Support structure of vehicle fuel cell

A supporting structure and fuel tank technology, which is applied to vehicle components, the arrangement combined with the fuel supply of the internal combustion engine, and the power plant, etc., can solve the problems of unreliable support, belt and bottom plate becoming smaller, etc., to prevent damage to the fuel tank and prevent fuel The effect of box damage, safe and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings. It should be added that each of the following embodiments is the best example, and does not limit its application and use range.

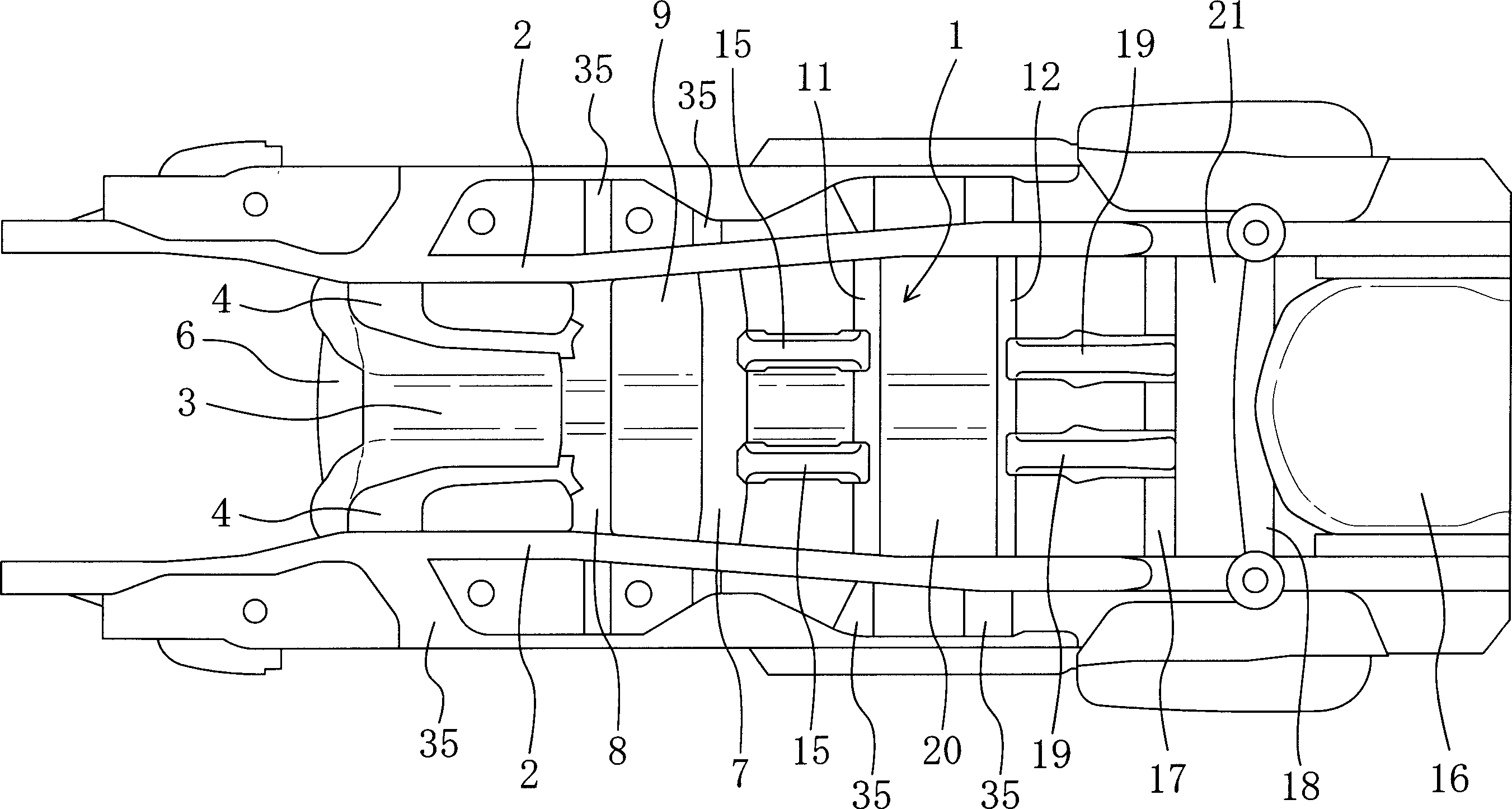

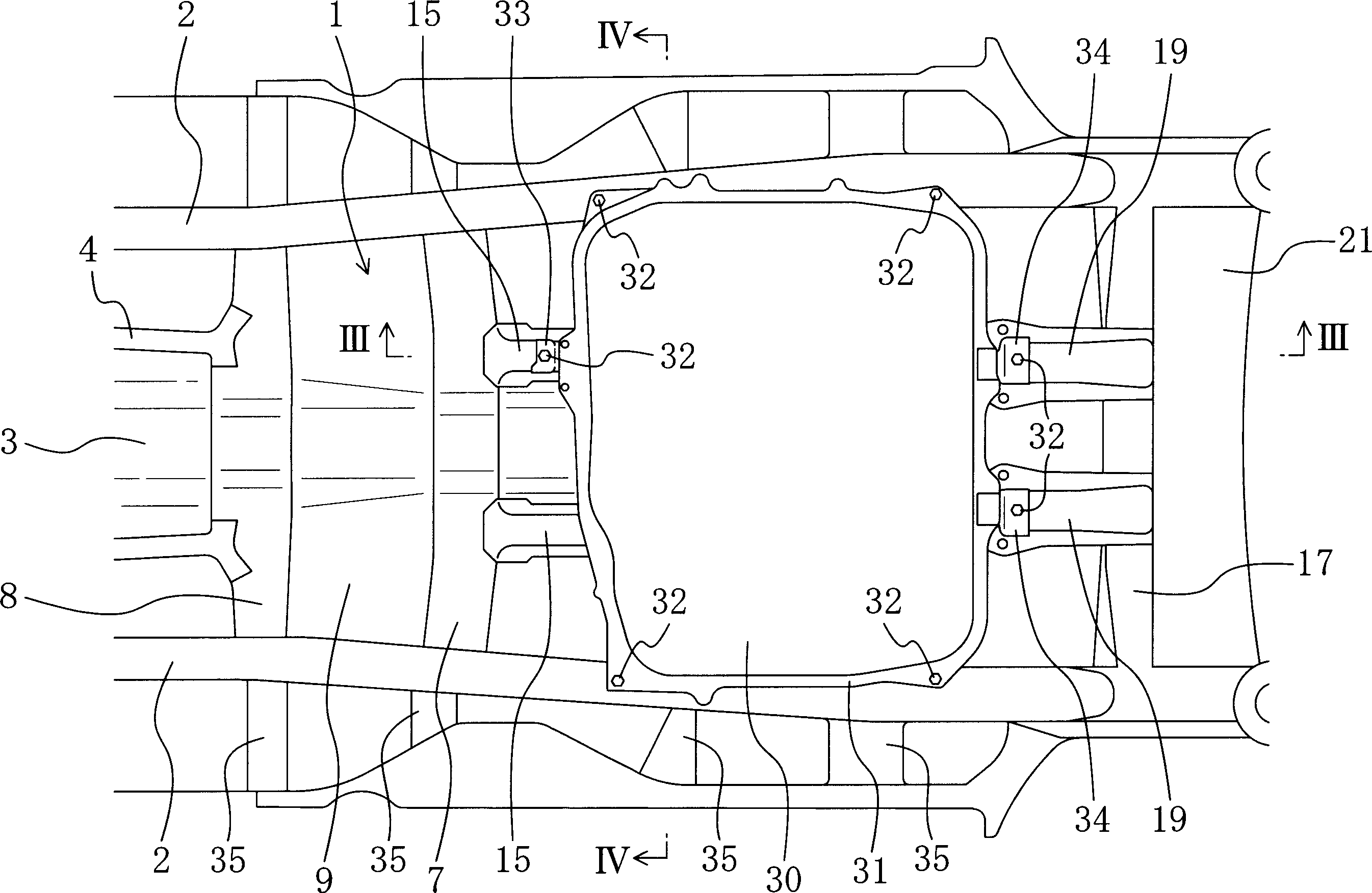

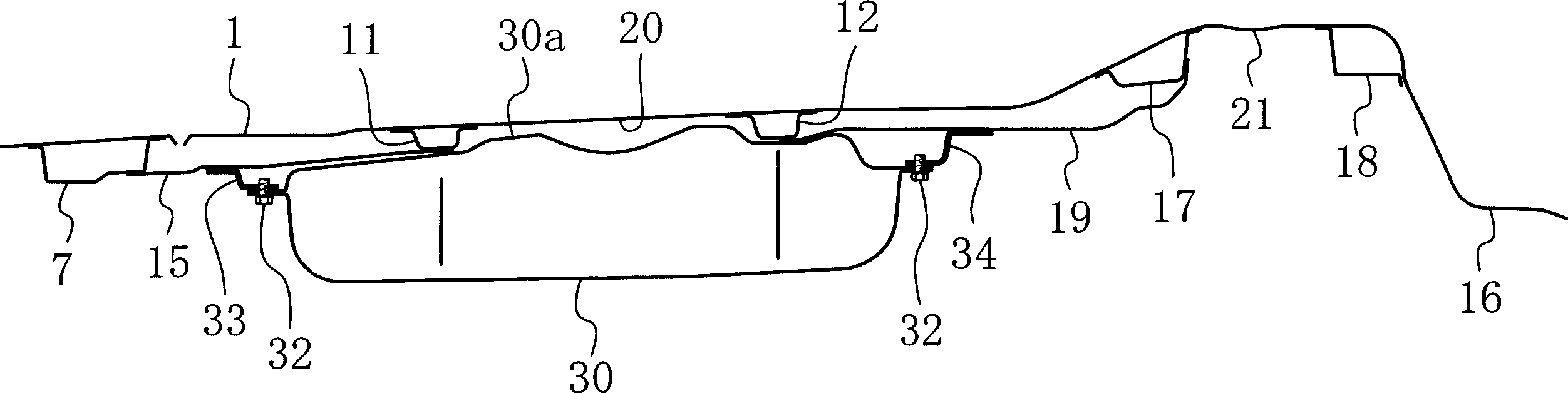

[0038] figure 1 The underbody of a fuel tank support structure of a vehicle comprising the present invention is shown. Under the floor 1 constituting the lower part of the vehicle body and on both sides of the floor 1 in the vehicle width direction, that is, on the inner sides of the floor 1 at a predetermined distance from both sides in the vehicle width direction, a pair of reinforcing underframes 2 extending forward and backward are provided. At the central portion in the vehicle width direction between the pair of underframes 2, a center tunnel 3 extending forward and backward protrudes toward the cabin side. A transmission (not shown) is installed on the lower side of the central channel 3 .

[0039] On the front sides of the pair of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com