Small gasifying incinerator

A kind of incinerator, small-scale technology, applied in the direction of incinerator, combustion method, combustion type, etc., to achieve the effect of promoting combustion effect, enhancing disturbance, and increasing combustion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

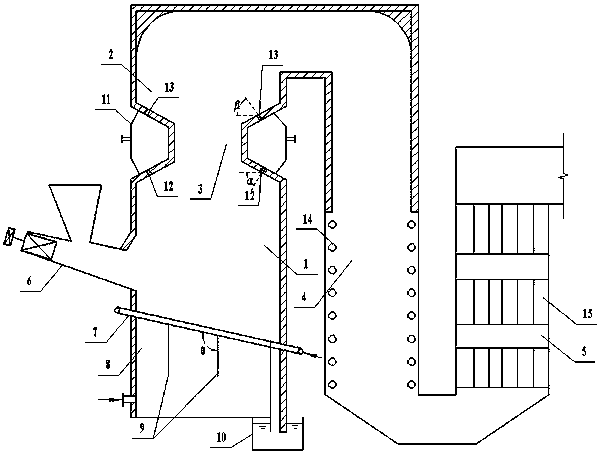

[0019] The specific embodiment of the present invention and working process will be further described below in conjunction with accompanying drawing.

[0020] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

[0021] The gasification incinerator described in the present invention is suitable for the gasification and combustion of miniaturized household garbage, and its capacity is 600,000 kcal / h to 3 million kcal / h based on the calorific value of domestic garbage.

[0022] like figure 1 As shown, a gasification incinerator includes a gasification zone 1 , a combustion zone, a burnout zone 5 and a feeding device 6 arranged in front of the gasification zone 1 .

[0023] The feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com