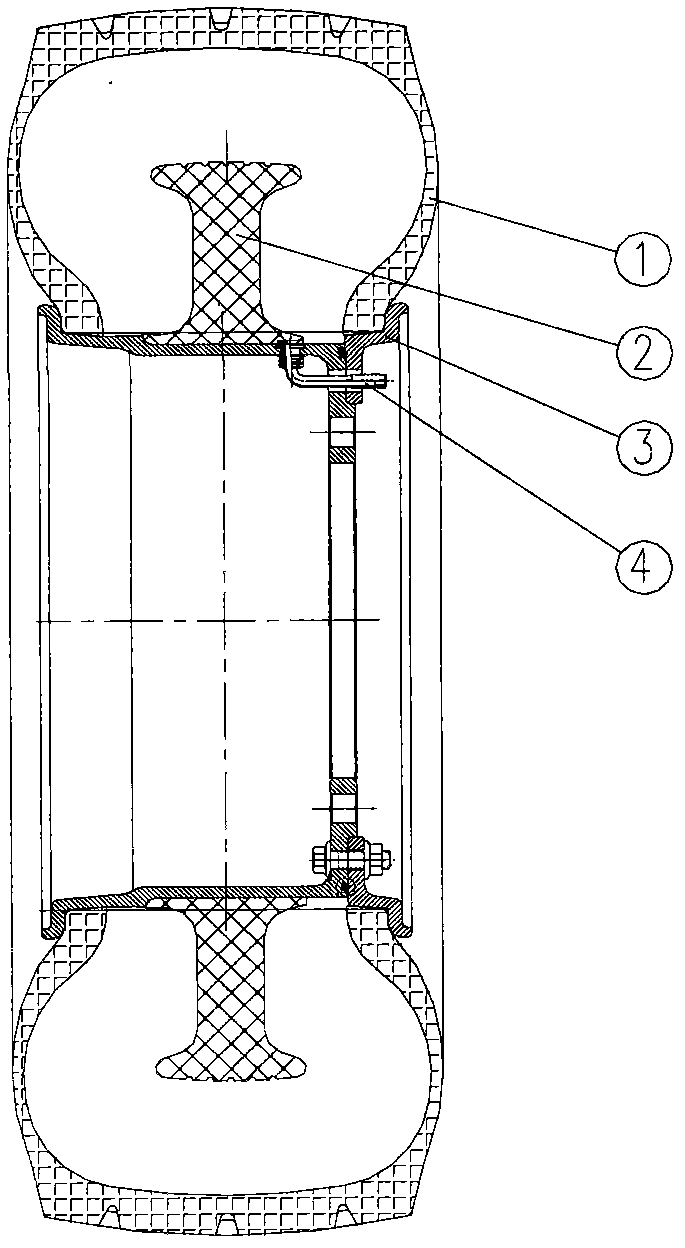

[0022] like Figure 1-4 As shown, the present invention consists of a tubeless tire 1, a hard support body 2, a large offset split aluminum alloy rim 3 and a valve 4.

[0023] The tubeless tire in the present invention adopts 365 / 80 R20 low-section radial tubeless tire, which has the characteristics of good side rigidity, strong adhesion, good heat dissipation, excellent high-speed stability, and high-speed driving safety.

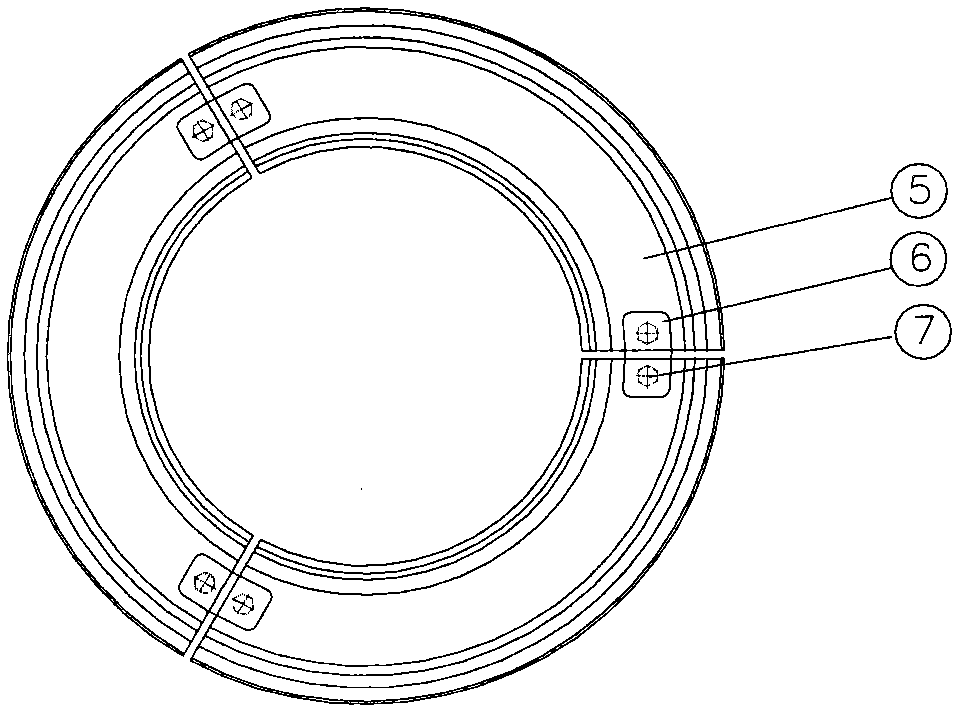

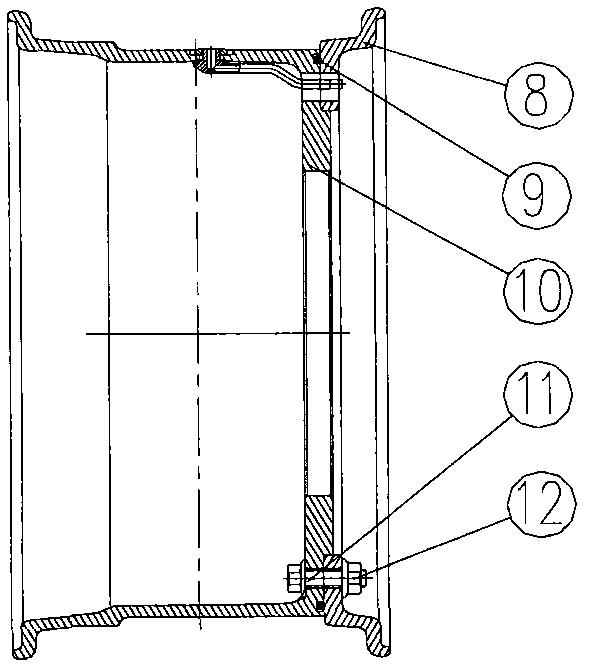

[0024] The large-offset split-type aluminum alloy wheel rim in the present invention, in order to meet the requirements of special vehicles, has a wheel offset of more than 90 mm, is made of 6061 aluminum alloy material, and is formed by a spinning processing method. Through special structural design to meet its rigidity requirements. The large offset split aluminum alloy rim is mainly composed of a rim outer body 8, a sealing ring 9, a rim inner body 10, fastening bolts 11 and nuts 12, which are assembled into one body during assembly. On the inner body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com