High-permeability diversion layer material and preparation method thereof

A permeability and diversion layer technology, applied in the field of high permeability diversion layer materials and their preparation, can solve the problems of poor instantaneous suction effect, poor diversion performance, poor permeability, etc. Good drainage and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

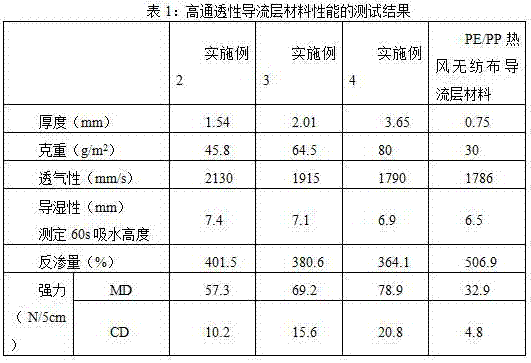

Examples

Embodiment 1

[0030] (1) The hydrophilic bi-component fiber and the water-repellent bi-component fiber with a fineness of 1.1-3D and a length of 38-51mm are divided into hydrophilic bi-component fibers: the water-repellent bi-component fiber is 50 - Blending at a ratio of 70:30-50, after feeding, opening, mixing and carding processes, after being stripped by a doffer, the cotton is stripped by a stripping roller (not passing through a condensing roller) to form the bottom fiber of a straight-laid network structure net, the grammage of the bottom fiber web is 10.8-20g / m 2 .

[0031] (2) The hydrophilic bicomponent fibers with a fineness of 1.5-3D and a length of 51mm and the hydrophilic special-shaped cross-section fibers of 4-6D and a length of 64-75mm are divided into hydrophilic bicomponent fibers: special-shaped Cross-sectional fibers are blended at a ratio of 25-40:60-75. After feeding, opening, mixing, carding, and upper and lower double doffer stripping processes, a fiber web layer w...

Embodiment 2

[0039] 1. Preparation of fiber raw materials

[0040] 1) Bottom fiber web fiber raw material

[0041] Choose PE / PP hydrophilic two-component fiber, the fineness is 1.1D, the length is 38mm, the content of hydrophilic oil agent on the surface of the fiber is 1.8%, and the PE / PP water-repellent two-component fiber is selected, the fineness is 3D, The length is 51mm, the content of water-repellent oil agent on the fiber surface is 1%, and the mixing ratio of PE / PP hydrophilic bi-component fiber and PE / PP water-repellent bi-component fiber is 50: 50;

[0042] 2) Fiber raw material of the upper layer web

[0043] Use PE / PP hydrophilic bi-component fiber with a fineness of 1.5D and a length of 51mm. The content of hydrophilic oil agent on the surface of the fiber is 1.8%. Use polyester special-shaped cross-section fiber with a fineness of 4D and a length of 64mm. The number is 3, the content of hydrophilic oil agent on the surface of the fiber is 0.2%, and the blending ratio is 25...

Embodiment 3

[0053] 1. Preparation of fiber raw materials

[0054] 1) Bottom fiber web fiber raw material

[0055] Choose PE / PET hydrophilic two-component fiber, the fineness is 2.2D, the length is 51mm, the content of hydrophilic oil agent on the surface of the fiber is 1%, choose PE / PP water-repellent two-component fiber, the fineness is 2.2D , length is 51mm, fiber surface water repellent oil agent content is 2%, according to the mixing ratio of PE / PP hydrophilic bicomponent fiber and PE / PP water repellent bicomponent fiber is 60: 40 blending;

[0056] 2) Fiber raw material of the upper layer web

[0057] Use PE / PET hydrophilic bi-component fiber with a fineness of 2.2D and a length of 51mm. The number is 5, the content of hydrophilic oil agent on the surface of the fiber is 0.38, and the blending ratio is 35:65 according to the mixing ratio of hydrophilic two-component fiber: special-shaped cross-section fiber;

[0058] 2. Preparation of bottom fiber web and upper layer fiber web

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com