Patents

Literature

43results about How to "Easy to stratify" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based liquid rubber waterproof paint and preparation method thereof

InactiveCN103965783AStrong surface adhesionImprove stabilityConjugated diene hydrocarbon coatingsChloropene polymer coatingsWater basedMagnesium salt

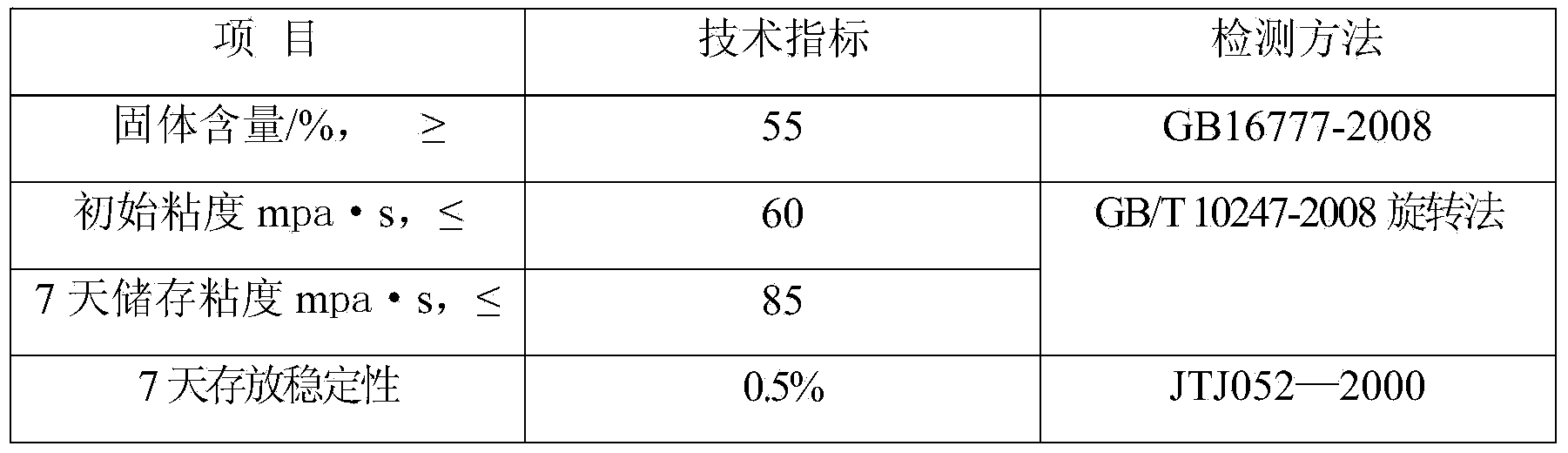

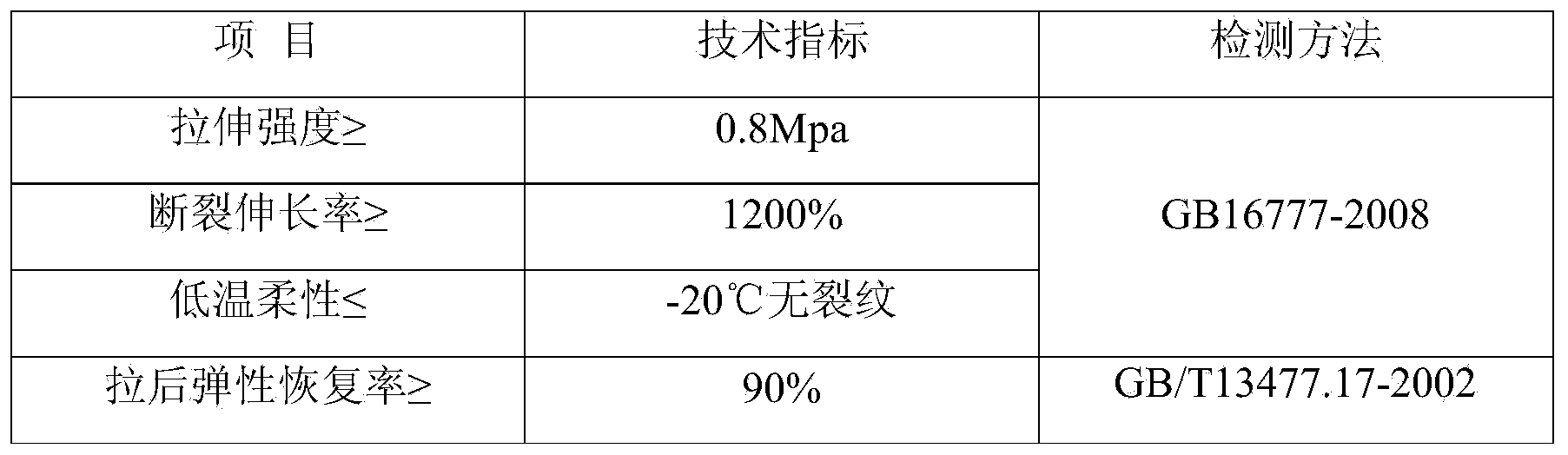

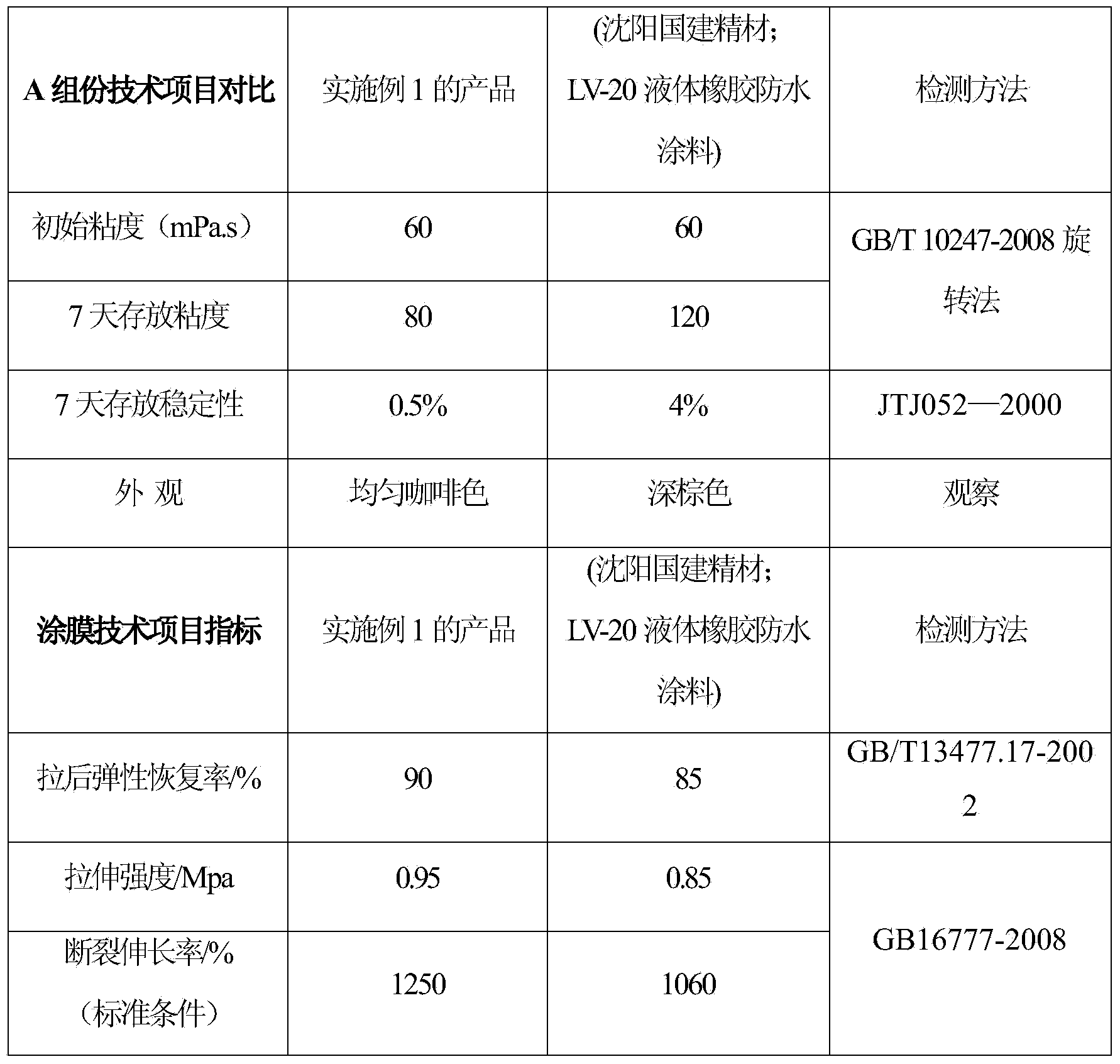

The invention discloses a water-based liquid rubber waterproof paint, comprising a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 35-65 parts of emulsified asphalt, 5-40 parts of chloroprene rubber emulsion, 5-40 parts of styrene-butadiene latex, 0.1-10 parts of polyvinyl alcohol (PVA) stabilizer, 0.1-5 parts of anionic dispersant, 0.1-5 parts of defoamer and 0.1-10 parts of pH modifier; the component B comprises the following raw materials in parts by weight: 75-95 parts of water and 5-25 parts of soluble calcium salt and magnesium salt. The water-based liquid rubber waterproof paint belongs to a water-based dual-component waterproof paint, and the component A and the component B are sprayed and mixed by special spray equipment in use according to a certain ratio, so as to instantaneously solidify and form a film. The water-based liquid rubber waterproof paint can be sprayed on any substrate surface, and is especially good in surface adhesion on metal, concrete, plastic and the like.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

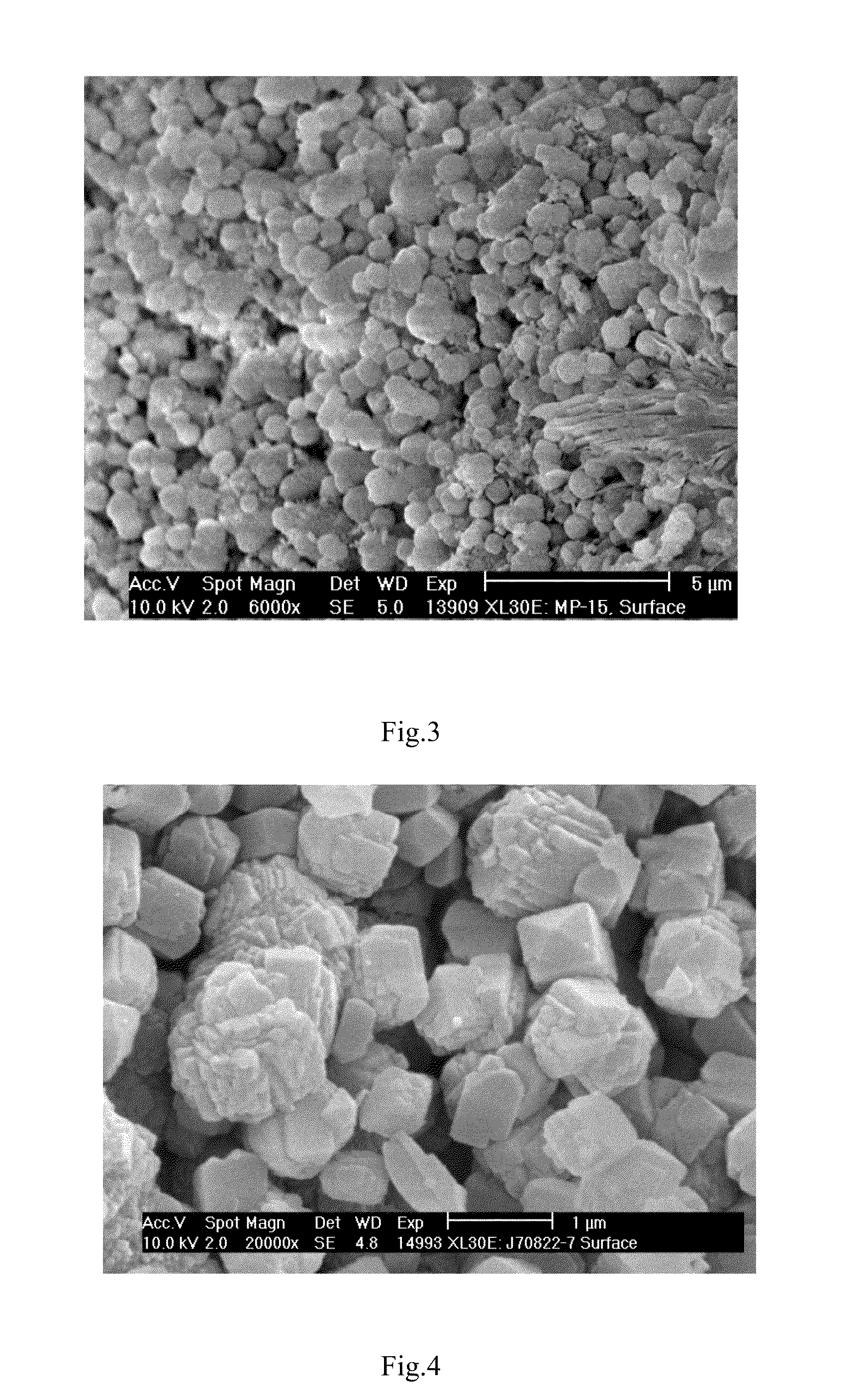

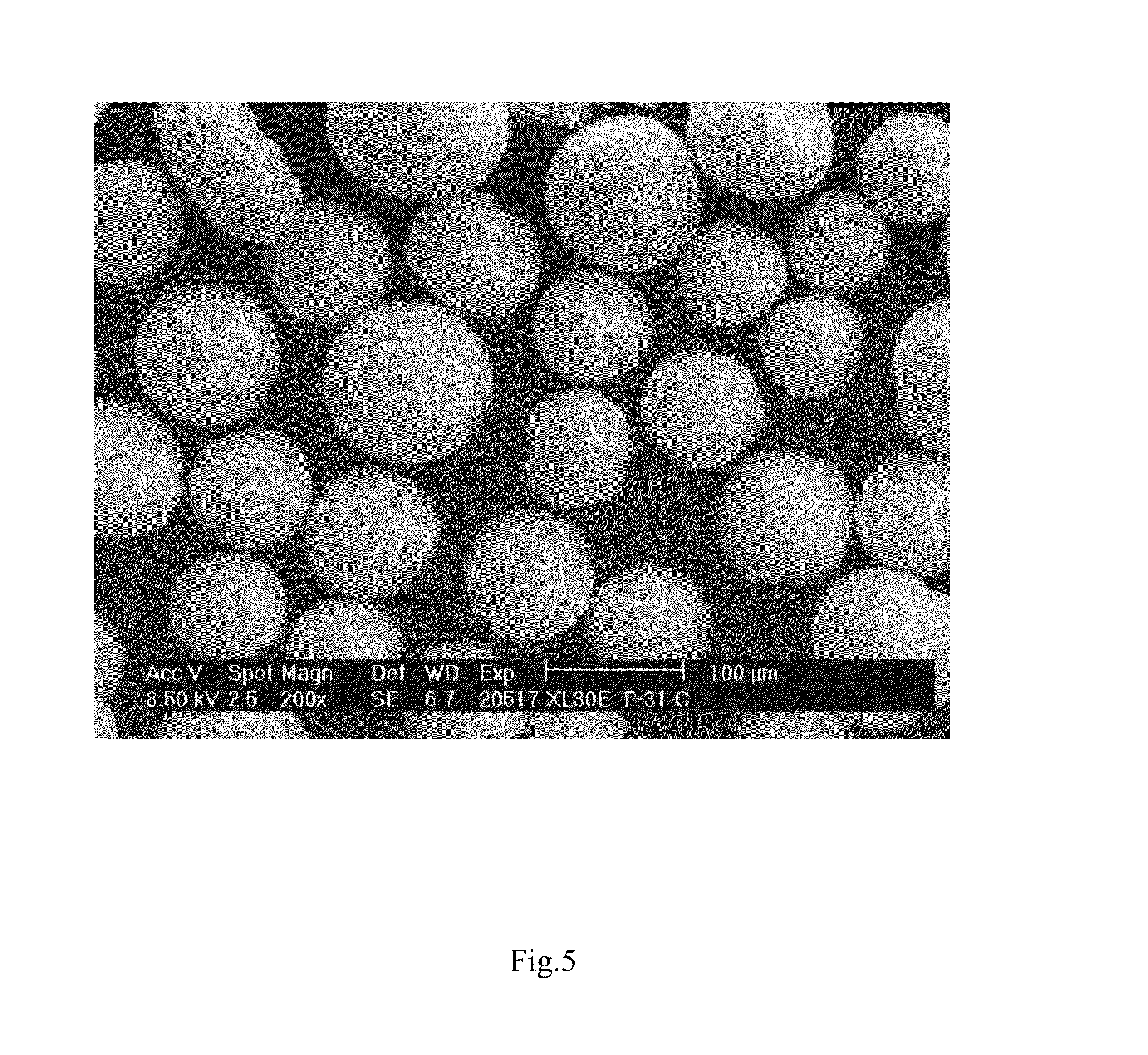

Binderless Molecular Sieve Catalyst and a Preparation Method Thereof

ActiveUS20130225397A1High activityGreat pore volumeAluminium compoundsMolecular sieve catalystsLow activityMolecular sieve

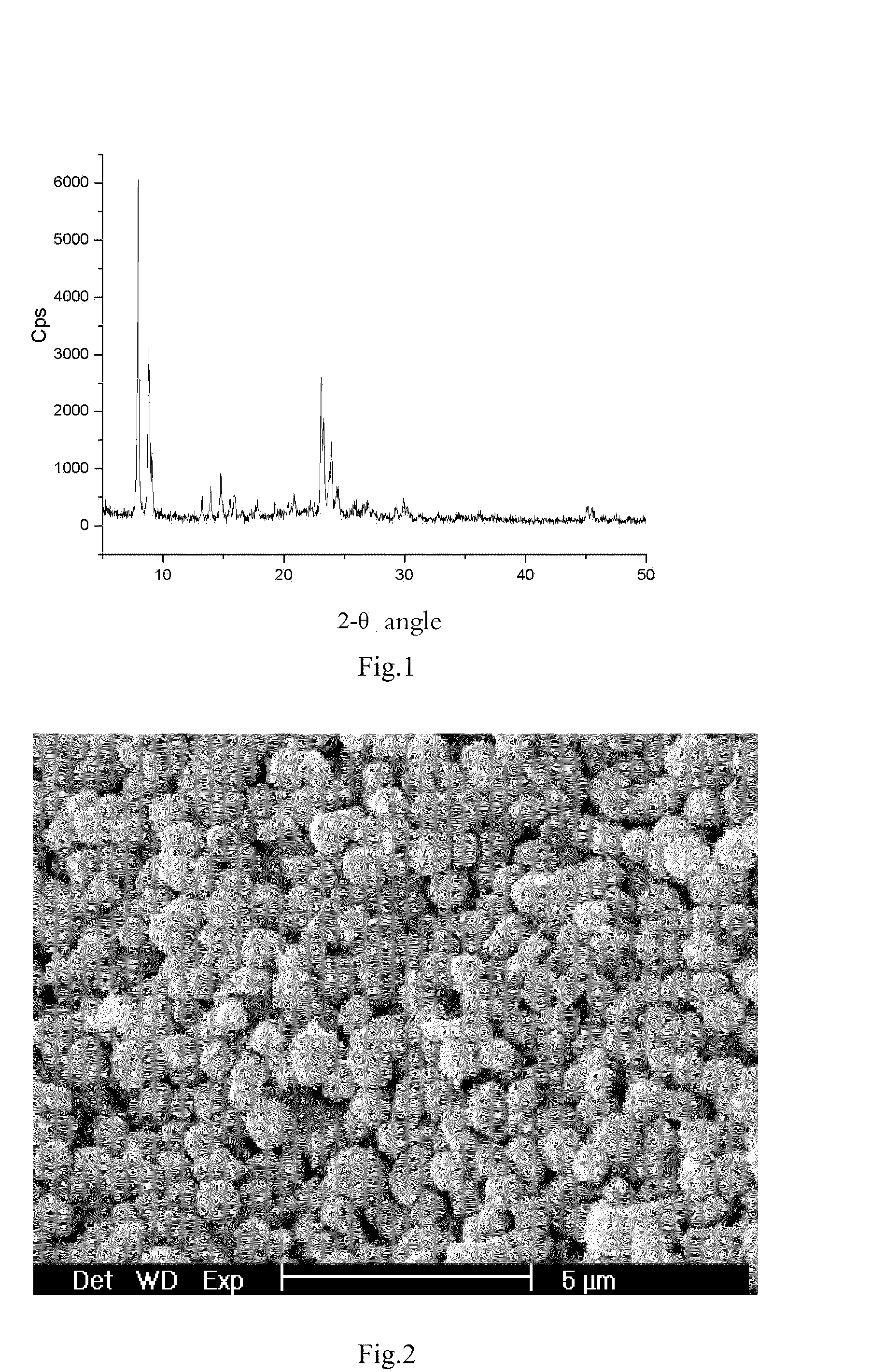

The present invention relate to a binderless molecular sieve catalyst and a process for preparing the same, which are mainly useful for solving the problems of the current catalysts, such as lower activity, less pore volume and worse diffusivity. The present invention relates to a novel binderless molecular sieve catalyst, comprising, based on the weight of the catalyst, 90-100 wt. % of a molecular sieve, 0-10 wt. % of a binder, and 0-10 wt. % of an anti-wear agent, wherein said catalyst has a pore volume of 0.1-0.5 ml / g, an average pore diameter of 50-100 nm, and a porosity of 20-40%; the anti-wear agent is selected from the rod or needle-like inorganic materials having a length / diameter ratio of 2-20. Said catalyst has the advantages of higher activity, greater pore volume, larger average pore diameter and porosity, and better diffusivity, and well solves said problems and can be used for the industrial preparation of binderless molecular sieve catalysts.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method for compound preparation comprising aspirin and alkaline drugs

The invention relates to a preparation method for a compound preparation comprising aspirin and alkaline drugs. The main technical points of the invention are that: the aspirin is prepared by dry granulation; the granulated aspirin and granules prepared by alkaline medicaments are pressed into double-layer tablets by a double-layer tablet machine; and then the double-layer tablets are coated. The aspirin is not stable and is easily hydrolyzed to generate free salicylic acid, so the dry granulation is adopted; the prepared double-layer tablets can prevent that the alkaline drugs quicken hydrolyzation of the aspirin; and the prepared coated tablets can be moistureproof, prevent that double layers of the double-layer tablets from being separated or expanded, and guarantee quality and stablity of products.

Owner:北京迈劲医药科技有限公司

Method for making micro powder ceramic polished brick have vivid stone effect

The method of making polished fine powder ceramic tile possess vivid stone material effect is the secondary material distributing process with the facing material. The present invention features the facing material powder for secondary material distributing, and the fine powder is prepared with the materials including clay, quartzite, feldspar powder, calcspar powder, talcum powder and silicate melt of expansion coefficient 200-250, and consists of CaO 10-25 wt%, MgO 0.5-5 wt%, Al2O3 3-16 wt%, SiO2 57-63 wt%, B2O3 1-2 wt%, ZnO 2-8 wt% and K2O+Na2O 1-8 wt%. The polished fine powder ceramic tile of the present invention has vivid stone effect and may be used in replace decorating natural stone material.

Owner:叶荣崧

Chinese medicinals pulverization method

InactiveCN1994332AAddressing Adaptive IssuesTo break through the technical difficulties of the continuous reduction in the efficiency of conventional ultrafine grindingPowder deliveryPill deliveryMedicineDrug

Owner:北京凯瑞创新医药科技有限公司

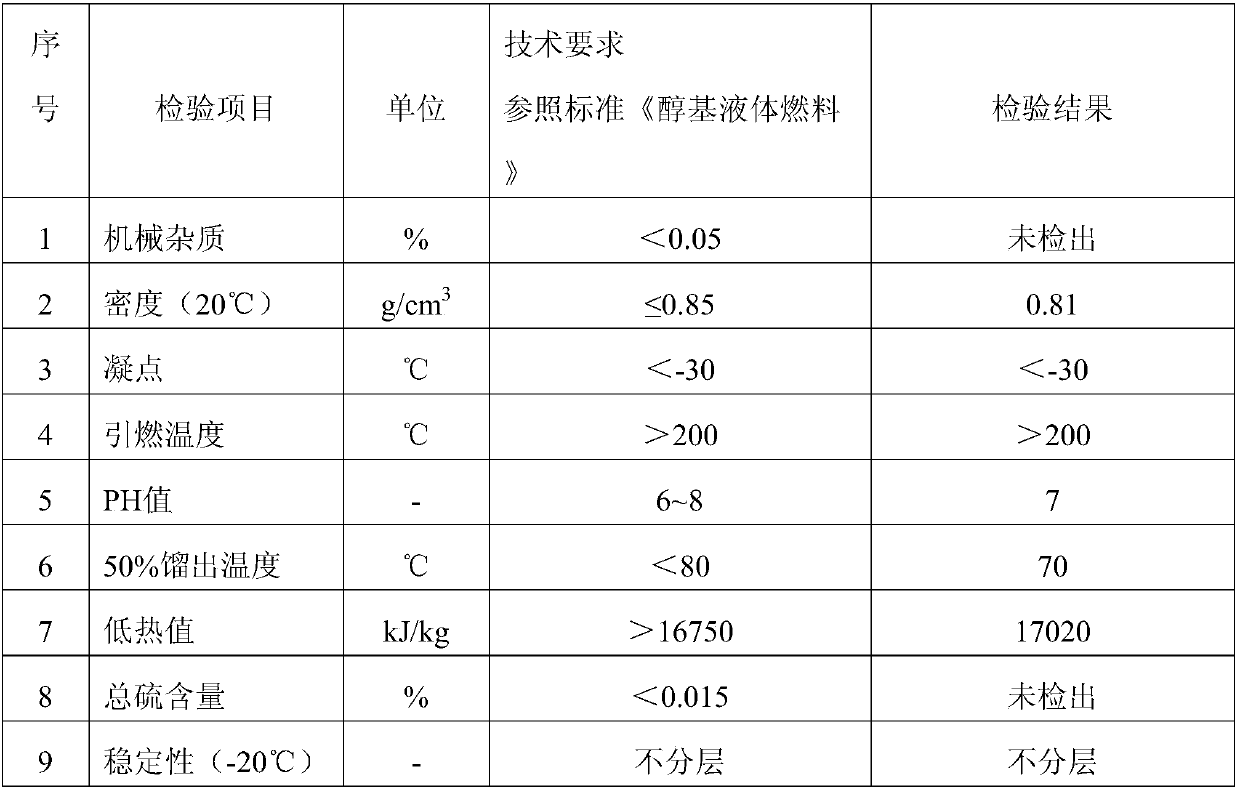

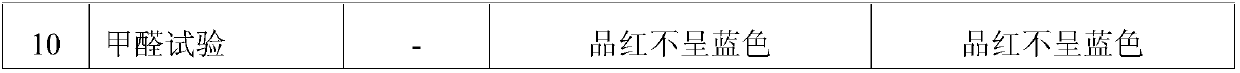

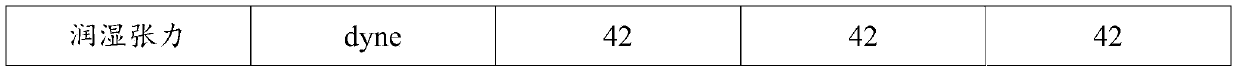

Environmental protection methanol diesel oil

InactiveCN101033419AEasy to stratifySolve the problem of cold start at low temperatureLiquid carbonaceous fuelsPetroleumMethanol

This invention relates to an environment protection methyl alcohol gasoline taking diesel oil, methyl alcohol, isobutanol, toluol and n-butyl alcohol as the raw materials to mix them in a container fully and uniformly under normal temperature and pressure to get a liquid product, which can be used in stead of diesel oil and reduces solidifying point of diesel oil .

Owner:北京福众金源环保科技有限公司

Universal methyl alcohol diesel

InactiveCN101376848AEasy to stratifySolve technical problems such as poor cold start at low temperatureLiquid carbonaceous fuelsEthyl acetateOleic Acid Triglyceride

The invention discloses universal carbinol diesel oil the composition prescription of which is as follows: 60 to 85 portions of diesel oil, 10 to 30 portions of carbinol, 0.5 to 3.0 portions of oleic acid, 1.0 to 2.0 portions of ethyl acetate, 0.5 to 1.5 portions of sherwood oil, 0.5 to 1.2 portions of cyclopentyl-dicyclopentadienyl iron, 0.3 to 1.5 portions of isoamyl nitrite, 0.5 to 1.5 portions of normal butanol as well as 0.5 to 1.2 portions of isoamylol; the mixture ratio is volume portion. The cetane value of the product achieves 53 and the flash point thereof achieves 80 DEG C; the tail gas exhaustion can meet the requirements of Euro III Standard, thus completely solving the technical difficulties like easy carbinol-oil separation, ill low temperature cool starting and needing not to change any device to locomotives, ships and commercial diesel engine; the universal carbinol diesel oil can be directly used or mixed, is not restrained by seasons and regions; the oil saving rate can achieve 10 to 15 percent; besides, the needed materials and auxiliaries are broad in sources, is low in price and is remarkable in economic benefits. The universal carbinol diesel oil can be popularized and applied.

Owner:上海龙津石油有限公司

Methanol diesel oil for automobile

InactiveCN101368115AEasy to stratifySolve technical problems such as poor cold start at low temperatureLiquid carbonaceous fuelsEthyl acetateOleic Acid Triglyceride

The invention discloses methanol-diesel for vehicle. According to volume portion, the composition formulation comprises 20 to 65 portions of diesel oil, 30 to 70 portions of methanol, 0.5 to 1.5 portions of oleic acid, 0.5 to 2.0 portions of ethyl acetate, 0.5 to 1.0 portions of diphenyl carbonate, 0.5 to 1.5 portions of petroleum ether, 0.3 to 0.7 portions of cyclopentyl ferrocen, 0.2 to 0.8 portions of nitric acid iso-octyl, 0.5 to 2.0 portions of normal butyl alcohol and 0.5 to 1.5 isobutyl alcohol. The formulation is suitable for the normal diesel oil of any label, the technical problems that the methanol-diesel is easy to be delaminated and the low temperature cool start is imperfect are solved, and the source of the required raw materials and auxiliary materials is wide and the price is low; the cetane value of the formulated methanol-diesel for vehicle can reach 57, the flash point can reach 88 DEG C, and the exhaust emission is accorded with the requirements of the 3# European standard; the using of the methanol-diesel for vehicle has important social significance and economic value for energy conservation and environmental protection.

Owner:SHANGHAI SHUNTIAN CHEMISTERY TECH

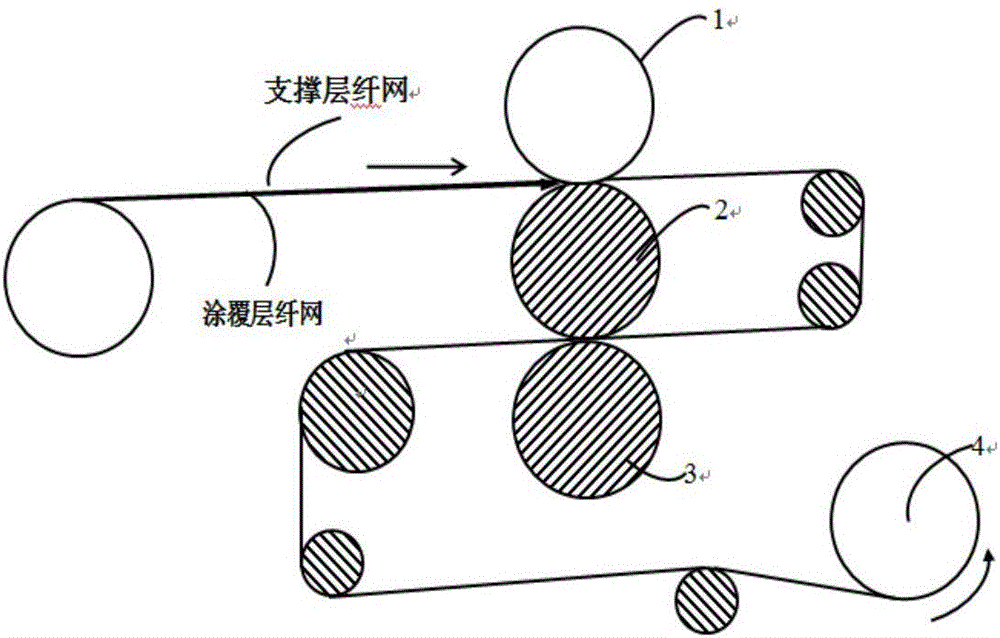

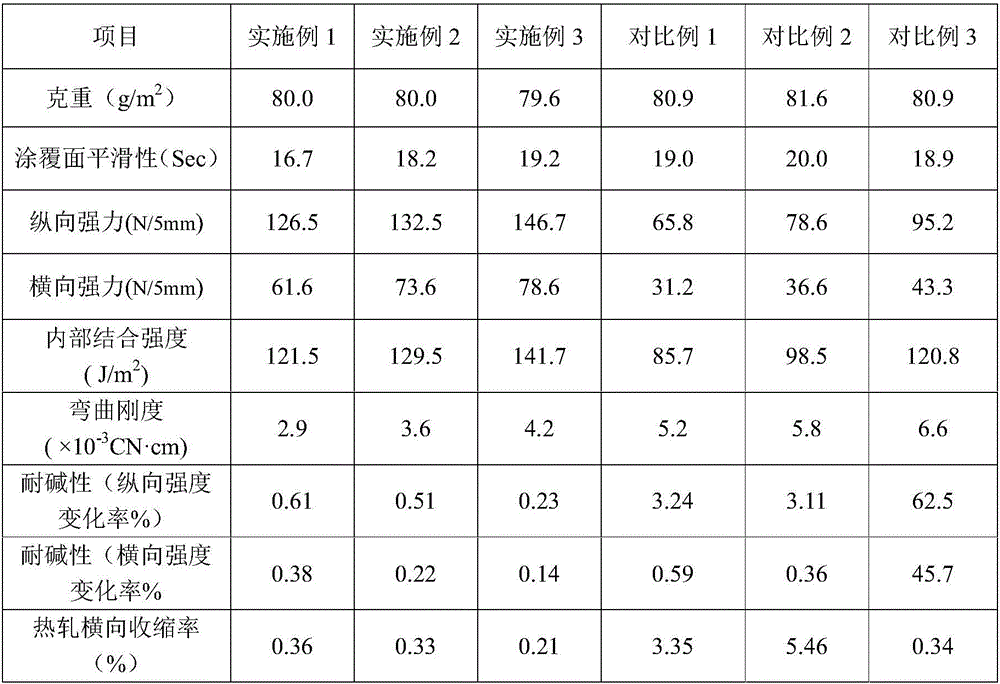

Double-layer alkali-resisting separation membrane support material and preparing method thereof

ActiveCN106582313ASolve the problem that it cannot be used in an alkaline environment for a long timeEffective tangleSemi-permeable membranesFibre typesHardnessSupport materials

The invention discloses a double-layer alkali-resisting separation membrane support material and a preparing method thereof. The double-layer alkali-resisting separation membrane support material comprises a coating layer and a support layer, and is prepared by spunlace and hot rolling calendaring. A thin diameter polypropylene fiber and a meldable fiber are adopted as raw materials by the coating layer, a thick diameter polypropylene fiber and a certain amount of meldable fiber are adopted as the raw materials by the support layer, through the steps of beating, pulp forming and the like, the raw materials are conveyed by different pulp supply systems to double-layer forming wet method equipment to prepare the pulp into a net respectively, and the double-layer alkali-resisting separation membrane support material is formed after spunlace and hot rolling calendarin. The double-layer alkali-resisting separation membrane support material adopts the technology, solves the problem that the double-layer separation membrane support body is poor in alkali resistance, prone to separated layers, low in strength, poor in flexibility and the like, and the double-layer separation membrane support material with an excellent alkaline resistant property, good interlayer binding force, a stable shape and state and moderate hardness and softness is prepared at low hot rolling pressure and temperature.

Owner:FOSHAN S L P SPECIAL MATERIALS +1

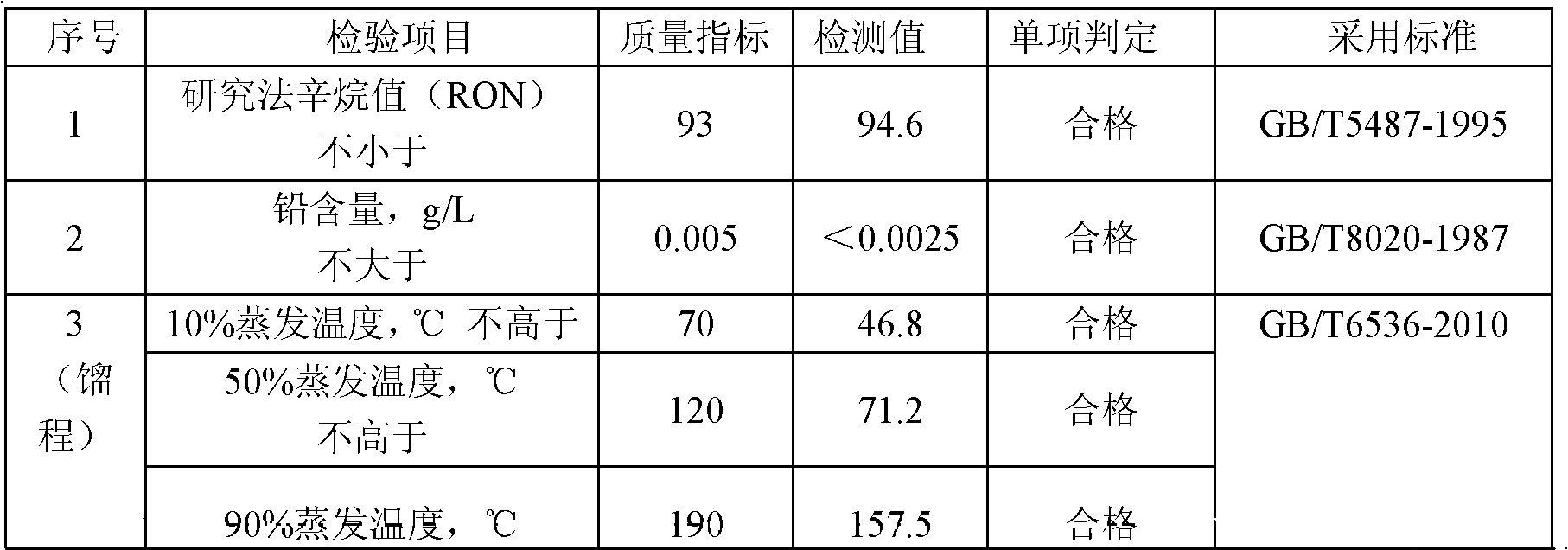

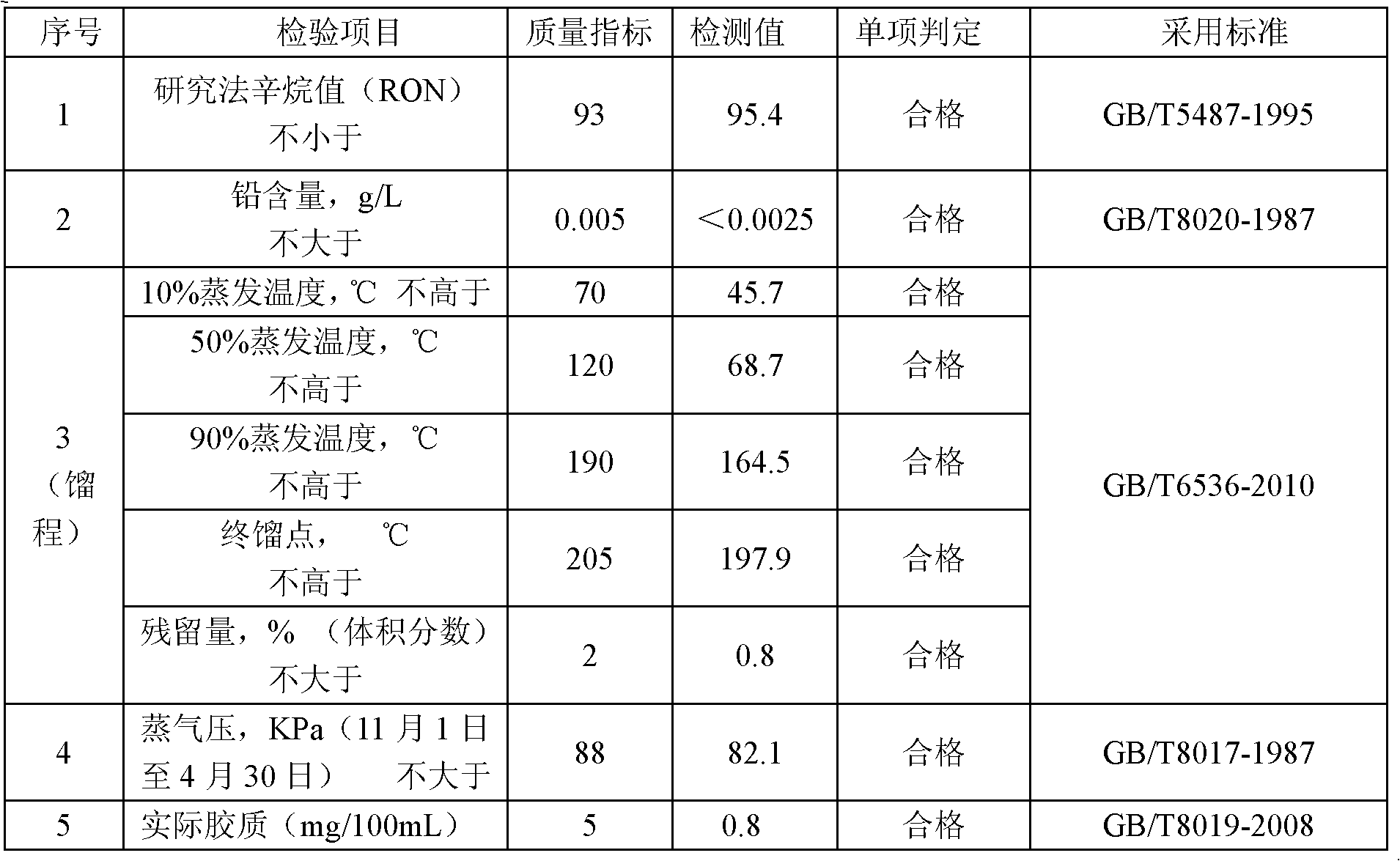

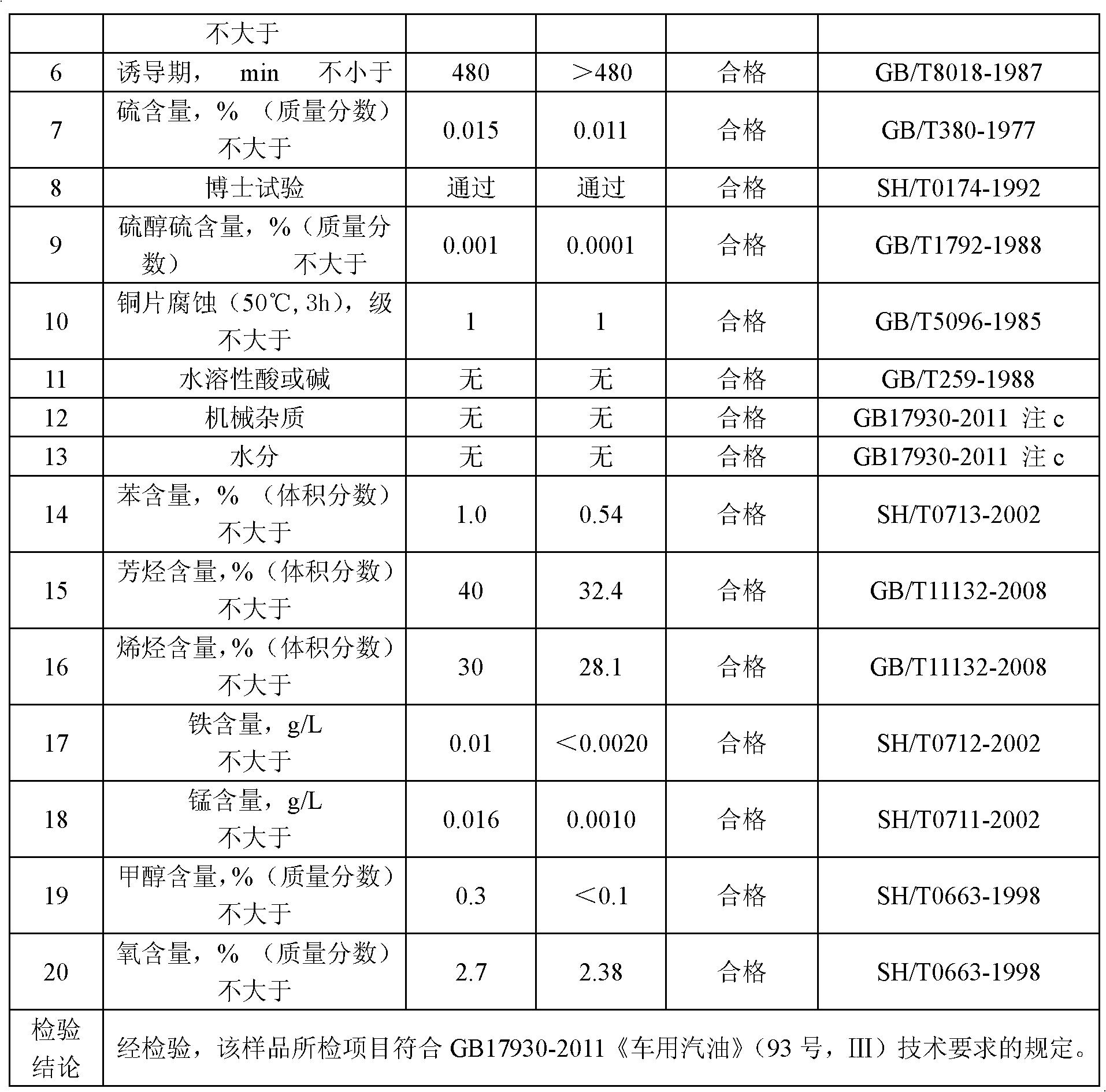

Clean motor gasoline

InactiveCN102559298AAlleviate resource shortagesImprove combustion efficiencyLiquid carbonaceous fuelsTert-butyl ethyl etherNaphtha

The invention discloses clean motor gasoline. The motor gasoline is prepared from the following raw materials in percentage by weight: 2 to 50 percent of methyl acetate, 30 to 95 percent of normal gasoline, 2 to 20 percent of additive A and 1 to 10 percent of additive B, wherein the additive A is one or a combination of more than two of naphtha, petroleum ether and solvent oil; and the additive B is one or a combination of more than two of methyl ten-butyl ether, methylal, cyclopentadiene manganese tricarbonyl, methyl cyclopentadiene manganese tricarbonyl, iso-heptyl ester, tert-butyl ethyl ether, isopropanol, C7 aromatic hydrocarbon, C8 aromatic hydrocarbon and C9 aromatic hydrocarbon. Through detection of authorities, results prove that various indexes of the fuel meet the motor gasoline standard of China, and the fuel has the characteristics of high octane number, high cleanness, low energy consumption and strong power.

Owner:XIAN SHANGHUA TECH DEV CO LTD +1

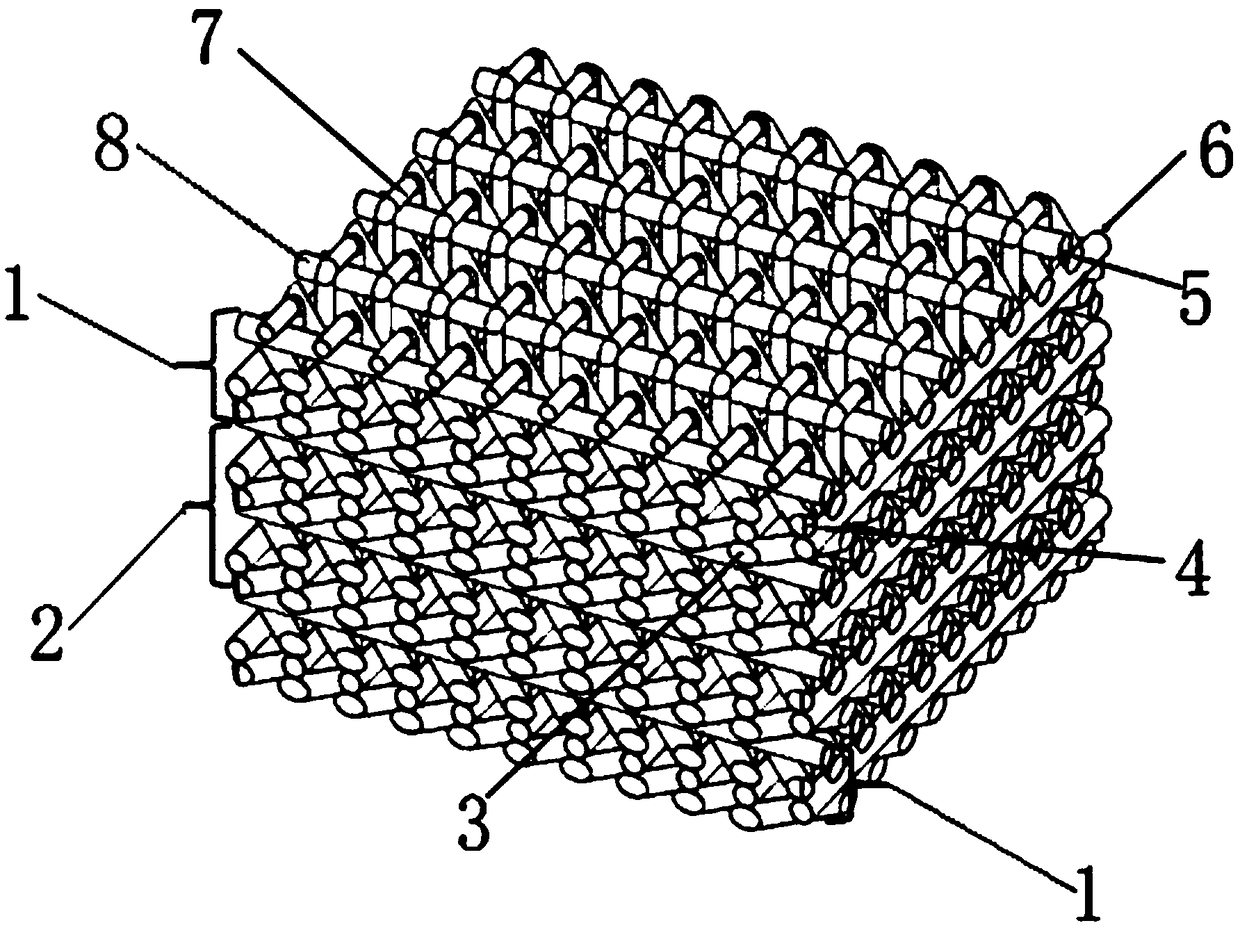

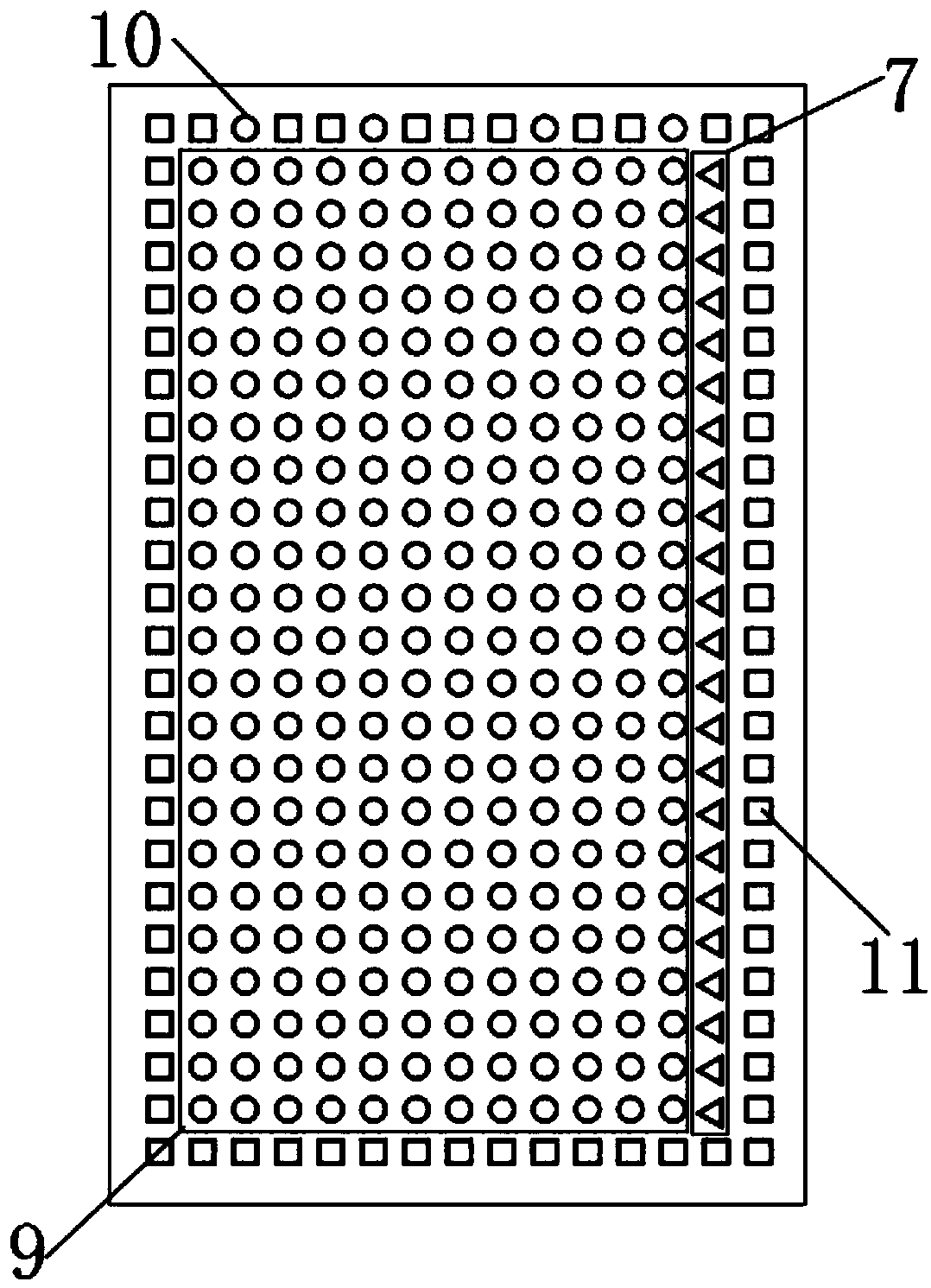

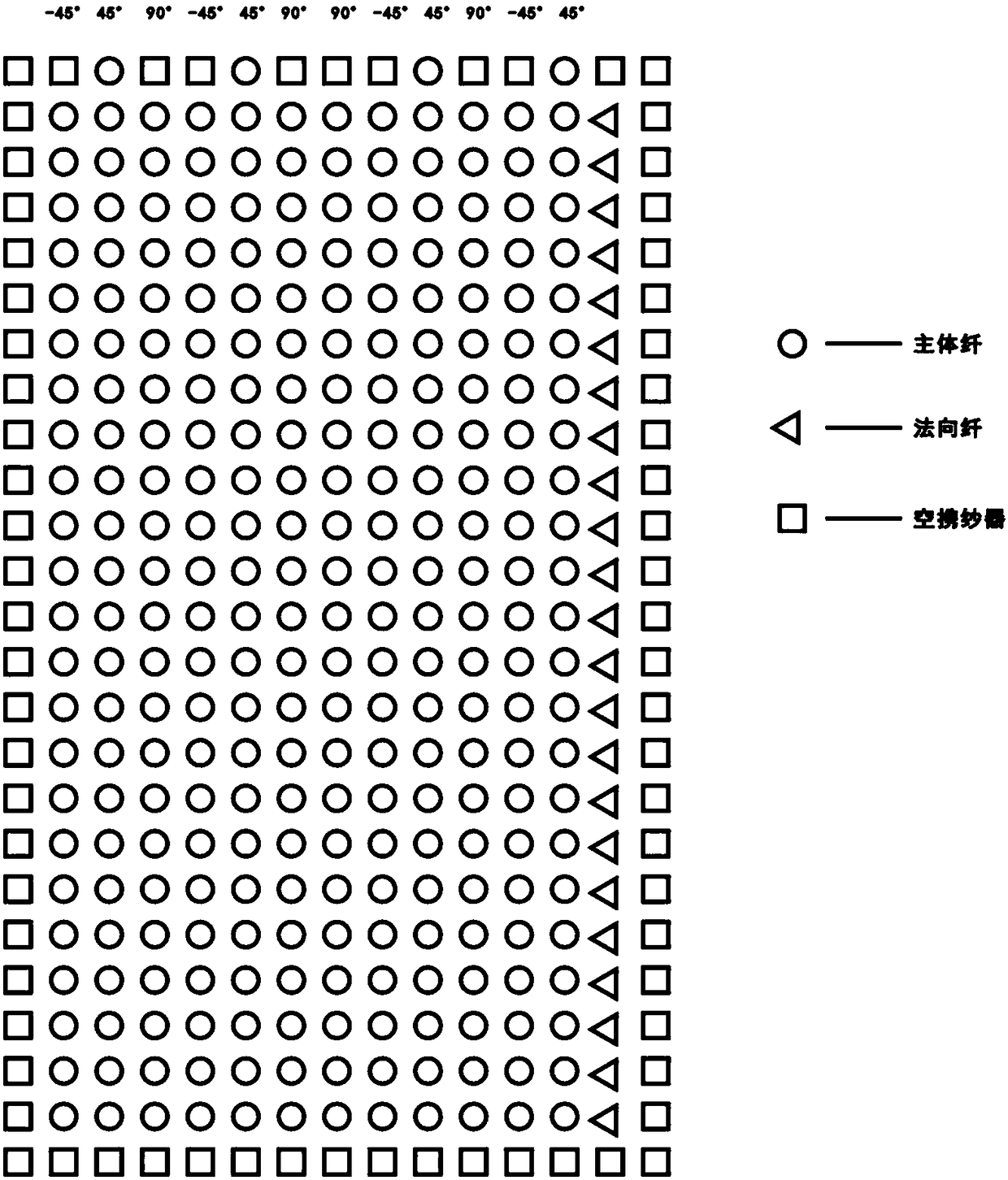

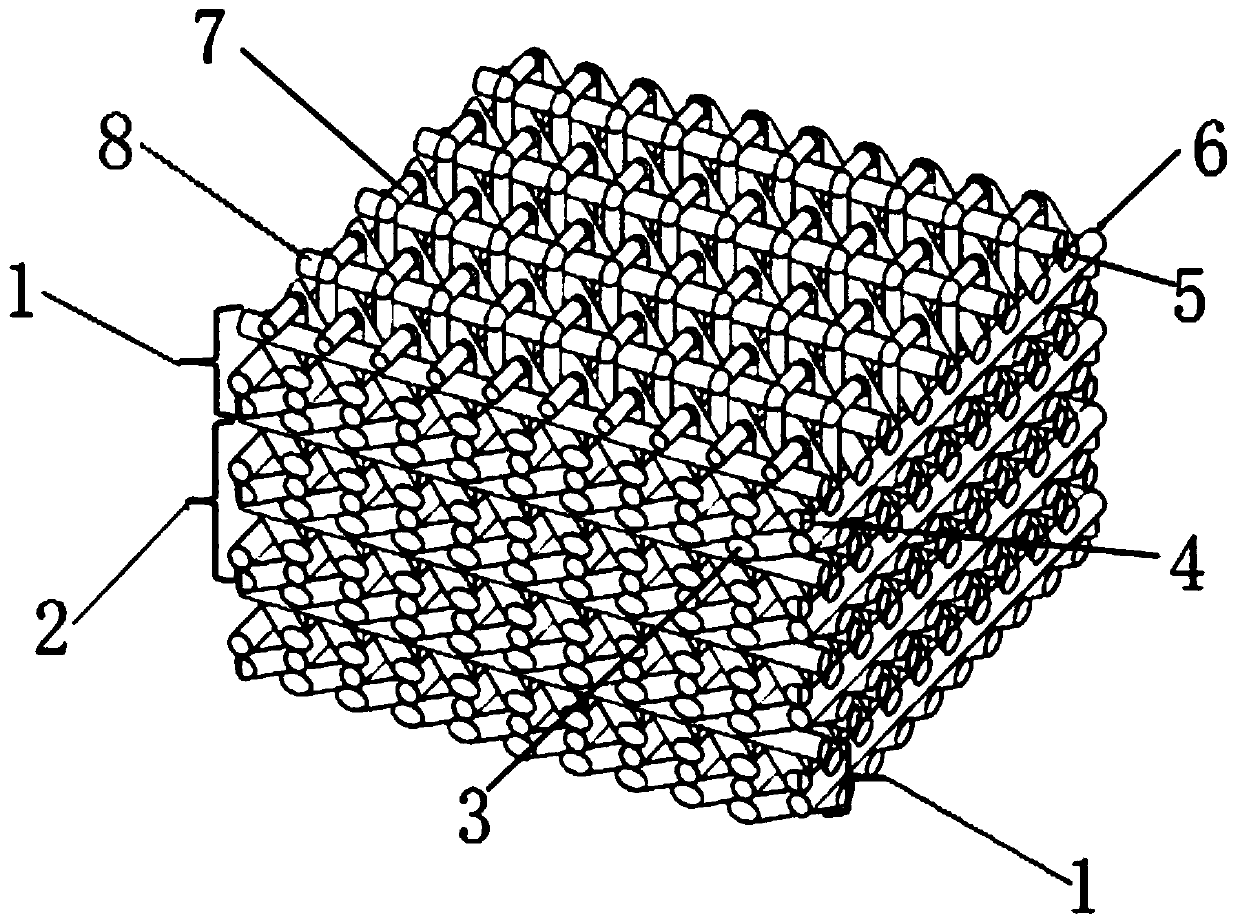

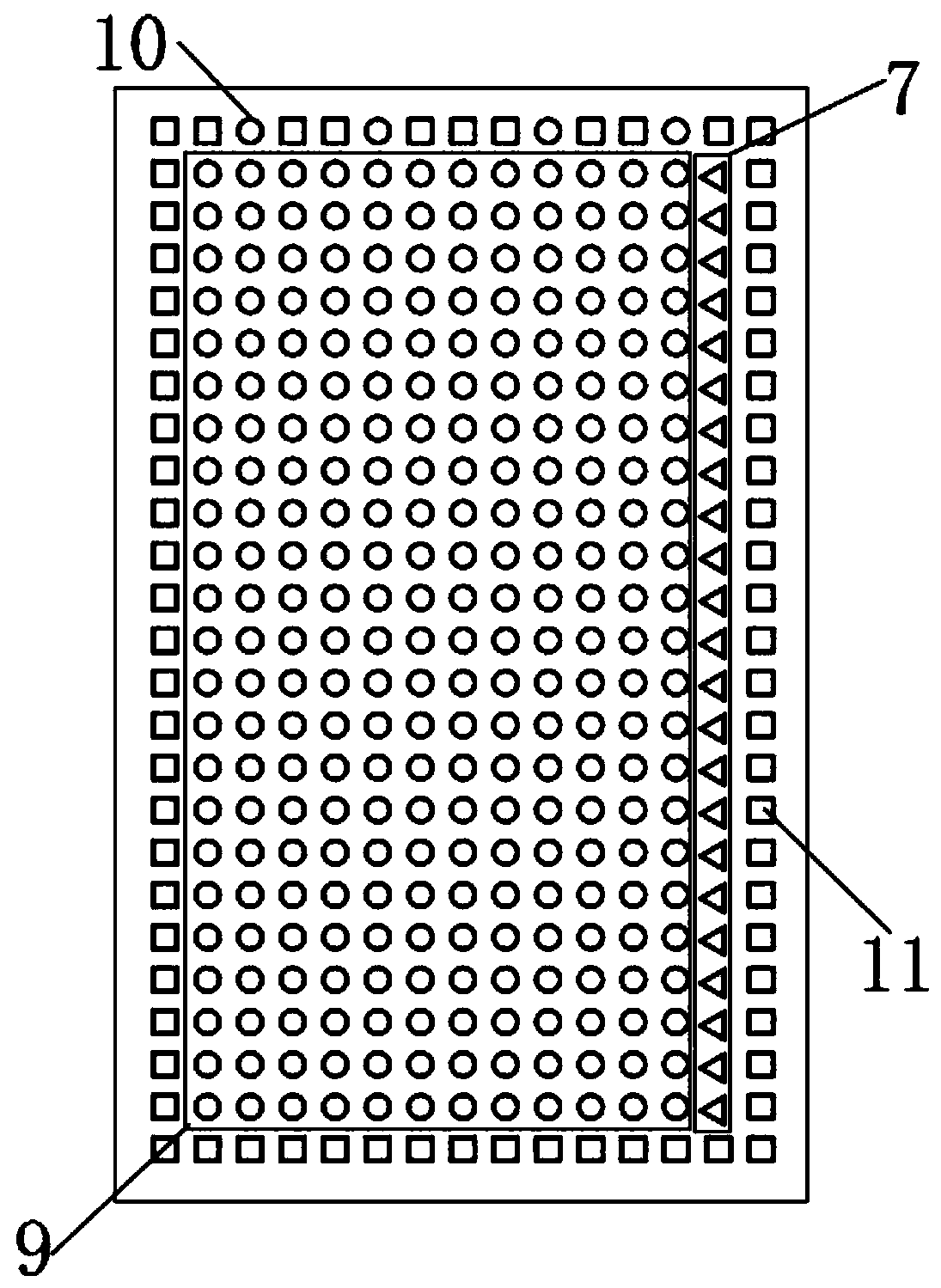

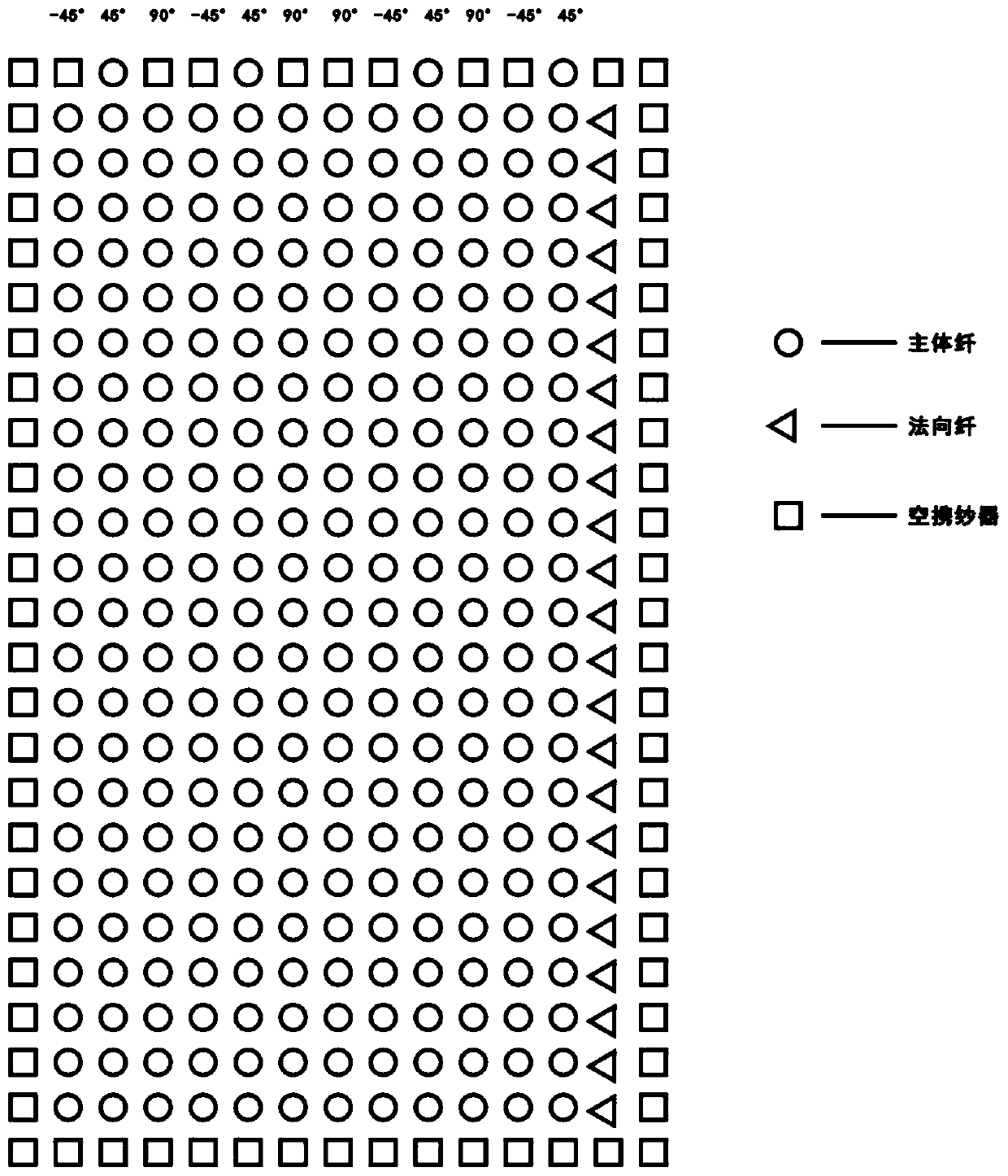

In-plane quasi-isotropic structure-stealthy composite material and preparation method thereof

The invention discloses an in-plane quasi-isotropic structure-stealthy composite material and further comprises a preparation method of the in-plane quasi-isotropic structure-stealthy composite material. The in-plane quasi-isotropic structure-stealthy composite material comprises a base body and a reinforcement body which are composited and solidified through a VARTM process. The base body is madeof resin; the reinforcement body is made of sandwich-type three-dimensional stereo woven material, the woven material is composed of a plurality of mutually-parallel fiber layers and normal fibers perpendicular to the fiber layers, and the fiber layers are bound together by the normal fibers through a weaving method. The preparation method specifically comprises the following steps of 1, weavingof the reinforcement body; 2, reinforcement body moulding; 3, glue injecting and solidifying; and 4, demoulding. The problems that as for a stealthy composite material in the prior art, the electromagnetic property is isotropic, the anti-impact property is poor, and the stealthy composite material is likely to be layered after being impacted are solved.

Owner:浙江世涛鼎革新材料有限责任公司

Methanol diesel-oil modified alcohol additive

InactiveCN101024786AEasy to stratifySolve the technical problem of poor cold start at low temperatureLiquid carbonaceous fuelsIsobutyl alcoholPetroleum

The invention relates to a methanol diesel oil modification alcohol additive that uses normal butyl alcohol, ferrocene and isobutyl alcohol as raw material, and whisking equal in the volume under room temperature and normal pressure to gain the product. It adds 1-3% additive into methanol to gain modified mellow after whisking, and adding the mellow into 0# diesel oil to gain the methanol diesel oil. The diesel oil condensation point would be decreased by adjusting the methanol diesel oil and the pollution would be sharply decreased. It has great social benefits and economic benefits.

Owner:北京福众金源环保科技有限公司

Method for manufacturing composite welding blade

InactiveCN102049583AHigh bonding strengthSimple production processSoldering apparatusActive agentThermal stability

The invention discloses a method for manufacturing a composite welding blade, which comprises the following processes of: firstly, forming a groove matched with a tool bit on a matrix; secondly, placing the tool bit in the groove of the matrix; thirdly, filling a solder into a gap between the tool bit and the matrix, and then fixing; and finally, heating the assembled blade, and cooling the heated blade to obtain the composite welding blade. Based on the total mass of the solder, the solder comprises 60 to 95 percent of bonding agent, 25 to 1 percent of reinforcing agent and 15 to 0.5 percent of active agent; and the bonding agent, the reinforcing agent and the active agent are mixed uniformly to form the solder. The bonding agent, reinforcing granules, the active agent and the like are introduced, a transition phase substance is formed between the metal matrix and the composite tool bit in an alloying combination mode, and the transition phase plays a role in firmly connecting the matrix and the composite tool bit and has high strength and thermal stability.

Owner:FUNIK ULTRAHARD MATERIAL

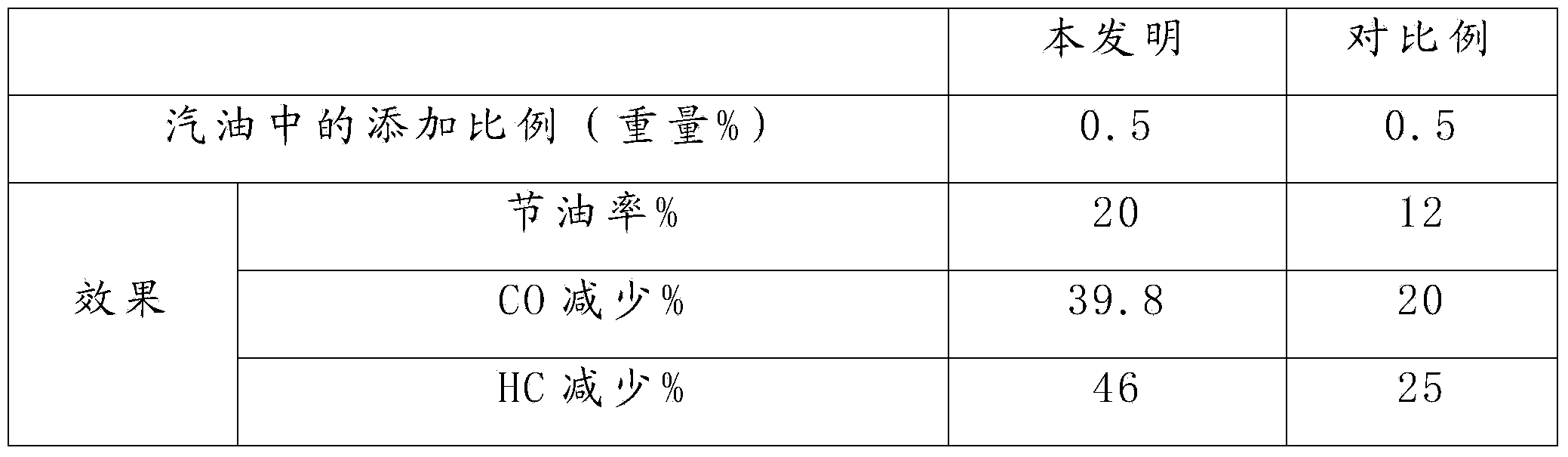

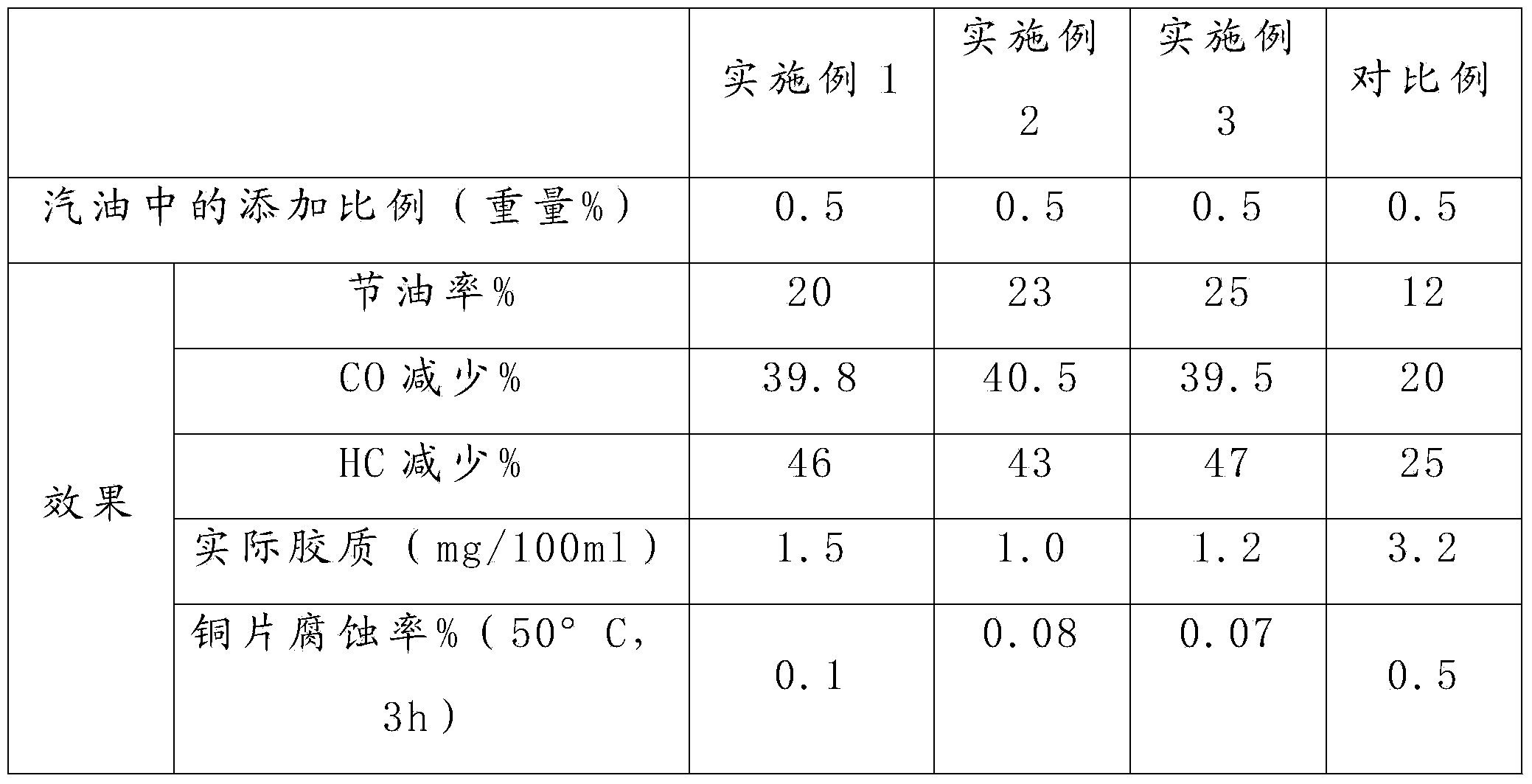

Alcohol gasoline additives and preparation method thereof

The invention belongs to the technical field of gasoline additives and in particular relates to alcohol gasoline additives and a preparation method thereof. The alcohol gasoline additives are prepared from the following materials in parts by weight: methanol, alcohol, isopropanol, methyl tertiary butyl ether, diethyl ether, polyisobutene imidodicarbonic diamide, methyl cyclopentadienyl manganese tricarbonyl, acetone, methyl isobutyrate and maleic anhydride. The alcohol gasoline additives disclosed by the invention not only solve a phenomenon that alcohol oil is easy to layer, bad in low-temperature cold starting and aired up at a high temperature, but also solve a problem that alcohol fuel has lager corrosion under an acid condition.

Owner:SHANDONG TAIDE NEW ENERGY

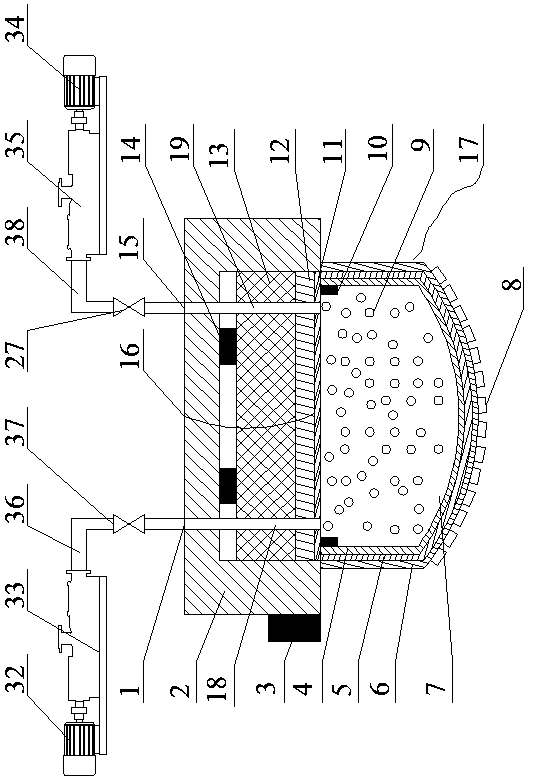

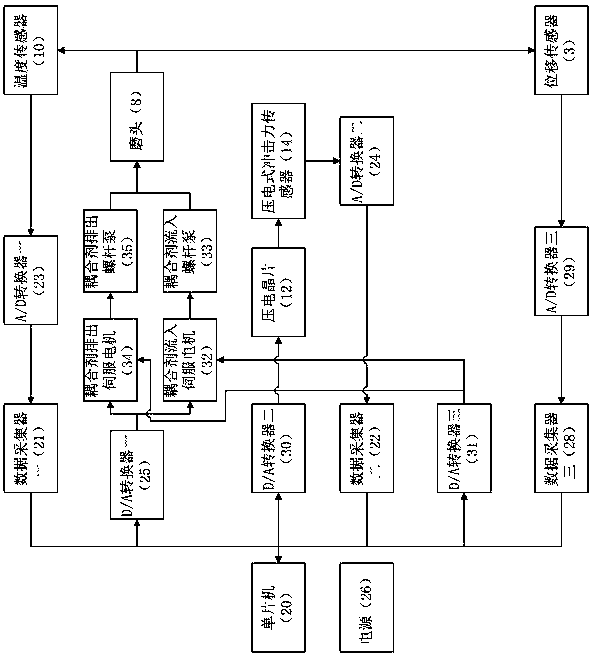

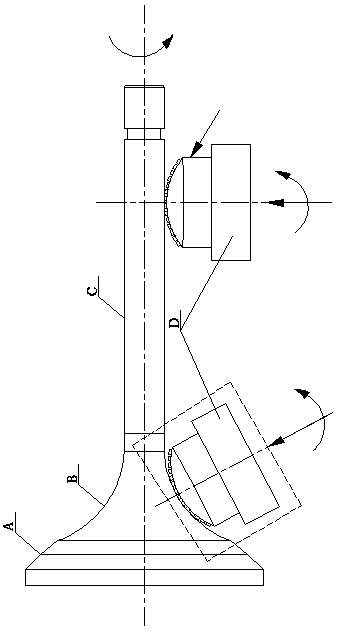

Ultrasonic combined adaptive anti-fatigue precision machining system and method of multi-curvature curved surface

ActiveCN108481138AImprove polishing efficiencyImprove fatigue lifeGrinding machine componentsGrinding machinesCouplingEngineering

The invention discloses an ultrasonic combined adaptive anti-fatigue precision machining system and method of a multi-curvature curved surface, and belongs to the field of mechanical precision machining common technologies. The ultrasonic combined adaptive anti-fatigue precision machining system and method of the multi-curvature curved surface aim to solve the technical problem of how to machine acurved surface of a key part with the multi-curvature curved surface while guaranteeing that the part has the anti-fatigue performance of a part with the multi-curvature curved surface. According tothe adopted technical scheme, the ultrasonic combined adaptive anti-fatigue precision machining system structurally comprises a flexible grinding head device and a control unit. The control unit is electrically connected with and has control over the flexible grinding head device, an ultrasonic coupling agent circulation structure and an impact vibration structure. The flexible grinding head device is used for machining the multi-curvature curved surface of the part. The control unit is used for having control over the working state of the flexible grinding head device. The flexible grinding head device comprises a flexible adjustment box body, the ultrasonic coupling agent circulation structure and the impact vibration structure. The impact vibration structure is arranged in the flexibleadjustment box body. The interior of the flexible adjustment box body communicates with the ultrasonic coupling agent circulation structure. The invention further discloses the ultrasonic combined adaptive anti-fatigue precision machining method of the multi-curvature curved surface.

Owner:QILU UNIV OF TECH

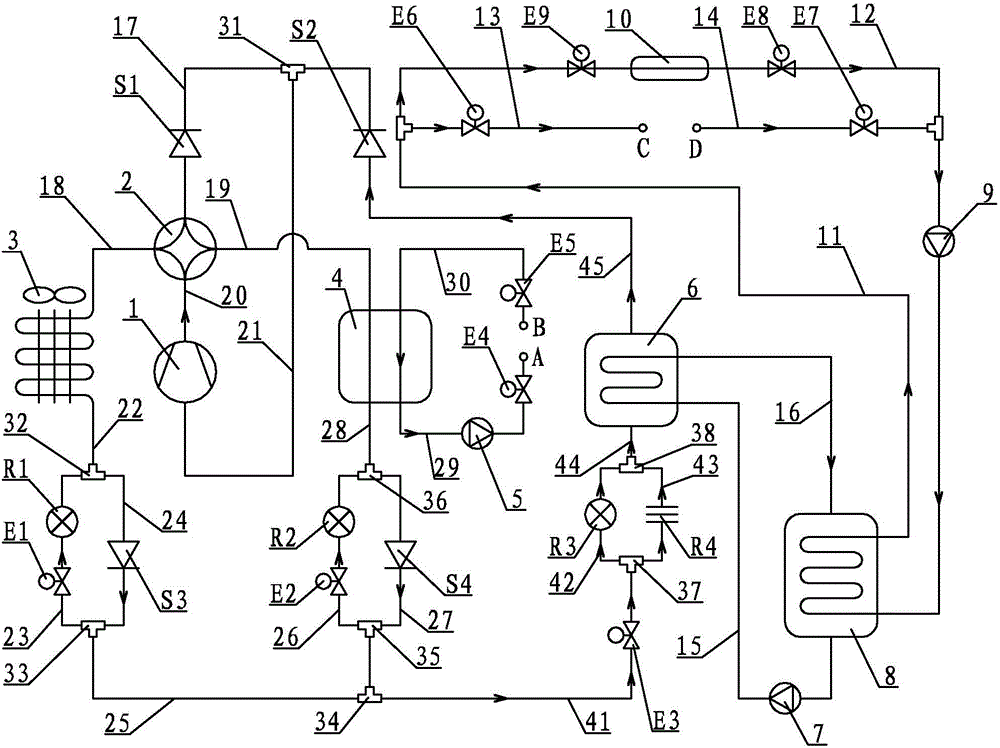

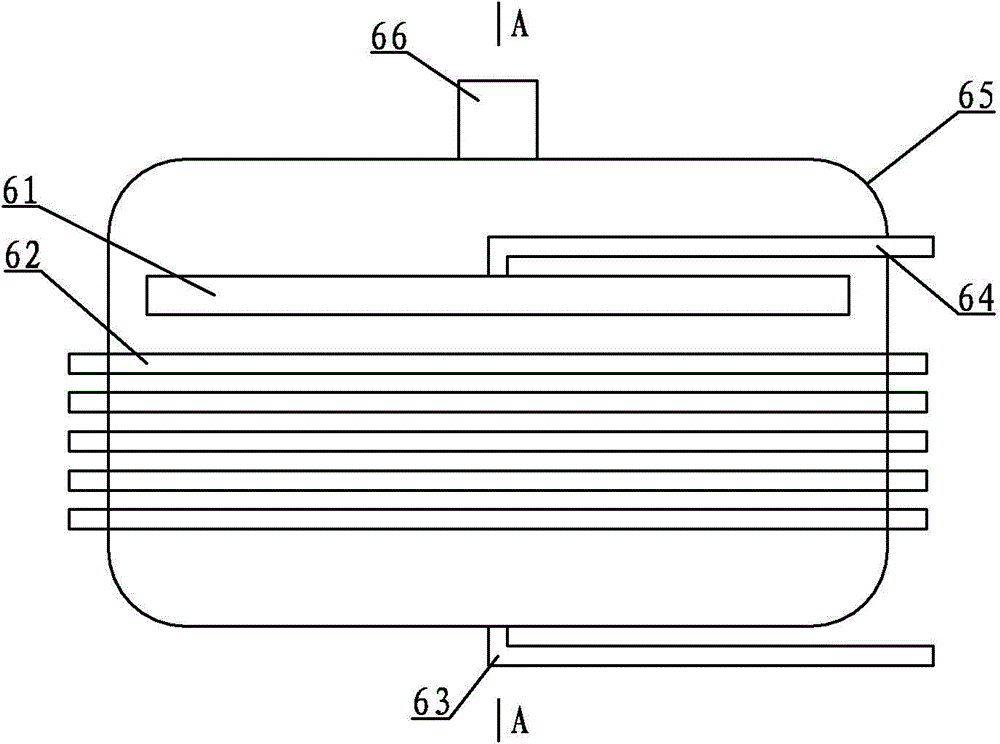

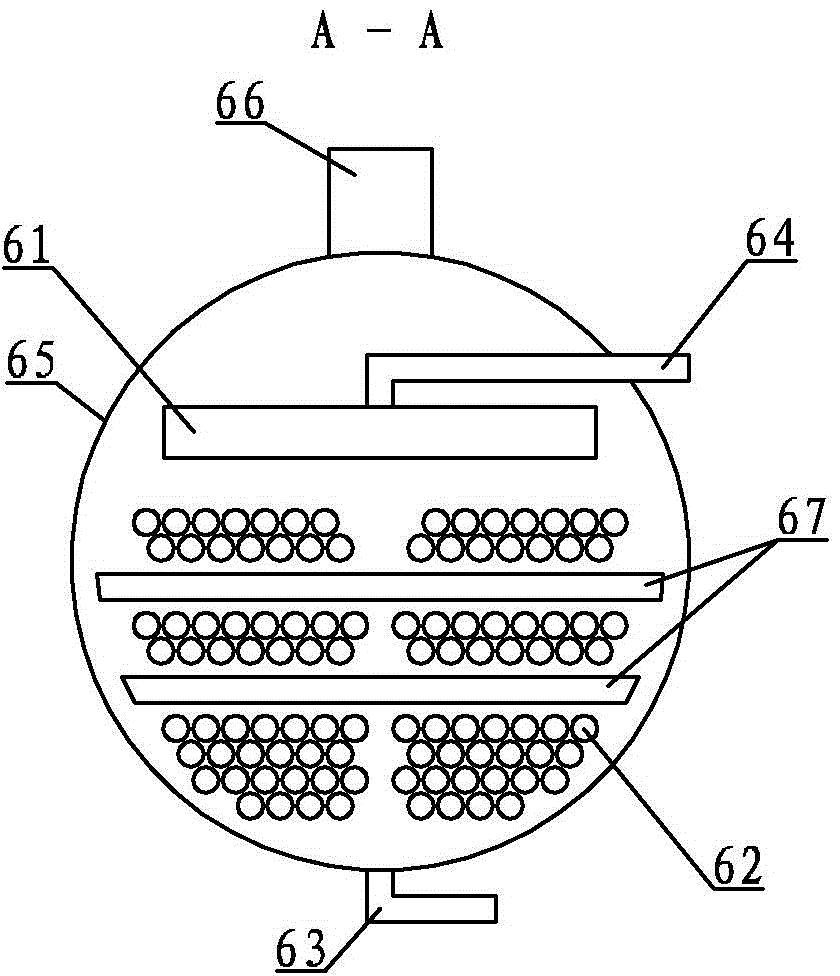

Flowing phase-change energy storing type falling-film evaporating heat pump unit

ActiveCN104406329AReasonable structureGuaranteed uniformityHeat pumpsRefrigeration safety arrangementEmulsionEnergy coupling

The invention provides a flowing phase-change energy storing type falling-film evaporating heat pump unit. The flowing phase-change energy storing type falling-film evaporating heat pump unit is that an inner water pipe inlet, a medium water pipe inlet and an outer water pipe inlet are all connected with a pump-out end of a water pump; an inner water pipe outlet, a medium water pipe outlet and an outer water pipe outlet are all connected with an inlet of a solar thermal collector; an outlet of the solar thermal collector is connected with a suction inlet of the water pump through a second pipeline; the outlet end of a phase-change micro-emulsion discharge pipe is connected with the suction end of a stainless steel magnetic pump; the inlets of a plurality of groups of phase-change micro-emulsion external surface enhanced pipe bundles are all connected with the pump-out end of the stainless steel magnetic pump, and the outlets of the plurality of groups of phase-change micro-emulsion external surface enhanced pipe bundles are all connected with a phase-change micro-emulsion feeding pipe of an energy storing tank; and an electric four-way reversing valve and a falling-film energy storing evaporating device are respectively connected with a compressor, an outdoor side fin type tubular air heat exchanger and a refrigerant / water drying type heat exchanger. The flowing phase-change energy storing type falling-film evaporating heat pump unit is applied to a solar energy and air energy coupling heat pump system.

Owner:HARBIN INST OF TECH

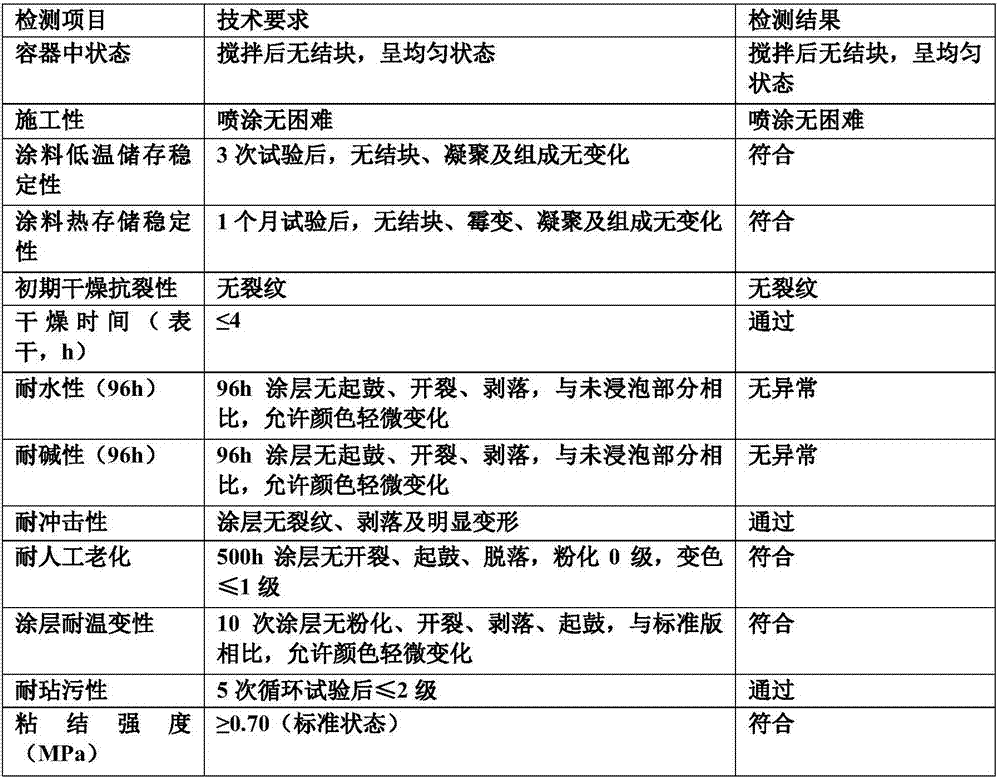

Stone-like coating for outer wall

The invention relates to the field of wall surface coatings, in particular to a stone-like coating for an outer wall. The stone-like coating is prepared from the following components in parts by mass:100 to 200 parts of emulsion, 300 to 400 parts of colored sand, 7 to 15 parts of a thickening agent, 0.5 to 1 part of a pH regulator, 8 to 15 parts of a coalescing agent, 0.5 to 1 part of a dispersing agent, 0.5 to 1 part of a defoaming agent, 0.5 to 1 part of a bactericide, 5 to 10 parts of a water repellent and 150 to 200 parts of deionized water, wherein the colored sand is used after being subjected to spray drying by using an aqueous solution of a chitosan / PEG blender. According to the stone-like coating for the outer wall, disclosed by the invention, the problems of high possibility oflayering, low film forming and drying speed and the like of an existing stone-like coating can be effectively solved; meanwhile, the usage of the colored sand in the formula is greatly reduced, so that the cost is reduced, and the application of natural colored sand in the coating is also facilitated.

Owner:YIWU INDAL & COMMERICAL COLLEGE

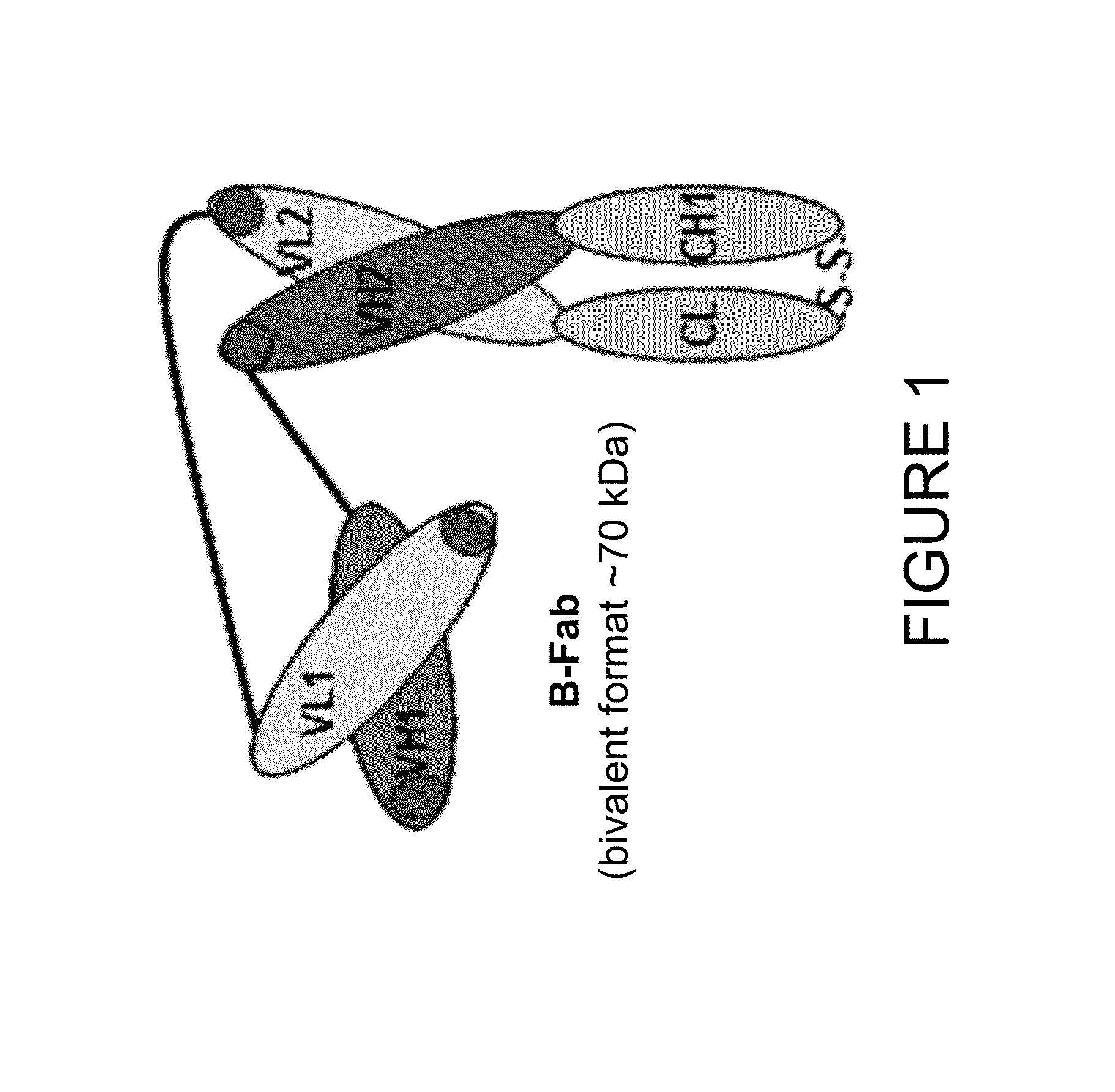

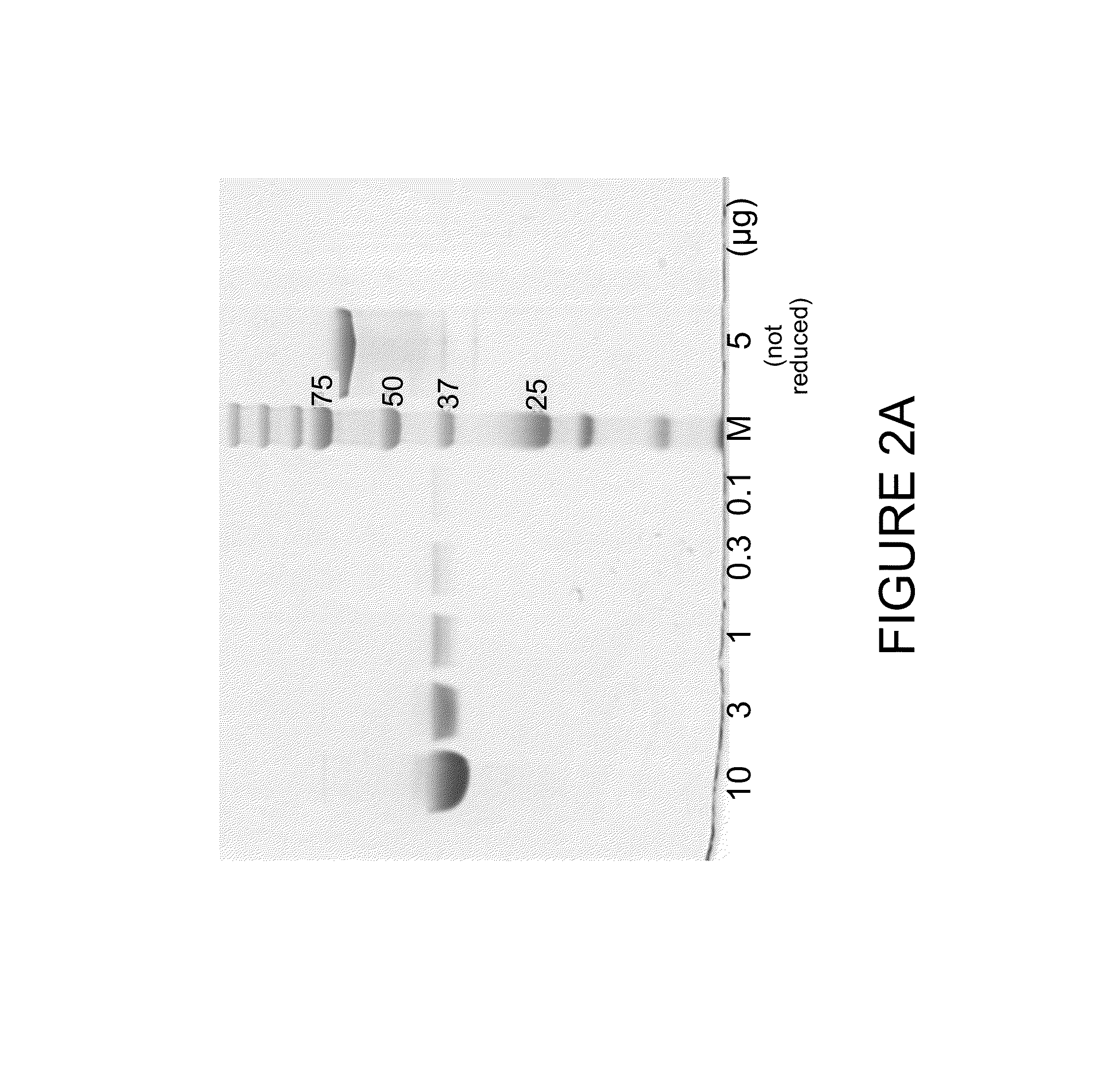

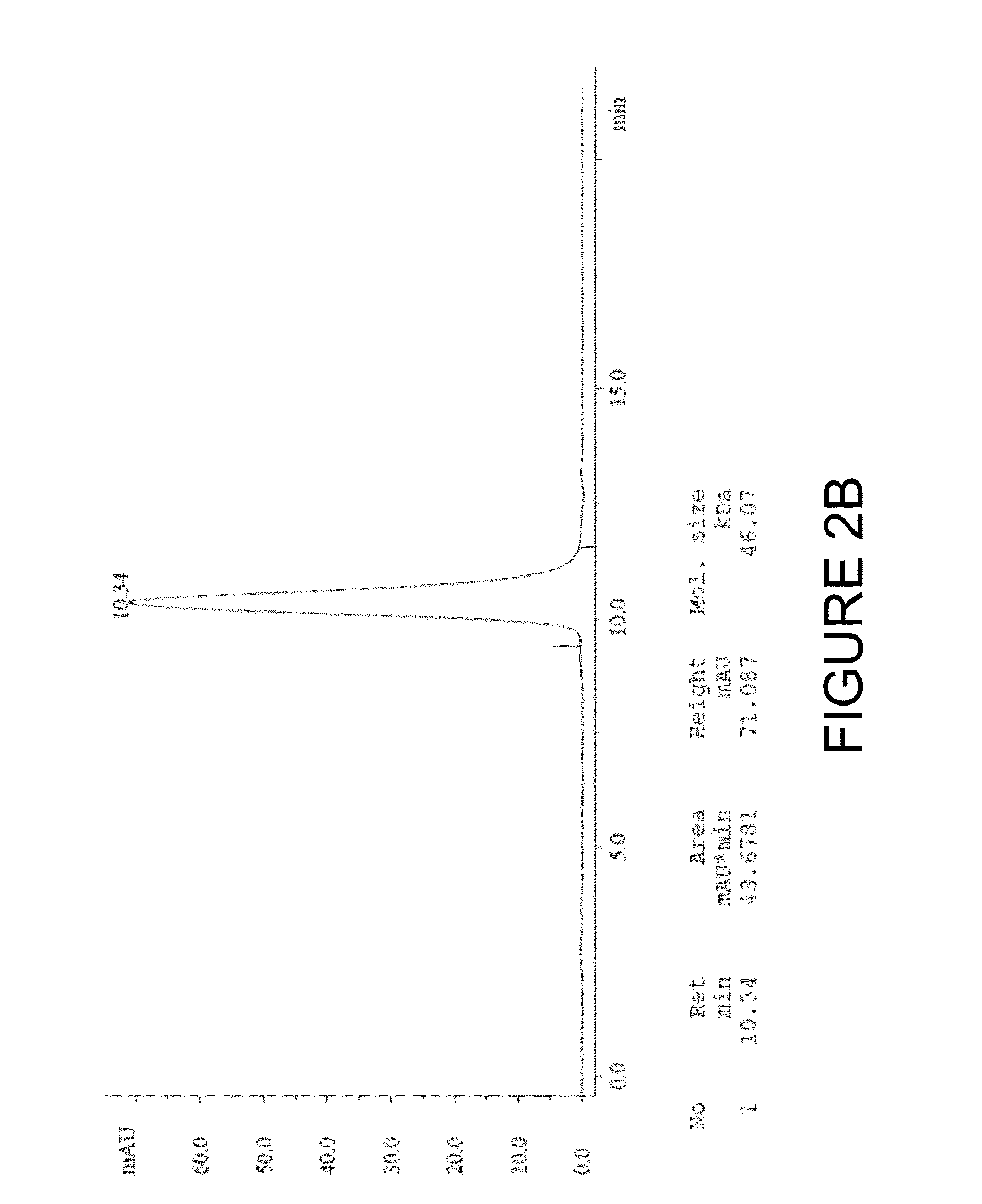

Immuno imaging agent for use with antibody-drug conjugate therapy

ActiveUS20140256916A1Easy to stratifyFacilitates early evaluationFermentationPlant genotype modificationMedicineImaging agent

The invention relates to a companion diagnostic antibody-like binding protein based on the humanized monoclonal antibody, DS6, to be used as diagnostic tool for in vivo detection and quantification of the tumor-associated MUC1-sialoglycotope, CA6.

Owner:SANOFI SA

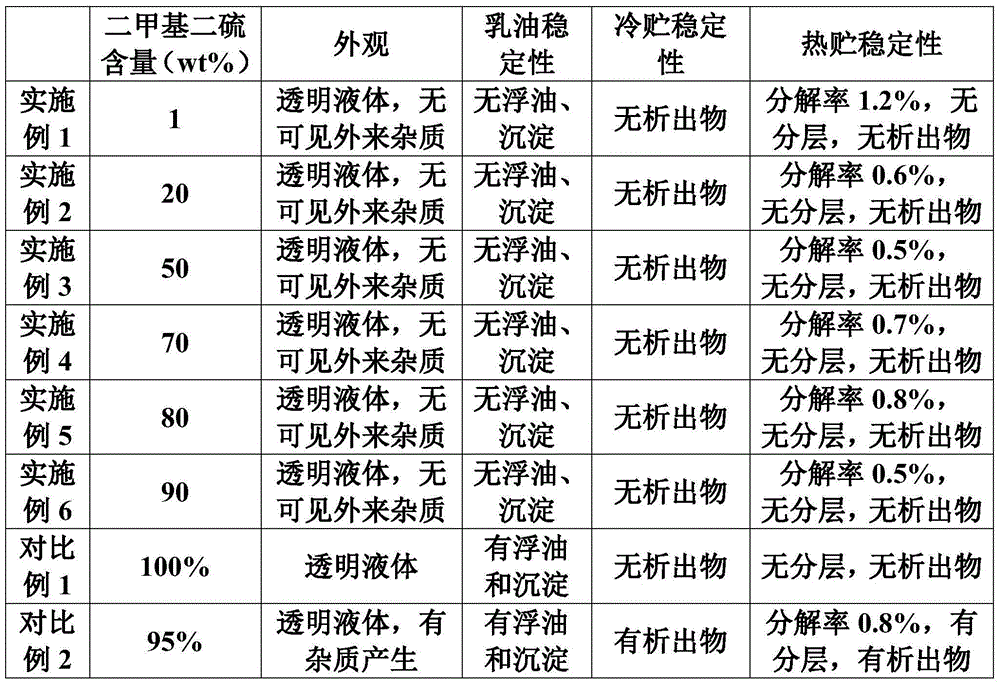

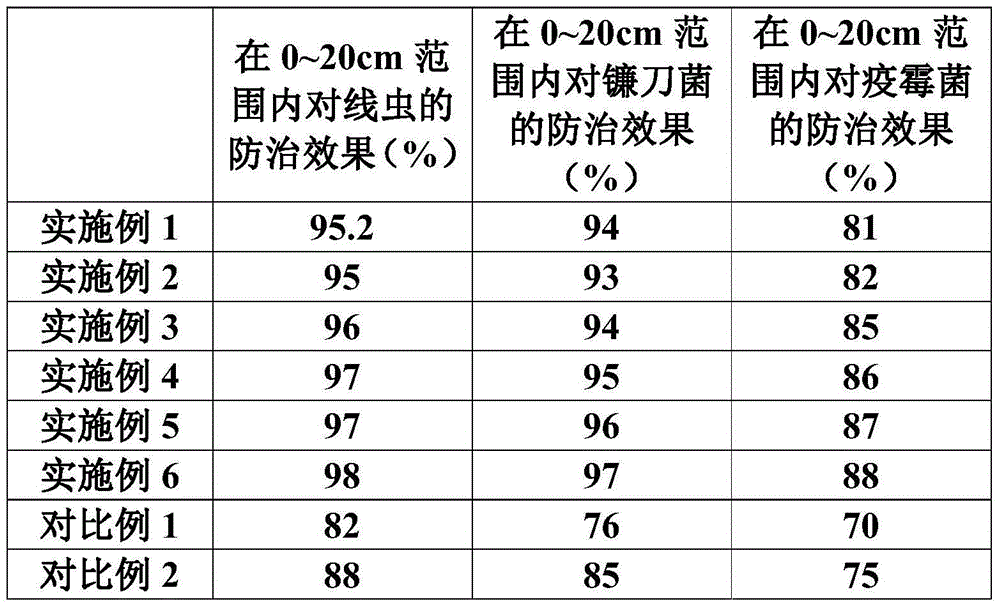

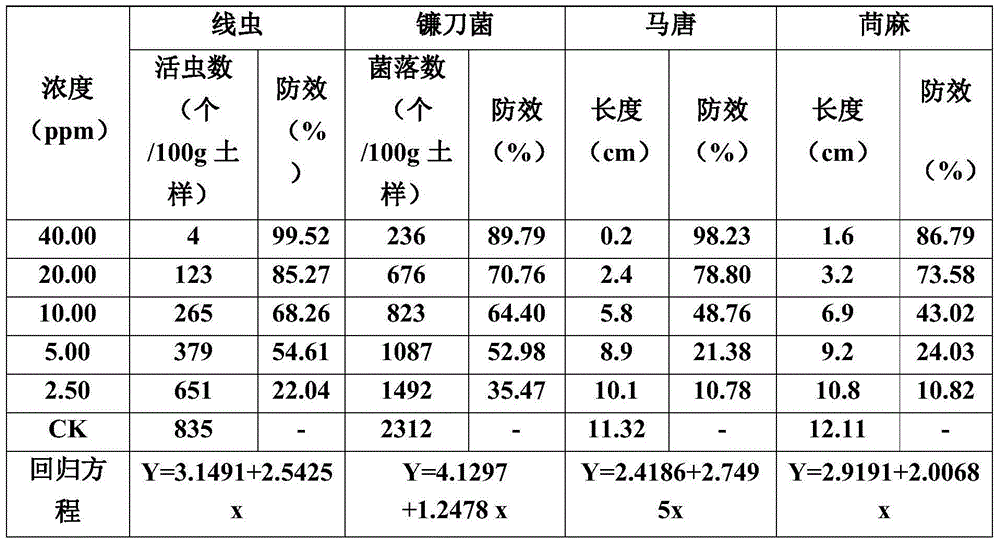

Dimethyl disulfide missible oil, preparation method of dimethyl disulfide missible oil, emulsion in water and capsule

The invention discloses dimethyl disulfide missible oil, a preparation method of the dimethyl disulfide missible oil, an emulsion in water and a capsule. The dimethyl disulfide missible oil comprises, by mass, 1-90% of dimethyl disulfide, 10-20% of an emulsifier and 0-80% of an organic solvent. Through use of the emulsifier and the organic solvent in dimethyl disulfide, the problem that dimethyl disulfide is insoluble in water and is not emulsified easily to form coarse missible oil which is unstable in drip irrigation in the farmland. The dimethyl disulfide missible oil has the advantages of small particles, uniform particle distribution, difficult layering or demulsification, and long stabilization time, ensures prevention and control effects and is suitable for drip irrigation. The preparation method is free of an organic solvent and saves a cost. Because of high missible oil content, the dimethyl disulfide missible oil has good effects of preventing and controlling soil nematodes, soil borne pathogenic fungi, weed and underground insects.

Owner:北京格林泰姆科技有限公司

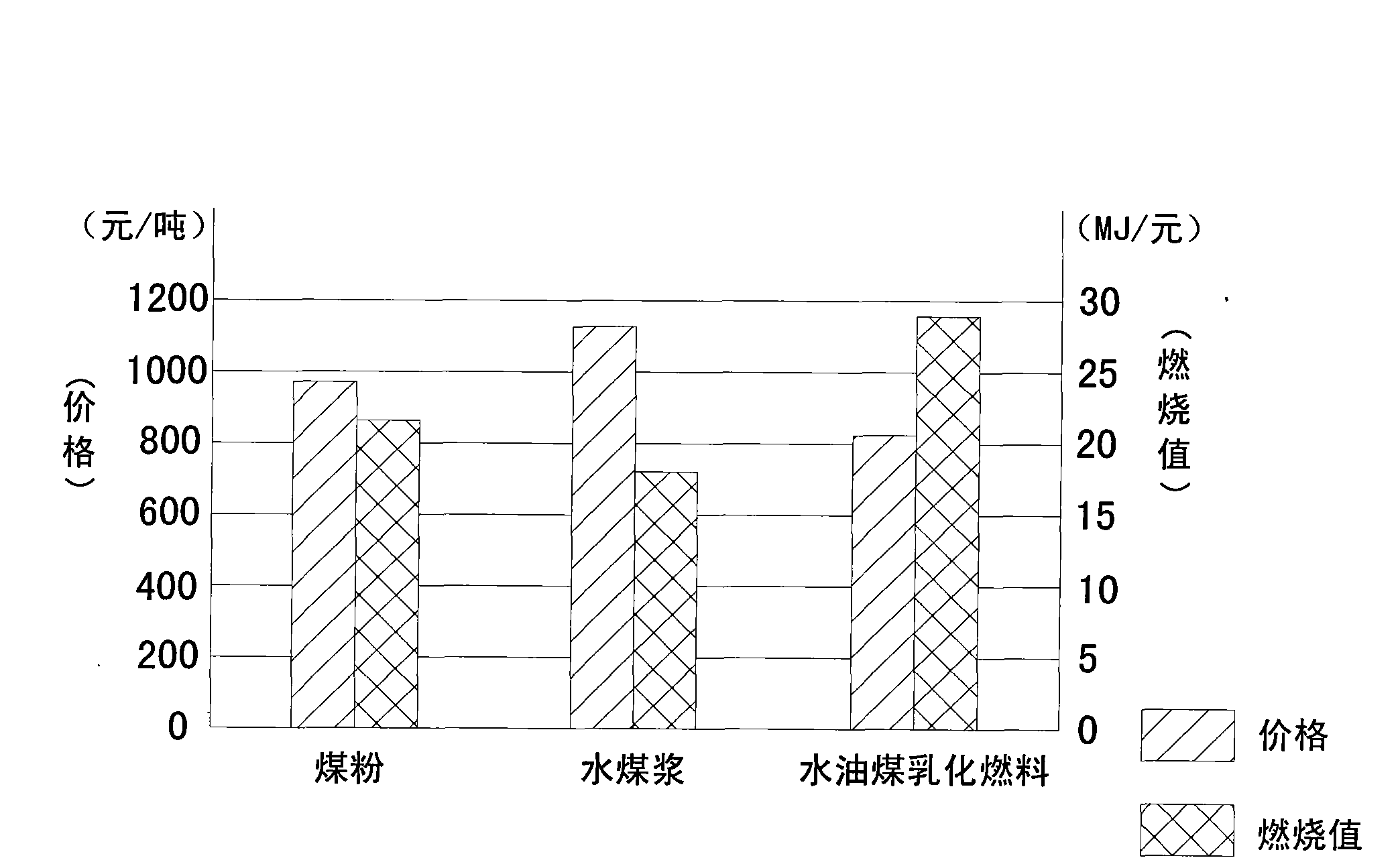

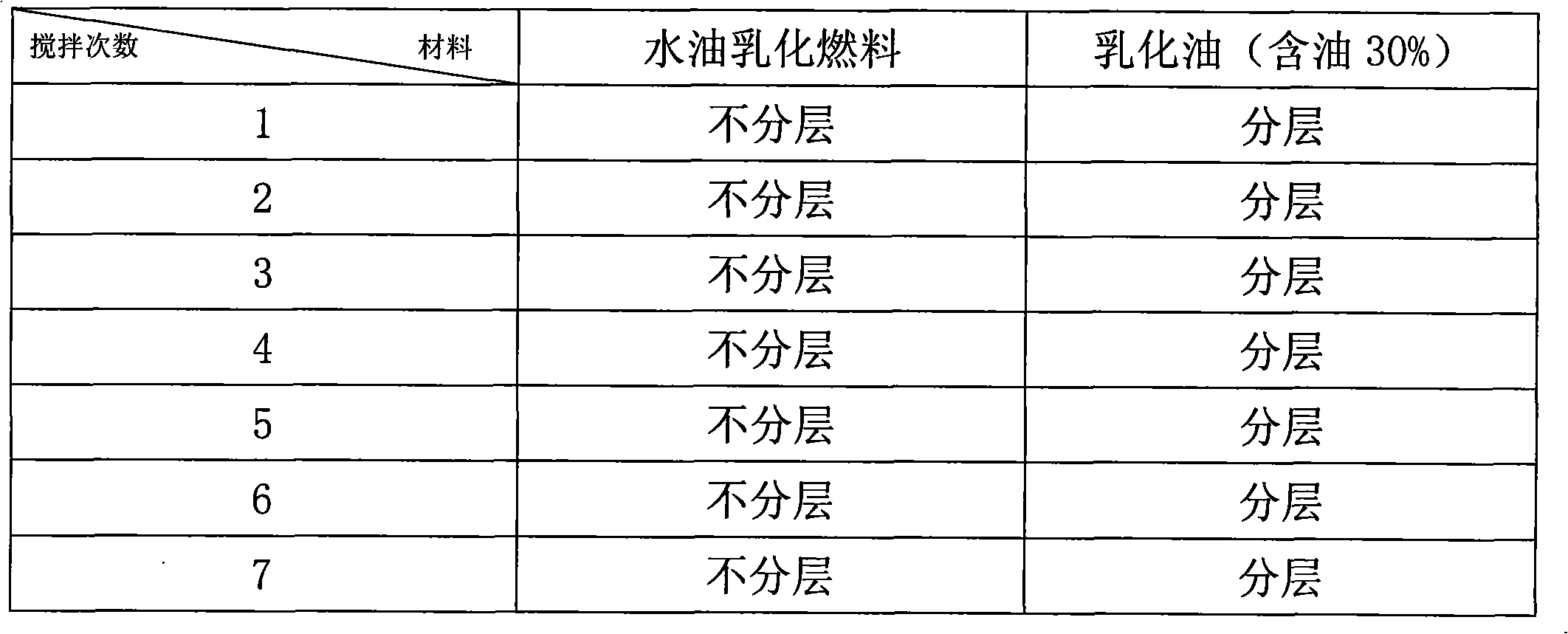

Water-oil-coal emulsified fuel and preparation method thereof

InactiveCN101633857ABurn completelyEmission reductionSolid fuelsLiquid carbonaceous fuelsEmulsified fuelPollution

The invention discloses a water-oil-coal emulsified fuel which is prepared by the following raw materials according to the parts by weight: 10-40 parts of coal powder and 30 parts of emulsified oil. The preparation method comprises the following steps: (1) first preparing the emulsified oil: weighting 20.4-26.4 parts of water, 3-9 parts of diesel oil and 0.6 part of emulsifier, then mixing the three components, stirring the mixture with a stirrer to emulsive state and obtaining emulsified diesel oil; (2) adding coal powder in prepared emulsified oil and stirring the mixture evenly which contains 30 parts of emulsified oil and 30 parts of coal powder. The beneficial effects of the invention are as follows: the emulsified fuel can increase the contact area of coal powder used in combustion reaction with the help of the combustion explosion of water and oil molecules, ensure the coal powder to burn more completely and increase the combustion efficiency; meanwhile, the emulsified fuel can not generate black smoke when burning so as to not only reduce the pollutant discharge but also solve the problems that water-coal-slurry is easy to demix, secondary pollution is easy to cause and the like in China.

Owner:SHANGHAI SHANGDE EXPERIMENTAL SCHOOL

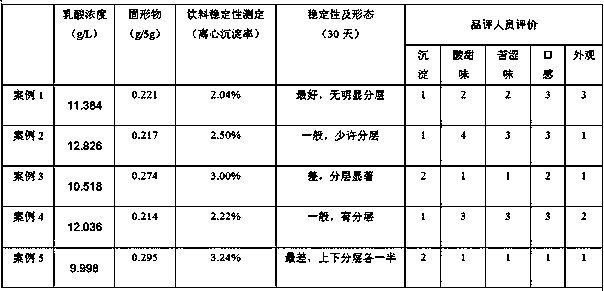

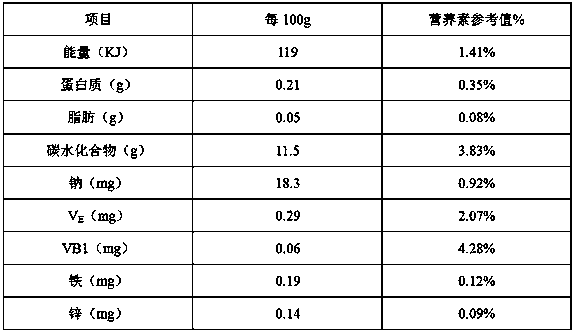

Fermented red rice beverage and preparation method thereof

The invention relates to the technical field of beverages and foods, in particular to a fermented red rice beverage and a preparation method thereof. The preparation method comprises the steps of withred brown rice as a raw material, adding 0.04% of alpha-amylases, performing enzymolysis and gelatinizing for 1h, performing inoculation on the inner part of a fermenter with 3% of monascus ruber liquid and 5% of lactobacilli bacterial liquid, wherein the concentration of bacterial liquid is 1*10<7>cfu / mL, performing bacterium mixing fermentation at 37 DEG C for 24h, and performing two-stage homogenizing at 50 DEG C, homogenizing pressure for the first time is 20MPa, homogenizing pressure for the second time is 35MPa, and the homogenizing time each time is 3min. By the method, the fermented red rice beverage which is fine and smooth in mouth feel and moderate in sour and sweet taste is obtained, the fermented red rice beverage has good color of natural red rice and good color of red yeastrice, and under the condition that no stabilizing agents and no fresh keeping agents are added to products, the fermented red rice beverage is good in stability and has certain activity efficacy.

Owner:FUZHOU UNIV

Alcohol fuel additive and preparation method thereof

InactiveCN108034461AHigh calorific valueAct as a solubilizerLiquid carbonaceous fuelsFuel additivesAlternative fuelsAlcohol fuel

The invention discloses an alcohol fuel additive and a preparation method thereof, and belongs to the technical field of fuel additives. The alcohol fuel additive is prepared from the following raw materials in parts by weight: 15 to 25 parts of fusel oil, 10 to 15 parts of fuel value enhancer, 5 to 10 parts of stabilizer, 3 to 6 parts of neutralizer, 2 to 5 parts of solubilizer, 3 to 5 parts of anti-swelling agent; 2 to 6 parts of anti-oxidation and anti-gel agent. The raw materials are stirred and mixed by a certain order of addition and conditions to obtain the alcohol fuel additive. The alcohol fuel additive can solve problems of low calorific value in existing alcoholic automotive fuels, poor compatibility of various raw materials, easy delamination of fuel when exposed to water, corrosiveness of alcohols, swelling to rubber, gum formation during use and the like. The preparation method is simple, low in cost, convenient to use, environmentally friendly, and economic and feasible.The alcohol fuel additive can be used as an alternative fuel for gasoline and can solve an increasingly depleted petroleum energy problem.

Owner:柳州市金升汽车配件有限公司

Nutrient enrichment type egg product suitable for bodybuilding crowds

InactiveCN106509535AMeet protein needsImprove protein qualitySugar food ingredientsFood thermal treatmentVitamin CLycopene

The invention discloses a nutrient enrichment type egg product suitable for bodybuilding crowds. The nutrient enrichment type egg product is made from the following components in parts by weight: 25-35 parts of egg white liquid, 10-15 parts of concentrated whey protein, 10-15 parts of white granulated sugar, 10-20 parts of fruit and vegetable juice and 50-55 parts of water. The made egg product disclosed by the invention is rich in carotenoid, lycopene and vitamins such as vitamin C, not only can provide high-quality protein and carbohydrate, but also is free from fat, and is delicious, convenient to carry, and compact in texture characteristics; a mixed system of egg white, the condensed whey protein, the white granulated sugar and the fruit and vegetable juice is stable and is not layered, and the product is fine, smooth and tender in mouth feel, and good in water retention property; and therefore, the egg product can well meet the requirements of bodybuilding crowds and athletes for protein and vitamins, contributes to promoting anabolism, stimulates muscle growth, and is better than conventional products such as protein powder in nutrient functions.

Owner:蛋泵科技(成都)有限公司

Acrylic acid grafted modified chlorinated polyether resin emulsion anticorrosion coating material and preparation method thereof

The present invention provides an acrylic acid grafted modified chlorinated polyether resin emulsion anticorrosion coating material, which is prepared from the following components by weight: 60-70% of an acrylic acid grafted modified chlorinated polyether resin emulsion, 5-7% of zinc phosphate, 10-15% of composite iron titanium powder, 5-10% of talc powder, 3-6% of titanium dioxide, 0.1-0.5% of an anti-foaming agent, 0.5-1.0% of a dispersant, and 0.5-1.0% of a thickener, wherein the acrylic acid grafted modified chlorinated polyether resin emulsion is prepared from the following components by weight: 10-20% of chlorinated polyether resin, 0-30% of propylene glycol butyl ester, 1-3% of butyl methacrylate, 3-5% of ethyl acrylate, 4-7% of methyl methacrylate, 2-5% of 2-ethylhexyl acrylate, 0.1-1% of benzoyl peroxide, and the balance of deionized water. According to the present invention, the coating material contains the copolymerized vinyl chloride ether so as to provide good adhesion, such that the disadvantages of other chlorine-containing polymer resins are basically solved.

Owner:SHANGHAI JIANYE TECH ENG

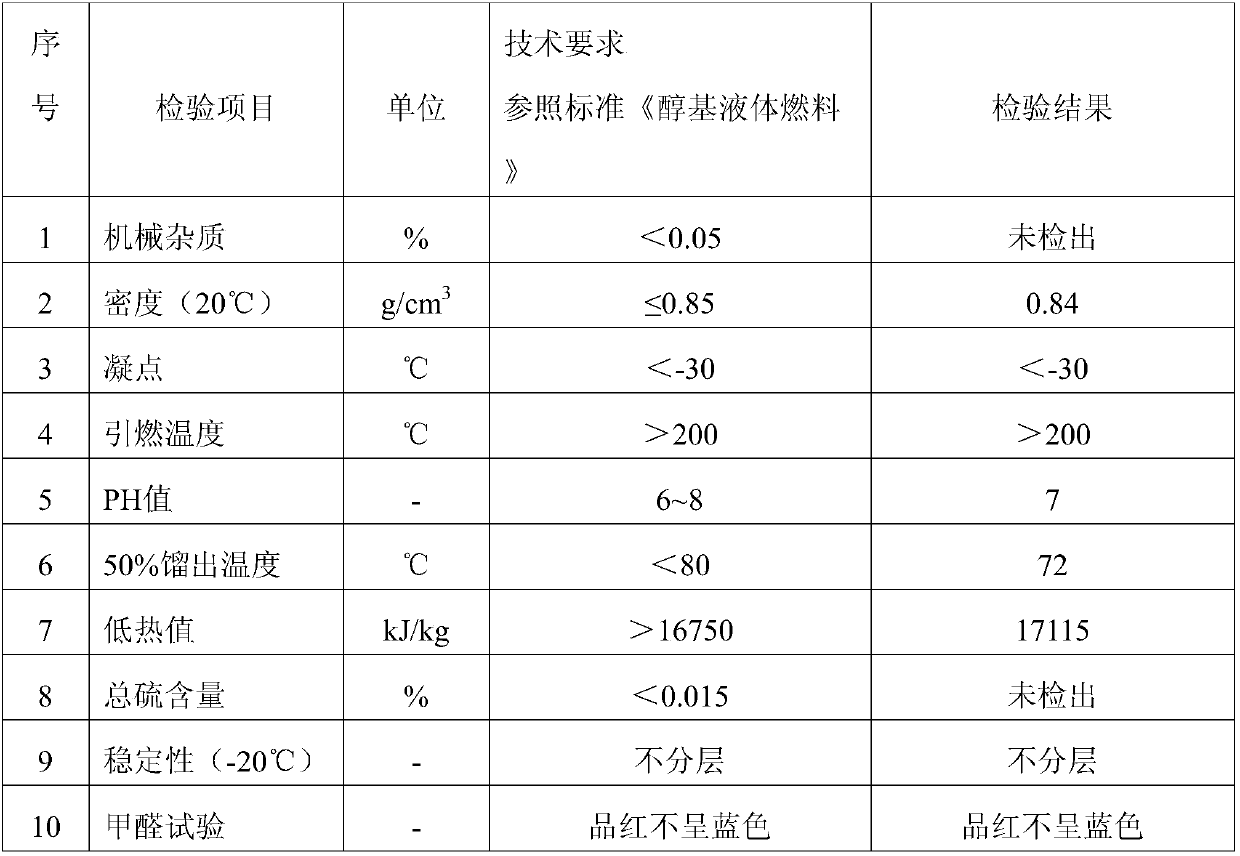

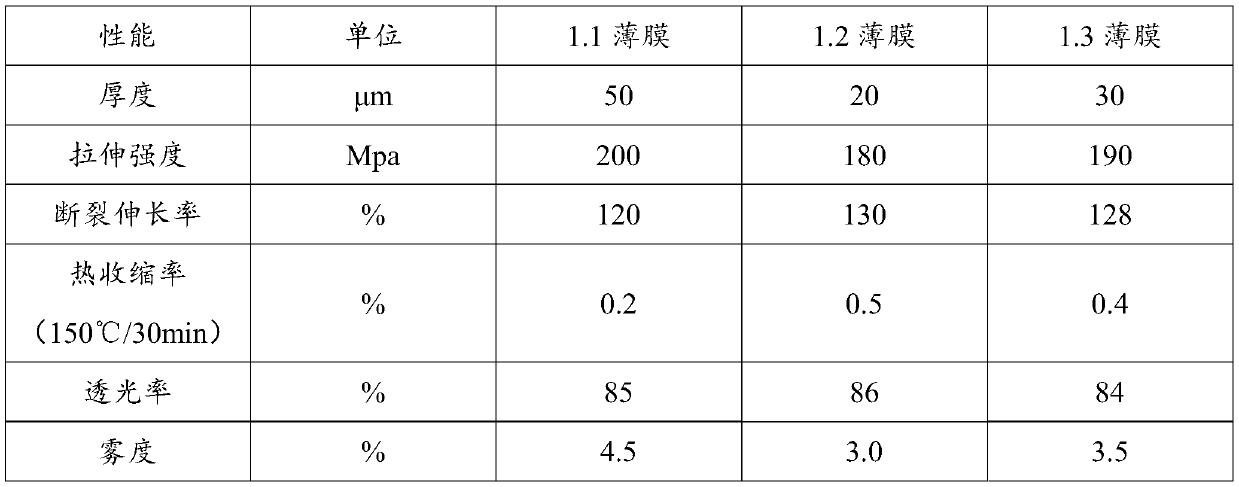

Medical super-tough puncture-resistant high-barrier composite film and preparation method thereof

ActiveCN109968777AGood printability and barrier propertiesControllable thicknessFlexible coversWrappersPolyamidePolyester

The invention relates to a medical super-tough puncture-resistant high-barrier composite film and a preparation method thereof. A multilayer laminated structure of polyester with a high-melting-pointcrystal form and crystalline polyamide resin is selected as a core layer of the composite film, so that the characteristics of puncture resistance and high barrier are achieved; an inner surface layeris prepared by adopting low-melting-point amorphous polyester, has good low-temperature heat sealing performance, and can have good binding force with the core layer, so that the problem of easy layering with the core layer is solved; and the outer surface layer is prepared by adopting low-crystallinity copolymerized polyester, has good printing and barrier performance, and has good adhesive force with the core layer. According to the invention, a multi-layer co-extrusion and lamination technology is used for carrying out processes such as die head extrusion, stretching and the like, so thatthe composite film with controllable thickness, easy molding and relatively high film yield is prepared. Meanwhile, the raw materials are cheap and are easily available, the preparation process is easy to control, and the composite film has industrial production and practical application values.

Owner:SHANDONG UNIV

Emamectin benzoate B2 suspending agent and preparation method thereof

PendingCN114176072AIncrease lethalitySolve pollutionBiocideAnimal repellantsEngineeringSuspending Agents

The emamectin benzoate B2 suspending agent is prepared from the following components in percentage by mass: 1%-15% of emamectin benzoate raw medicine, 3%-6% of a dispersing agent, 1%-2% of a thickening agent, 3%-5% of an anti-precipitating agent, 0.1%-0.3% of a defoaming agent, 2%-5% of an anti-freezing agent, 0.1%-0.3% of a preservative, 1%-2% of an antioxidant and the balance of deionized water. The invention relates to a preparation method of an emamectin benzoate B2 suspending agent. The preparation method comprises the following steps: adding deionized water into a modulation kettle; mixing the emamectin benzoate active compound with the auxiliary agent, adding the mixture into the modulation kettle, supplementing with deionized water, stirring, and uniformly mixing; feeding the mixed material into a shearing kettle for shearing; pouring the sheared mixed material and the auxiliary agent into a sand mill for grinding; and sampling, and discharging after all detected indexes are qualified to obtain a finished product. The product is a biological pesticide which is efficient, broad in spectrum, low in toxicity, low in residue and long in lasting period, has a good killing effect on lepidoptera pests, is pollution-free, is a first choice for agricultural products, does not generate waste gas, waste water and waste residues in the production process, is free of dust harm and is safe to operators and the environment.

Owner:HEBEI XINGBAI AGRI SCI & TECH CO LTD

Emulsified oil for cutting glass balls

The invention discloses emulsified oil for cutting glass balls. The emulsified oil is prepared from the following raw materials in parts by weight: 100 to 154 parts of machine oil, 1 to 10 parts of 702, 0.5 to 5 parts of triethanolamine borate and 1 to 10 parts of Turkey red oil. According to the glass ball cutting emulsified oil, the pH value is increased through triethanolamine borate, the extreme pressure lubricity is improved, high-temperature lubrication is better, the problems of high base number and easy layering are solved, MBM serves as a preservative, the glass ball cutting emulsified oil is a green and environment-friendly product, the body health of an operator is considered, the good preservative effect is also considered, and the glass ball cutting emulsified oil does not deteriorate after being used by two amounts; vulcanized cottonseed oil is used as an extreme pressure agent, high-temperature lubrication in the glass water cutting process at the temperature of more than 1 thousand DEG C is just catered, the vulcanized cottonseed oil has the characteristics that the higher the temperature is, the better the lubrication is, the cutting task is well completed, a precious cutter is well protected, the cutting speed is high, the efficiency is very high, and the cleaning property and effectiveness of the formula are improved by adding NP-10; the cleaning agent of NP-10 is very good and has very strong emulsifying ability.

Owner:山东三晶润滑科技有限公司

A kind of in-plane quasi-isotropic structure-stealth composite material and its preparation method

The invention discloses an in-plane quasi-isotropic structure-stealthy composite material and further comprises a preparation method of the in-plane quasi-isotropic structure-stealthy composite material. The in-plane quasi-isotropic structure-stealthy composite material comprises a base body and a reinforcement body which are composited and solidified through a VARTM process. The base body is madeof resin; the reinforcement body is made of sandwich-type three-dimensional stereo woven material, the woven material is composed of a plurality of mutually-parallel fiber layers and normal fibers perpendicular to the fiber layers, and the fiber layers are bound together by the normal fibers through a weaving method. The preparation method specifically comprises the following steps of 1, weavingof the reinforcement body; 2, reinforcement body moulding; 3, glue injecting and solidifying; and 4, demoulding. The problems that as for a stealthy composite material in the prior art, the electromagnetic property is isotropic, the anti-impact property is poor, and the stealthy composite material is likely to be layered after being impacted are solved.

Owner:浙江世涛鼎革新材料有限责任公司

A kind of modified silica sol and its preparation method and application in all water-based foamed polyurethane spray foam

The invention discloses a modified silica sol, a preparation method thereof and an application in all-water-based foaming polyurethane spray foam. The raw material components of the modified silica sol include: deionized water 40%~ 60%, silica sol 20% ~ 40%, cosolvent 8% ~ 16%, pH regulator 2% ~ 8%, silane coupling agent A 2% ~ 6%, silane coupling agent B 2% ~ 6% ; The silane coupling agent A refers to the silane coupling agent containing lipophilic groups, and the silane coupling agent B refers to the silane coupling agent containing hydrophilic groups. The preparation method includes the following steps: adding deionized water, co-solvent, silica sol, co-solvent, and pH regulator into the reactor, stirring and mixing for 20-30 minutes, the pH value is 7.5-8, heating up to 40-80°C, and starting Add the silane coupling agents A and B dropwise, and continue to stir at 40-80°C for 2-3 hours after the dropwise addition to obtain the modified silica sol. The modified silica sol is used in the polyol component of the all-water-based foaming polyurethane spraying foam, and solves the problems of poor compatibility and easy delamination of the polyol component caused by high water content.

Owner:LIMING RES INST OF CHEM IND

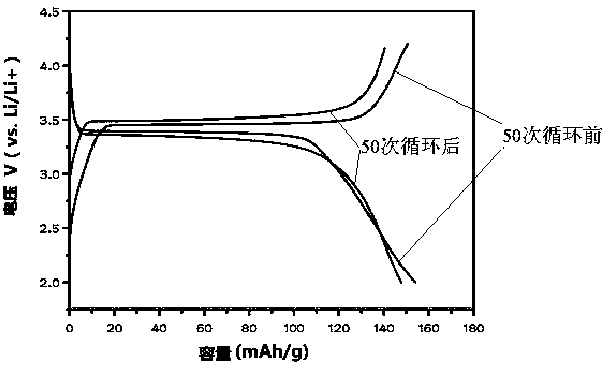

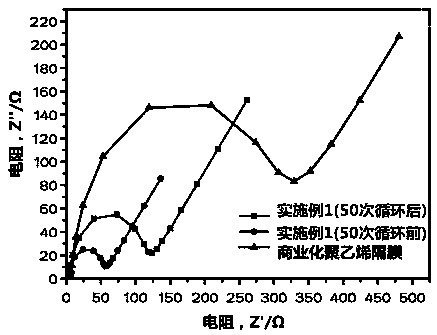

A kind of pet non-woven fabric-based composite lithium-ion battery diaphragm with nanopore and preparation method thereof

ActiveCN105514324BHigh porosityLow heat shrinkageCell seperators/membranes/diaphragms/spacersSecondary cellsPolymer sciencePolyvinyl alcohol

The invention discloses a PET non-woven fabric-based composite lithium-ion battery diaphragm with a nano-pore size and a preparation method thereof. The lithium-ion battery diaphragm of the invention is composed of the following raw materials: a hydrophilic PET non-woven fabric base material and a polymer , small pores of 1-500nm are evenly distributed on the hydrophilic PET non-woven fabric base material, the porosity is 50-70%, and the polymer is filled in the small pores of the hydrophilic PET non-woven fabric base material, so The high molecular polymer is polyvinyl alcohol or sodium hydroxymethyl cellulose; the high molecular polymer is filled in the pores of the PET hydrophilic non-woven fabric by means of ultrasonic, vacuum impregnation, and hot rolling after low temperature drying. , the PET non-woven fabric-based composite lithium-ion battery separator with nanopores of the present invention has the advantages of high porosity, small thermal shrinkage, small lithium ion mass transfer resistance, and excellent electrochemical performance. The preparation of the present invention The method has few steps, is easy to operate, does not involve the use of toxic reagents in the preparation process, has high safety, is suitable for PET hydrophilic non-woven fabrics with various surface densities and high air permeability as a base material, and can realize industrial production.

Owner:SHANDONG TAIPENG ENVIRONMENTAL PROTECTION MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com