Gas-solid separation and re-coupling type biomass clean combustion device and combustion method

A combustion device and solid-phase combustion technology, applied in the direction of combustion methods, solid fuel combustion, combustion equipment, etc., can solve the problems of not clean combustion, unfavorable miniaturization promotion, scattered overall layout, etc., to achieve easy clean combustion, high air supply volume Reasonable arrangement of combustion field and improvement of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

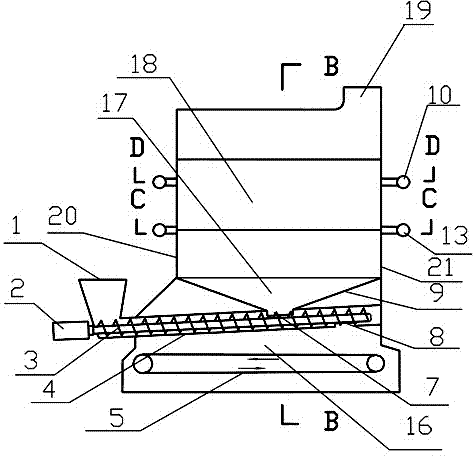

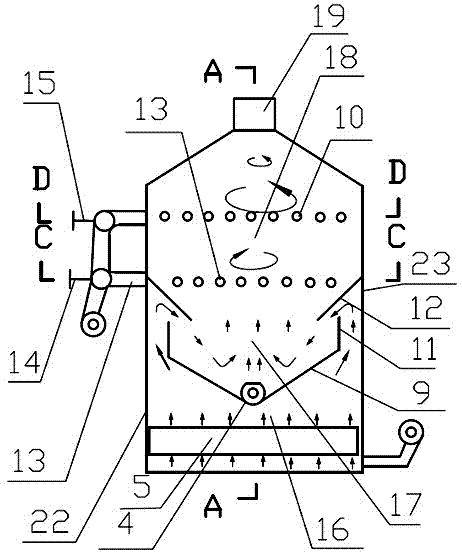

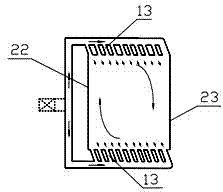

[0025] Embodiment 1: A gas-solid two-phase separation re-coupled biomass clean combustion device, which includes a cuboid furnace and is sequentially arranged in the furnace from bottom to top: a chain grate 5, a solid phase above the chain grate 5 Combustion chamber 16, is positioned at the reduction reaction chamber 17 above solid phase combustion chamber 16, is positioned at the gas phase combustion chamber 18 above reduction reaction chamber 17; Also has the solid phase combustion air supply system that communicates with solid phase combustion chamber 16, and gas phase combustion chamber 18 connected gas-phase combustion primary and secondary air supply systems; a screw conveyor is also provided, and the screw conveyor includes a cylindrical spiral tube 4 and a screw shaft 3 arranged in the spiral tube 4, and a driving motor 2 for driving the screw shaft 3, An open hopper 1 connected to the feed end of the spiral tube 4; the front part of the spiral tube 4 extends into the ...

Embodiment 2

[0033] Example 2: A gas-solid two-phase separation and coupling biomass clean combustion method based on the gas-solid two-phase separation and coupling biomass clean combustion device in Example 1. When the biomass passes through the screw feeder, it is fed by the spiral tube 4 The temperature of the solid-phase combustion below is heated and decomposed into gas-solid two-phase; the gas phase flows along the upward spiral tube to the gas-phase outlet 7, enters the reduction reaction chamber 17, and flows out from the solid-phase combustion chamber 16 through the baffle ribs 6 and After returning to the smoke picking plate 12, most of the particulate matter containing NO x The flue gas is mixed, and the reducing components and NO flowing out of the gas phase outlet 7 x N 2 , to reduce NO in flue gas x The mixed gas after the reduction reaction flows upwards and enters the gas phase combustion chamber 18, and mixes again with the swirl air coming in from the primary swirl air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com