Industrial gas burner

An industrial gas and burner technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of complicated structure, poor flame stability, high pressure and cleanliness requirements, so as to avoid clogging and deposition, and overcome backlash fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

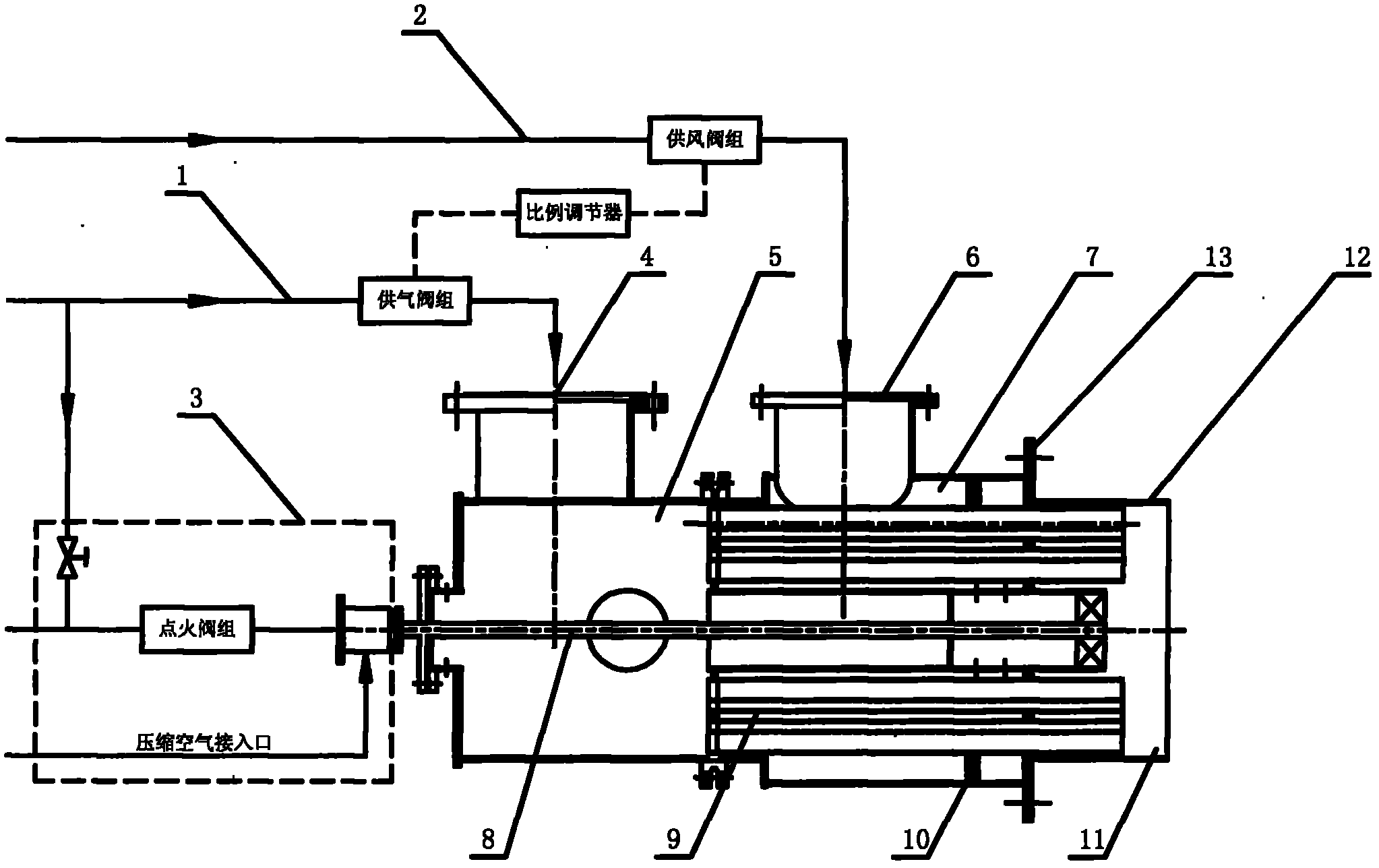

[0025] Accompanying drawing is embodiment of the present invention.

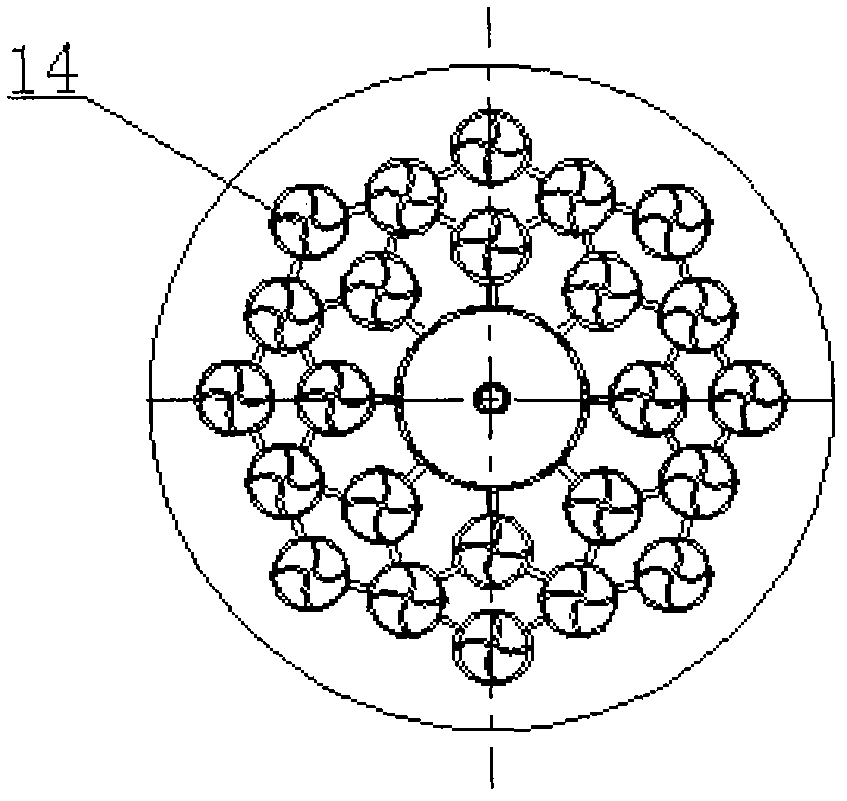

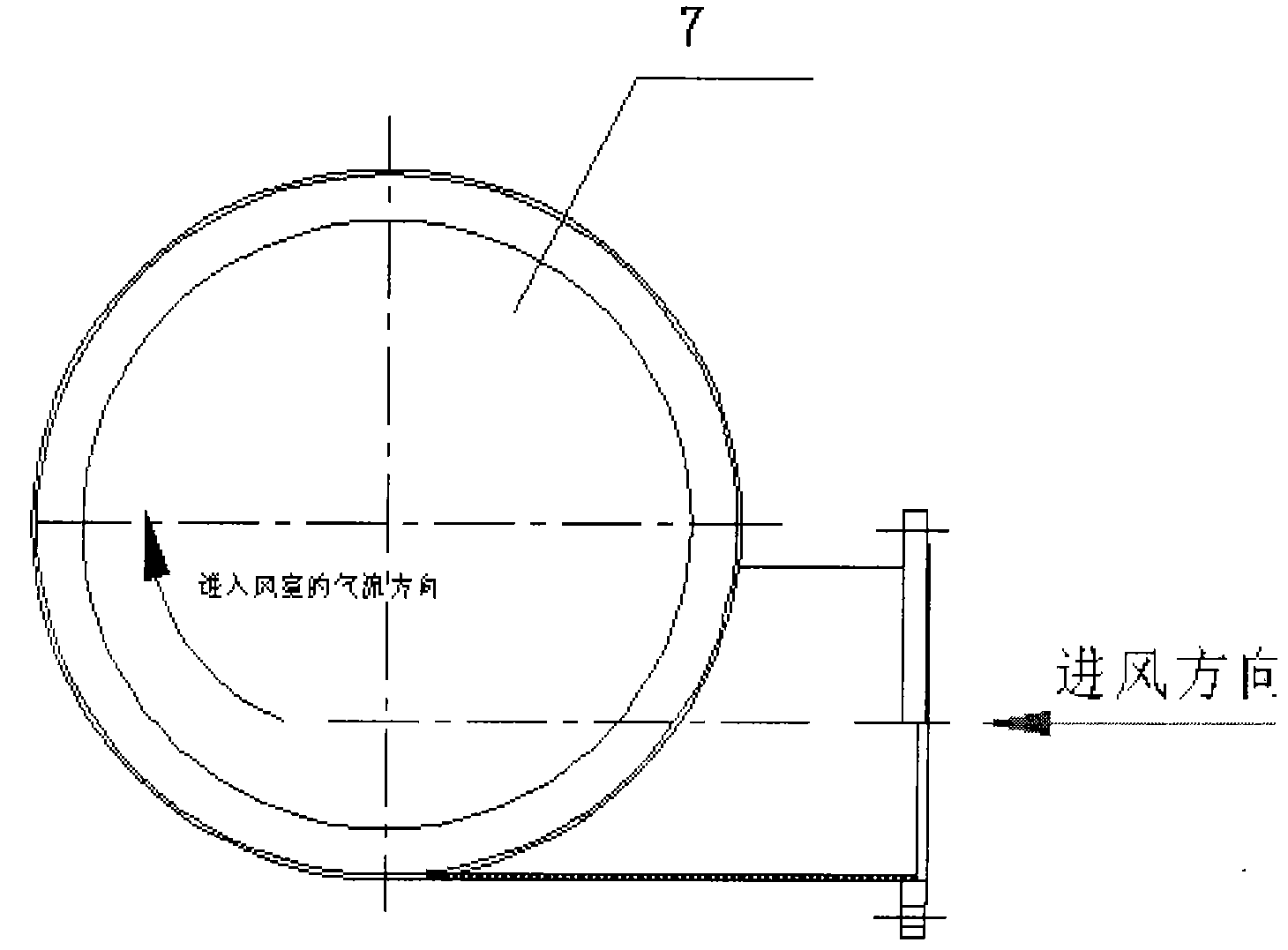

[0026] attached figure 1 The medium fuel gas enters the gas chamber 5 from the gas supply pipeline 1 through the air inlet 4 . The gas chamber 5 is separated from the air chamber 7 with a dividing plate. A gas distribution tube bundle 9 is arranged on the partition, and the gas distribution tube bundle 9 reaches the air-mixing combustion zone 11 for mixed combustion with the combustion-supporting air. In this embodiment, 24 gas distribution pipes have been used (see attached figure 2 ), each gas distribution pipe is provided with holes communicating with the combustion air chamber 7 (these holes are not shown in the figure). The diameter of the hole is Φ14mm. The length of the guide vane is 50-90 mm, the lead of the guide vane is 1, the diameter of each gas distribution pipe is 45 mm, and the length is 900 mm. The combustion-supporting air enters the combustion-sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com