Water-based liquid rubber waterproof paint and preparation method thereof

A water-based liquid rubber and waterproof coating technology, which is applied in asphalt coatings, chloroprene homopolymer coatings, coatings, etc., and can solve problems such as easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

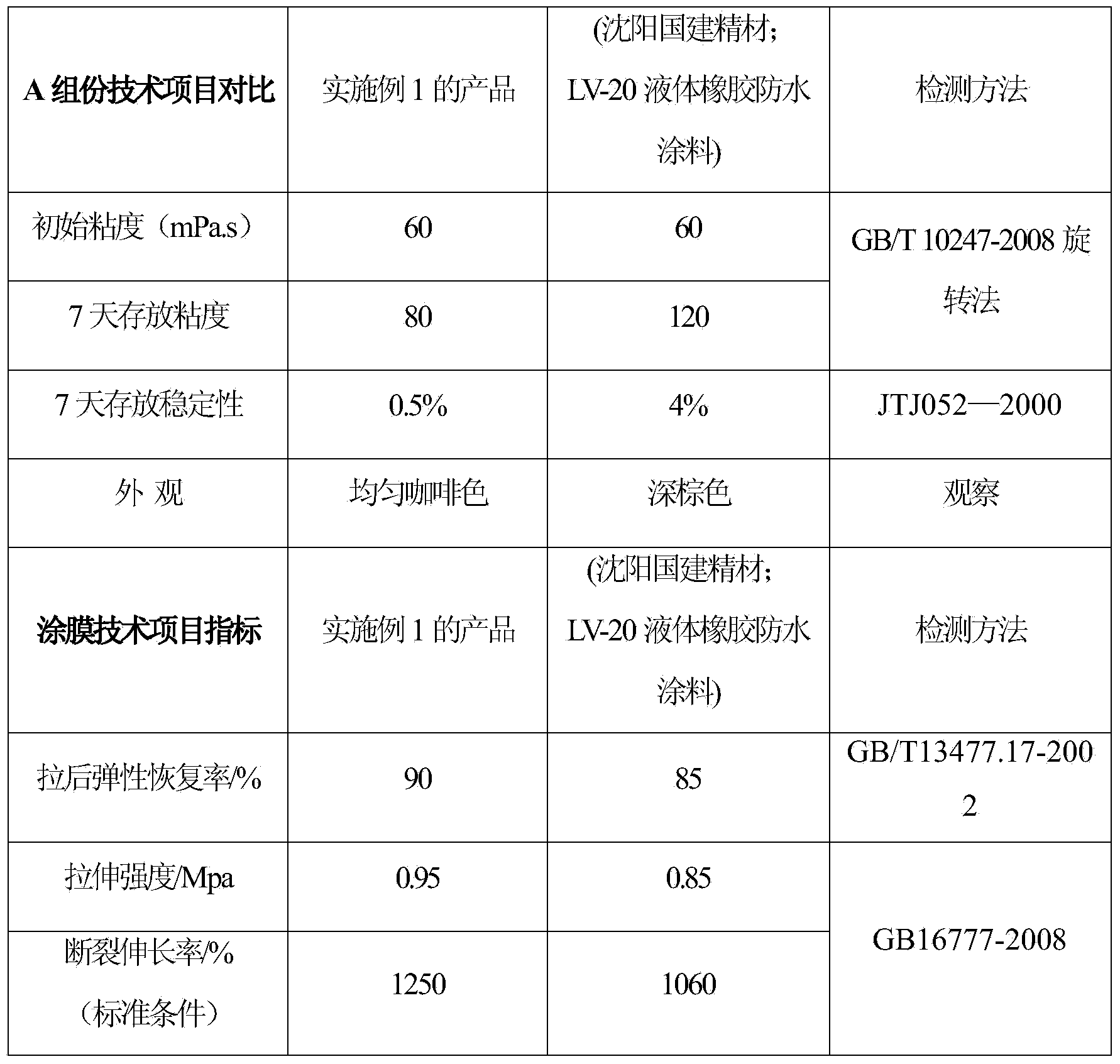

Embodiment 1

[0084] Add 2kg pH sodium hydroxide regulator, 5kg PTR-II anionic emulsifier, appropriate (4kg) PVA stabilizer (Bayer Company), 800kg deionized water, etc. -Ⅱ Anionic emulsifier, sodium hydroxide pH regulator, etc. are stirred, dispersed and dissolved, and the 90# heavy traffic asphalt in the asphalt mixing tank is heated to 140°C, and a proportional metering pump is used to calculate a certain ratio (according to the desired solid content) Determined) 80°C anionic emulsifier solution and 140°C 90# heavy traffic asphalt are pumped into the horizontal colloid mill, emulsified by high-speed shearing in the colloid mill, and emulsified asphalt with a solid content of 55% is prepared, and the sieve residue of 300 mesh sieve is less than 1‰, the particle size of the emulsion is 1-10 mm, the appearance is brown, and it is pumped into the emulsified asphalt product storage tank.

[0085] Then add more than 520kg of self-made emulsified asphalt, an appropriate amount (30kg) of PVA stab...

Embodiment 2

[0090] Add 3kg of sodium hydride pH regulator, 4kg of PTR-I anionic emulsifier, appropriate amount of PVA stabilizer, 800kg of deionized water, etc. into the stainless steel emulsifier stirring tank, stir, disperse and dissolve the emulsifier pH regulator at 80°C , heat the 90# heavy-duty asphalt in the asphalt mixing tank to 150°C, use a proportional metering pump to pump the 80°C anionic emulsifier solution and 140°C 90# heavy-duty asphalt into the horizontal colloid mill in a certain proportion, and pass through the colloid Grinding high-speed shear emulsification to prepare emulsified asphalt with 55% solid content, 300-mesh sieve to filter residue less than 1‰, emulsion particle size 1-10mm, brown appearance, pump into emulsified asphalt product storage tank. Then add 550kg self-made emulsified asphalt, appropriate amount of special PVA stabilizer, defoamer and other additives to the modified asphalt dispersion tank in order, adjust the pH value to 10-11, rotate the speed ...

Embodiment 3

[0094]Add 3kg of potassium hydroxide pH regulator, 4kg of PTR-II anionic emulsifier, appropriate amount of PVA stabilizer, 800kg of deionized water, etc. into the stainless steel emulsifier stirring tank, stir, disperse and dissolve the emulsifier pH regulator at 80°C , heat the 90# heavy-duty asphalt in the asphalt mixing tank to 150°C, use a proportional metering pump to pump the 80°C anionic emulsifier solution and 140°C 90# heavy-duty asphalt into the horizontal colloid mill in a certain proportion, and pass through the colloid Grinding high-speed shear emulsification to prepare emulsified asphalt with 55% solid content, 300-mesh sieve to filter residue less than 1‰, emulsion particle size 1-10mm, brown appearance, pump into emulsified asphalt product storage tank. Then add 530kg self-made emulsified asphalt, appropriate amount of special PVA stabilizer, defoamer and other additives to the modified asphalt dispersion tank in order, adjust the pH value to 10-11, rotate the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com