Patents

Literature

75results about How to "Good use strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-permeability diversion layer material and preparation method thereof

ActiveCN106937902AReduce heavinessGood moisture permeabilityAbsorbent padsBaby linensFiberReverse osmosis

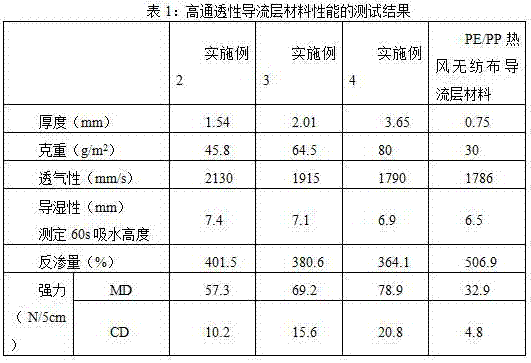

The invention discloses a high-permeability diversion layer material and a preparation method thereof, and relates to the field of disposable sanitary products. The preparation method of the high-permeability diversion layer material is characterized in that by compound-superimposing and selecting an upper layer vertical net and a bottom layer direct laying net, matching coarse denier profiled cross-section fibers and fine denier hydrophilic double components in the upper layer vertical net, reasonably matching hydrophilic and water-repellent double-component fiber in the bottom layer direct laying net, selecting a hot air penetration thermal stabilization mode and reasonably selecting lustring and setting technological parameters of a hot pressing roll, the high-permeability diversion layer material with good permeability is prepared. Therefore, the technical problems of poor diversion performance, inability in storing liquid, poor transient sucking effect, complex technology, poor permeability and difficulty in quantity production of a diversion layer material are solved, and the effects of enabling the diversion layer material to have good abilities of transient suction property, diversion property, barrier property and temporary liquid storage and to have good effects of ventilation, moisture permeation and reverse osmosis prevention are achieved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

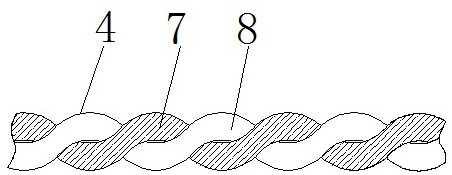

Collagenous fiber fancy yarn and preparing method thereof

The invention discloses a collagenous fiber fancy yarn and a preparing method thereof and relates to the field of textiles. The preparing method of the collagenous fiber fancy yarn comprises the steps that a wet method is adopted for extracting collagenous fibers with the length ranging from 8 mm to 40 mm from blue and wet scrap leather; short collagenous fibers and long collagenous fibers are obtained after the collagenous fibers are subjected to two opening processes and a long fiber removing and separating process; the short collagenous fibers are prepared into fiber knot balls through a pearl wool ball twisting machine; the fiber knot balls and the long collagenous fibers are fed to a carding machine together, and the collagenous fiber fancy yarn is obtained after the processes of carding, thick combining and yarn thinning. According to the preparing method of the collagenous fiber fancy yarn, the collagenous fiber with different lengths are extracted from the blue and wet scrap leather, the short collagenous fibers are prepared into the fiber knot balls and then prepared into the collagenous fiber fancy yarn together with the long collagenous fibers, the problem that the extracted short collagenous fibers cannot be well used is solved, and the purpose of fully utilizing the short collagenous fibers extracted from the blue and wet scrap leather is achieved.

Owner:JIAXING UNIV

Synthesis for weak hydrophobic framework amide resin and application of the same in purifying gingko total lactone

InactiveCN101100495AGood use strengthGood synergyGinkgophyta medical ingredientsLactone synthesisFlavones

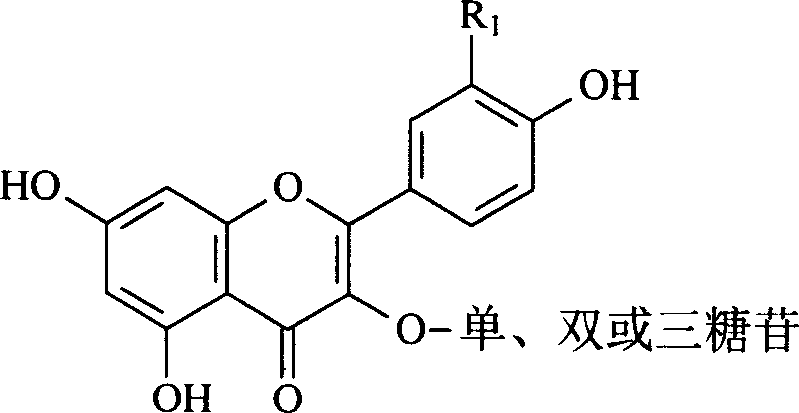

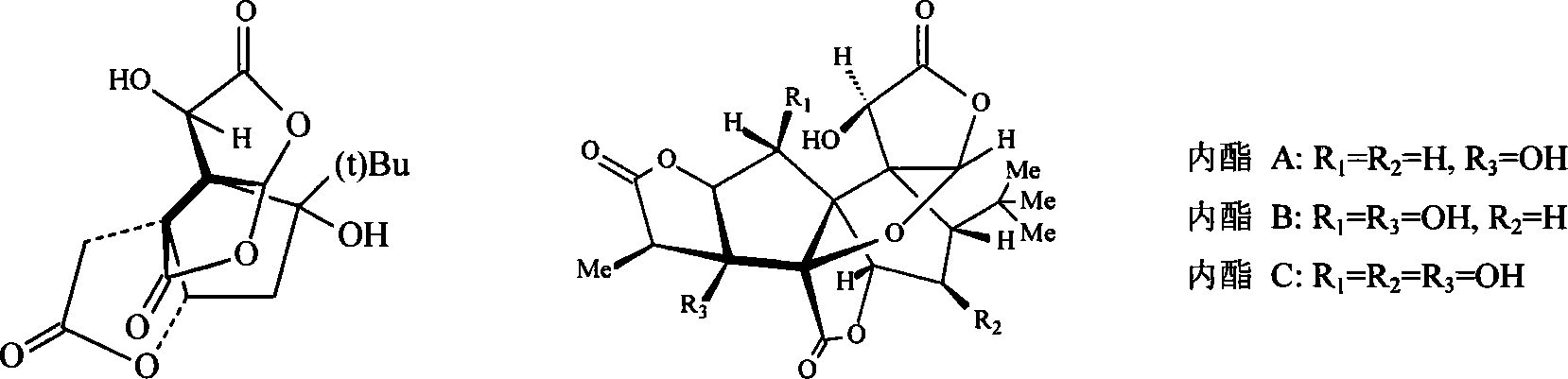

Synthesis of amide adsorptive resin with weak hydrophobic skeleton is carried out by co-polymerizing methyl acrylate with vinyl benzene to obtain ester-based resin, aminolyzing for ester base, acidylating to obtain amide adsorptive resin with weak hydrophobic skeleton, adsorbing flavone compound from Ginkgo extract onto resin by the resin and hydrogen bond synergistic function, flowing ginkgo-lactone, re-crystallizing and eluting to obtain final product. The purity is above 90%, it's simple and non-toxic, it has friendly environment and can be used to supply experimental samples for development of ginkgo lactone.

Owner:NANKAI UNIV

Preparation method and application of kapok fiber non-woven mask base material

ActiveCN104975492ATake full advantage of the water retention effectTake full advantage of the slow release effectCosmetic preparationsToilet preparationsCardingKapok fiber

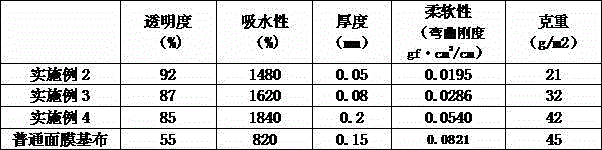

The invention provides a preparation method and application of a kapok fiber non-woven mask base material, belonging to the field of skincare. The preparation method of the kapok fiber non-woven mask base material, provided by the invention, comprises the following steps: a. carrying out light-alkali partial degreasing treatment on kapok fiber; b. carrying out hollowness degree recovery and softening treatment on the kapok fiber damaged to flat tape shape in the pretreatment process; c. carrying out dehydration drying treatment on the kapok fiber so as to obtain kapok fiber with good spinnability; d. carrying out opening and mixed carding on the kapok fiber to obtain a kapok fiber web; e. carrying out reinforcement treatment on the kapok fiber web by adopting a high-pressure spray method; f. drying the kapok fiber web after reinforcement treatment to obtain the kapok fiber non-woven mask base material. Kapok fiber with high degree of hollowness is adopted for the kapok fiber non-woven mask base material provided by the invention; in use, water absorbed in the fiber cavity can be slowly released, and thus the mask has good moisturizing and water locking effects, is light in gram weight, soft in hand feeding and good in fitness, and further is good in application prospect.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Casting-molded aluminum-silicon lightweight refractory material

The invention belongs to the technical field of refractory materials, and discloses a casting-molded aluminum-silicon lightweight refractory material which comprises raw materials and solvents, wherein the raw materials comprise ceramic powder as base packing; the solvent comprises water, a thickening agent and a dispersing agent; the raw material of the aluminum-silicon lightweight refractory materials further comprise pure calcium aluminate cement and ceramic fiber for improving the strength and the thermal shock resistance of a product; the solvent further comprise silica sol; the pure calcium aluminate cement and the silica sol act together to complete the hardening process of the refractory material; when the refractory material is hardened, the pure calcium aluminate cement is hydrated and hardened in a solvent and acts with the silica sol to form the framework of the lightweight refractory material, and the ceramic powder and water molecules can be adhered to the framework of the lightweight refractory material. The casting-molded aluminum-silicon lightweight refractory material has the characteristics of fine aperture, uniformity in distribution, good thermal insulation property, high strength, good erosion resistance and good washout resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Odorless silicone sealant

ActiveCN103131380AFast curingGood use strengthNon-macromolecular adhesive additivesOther chemical processesPolymer scienceVulcanization

The invention relates to odorless silicone sealant. The technical scheme is as follows: the odorless silicone sealant is prepared from the following raw materials in percentage by weight: 76-80% of modified room temperature vulcanized silicon rubber, 9-12% of gas-phase silicon dioxide, 7-9% of dimethyl silicon oil, 0.8-1% of crosslinking agent, 1.4-1.6% of titanium complex, 0.06-0.1% of catalyst and 0.8-1% of coupling agent. The silicone sealant provided by the invention causes no corrosion, can only release about 1% of small-molecule alcohol substances (methanol and ethanol) in the curing process, has low odor and is environment-friendly.

Owner:LIAONING LVSHI CHEM GROUP

Pouring molding aluminum-silicon series light refractory material

The invention belongs to the technical field of refractory materials, and provides a pouring molding aluminum-silicon series light refractory material. The aluminum-silicon series light refractory material comprises raw materials and solvents. The raw materials comprise ceramic powder as a basic filler, and the solvents comprise water, a thickener and a dispersant; the raw materials of the aluminum-silicon series light refractory material also comprise pure calcium aluminate cement and ceramic fiber to improve the strength and thermal shock resistance of the product. The solvents also comprise silica sol. The pure calcium aluminate cement is combined with the silica sol to complete the hardening process of the refractory material together. During the hardening process of the refractory material, the pure calcium aluminate cement hydrates and hardens in the solvents and interacts with the silica sol to form a framework of the lightweight refractory material, and thus the ceramic powder and water molecules are adsorbed on the framework of the lightweight refractory material. The pouring molding aluminum-silicon series light refractory material has the characteristics of small pore diameter, good heat insulation property, uniform distribution, high strength, good erosion resistance and good erosion resistance.

Owner:长兴县新宏信耐火材料有限公司

Building exterior wall coating and preparation method thereof

InactiveCN107418332AWide variety of sourcesSimple preparation processEpoxy resin coatingsCelluloseEpoxy

The invention discloses a building exterior wall coating. The building exterior wall coating is composed of raw materials including, by weight part, 10-16 parts of waterborne acrylic resin, 6-10 parts of waterborne epoxy resin, 3-6 parts of sodium silicate, 25-34 parts of ceramsite, 4-8 parts of emery powder, 2-5 parts of gypsum powder, 0.5-2 parts of lignocellulose, 0.1-0.5 part of hydrophobic powder, 2-8 parts of titanium dioxide, 2-4 parts of dispersing agent, 15-25 parts of dimethylbenzene, 8-14 parts of duckweed, 5-12 parts of reed and 4-8 parts of shale. The invention also discloses a preparation method of the building exterior wall coating. The building exterior wall coating is extensive in raw material sources, simple in preparation process and applicable to large-scale industrial production; the raw materials can achieve synergistic effects, are high in application strength, waterproof performance and antibacterial effects, long in service life, free from fracturing, peeling, ageing and the like and capable of meeting the usage requirements of people.

Owner:孙洁

Degradable high-strength composite air bubble film and processing method thereof

InactiveCN109294027AEasy to observeEasy to assistSynthetic resin layered productsTectorial membranePlasticizer

The invention provides a degradable high-strength composite air bubble film and a processing method thereof, and solves technical problems that the existing composite air bubble film is too simple instructure, unable to be quickly degraded after being discarded, etc. The degradable high-strength composite air bubble film consists of outer layers and an inner layer. The outer layers are protectivefilms and the inner layer is an air bubble film. The air bubble film consists of the following raw materials in parts by weight: 42-54 parts of polyethylene, 1.3-1.8 parts of flame retardants, 0.6-1.1 parts of antimicrobial agents, 0.5-1.2 parts of plasticizers and 2.2-4.6 parts of biodegradable additives. The invention has an advantage of convenient degradation.

Owner:TONGXIANG KAIRUI PACKAGING MATERIAL

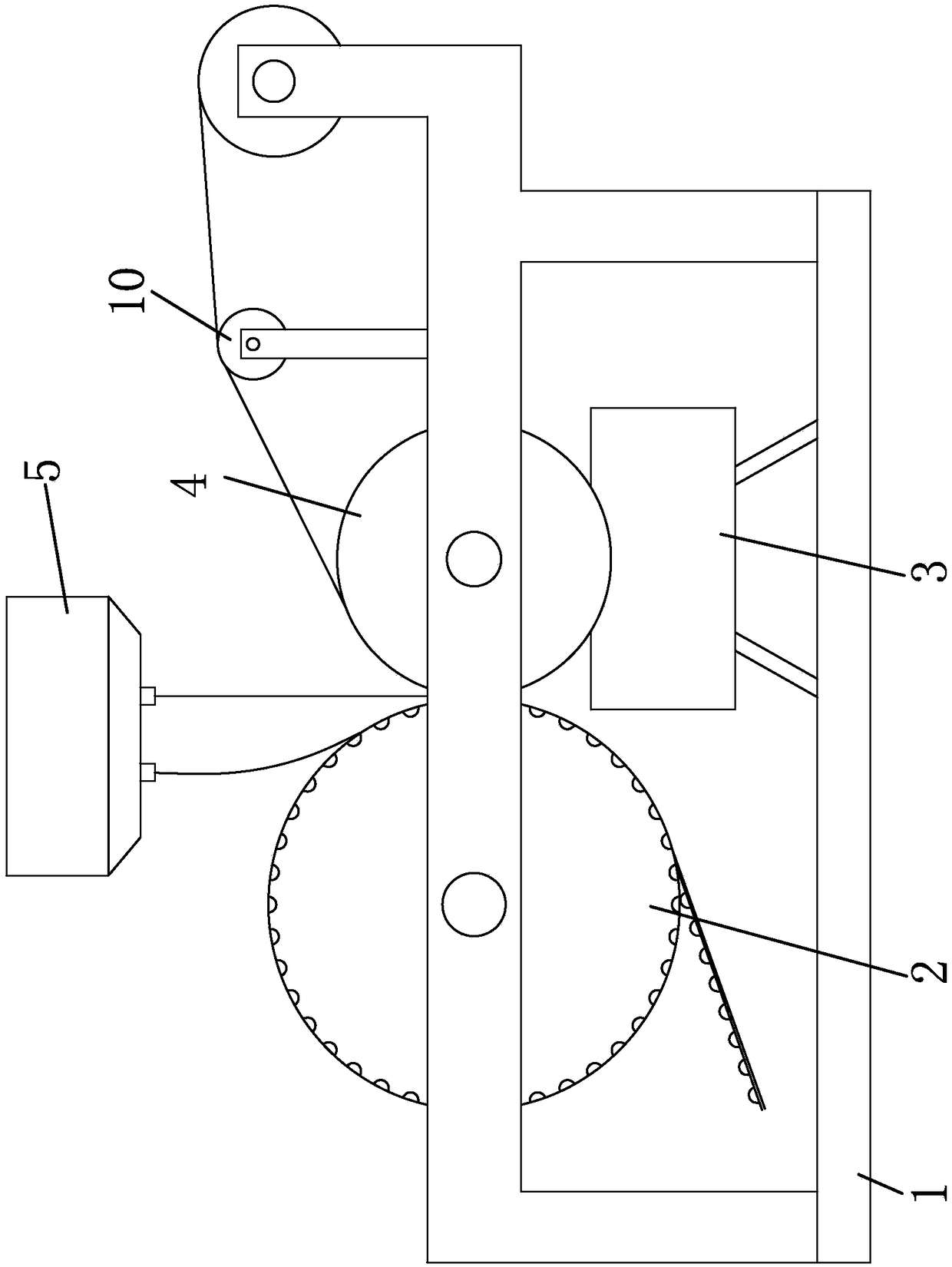

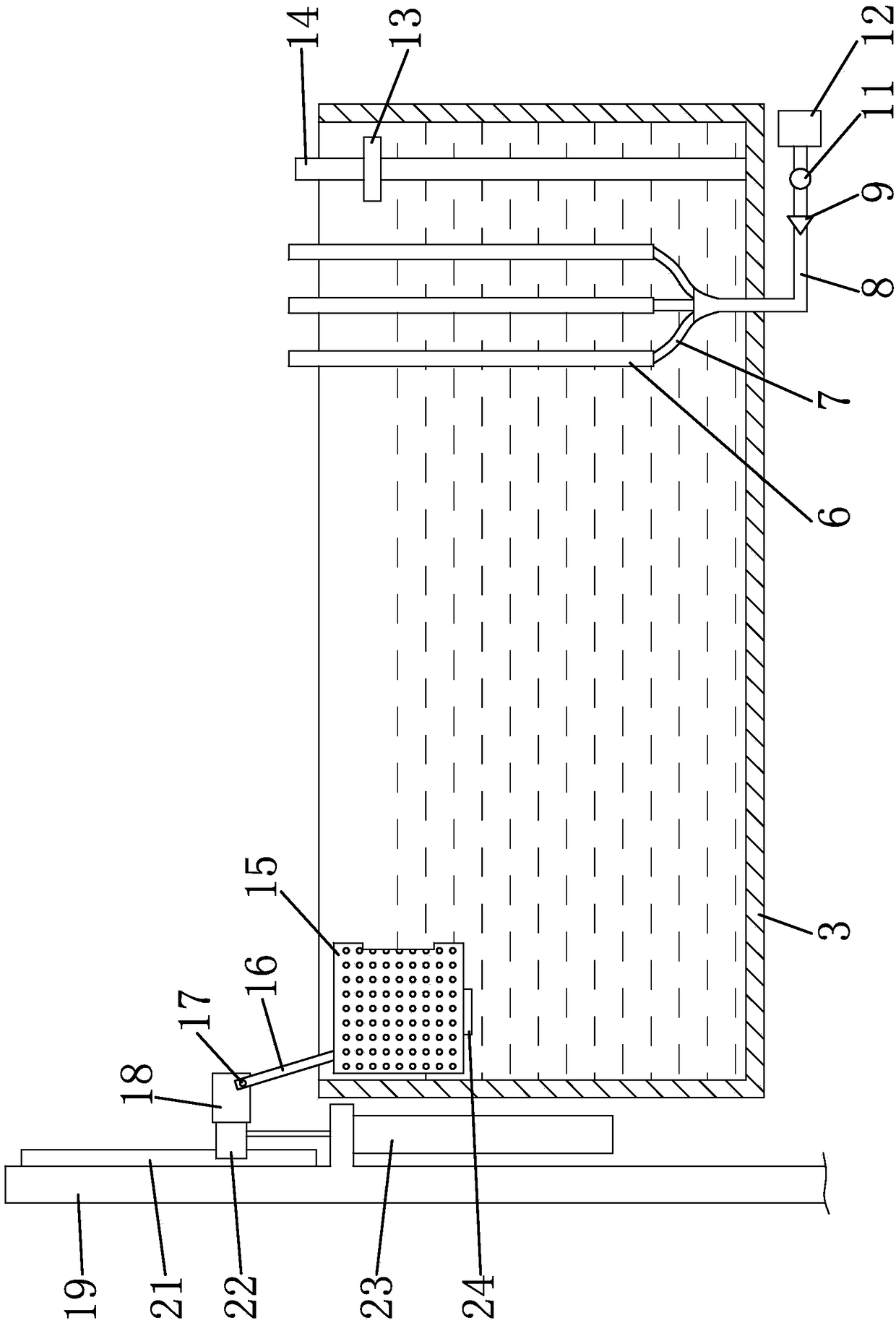

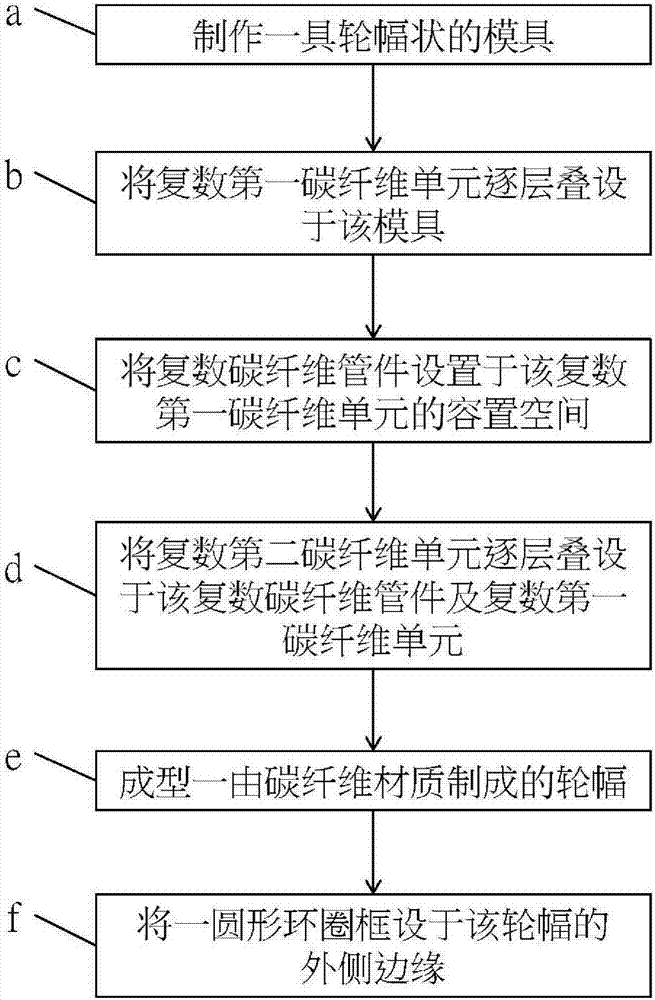

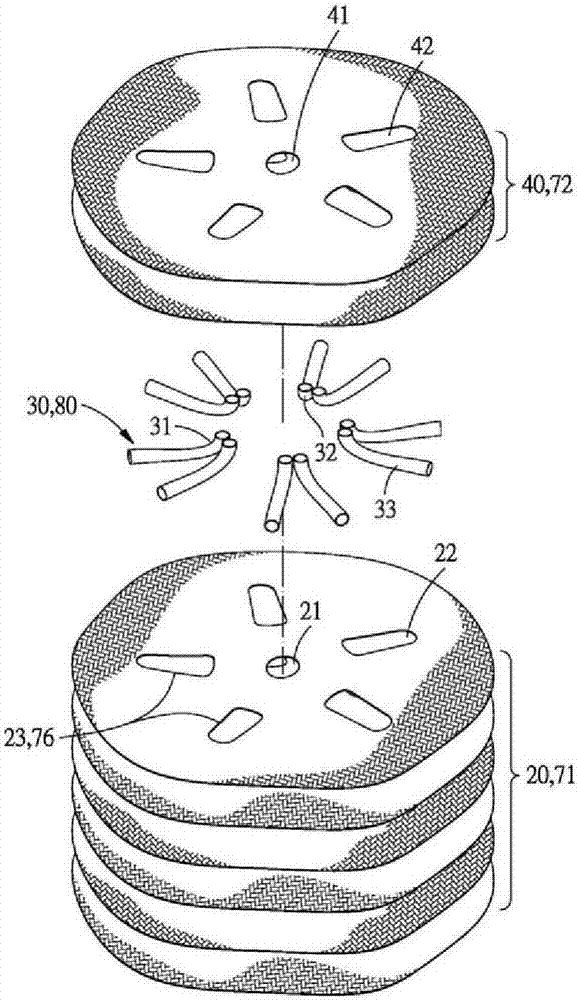

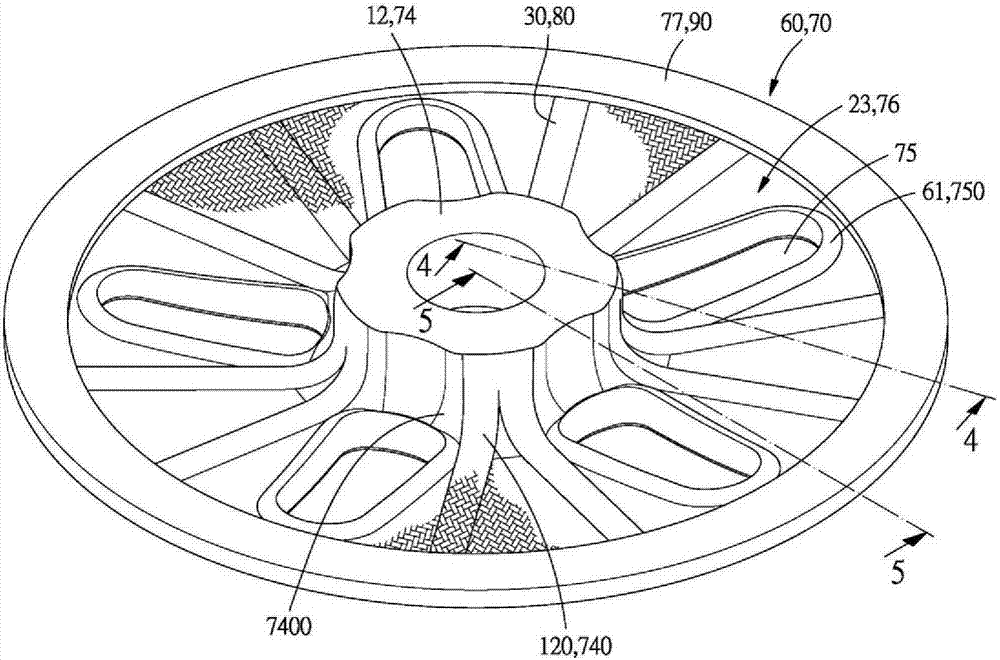

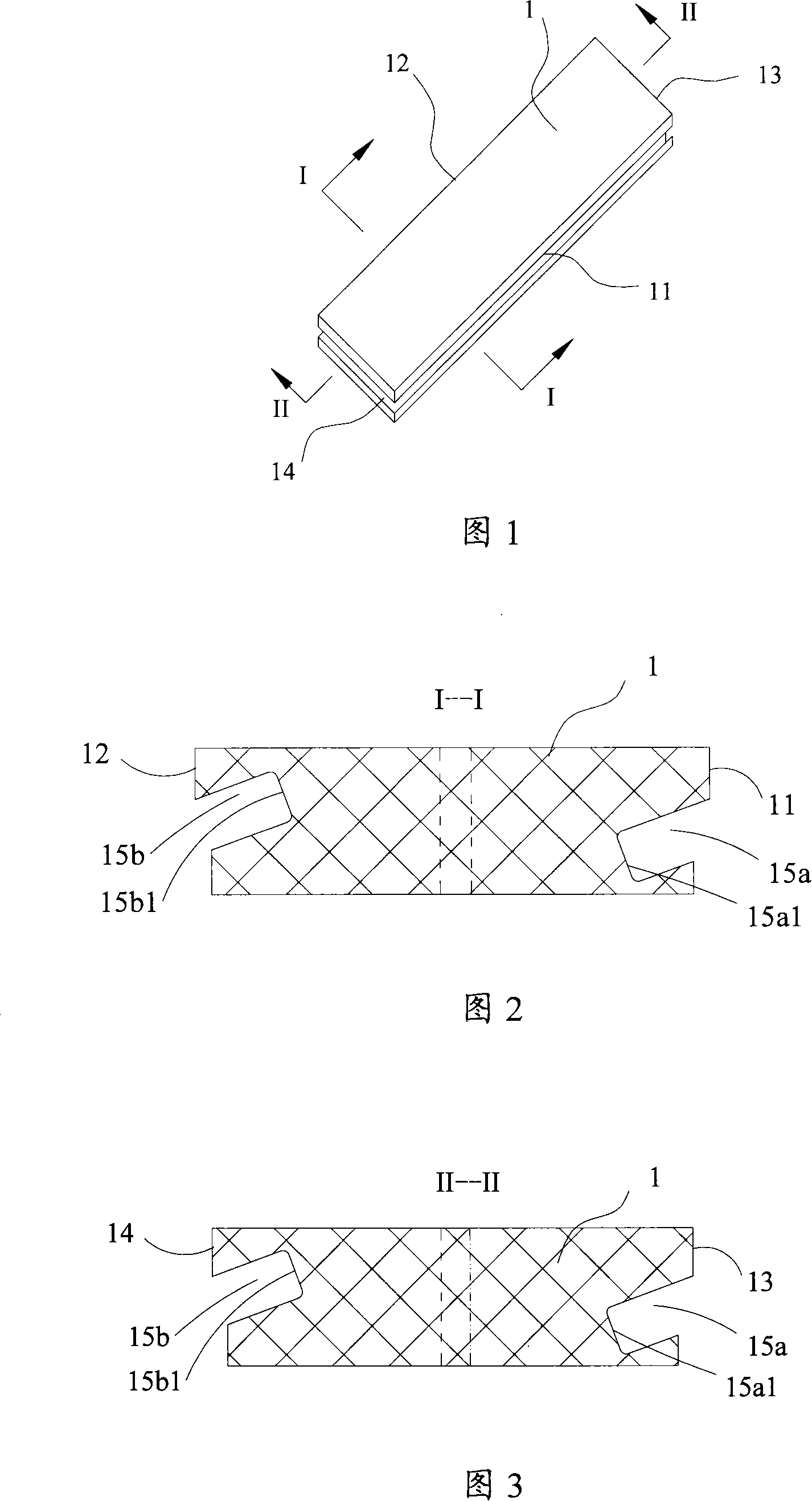

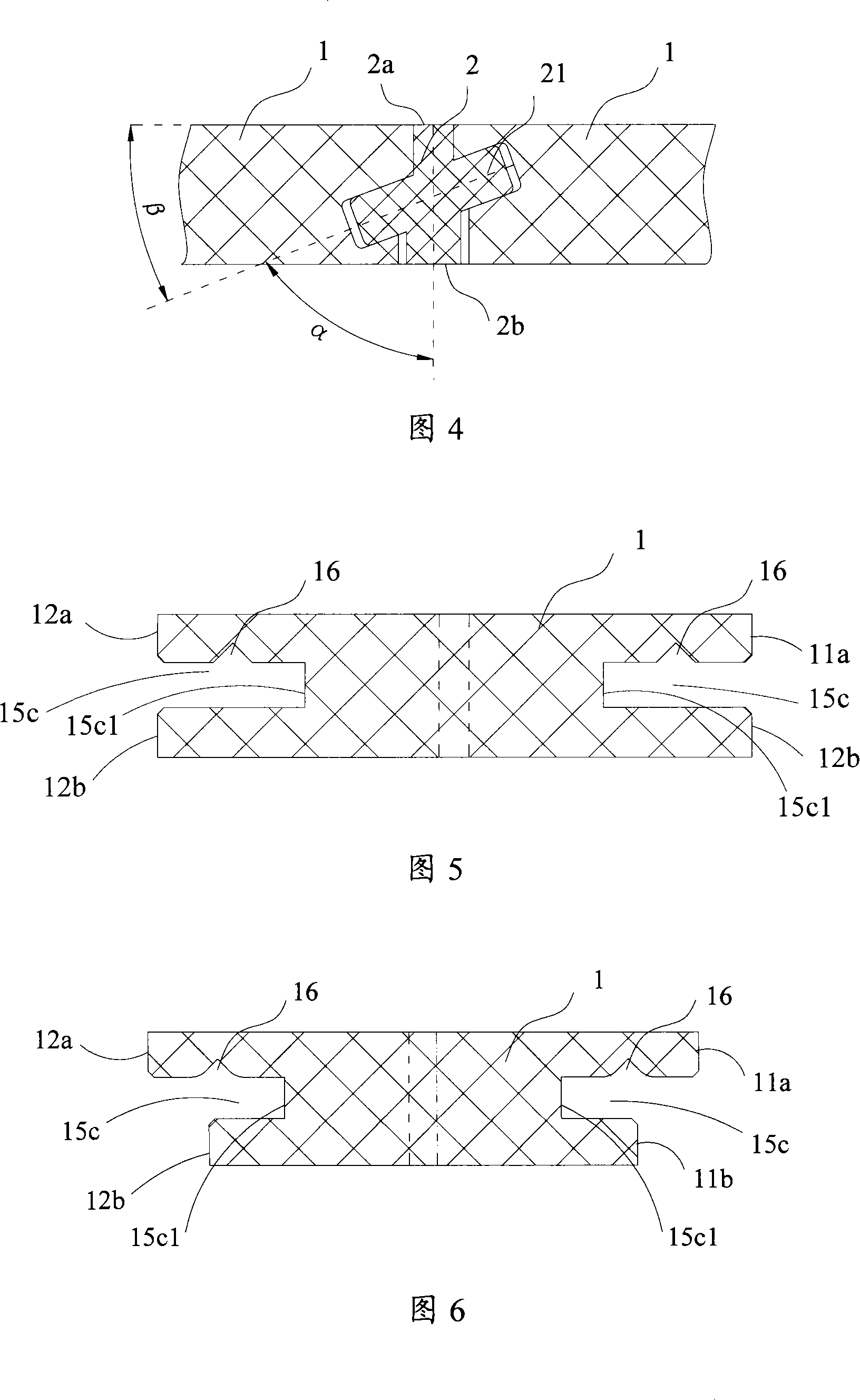

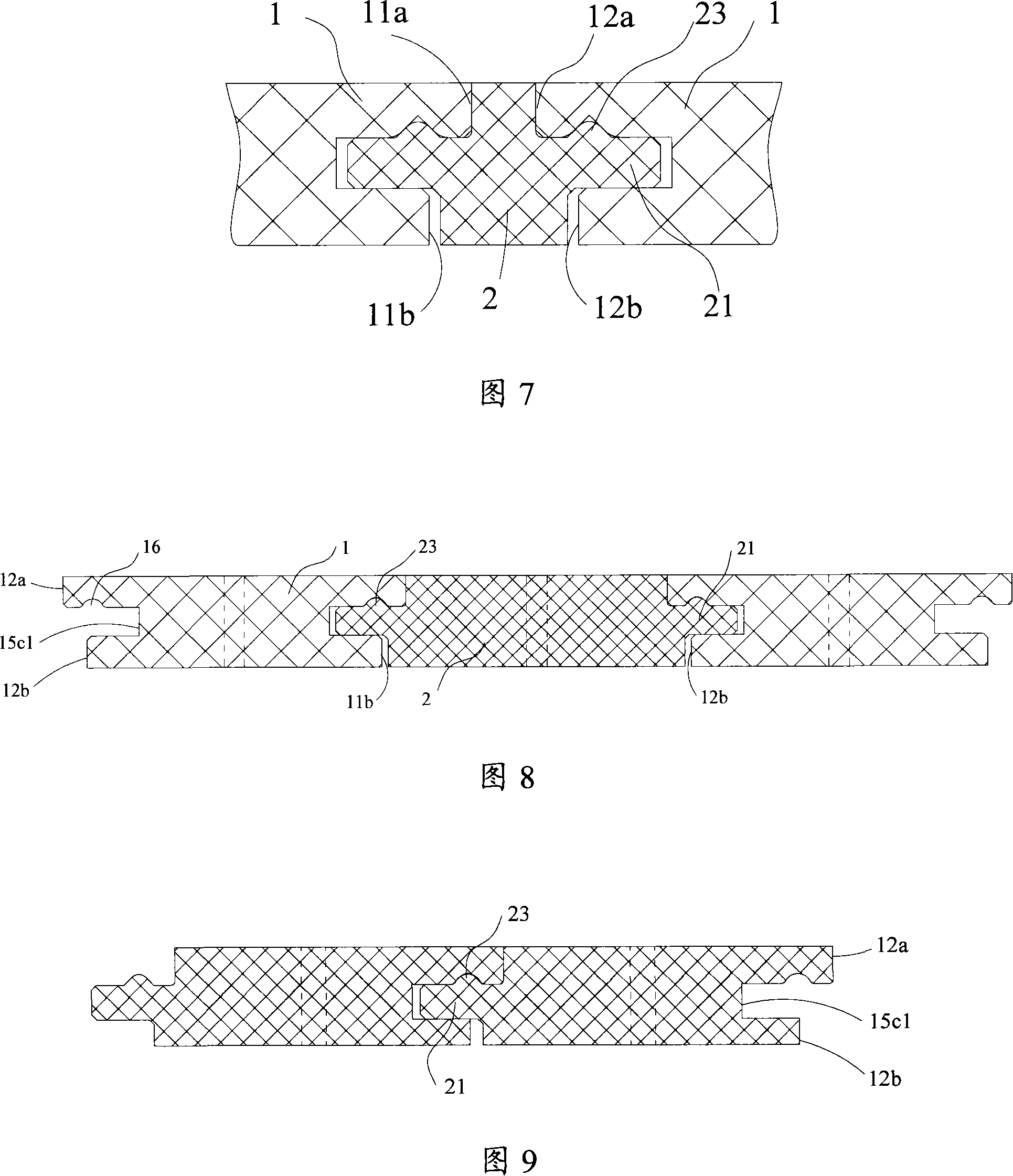

Spoke made from carbon fiber composite material and manufacturing method thereof

The invention discloses a spoke made from a carbon fiber composite material and a manufacturing method thereof. The spoke comprises a spoke prepared by stacking a plurality of carbon fiber materials layer by layer. A bearing unit with an annular face is arranged on the spoke in a convex manner, and a plurality of fastening holes are formed through close to the periphery of the outer side of the bearing unit, and an accommodating space is formed between two adjacent fastening holes; a protruding carbon fiber reinforcing rib is arranged on the edge of each fastening hole, and a plurality of carbon fiber pipe fittings are arranged in the accommodating space; as the first end portions and the second end portions of the plurality of carbon fiber pipe fittings are separately located on the annular face of the bearing unit and the position of the accommodating space, the bearing unit and the accommodating space can be grasped simultaneously by means of the plurality of carbon fiber pipe fittings when the spoke is impacted, so that the condition that the spoke is directly broken or is locally damaged is avoided. Better using strength in use can be obtained, and the practical function characteristic is further enhanced in integral implementation of the spoke.

Owner:翁庆隆

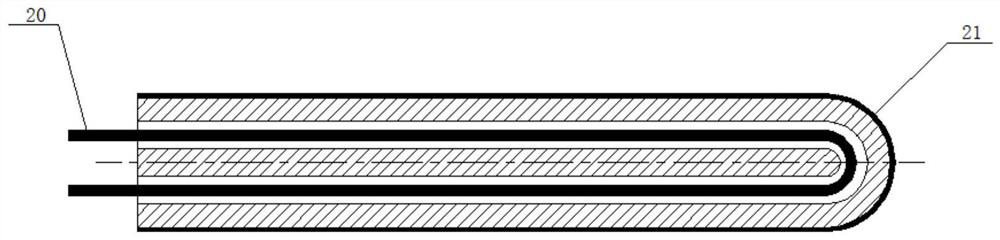

Polyvinylidene fluoride/liquid crystal blending microporous membrane and preparation method thereof

The invention discloses a polyvinylidene fluoride / liquid crystal blending microporous membrane and a preparation method thereof. The microporous membrane comprises the following components by mass percentage (wt%):10-30% of polyvinylidene fluoride, 0.4-4% of macromolecule lyotropic liquid crystal, 56-88.6% of organic solvent and 1-10% of additive. The preparation method comprises the following components of the microporous membrane by mass percentage (wt%) and the following steps: (1) 25-27% of cyanoethyl cellulose or cyanoethyl-ethyl cellulose is dissolved into 25-75% of N,N-dimethyl fomamide, N,N-dimethyl acetamide, N,N-dimethyl sulfoxide, glacial acetic acid or crylic acid, is put in constant temperature of 50 DEG C for 12 hours, and is stood for 72 hours at room temperature to form lyotropic liquid crystal; (2) microporous membrane components are weighted; (3) the organic solvent, polyvinylidene fluoride and additive are evenly mixed, and then the lyotropic liquid crystal is addedto form membrane forming liquid; (4) the traditional technology and devices are used for weaving a hollow-fibre membrane or a striking flat membrane; and (5) the obtained microporous membrane is dipped in protection liquid for 3-24 hours to obtain the microporous membrane of the invention.

Owner:TIANJIN POLYTECHNIC UNIV +1

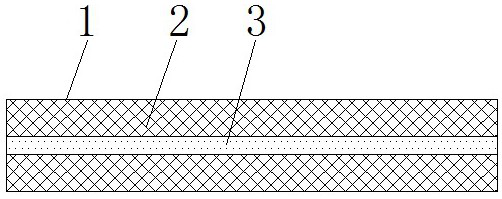

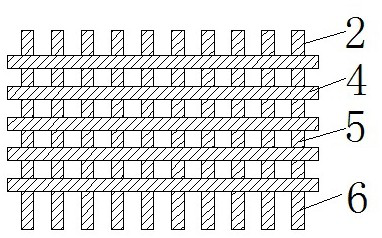

Waterproof breathable fabric compounding method

InactiveCN111688296AThe material is light and softGood use strengthLamination ancillary operationsControlling laminationPolyesterPolymer chemistry

The invention discloses a waterproof breathable fabric compounding method. A produced waterproof breathable fabric comprises a fabric body, the fabric body comprises two blended breathable layers anda macromolecule waterproof breathable material layer, the macromolecule waterproof breathable material layer is located between the two blended breathable layers, each blended breathable layer comprises blended wefts and blended warps, and the blended wefts and the blended warps both comprise cotton fibers and polyester fibers. According to the compounding method, the fabric body, the blended breathable layers, the macromolecule waterproof breathable material layer, the blended wefts, the blended warps, an antistatic coating, cotton fibers and polyester fibers are adopted, so that the fabric can achieve the effect of comfort in use and wearing; the fabric is lighter and softer in material and better in use strength, the fabric can be lighter and more comfortable for a user to wear by determining the use thickness of the blended breathable layers and the macromolecular waterproof breathable material layer, and the use strength and use flexibility of the fabric can be effectively ensuredby determining the use twist of the blended wefts and the blended warps.

Owner:SUZHOU QIYAN NEW MATERIAL TECH CO LTD

Preparation method of phenolic resin with cross-linked amino structure and application thereof

ActiveCN103265675AGood use strengthIncrease polarityOther chemical processesSolid sorbent liquid separationCross-linkFiltration

The invention discloses a preparation method of phenolic resin with a cross-linked amino structure, which comprises the following steps of: 1) dissolving phenol, paraformaldehyde and sodium hydroxide in ethylene glycol, heating and preserving heat, and adding paraformaldehyde and a polyamine compound to obtain a reaction phase; 2) preparing Tween80-containing turbine oil with mass concentration of 1% as a dispersion phase; and 3) mixing the dispersion phase and the reaction phase for polymerization reaction, and performing filtration, washing and extraction to obtain the target object. The prepared phenolic resin with a cross-linked amino structure is used for extracting a high-purity curcumin compound from turmeric. The method disclosed by the invention has the advantages that the phenolic resin has good strength in use, and the polarity of resin is improved due to the existence of phenolic hydroxyl; under the hydrogen bond effect of the phenolic resin, a high-purity turmeric extract can be obtained through a simple one-step technology of 'adsorption-elution'; and moreover, the production cost is low, the extraction efficiency is high, and the method is suitable for large-scale industrial production.

Owner:河北利江生物科技有限公司

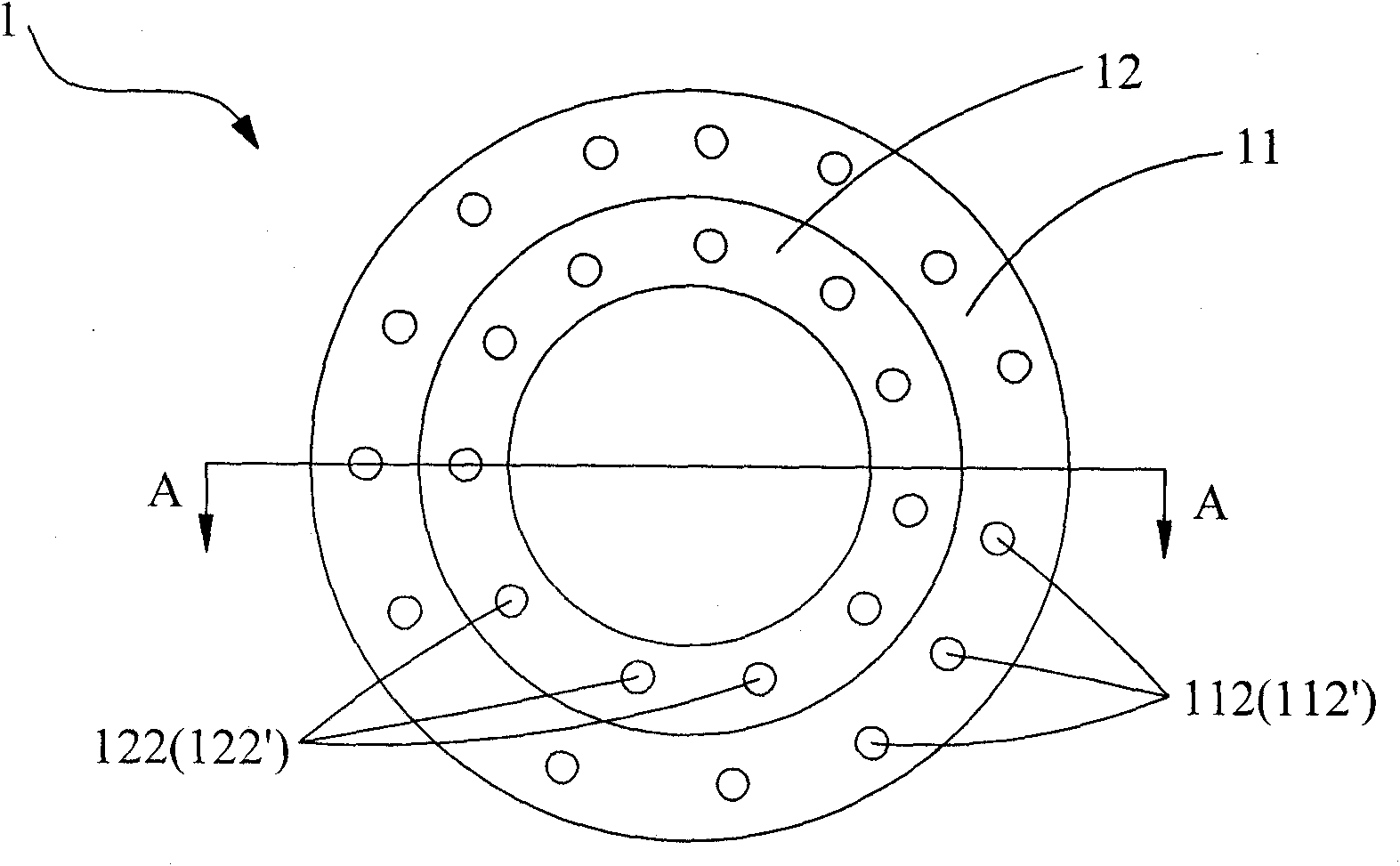

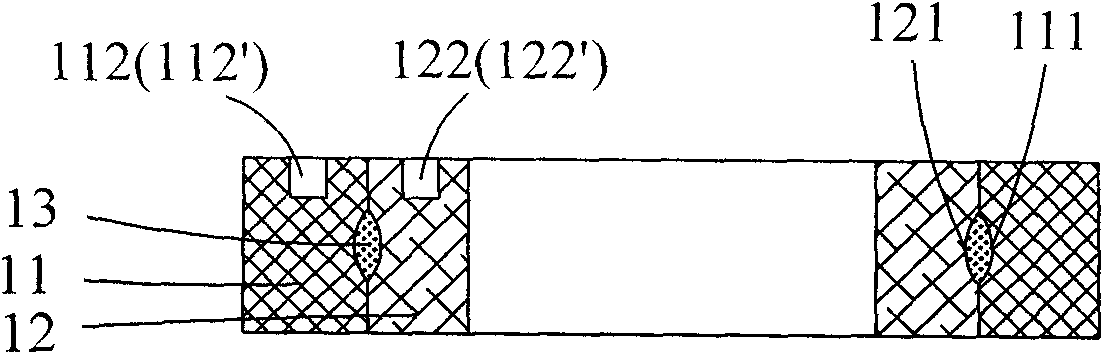

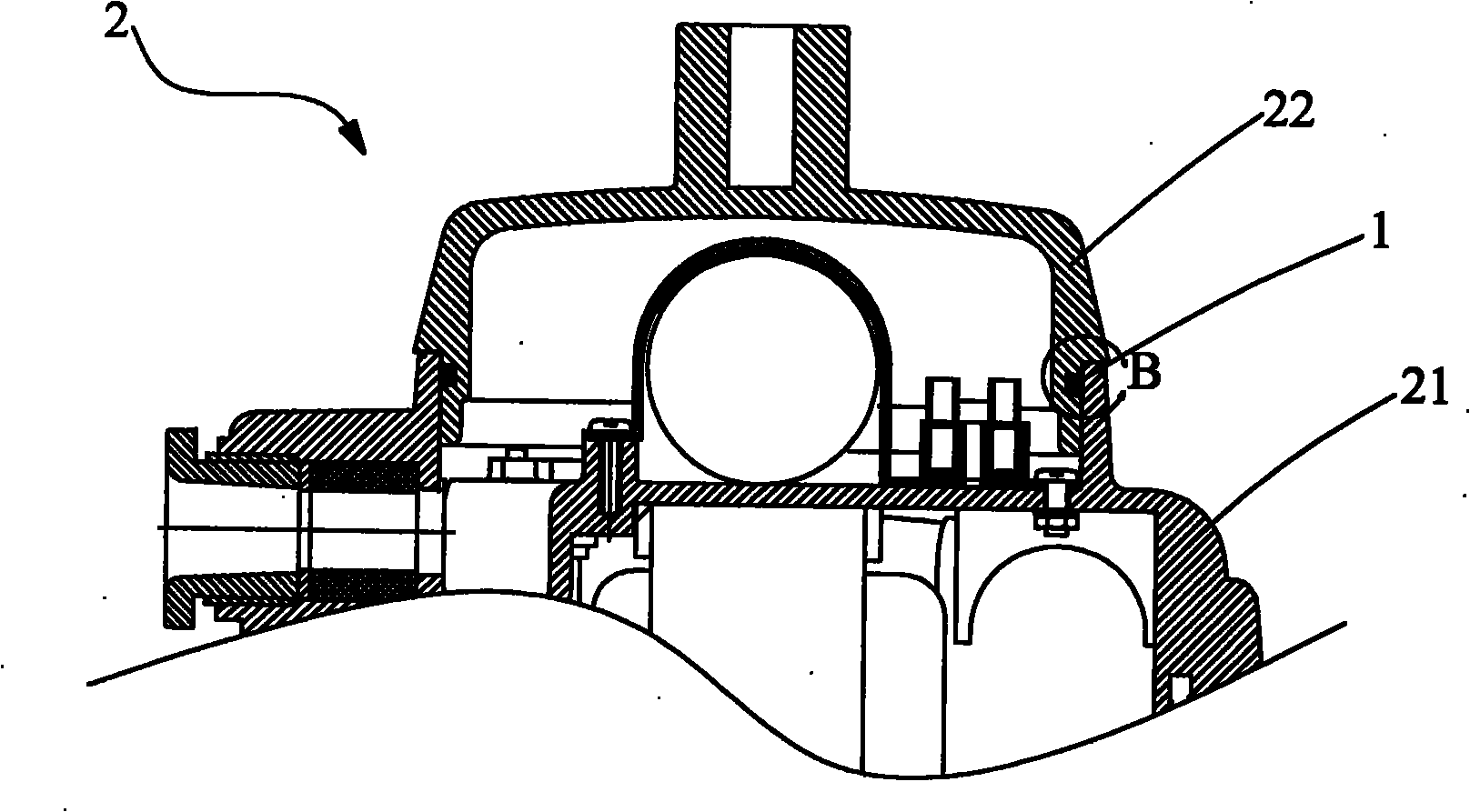

Sealing device for lamp

InactiveCN101858588AGuaranteed waterproof performanceAvoid damageGas-tight/water-tight arrangementsLubricationLubricant

The invention relates to a sealing device used for a lamp. The sealing device comprises a first sealing ring and a second sealing ring which are cooperatively used, wherein grooves are formed on both contact surfaces of the first sealing ring and the second sealing ring which are matched, and the grooves are formed full of lubricant. The sealing device for the lamp adopts two sealing rings, and compared with the prior art which adopts one sealing ring, the sealing device has the advantages that: the strength and the elasticity are higher due to the cooperatively used two sealing rings; the requirements on radial thickness or axial thickness of a single sealing ring of the two sealing rings are lower than those of the original one sealing ring; and the processing and the processing are easier. Simultaneously, the lubricant is filled between the two sealing rings; and therefore, on the one hand, the effect of sealing and waterproofing of the lamp is ensured, and on the other hand, the friction between the lamp and the two sealing rings are greatly reduced through the lubrication action of the lubricant when the lamp are disassembled, the lamp can be disassembled by only applying little force, time and labor are saved, damage on the sealing rings due to overstress in the disassembling is avoided, the service life of the sealing rings is prolonged, and the cost is saved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A Synthetic Process of High Temperature Corrosion Shock Resistant Alloy

The invention relates to the field of hard alloy processing, and particularly relates to a high-temperature corrosion resistant impact alloy synthesis process, aiming at solving the problem that the prior art can not guarantee relatively good impact resistance based on relatively good wear resistance. In the process provided by the invention, the tungsten carbide powder of medium and coarse particles is added, and the high-temperature corrosion resistant impact alloy is synthesized through the processes of common grinding, wet grinding, filtering, drying, secondary filtering, pressure sintering and the like. In the process provided by the invention, by adopting the tungsten carbide powder of medium and coarse particles, the impact alloy has perfect use strength and impact toughness at high temperature over 1,000 DEG C and also has good wear resistance and high-temperature oxidation corrosion resistance, the product has good stability, and the service life is prolonged by 1.5-2 times.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE CO LTD

Floor plate

Owner:刘向飞

Fireproof building coating, and preparation method thereof

InactiveCN107629559AWide variety of sourcesStrong surface adhesionFireproof paintsOther rubber coatingsCelluloseFiber

The invention discloses a fireproof building coating. The fireproof building coating is composed of, by weight, 0.6 to 3 parts of cellulose, 10 to 16 parts of ceramsite, 12 to 20 parts of an emulsion,16 to 24 parts of heavy calcium carbonate, 8 to 16 parts of diatomite, 80 to 120 parts of waste rubber, 36 to 60 parts of polypropylene, 8 to 12 parts of zeolite powder, 3 to 6 parts of paraffin, 6 to 10 parts of glass bead, 2 to 4 parts of talcum powder, 2 to 6 parts of bamboo fiber, 1 to 2 parts of a water repellent, 1 to 3 parts of an antifoaming agent, 2 to 5 parts of a dispersant, 5 to 9 parts of guar gum, 10 to 15 parts of lemon, and 4 to 10 parts of Chinese herbaceous peony. The invention also discloses a preparation method and an application method of the fireproof building coating. The fireproof building coating is high in surface adhesive force, possesses excellent fire resistance, weatherability, and using strength, and is capable of satisfying using requirements of people.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

Anti-corrosion and anti-cracking process for furniture plates

InactiveCN112898903AImprove anti-corrosion performanceImprove crack resistanceAntifouling/underwater paintsPaints with biocidesMeth-Physical chemistry

The invention discloses an anti-corrosion and anti-cracking process for furniture plates. The process comprises the following steps: uniformly adding a water-based resin, acrylic emulsion, a wetting agent, methyl n-amyl ketone, a dispersing agent and graphene oxide into a high-speed stirrer, and carrying out high-speed mixing and stirring at a rotating speed of 200-500 r / min for 20-30 min to obtain a mixture; putting the mixture into a reaction kettle, adding a defoaming agent, water, a film forming aid and a preservative, fully mixing and stirring, and carrying out heating and mixing treatment for 40-60 min at a temperature of 45-60 DEG C and a mixing speed of 500-600 r / min to obtain an anti-corrosion environment-friendly paint for standby application; and carrying out rough machining treatment on a to-be-treated plate. According to the present invention, the corrosion resistance is high, the use strength is good, the plate has characteristics of high corrosion resistance and good anti-cracking effect, and can be used in the low-temperature environment and the high-temperature environment, the cracking phenomenon generated after thermal expansion and cold contraction is effectively avoided, and the water-based resin is adopted as the main material so as to provide the good environmental protection effect during the use without damaging the environment and the human body.

Owner:湖南崀山家俱有限公司

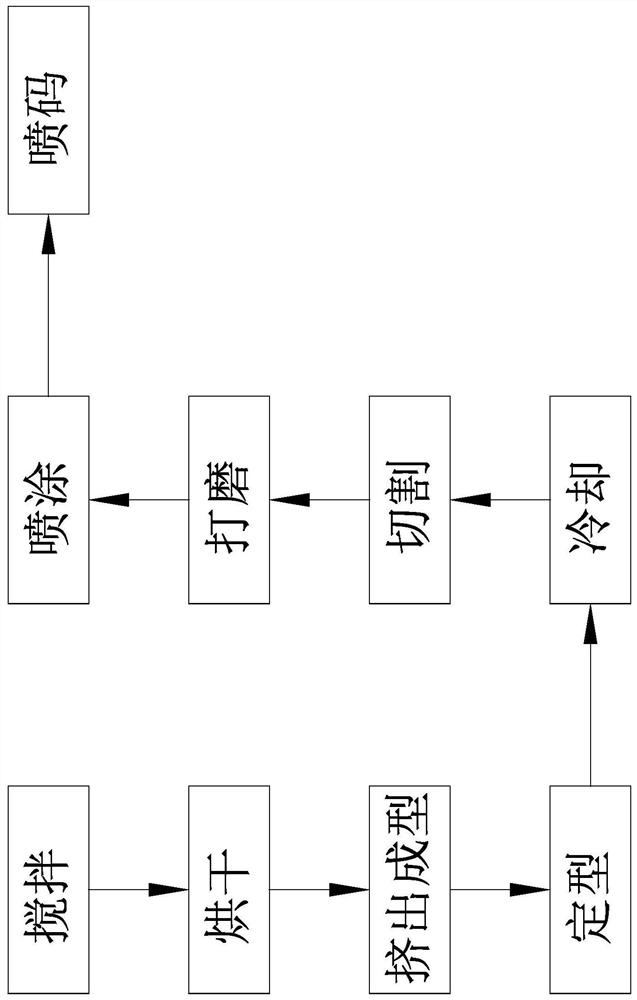

Manufacturing method of high-strength anti-aging cable protection pipe

InactiveCN111941889AImprove protectionFast preparationEdge grinding machinesElectrical apparatusMasterbatchPlasticizer

The invention provides a manufacturing method of a high-strength anti-aging cable protection pipe. The manufacturing method comprises the following steps of a, stirring, wherein 100 parts of high-density polyethylene resin, 0.8-2.2 parts of an antioxidant, 1-4 parts of a lubricating agent, 0-40 parts of a filling agent, 6-20 parts of a plasticizer, 0.5-1.5 parts of a stabilizer and 4-8 parts of color masterbatch are weighed and placed into a stirrer for stirring treatment; b, drying, wherein a mixture is dried through a drying machine; c, extrusion and molding, wherein extrusion treatment of the mixture is carried out through an extruder, and the mixture enters a mold for molding treatment after extrusion; d, shaping, wherein shaping treatment of a semi-finished pipe is carried out; e, cooling, wherein the semi-finished pipe is cooled through cooling equipment; f, cutting, wherein the semi-finished pipe is cut through slitting equipment; g, polishing, wherein an end opening of the semi-finished pipe is polished through an end opening polishing device; h, spraying, wherein surface spraying treatment of the semi-finished pipe is carried out through a surface treatment device; and i,code spraying, wherein code spraying treatment of the semi-finished pipe is carried out through an automatic code spraying machine.

Owner:浙江振飞塑业有限公司

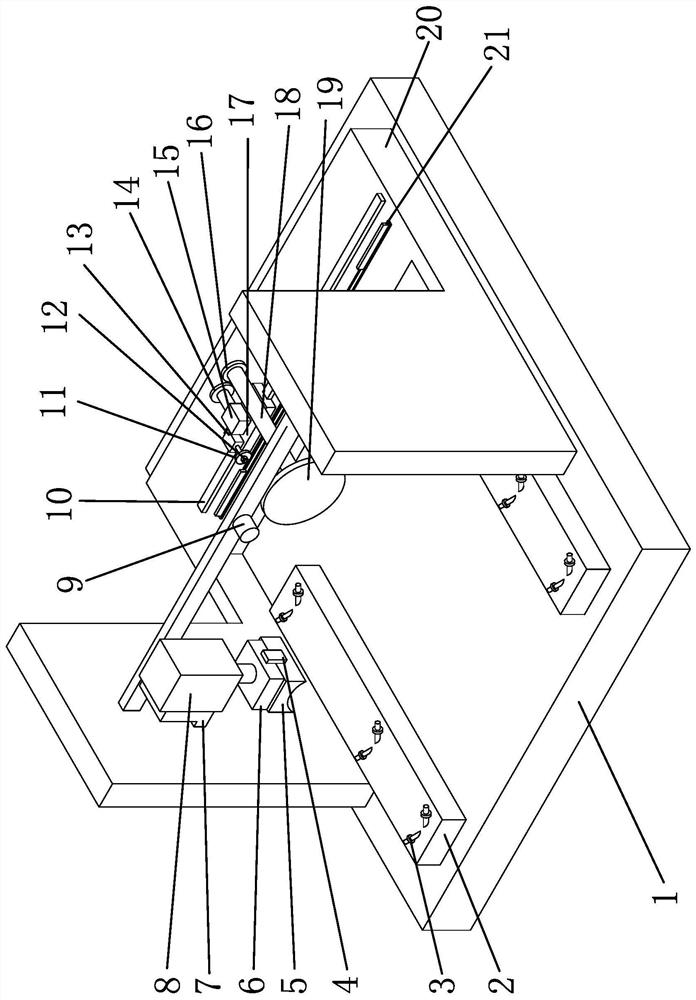

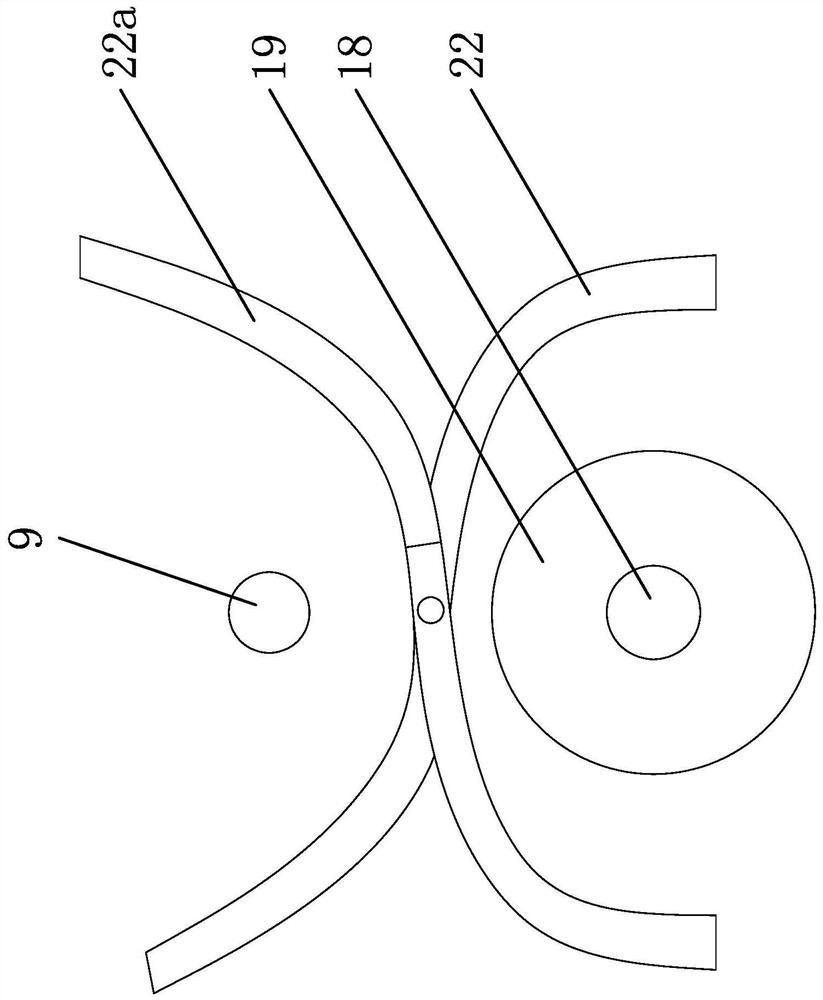

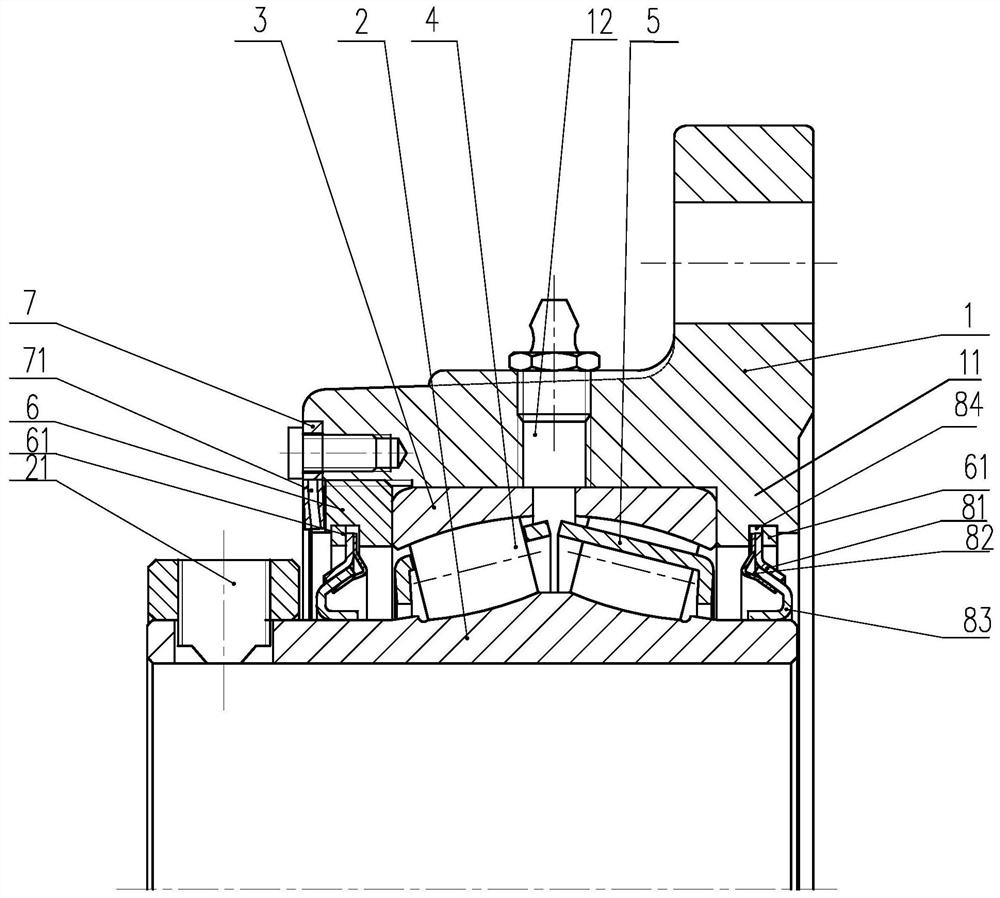

Self-aligning roller bearing capable of adjusting clearance

InactiveCN112610600AEasy to installPrevent deviationRolling contact bearingsBearing componentsEngineeringStructural engineering

The invention discloses a self-aligning roller bearing with an adjustable clearance. The self-aligning roller bearing comprises a bearing seat, and an inner ring and an outer ring which are coaxially arranged, wherein a positioning step is formed at one end of the bearing seat, the outer ring is arranged in a split mode to form two outer sub-rings, the two outer sub-rings are both installed on the bearing seat, one outer sub-ring abuts against the positioning step, roller paths are arranged at the positions, corresponding to the two outer sub-rings, of the outer wall of the inner ring, retainers are arranged between the two outer sub-rings and the inner ring, rollers are arranged in the retainers and rotationally matched with the roller paths, the other end of the bearing seat is in threaded fit with an adjusting check ring, the adjusting check ring abuts against the side walls of the outer sub-rings, a pressing ring used for fastening the adjusting check ring is further arranged on the bearing seat, and dustproof covers are arranged between the positioning step and the inner ring and between the pressing ring and the inner ring. The clearance is convenient to adjust, and meanwhile, the structure is simple, operation is convenient and fast, and the use effect of the product is improved.

Owner:C&U CO LTD +1

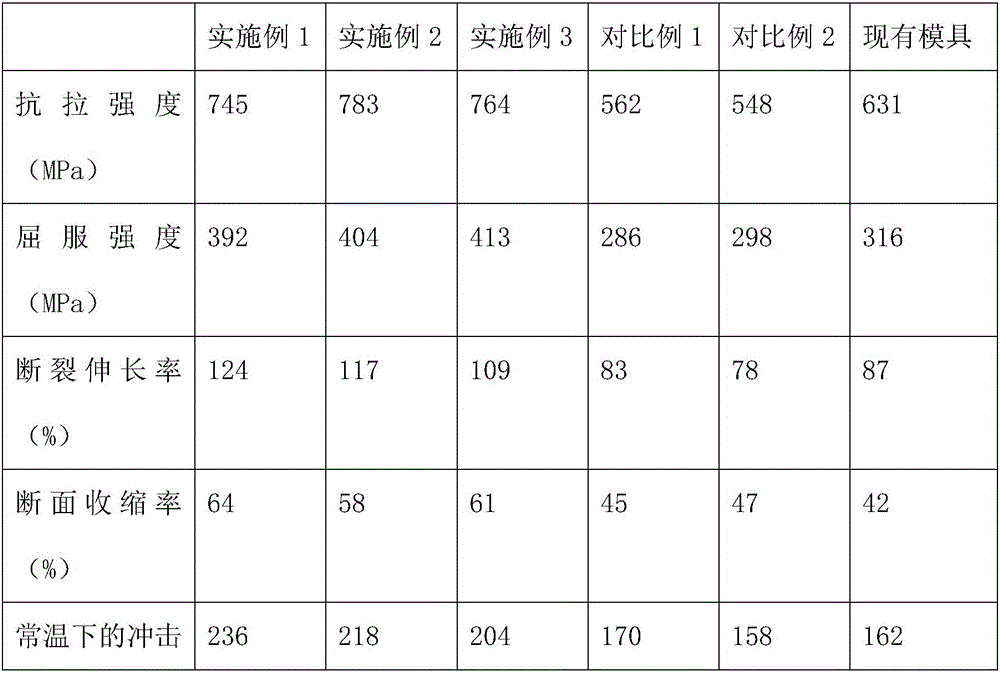

Automobile die manufacturing process

The invention discloses an automobile die manufacturing process which comprises the following steps: 1, putting die steel into a smelting furnace, adding silicon carbide fiber and glass fiber into the smelting furnace, heating a mixture in the smelting furnace, and then carrying out a series of thermal treatment; 2, placing the mixture in the smelting furnace into liquid nitrogen for treatment for 3 to 6 hours, and carrying out carburizing treatment on the surface of the mixture; 3, designing the shape and the size of a die through three-dimensional software; 4, machining the die steel through a numerical control machine tool, and polishing the excircle through a grinding machine to obtain the smoothness and the size of the die; 5, treating the machined die; and 6, carrying out finish milling and die repairing on the die subjected to thermal treatment to obtain a finished product. The manufacturing process disclosed by the invention is simple; the production period of the existing automobile die is greatly shortened; the manufactured die is high in use strength and high in wear resistance and use flexibility; and the service life of the product is greatly prolonged.

Owner:JIANGSU YUYAN MOLDING CO LTD

Glass wool used for AGM separating plate

The invention relates to the technical field of basic electric elements, in particular to glass wool used for an AGM separating plate. The glass wool used for the AGM separating plate is prepared fromthe following raw materials in parts by weight: 80-120 parts of compound glass wool fiber yarns, 10-20 parts of a binder and 2-7 parts of a corrosion inhibitor. The glass wool used for the AGM separating plate is high in purity and good in mechanical strength and chemical stability and has good acid and base resistance and high use intensity, and the AGM separating plate prepared by adopting theglass wool used for the AGM separating plate has relatively good usability in a lead-acid storage battery.

Owner:ZHEJIANG CHANGTONG SCI & TECH

Machining process of linear guide

The invention discloses a machining process of a linear guide. The process comprises the following steps of firstly, selecting a corresponding number of steel raw materials according to the material demand of a product, and then extruding the selected steel raw materials into a profile; cutting the profile into a plurality of sections of guide rails according to the requirements of a drawing, and then machining two sides of the guide rails through a multi-shaft different cutter to form chutes; then putting the guide rails obtained in the above-mentioned step into a heating furnace to be heated to 800-1000 DEG C, conducting heat preservation for 1-3 h, then cooling the guide rails to 200-220 DEG C, conducting heat preservation for 1-2 h, and finally cooling the guide rails to the room temperature; and then grinding and scraping the guide rails obtained in the above-mentioned step firstly to obtain the guide rails conforming to machining parameters, and then conducting galvanization treatment. By adopting the machining process designed by the invention, the linear guide can have good use strength and mechanical performance, the machining process is simple and efficient, meanwhile, the machined linear guide is high in precision, the quality of the guide rail is guaranteed, the service life is prolonged, and the requirements of customers can be met.

Owner:丽水市东远轴承科技有限公司

Glazing cement and preparation technology thereof

The invention discloses glazing cement. The glazing cement is prepared from, by weight, 20-30 parts of inorganic gel, 2-6 parts of reinforced fibers, 4-6 parts of calcium oxide, 3-5 parts of magnesiumoxide, 3-5 parts of potassium oxide, 1-3 parts of basic cupric carbonate, 8-10 parts of organic modified resin, 2-4 parts of calcium carbonate, 5-7 parts of modified tourmaline powder, 8-10 parts ofepoxy resin, 10-15 parts of iron ore powder, 20-30 parts of clay, 20-30 parts of fluorgypsum, 30-40 parts of river sand, 10-12 parts of a cement reinforcing agent, 0.5-1.5 parts of a retarder, 1-3 parts of a modifying agent, 2-4 parts of a coupling agent, 1-3 parts of an adjusting agent, 0.5-1.5 parts of a water reducer and 0.5-1.5 parts of a flexibilizer. The glazing cement is simple in preparation method, labor hours and energy consumption are reduced, the cost is reduced, and the glazing cement is good in prospect when used for architecture.

Owner:河南中釉环保科技有限公司

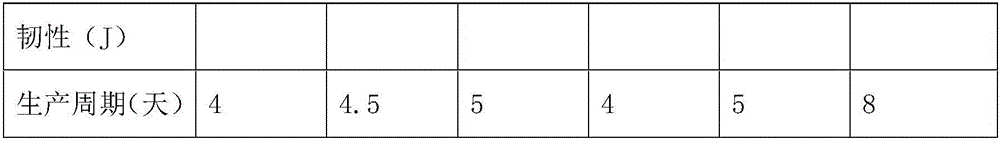

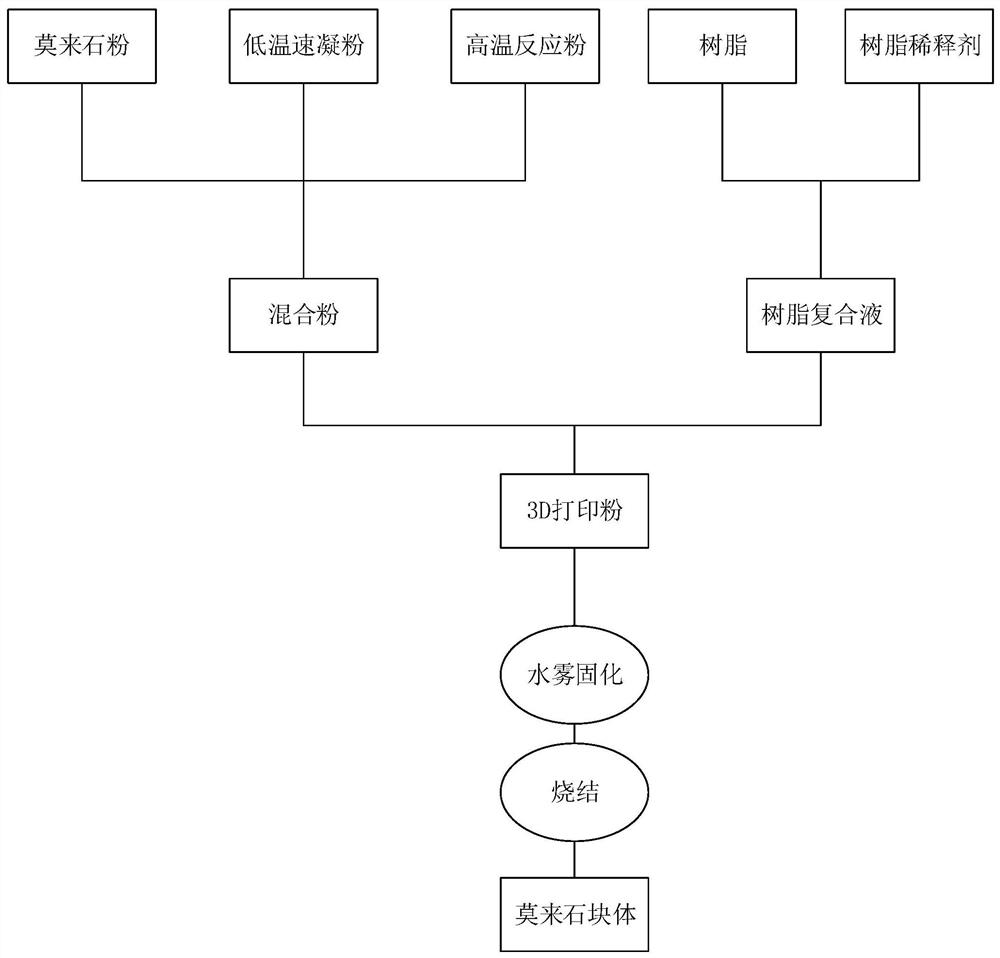

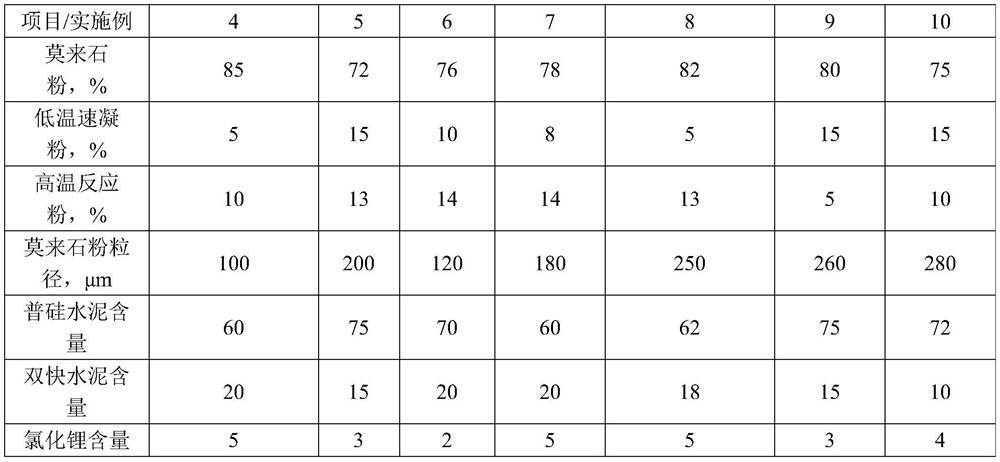

Mullite mixed powder and preparation method thereof, and application in 3D printing

ActiveCN111943690AGood environmental effectThe preparation method is simple and easy to obtainAdditive manufacturing apparatus3d printMullite

The invention discloses mullite mixed powder and a preparation method thereof, and application in 3D printing. In the application process, 3D printing forming of complex shapes of mullite blocks is achieved through layered water mist curing of mixed mullite powder in a 3D manner, and finally high-temperature reaction powder reacts with the mullite powder at a high temperature to obtain the porousmullite body with certain strength. According to the method, porous mullite crystals are prepared by adopting a mode of combining 3D printing with sintering, and accurate control of shape and performance parameters is realized by controlling component differences in 3D printing powder. In the 3D printing process, water is adopted as a 3D printing curing agent, so that the forming mode is simple and environmentally friendly.

Owner:山西高速公路工程检测有限公司 +2

Two-component odor-removing hollow glass silicone sealing glue

InactiveCN108070339AFully crosslinkedImprove rheologyNon-macromolecular adhesive additivesCross-linkDibutyltin dilaurate

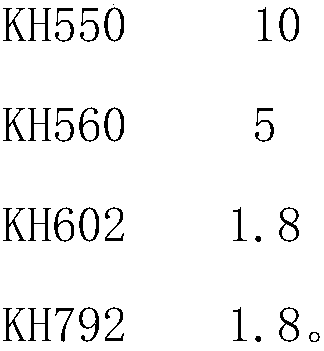

The invention relates to a two-component odor-removing hollow glass silicone sealing glue, which is prepared by mixing a component A and a component B. In the prior art, auxiliary agents such as KH550, KH560, KH602 and KH792 and a glue are mixed so as to be used. According to the present invention, the technology is different from the prior art, and comprises: carrying out mixing cross-linking onthe four components such as KH550, KH560, KH602 and KH792 so as to completely perform cross-linking, and dibutyltin dilaurate is added to the component B, such that the product of the present invention has advantages of good odor removing effect and strong bonding strength, wherein the detection results show that the content of methanol, ethanol and other small molecule alcohol substances is about1%, and the bonding strength can achieve 0.86 MPa while the film plating glass bonding strength of the existing ketoxime type silicone glue is only 0.46 MPa; and the two-component odor-removing hollow glass silicone sealing glue is economical, environmentally friendly, safe and effective, and is suitable for promotion, production and use.

Owner:TIANJIN HONGTAI GLASS CO LTD

Preparation method of insulation thermal-conductive canvas

The invention discloses a preparation method of insulation thermal-conductive canvas. The method is characterized by comprising the following preparation steps: step 1, performing twill weaving on polyester fibers by using a braiding machine, wherein the polyester fibers adopt 50-100 D of filaments; step 2, mixing a polyamide hot melt adhesive and phenolic resin according to a mass ratio of the polyamide hot melt adhesive to the phenolic resin of (3-5):1, placing the obtained mixture in a beaker, performing melting under heating and stirring, and performing uniform mixing to obtain an adhesivefor standby application; step 3, preparing a polyimide film insulation layer material; and step 4, performing bonding. The method provided by the invention modifies the technical problem that a current conductor protective layer has a low service life, is greatly affected by the environment, easily accumulates internal energy and cannot release the internal energy in time; and the insulation conductor canvas prepared by adopting the method is an excellent heat conductor, polyester canvas is compounded with a polyimide film, so that the insulation conductor canvas has higher insulation performance, and at the same time, the polyester canvas has better strength during use to prevent a conductor from being stretched and deformed under external force.

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

Cement pile material composition containing rice husks and crushed stone and preparation method of cement pile containing rice husks and crushed stone

The invention discloses cement pile material composition containing rice husks and crushed stone and a preparation method of a cement pile containing the rice husks and the crushed stone. The composition comprises cement, fly ash, the rice husks, plant ash, white glue, the crushed stone and water; in terms of 100 parts by weight of the cement, the composition comprises 20-70 parts of the fly ash, 10-50 parts of the rice husks, 5-30 parts of the plant ash, 10-30 parts of the white glue, 1-10 parts of the crushed stone and 50-100 parts of the water. The cement, the fly ash, the rice husks, the plant ash, the white glue, the crushed stone and the water are mixed and put into a mold for molding, the cement pile is prepared, so that the cement pile prepared from the materials which are mixed and put into the mold have natural components, and accordingly, the cement pile has less environmental pollution during actual use, still has higher use strength during use and has greatly improved applicability to the environment.

Owner:ANHUI WUHU FLY QI CEMENT PROD

Odorless silicone sealant

ActiveCN103131380BFast curingGood use strengthNon-macromolecular adhesive additivesOther chemical processesPolymer scienceVulcanization

The invention relates to odorless silicone sealant. The technical scheme is as follows: the odorless silicone sealant is prepared from the following raw materials in percentage by weight: 76-80% of modified room temperature vulcanized silicon rubber, 9-12% of gas-phase silicon dioxide, 7-9% of dimethyl silicon oil, 0.8-1% of crosslinking agent, 1.4-1.6% of titanium complex, 0.06-0.1% of catalyst and 0.8-1% of coupling agent. The silicone sealant provided by the invention causes no corrosion, can only release about 1% of small-molecule alcohol substances (methanol and ethanol) in the curing process, has low odor and is environment-friendly.

Owner:LIAONING LVSHI CHEM GROUP

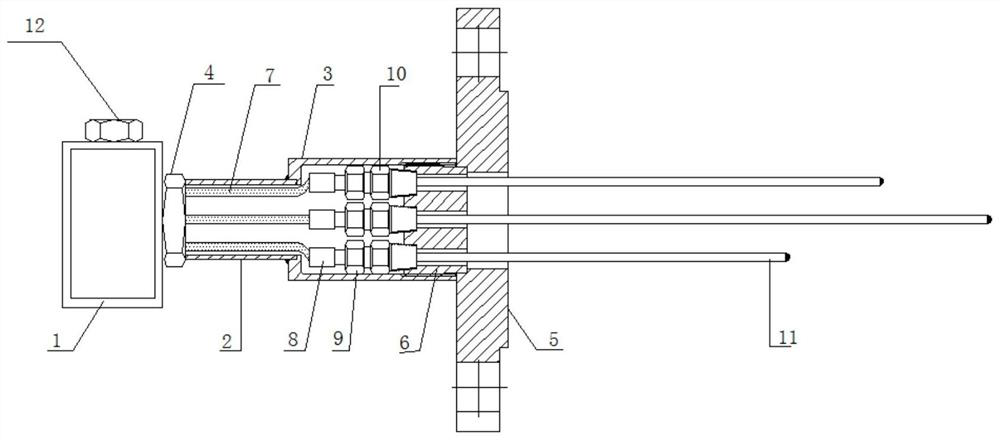

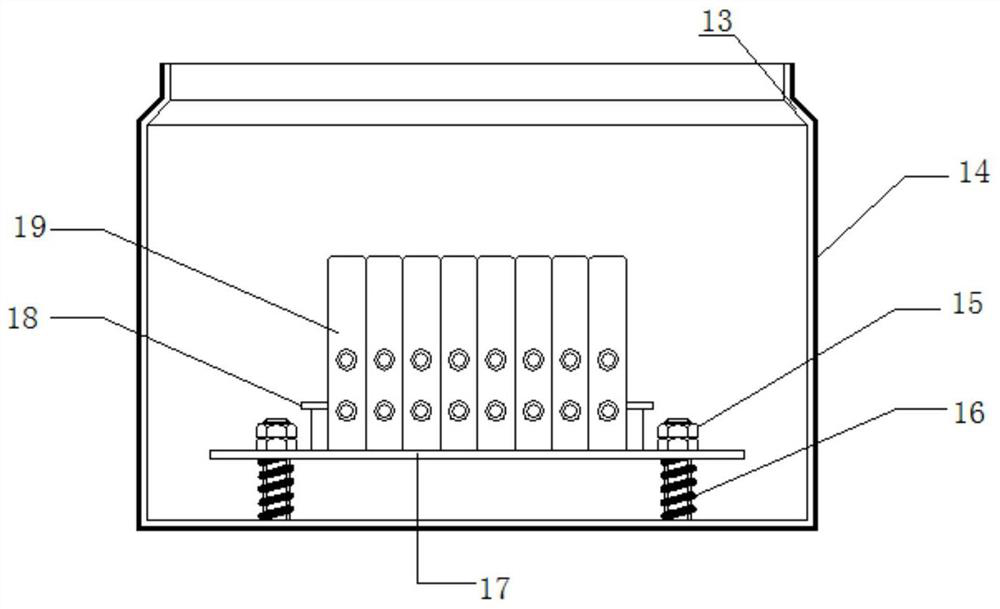

Special multi-point temperature measuring device for adsorption tower

PendingCN113252200AEasy to bundleQuick releaseThermometer detailsThermometers using electric/magnetic elementsThermistorTower

The invention discloses a special multi-point temperature measuring device for an adsorption tower, and the device comprises a junction box, a connecting pipe which is connected to the outer wall of one end of the junction box through a locking nut, a connecting sleeve A which sleeves the tail end of the connecting pipe, and a flange which is connected to the tail end of the connecting sleeve A. A connecting sleeve B is clamped between the connecting sleeve A and the flange. Threaded holes distributed at equal intervals are formed in one end of the connecting sleeve B, temperature measuring components are inserted into the threaded holes, a wire is arranged in the connecting pipe, and a protective cap is connected to one end of the wire in a pressing mode. Compared with a traditional single-point temperature measuring device, the temperature measuring device only needs one set of fixing equipment and one temperature measuring pipeline, signal lines of the temperature measuring device are convenient to bundle, the adsorption tower is cleaner, disassembly and maintenance are convenient, corrosion resistance is high, anti-seismic performance is high, external moisture and dust can be isolated, the internal structure can be effectively protected, and by adopting the non-winding platinum thermistor element, the service life is greatly prolonged, and the anti-seismic property is greatly improved.

Owner:重庆迪洋仪表有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com