Patents

Literature

254results about How to "Achieve combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

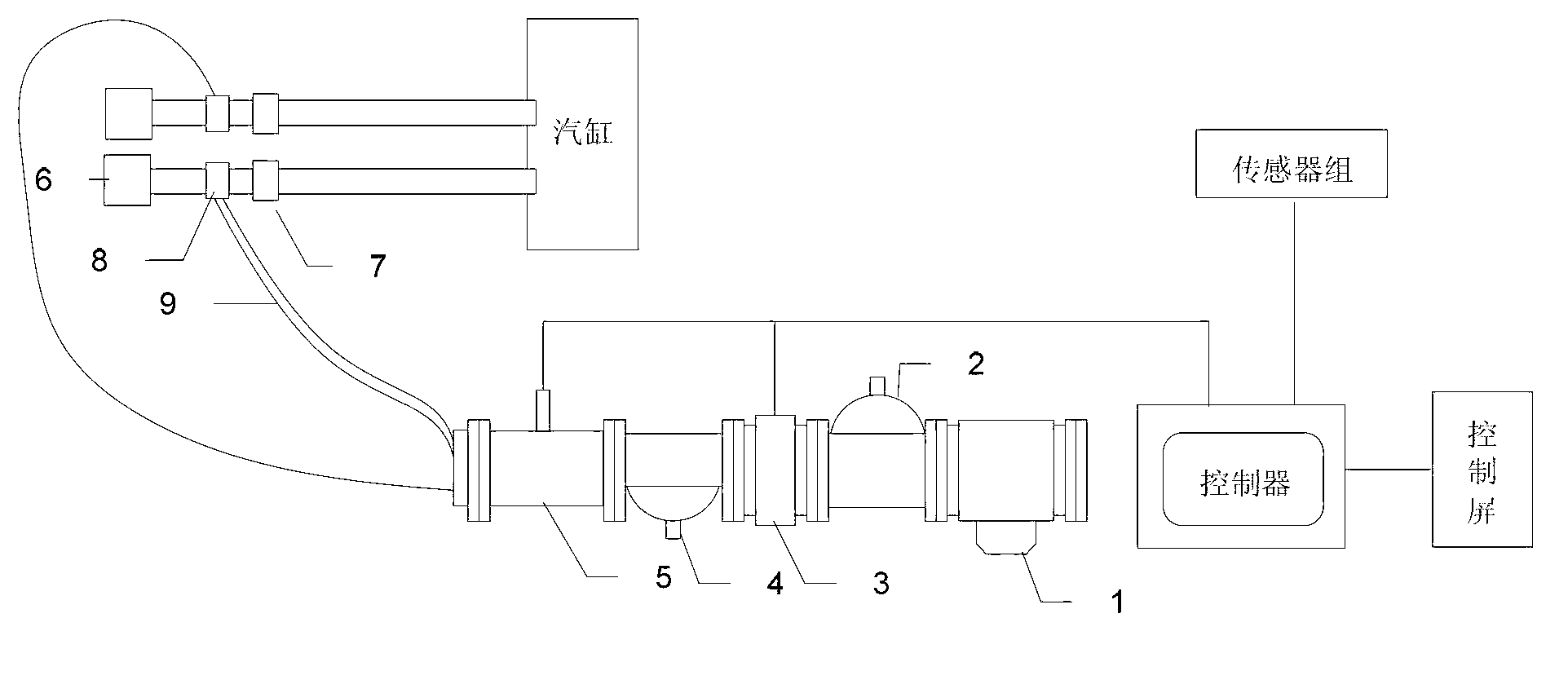

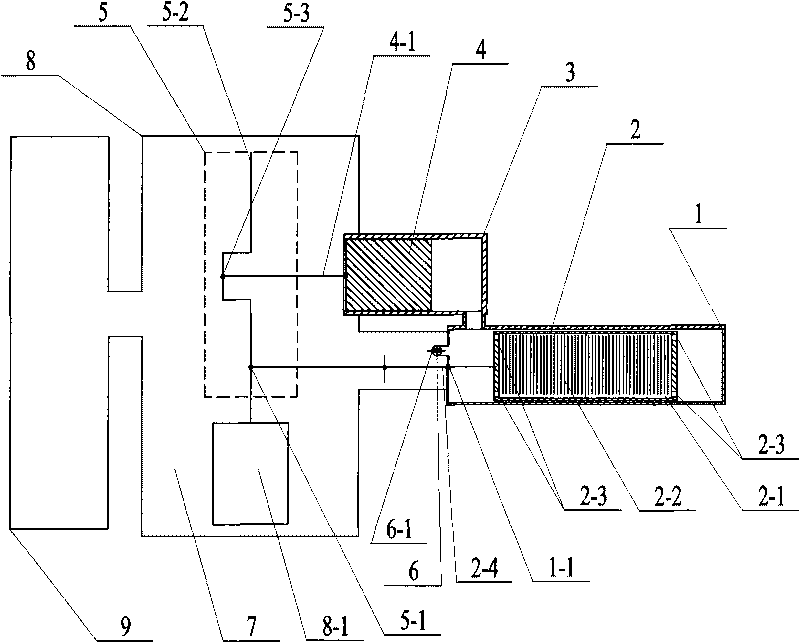

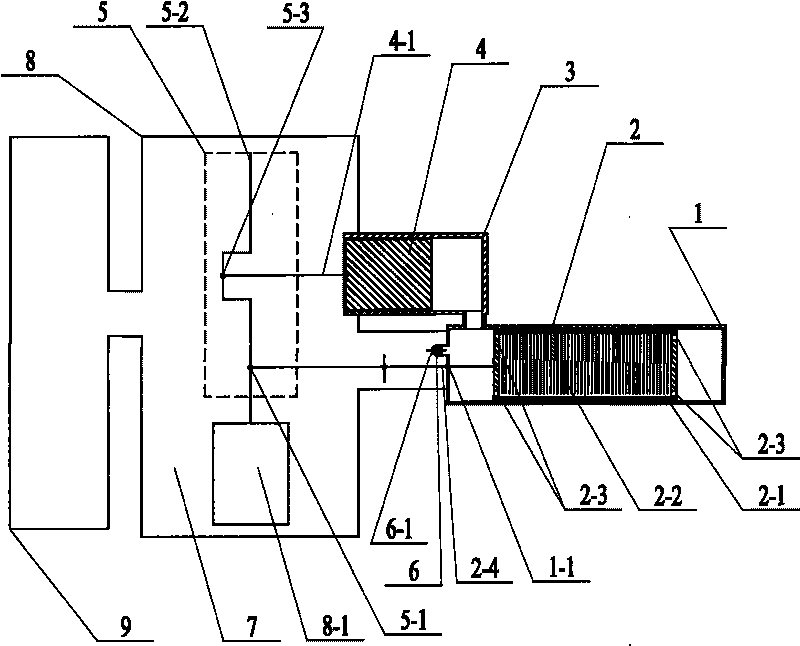

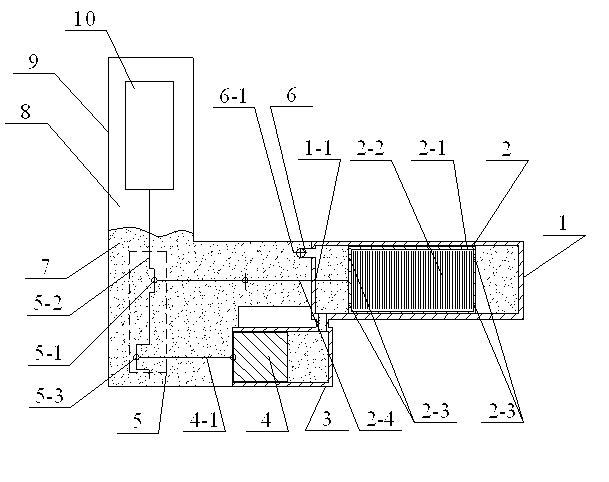

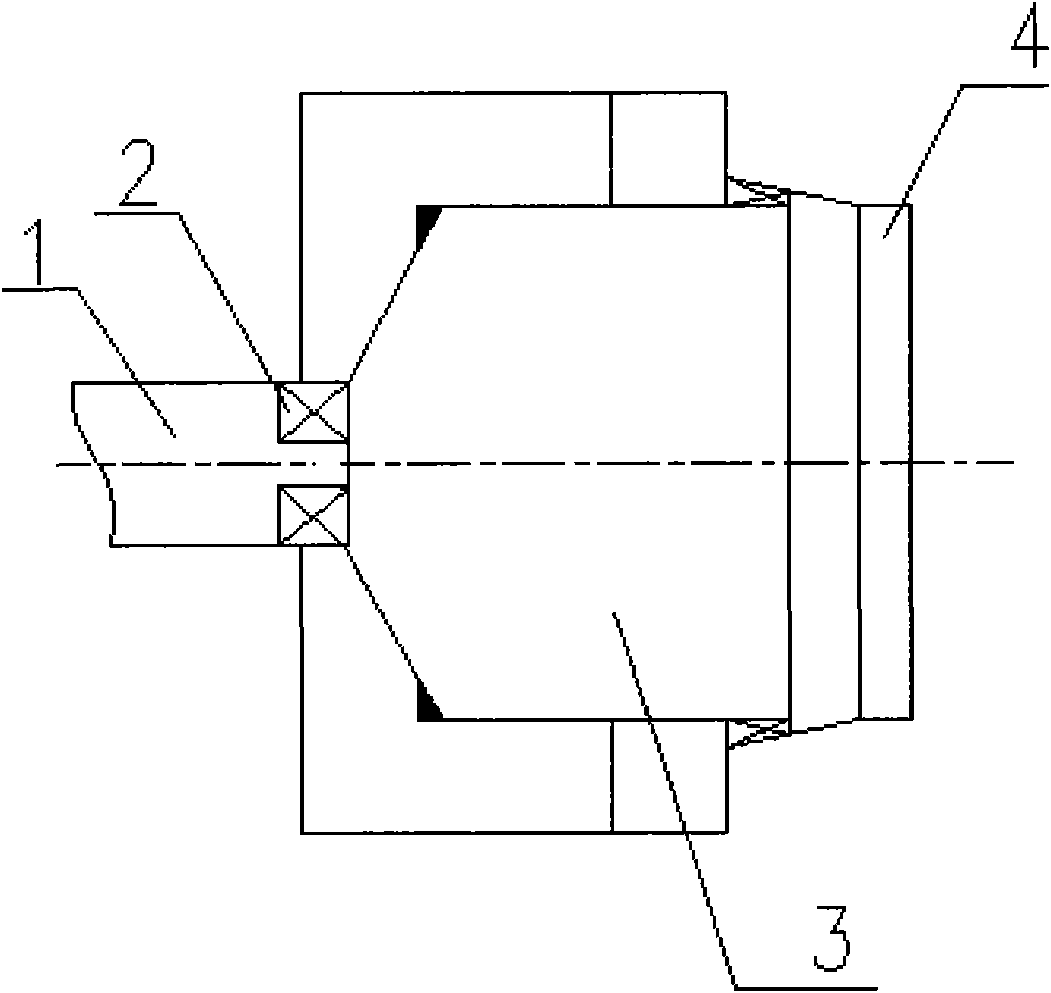

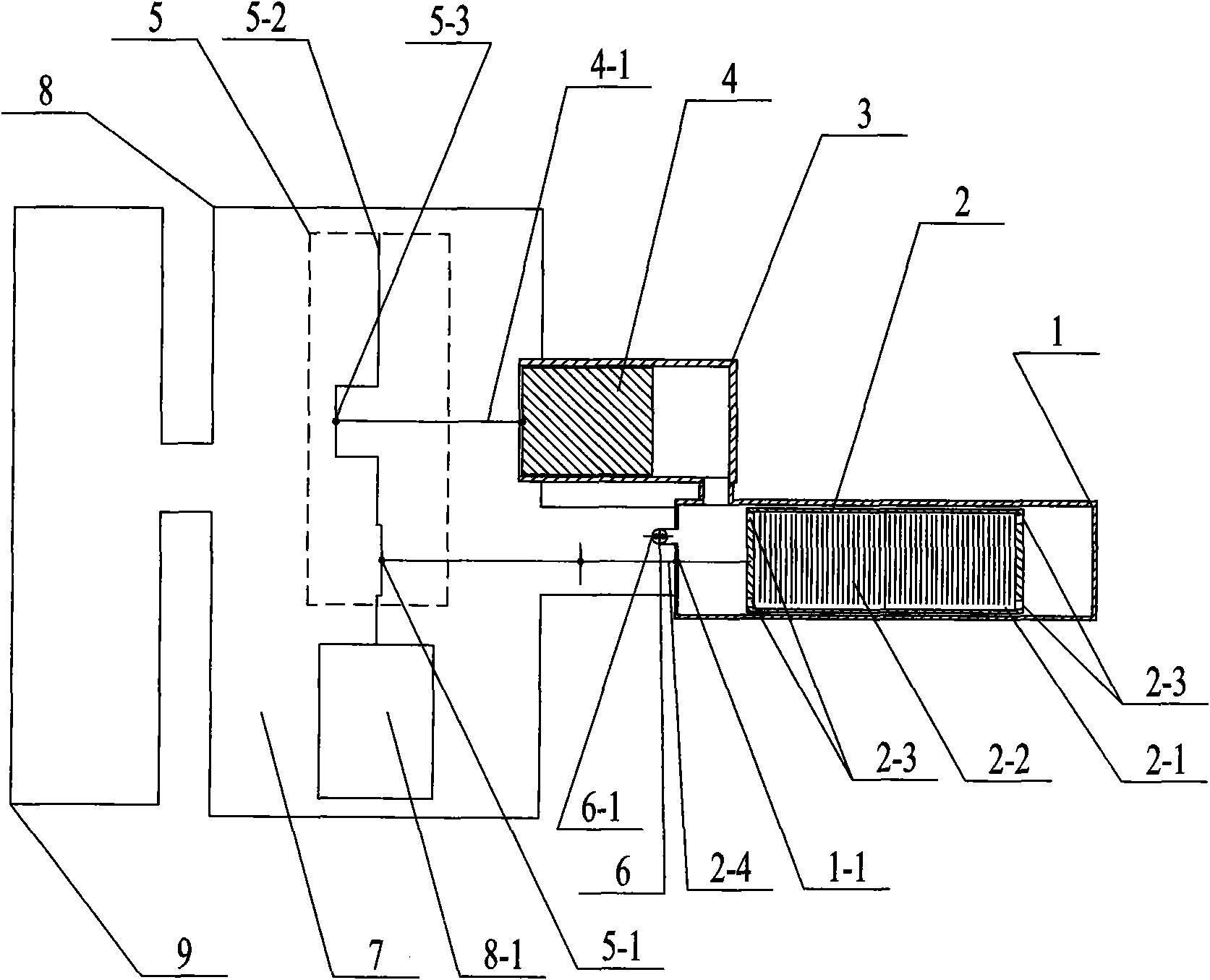

Dual-fuel modified system

ActiveCN103321782ACut off the supplyAchieve combustionInternal combustion piston enginesFuel supply apparatusControl systemEngineering

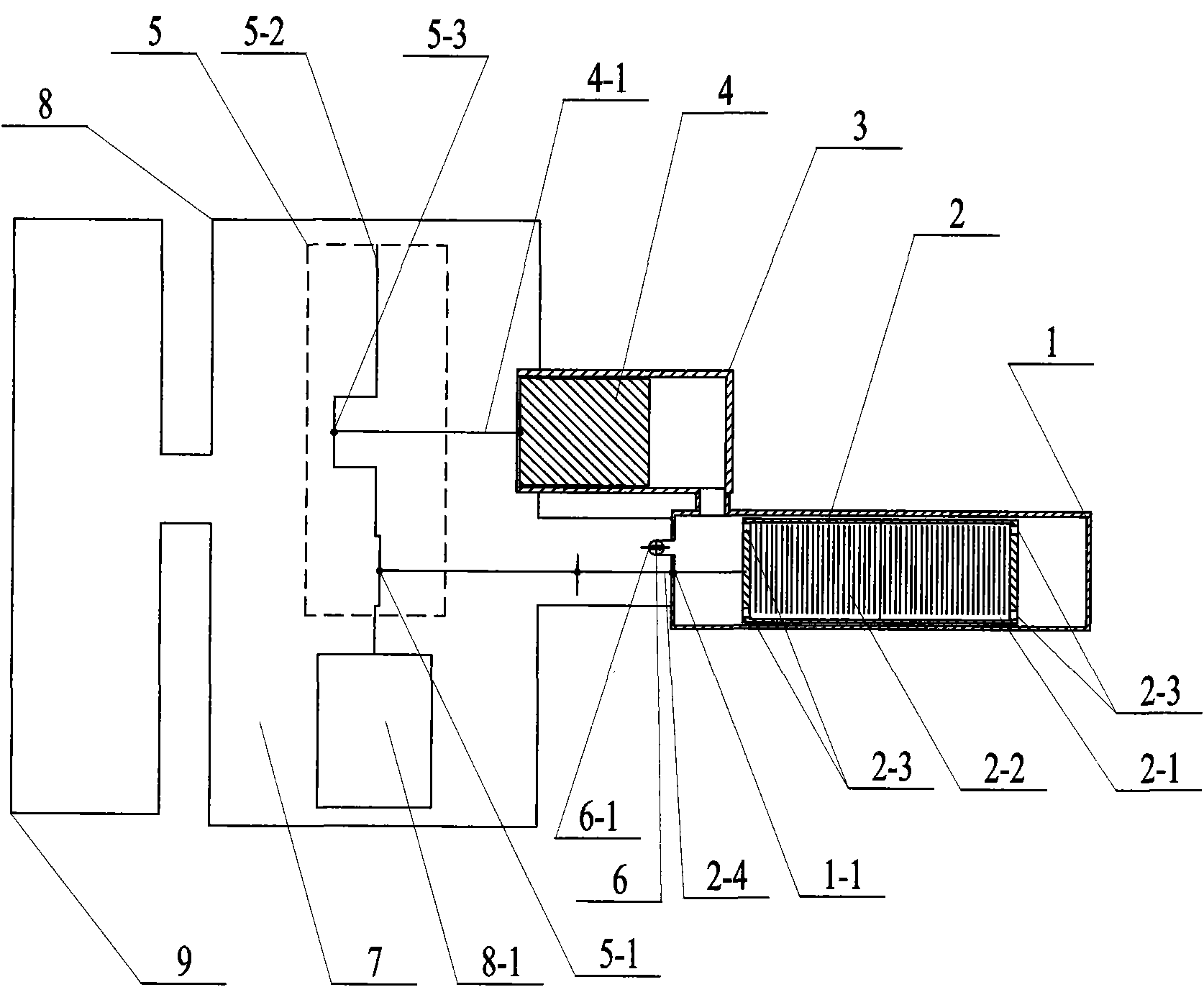

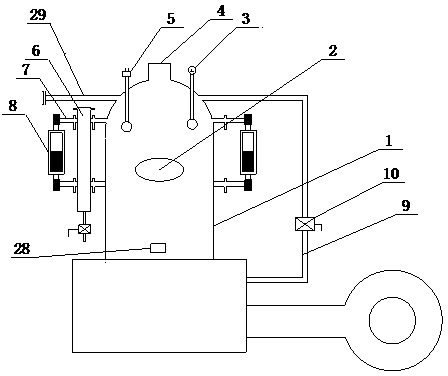

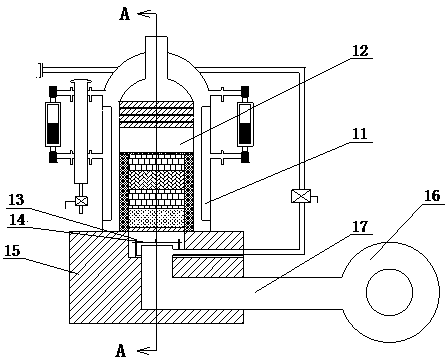

The invention discloses a dual-fuel modified system. A natural gas supply system comprises a natural gas main pipeline, a mixer, a sensor set and a control system. The control system is in communication connection with the sensor set and an electromagnetic switch valve in the natural gas main pipeline. The dual-fuel modified system is started under the mode of diesel oil. When operation signals transmitted by the sensor set are within a preset range, the control system controls the electromagnetic switch valve to be opened, and when the operation signals transmitted by the sensor set are beyond the preset range, the control system controls the electromagnetic switch valve to be closed. According to the dual-fuel modified system, the natural gas main pipeline, the mixer, the sensor set and the control system are arranged on the basis of an original diesel engine, the original diesel engine and an ECU of the original diesel engine are not modified largely, the modifying process is simple, the modifying cost is low, and therefore the feasibility for modifying the large-scale diesel engine to the dual-fuel modified system is improved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

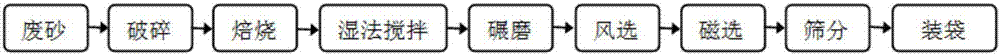

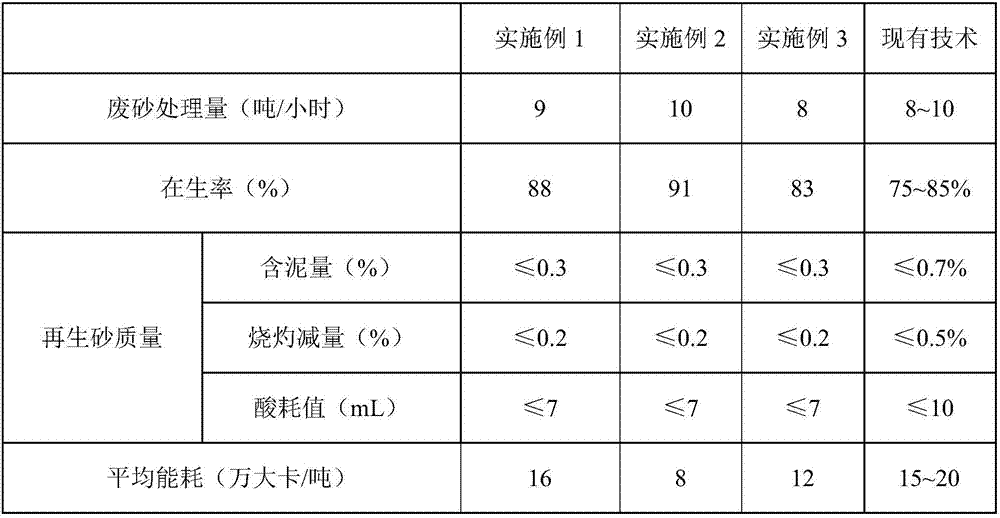

Waste foundry sand regeneration method

InactiveCN107983907AQuality improvementHigh regeneration rateMould handling/dressing devicesEnvironmental resistanceRecovery method

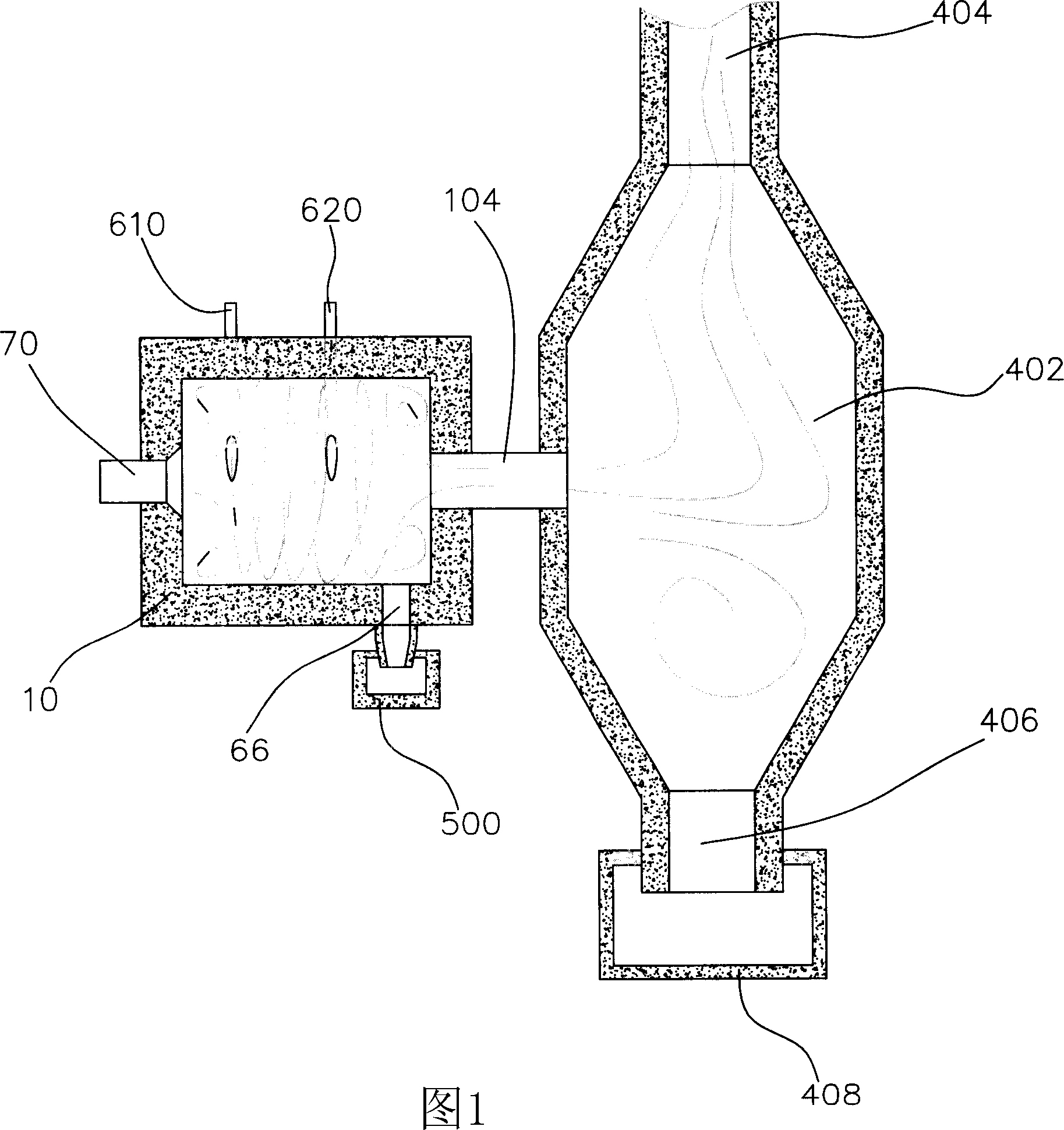

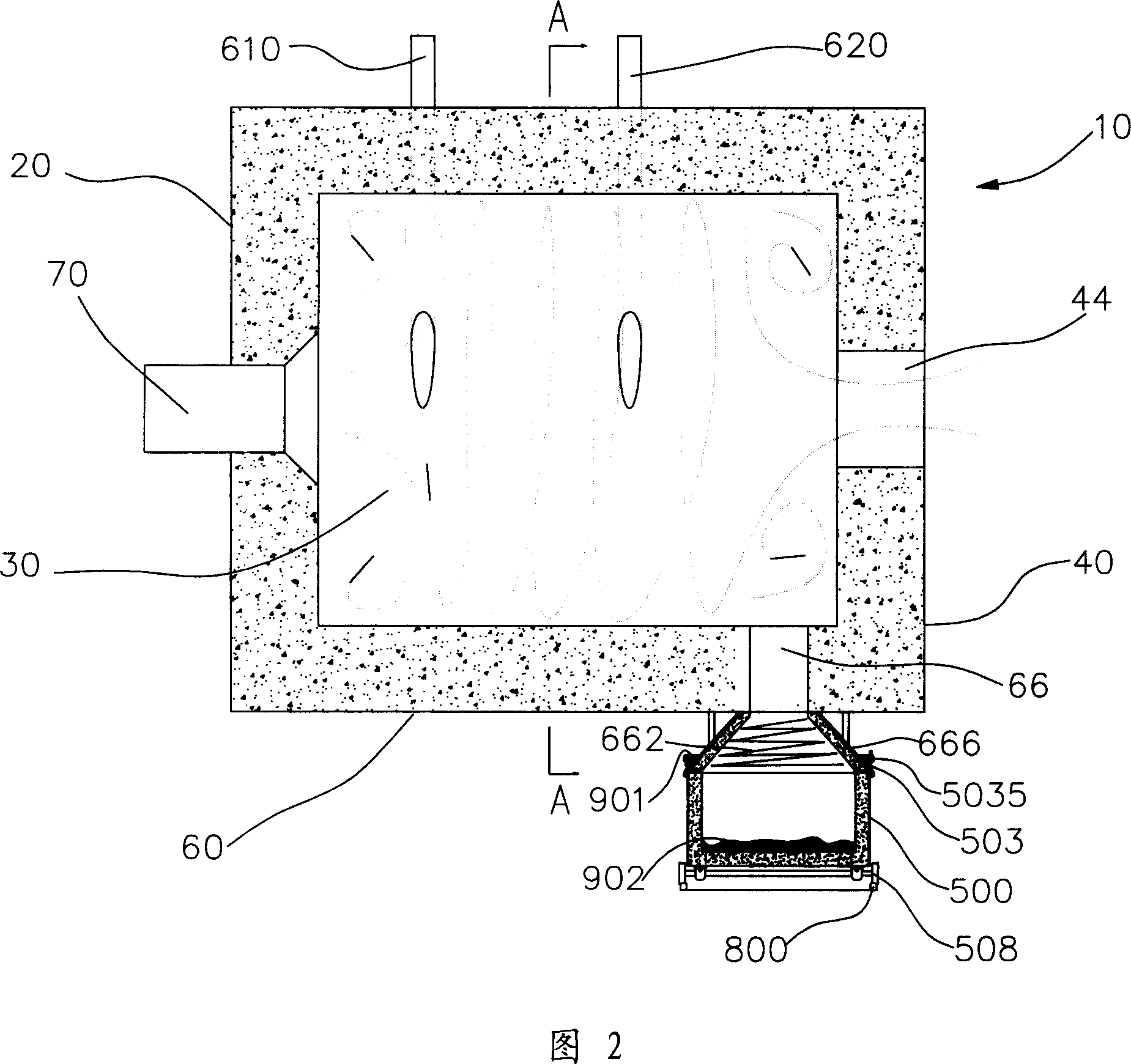

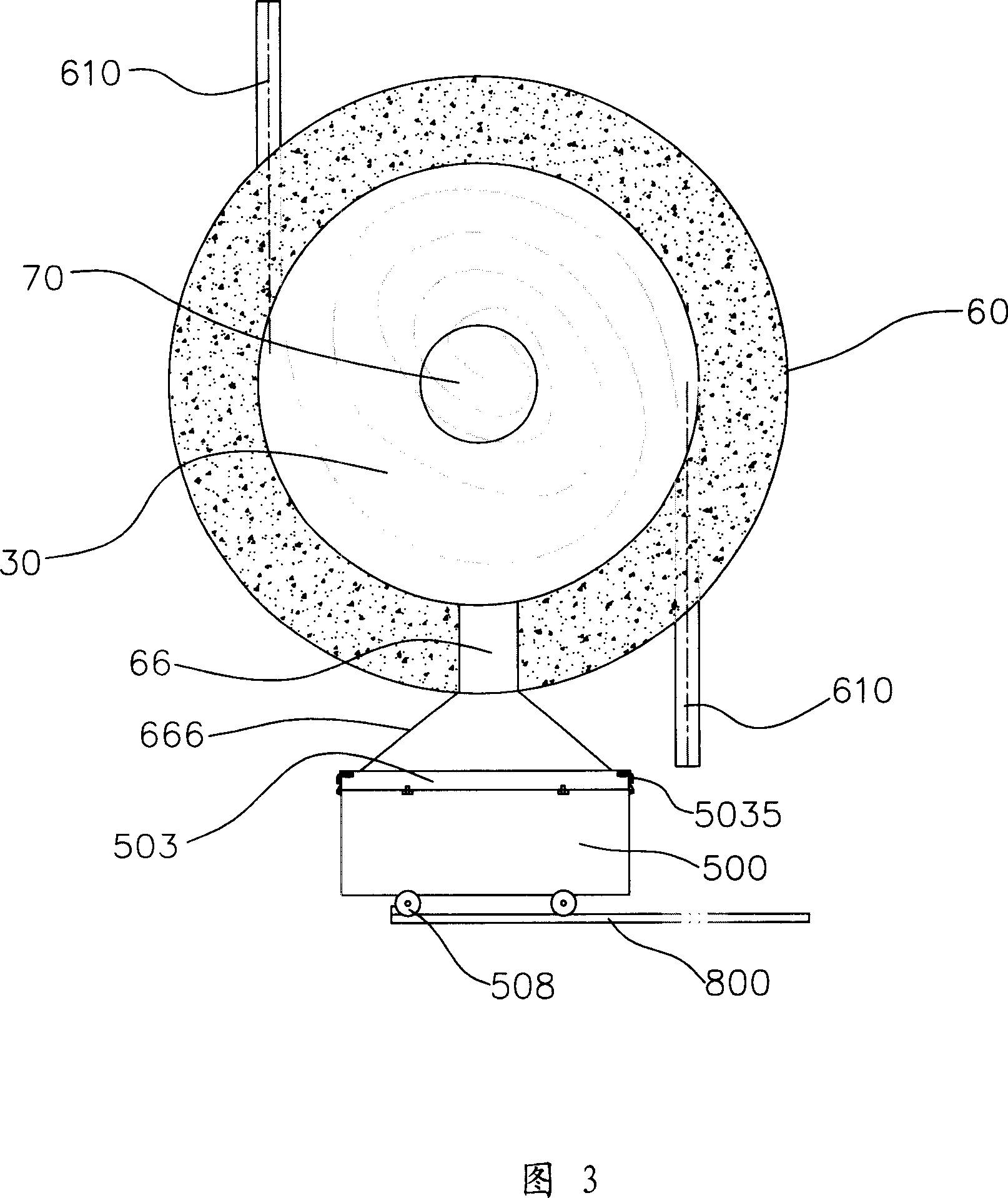

The invention provides a waste foundry sand regeneration method, belongs to the field of environment-friendly regeneration, and particularly relates to a recovery method for waste casting materials. According to the waste foundry sand regeneration method, procedures are successive and reasonable, operation is easy and convenient, and the regeneration rate is high. The waste foundry sand regeneration method comprises the steps of (1) breaking of waste foundry sand, (2) roasting, (3) wet stirring, (4) grinding, and (5) winnowing and magnetic separation. According to the waste foundry sand regeneration method, the heating procedure, the wet stirring procedure and the mechanical grinding procedure are more successive and reasonable, sand reclaimed through the method is high in quality, the regeneration rate is high, and thus, the waste foundry sand regeneration method has good technical feasibility and applicability; and by adoption of the waste foundry sand regeneration method, no poisonous and harmful waste is discharged in the treatment process, zero emission is achieved, and the purpose of environmental protection is achieved.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

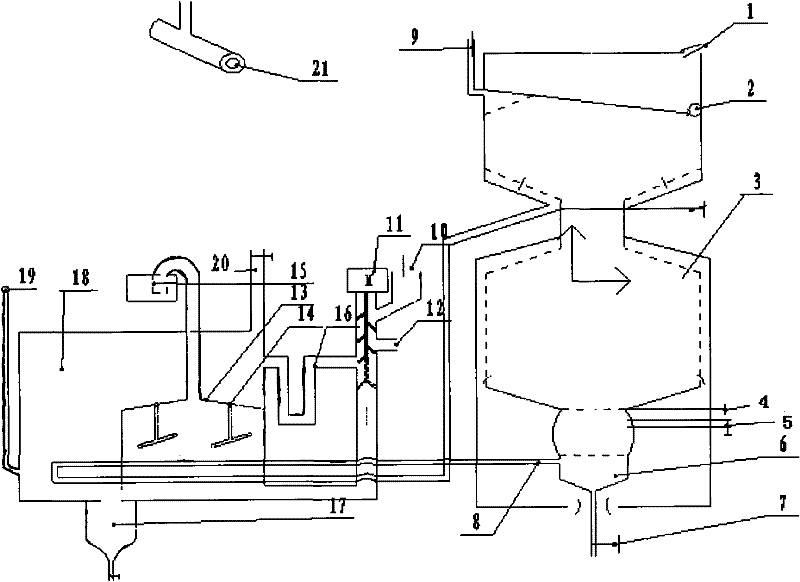

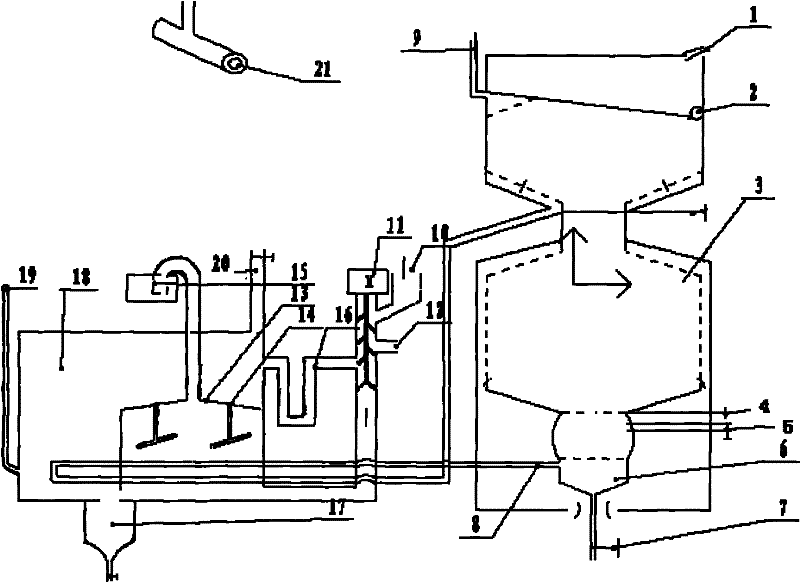

Domestic garbage innocently using and treating system

InactiveCN102125924AAchieve combustionAchieve decompositionBio-organic fraction processingSolid waste disposalNutrientDecomposition

The invention discloses a residence community domestic garbage treating system. The system comprises a garbage burning system, a garbage decomposing system and a garbage decomposition liquid ecological using system, wherein the garbage burning system comprises a burnable garbage throwing pool, a crushing and drying box and a burning and drying device; and the domestic garbage decomposing system comprises a decomposable garbage throwing pool, a spiral propelling crusher, a primary decomposing pool, a gas-liquid guide pipe, a scum recovering pool, a U-shaped secondary scum recovering pipe, a fermentation sediment recovering pool and a secondary decomposing pool. The three systems interact with one another to burn the garbage without smoke and decompose the garbage without pollution, and decomposition liquid also can be used for growing plants at building roofs, balconies and public lawns, so that the indoor temperature and outdoor light pollution are reduced, and the content of nutrients in domestic sewage is lowered.

Owner:周万松

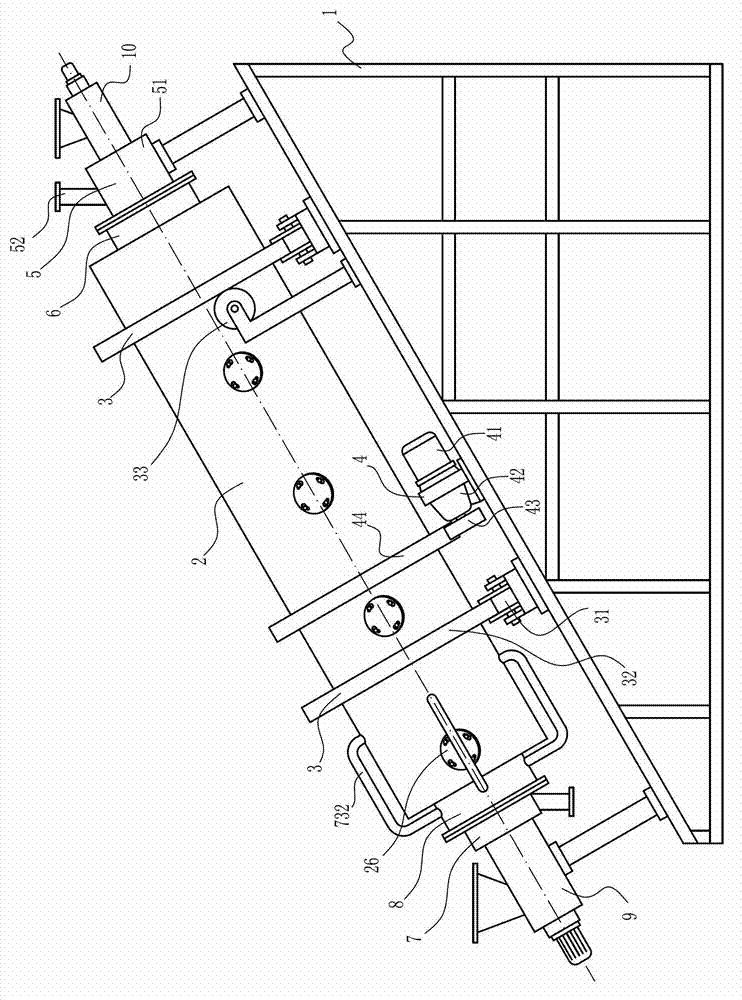

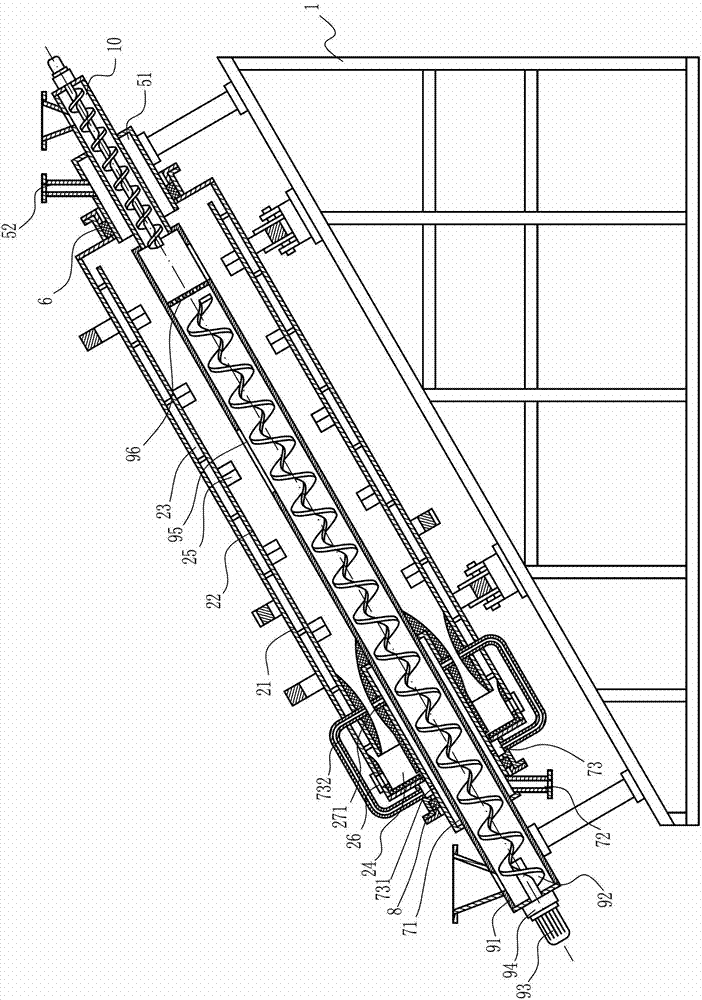

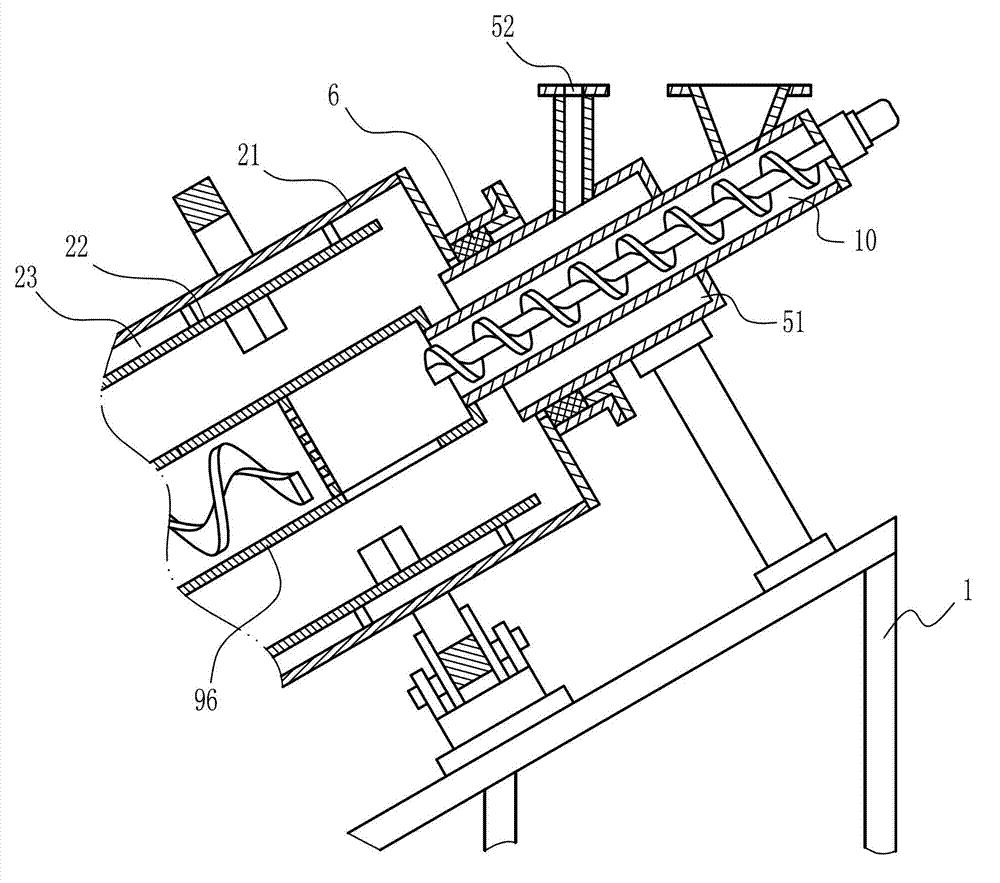

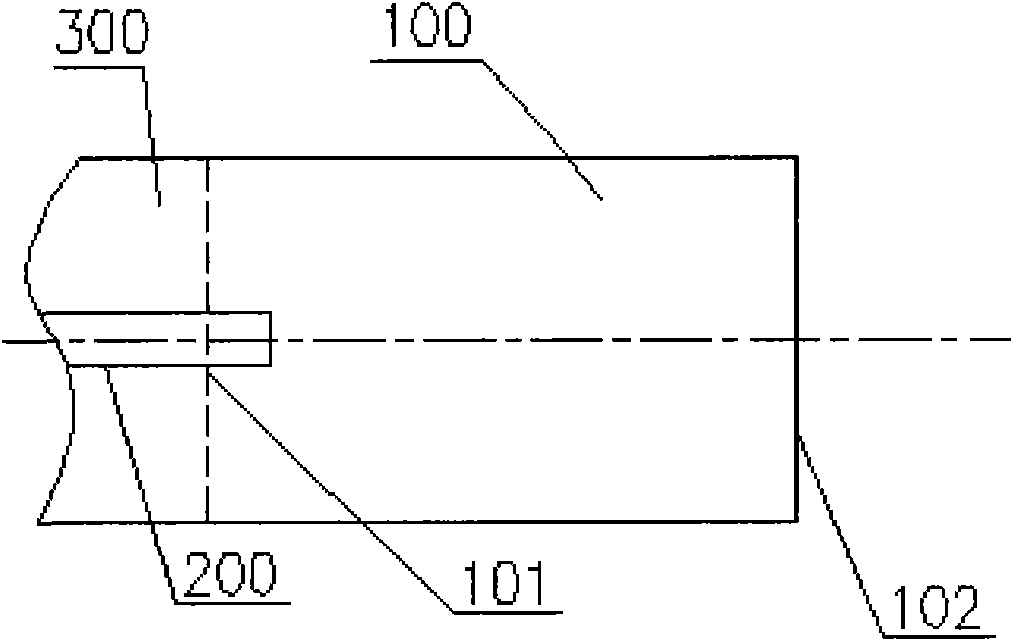

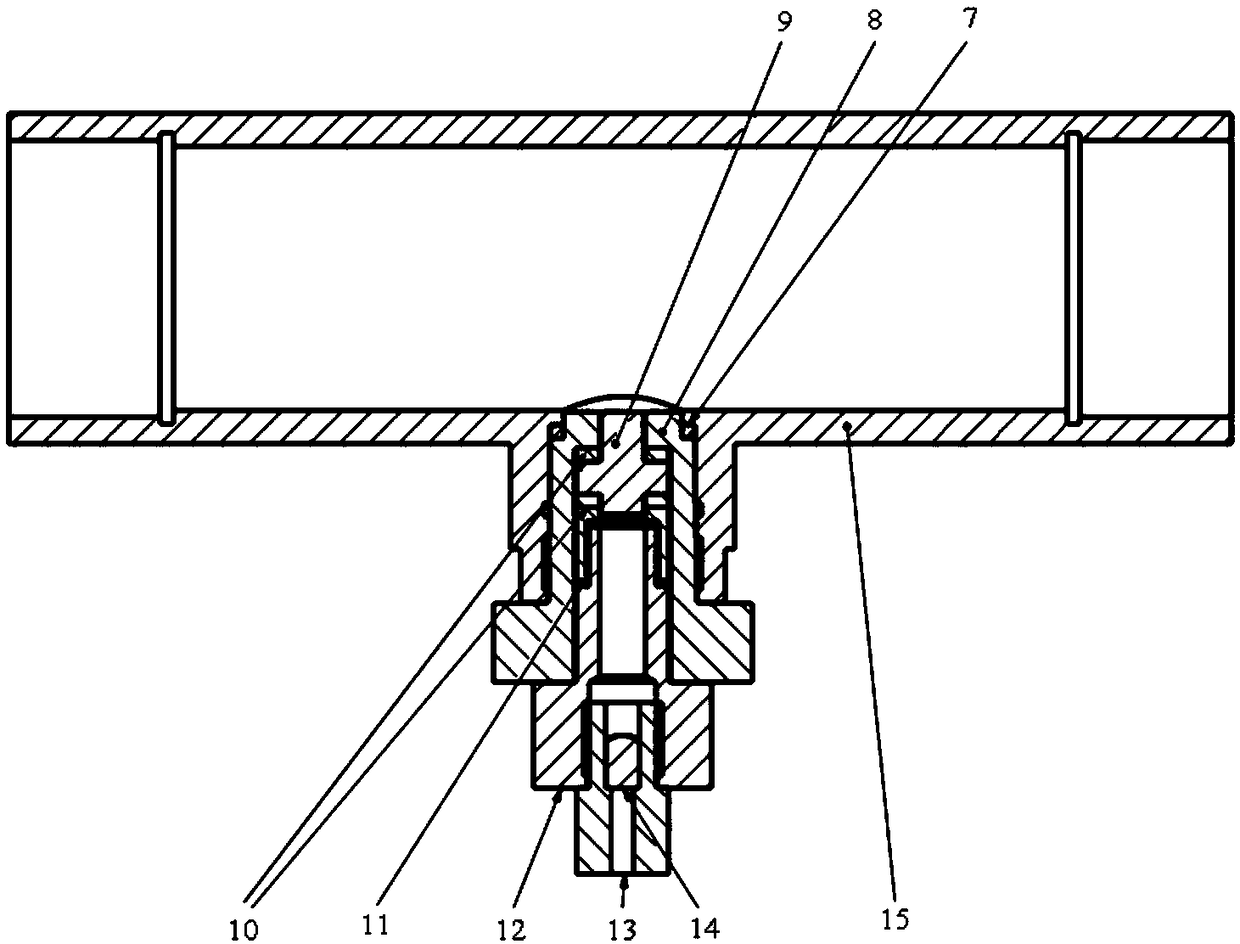

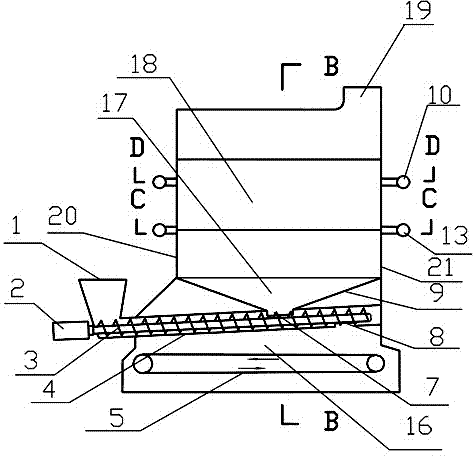

Wet sewage sludge combustion furnace

ActiveCN102889599AAchieve combustionConcentrated and dried with high efficiencyIncinerator apparatusSocial benefitsCombustion

The invention discloses a wet sewage sludge combustion furnace which comprises a machine frame, wherein the machine frame is provided with a barrel type furnace body in an inclining manner, and a riding wheel device and a furnace body revolution driving device are arranged between the barrel type furnace body and the machine frame; the machine frame is fixedly provided with a sludge granulation spiral conveyer, and a discharge end of the sludge granulation spiral conveyer stretches into the upper part of the interior of the barrel type furnace body; and the upper end of the sludge granulation spiral conveyer is provided with a steam exhausting device and a granulation discharge hole. The wet sewage sludge combustion furnace provided by the invention can concentrate the sludge in a sludge transport process, the subarid sludge is extruded and granulated through the granulation discharge hole, the sludge grains are driven by the revolving barrel type furnace body to continually roll and dry so as to move to a hearth position, and turn into flammable grains at the heart position, and the combustion of the sludgy is realized. The wet sewage sludge combustion furnace provided by the invention has the advantages that the structure is compact, the sludge concentration drying efficiency is high, an energy source is not wasted, the sludge incineration is thorough, the technical bottle neck of sludge incineration is fully solved, and the wet sewage sludge combustion furnace has great economic and social benefits and popularization and application values.

Owner:刘振亮

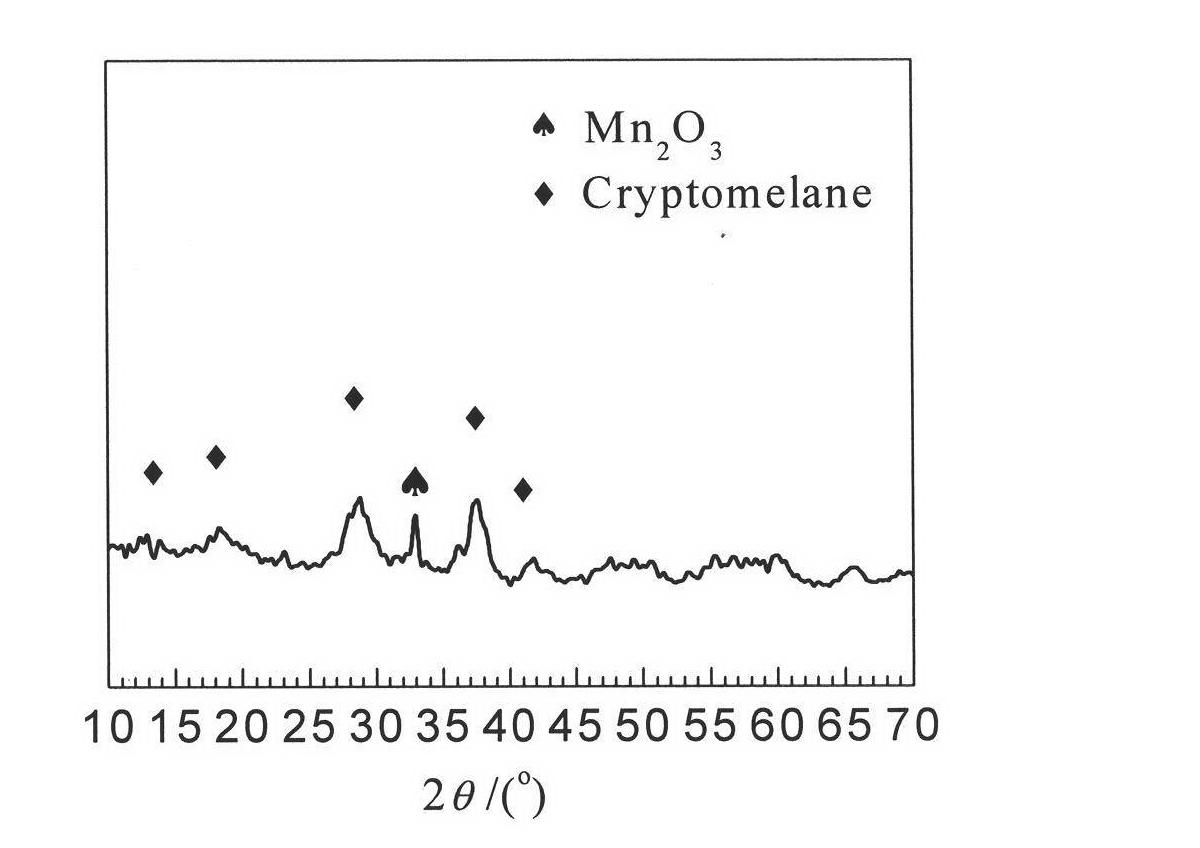

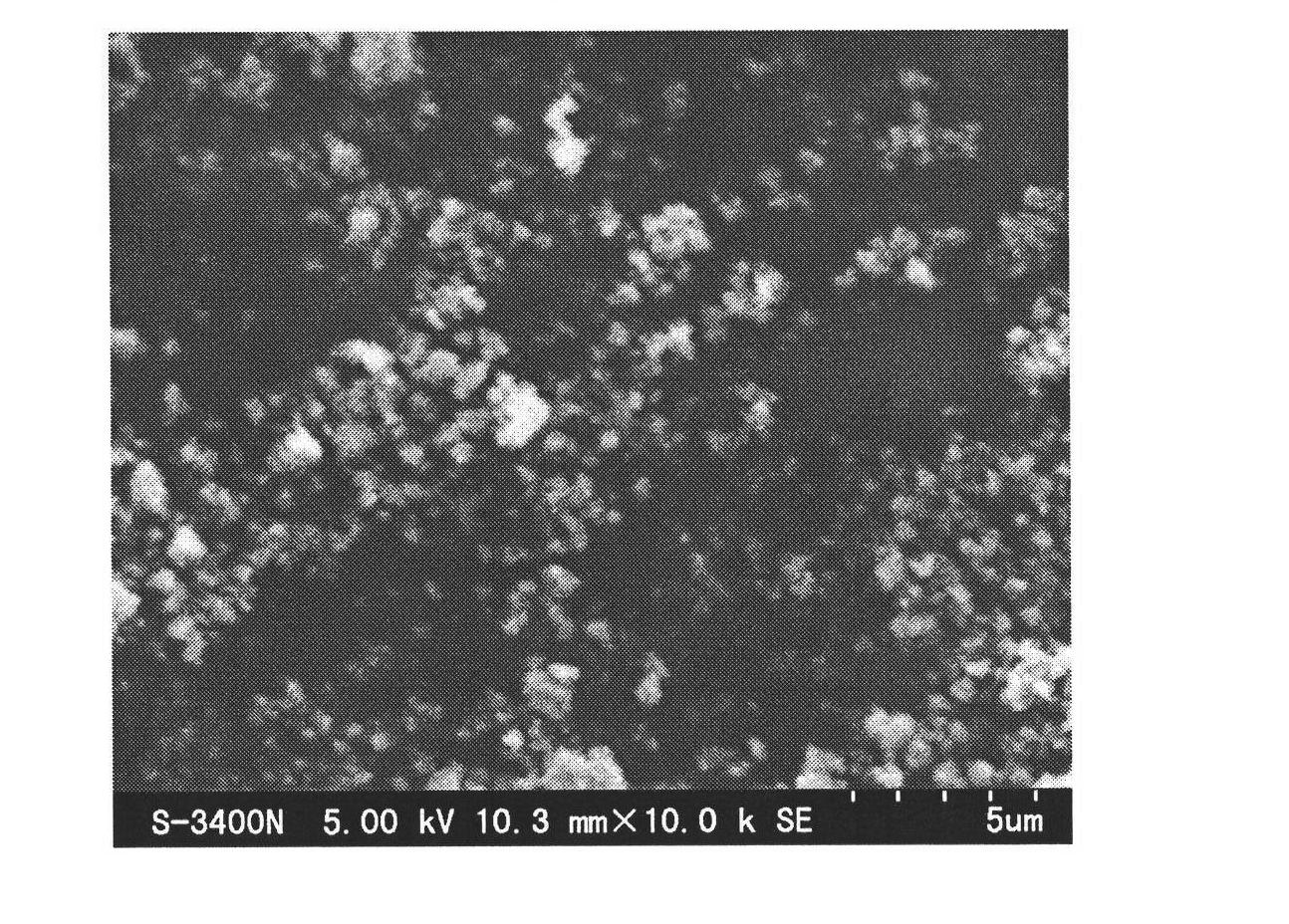

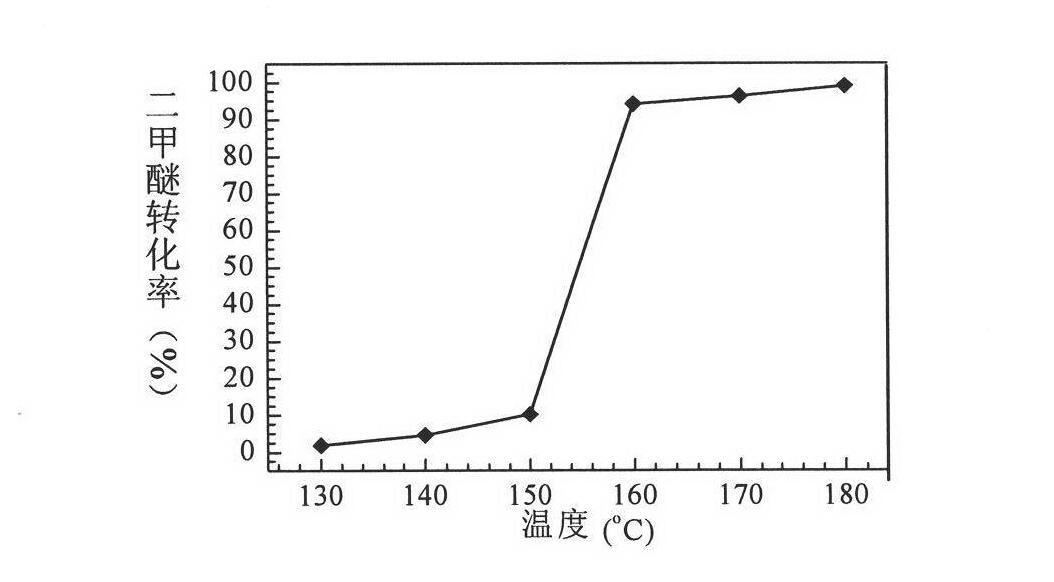

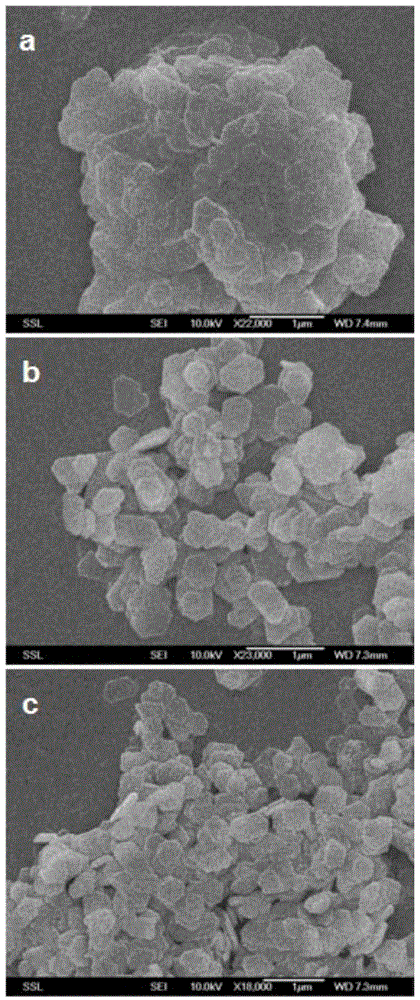

Metal ion doped manganese oxide catalyst, preparation method and use thereof

InactiveCN101791559AGood catalytic combustion performanceAchieve combustionFuel additivesMetal/metal-oxides/metal-hydroxide catalystsWater bathsManganese oxide

The invention discloses a metal ion-doped manganese oxide catalyst, a preparation method and use thereof; the preparation method of the catalyst comprises the following steps: preparing a Birnessite type manganese oxide precursor of the catalyst using sol-gel process; introducing metal ions into the space between layers of manganese or the frame of manganese in a water bath at the temperature of 40-80 DEG C with immersion method; and roasting for 1-48h at the temperature of 110-480 DEG C in gas atmosphere so as to obtain a catalyst of variable structure. The catalyst shows a high low-temperature activity in catalytic combustion reaction of dimethyl ether, thus the catalyst can serve as a high-efficient catalyst for combustion of dimethyl ether.

Owner:GUANGDONG UNIV OF TECH

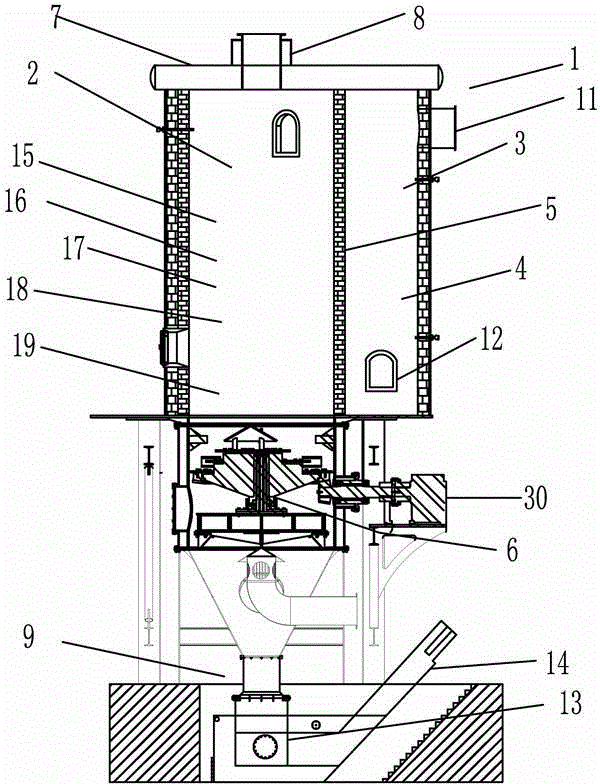

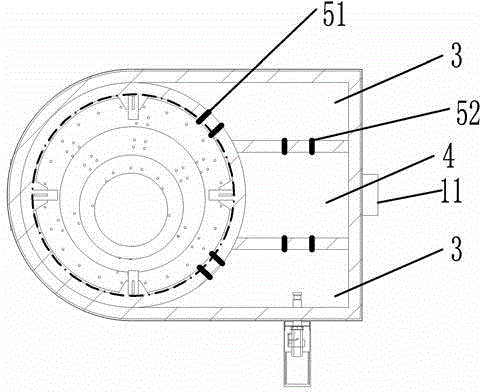

Novel pyrolysis gasification melting environment-friendly furnace and method for processing wastes of novel pyrolysis gasification melting environment-friendly furnace

The invention provides a novel pyrolysis gasification melting environment-friendly furnace, which comprises a furnace body, a driving mechanism and a slag discharge mechanism, wherein a material inlet is arranged on a furnace cover which is arranged on the top end of the furnace body, a first and a second combustion process chambers are arranged on the upper portion of the furnace body, a rotating furnace grate is arranged on the lower portion of the furnace body, the bottom end of the furnace body is respectively connected with the slag discharge mechanism and an air supply port, the rotating furnace grate is fixedly connected with the driving mechanism through a driving mechanism interface, the first and the second combustion process chambers are adjacently arranged on the same horizontal plane, are insulated through a high temperature thermal conductive wall, and are communicated through a first connecting channel, the upper portion of the first combustion process chamber is communicated with the material inlet, the lower portion of the first combustion process chamber is communicated with the position of the rotating furnace grate, and a flue is arranged on the upper portion of a shell of the second combustion process chamber. The invention further provides a method for processing wastes of the novel pyrolysis gasification melting environment-friendly furnace. The novel pyrolysis gasification melting environment-friendly furnace and the method for processing the wastes of the novel pyrolysis gasification melting environment-friendly furnace can completely pyrolyze smoke during the combustion process, and prevents poisonous and harmful ingredients in the smoke from overflowing.

Owner:广东昕旺环保科技发展有限公司

Zero-leakage external combustion heat engine

InactiveCN101737193AAchieve high efficiency and energy savingGreat power/weight ratioEngine sealsStirling type enginesCombustionExternal combustion engine

The invention discloses a zero-leakage external combustion heat engine, which relates to the technical field of heat energy conversion and solves the problems that the thermal conversion efficiency of the traditional internal-combustion engine is low and combustion is imperfect and the traditional Stirling engine has high cost, smaller ratio of power / weight and is difficult to seal, thus, zero-leakage cannot be realized due to the existence of an expansion chamber, a compression chamber, a heater, a cooling chamber, a regenerator and the like . The gas-guide cylinder cavity of the zero-leakage external combustion heat engine is communicated with the upper part of the work applying cylinder cavity to form a sealed cavity which is connected with an external ventilating valve. The conductive starting point of the ventilating valve is determined in such a way that the gas-guide piston moves between the previous 20 degrees and the next 20 degrees at the top end of the high temperature end of the gas-guide cylinder cavity. The conductive angle of the ventilating valve ranges from 5 degrees to 30 degrees. All mobile sealing positions and the external ventilating ends of the ventilating valve are sealed in a sealed shell. The invention has the advantages of converting combustion heat energy of fuel directly to efficient mechanical energy, thereby realizing zero-leakage and super ratio of power / weight with the conversion efficiency of 20-80%.

Owner:雷涛

Supercritical fluid-type external-combustion heat engine

ActiveCN102797589AHigh heat conversion efficiencyAchieving Zero LeakageHot gas positive displacement engine plantsStirling engineHeat engine

The invention relates to the technical field of heat energy conversion and discloses a supercritical fluid-type external-combustion heat engine for overcoming the problems of low heat conversion efficiency and atmospheric pollution caused by incomplete combustion, and high noise in the present internal-combustion engines, the problems of low power / weight radio and incapability of zero leakage due to difficulty in sealing in the present Stirling engines. According to the invention, carbon dioxide and a gas working medium are filled in an airtight shell, the pressure in the airtight shell ranges from 7.4 MPa to 10 MPa, so that the carbon dioxide is in a supercritical carbon dioxide fluid state; and the interior of a gas guide cylinder cavity, a gas guide piston, the interior of a work-applying cylinder cavity, a work-applying piston, a flywheel crankshaft assembly and a valve are all immersed in the supercritical carbon dioxide fluid, the heat end temperature of the gas guide cylinder cavity is set to be between 60 DEG C and 130 DEG C, and the cold end temperature of the gas guide cylinder cavity is set be between 32 DEG C and 40 DEG C. By the supercritical fluid-type external-combustion heat engine disclosed by the invention, the heat energy at a temperature being higher than 50 DEG C can be directly and efficiently converted to mechanical energy and then to electrical energy, and then zero leakage can be realized. The efficiency of the heat energy-mechanical energy conversion is 20-80%.

Owner:HARBIN XIANGKAI TECH DEV

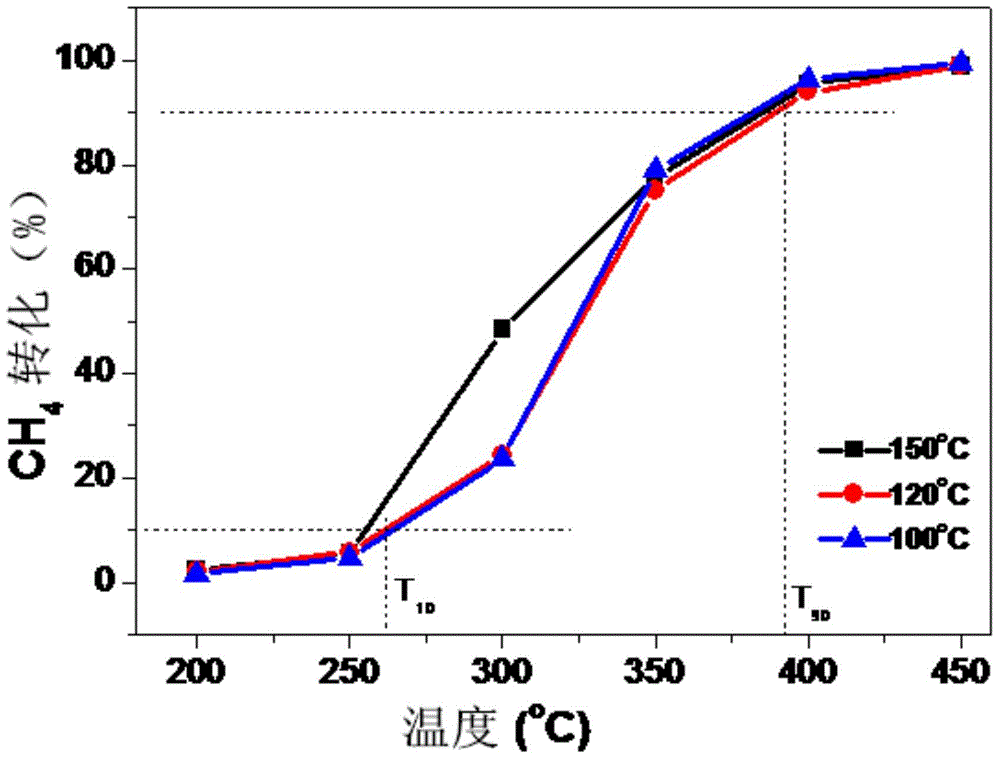

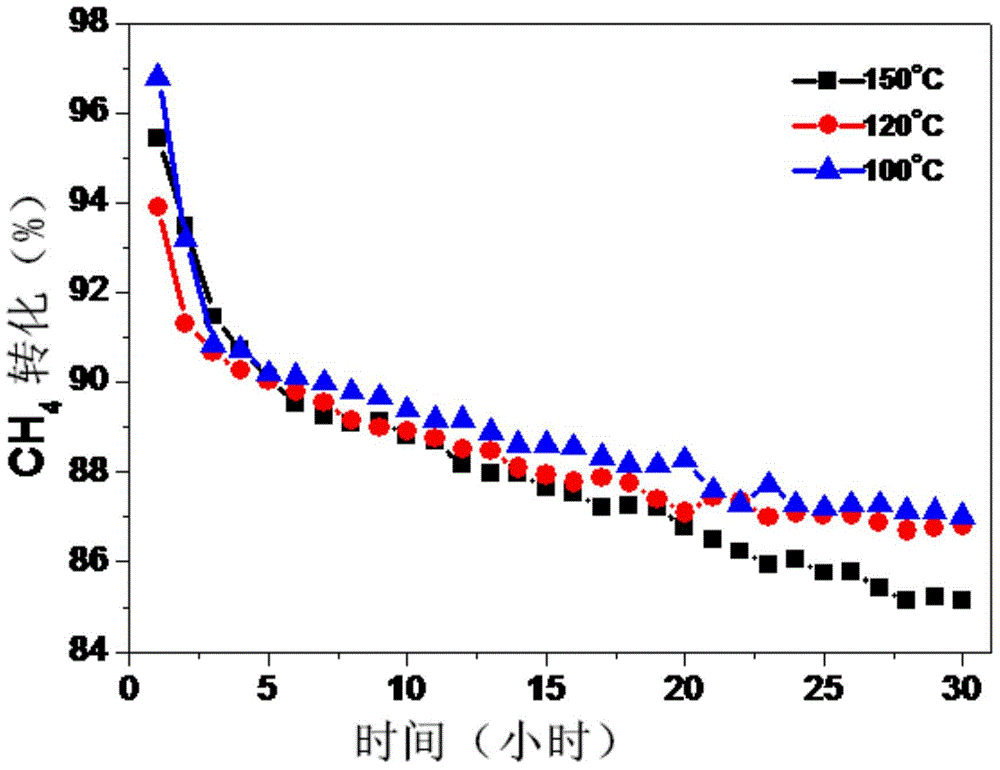

Preparation method of Co3O4 catalyst, and application of the catalyst in catalytic combustion of methane

InactiveCN105983408ALow costSimple processFuel additivesCobalt oxides/hydroxidesCobalt(III) oxideChemistry

The application discloses a preparation method of a Co3O4 methane catalytic combustion catalyst and an application of the catalyst in low-temperature combustion of methane. The preparation method includes the steps of mixing a polyol water solution of bivalent cobalt salt and a polyol water solution of strong alkali, heating the mixture at a constant temperature in a sealed reaction kettle, and washing, drying and roasting the mixture to obtain the catalyst. The preparation method is low in cost, is simple in preparation and is easy to promote, has high activity, good stability, low ignition temperature, and can achieve complete combustion of methane in low concentration at a low temperature. The catalyst, compared with a noble metal catalyst, is low in cost, so that the catalyst has a potential prospect in the fields of hydrocarbon purification of automobile exhaust, high-effective combustion and utilization of domestic natural gas, etc.

Owner:NAT UNIV OF SINGAPORE SUZHOU RES INST +1

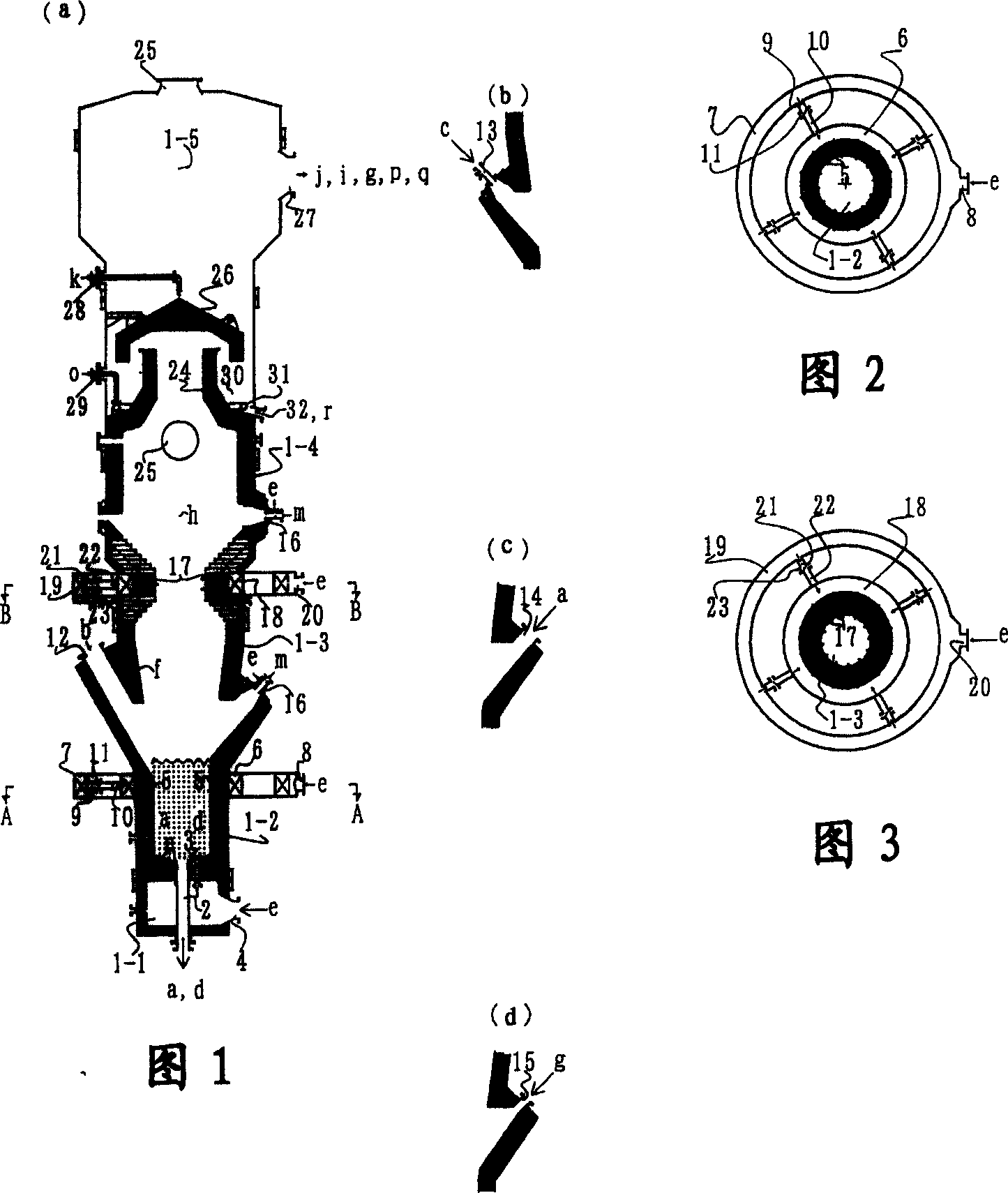

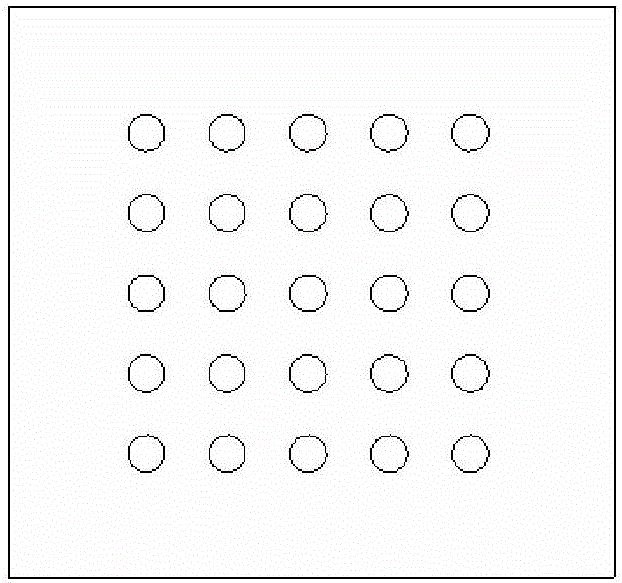

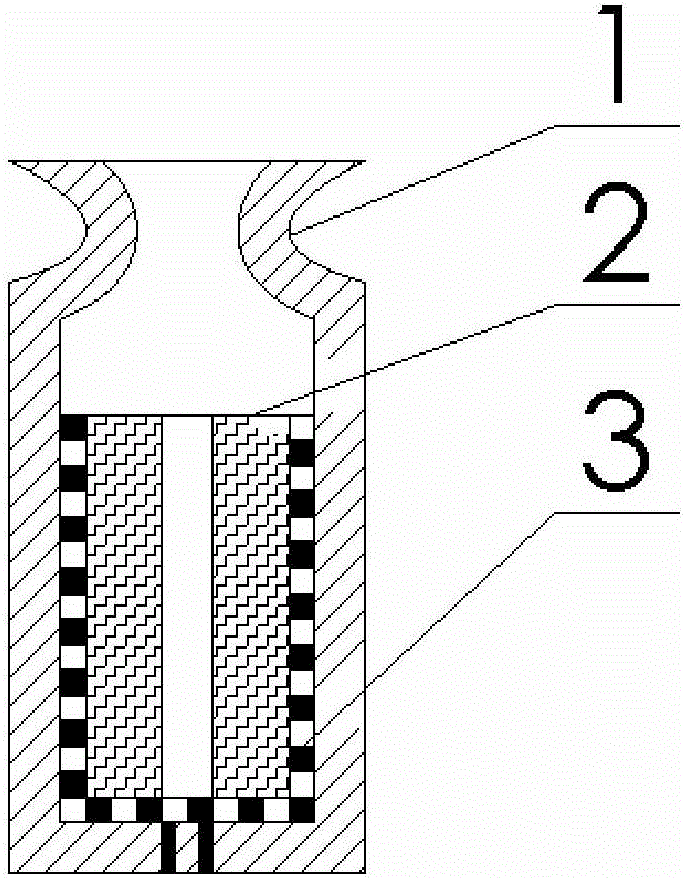

Pulverized coal burner and boiler with same

ActiveCN102032563AAchieve combustionOptimizationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberNitrogen

The invention discloses a pulverized coal burner and a boiler with the same. The disclosed pulverized coal burner comprises a heat source and an internal burning chamber, wherein the internal burning chamber ensures that an internal pulverized coal flow has a predetermined excess air coefficient; the heat source is positioned in the internal burning chamber; the internal burning chamber is provided with an inlet, a long cylindrical main burning chamber and an outlet; the heat source can ignite pulverized coal which passes through the internal burning chamber and ensures that the pulverized coal reducibly burns in the internal burning chamber; preferably, the internal burning chamber comprises the main burning chamber and a decelerating inlet section; and the sectional area of the decelerating inlet section is less than that of the main burning chamber. The internal burning chamber of the pulverized coal burner can maintain a smaller air coefficient, so reducing atmosphere is formed in the internal burning chamber; the pulverized coal reducibly burns in the internal burning chamber, so the pulverized coal flow enters a hearth in the form of high-temperature pulverized coal burning flame to improve the burning stability of the pulverized coal; meanwhile, the reducing burning can also convert a nitrogen element into a reducing intermediate product, so that fuel type nitrogen oxides are prevented from being produced.

Owner:YANTAI LONGYUAN POWER TECH

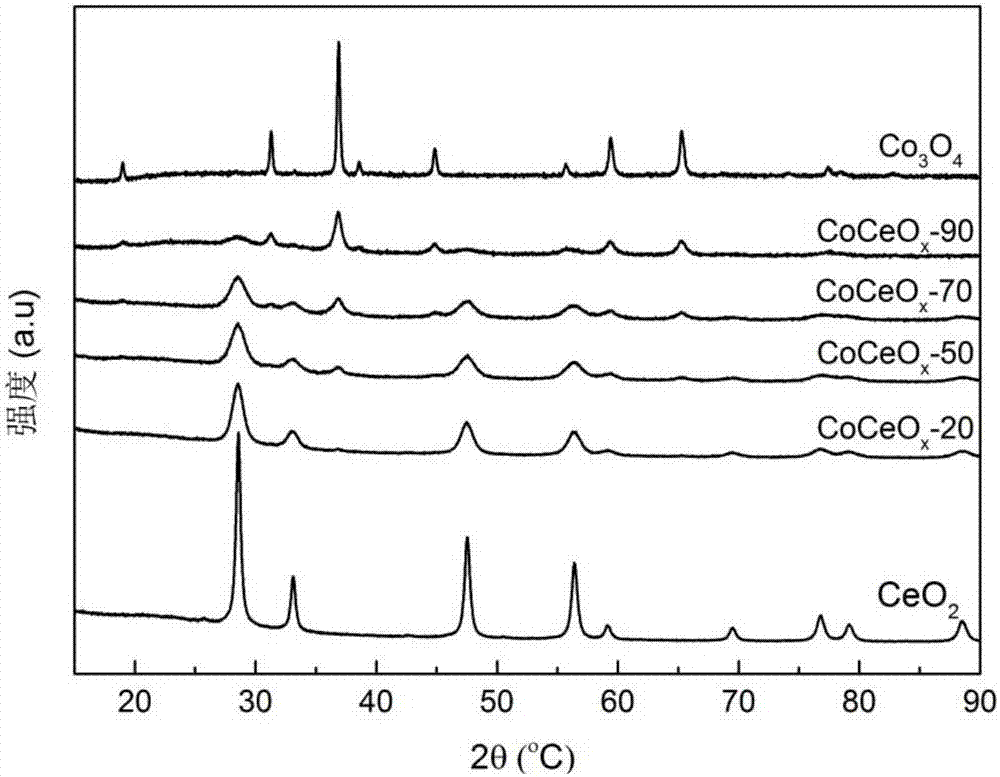

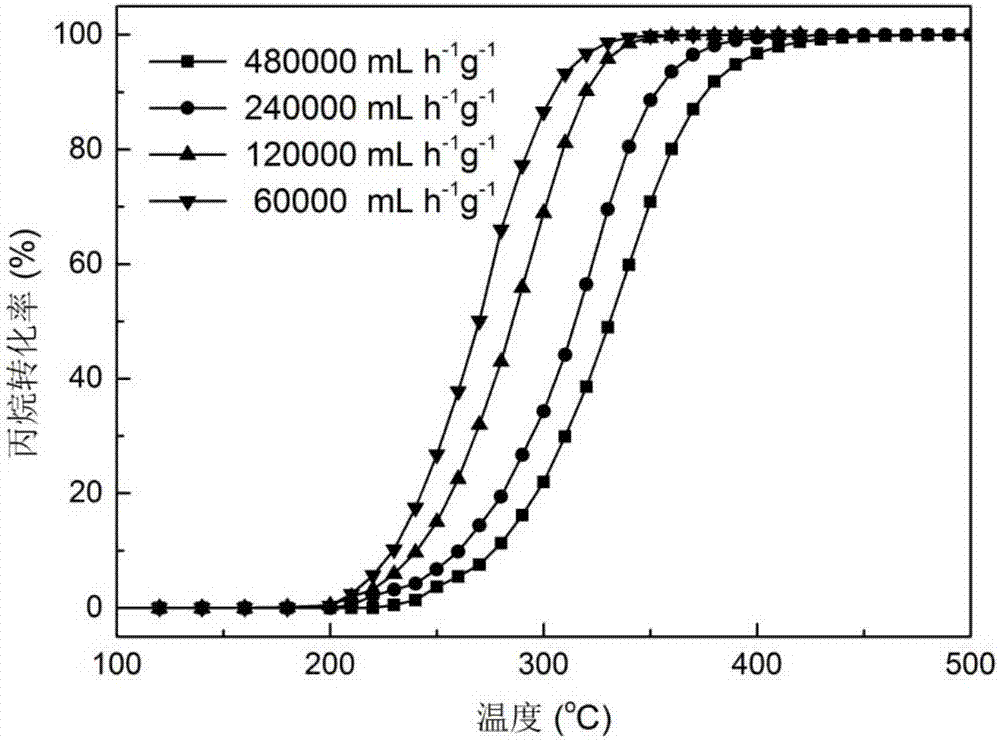

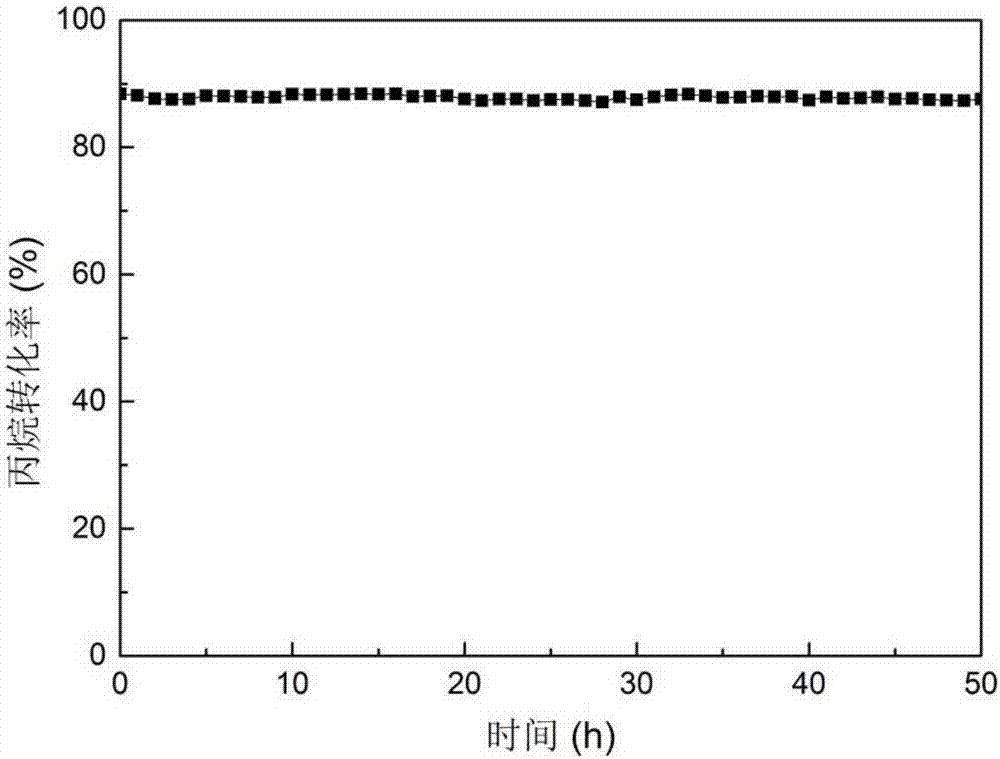

Preparation method of propane catalytic combustion composite oxide catalyst and application of catalyst

InactiveCN107952441AHigh activityImprove stabilityCatalyst activation/preparationIncinerator apparatusCeriumCobalt

The invention belongs to the technical field of VOCs (volatile organic chemicals) catalytic combustion environment protection, and relates to a preparation method of a propane catalytic combustion composite oxide catalyst and an application of the catalyst. According to the preparation method of the catalyst, a cerium cobalt composite oxide is prepared by a citric acid method and can be applied topropane catalytic combustion reaction. The provided cerium cobalt composite oxide propane catalytic combustion catalyst is high in activity, good in stability and low in initiation temperature; complete combustion of low-concentration propane can be realized at lower temperature; compared with a precious metal catalyst, the catalyst is lower in cost; therefore, the catalyst has a potential application prospect in the aspect of industrial waste gas purification.

Owner:DALIAN UNIV OF TECH

Energy-saving stove

InactiveCN101581455AAvoid performance lossHigh flame temperatureDomestic stoves or rangesLiquid heating fuelCombustionHeat losses

The invention provides an energy-saving stove. The stove comprises a mixing chamber of fuel and air, the mixing chamber is communicated with a jet hole on a combustion head; the combustion head is arranged in a furnace tank circled by a stove ring and a stove bottom; the closed furnace is provided with a smoke gas outlet; a smoke gas flow passage is formed between the combustion head and the smoke gas outlet; the smoke gas flow passage is provided with porous thermal storage radiant panels for stopping. The energy-saving stove has the advantages of small heat loss and high heat efficiency.

Owner:ZHEJIANG UNIV OF TECH

Rotation burning type burning device

The provides a rotatablely burning type incinerator for incinerating the wastes, characterized in that: a circulating water wet wall type gas cooling room including an exhaust gas energency drain, air vent, shade and aeration tank is mounted on the most top of a double layer rotary flow layer type incinerator of JP 2985058 and the circulating water wet wall type gas cooling room is integrated with the double layer rotary flow layer type incinerator.

Owner:五味吉男 +1

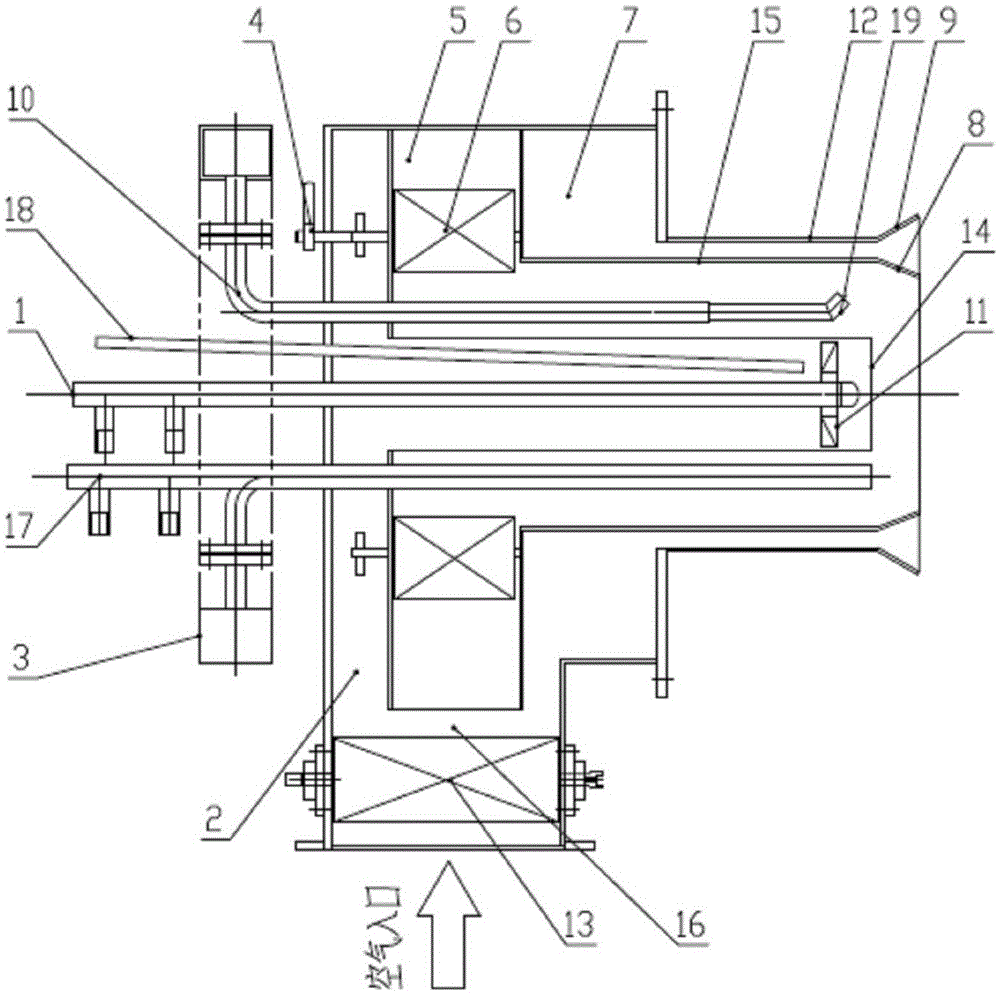

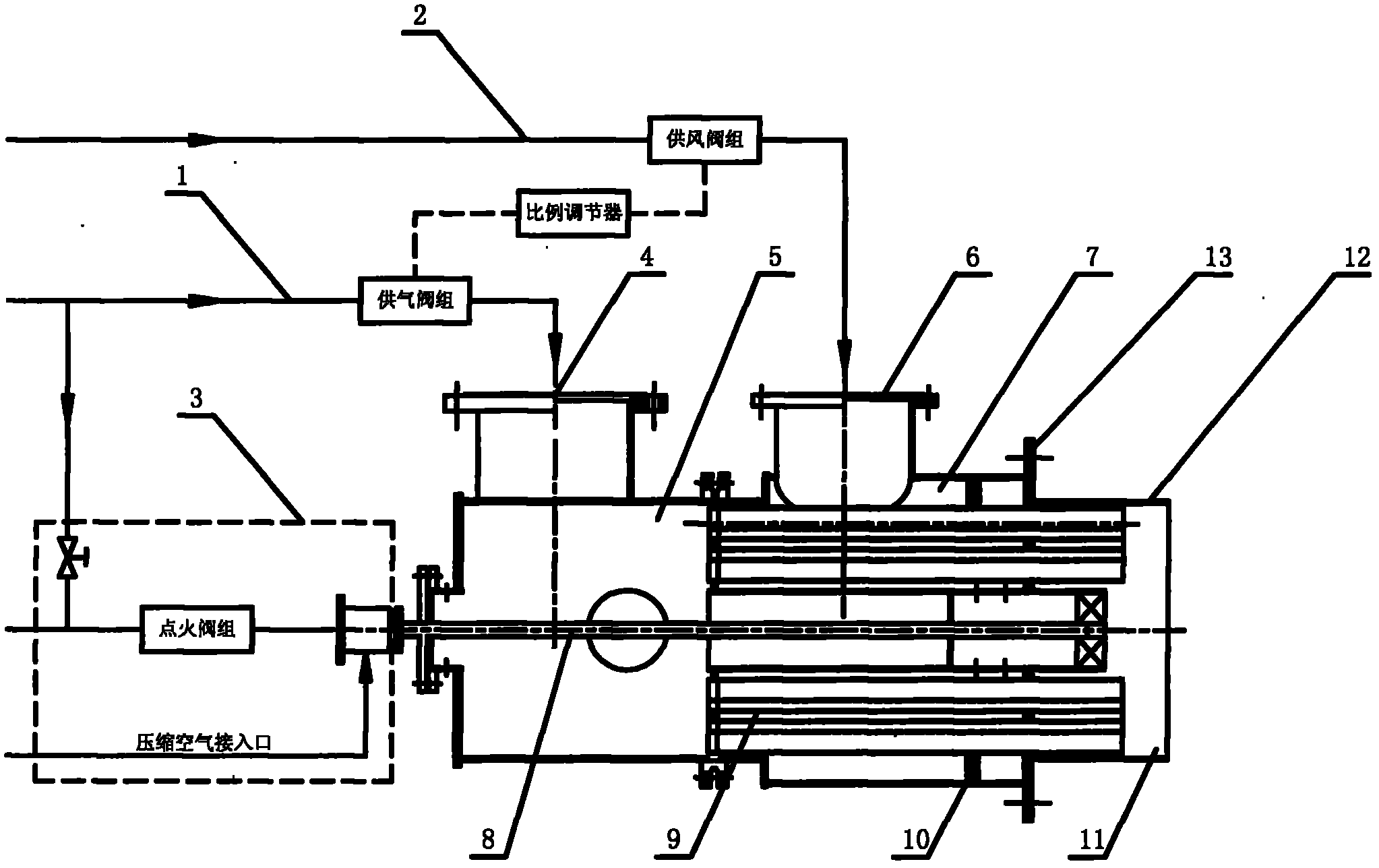

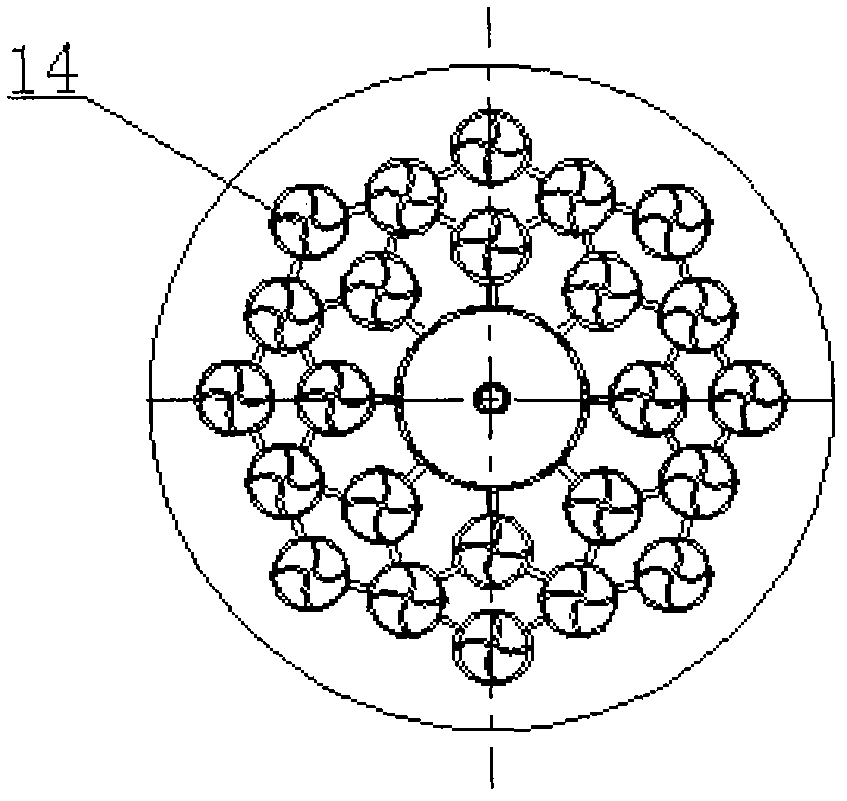

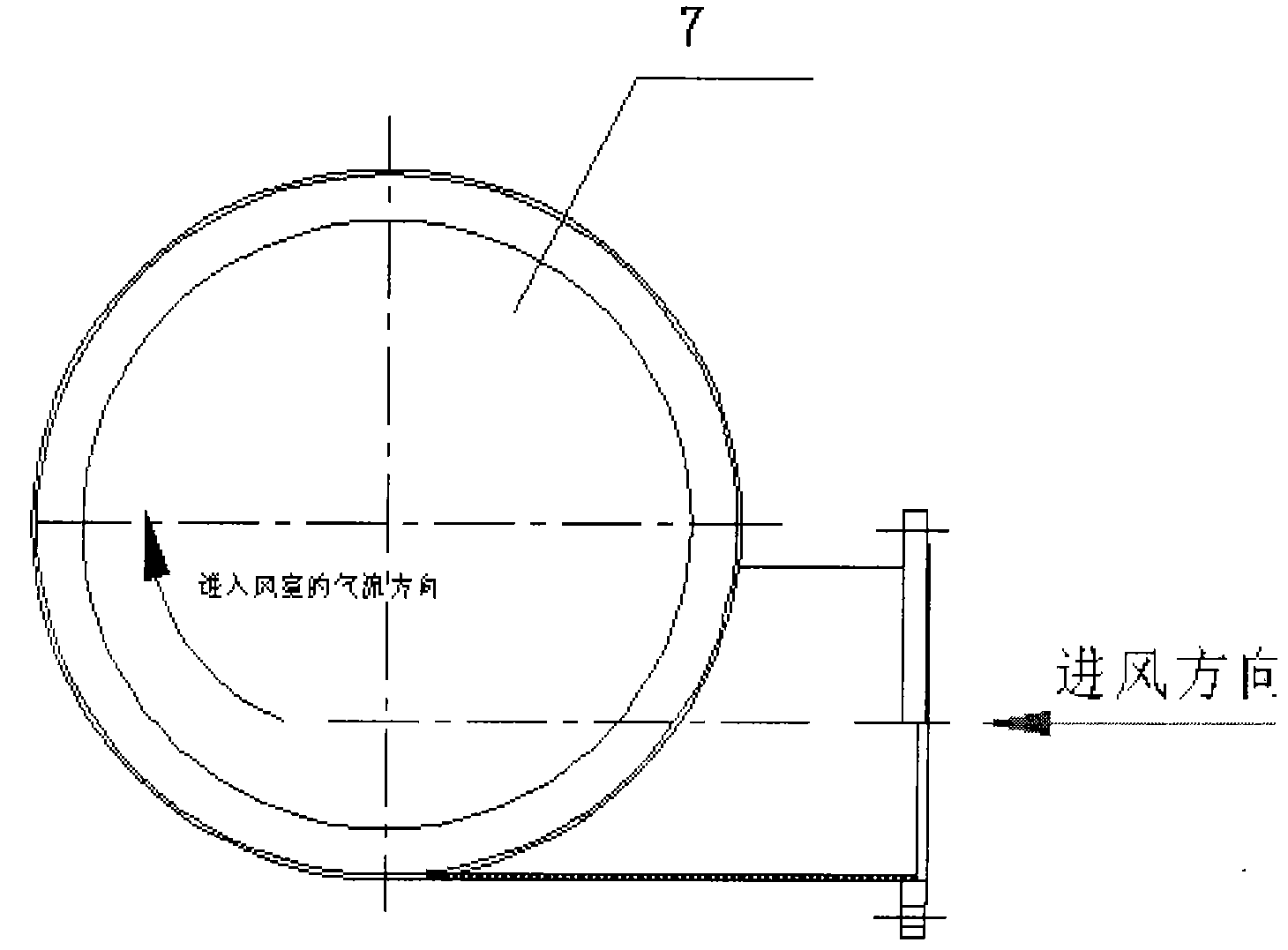

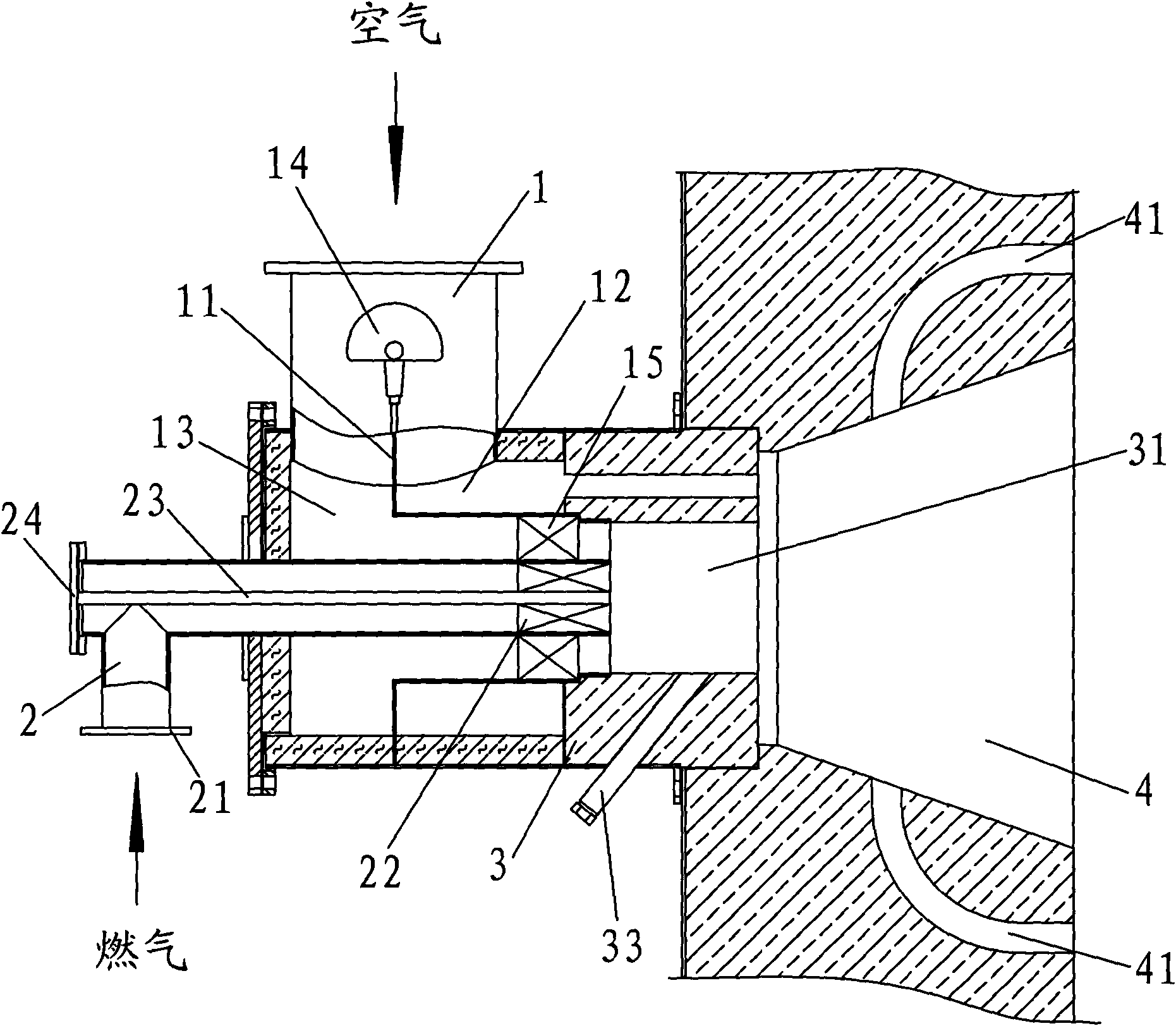

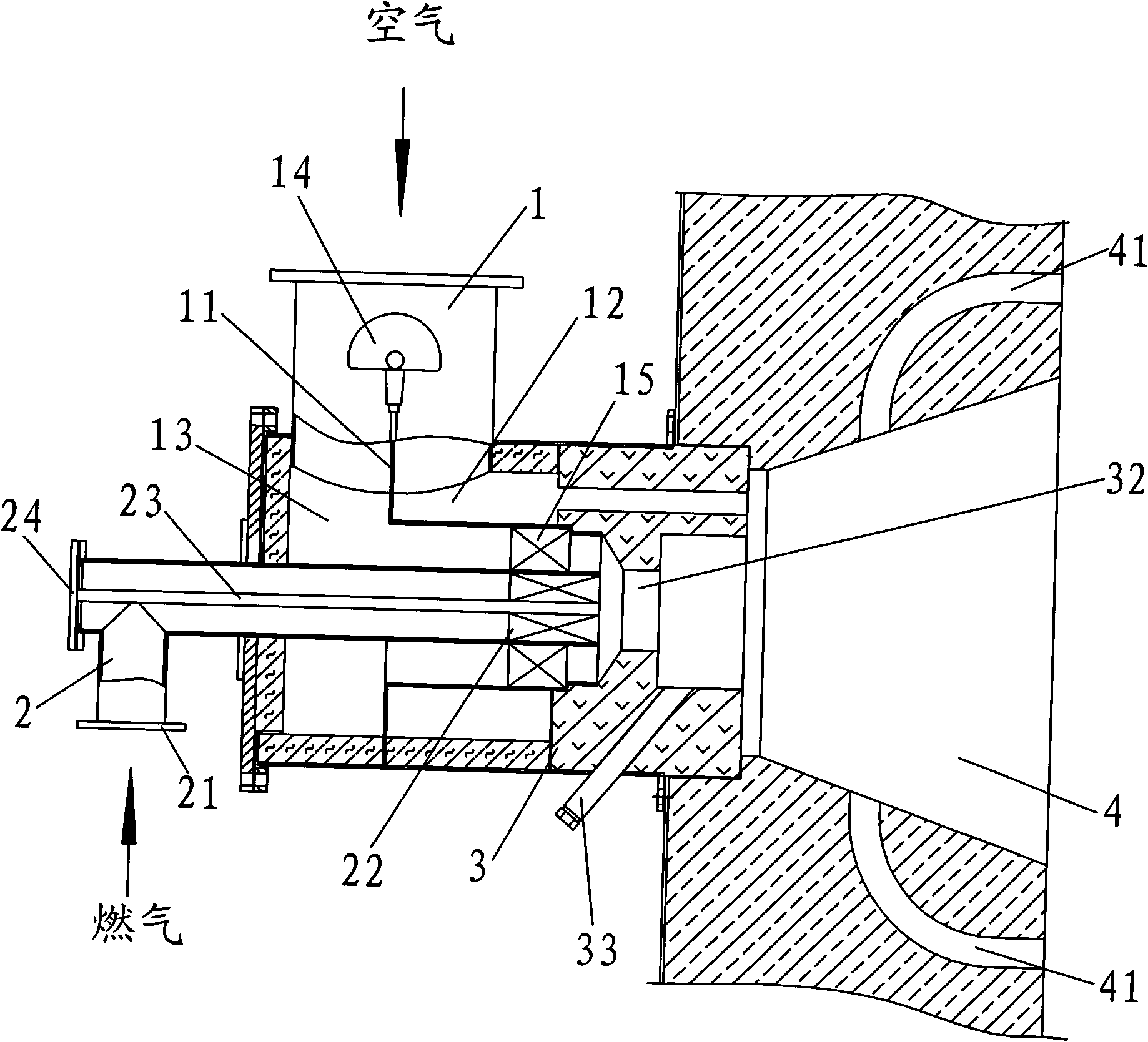

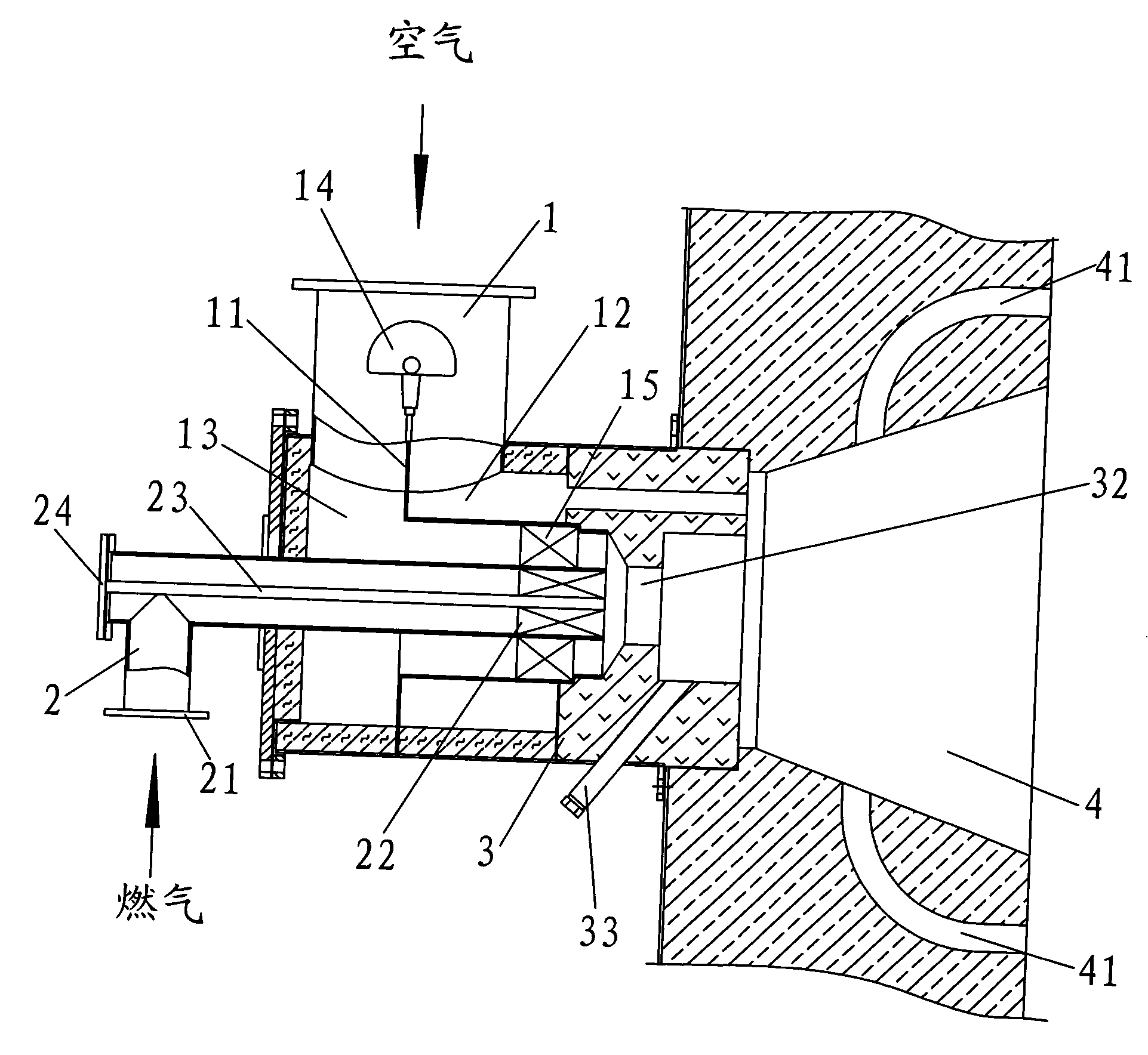

Crude oil and fuel gas rotational flow low-nitrogen burner of steam-injection boiler for burning crude oil and fuel gas

InactiveCN105526589ABurning stronglyRaise the combustion temperatureBurnersNon-combustible gases/liquids supplyNitric oxideLow nitrogen

The invention discloses a crude oil and fuel gas rotational flow low-nitrogen burner of a steam-injection boiler for burning crude oil and fuel gas. According to the air flowing direction, the crude oil and fuel gas rotational flow low-nitrogen burner sequentially comprises an air inlet, a control damper, a center air chamber, secondary air chambers, surrounding air chambers, a secondary air spraying opening and a surrounding air spraying opening. Center air sequentially flows through the center air chamber, a center air tube and the burner. Secondary air sequentially flows through one secondary air chamber, a secondary air spinning disk, the other secondary air chamber and the secondary air spraying opening. Surrounding air sequentially flows through one surrounding air chamber, the other surrounding air chamber and the surrounding air spraying opening. According to the burner, burning air is reasonably graded and organized, graded burning of crude oil and fuel gas is achieved, generation of nitric oxide is effectively reduced, and nitrogen discharging is reduced; and in addition, the crude oil and fuel gas rotational flow low-nitrogen burner is simple in system, easy to maintain, low in maintenance cost and long in service life.

Owner:南京创能电力科技开发有限公司

Industrial gas burner

ActiveCN102052677AOvercome temperingAvoid clogging and depositsGaseous fuel burnerProcess engineeringCombustion chamber

The invention discloses a burner for burning an industrial gas. The structure of the industrial gas burner is as follows: a gas chamber is arranged at the tail end of a gas supply pipe, the gas chamber is separated from an air chamber by a partition plate, a gas distribution pipe bundle is arranged on the partition plate and positioned inside the air chamber, guide vanes are arranged inside the individual gas distribution pipes, holes are formed on the walls of the individual gas distribution pipes and communicated with the air chamber, and the distance from the tail end on the downstream side of the gas distribution pipe bundle to the margin of the tail end of the air chamber ranges from 30 mm to 50 mm, which defines a space that serves as a gas and air mixing and combustion chamber.

Owner:兰州泰得燃烧设备工程有限公司

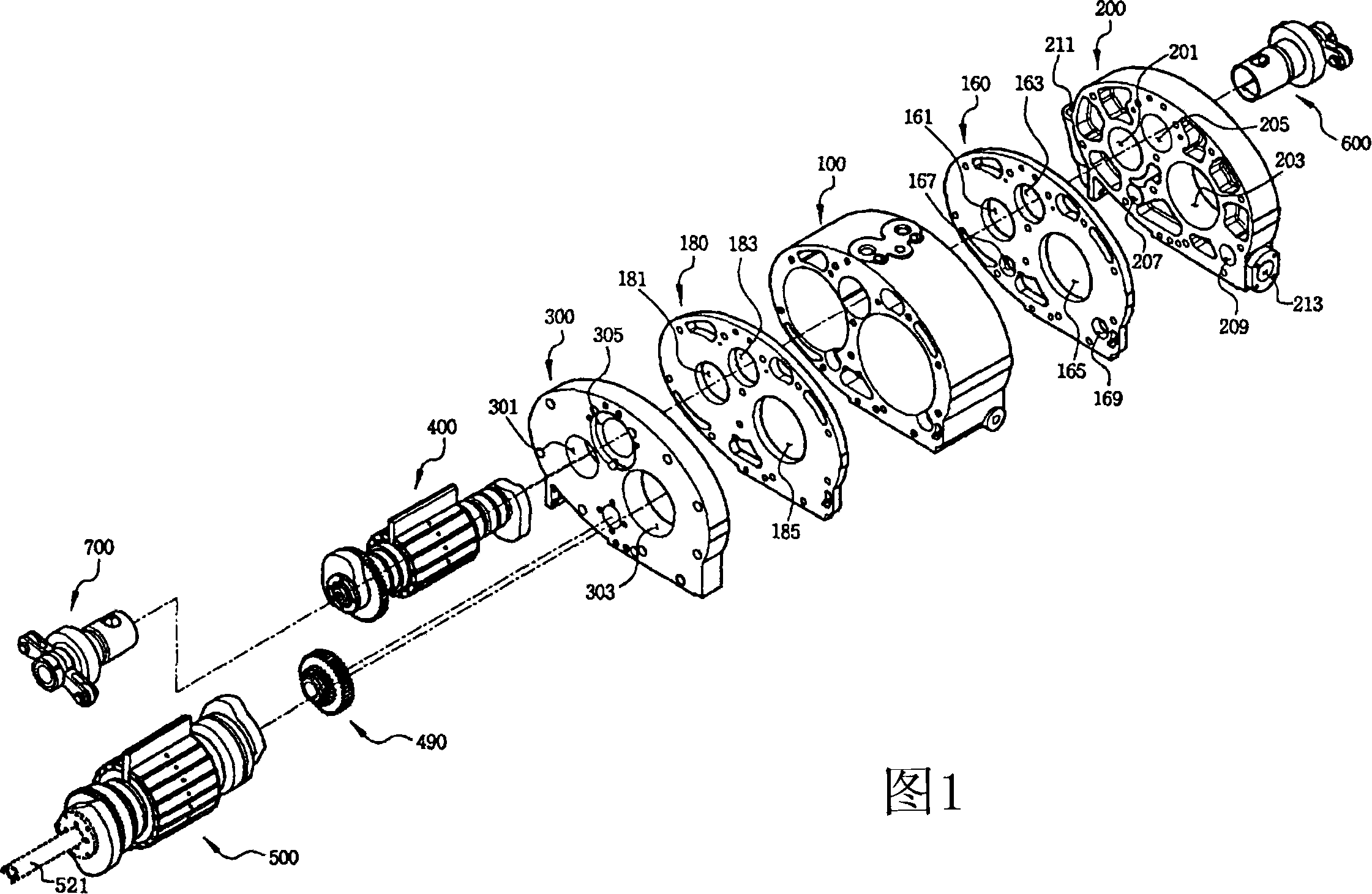

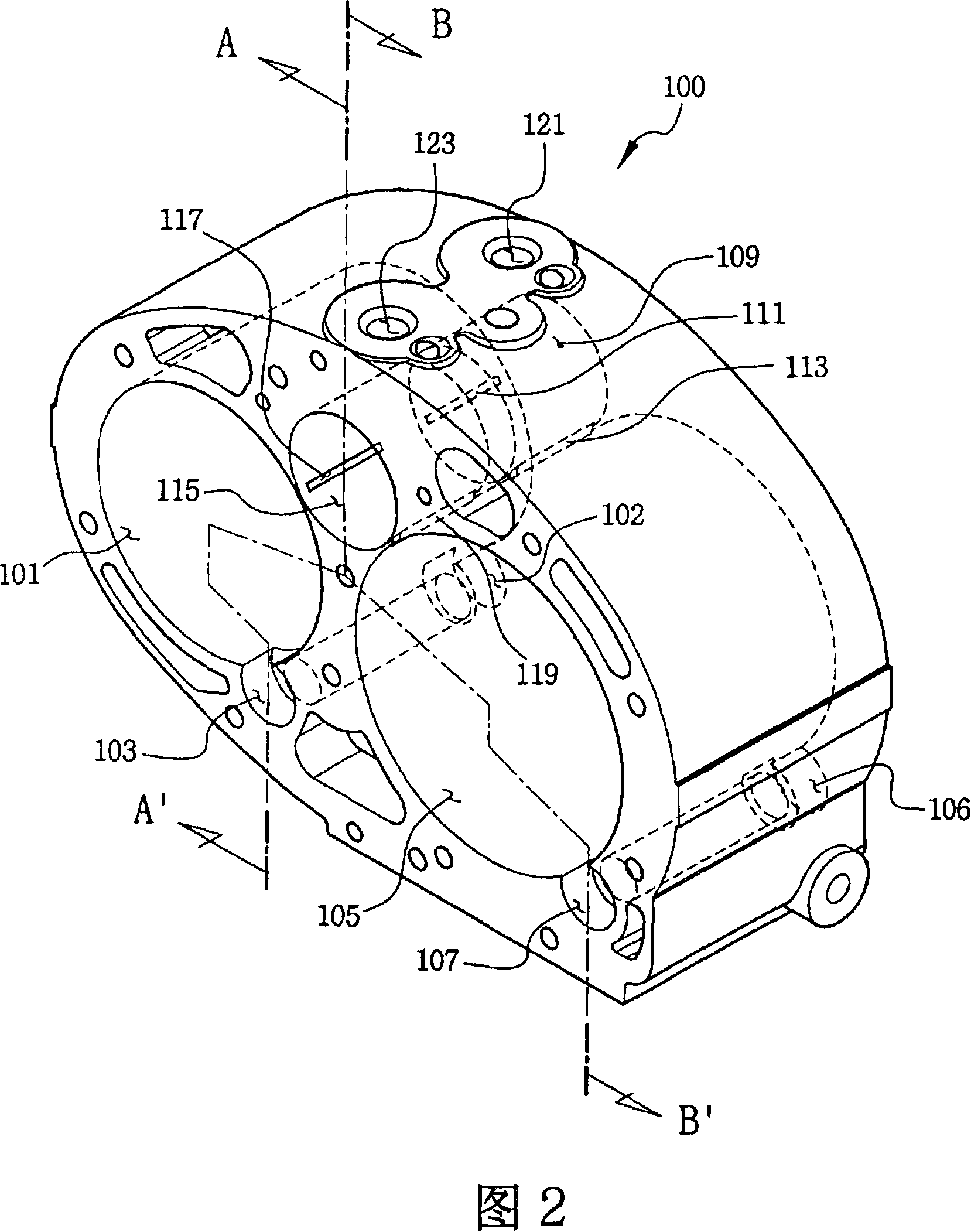

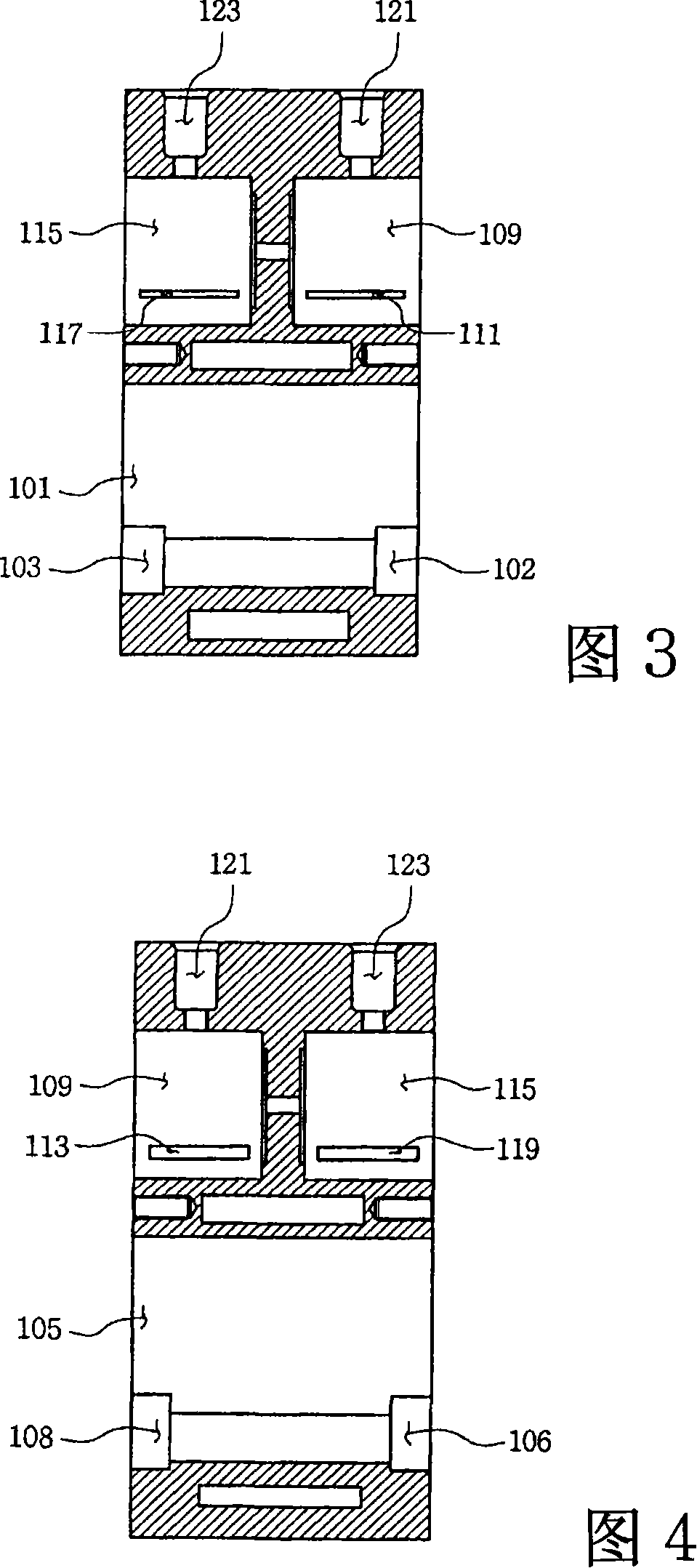

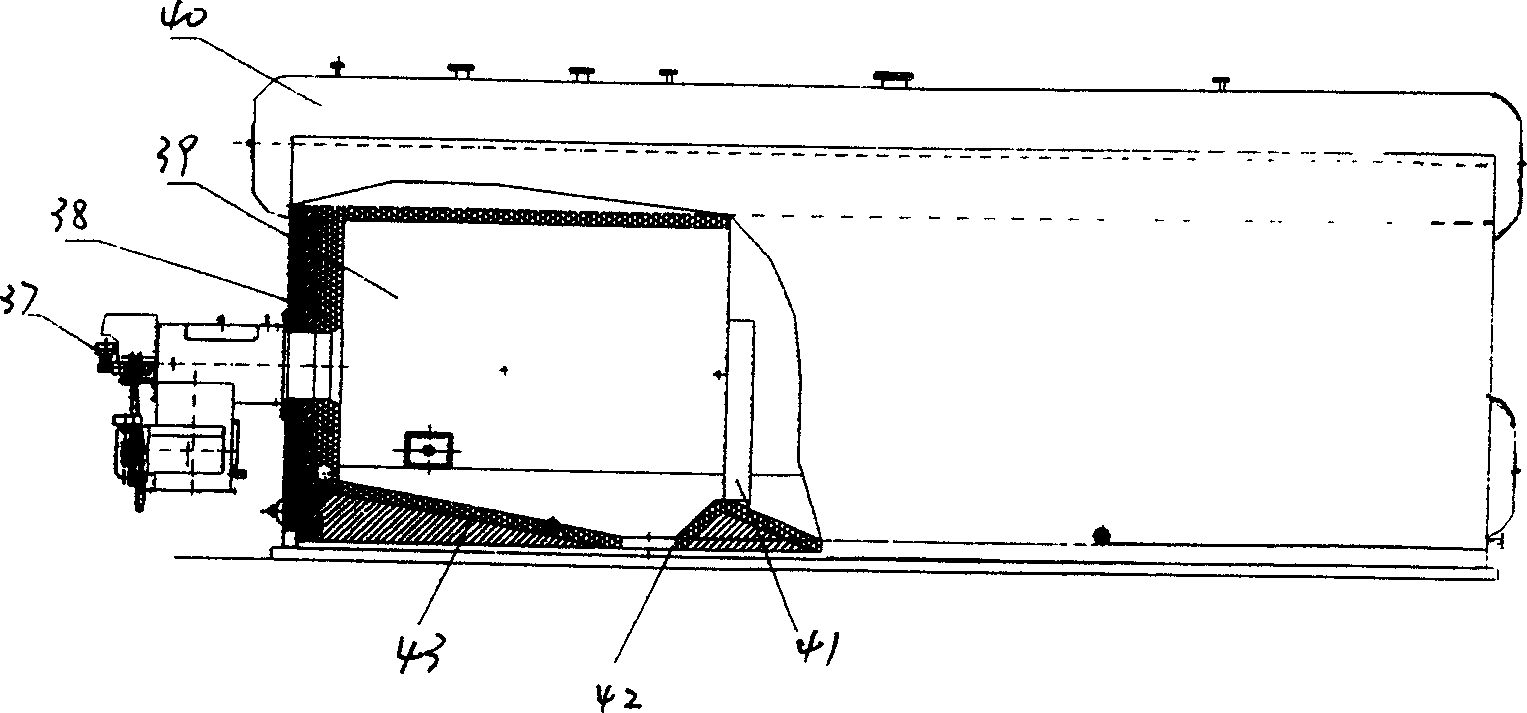

Rotary engine

InactiveCN101133236AStress minimizationMaximize efficiencyInternal combustion piston enginesValve drivesCombustion chamberRotary engine

Owner:孟爀在

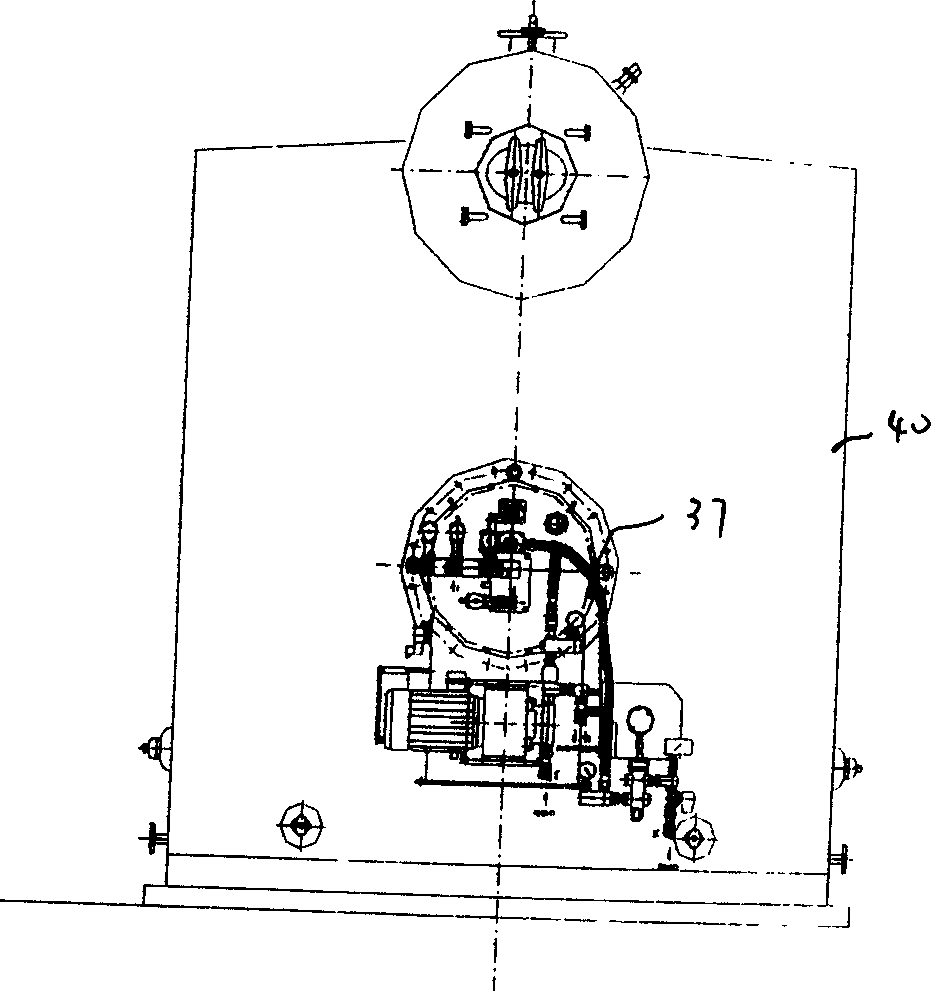

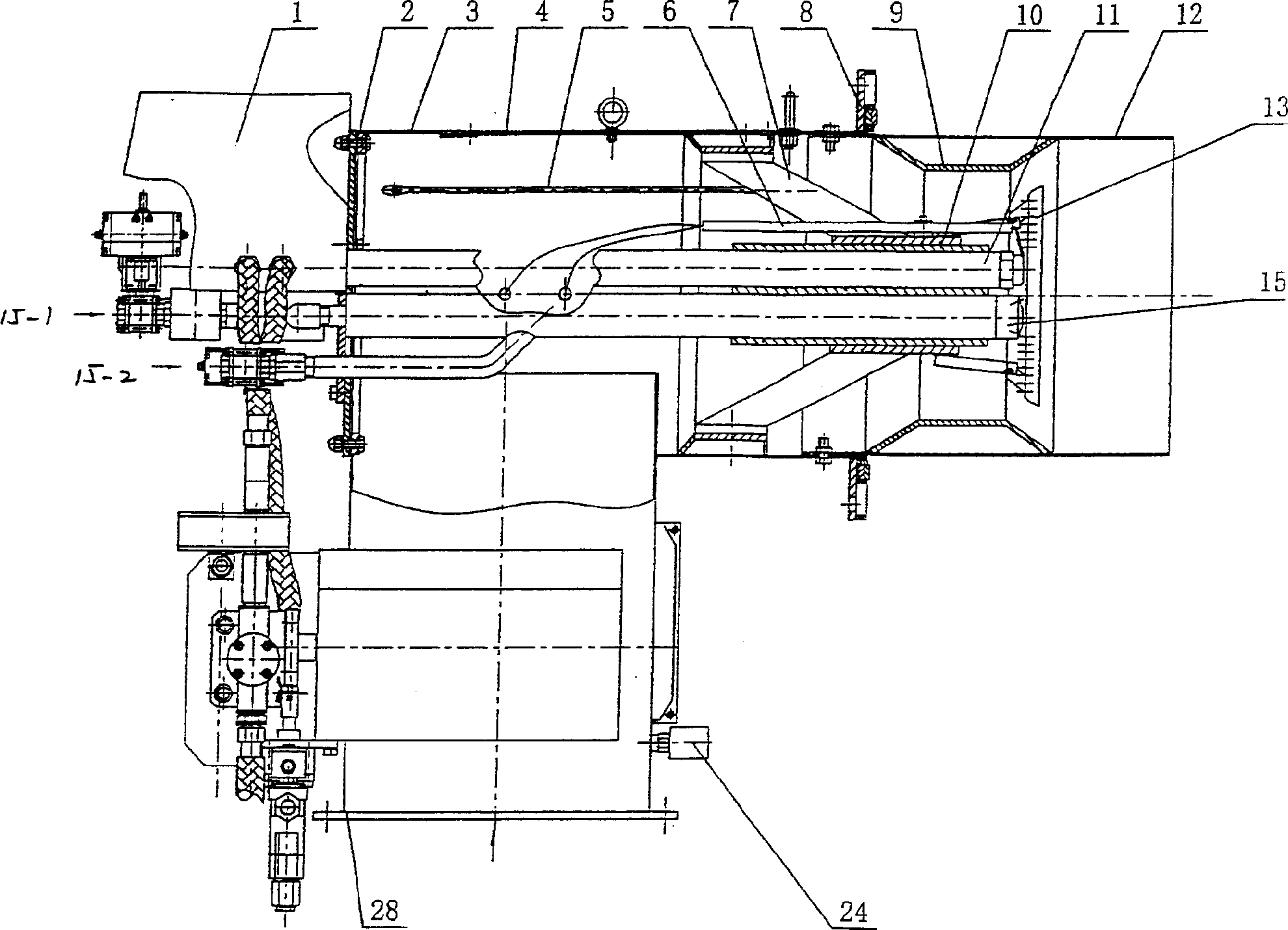

Frequency conversion and automatically controlled dual-purpose boiler with built-in precombustion chamber using coal water slurry or oil as fuel

ActiveCN1731014AStrong integrityFully configuredBurnersCombustion using multiple fuelsAutomatic controlCoal water

The automatically controlled frequency varying burning two-purpose coal water slurry and oil boiler with pre-combustor includes one boiler body and one combustor connected to the front end of the boiler body. In the front part inside the boiler body, there is one pre-combustor integrated with the boiler body. The combustor is automatic split two-purpose one capable of burning coal water slurry and oil, and includes casing, spray gun assembly, spray gun executing part, controlling valve assembly, air door mechanism, oil pump and oil pump motor. The present invention has fast ignition, stable combustion, automatic control and capability of burning both coal water slurry and oil.

Owner:JIANGSU SHUANGLIANG BOILER +1

Minitype solid rocket engine structure based on 3D printing technology

The invention discloses a minitype solid rocket engine structure based on a 3D (Three Dimensional) printing technology, which comprises a three-spray-head printer, wherein the printer prints different materials of a design entity in each cross section, and prints a housing, an explosive column and a metal igniter into an integrated structure; the housing consists of a combustion chamber, a spray pipe and a front end socket; the spray pipe is provided with a convergent section and an expansion section; the metal igniter is positioned on the inner surface of the combustion chamber; a lead wire of the metal igniter is led out from the front end socket, and connected with a control chip in an independently addressing manner; different quantities of metal igniters are triggered, and directly ignite the explosive columns in the combustion chambers; the metal igniters are made of copper materials; and the explosive columns are made of any one of solid propellant materials. The minitype solid rocket engine structure is easy to ignite, reliable in sealing, and simple; a total impulse is higher; a minitype engine array is formed by printing multiple minitype engines which are in the same size and are arranged and distributed at equal intervals; the operation is concise; and a technology cycle is short.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Oxygen-enriched and combustion-supporting device suitable for low calorific value fuel gas

InactiveCN102032571AReduce pollutionAchieve combustionIndirect carbon-dioxide mitigationGaseous fuel burnerRotational flowAir–fuel ratio

The invention relates to an oxygen-enriched and combustion-supporting device suitable for low calorific value fuel gas, which mainly comprises a combustion-supporting gas pipeline, a fuel gas pipeline, a burner nozzle and a combustion passage, wherein a baffle plate is fixed inside the combustion-supporting gas pipeline, the combustion-supporting gas pipeline is divided into a straight flow pipeline and a rotational flow pipeline, and a combustion-supporting swirler is arranged in the rotational flow pipeline; and the straight flow pipeline, the rotational flow pipeline and the fuel gas pipeline are respectively communicated with the combustion passage through the burner nozzle. The oxygen-enriched and combustion-supporting device suitable for the low calorific value fuel gas can be suitable for the oxygen-enriched combustion of low calorific value coal gas, can satisfy the use requirements on various working conditions without exchanging the burner nozzle under conditions that the fuel gas calorific value and the oxygen-enriched concentration of combustion-supporting air fluctuate singly or doubly in a larger range, realizes the complete combustion of low air-fuel ratio, finally achieves the purpose of saving energy and reducing emission and overcomes the defect of the traditional combustion device.

Owner:ANSHAN PUBEIDA TECH

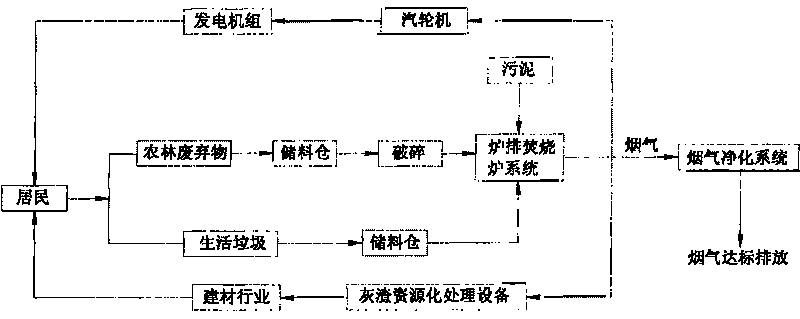

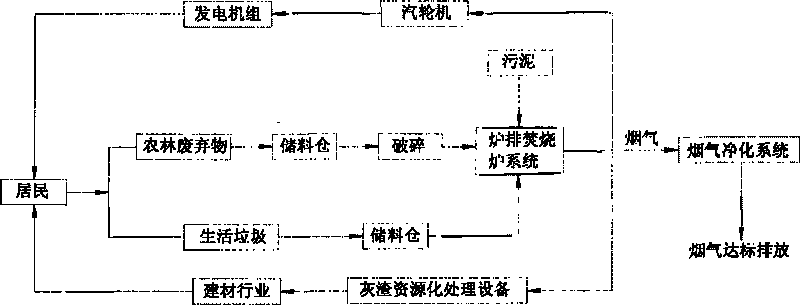

Method for mixed burning of agriculture and forestry waste, sludge and household garbage by using grate furnace

The invention relates to the technical field of energy environmental engineering and provides a method for mixed burning of agriculture and forestry waste, sludge and household garbage by using a grate furnace. The method comprises burning the agriculture and forestry waste, sludge and household garbage in a grate garbage burning furnace, igniting by using agriculture and forestry waste, and adding household garbage and sludge in the furnace to realize mixed burning when the temperature of the furnace rises to 850 DEG C, wherein the mass percent of the agriculture and forestry in the mixed fuel is within 40 percent, the mass percent of sludge in the mixed fuel is within 30 percent, the burning temperature of the grate burning furnace is controlled at 850 to 1000 DEG C, and the smoke gas generated by burning stayed in the furnace is controlled above two seconds. The invention is low in the cost, improves the burning efficiency of the garbage burning furnace, solves the problem of pollution caused by the sludge, ensures that the agriculture and forestry waste can be recycled, reduces discharge of pollutants, particularly heavy metal and dioxin and reduces the consumption of fossil energy.

Owner:SOUTHEAST UNIV

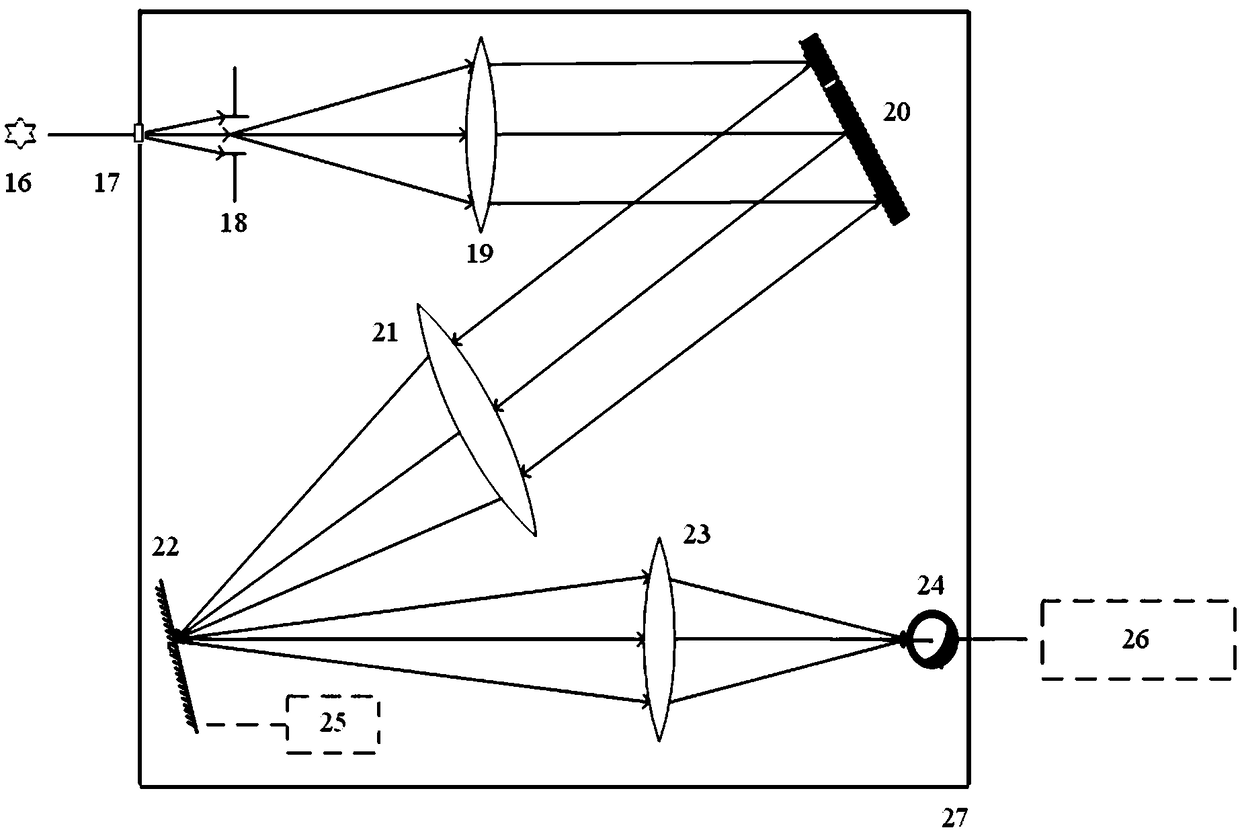

Multispectral temperature measuring device based on digital micro-mirror device

ActiveCN109141652AHigh energyUnattenuated incidenceSensing radiation from gases/flamesPyrometry using electric radation detectorsSpectral emissionDigital micro mirror device

The present invention discloses a multispectral temperature measuring device based on a digital micro-mirror device. The problem is solved that the real temperature cannot be obtained in the prior art. In the device, light source radiation spectral signals are transmitted to a DMS spectrograph by a heat-resistant and impact-resistant optical detection unit through two sections of optical fibers, are incident into a spectral imaging system through a silt and are collimated to compound color parallel light by a front lens, the compound color parallel light is subjected to dispersion at the surface of a reflective ruled grating to a spectrum band which is converged by the lens, is incident into different positions of the DMD in order according to the wavelength sequence for wavelength gatingand is focused on a single-point detector by the lens for spectrum collection, and finally, an upper computer is employed to perform high-speed spectrum parallel processing and Hadamard inverse transformation decoding to obtain the real temperature and the spectral emissivity of the light source. The device is high in speed, high in resolution, high in signal-noise ratio and very high in adaptivecapacity to environment, is suitable for the real-time measurement of the explosive and powder combustion and explosion flame radiation temperature, and is also suitable for measurement of the temperature of the surface of a high-temperature part.

Owner:XIAN MODERN CHEM RES INST

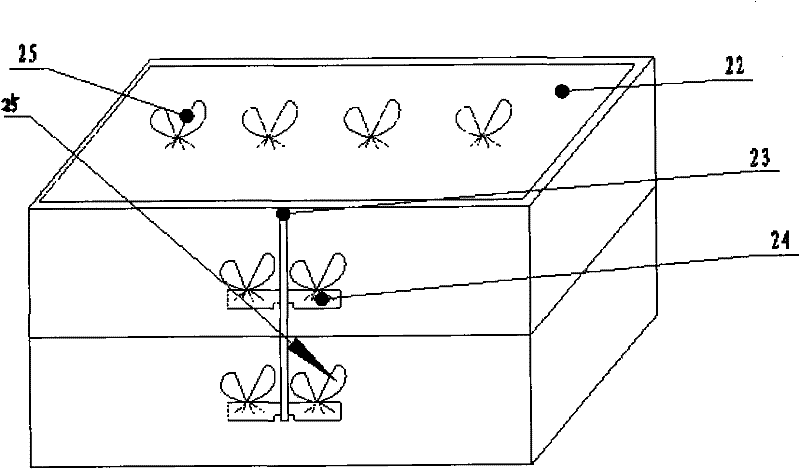

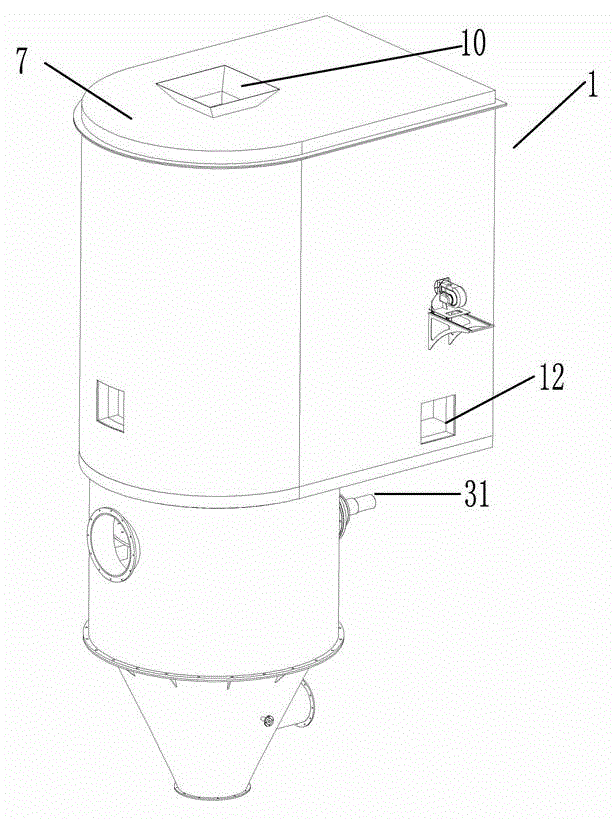

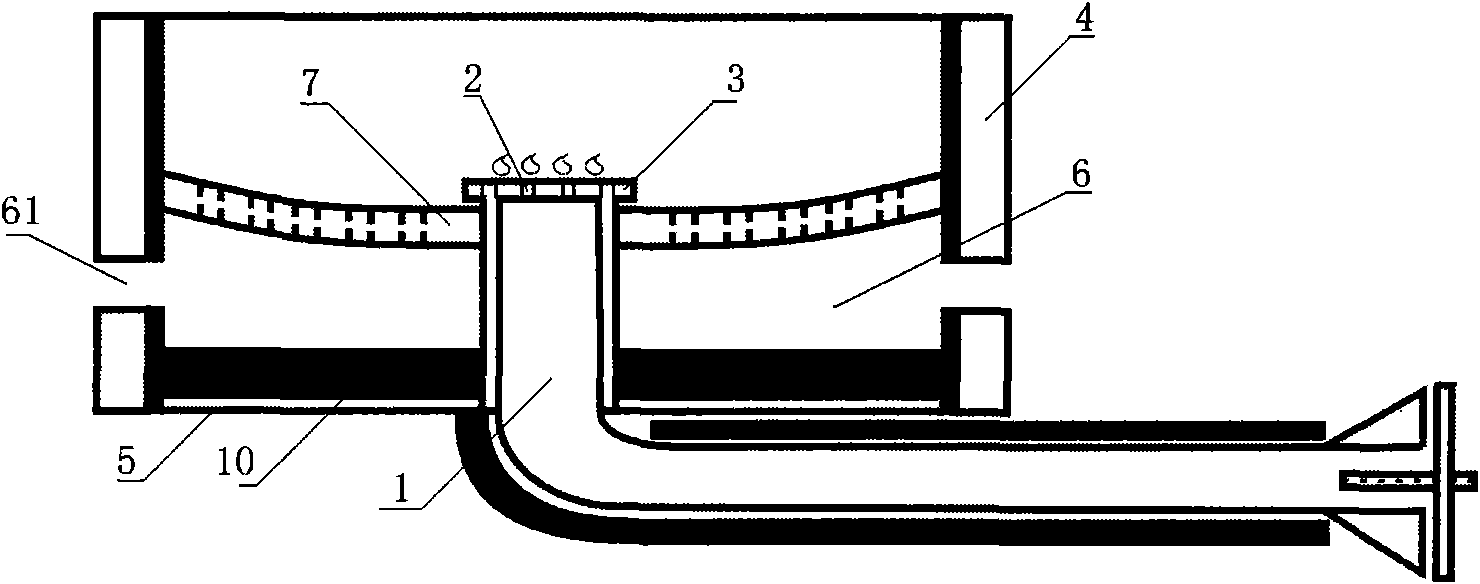

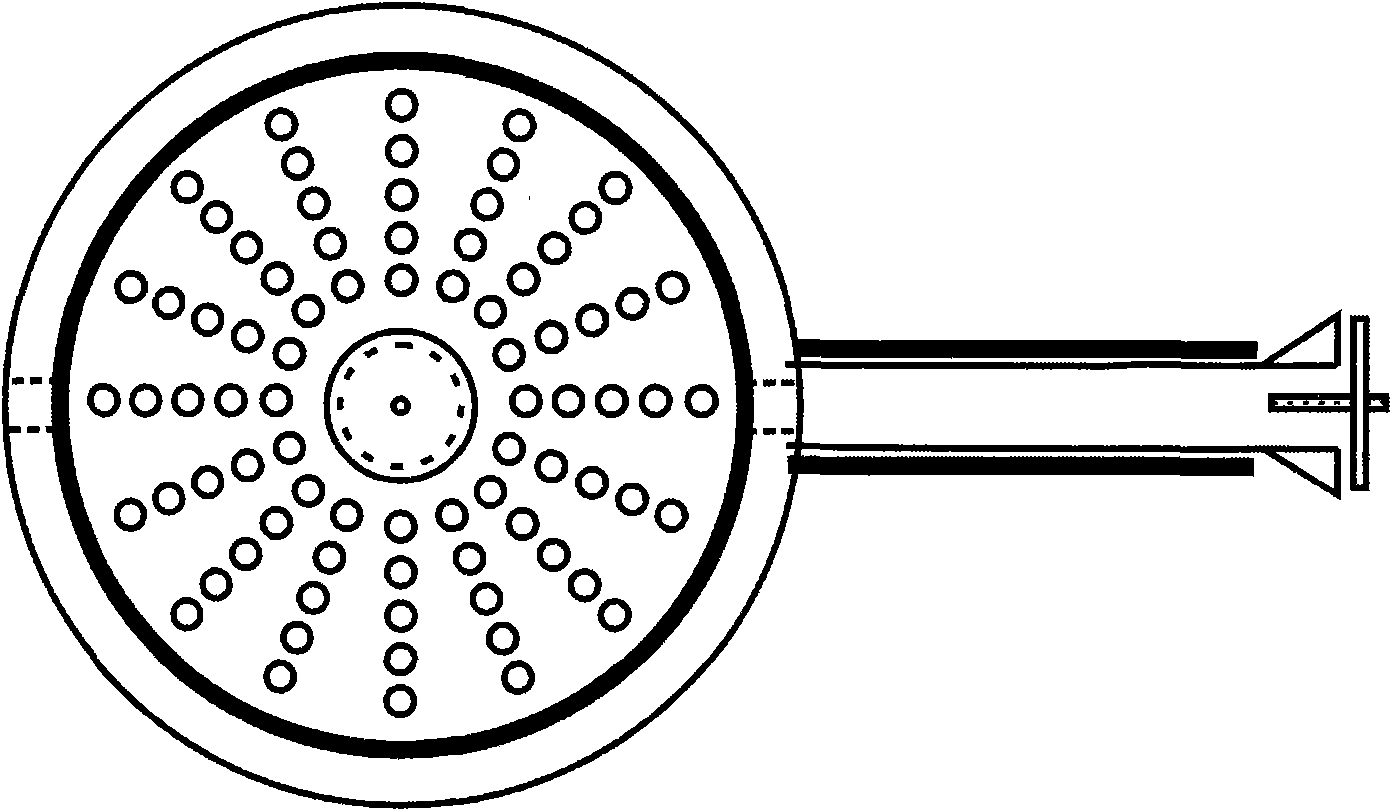

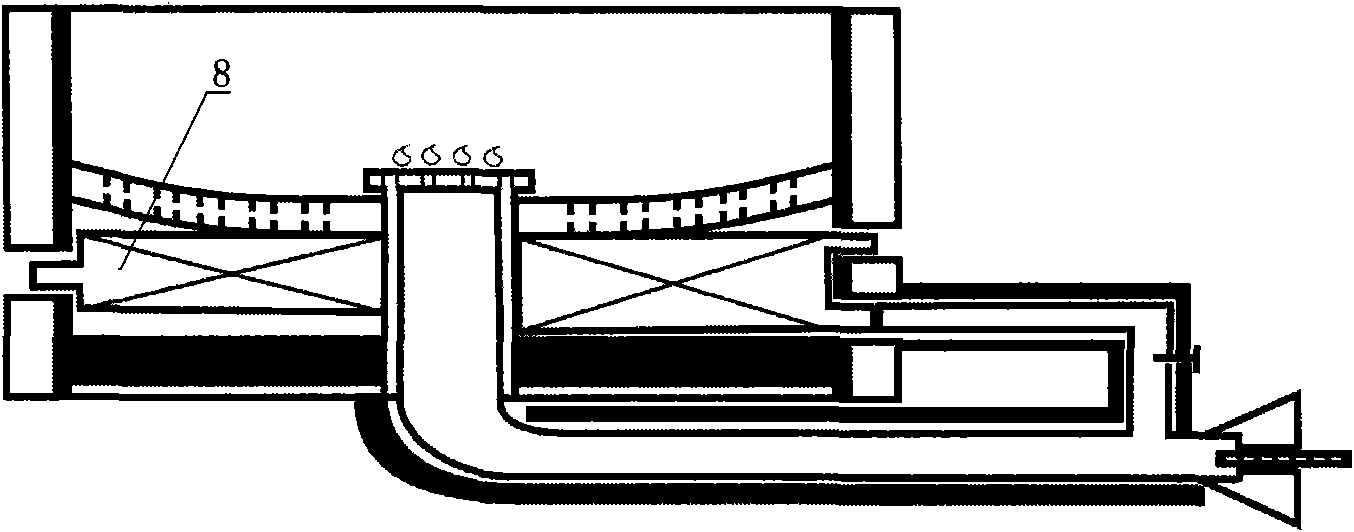

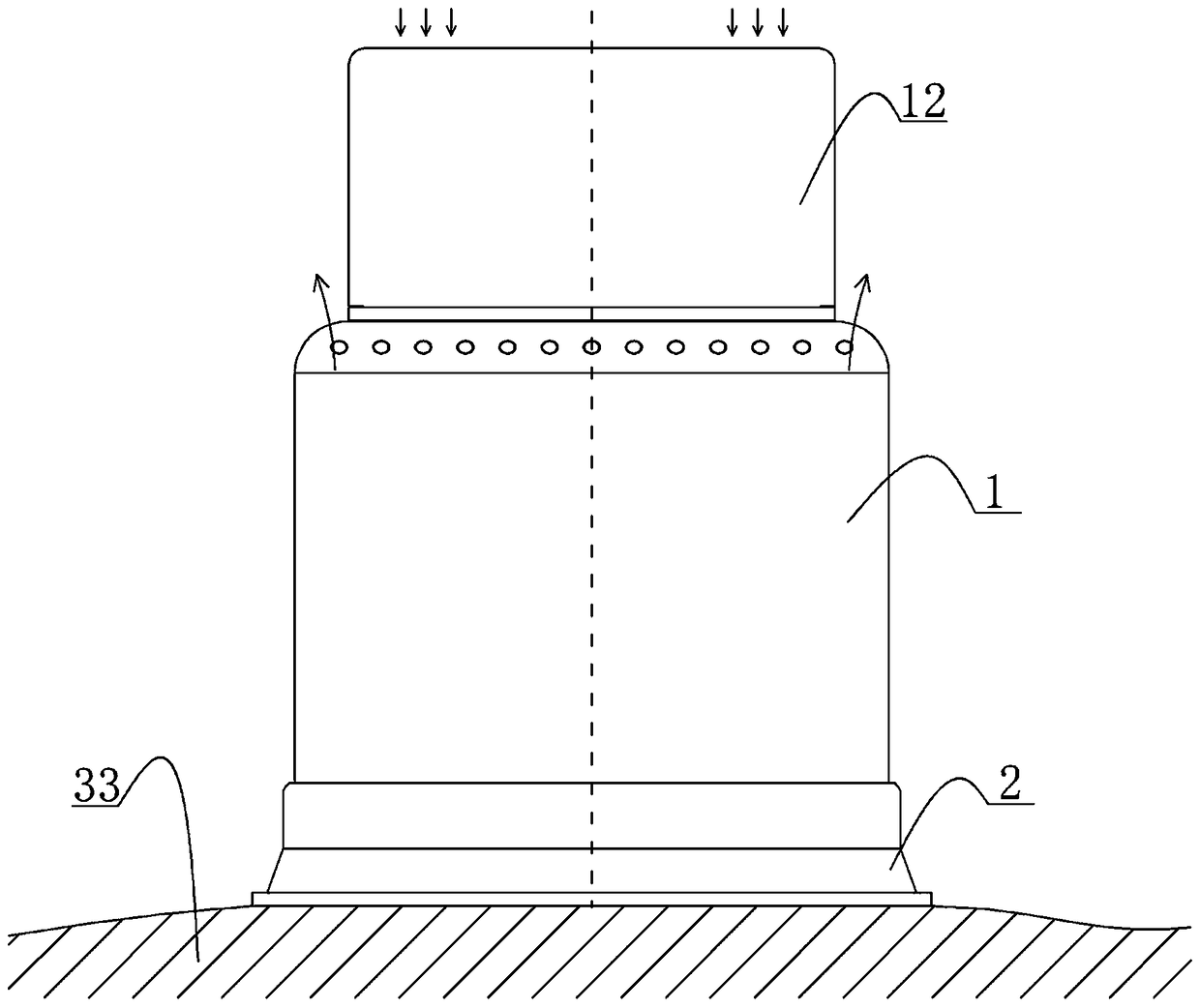

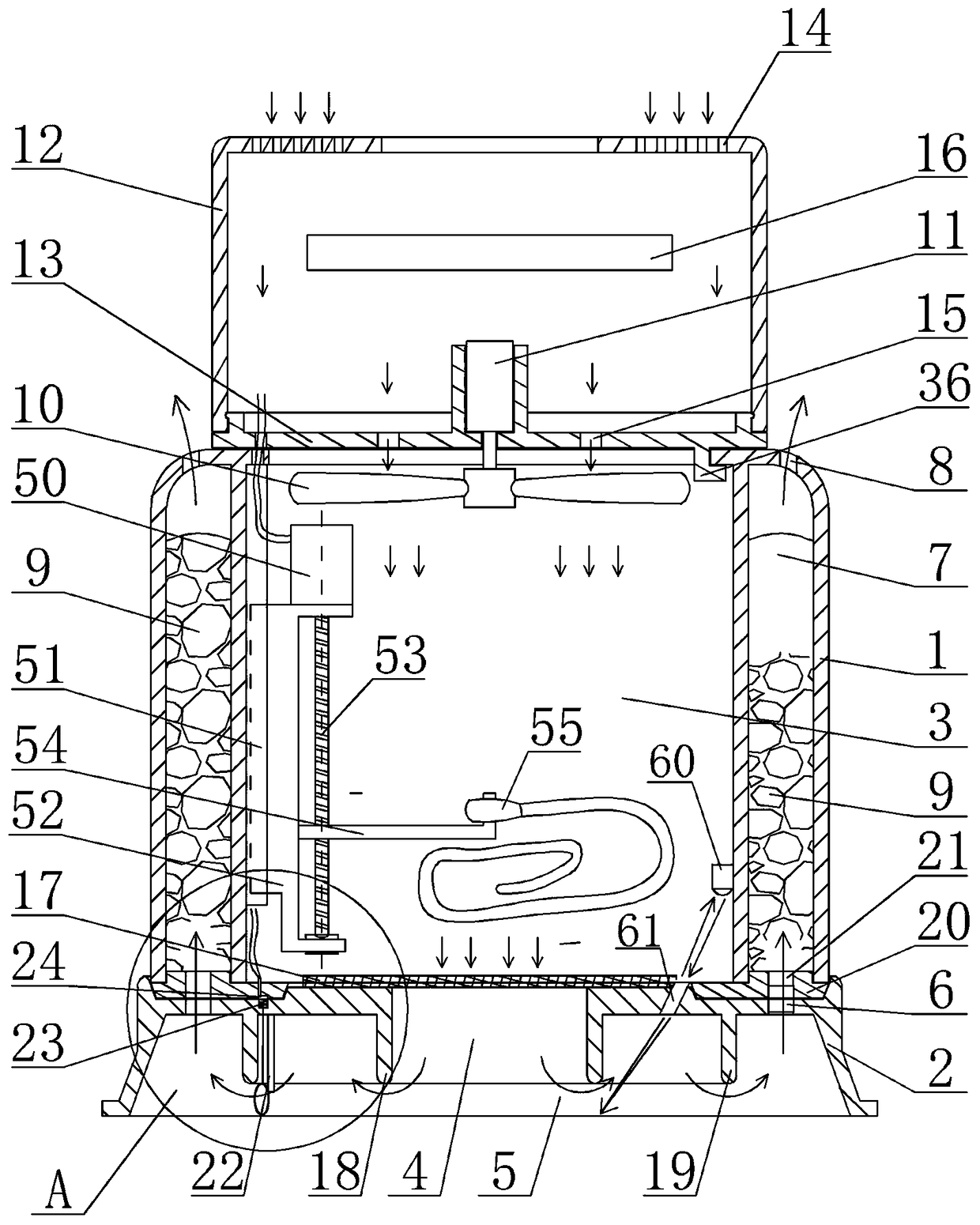

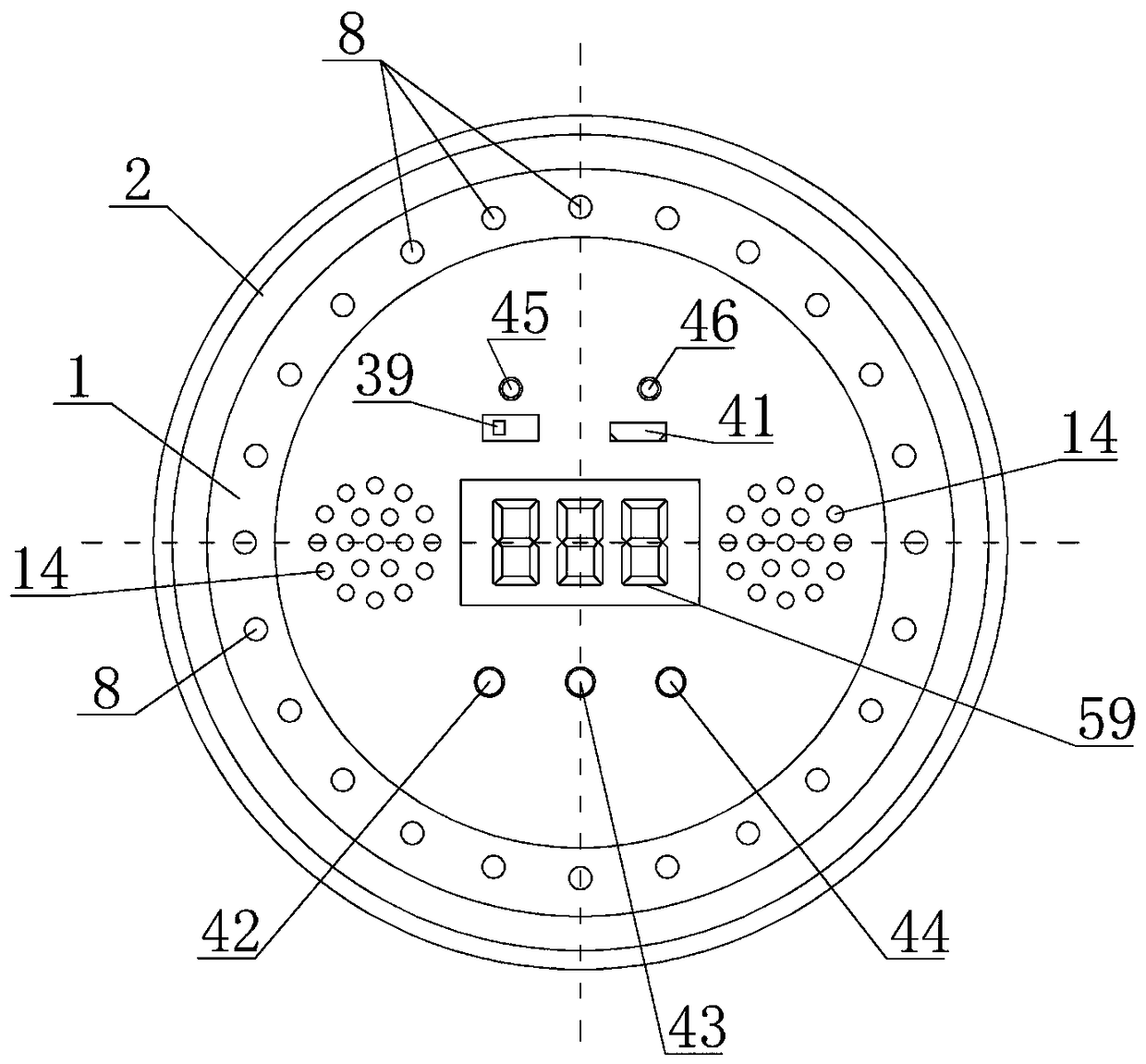

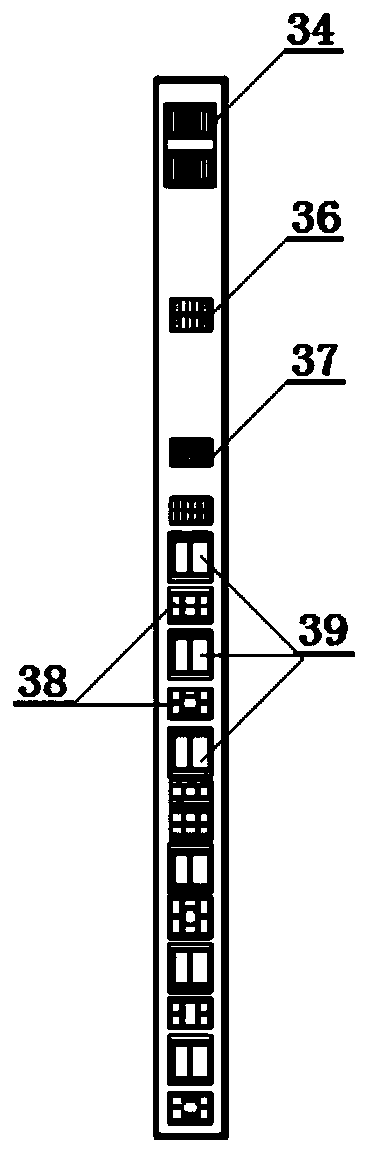

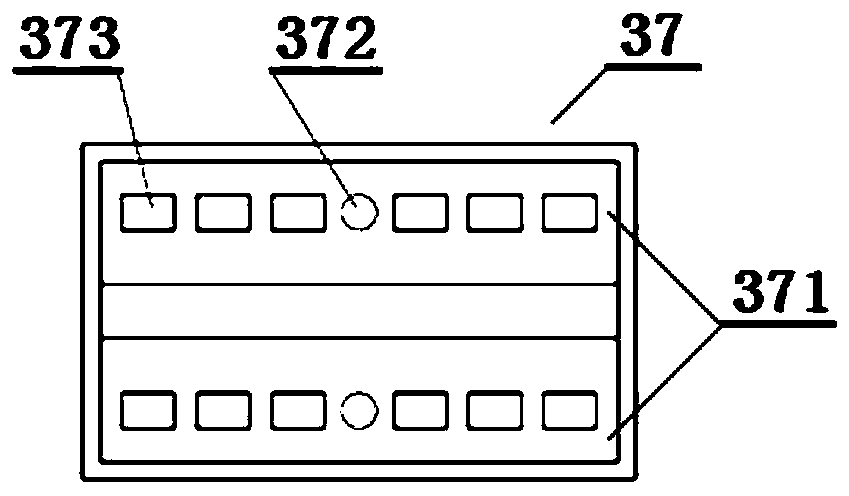

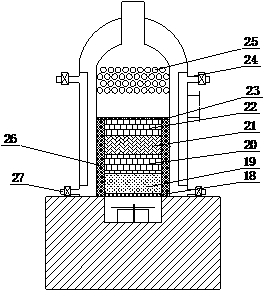

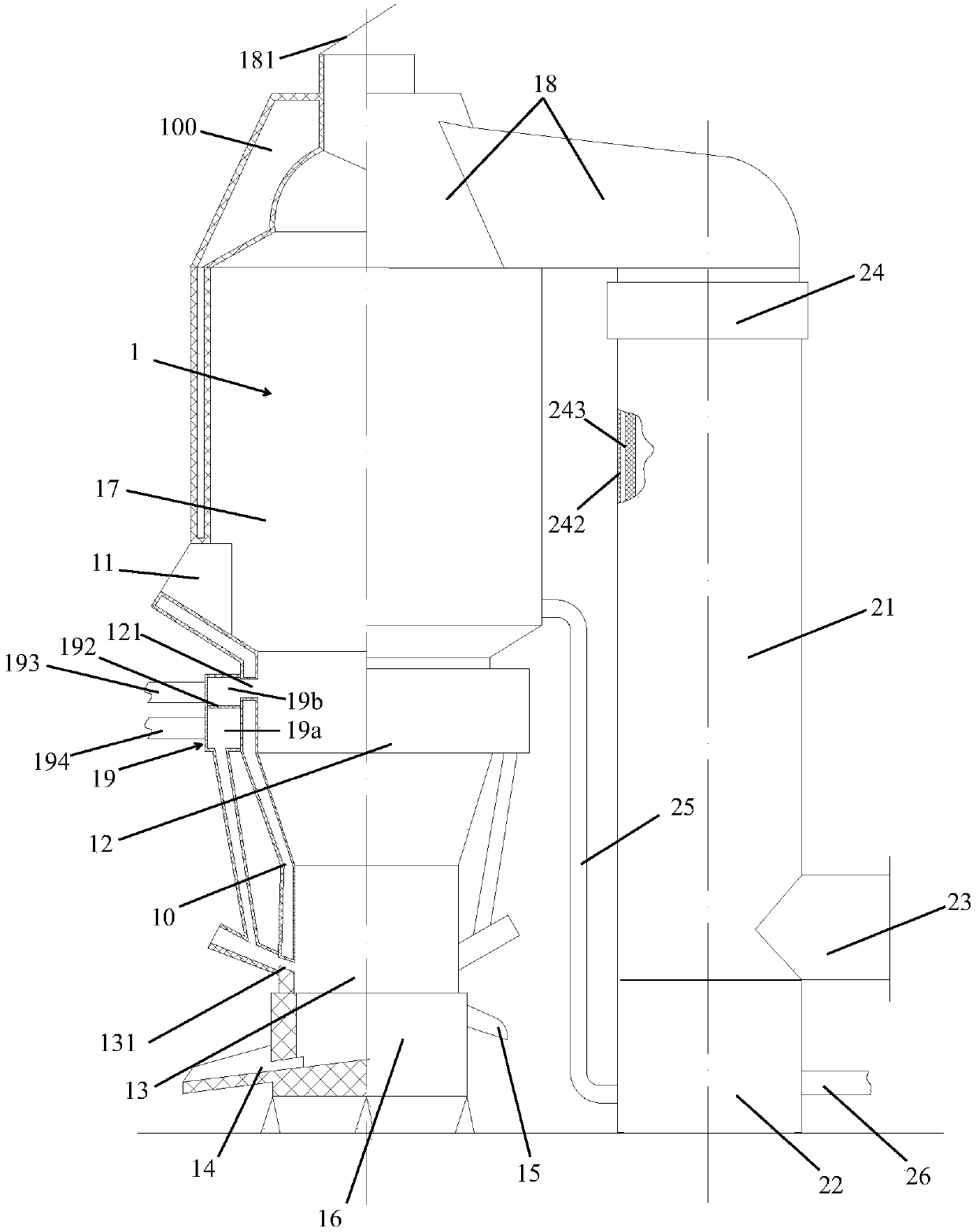

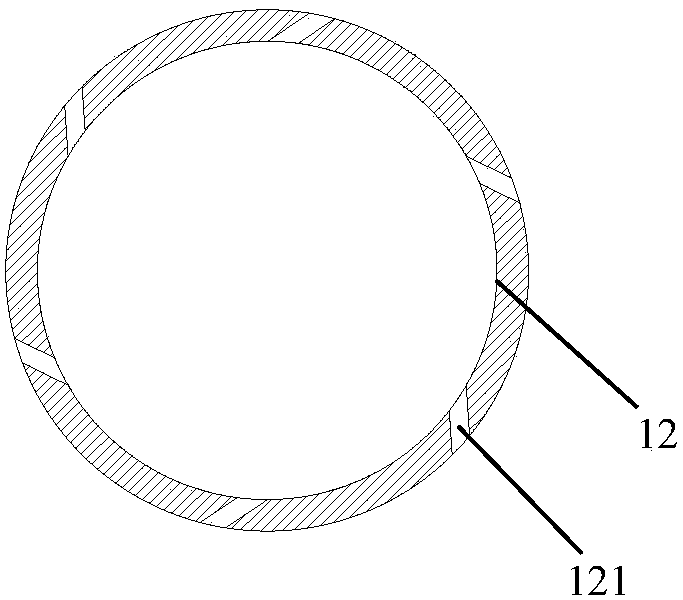

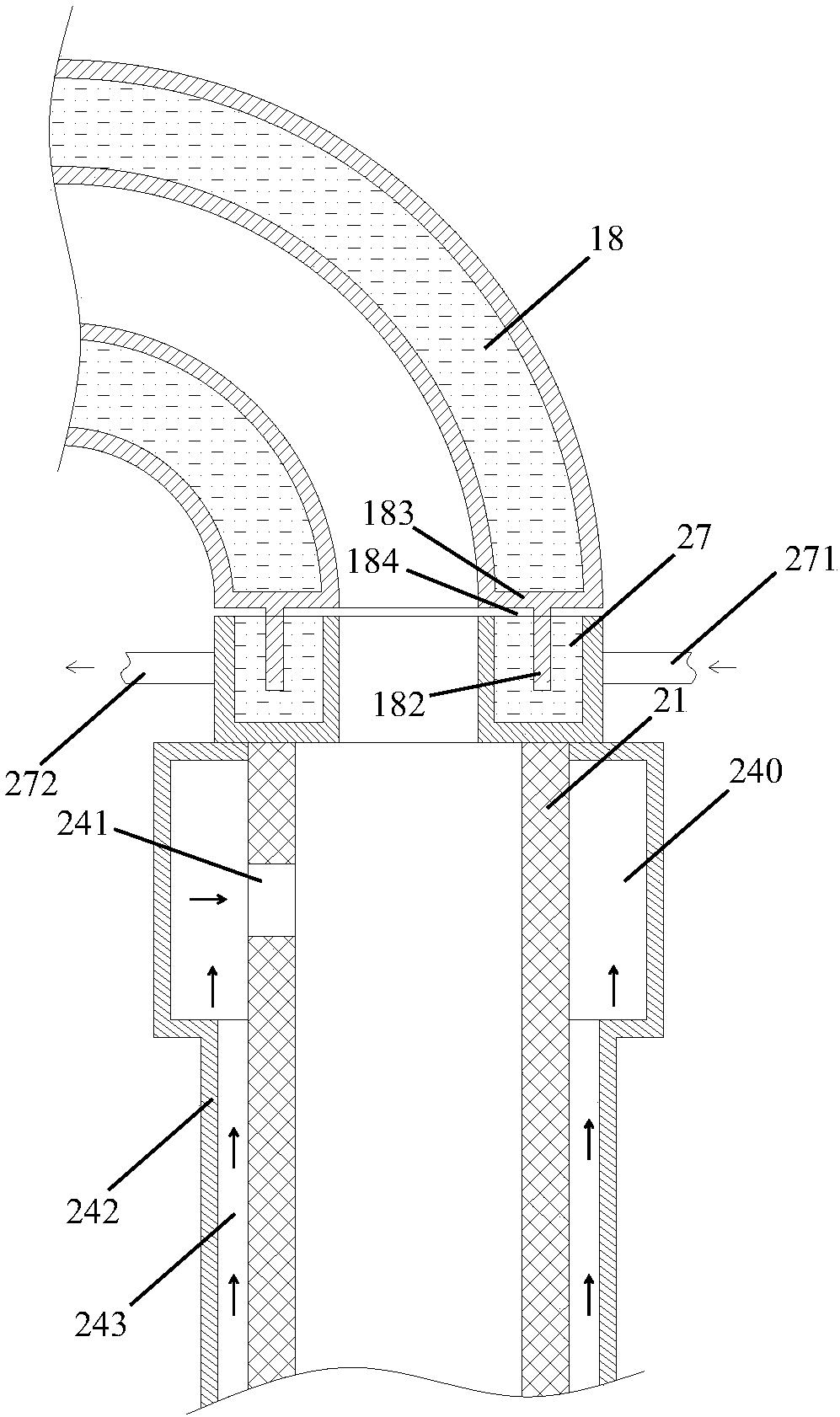

Automatic temperature control smoke-free moxa-moxibustion instrument

PendingCN108635211AAchieve combustionFully contactedDevices for heating/cooling reflex pointsAirflowTreatment effect

The invention discloses an automatic temperature control smoke-free moxa-moxibustion instrument which comprises a housing, a base, an air circulating device, a bearing device and a control circuit. The base is fixed below the housing. The inside of the housing is an inner cavity, and the bearing device is arranged in the inner cavity and used for placing a moxa-moxibustion material to be burned. The automatic temperature control smoke-free moxa-moxibustion instrument is characterized in that the lower end of the base is open, a moxa-moxibustion cavity for making moxa-moxibustion smoke in contact with a part to be treated is formed in the lower portion of the base, an air outlet cavity for making the inner cavity communicated with the moxa-moxibustion cavity is formed in the center of the base, and lower air outlet holes for making moxa-moxibustion smoke escape are formed in the periphery of the base. The air circulating device is used for forming airflow sequentially flowing in the inner cavity, the moxa-moxibustion cavity and the lower air outlet holes. The automatic temperature control smoke-free moxa-moxibustion instrument achieves long-time and full contact between moxa-moxibustion smoke and the human body, can make the medical effect of the moxa-moxibustion material completely played, is conductive to prevention and treatment of human diseases and has remarkable advantages, and the problem is solved that the escaping direction of existing moxa-moxibustion smoke causes poor treatment effect.

Owner:李洪湘

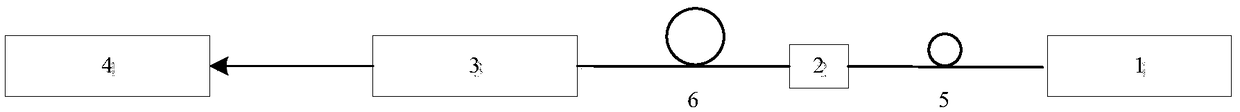

Zero leakage external firing heat engine

InactiveCN101915178AHigh power/weight ratioAchieving Zero LeakageEngine sealsStirling type enginesCombustionMechanical energy

The invention discloses a zero leakage external firing heat engine, which relates to the technical field of heat energy conversion. The zero leakage external firing heat engine aims to solve the problem of the low heat conversion efficiency and insufficient combustion of the conventional internal combustion engine, the problem that the conventional Stirling engine has a low power-to-weight ratio and zero leakage cannot be realized due to difficulties in sealing, and the like. An outward ventilation valve is connected with a closed chamber formed by communicating an air guiding cylinder chamber with the upper part of a dowork cylinder chamber; a conduction start point of the ventilation valve is that an air guiding piston moves between positions which are 20 degrees in front of and behind the top of the high temperature end of the air guiding cylinder chamber; the conduction angle of the ventilation valve 6 is between 5 and 30 degrees; and all movable sealing positions and the outward ventilation port of the ventilation valve are sealed in a closed shell. The zero leakage external firing heat engine can directly and efficiently convert combustion heat energy of fuels into mechanical energy and realize zero leakage; the internal movable sealing part technology of the engine can meet working requirements by adopting the prior art; the power-to-weight ratio is extremely high; and the convention efficiency is 20 percent to 80 percent.

Owner:雷涛

Ceramic hot-blast furnace by emusified coking slurry cyclone burner

InactiveCN101029728AQuality assuranceImprove cleanlinessCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneSlurry

This invention discloses a ceramic air heating furnace with the emulsification slurry wind burning device including vertical air heating furnace and the emulsification slurry wind burning device. The air heating furnace includes an egg-shape furnace chamber and the heat air opening. The emulsification burning device consists of a front end wall, back end wall and the side crust inside which forms a cylindraceous burning space. There are at least one emulsification burning device and at least a fuel burning device or at least air burning device. The back end wall has an outlet opening which connects to the egg-shape furnace chamber by the pipe. The side of the crust sets two or more tangential wind inlet openings and there are at least one dreg outlet opening near the back end wall at the side of the bottom of the burning space. The ceramic air heating furnace of this invention utilizes the emulsification burning device and the emulsification slurry as fuel so as to save the cost and maximize the utilization of the resource.

Owner:GUANGZHOU DEVOTION THERMAL TECH

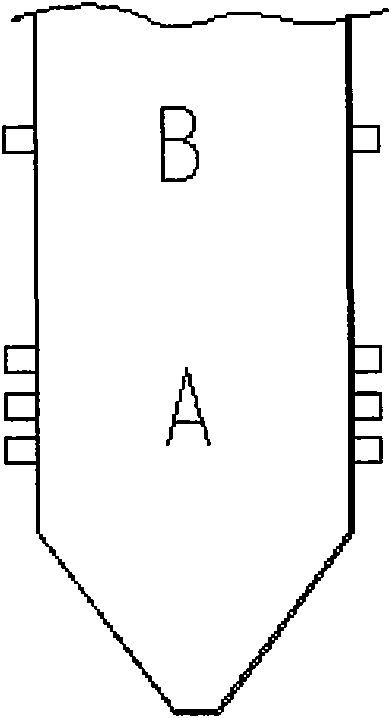

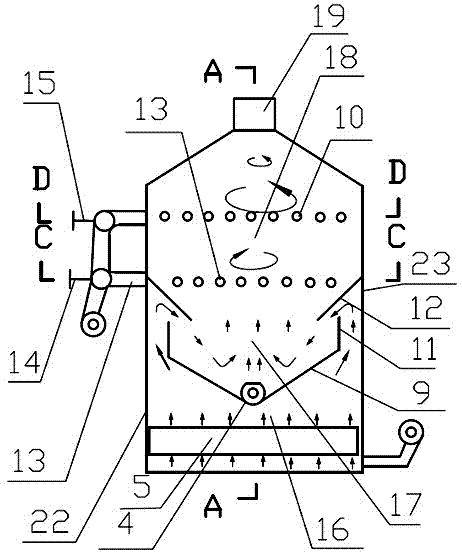

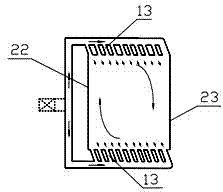

Gas-solid separation and re-coupling type biomass clean combustion device and combustion method

ActiveCN104713078AAchieve separationAchieve combustionSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidCombustion chamber

A gas-solid separation and re-coupling type biomass clean combustion device comprises a spiral feeding system, a chain furnace grate, a solid combustion chamber, a reduction reaction chamber, a gas combustion chamber, a solid combustion air supply system, a primary gas combustion air supply system, a secondary gas combustion air supply system and a cuboid hearth. The spiral feeding system comprises an open hopper, a drive motor, a feeding shaft with a spiral fin and a spiral pipe. The device is provided with the independent reduction reaction chamber, the independent solid combustion chamber and the independent gas combustion chamber. A combustion method of the gas-solid separation and re-coupling type biomass clean combustion device includes the steps that biomass is firstly dissolved into gas and solid through self heat supply, dust of smoke generated after solid combustion is removed, a reduction reaction is conducted on the smoke and gas generated after thermolysis, and NOx is reduced; primary combustion and secondary combustion are conducted, generation of NOx is controlled, and combustion is thorough.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI +1

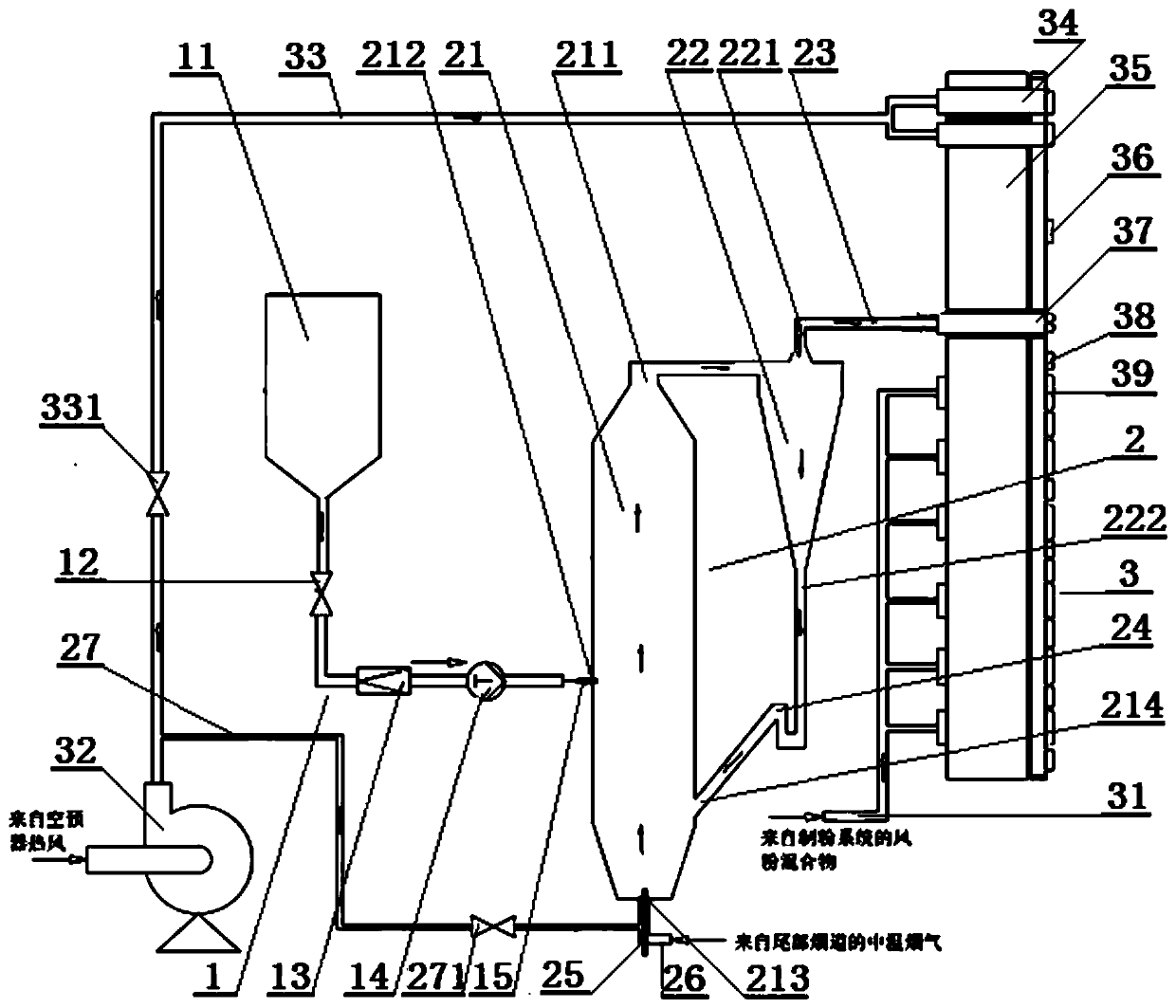

Composite reducing type low NOx emission device suitable for power station boiler

PendingCN111140865ACurb emissionsReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoal waterPower station

The invention relates to a composite reducing type low NOx emission device suitable for a power station boiler. The composite reducing type low NOx emission device comprises a coal water slurry generation mechanism, a coal water slurry pyrolytic reaction mechanism and a composite reducing type combustion device, wherein the coal water slurry generation mechanism has the function of treating coal powder into coal water slurry and is internally provided with a coal water slurry tank, the coal water slurry pyrolytic reaction mechanism has the function of pyrolysis generation of pyrolysis gas withreducing active components and is internally provided with a pyrolysis reactor and a cyclone separator, and the composite reducing type combustion device has the function of deeply reducing of NOx incombustion smoke. By adoption of high-speed separation air and the proper over fire air rate, the created oxygen content in the combustion area is smaller than 1%, the NOx generated low-oxygen area in combustion can be restrained, a composite spraying port is utilized for conveying pyrolysis gas generated through the coal water slurry pyrolytic reaction and internally containing reducing active components and ammonia into the area, the reducing reaction with NOx in smoke happens in the reducing atmosphere, the limitation of usage of a temperature window during NOx reducing through a conventional reducing agent is broken through, furnace interior efficient combustion and economical reducing are ensured, the NOx concentration in smoke is totally reduced, and NOx ultra-low emission of a coalpowder combustion furnace is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Water combustion boiler

ActiveCN103453660ARelease moreNo pollution in the processSteam generation heating methodsSolid fuel combustionWater storageCombustion chamber

The invention discloses a water combustion boiler which comprises a boiler with an inner cavity. A boiler door is formed in the wall of the boiler, a water jacket is nested in the inner cavity of the boiler, the inner wall of the boiler is used as the outer wall of the water jacket, and a water storage cavity is formed between the inner wall of the water jacket and the inner wall of the boiler; a combustion chamber is formed by the inner wall of the water jacket in an enclosed manner; a ventilation system, water inlet pipes, a steam exhaust pipe, a smoke vent and a steam supply pipe are respectively fixedly arranged on the outside of the boiler, the ventilation system is communicated with the combustion chamber, the water inlet pipes are communicated with the water storage cavity, the steam exhaust pipe and the smoke vent are communicated with the inner cavity of the boiler, and the steam supply pipe is simultaneously communicated with the combustion chamber and the top of the inner cavity of the boiler; an ignition system and a combustion-supporting carrier are fixed into the combustion chamber. The water combustion boiler has the advantages that large quantities of electrons can be released by metal atoms of the combustion-supporting carrier at high temperatures, heat can be released, and hydrogen decomposed from steam can be assisted to be combusted, so that a large quantity of heat can be released; the water combustion boiler is suitable to be used as heating equipment and applicable to modification projects of coal combustion boilers, gas combustion boilers and oil combustion boilers in the fields of power plants and heating, the industrial and agricultural fields and the like, the steam and other fuel can be combusted jointly to generate the heat, so that fifty percents of fuel can be saved on the premise that the same quantity of heat is provided.

Owner:林亮星

Circuit board incineration smelting furnace and circuit board incineration smelting method

ActiveCN107726331AEmission reductionIncrease profitEmission preventionIncinerator apparatusThermal energyBrick

The invention discloses a circuit board incineration smelting furnace and a circuit board incineration smelting method adopting the circuit board incineration smelting furnace. The circuit board incineration smelting furnace comprises a main furnace body arranged vertically and a reversal combustion tower. The main furnace body is provided with a charging port, a waste material combustion chambercommunicating with the charging port, a smelting chamber located below the waste material combustion chamber, a boiling combustion chamber located above the waste material combustion chamber and a smoke collection hood located above the boiling combustion chamber. The reversal combustion tower communicates with the smoke collection hood. A smoke dust settling chamber is arranged below the reversalcombustion tower. A pneumatic carrier pipe communicates between the boiling combustion chamber and the smoke dust settling chamber. The lower side of the smoke dust settling chamber is further provided with a Venturi feed pipe. By means of the technical scheme, the utilization rate of thermal energy is increased, emissions of poisonous and harmful gas are reduced, and the combustion efficiency ishigh; the early-period treatment cost is reduced, energy is saved by 50%, consumption of refractory materials such as refractory bricks is reduced, and the service cycle of the furnace is prolonged.

Owner:邹资生

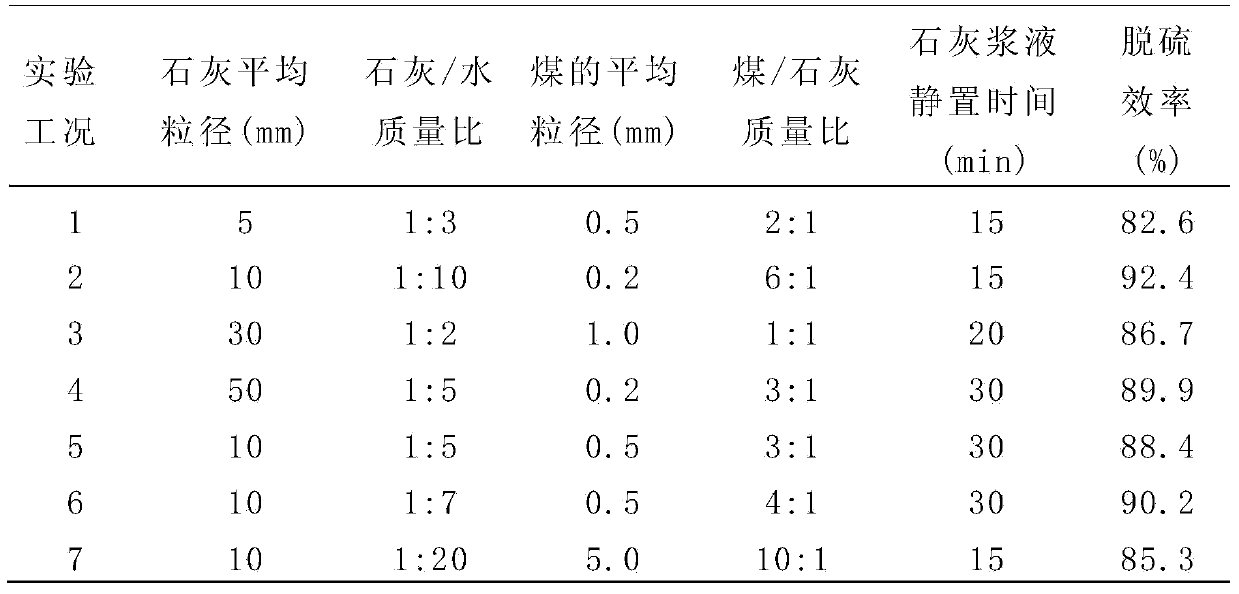

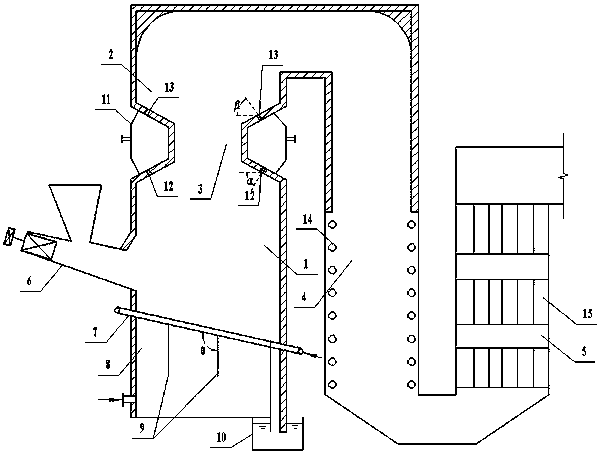

Coal mixture with desulfurization effect and preparation method and application of coal mixture

ActiveCN104208998AIncrease profitImprove self-desulfurization efficiencyDispersed particle separationCalcium hydroxideCoal particle

The invention discloses a coal mixture with a desulfurization effect and a preparation method and application of the coal mixture, relating to the technical field of coal cleaning. The coal mixture with the desulfurization effect is characterized by being prepared by mixing massive lime raw materials, coal particles and water according to a certain ratio, grinding massive lime into ultrafine calcium hydroxide particles which are attached to the surfaces and inner pores of the coal particles and reducing the water content, and the coal mixture can be directly used as a coal processing and utilization raw material. By the method, the self-desulfurization of coal and the utilization rate of a desulfurizing agent can be obviously improved; furthermore, the process of adding the desulfurizing agent into a coal utilization device is simplified, and the investment and the use cost of desulfurizing equipment are lowered.

Owner:TSINGHUA UNIV

Small gasifying incinerator

PendingCN108644779AAchieve combustionImprove applicabilityIncinerator apparatusNon-combustible gases/liquids supplyEngineeringWater cooling

The invention discloses a small gasifying incinerator. The small gasifying incinerator comprises a gasifying zone, a burning zone, a burning-out zone and a feeding device. The burning zone comprises afirst burning zone portion and a second burning zone portion which are arranged in an n shape. The first burning zone portion is disposed above the gasifying zone, and a uniformly-contracted throat is formed at the connecting position of the gasifying zone and the first burning zone portion. The burning-out zone communicates with the bottom of the second burning zone portion, and then a turn-backtype material flow channel is formed. A fire grate which is obliquely downward is disposed at the bottom of the gasifying zone, and air or water cooling is applied to the interior of the fire grate.A first air chamber is disposed at the bottom of the fire grate, and baffles are disposed in the first air chamber. A material falling channel is disposed at the tail end of the fire grate, and a water seal trough is disposed at the bottom of the material falling channel. A second air chamber is disposed outside the throat in an encircling mode, and communicates with the throat through secondary air openings and tertiary air openings. The secondary air openings are formed in the downward oblique surfaces of the throat, the tertiary air openings are formed in the upward oblique surfaces of thethroat, and the rotation direction formed by outflowing air of the secondary air openings is opposite to the rotation direction formed by outflowing air of the tertiary air openings. Materials are dried and gasified on the oblique fire grate of the small incinerator, so that the materials are reacted uniformly and stably, and the gasification rate and the burning-out rate are improved through reasonable air distribution.

Owner:北京禾适科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com