Hybrid psc girder having reverse t-shaped cross section and method for constructing slab using same

A technology for concrete slabs and concrete beams, applied to floors, bridges, bridge materials, etc., can solve the problems of economical decline, strength reduction, and increase in production costs, and achieve the effects of improving stability, increasing strength, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the present invention will be described in detail with reference to the embodiments shown in the drawings, but the shown embodiments are examples for clearly understanding the present invention, and the present invention is not limited thereto.

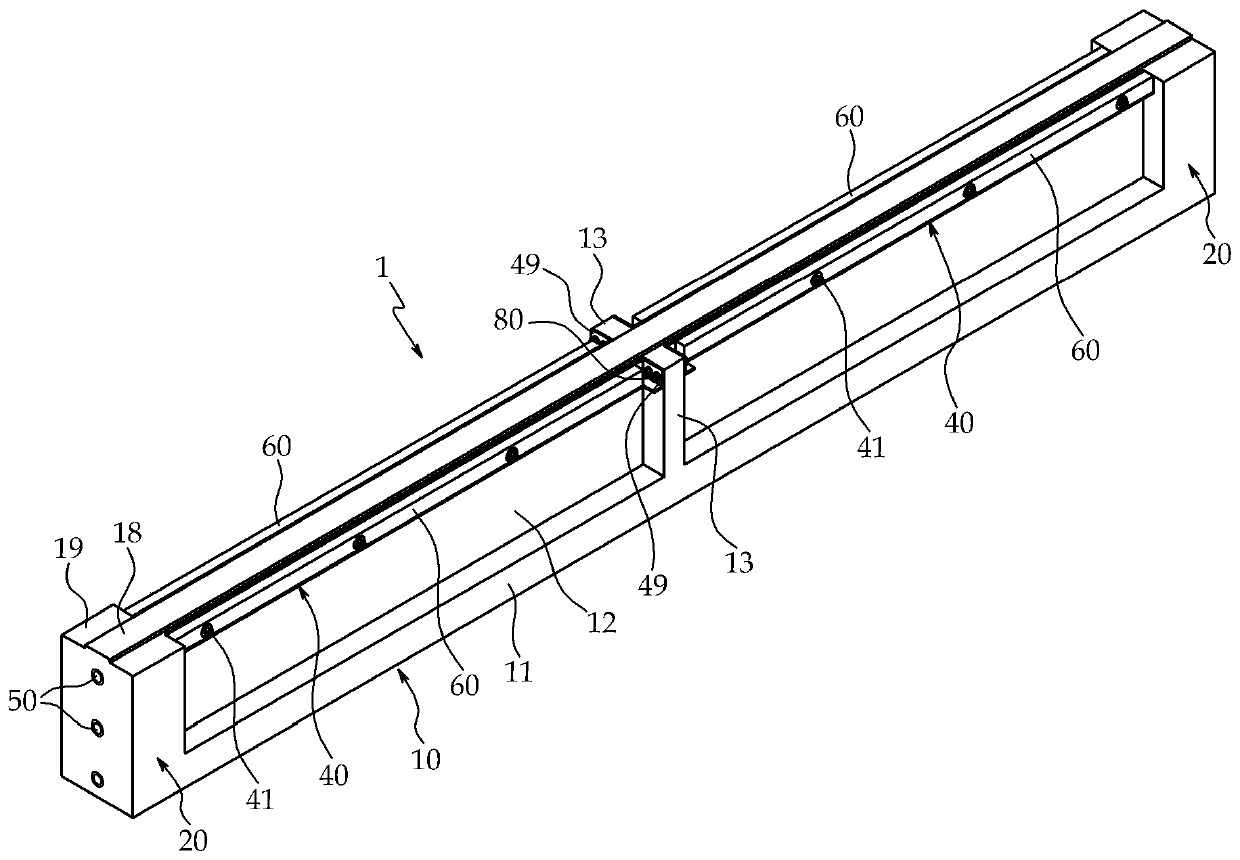

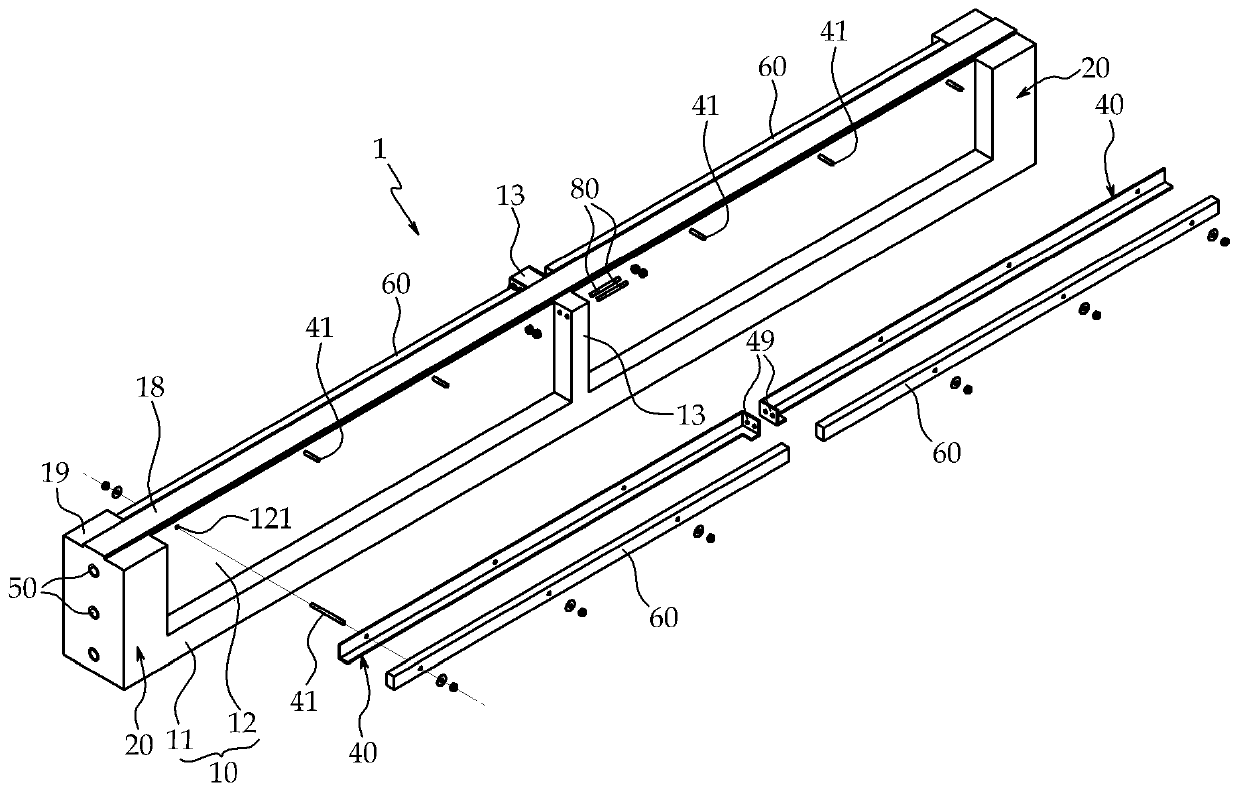

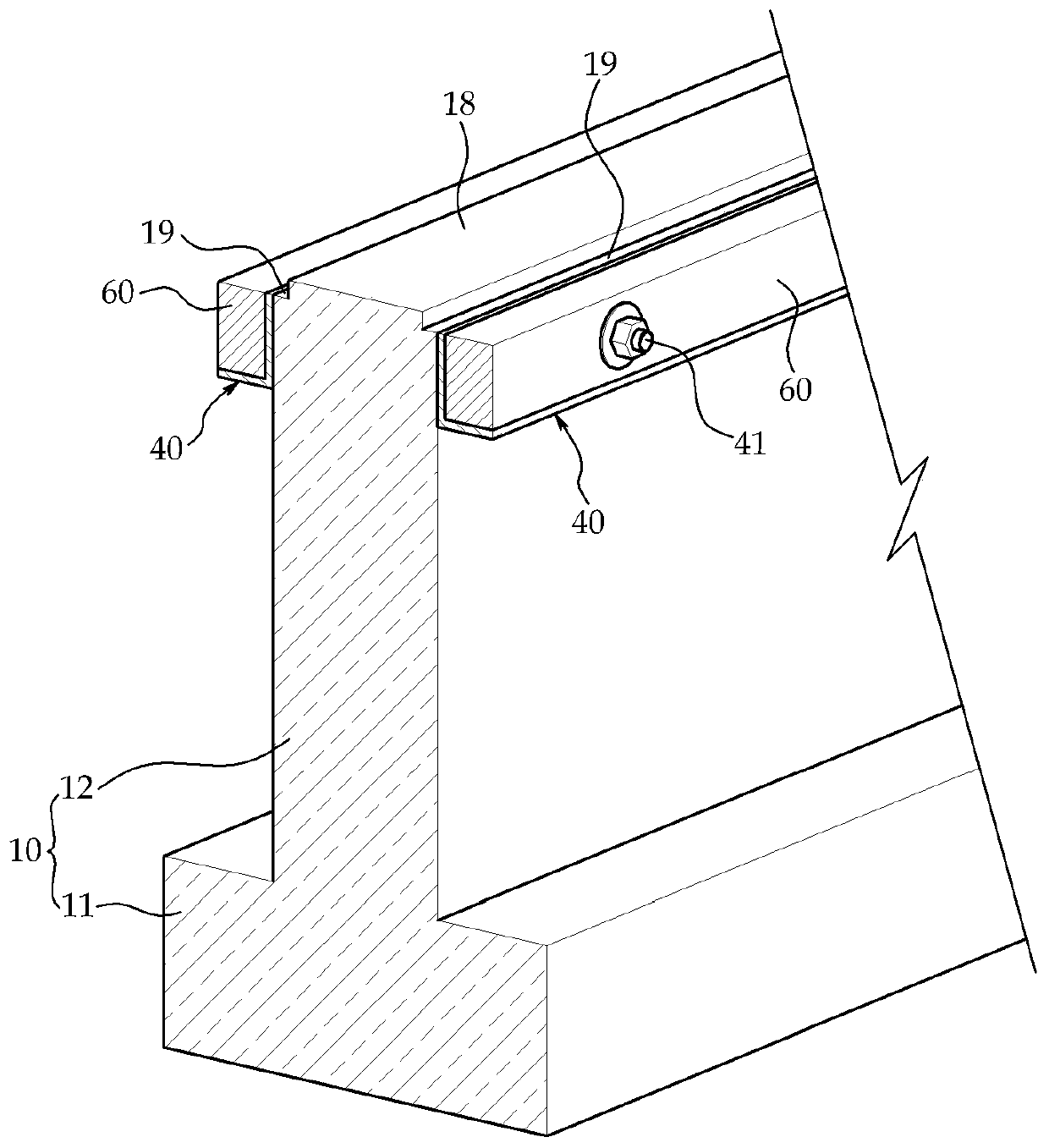

[0046] figure 1 It is a perspective view of the inverted T-section hybrid prestressed concrete beam of the present invention, figure 2 is said figure 1 The exploded perspective view of image 3 is cutting the figure 1 An enlarged perspective view of the central medial part of Figure 4 It is a sectional view showing various embodiments of the coupling hole of the inverted T-section hybrid prestressed concrete beam of the present invention.

[0047] Such as Figure 1 to Figure 3 As shown, in the inverted T-section hybrid prestressed concrete beam 1 of the present invention, the central body portion 10 having an inverted T-shaped cross-section is formed with a predetermined length, and the rectangular end parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com