Water-oil-coal emulsified fuel and preparation method thereof

A technology for emulsified fuel and water, oil and coal, which is used in fuels, solid fuels, fuel additives, etc., can solve the problems of secondary pollution of transportation machinery, insufficient combustion black smoke, and separation of polluted water and coal, and achieves reduction of pollutant emissions, The effect of improving combustion efficiency and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh the raw materials of the following weight percentages:

[0030] 10% n-decyl alcohol 10% n-octanol 5% petroleum ether 30% n-butanol

[0031] Naphthenic acid 8% Oleic acid 25% Glycerin 2% Ammonia 1%

[0032] Span 80 8% Sodium Dodecyl Benzene Sulfonate 1%.

[0033] Its preparation method is: pour n-decyl alcohol, n-octanol, petroleum ether, and n-butanol in the above weight percentages into a reaction kettle with a rotation speed of 400-400 rpm and stir, and then stir and fuse under normal temperature and fireproof and explosion-proof conditions. , then add the naphthenic acid, oleic acid, and glycerin of the above proportioning ratio successively and stir, then add the naphthenic acid, oleic acid, and glycerin for stirring, then add the sodium dodecylbenzenesulfonate, ammonia water, and The disc 80 is made by adding it into the reactor and stirring for 20 minutes. It is packed in barrels and sealed, and each barrel is filled with 180kg.

Embodiment 2

[0035] Weigh the raw materials of the following weight percentages:

[0036] N-decyl alcohol 30% n-octanol 20% petroleum ether 15% n-butanol 10%

[0037] Naphthenic acid 2% Oleic acid 10% Glycerin 6% Ammonia 3%

[0038] Span 80 2.5% Sodium Dodecyl Benzene Sulfonate 1.5%.

[0039] The preparation process of this embodiment is the same as that of Example 1.

Embodiment 3

[0041] Weigh the raw materials of the following weight percentages:

[0042] N-decyl alcohol 28% n-octanol 18% petroleum ether 13% n-butanol 13%

[0043] Naphthenic acid 4% Oleic acid 12% Glycerin 5% Ammonia 2%

[0044] Span 80 4.5% Sodium dodecylbenzene sulfonate 0.5%.

[0045] The preparation process of this embodiment is the same as that of Example 1.

PUM

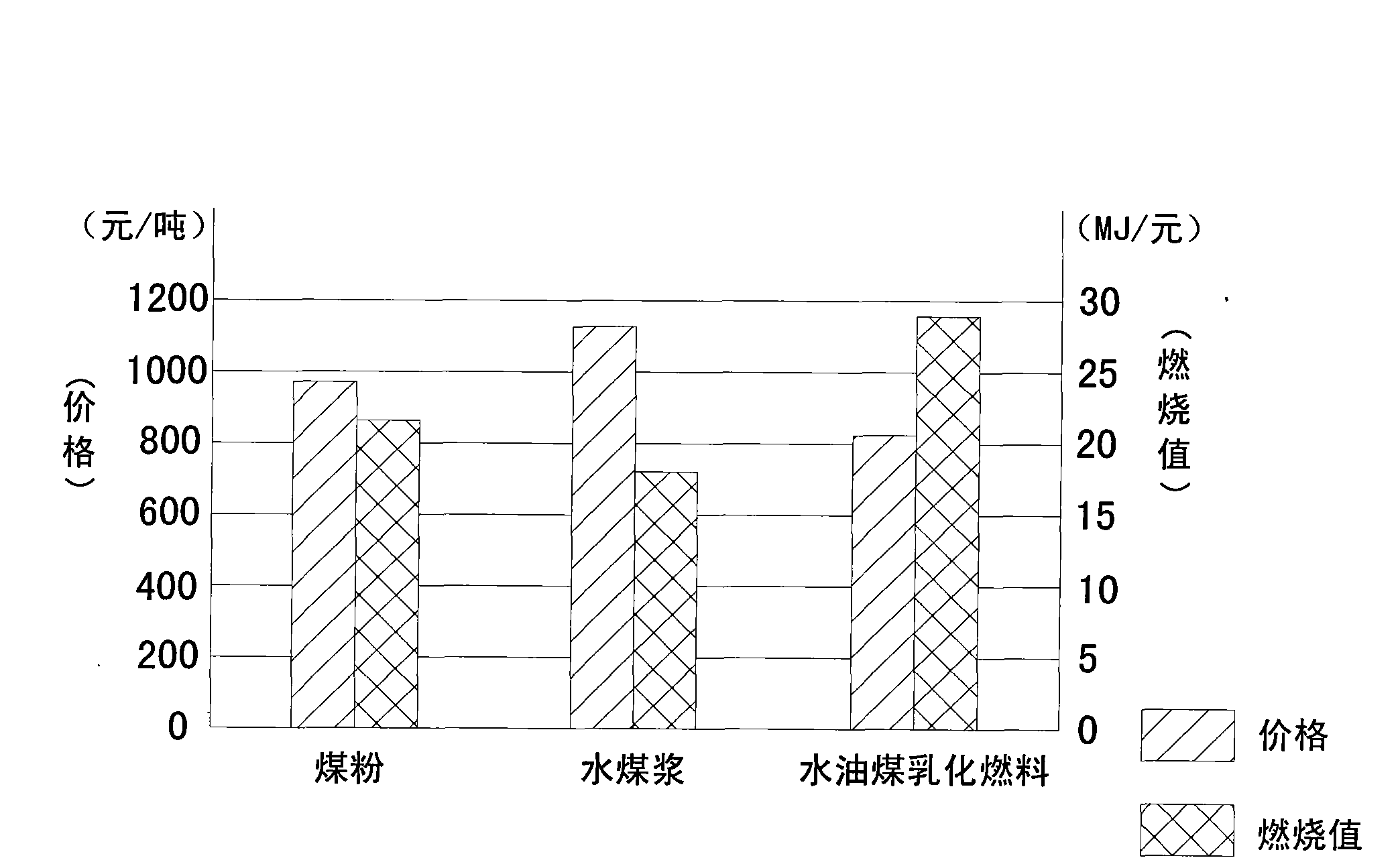

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com