Mullite mixed powder and preparation method thereof, and application in 3D printing

A technology of mullite powder and mixed powder, applied in the direction of additive processing, can solve the problems of poor environmental protection performance of resin-based materials and high cost of light curing, and achieve the effect of good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

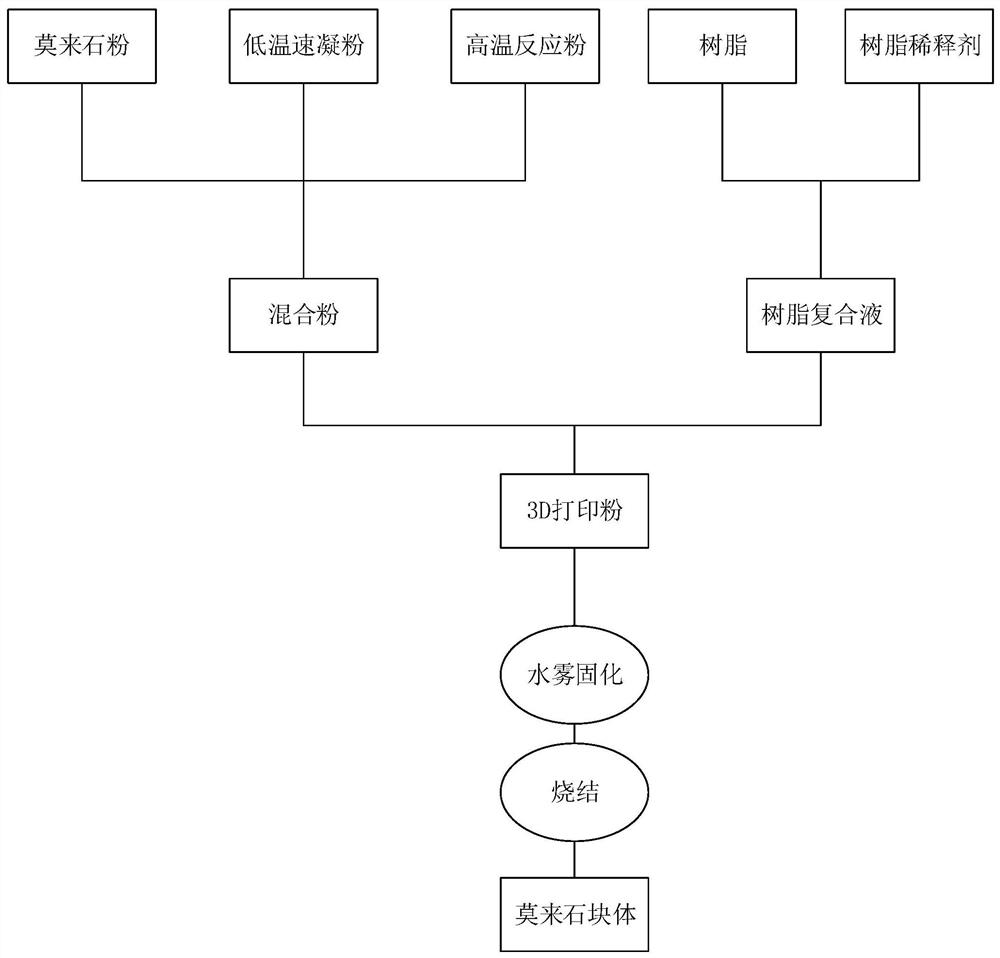

[0023] The invention discloses a mullite mixed powder and its preparation method and its application in 3D printing. It is a water-based solidified 3D printing mullite mixed powder and a 3D printing method. The method comprises the following steps:

[0024] Step 1, mix and dry

[0025] Mix mullite powder, low-temperature quick-setting powder and high-temperature reaction powder according to the mass ratio of 70% to 85%, 5% to 15% and 5% to 15%, and the ratio of the three is 100%. Dry in medium for more than 24h at a temperature of 80°C to prepare a mixed powder.

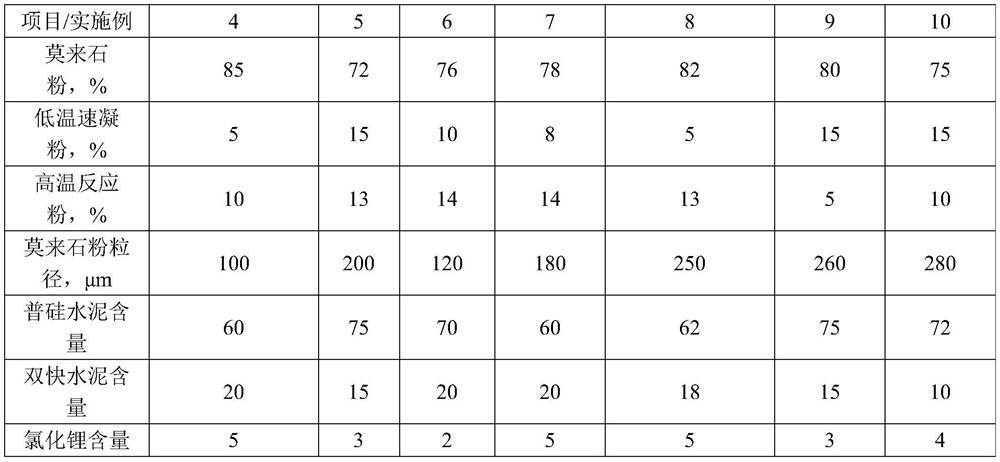

[0026] Among them, the mullite powder is the powder obtained by ball milling after sintering and heat preservation at 1500°C for 2 hours. The particle size of the powder is 100-300 μm. The mixed powder composed of sodium has a mass ratio of 60-75%, 10-20%, 2-5%, 1-8%, 4-7%.

[0027] The high-temperature reaction powder is composed of metal lithium, aluminum powder and silicon powder, wherein the mass proportion of ...

Embodiment 1

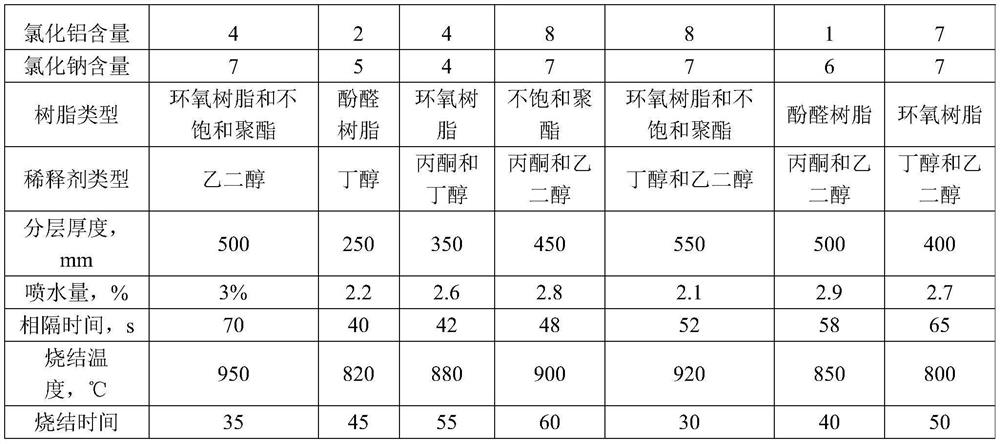

[0034] The proportions of mullite powder, low-temperature quick-setting powder, and high-temperature reaction powder are 70%, 15%, and 15% respectively. Mullite powder is ball milled after sintering at 1500°C, and the particle size of the powder is 150 μm. After the three powders are mixed, they must be dried in a drying oven for more than 24 hours at a temperature of 80°C. Low-temperature quick-setting powder is a mixed powder composed of ordinary silicon cement, double-fast cement, lithium chloride, aluminum chloride, and sodium chloride, and its proportions are 65%, 20%, 5%, 3%, and 7%. . The high-temperature reaction powder is mainly composed of lithium-aluminum-silicon-based glass powder, wherein the mass fraction of aluminum is 15%. Glass powder particle size 2mm. Mullite mixed powder, low-temperature quick-setting powder, and high-temperature reaction powder are granulated through resin mixed liquid. The resin is a composite resin of phenolic resin and epoxy resin. Th...

Embodiment 2

[0036]The proportions of mullite powder, low-temperature quick-setting powder, and high-temperature reaction powder are 75%, 10%, and 15% respectively. The mullite powder is obtained by ball milling after sintering at 1500°C, and the particle size of the powder is 230 μm. After the three powders are mixed, they must be dried in a drying oven for more than 24 hours at a temperature of 80°C. Low-temperature quick-setting powder is a mixed powder composed of ordinary silicon cement, double-fast cement, lithium chloride, aluminum chloride, and sodium chloride, and its proportions are 75%, 10%, 5%, 3%, and 7%. . The high-temperature reaction powder is mainly composed of lithium-aluminum-silicon-based glass powder, wherein the mass fraction of aluminum is 18%. Glass powder particle size 0.5μm. Mullite mixed powder, low-temperature quick-setting powder, and high-temperature reaction powder are granulated through resin mixed liquid. The resin is a composite resin of phenolic resin a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com