Wet sewage sludge combustion furnace

An incinerator and wet sludge technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of strong hydrophilicity of sludge, difficult removal of water, high moisture content of sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

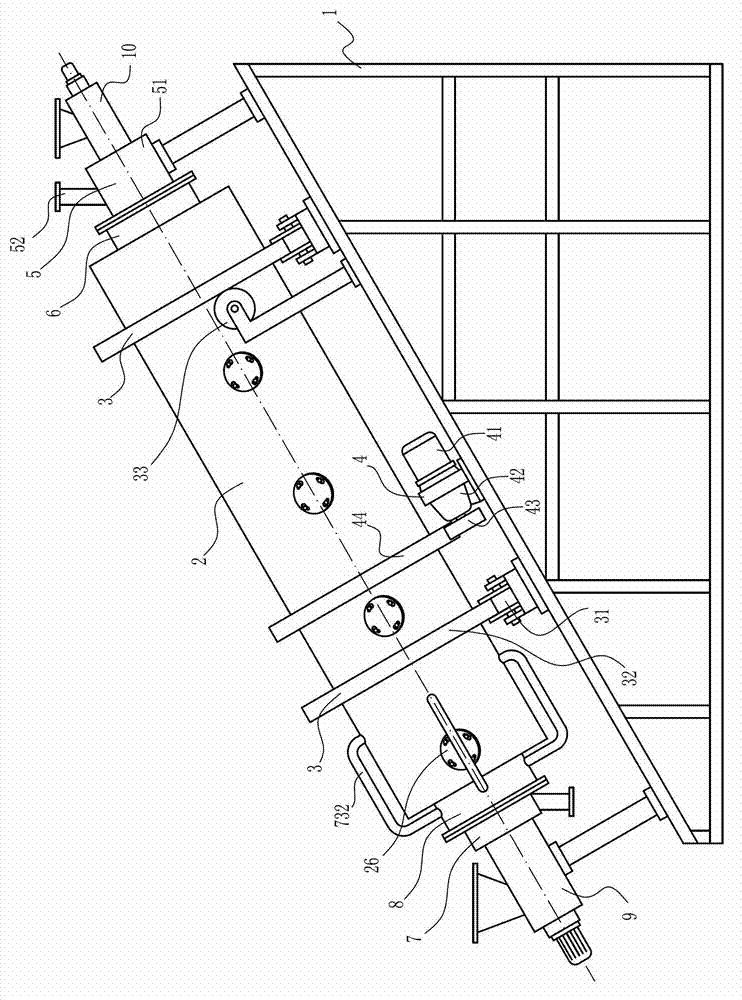

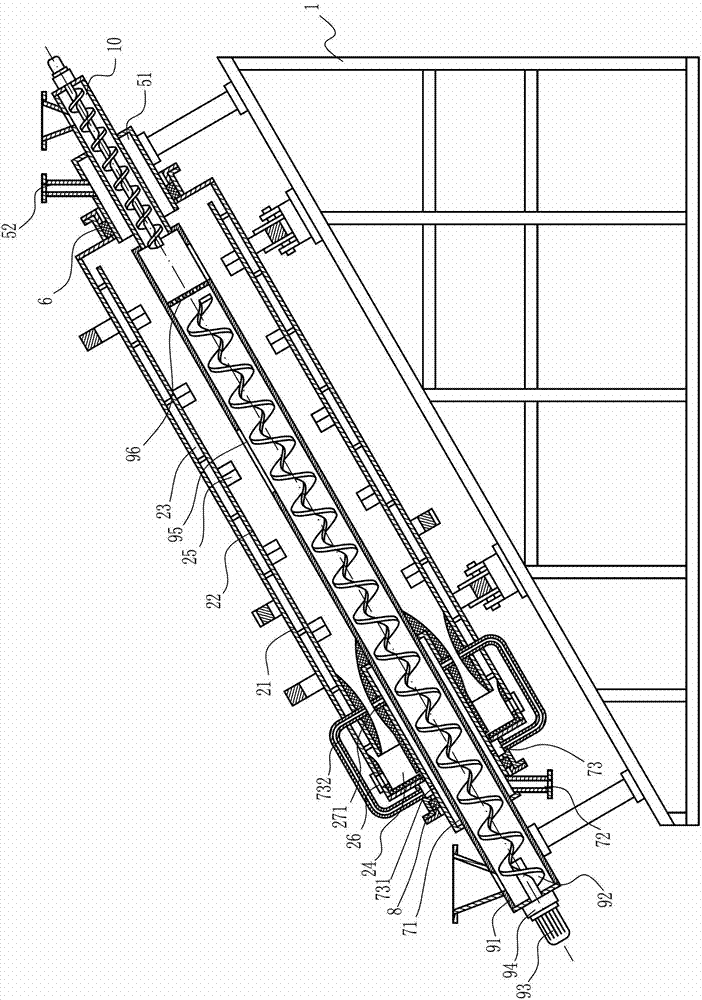

[0032] Embodiment one: if figure 1 with figure 2 As shown, the wet sludge incinerator includes a frame 1, and a cylindrical furnace body 2 is installed obliquely on the frame 1. In this embodiment, the oblique installation of the cylindrical furnace body 2 refers to the oblique installation relative to the horizontal plane. , the angle of inclined installation is determined according to the characteristics and components of the sludge; of course, a hydraulic or mechanical angle adjustment device can also be installed on the frame 1, so that the cylindrical furnace body 2 can be used for sludge with different components or humidity It has the best inclination angle to ensure that this embodiment is in the best working condition.

[0033]A supporting wheel device 3 and a furnace body rotation driving device 4 are installed between the cylindrical furnace body 2 and the frame 1 . The supporting roller device 3 includes at least two pairs of supporting rollers 31 installed on t...

Embodiment 2

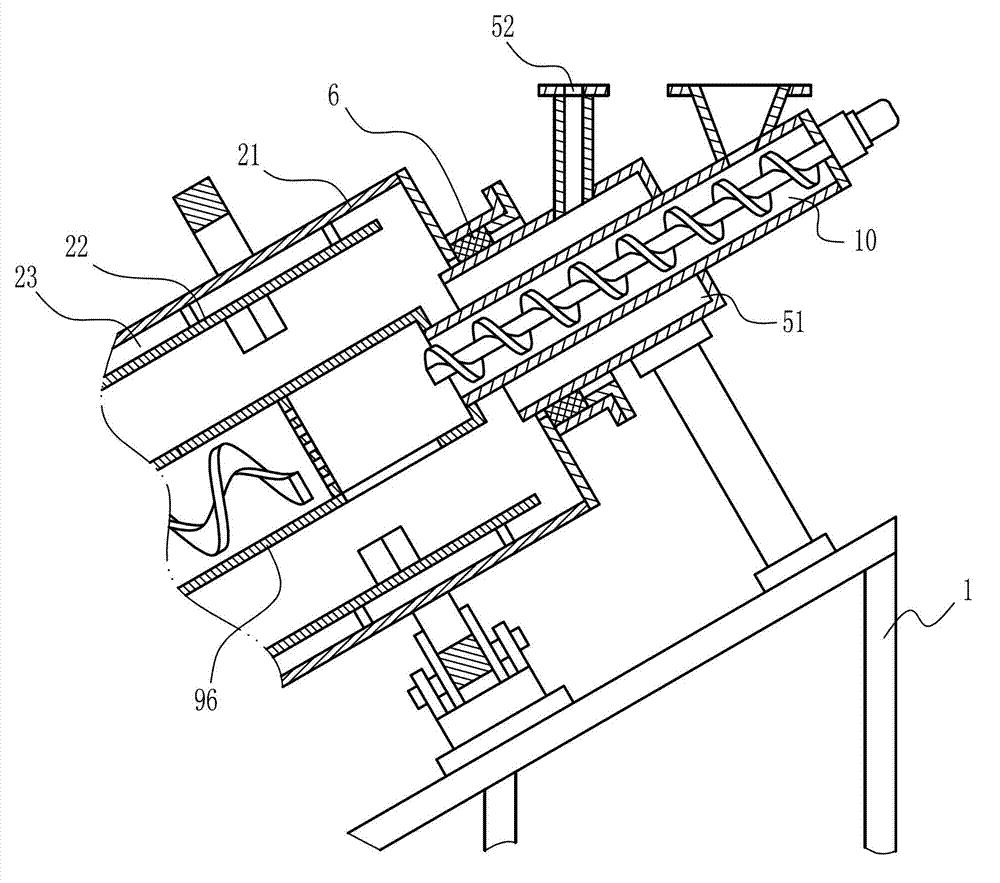

[0044] Embodiment two: if Figure 5 As shown, the wet sludge incinerator includes a frame 1, and a cylindrical furnace body 2 is installed obliquely on the frame 1. In this embodiment, the oblique installation of the cylindrical furnace body 2 refers to the oblique installation relative to the horizontal plane. , the angle of inclined installation is determined according to the characteristics and components of the sludge; of course, a hydraulic or mechanical angle adjustment device can also be installed on the frame 1, so that the cylindrical furnace body 2 can be used for sludge with different components or humidity It has the best inclination angle to ensure that this embodiment is in the best working condition.

[0045] A supporting wheel device 3 and a furnace body rotation driving device 4 are installed between the cylindrical furnace body 2 and the frame 1 . The supporting roller device 3 includes at least two pairs of supporting rollers 31 installed on the frame 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com