Patents

Literature

88results about How to "Strong surface adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based liquid rubber waterproof paint and preparation method thereof

InactiveCN103965783AStrong surface adhesionImprove stabilityConjugated diene hydrocarbon coatingsChloropene polymer coatingsWater basedMagnesium salt

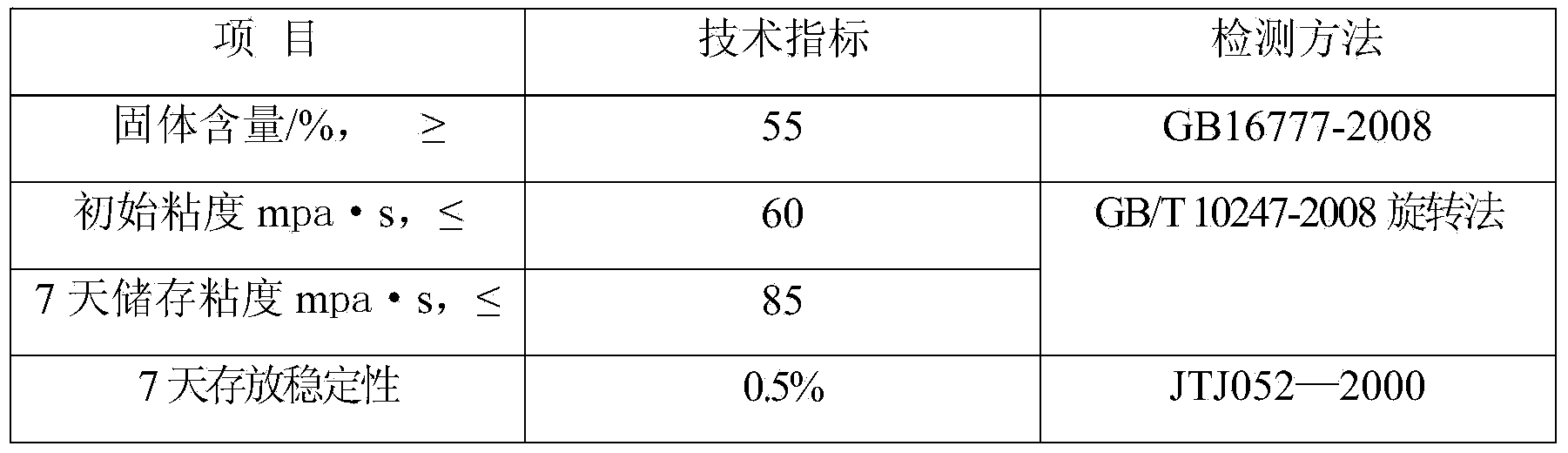

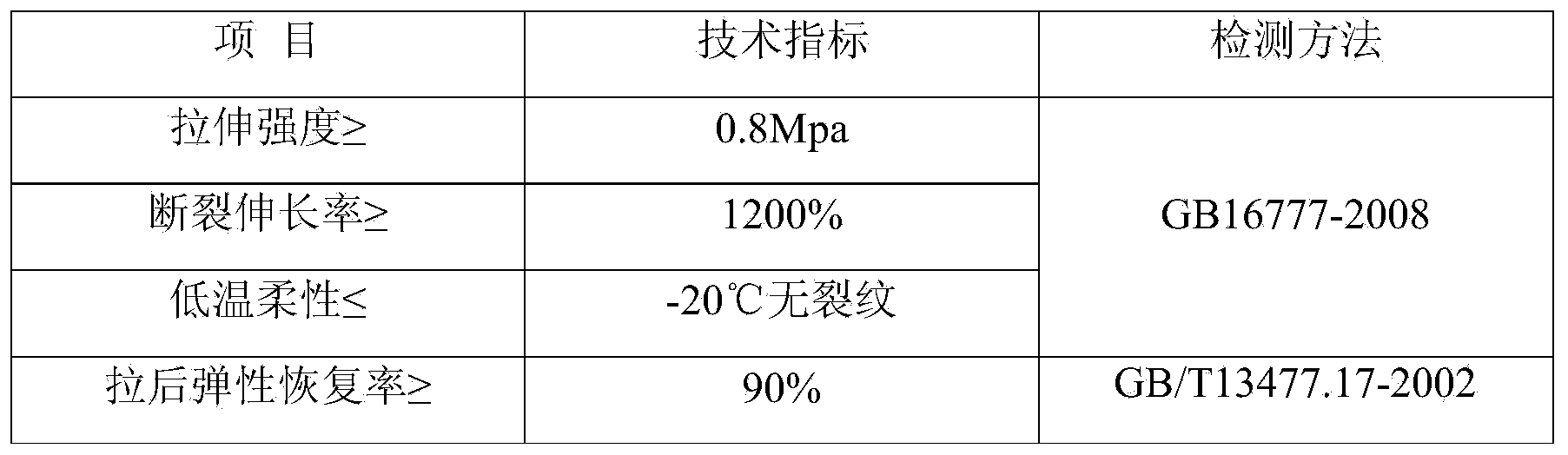

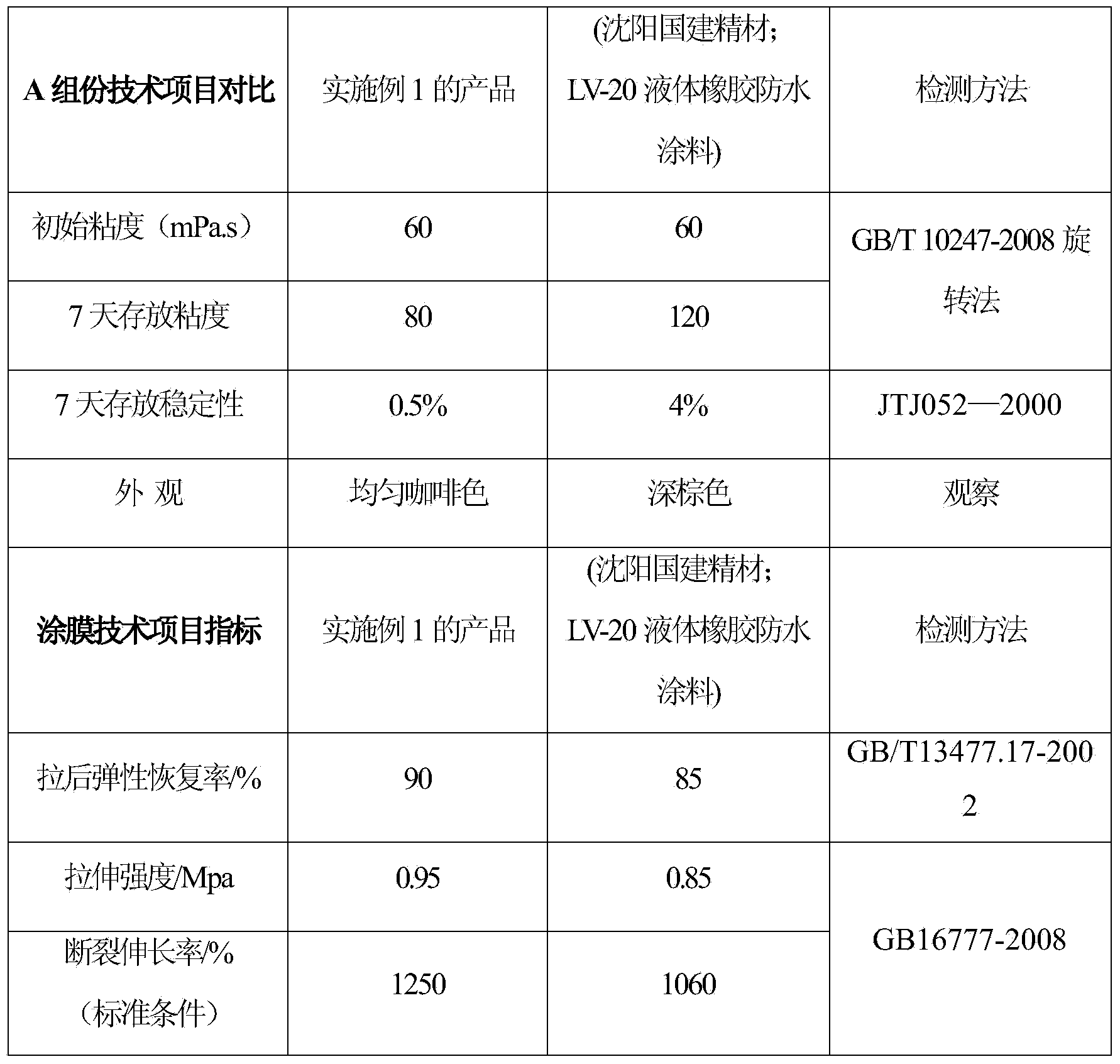

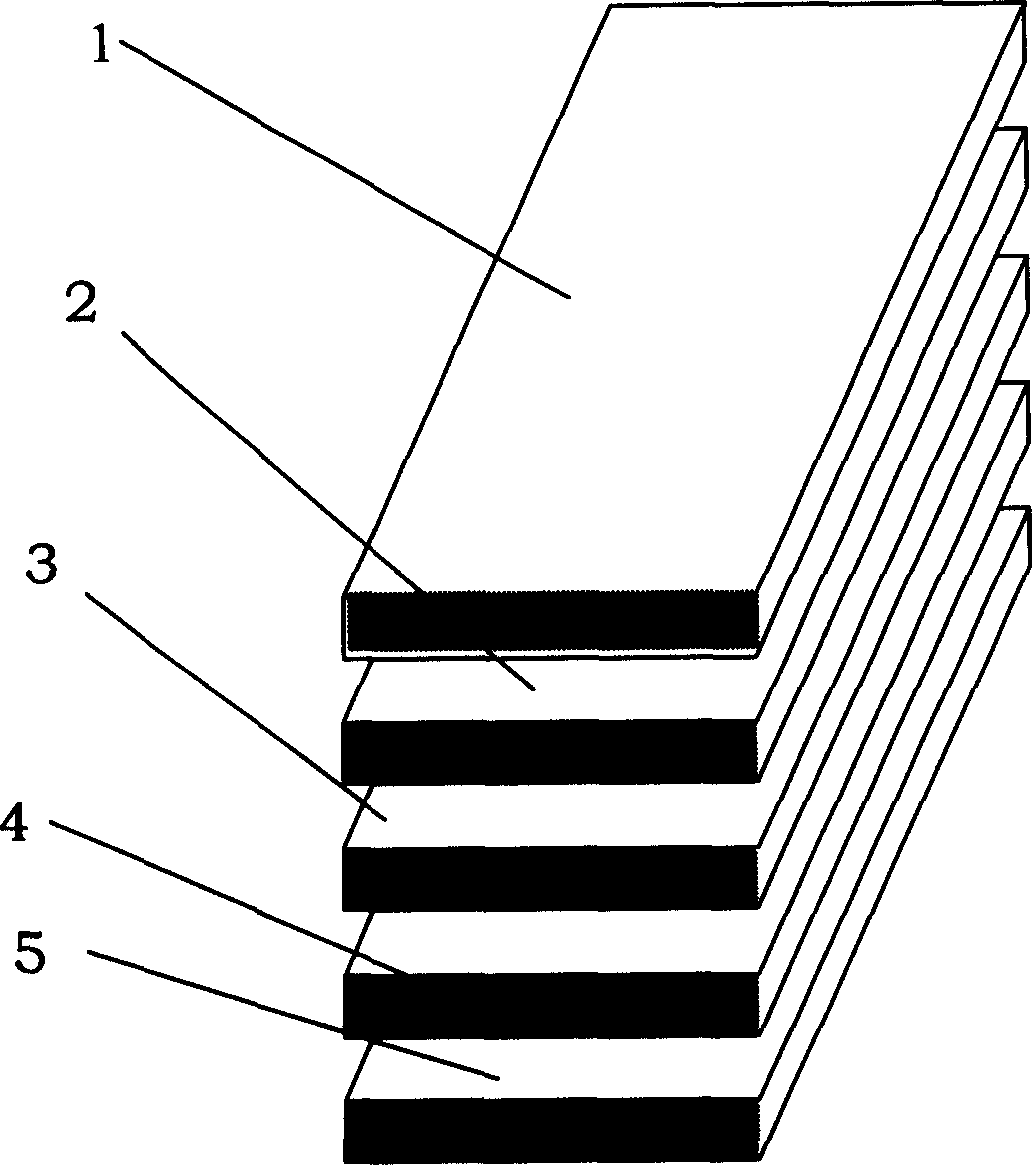

The invention discloses a water-based liquid rubber waterproof paint, comprising a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 35-65 parts of emulsified asphalt, 5-40 parts of chloroprene rubber emulsion, 5-40 parts of styrene-butadiene latex, 0.1-10 parts of polyvinyl alcohol (PVA) stabilizer, 0.1-5 parts of anionic dispersant, 0.1-5 parts of defoamer and 0.1-10 parts of pH modifier; the component B comprises the following raw materials in parts by weight: 75-95 parts of water and 5-25 parts of soluble calcium salt and magnesium salt. The water-based liquid rubber waterproof paint belongs to a water-based dual-component waterproof paint, and the component A and the component B are sprayed and mixed by special spray equipment in use according to a certain ratio, so as to instantaneously solidify and form a film. The water-based liquid rubber waterproof paint can be sprayed on any substrate surface, and is especially good in surface adhesion on metal, concrete, plastic and the like.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Putty for building external wall

InactiveCN101935196AStrong adhesionEasy constructionHydroxypropylmethyl celluloseCorrosion resistant

The invention discloses putty for a building external wall, which is made from the following raw materials in parts by weight: 20-40 of white cement, 5-10 of sierozem, 50-70 of powdered whiting, 5-10 of precipitated calcium carbonate, 0.2-0.3 of hydroxypropyl methylcellulose, 2-4 of re-dispersible latex powder, 0.1-0.3 of polypropylene staple fiber, 0.2-0.4 of moisture repellent and 0.3-0.5 of thixotropic lubricant. The putty is mainly used for direct renovation of an old finishing surface, and has high binding power and excellent water resisting property and ventilation property to a renovated substrate. The putty has the advantages of high strength, corrosion resistance, scrub resistance, high cracking resistance and convenient construction. All raw materials are non-volatile chemical substances, therefore, the putty is a comprehensive environment-friendly green product without toxicity or harms.

Owner:赵明

High-performance coating for composite material

ActiveCN103805041AImprove heat resistanceImprove hydrophobicityPolyurea/polyurethane coatingsCyanate compoundPrepolymer

The invention brings forward a high-performance coating for a composite material. The coating uses organosilicon modified polyurethane as a main resin component and comprises the following components by weight: 10 to 50 parts of polyurethane prepolymer and 5 to 30 parts of organosilicon modified polyurethane, wherein the organosilicon modified polyurethane is one selected from or a mixture of a block copolymer and a grafted copolymer, the content of organosilicon in the organosilicon modified polyurethane is 5% to 35%, the molecular weight of the organosilicon modified polyurethane is 2000 to 50000, the polyurethane prepolymer is one selected from or a mixture of cyanate prepolymer, hydroxyl terminated prepolymer, silicyl terminated prepolymer and acrylate terminated prepolymer, and the molecular weight of the polyurethane prepolymer ranges from 1000 to 100000. The coating provided by the invention has good heat resistance, hydrophobicity and weatherability; in use of the elastic coating, spraying pretreatment of a material surface is not needed, and the elastic coating has good adhesion.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Heat-resistant and corrosion-resistant epoxy coating for heat-resistant and corrosion-resistant power distribution cabinet shell

InactiveCN106833261AImprove mechanical propertiesEffective in promoting dispersionAnti-corrosive paintsEpoxy resin coatingsPolyvinyl alcoholPolyphenol

The invention discloses a heat-resistant and corrosion-resistant epoxy coating for a heat-resistant and corrosion-resistant power distribution cabinet shell. The heat-resistant and corrosion-resistant epoxy coating is prepared from the following raw materials in parts by weight: 20-40 parts of bisphenol A type epoxy resin, 10-20 parts of polyphenols glycidyl ether epoxy resin, 5-15 parts of novolac epoxy, 6-14 parts of aminoethyl piperazine, 1-2 parts of coalescing agent, 2-4 parts of trimethyl phosphate, 2-6 parts of modified asbestos, 2-4 parts of zeolite powder, 6-10 parts of mica powder, 2-4 parts of glass beads, 1-6 parts of porous powder quartz, 2-6 parts of coal ash, 1-4 parts of cornstalk, 2-5 parts of bentonite, 1-4 parts of carbon black, 5-12 parts of zinc phosphate, 0.5-1.5 parts of antibacterial agent, 2-4 parts of defoaming agent, 5-15 parts of polyvinyl alcohol, and 40-80 parts of water. The epoxy coating disclosed by the invention has extremely high heat stability and corrosion resistance, is not only excellent in airtightness, and but also strong in surface adhesion; and meanwhile, the smearing tenacity can be effectively enhanced, and the smeared coating is hard to break even encountering strong impact.

Owner:ANHUI LIAOYUAN ELECTRIC EQUIP MFG

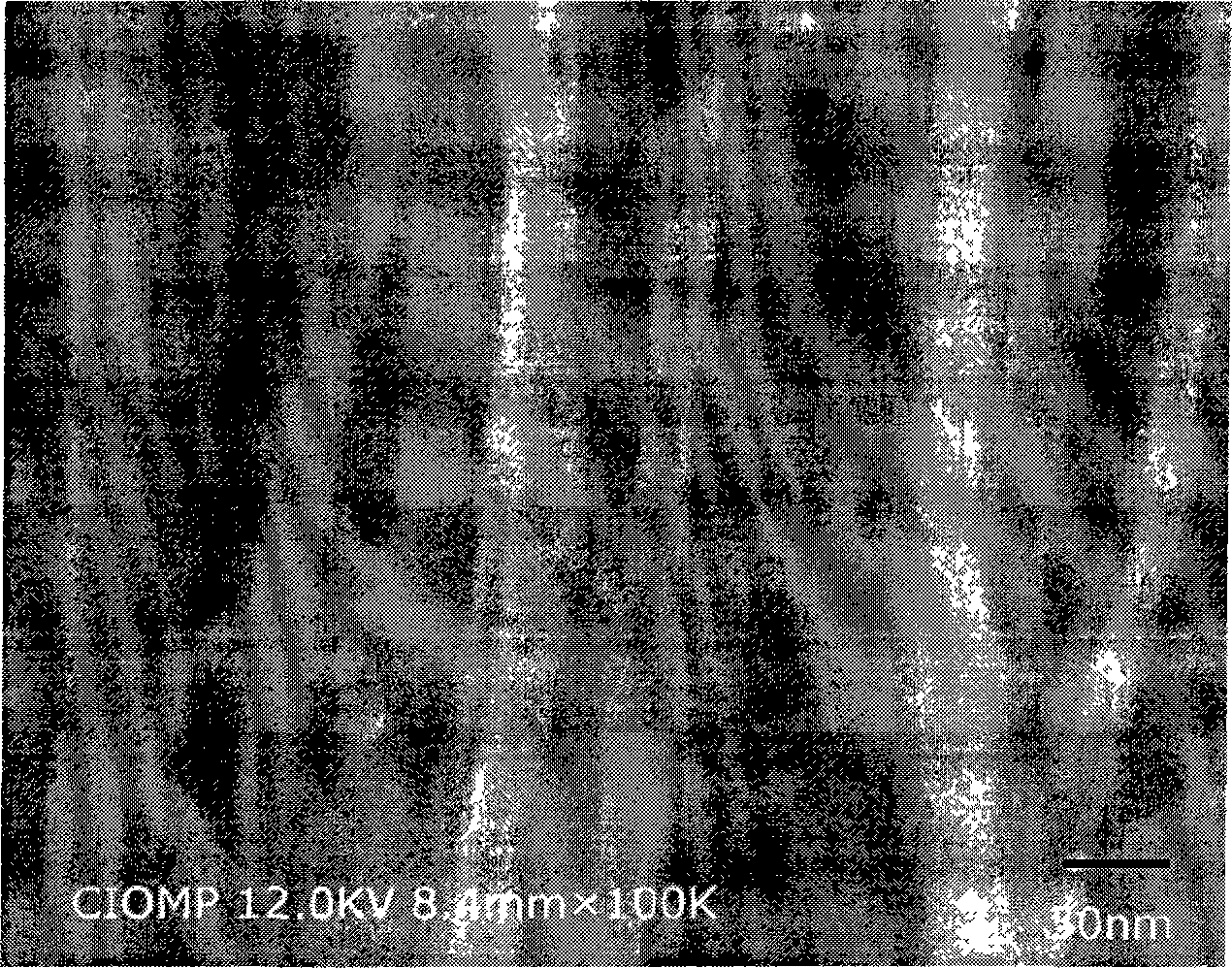

Nano-silver flexible conductive membrane and preparation method thereof

ActiveCN103992495AStable electrical conductivity on the surface of the filmLow resistivityConductive layers on insulating-supportsPretreated surfacesCellulosePolyethylene glycol

The invention relates to the technical field of conductive membranes, particularly to a nano-silver flexible conductive membrane and a preparation method thereof. The nano-silver flexible conductive membrane comprises a PET substrate layer, wherein corona treatment is performed on the surface of the PET substrate layer; a conductive coating layer which is arranged on the surface of the PET substrate layer comprises the following raw materials in percentage by weight: 50-75% of absolute ethyl alcohol, 2-5% of terpilenol, 1-3% of acetyl tributyl citrate, 2-8% of joint cement, 1-5% of polyethylene glycol 400, 2-3% of span 85, 1.5-3% of ethyl cellulose, 3-8% of silver powder of 20-40 nanometers, and 10-18% of silver powder of 150-450 nanometers. The nano-silver flexible conductive membrane, provided by the invention, has the characteristics of stable surface conductivity of the formed film, low resistivity, high light transmittance and strong adhesive force. The preparation process of the nano-silver flexible conductive membrane is simple and mature, coating equipment is simple, the operation is convenient, the cost is low, and the nano-silver flexible conductive membrane facilitates popularization and application.

Owner:杨佳雯

High sealing cold punching press shaped bubble cup plustic aluminium composite hard sheet and its production technology

A laminated hard plastics / aluminium plate with surficial PVC layer, and high sealing nature and able to be shaped by punch is prepared from at least one polyester (or polyamide) film treated by corona impact, at least one aluminium foil and one surficial PVC film through adhering them together by use of high-adhesion adhesive.

Owner:刘继福

Diamond compound film piece used for absolute bolometer and method for producing the same

InactiveCN101246050AStrong surface adhesionImprove adaptabilityRadiation pyrometryCatalytic methodComposite film

The present invention relates to a radiation-absorbing heat exchange sheet material on the absolute bolometer for measuring the solar radiation, especially to a diamond composite film used on the absolute bolometer and the preparing method thereof. The diamond composite film used on the absolute bolometer in the invention is prepared by compounding the pure diamond piece layer which is taken as the heat sink material and the black boron-doping diamond film that is taken as the light radiation absorbing material. The preparing method is firstly preparing the heat sink diamond piece with a one-time chemical vapor deposition, and then depositing the carbon nano-tube film layer on the diamond piece with a floating catalytic method. The diamond composite film of the invention has the advantages of strong heat and impact resistance, higher absorbing rate to the radiation and the rate is up to 99%, and stability for a long period; and the surface adhesions of the heat sink material and radiation-absorbing material are excellent. Thereby the measuring precision and sensitiveness of the bolometer can be increased and the measuring period can be shortened, and the adaptability of the absolute bolometer in the working condition of satellite is increased.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Two-dimensional code waterborne stereoscopic anti-counterfeit color-changing ink

The invention belongs to the technical field of two-dimensional codes, and particularly relates to a two-dimensional code waterborne stereoscopic anti-counterfeit color-changing ink. The ink is prepared from the following components in mass by percentage: 30% to 50% of aqueous acrylic resin solution; 15% to 25% of acrylic emulsion; 5% to 10% of waterborne polyurethane resin solution; 15% to 25% ofthermochromic powder; 10% to 20% of foaming agent; and 1.0% to 3.0% of auxiliaries. The thermochromic powder is a reversible thermochromic powder capable of changing from colorless to colored at 55 DEG C to 75 DEG C, and the foaming agent is a heat-expandable microcapsule. An anti-counterfeiting mark of the two-dimensional code using the ink (the anti-counterfeiting mark can be letters, numbers,graphics and the like, and can be connected with a database of a production company) is not visible at a normal temperature, and presents a three-dimensional shape at a high temperature, and the colorchanges from colorless to colored, the ink is strong in three-dimension, has clear edges and good friction resistance, is not easy to fall off, and is green and environmentally friendly. The color isreversible while a bulge is irreversible, and use of two-dimensional code is avoided being stolen while maintaining fun.

Owner:永发印务(东莞)有限公司

Method for impregnating graphite electrode by using ultrasonic principles

The invention relates to a method for impregnating a graphite electrode, particularly a method for impregnating a graphite electrode by using ultrasonic principles. The method comprises the following steps: (1) cleaning a processed graphite electrode, drying, and putting the graphite electrode into an impregnating container; (2) vacuumizing the impregnating container, and keeping the vacuum state; (3) injecting resin into the impregnating container, wherein the resin level is higher than the graphite electrode; (4) while keeping the temperature constant, starting a compressor and an ultrasonic device, and keeping the state; and (5) taking out the resin to obtain the impregnated graphite electrode. The impregnated artificial graphite electrode has the advantages of uniform distribution of various resins (including phenol formaldehyde resin, furan resin, vinyl ester resin, polytetrafluoroethylene, other mixed resins and the like), strong surface adhesion, greater impregnating depth, higher gain rate of the impregnated part, favorable heat exchange effect, high strength and high corrosion resistance, and effectively prolongs the service life of equipment.

Owner:青岛鸿源换热器有限公司

Lightweight fireproof filling material for metal door produced by expansion perlite and preparation method thereof

InactiveCN101215179AAct as waterproof and water-blockingWith thermal insulationThermal insulationAdhesive

The invention discloses a lightening fireproof filling material for producing metal door by expanded perlite and a process for preparation. The material comprises expanded perlite, magnesium oxide, magnesium sulfate, calcium hydroxide, aqueous adhesive and water proofing agent, the volume weight is between 200-300kg / m3, the proportionings of each component according to weight percentage respectively are that the expanded perlite takes 45-65, the magnesium oxide takes 15-25, the magnesium sulfate takes 5-15, the calcium hydroxide takes 0.5-4 and the aqueous adhesive takes 2-5. Employing the technical scheme, the product has the advantages of high mechanical strength, light weight, high grade of fire resistance, good effect of sound absorption and acoustic insulation, strong anti-weatherability, heat insulation, heat preservation and energy conservation, easy production and no poison, on hazard and no radiation and the like. The product can be widely used in metal door industry, architectural materials industry and the related industries.

Owner:ZHEJIANG MEIXIN IND CO LTD

Modified polypropylene material with high adhesion and preparation method thereof

The invention discloses a modified polypropylene material with high adhesion. The polypropylene material comprises the following raw materials in parts by weight: 60-80 parts of polypropylene resin, 10-30 parts of modified inorganic fillers, 4-8 parts of functional resin, 1-2 parts of epoxy resin, 0.5-1 part of a functional agent, 0.1-0.3 part of a nucleating agent, 0.1-1.0 part of an antioxidant and 0.1-1.0 part of a processing agent. In the modified polypropylene material, universal polypropylene is used as a basic material, so that the polarity of the polypropylene material is greatly improved by adopting a manner of adding the specific functional resin, epoxy resin, a functional agent and modified inorganic fillers and adjusting the ratio of the raw materials, therefore, the material has excellent surface adhesion and can be directly sprayed.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

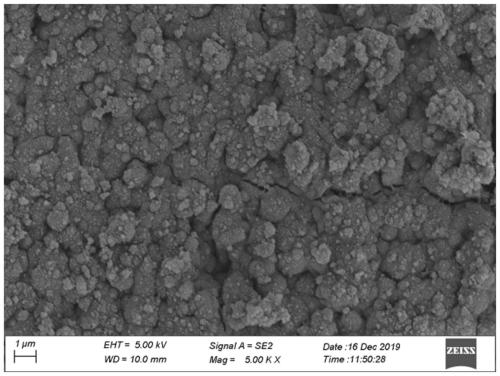

Composite powder for improving scouring resistance of carbon-containing refractory material and preparation method of composite powder

The invention belongs to the technical field of preparation of carbon-containing refractory material, and mainly relates to composite powder for improving scouring resistance of a carbon-containing refractory material and a preparation method of the composite powder. The provided composite powder for improving the scouring resistance of the carbon-containing refractory material is compounded from zirconium carbide particles and nano zirconium oxide, wherein the mass ratio of the nano zirconium oxide to the zirconium carbide particles in the composite powder is 0.5:1 to 1:0.5; the particle size of the zirconium carbide particles is 200-400 meshes, and the zirconium carbide particles are positioned in the center of the composite powder; the nano zirconium oxide is part of stable zirconium oxide of which the particle size is less than 30nm; the nano zirconium oxide is uniformly dispersed and is enwrapped on the outer surface of the zirconium carbide particles; and the particle size of the composite powder is between 80 meshes and 150 meshes. The composite powder provided by the invention ensures that zirconium oxide has strong adhesive force on the surface of zirconium carbide, and meanwhile, and the composite powder is crushed after drying to obtain an appropriate particle size, and finally obtain the nano zirconium oxide coated zirconium carbide composite powder.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

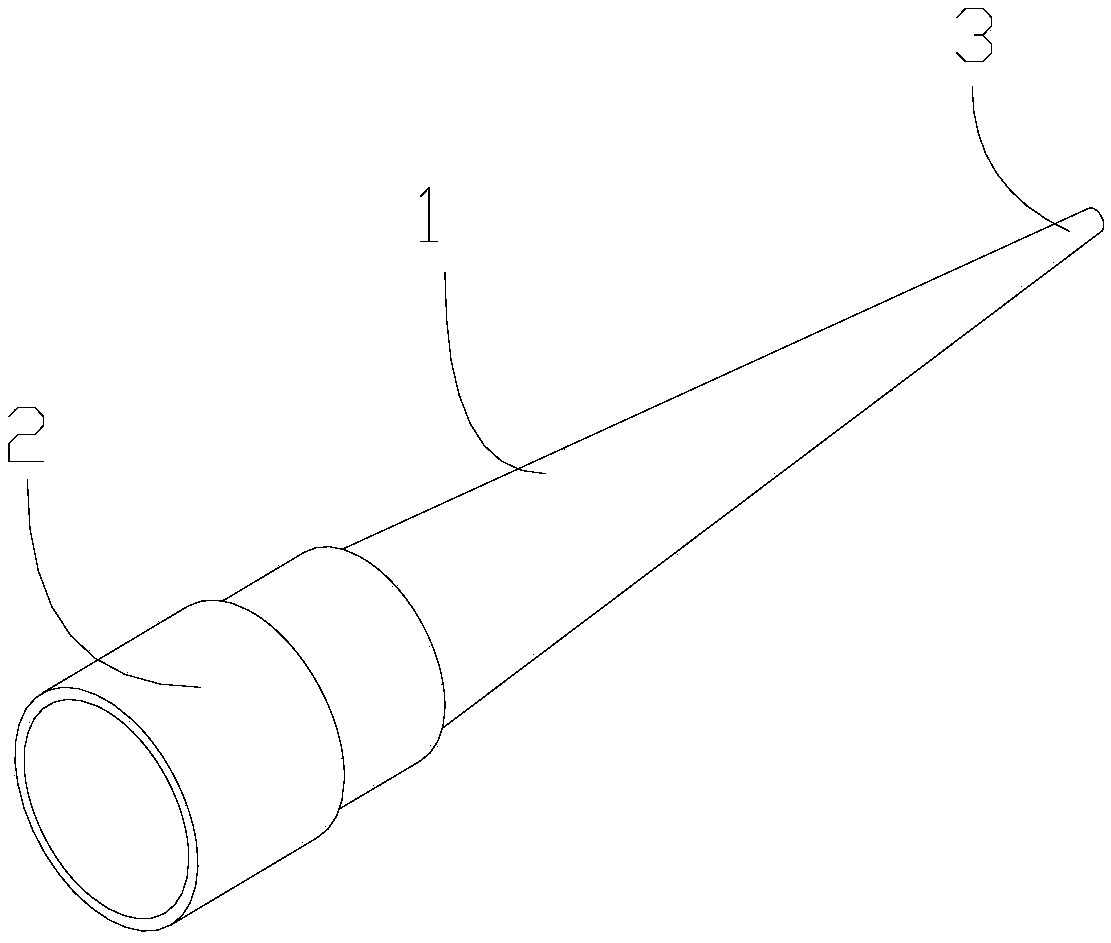

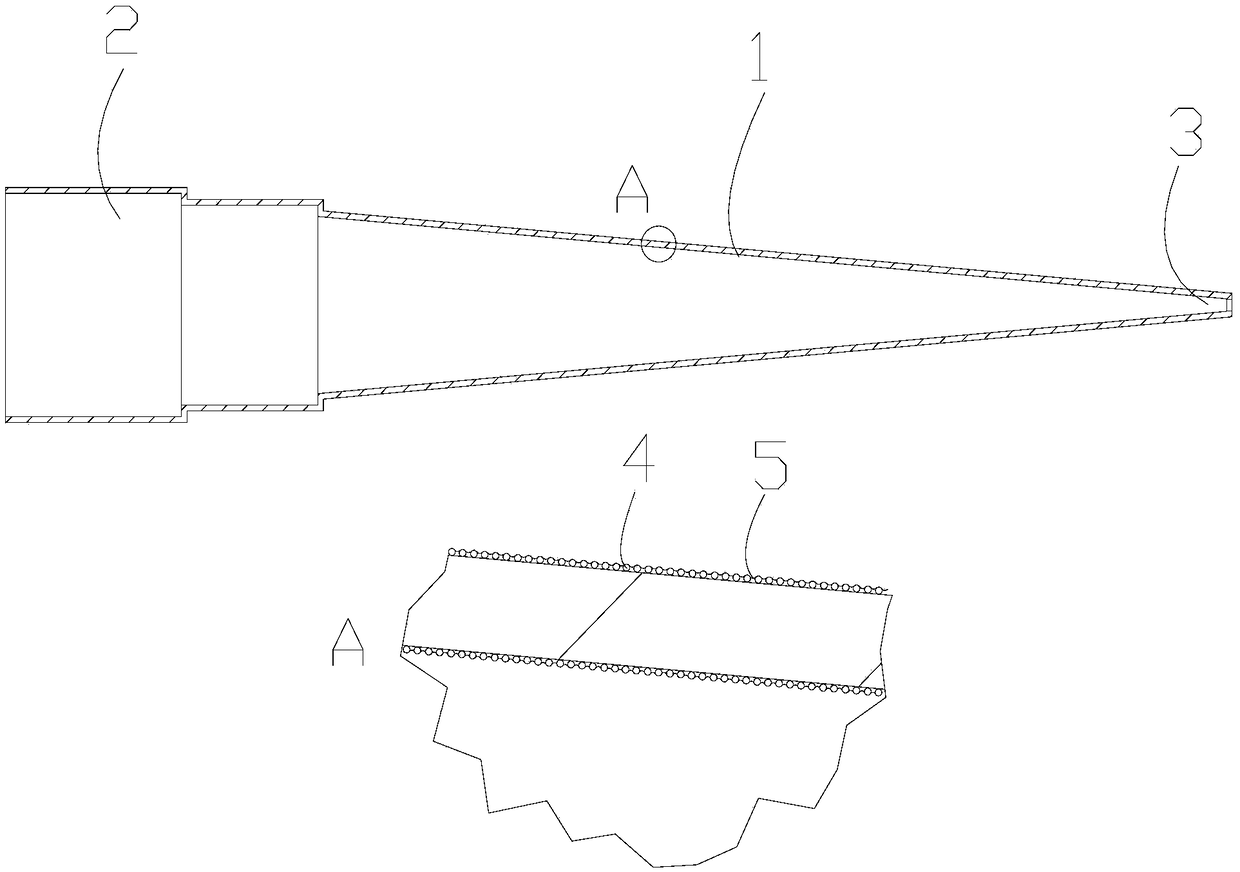

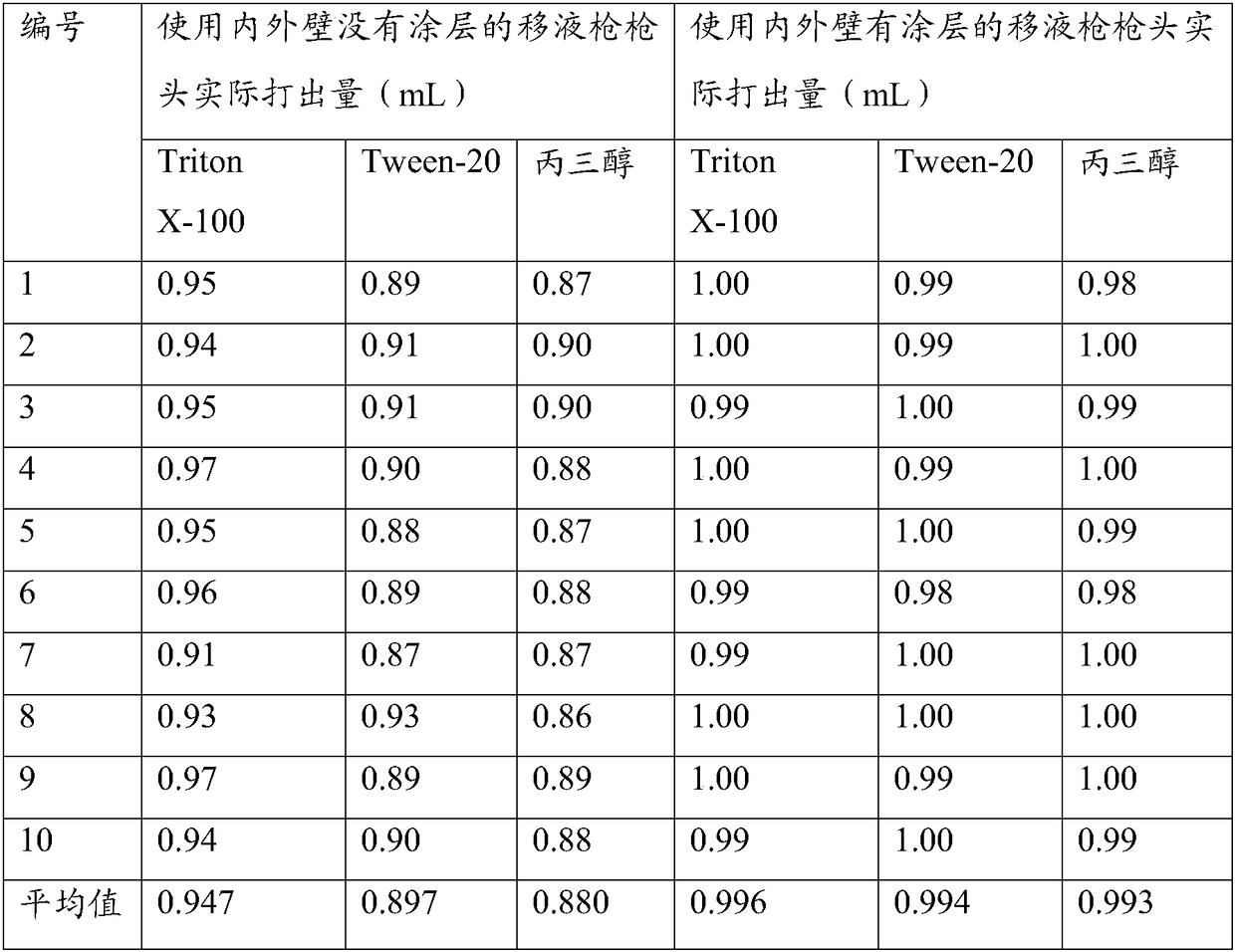

Pipette tip for sucking viscous liquid and preparation method thereof

The invention discloses a pipette tip for sucking viscous liquid. The pipette tip for sucking viscous liquid comprises a pipette tip body which is of a hollow tubular structure, and further comprisesa composite layer and a hydrophobic oil layer. The composite layer is arranged on the surface of the inner and outer tube walls of the pipette tip body, the composite layer comprises an amino acrylicresin and inorganic nano-particles; the surface of the composite layer has a nano-sized protruding structure formed by combining the amino acrylic resin and the inorganic nano-particles; the hydrophobic oil layer is arranged on the composite layer, and the hydrophobic oil layer comprises fluoroalkyl silane. The invention also discloses a preparation method of a pipette tip for sucking viscous liquid. The pipette tip for sucking viscous liquid disclosed the invention not only has good hydrophobicity, but also has oleophobicity, and is mainly used for sucking viscous liquid, effectively reducingthe residue of droplets on the surface of the tip, so that the volume of the droplets dropped is more precise; the spraying method is used to distribute the inorganic nano-particles evenly and make the coating thickness uniform, which is suitable for large-scale standardized production.

Owner:CHINA NAT INST OF STANDARDIZATION

Implementation method, application method and connection structure for welding tin-solderable conductor and tin-unsolderable matrix

InactiveCN105186253AAvoid electroplating copperAvoid tinningLine/current collector detailsSoldering apparatusCoaxial cableElectrical conductor

The invention discloses an implementation method for welding a tin-solderable conductor and a tin-unsolderable matrix. The implementation method comprises the following steps: preparing the tin-solderable conductor and the tin-unsolderable matrix; welding a tin-solderable metal layer which is formed on the tin-solderable conductor and the tin-unsolderable matrix through coating in advance; and cooling to congeal the soldering tin so as to fix connection between the tin-solderable conductor and the tin-unsolderable matrix. The implementation method, the application method and the connection structure for a welding tin-solderable conductor and a tin-unsolderable matrix has the advantages of improving the reliability and aesthetic property for coaxial cable welding, reducing the cost, improving the efficiency and reducing pollution.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

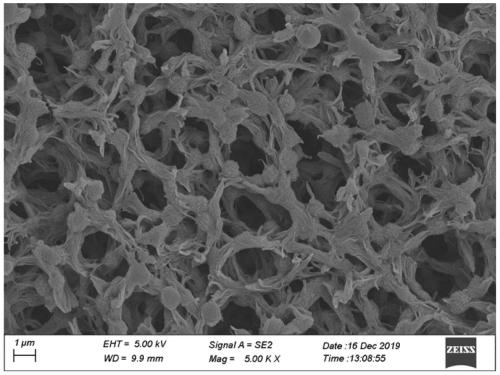

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AGood crack resistanceRapid prototypingNon-macromolecular adhesive additivesEpoxy resin adhesivesPliabilityPhysical density

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

Waterproof sound insulation wallpaper coat material

InactiveCN104711895AAdjustable temperatureImprove comfortWater-repelling agents additionCross-linkChemical reaction

The invention discloses a waterproof sound insulation wallpaper coat material. The waterproof sound insulation wallpaper coat material comprises, by weight, 8-12 parts of paraffin, 6-8 parts of aqueous latex, 3-5 parts of calcium carbonate powder, 2-4 parts of metal powder, 0.6-0.8 parts of a titanate coupling agent TMC-TTS, 0.2-0.4 parts of a dispersant, 0.3-0.5 parts of an adhesion promoter KH-560, 0.5-0.7 parts of a waterproof agent and 20-30 parts of deionized water. The melting temperature of paraffin is high, so the shape-stabilized phase change material is formed, and can effectively adjust the ambient temperature; a small amount of the radiation-free metal powder has strong adhesion force with the surface of a substrate, so the material has excellent sound absorbing and noise reducing functions; and the waterproof agent is added to reduce a cross-linking chemical reaction of hydrophilic groups in vegetable fibers with the waterproof agent, so the wallpaper material has a waterproof performance.

Owner:郝明先

Photocuring transfer printing material

ActiveCN103031066ACuring shrinkage is smallImprove wear resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyesterMethacrylate

The invention relates to a photocuring transfer printing material that can be printed on surfaces of transparent or semitransparent glass, plastic or rubber. The material comprises of the following components: 25-45% of oligomer, 30-50% of activated monomer, 2-8% of UV(ultraviolet) photoinitiator, 1-20% of superfine glass fiber, 0-5% of inert filler and 0-5% of organic solvent, wherein the oligomer is one or more of polyurethane acrylate, aliphatic polyurethane methacrylate, polyester acrylate and epoxy acrylate; the curing of the photocuring transfer printing material is caused by UV radiation; and the glass fiber is dipped with a silane coupling agent. The photocuring transfer printing material is small in curing shrinkage rate, high in wearing resistance and convenient to use, and has a strong adhesive force with surfaces of transfer printing substrates; and a construction process and a curing process of the material are basically the same with those of the traditional photocuring material.

Owner:NANTONG MEMTECH TECH

Environment-friendly high-performance furfural-free epoxy chemical grouting material, preparation method and application

InactiveCN102617983AAdjustable initial viscosityGel time controllableOther chemical processesSoil preservationEpoxyAdhesion force

The invention discloses an environment-friendly high-performance furfural-free epoxy chemical grouting material, which is prepared with 100 parts of epoxy resin, 100-150 parts of diluent, 8-20 parts of curing agents, 0.5 part of accelerators and 18 parts of other auxiliaries. Acetone is mixed with catalysts, benzaldehyde is dropped in at the room temperature, the reaction temperature is controlled to range from 20 DEG C to 40 DEG C, and reaction is performed for 0.5-5 hours, so that the diluent is obtained. The molar ratio of the benzaldehyde to the acetone is (0.8-2.5):1. The environment-friendly high-performance furfural-free epoxy chemical grouting material abandons toxic furfural and has an excellent mechanical performance and high surface adhesion force, the initial viscosity of slurry can be adjusted, and gelation time can be controlled. Moreover, the jet-grouted solid of the prepared grouting material is light in color, and the grouting material is capable of meeting the special requirements of a plurality of places on colors and can be widely used as building decoration materials and used for reservation of cultural relics and projects such as water plugging, water proofing, foundation reinforcement and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

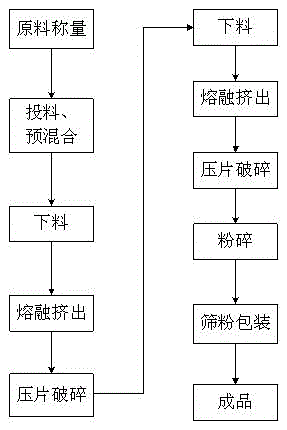

Acrylic acid transparent powdery paint for glazing and preparation method thereof

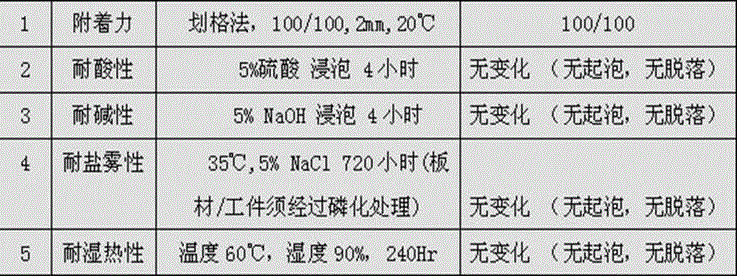

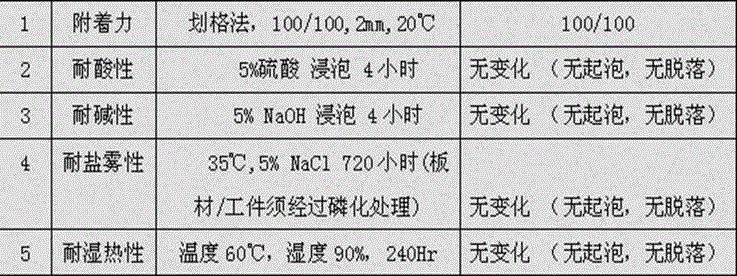

InactiveCN103980787AStrong surface adhesionGood acid and alkali resistancePowdery paintsBenzoinMethacrylic acid copolymer

The invention relates to an acrylic acid transparent powdery paint for glazing. The powdery paint includes resin, a levelling agent, a curing agent and benzoin; wherein the resin is a methacrylic acid copolymer, the levelling agent is a pure levelling agent without fillers and the curing agent is dodecanedioic acid. Through improvement of the formula and the preparation method, the acrylic acid transparent powdery paint is strong in surface adhesive force and is good in acid resistance, alkali resistance, salt spray resistance and heat and humidity resistance.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

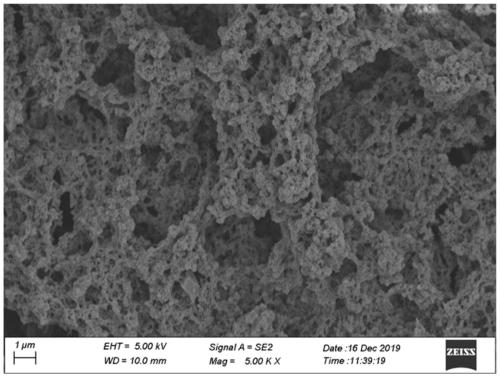

Modified separation membrane for membrane distillation, and preparation method and application thereof

ActiveCN111085119AGuaranteed uptimeStable permeate fluxMembranesSemi-permeable membranesMembrane distillationPolyvinylidene difluoride

The invention discloses a modified separation membrane for membrane distillation, and a preparation method and an application thereof. The modified separation membrane is prepared by the following steps: S1, performing surface activation on a polyvinylidene fluoride hydrophobic membrane, and preparing a dopamine solution or a plant polyphenol-chitosan solution; S2, performing surface hydrophilic layer coating modification on an activated polyvinylidene fluoride hydrophobic membrane by adopting the dopamine solution or the plant polyphenol-chitosan solution, and carrying out cleaning with water; S3, immersing the polyvinylidene fluoride membrane modified in the step S2 into a polycation electrolyte solution for coating modification, and carrying out cleaning with water; and S4, circularly repeating the steps S2 and S3 for 1-4 times, then repeating the step S2, and carrying out cleaning so as to obtain the modified separation membrane. The modified separation membrane provided by the invention simultaneously has a super-hydrophilic surface layer and a hydrophobic mass transfer layer, can treat pollutants containing low surface energy and keep long-term stable operation, and has highsalt rejection rate, stable permeation flux and high effluent quality.

Owner:SUN YAT SEN UNIV

Punching press shaped high sealing tropical type plastic aluminium composite hard sheet and production technology

Owner:刘继福

Gel water shutoff agent of high-temperature low-permeability storage layer

ActiveCN104312560AHigh viscosityHigh temperature low viscosityDrilling compositionCross-linkTetrabromobisphenol A

The invention provides a gel water shutoff agent of a high-temperature low-permeability storage layer. The gel water shutoff agent of the high-temperature low-permeability storage layer comprises the following components: 2-20wt% of a host, 0.5-5wt% of a cross-linking agent and the balance of water, wherein the host comprises a host A and a host B; the host A comprises 2-acrylic acid-1,1-dimehtyl ethyl ester, 2,2-bis(3,5-dibromo-4-hydroxyl phenyl) propane, 2, 2', 6, 6'-tetrabromobisphenol A; the host B comprises acrylamide, hydrolytic polyacrylamide or non-hydrolytic polyacrylamide, wherein a mass ratio of the host A to the component B is 1 to (1-2). The gel water shutoff agent provided by the invention is suitable for the high-temperature low-permeability storage layer and low in base fluid viscosity, and is easily injected to the deep part of the low-permeability storage layer, and has good viscosity, high tensile strength, high adhesive power, good high temperature resistance and good thermal stability after being cross-linked.

Owner:PETROCHINA CO LTD

Environment-friendly high-performance furfural-free epoxy chemical grouting material, preparation method and application

InactiveCN102617983BAdjustable initial viscosityGel time controllableOther chemical processesSoil preservationEpoxyBenzaldehyde

The invention discloses an environment-friendly high-performance furfural-free epoxy chemical grouting material, which is prepared with 100 parts of epoxy resin, 100-150 parts of diluent, 8-20 parts of curing agents, 0.5 part of accelerators and 18 parts of other auxiliaries. Acetone is mixed with catalysts, benzaldehyde is dropped in at the room temperature, the reaction temperature is controlled to range from 20 DEG C to 40 DEG C, and reaction is performed for 0.5-5 hours, so that the diluent is obtained. The molar ratio of the benzaldehyde to the acetone is (0.8-2.5):1. The environment-friendly high-performance furfural-free epoxy chemical grouting material abandons toxic furfural and has an excellent mechanical performance and high surface adhesion force, the initial viscosity of slurry can be adjusted, and gelation time can be controlled. Moreover, the jet-grouted solid of the prepared grouting material is light in color, and the grouting material is capable of meeting the special requirements of a plurality of places on colors and can be widely used as building decoration materials and used for reservation of cultural relics and projects such as water plugging, water proofing, foundation reinforcement and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

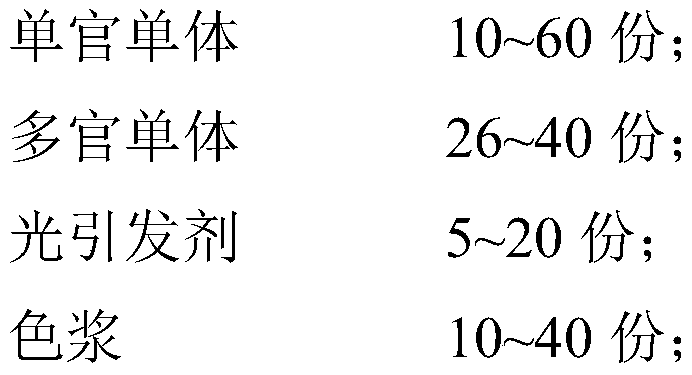

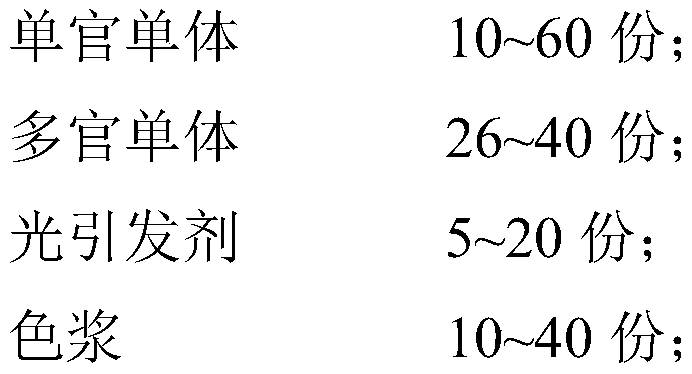

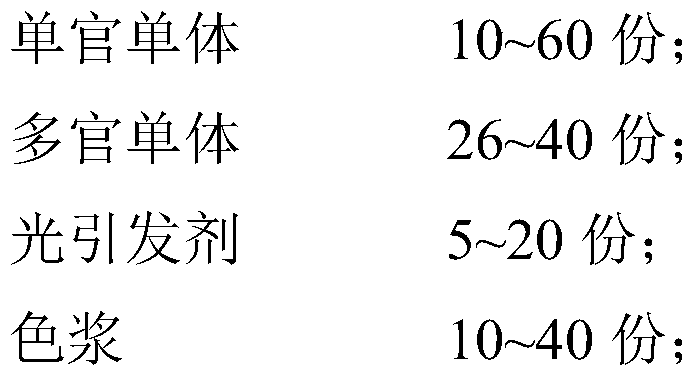

Quick-drying non-sticky ultraviolet (UV) ink-jet ink and preparation method thereof

InactiveCN109971253AFast curing rateStrong surface adhesionInksFunctional monomerPaint adhesion testing

The invention provides quick-drying non-sticky ultraviolet (UV) ink-jet ink and a preparation method thereof, and relates to the field of ink-jet ink. The ink provided by the invention comprises the following components: a single-functional monomer, a multi-functional monomer, a photoinitiator and color paste, wherein the number of functional groups of the multi-functional monomer is 2-20, and thephotoinitiator comprises a long-wavelength photoinitiator and a short-wavelength photoinitiator. A coating layer of the ink provided by the invention has a high curing rate and good surface dryness and bottom dryness. In addition, the surface adhesive force of coating layer of the ink is relatively high, a phenomena of bottom exposure cannot occur after a plurality of times of wiping, and the result of a paint adhesion testing is grade one or above (containing grade one).

Owner:TRENDVISION TECH(ZHUHAI) CO LTD

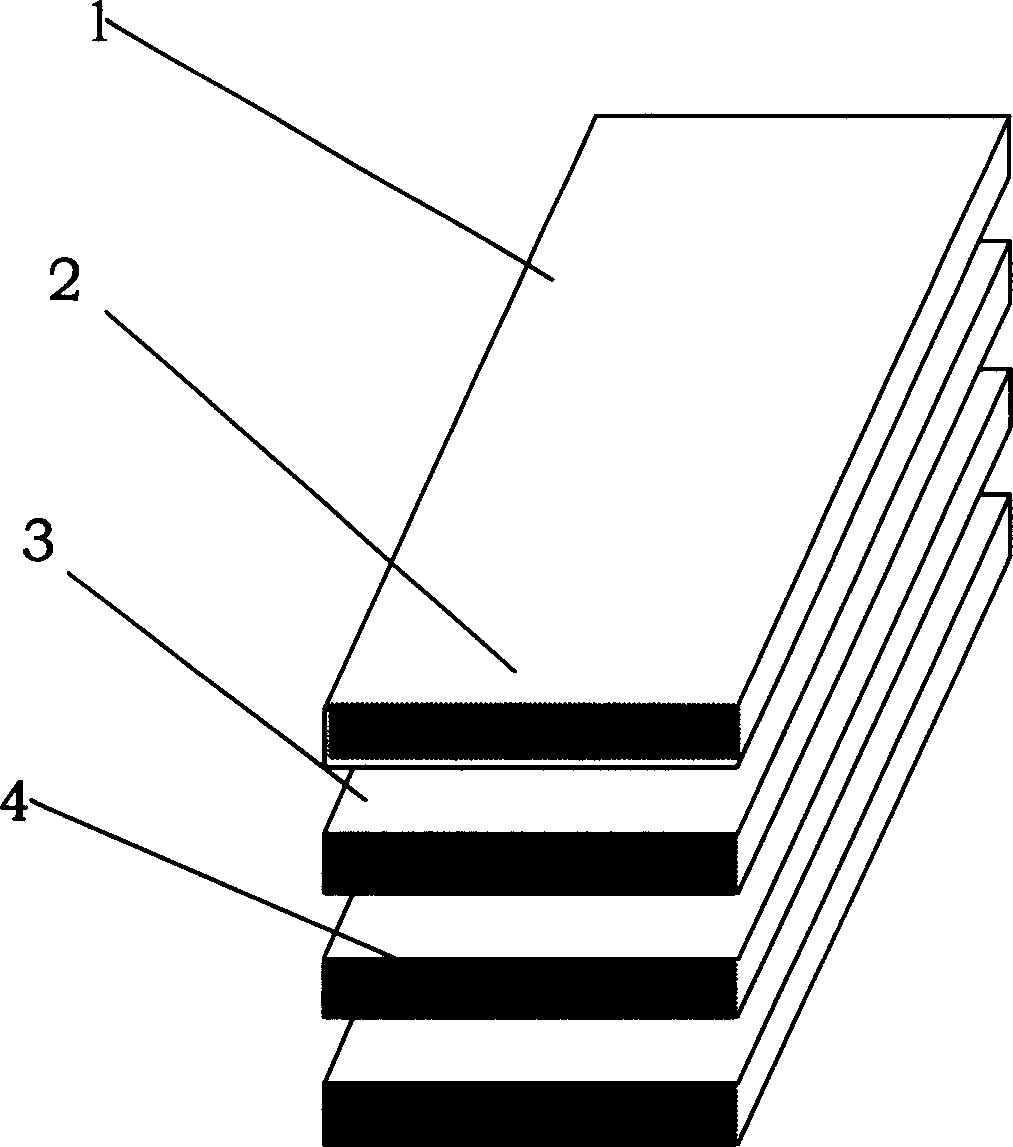

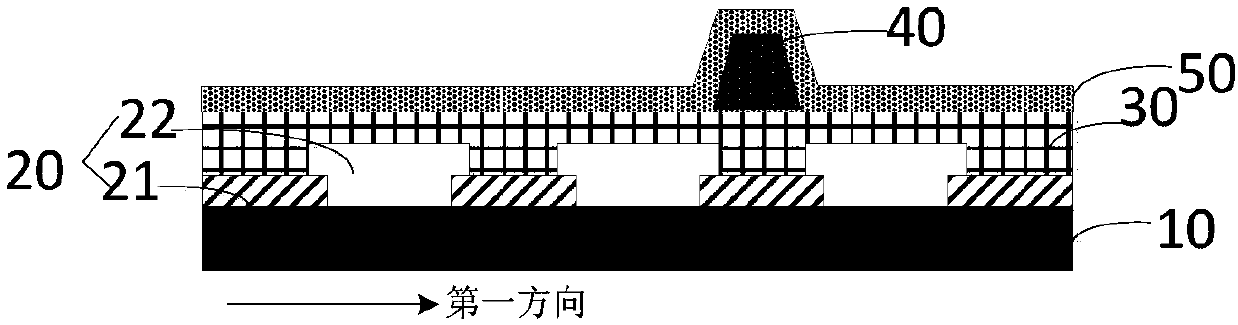

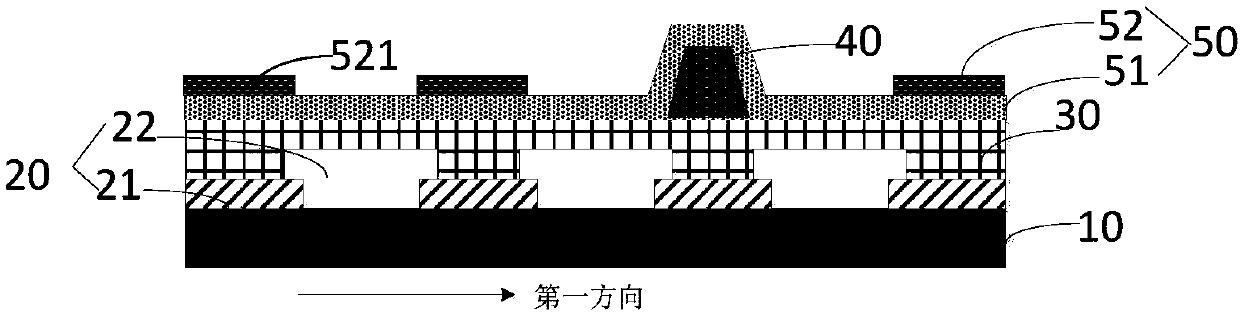

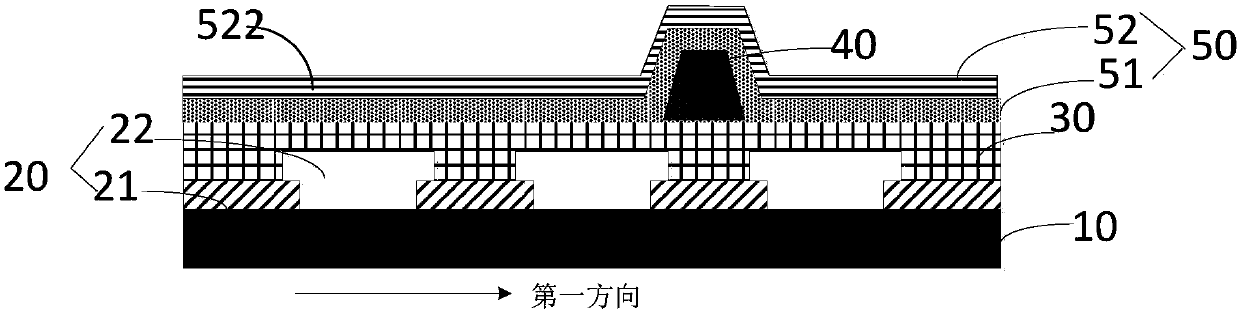

Color film substrate and preparation method thereof, and display device

ActiveCN107946345AStrong surface adhesionNot easy to fall offSolid-state devicesSemiconductor devicesColor filmDisplay device

The present invention provides a color film substrate and a preparation method thereof, and a display device. The color film substrate comprises: a substrate; a color film layer arranged on a first surface of the substrate and comprising a black matrix and color filters which are arranged in the same layer; a covering layer arranged on a surface, far away from the substrate, of the color film layer; a spacer arranged on a surface, far away from the substrate, of the covering layer; and an electrode arranged on a surface, far away from the substrate, of the covering layer, wherein the spacer iscovered with the electrode. The inventor discovers that: the spacer directly arranged on the surface of the covering layer has high anchoring strength to allow the spacer to be firmly attached to thesurface of the covering layer and not to be easily fell off, and therefore, the product yield rate is improved, the electrode is good in conductive performance and can effectively protect the spaces,the color film substrate is simple in structure, easy to realize and low in cost.

Owner:BOE TECH GRP CO LTD

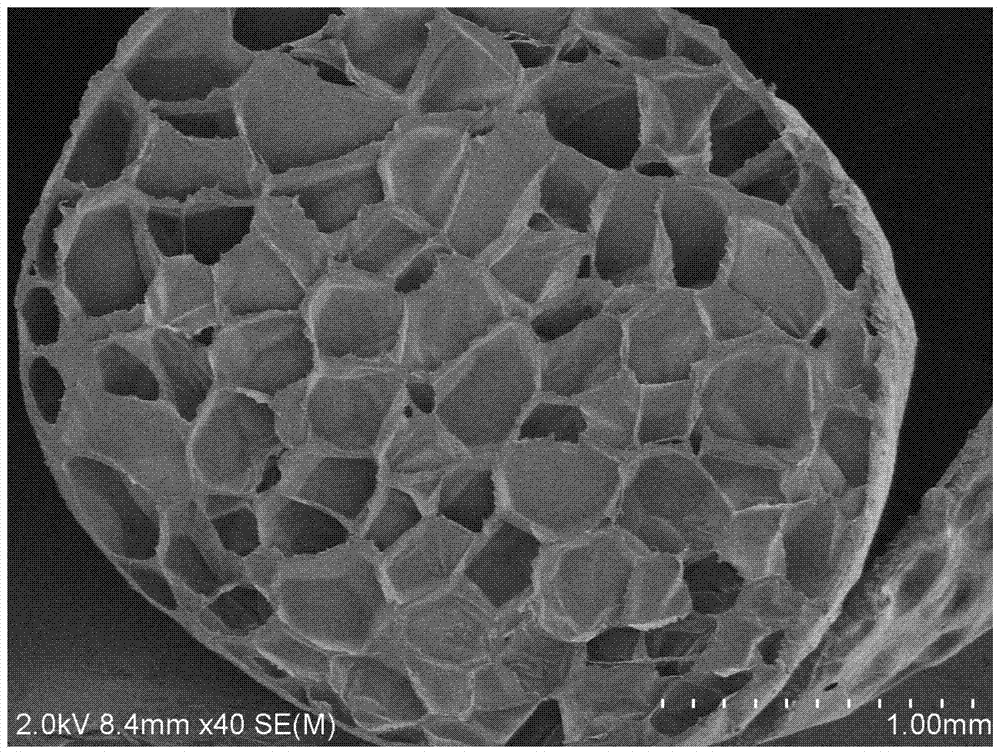

A kind of low shrinkage, high rebound epe beads and preparation method thereof

The invention discloses a low-shrinkage high-resilience EPE beads. The non-metallocene catalyzed LLDPE resin is adopted as the main base material so enable the EPE beads to have relatively high porosity by closed pore, and HDPE is used as an auxiliary material to enable the EPE beads to have rigidity and resilience after foaming; no anti-shrinkage agent needs to be added, and the porosity by closed pore of the EPE beads is as high as 95% or above, the shrinkage rate is as low as 2-3%, the foaming aperture is 200-300 micrometers, the surface glossiness is good, the light transmittance is high, the mechanical property is excellent, and the surface adhesive power is high; in addition, as inorganic gas in a supercritical state is used as a foaming agent, no heat preservation device is required after foaming, all needed is to feed steam of 0.3-3 KPa into the conveying pipeline of polyethylene resin particles, the continuous increase in foam pores of the polyethylene resin particles is completed through the fact that steam stays in the conveying pipeline for 30-120s; the production efficiency is high, and the energy consumption is low.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

Printing ink for anti-counterfeiting embossed tipping paper and preparation method of printing ink

The invention discloses printing ink for anti-counterfeiting embossed tipping paper. The printing ink is prepared from the following raw materials in parts by weight: 50 to 60 parts of acrylic resin,14 to 18 parts of polyvinyl alcohol, 7 to 10 parts of an ethylene-vinyl acetate copolymer, 5 to 20 parts of pigment, 1.5 to 2 parts of silicon dioxide, 0.8 to 2.4 parts of a dispersing agent, 0.5 to 0.8 part of a leveling agent, 1 to 1.4 parts of an antifoaming agent and 25 to 40 parts of a solvent. The printing ink for the anti-counterfeiting embossed tipping paper is prepared from finely selected raw materials; the contents of the raw materials are optimized, so product quality is improved; and the prepared printing ink for the anti-counterfeiting embossed tipping paper has the advantages ofhigh adhesive force with the surface of the tipping paper, good toughness, small possibility of fading, breaking, cracking and the like in the later embossing treatment process of the tipping paper,applicability to the anti-counterfeiting embossed tipping paper, good stability and good migration resistance.

Owner:浙江荣丰纸业有限公司

Stain-resistant stone-like coating

The invention discloses a stain-resistant stone-like coating. The stain-resistant stone-like coating is prepared from the following components in percentage by weight: 3-3.5% of lignocellulose, 2-3% of barium sulfate, 5-6% of sodium hexametaphosphate, 15-18% of silicone-acrylate emulsion, 0.3-0.5% of ethylene glycol, 55-60% of natural color sand, 3-5% of aluminum silicate, 1-3% of zeolite powder, 0.1-0.2% of titanium dioxide, 0.3-0.35% of thickener TT-935, 0.2-0.3% of ethyl cellulose, 0.02-0.05% of sym-triazine and 6-9% of water. The stain-resistant stone-like coating disclosed by the invention has not only the characteristics of waterproofness, aging resistance, high hardness and the like, but also the advantages of good bonding strength, crack resistance, surface adhesion, abrasion resistance and stain resistance.

Owner:NINGBO HOBOS ENERGY CONSERVATION & TECH

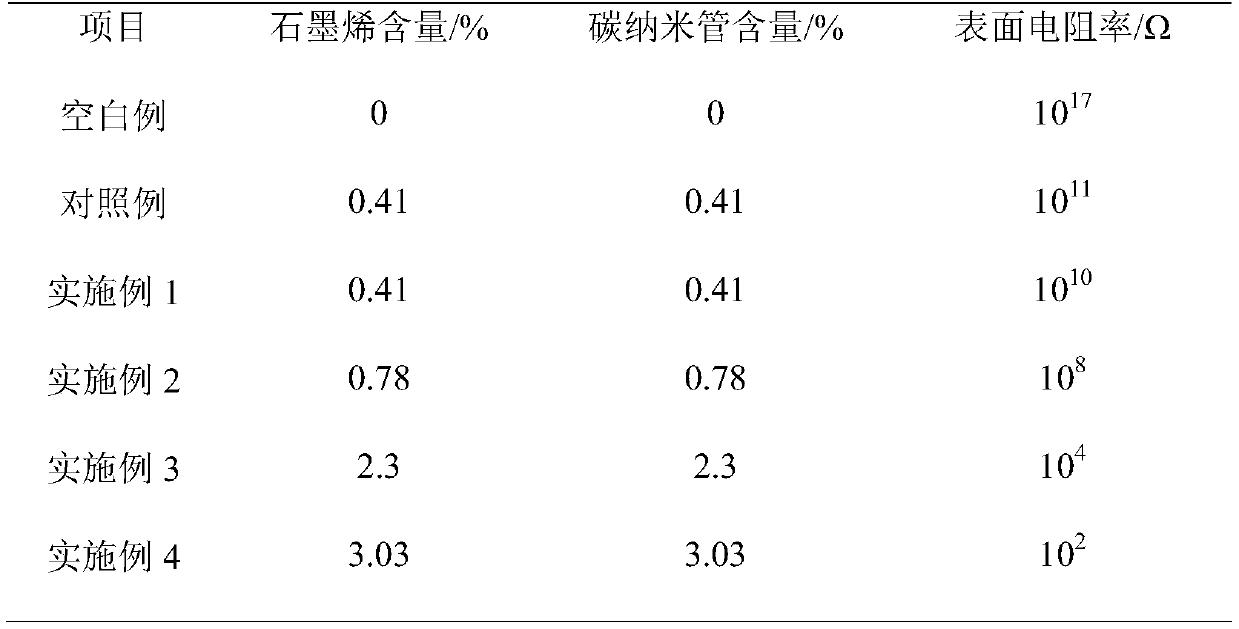

Antistatic coating and preparation method thereof, and application of antistatic coating

InactiveCN110938327AImprove mechanical propertiesImprove antistatic performanceElectrically-conductive paintsPolymer sciencePlasticizer

The invention discloses an antistatic coating and a preparation method thereof, and application of antistatic coating. The antistatic coating comprises the following component in parts by weight: 100parts of PVC paste resin, 0-50 parts of vinyl chloride-vinyl acetate paste resin, 2-8 parts of a stabilizer, 2-10 parts of calcium carbonate, 1-5 parts of stearic acid and 80-400 parts of graphene slurry, wherein the graphene slurry comprises the following components in parts by weight: 1-5 parts of graphene, 1-5 parts of carbon nanotubes, 100 parts of a plasticizer and 0.5-5 parts of polyvinylpyrrolidone, and the antistatic coating does not contain a solvent. The antistatic coating provided by the embodiment of the invention can effectively enhance the mechanical properties of the PVC base material on the premise of ensuring the antistatic effect of the PVC base material; and moreover, a coating formed by the antistatic coating is thin, so that the production cost can be effectively reduced.

Owner:上海烯古能源科技有限公司

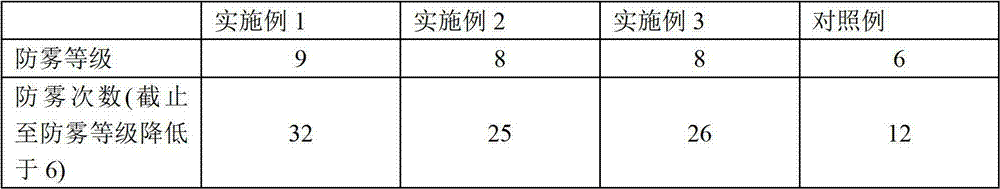

Long-acting antifogging agent for glass

InactiveCN102850997APrevent fog dropletsStrong surface adhesionOther chemical processesSURFACTANT BLENDTrisodium phosphate

The invention provides a long-acting antifogging agent for glass, which belongs to the technical field of daily chemical products. The long-acting antifogging agent comprises, by weight, 5 to 8 parts of ethanol, 2 to 4 parts of silica sol, 1 to 2 parts of octyltrimethoxysilane, 1 to 2 parts of methyltrimethoxysilane, 1 part of essence, 2 to 4 parts of lauramidopropyl betaine, 3 to 5 parts of sec-octylphenol polyoxyethylene ether, 15 to 18 parts of isopropanol, 3 to 6 parts of methyl n-butyl titanate, 2 to 3 parts of alkyl pyrrolidone, 1 part of trisodium phosphate, 3 to 4 parts of alkanolamide, 1 part of a surfactant and 20 to 40 parts of water. The antifogging agent for glass provided by the invention can effectively prevent formation of droplets on glass and action effects of the antifogging agent lasts for a long time.

Owner:苏州市德莱尔建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com