Elastomeric tire with arch shaped shoulders

A technology of elastomers and tires, applied in special tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of heat accumulation, unsurpassed cushioning and shock absorption performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

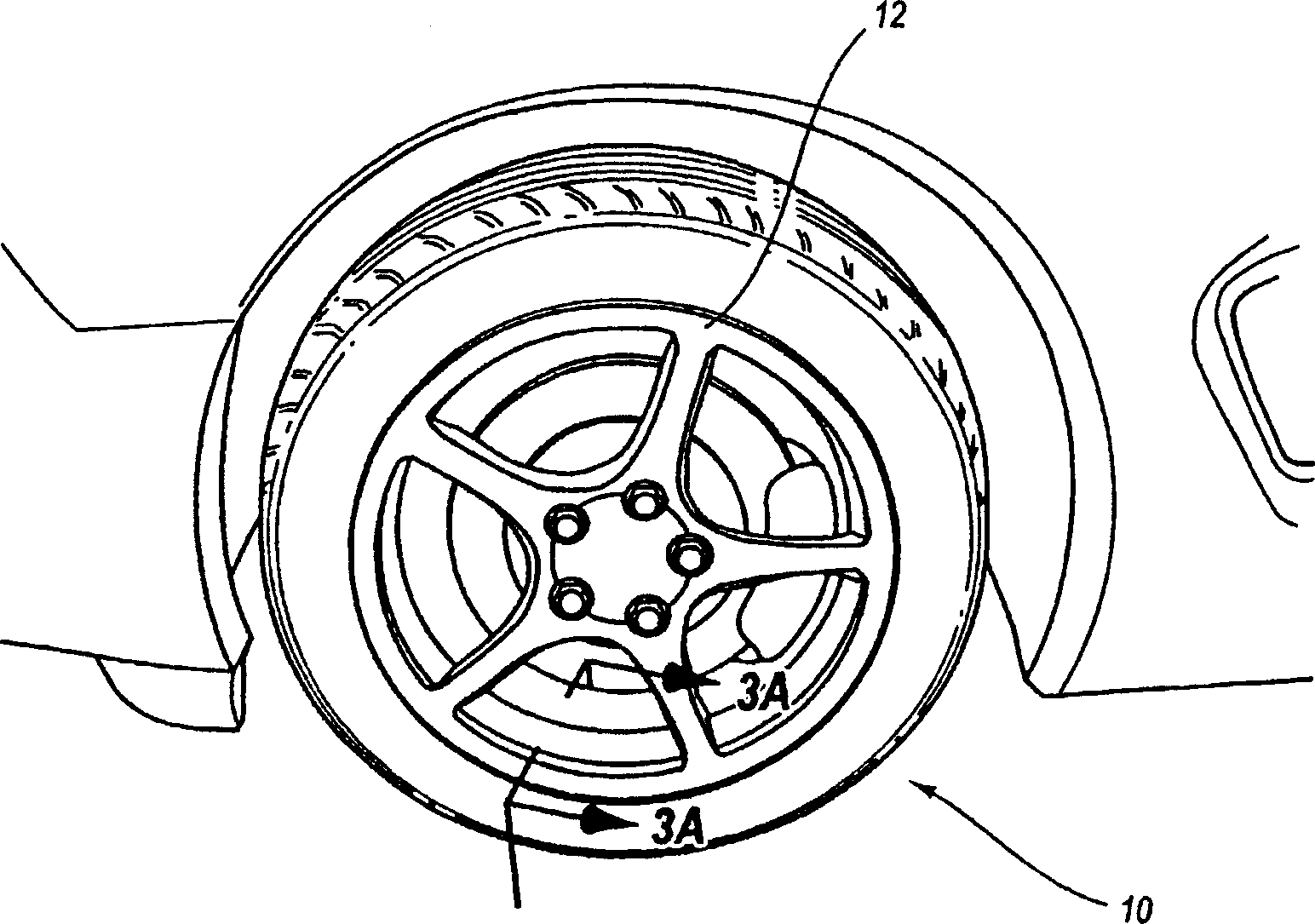

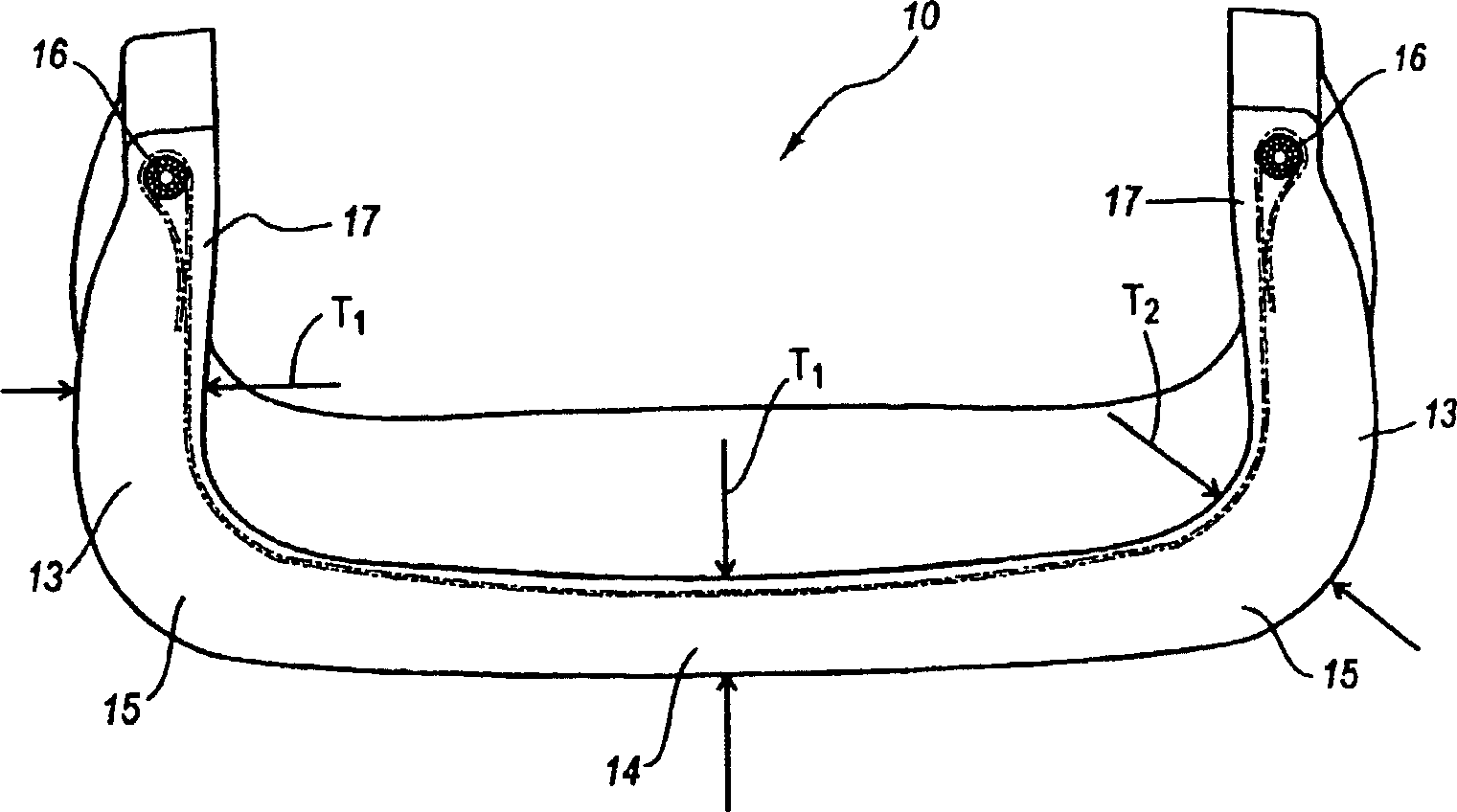

[0031] figure 2 shows an automobile tire 10 of the present invention mounted on a figure 1 On the rear wheel rim 12 of the sports car 11 shown in. The tire 10 comprises a casing or body, which is preferably made of an elastomeric material, such as a polyurethane material, and is preferably manufactured by spin casting methods as described in the Apparatus and Method patent US 4,855,096 to which the present inventor is a co-inventor. ; No. 4,943,323; No. 5,906,836 and No. 6,165,397 are disclosed. It should be understood, however, that the invention may be formed from other elastomeric materials, including natural or synthetic rubber, within the scope of the disclosure, and may be manufactured using methods and apparatus other than those disclosed in the U.S. patents above, wherein Including: molding, in which a polyurethane or rubber material in a liquid state is injected into a mould; or compression molding of a rubber material, in which the material is extruded in, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com