Patents

Literature

57results about How to "Solve backfire problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

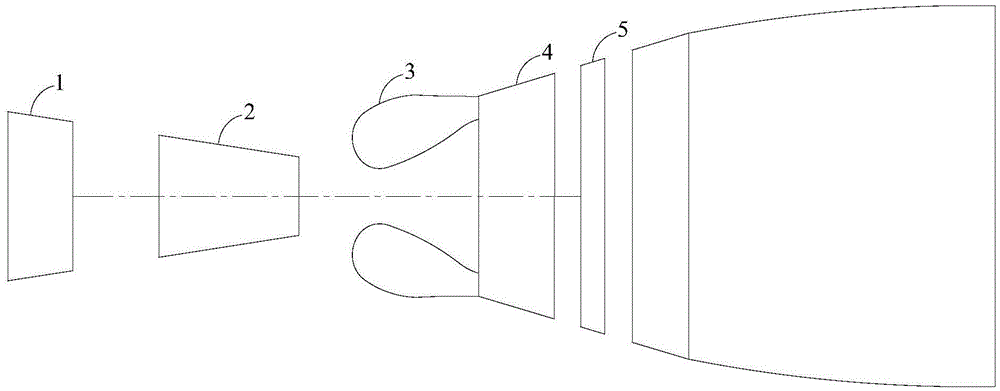

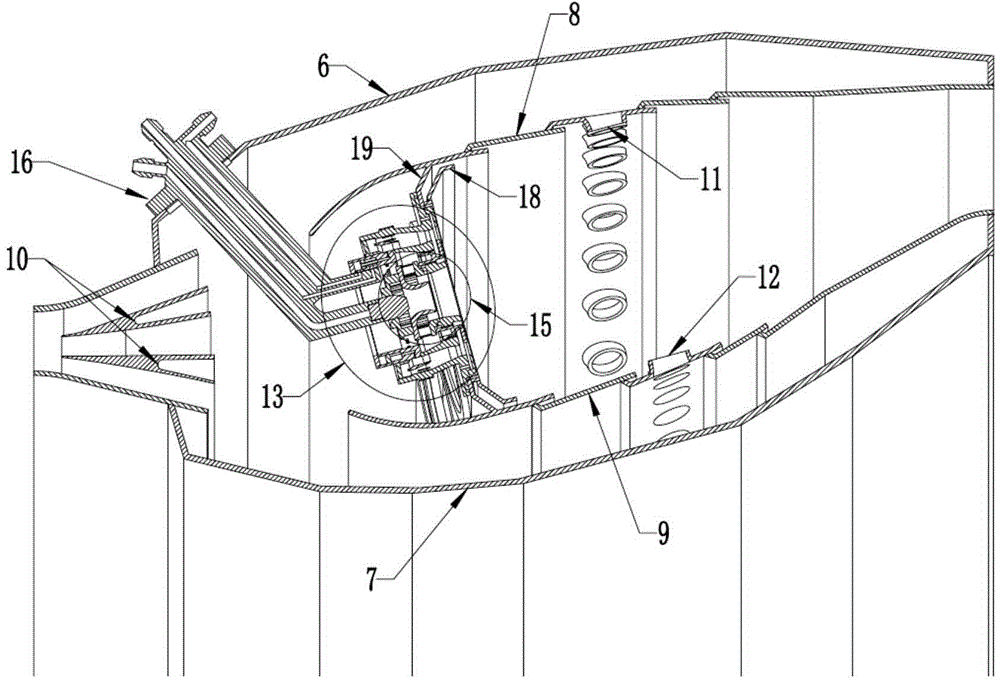

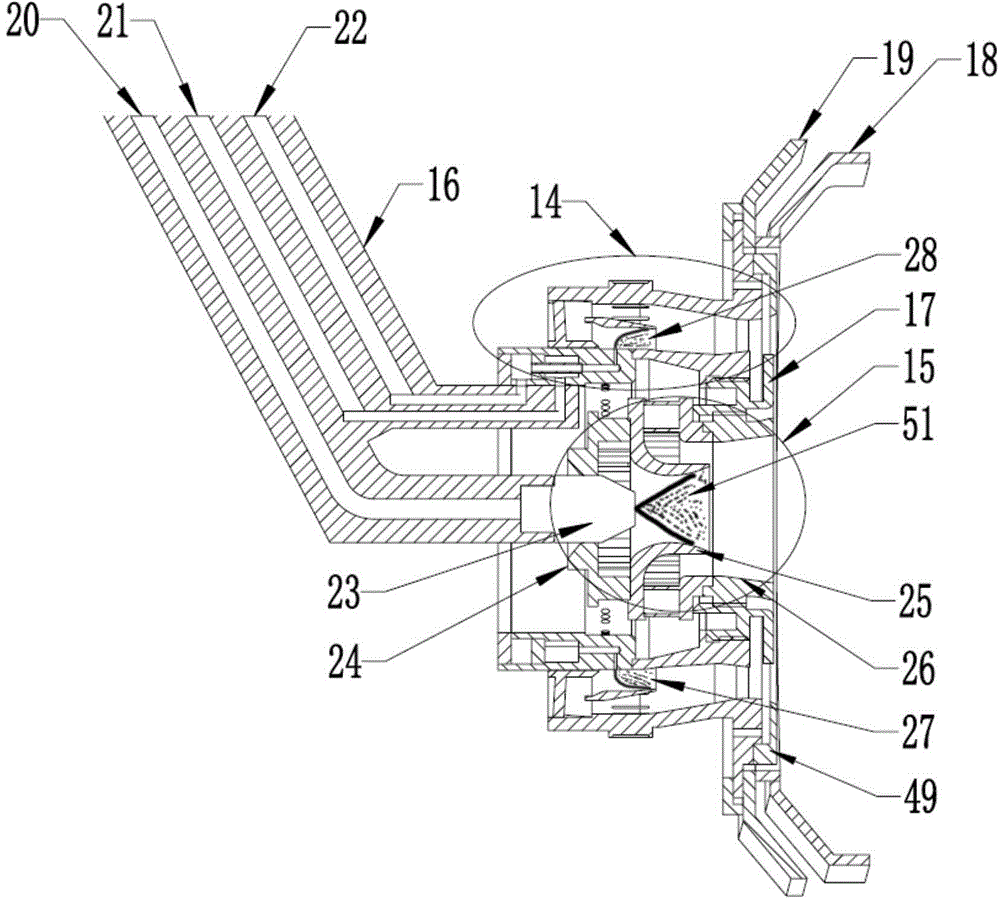

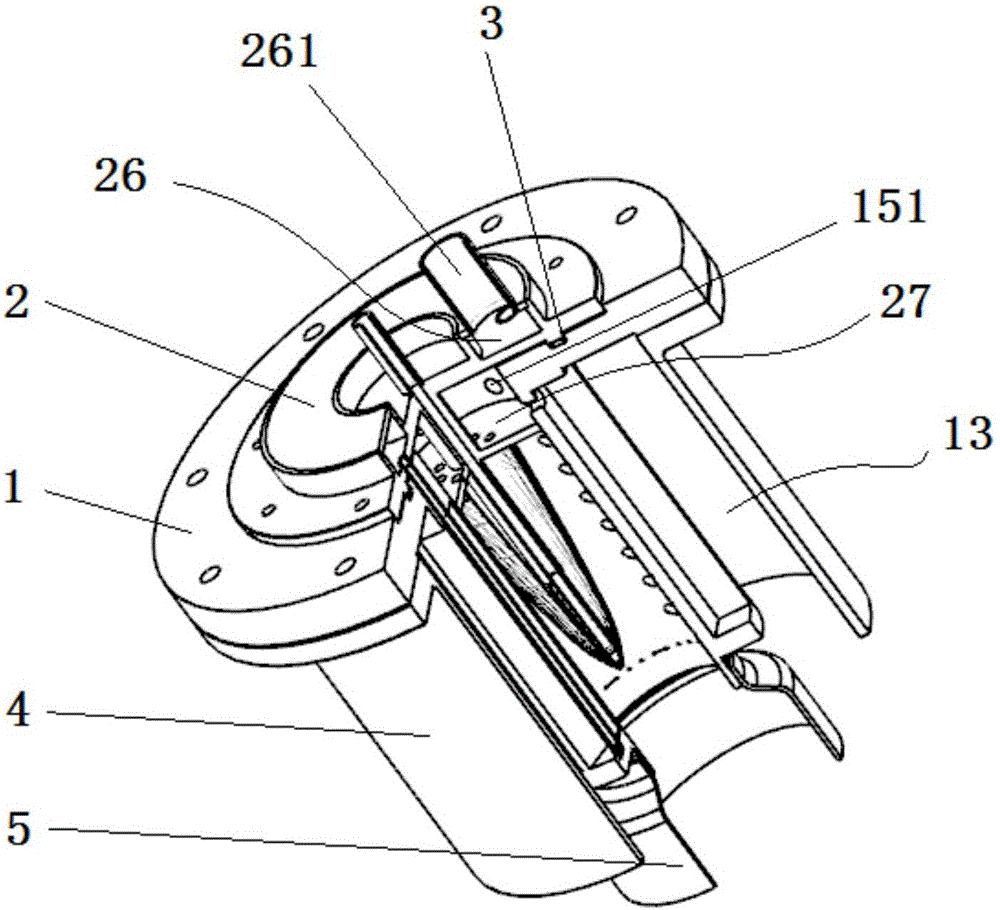

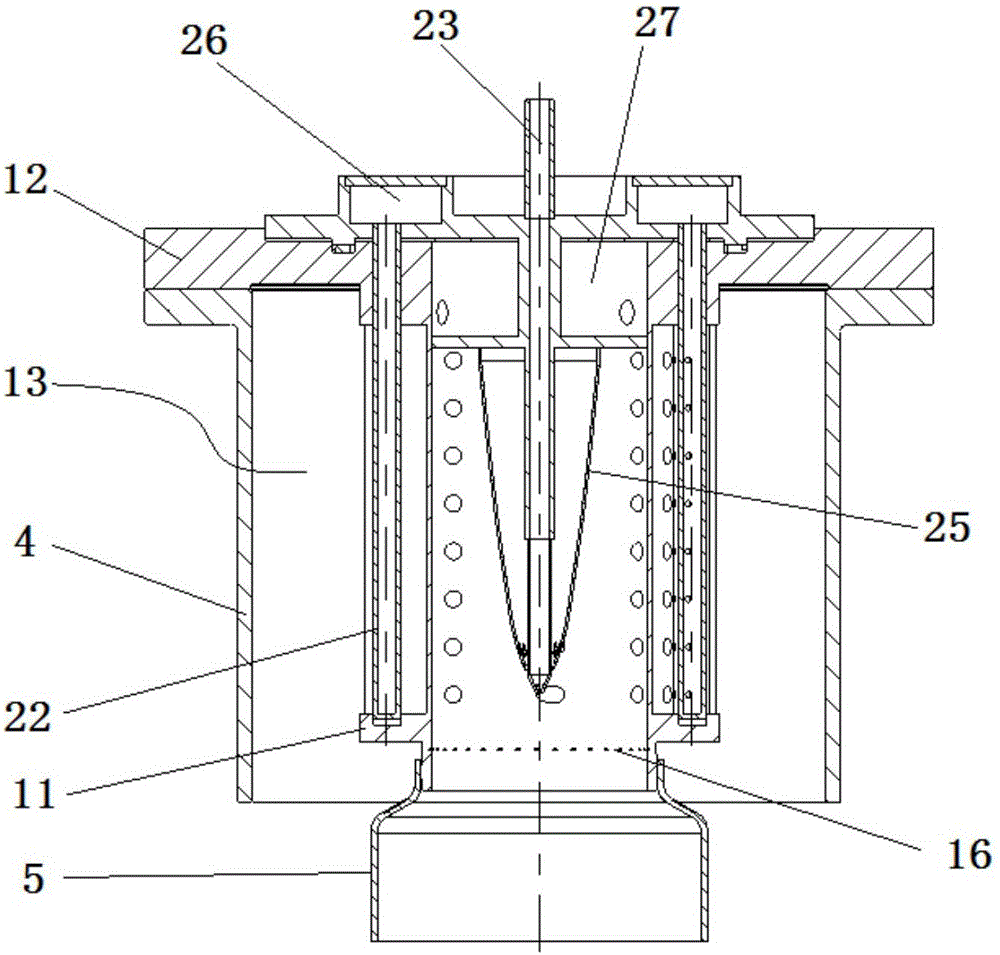

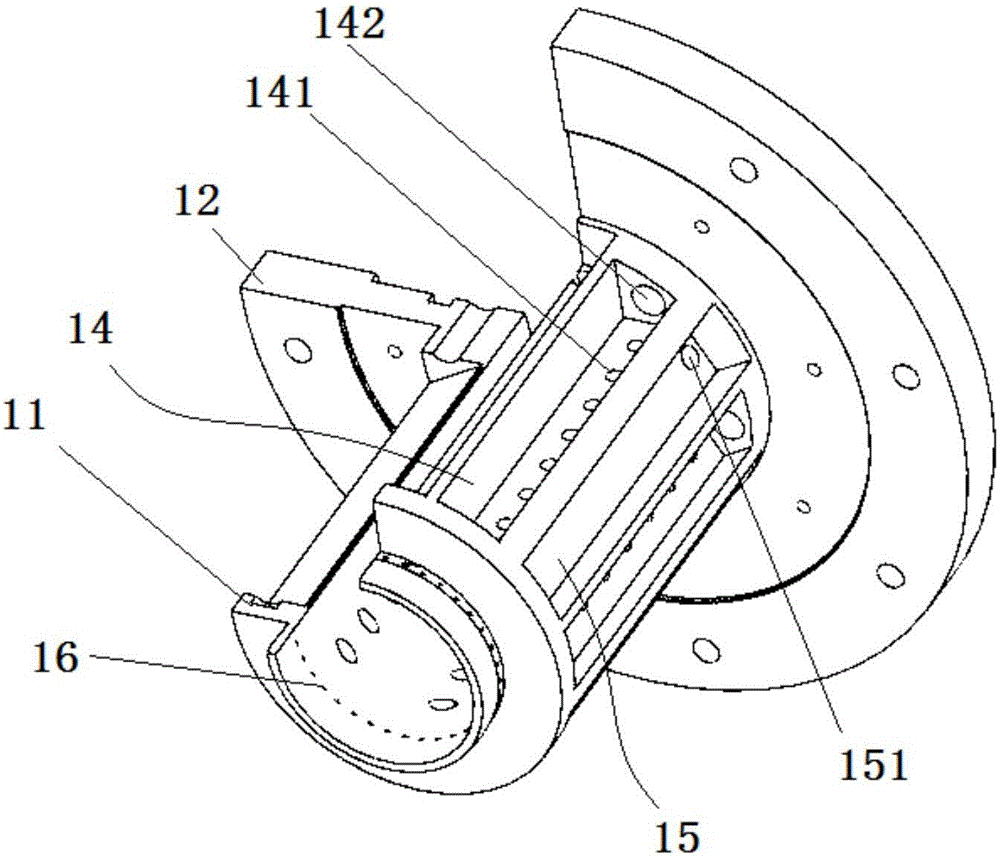

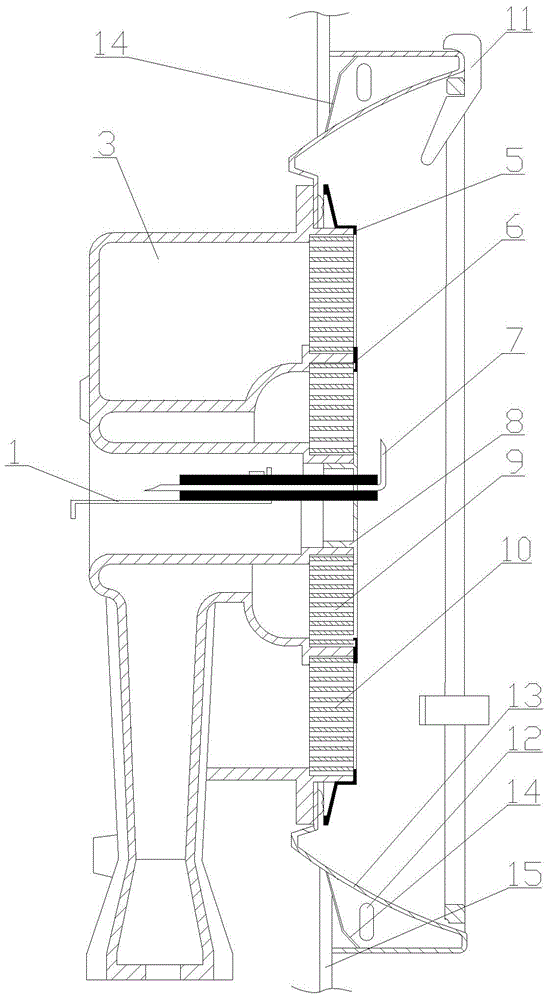

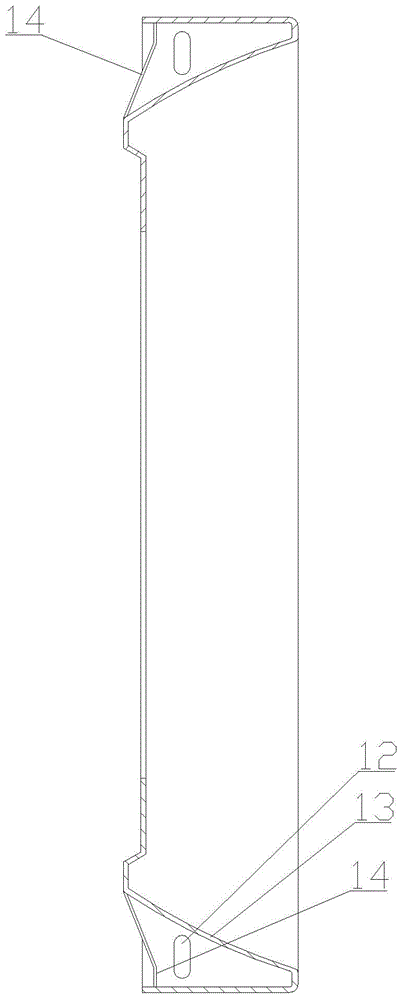

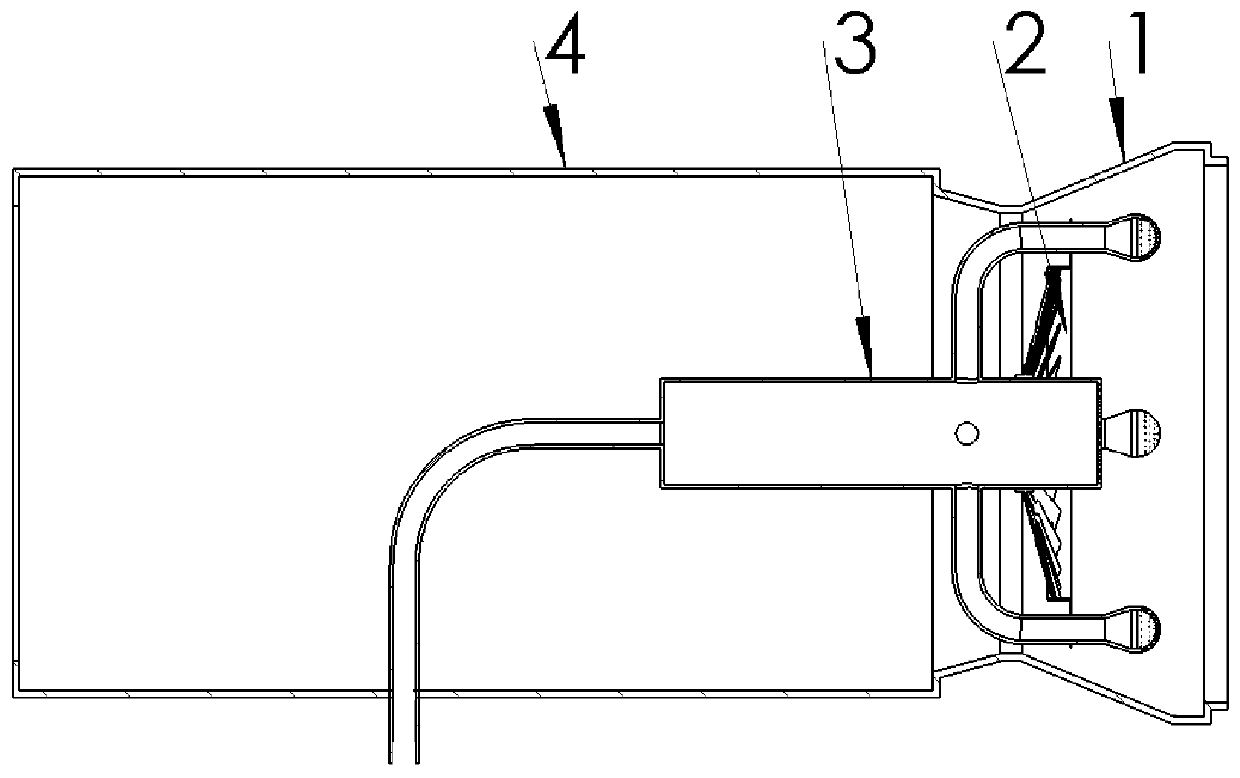

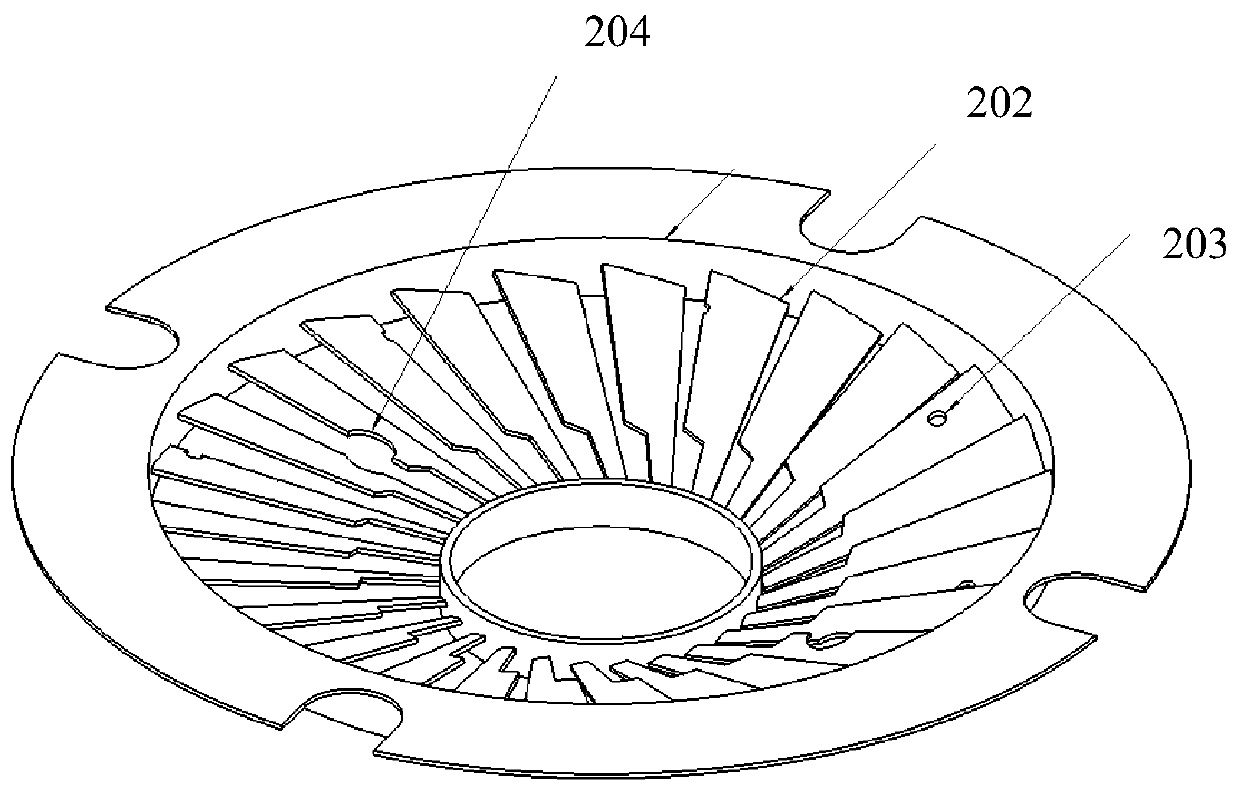

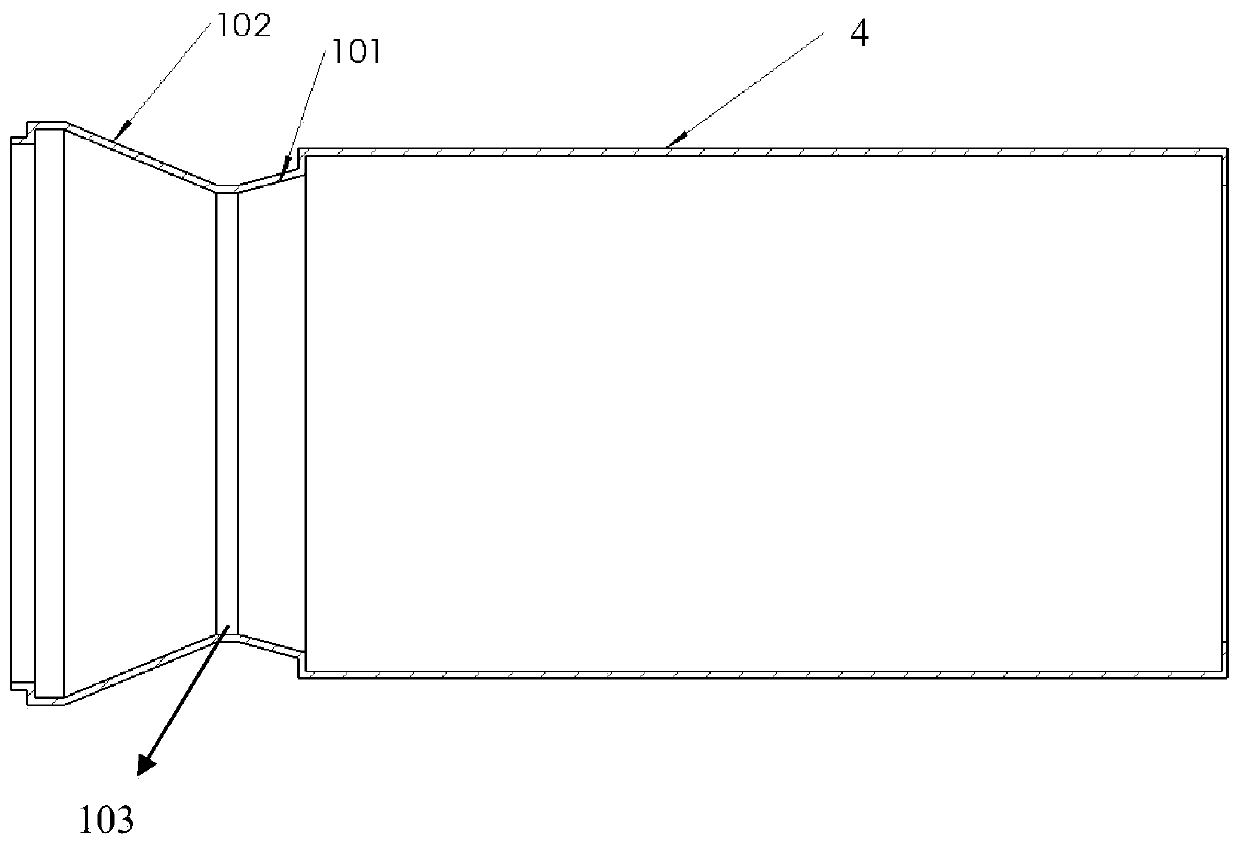

Lean oil premixing and pre-evaporating combustion chamber head structure with cyclone/pre-film plate integrated primary combustion stage

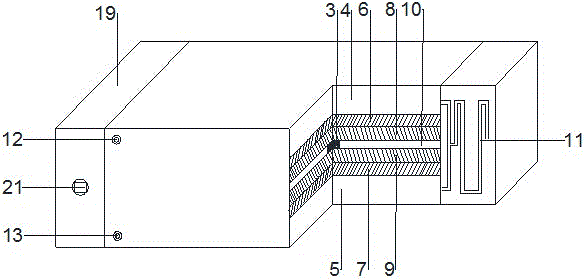

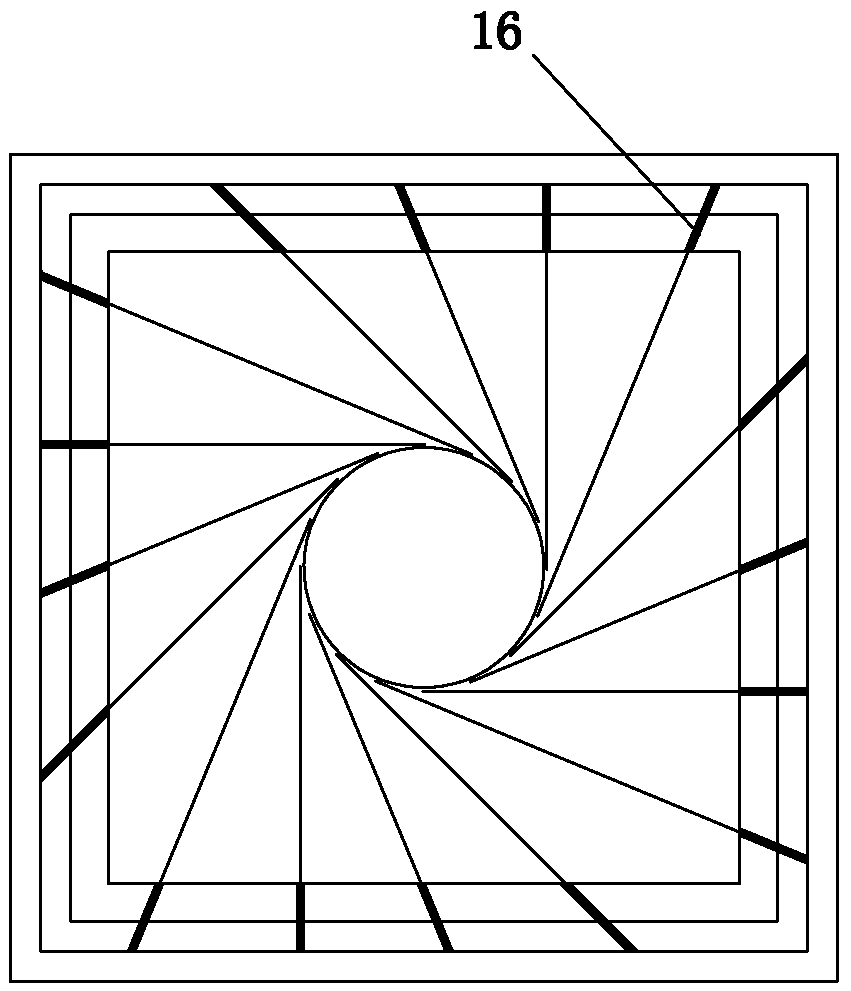

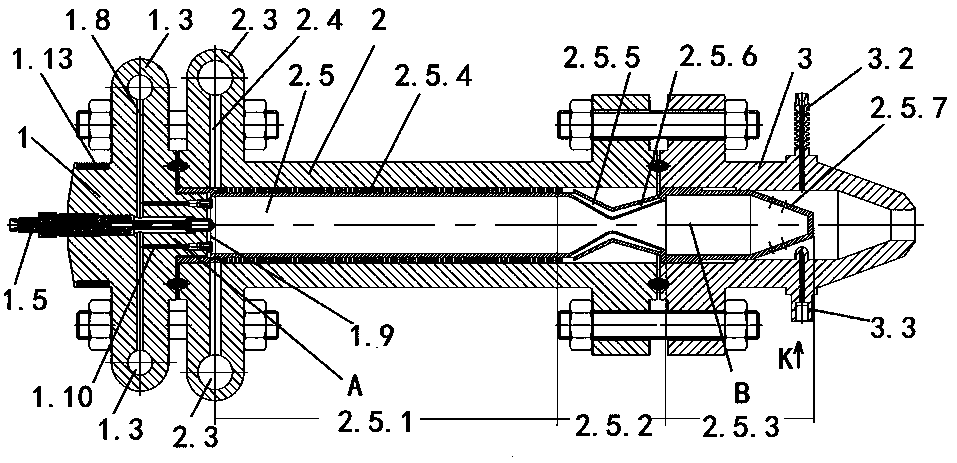

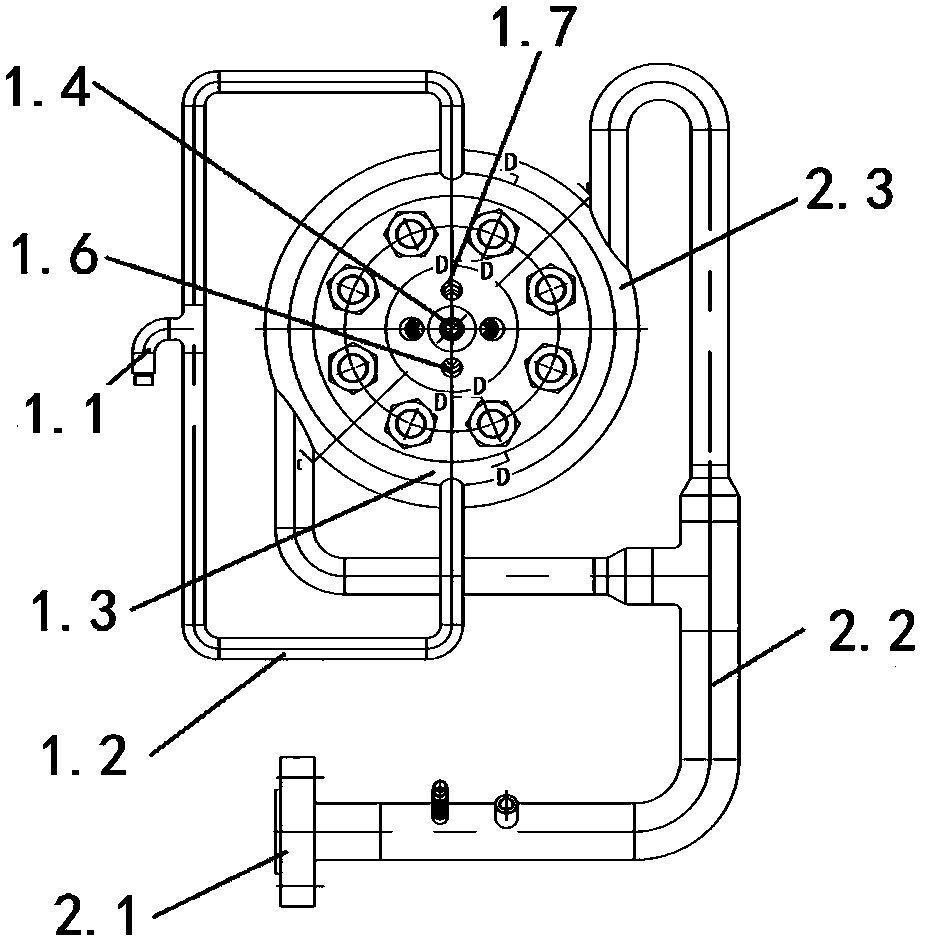

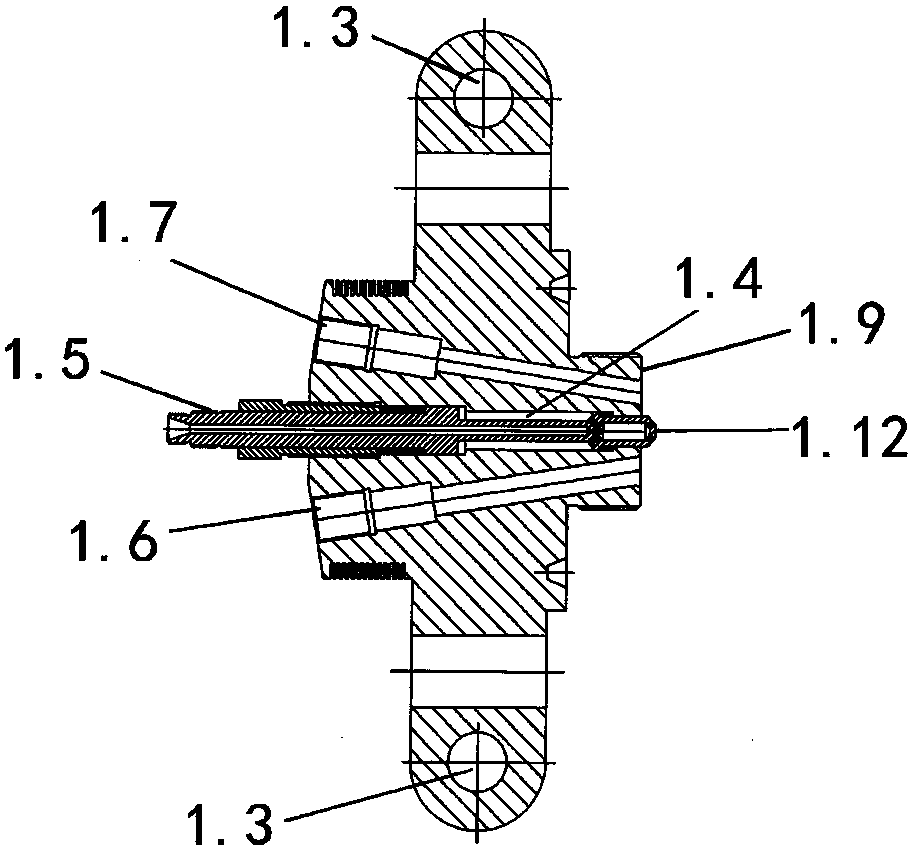

The invention relates to a lean oil premixing and pre-evaporating combustion chamber head structure with a cyclone / pre-film plate integrated primary combustion stage. A central staged combustion mode is adopted for the head structure and divided into a pre-combustion stage and the primary combustion stage, the mode of combining diffusive combustion and cyclone premixing combustion is adopted for the pre-combustion stage, the mode of premixing and pre-evaporating combustion mode is adopted for the primary combustion stage, and combustion pollutants can be effectively reduced. A cyclone / pre-film plate integrated structure is adopted for the primary combustion stage, the structure is simple and reliable, first-stage fuel and second-stage fuel form oil films on the same pre-film plate and are atomized, evaporated and mixed under the action of two strands of cyclones, an even oil and gas mixture can be easily formed at an outlet of the primary combustion stage, and the combustion pollutants are reduced. The design of dual oil paths of the primary combustion stage is beneficial to oil and gas matching of the combustion chamber under different working conditions, and the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aero-engine is further lowered. By means of the micro shrinkage type design of a primary combustion stage channel and the design of a backfire prevention ring, the backfire problem can be effectively solved, and the safety of the head of the combustion chamber is ensured.

Owner:BEIHANG UNIV +1

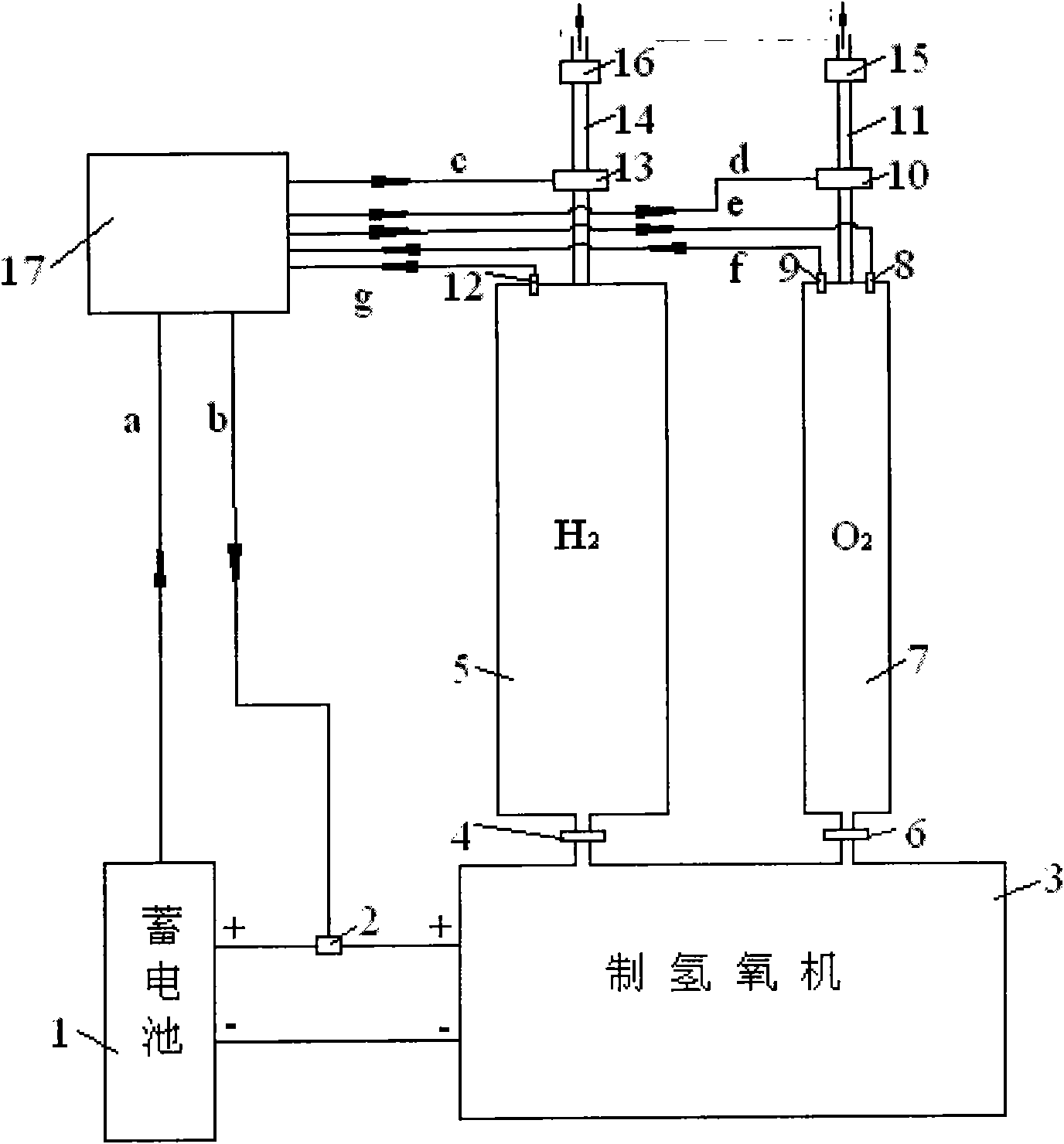

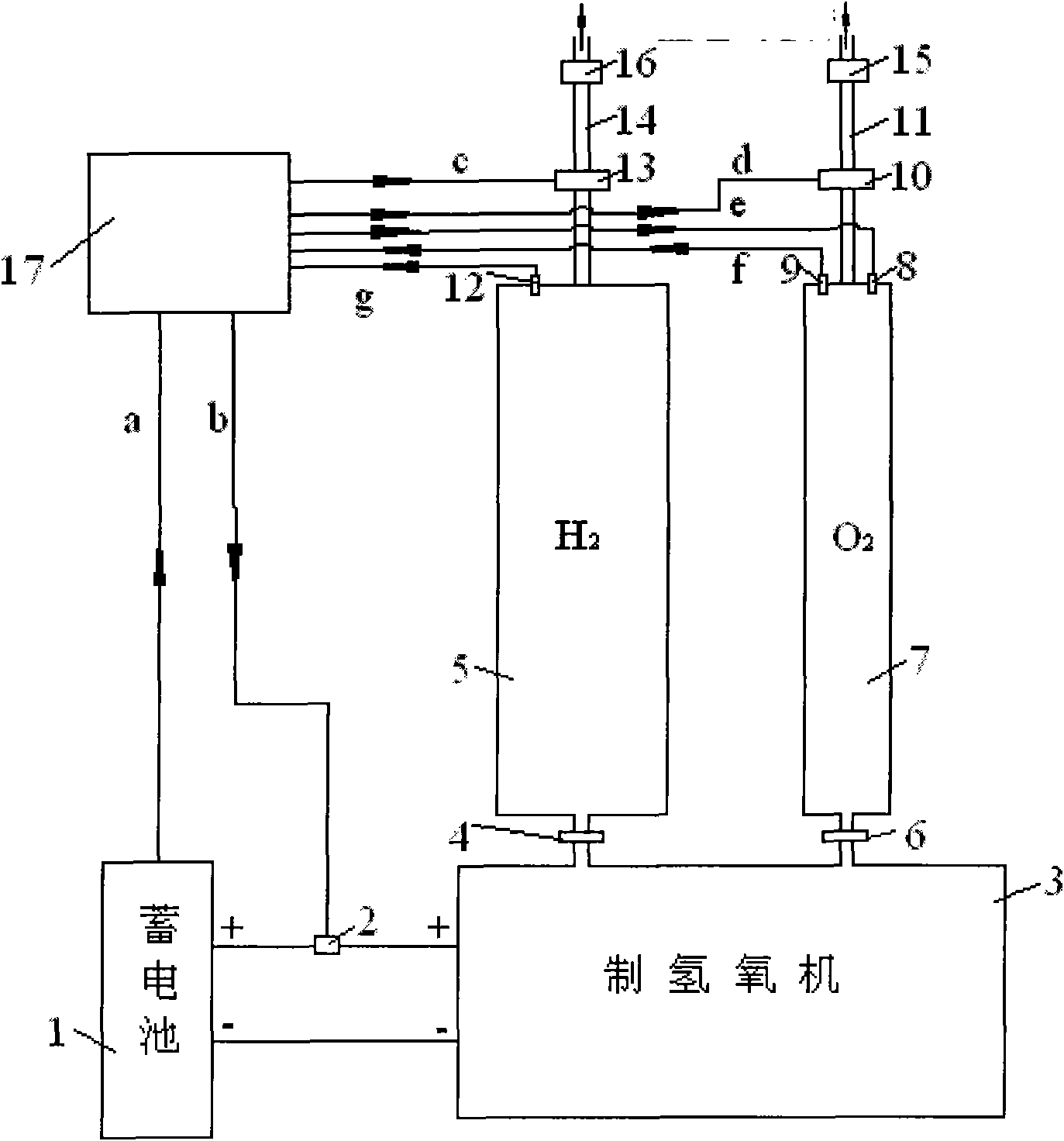

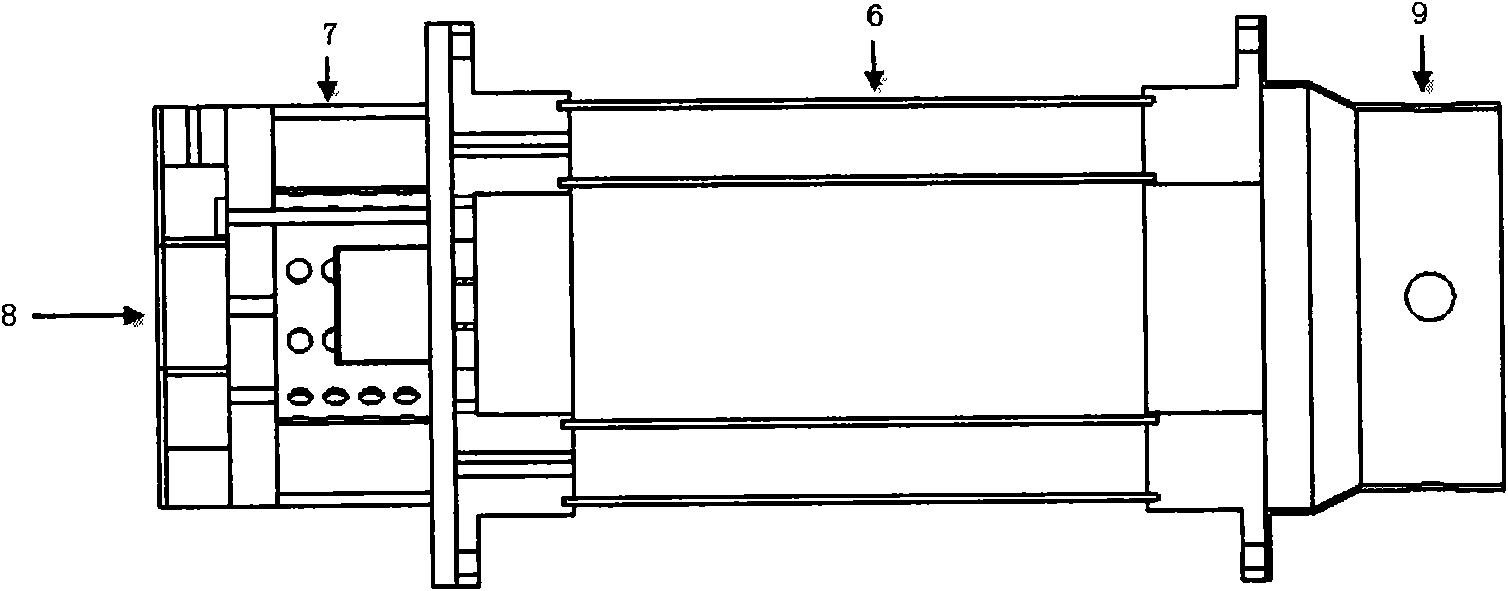

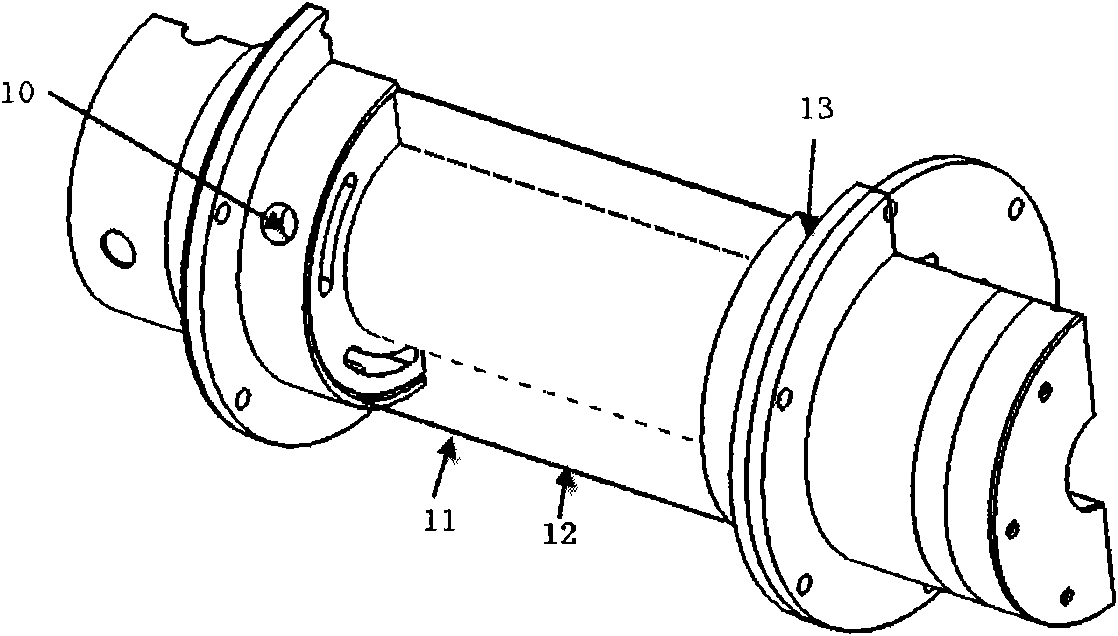

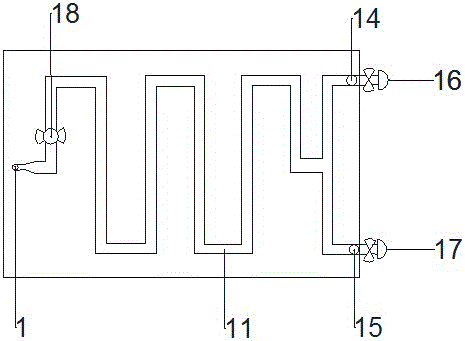

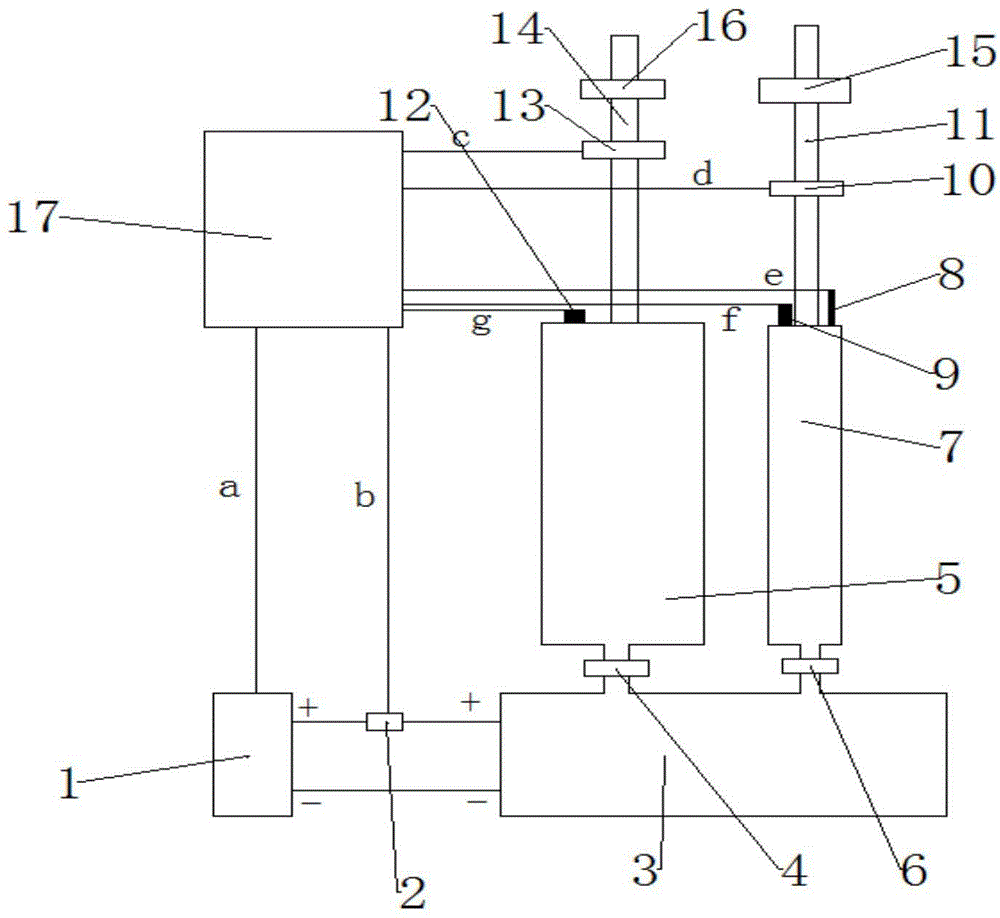

Device for preparing, storing and feeding vehicle-mounted hydrogen/oxygen and control method thereof

ActiveCN101956634AReduce weightReduce manufacturing costNon-fuel substance addition to fuelInternal combustion piston enginesOxygen tankSolenoid valve

The invention discloses a device for preparing, storing and feeding vehicle-mounted hydrogen / oxygen and a control method thereof, particularly relating to prepare, store and feed the hydrogen and the oxygen on a vehicle. In the system, based on reserving an engine storage battery, a vehicle-mounted hydrogen and oxygen preparing device, a hydrogen and oxygen storing device, a hydrogen and oxygen preparing, storing and electronicaly control unit are increased, wherein, according to an accumulator voltage signal, and a hydrogen and oxygen storage tank pressure signal, the electronicaly control unit controls opening and closing of a hydrogen and oxygen preparing machine switch relay, an oxygen tank unidirectional gas discharging valve, an oxygen supply linear solenoid valve and a hydrogen supply pipeline solenoid valve, thus realizing the preparation, storing, feeding, and controlling of the hydrogen and the oxygen on the vehicle. The system has the advantages of realizing the preparation and storing of the hydrogen and the oxygen on the vehicle, ensuring that the vehicle can utilize the hydrogen and the oxygen prepared by the system in the last-time operation when in cold starting, so as to realize the starting of pure hydrogen or pure hydrogen-oxygen gas mixture for the increasing of the hydrogen and oxygen storing device, thereby greatly reducing HC and CO emission when a gasoline engine is started.

Owner:BEIJING UNIV OF TECH

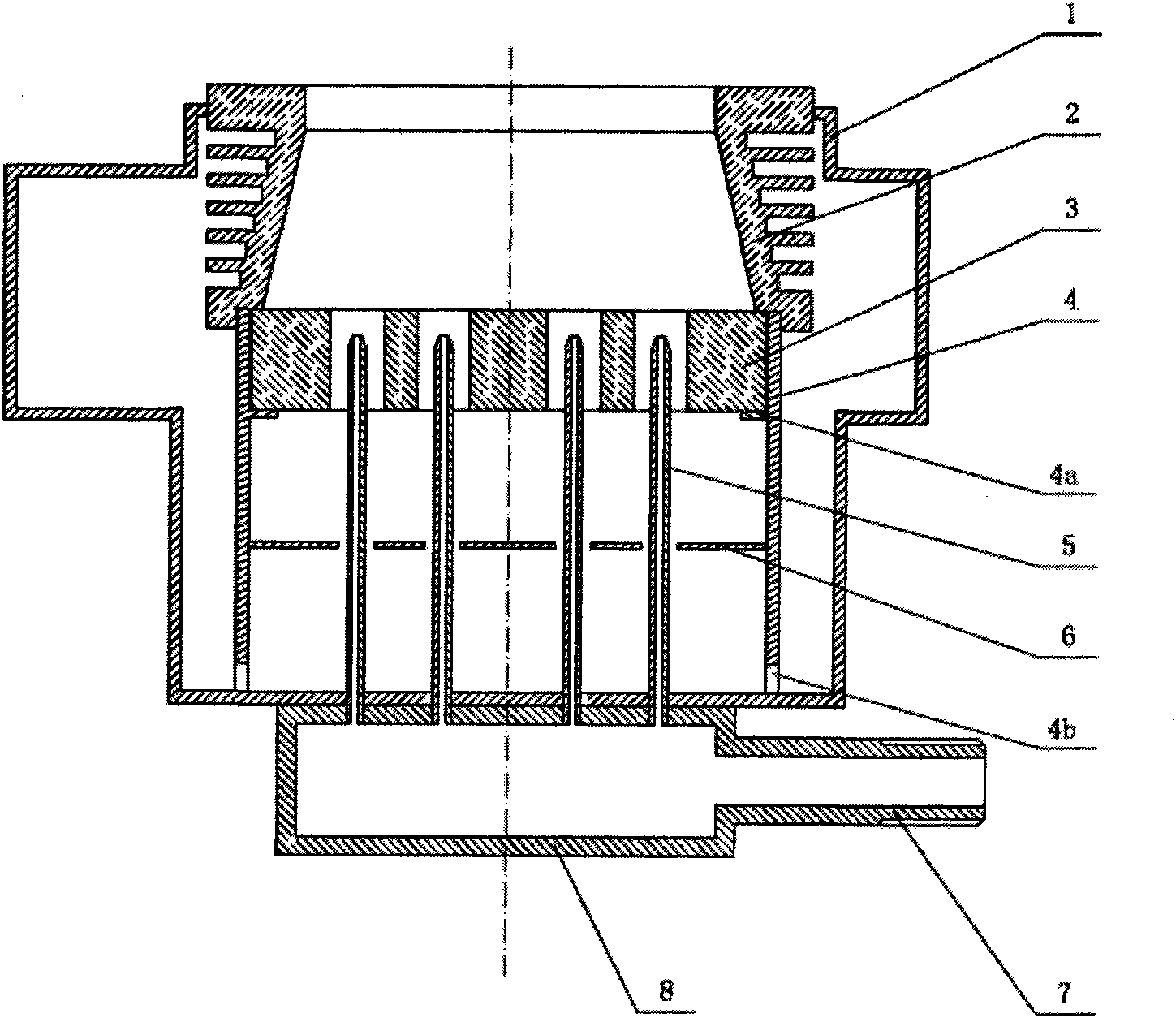

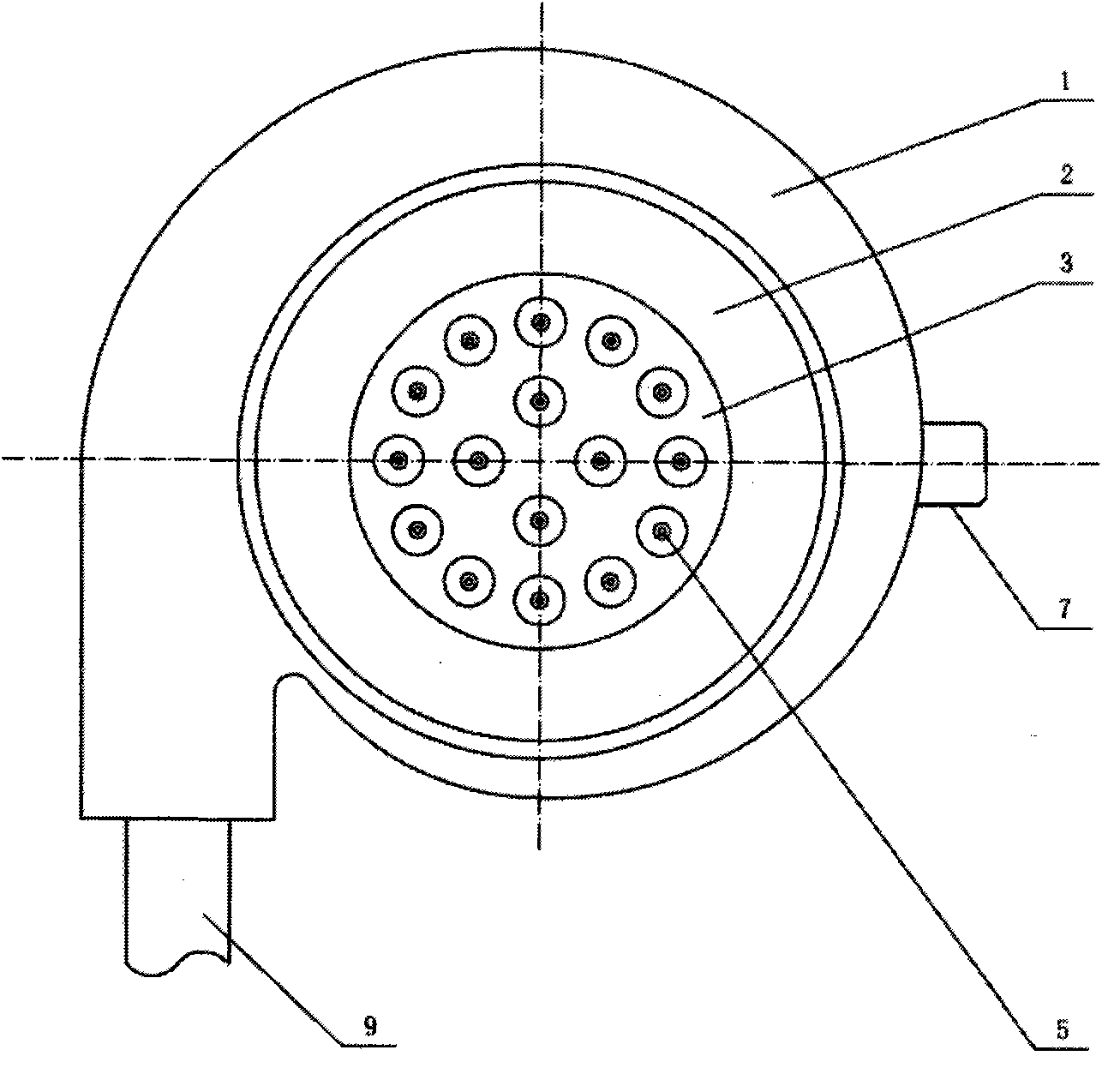

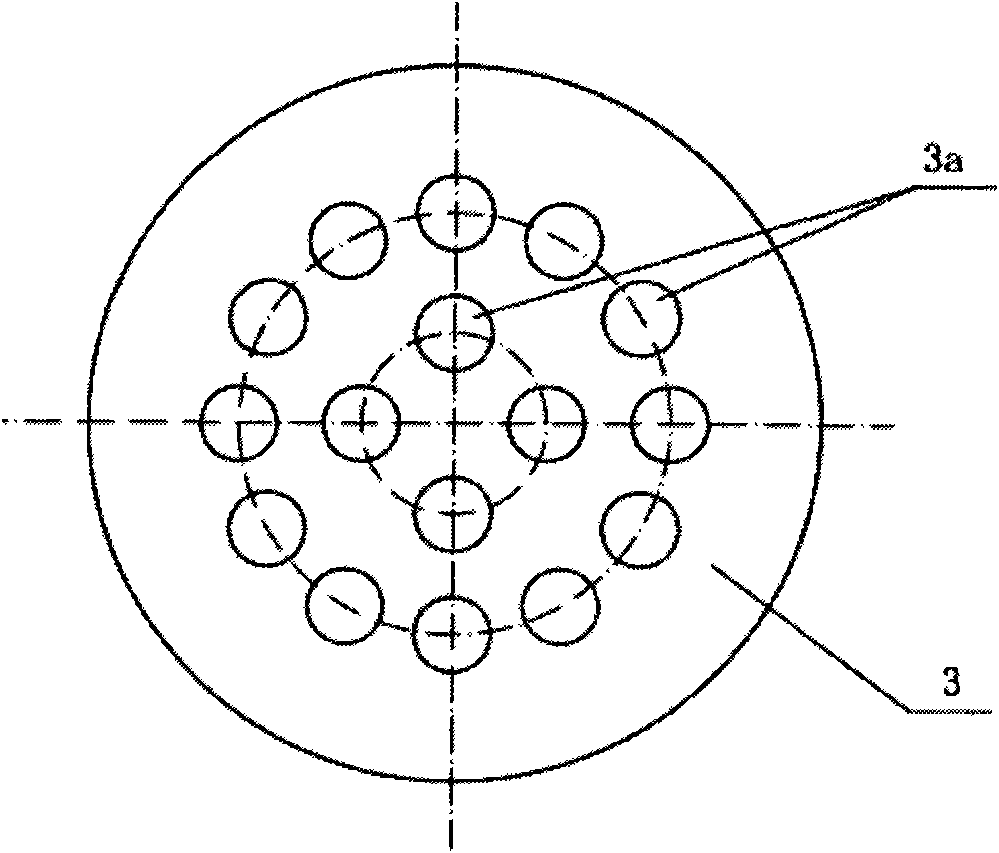

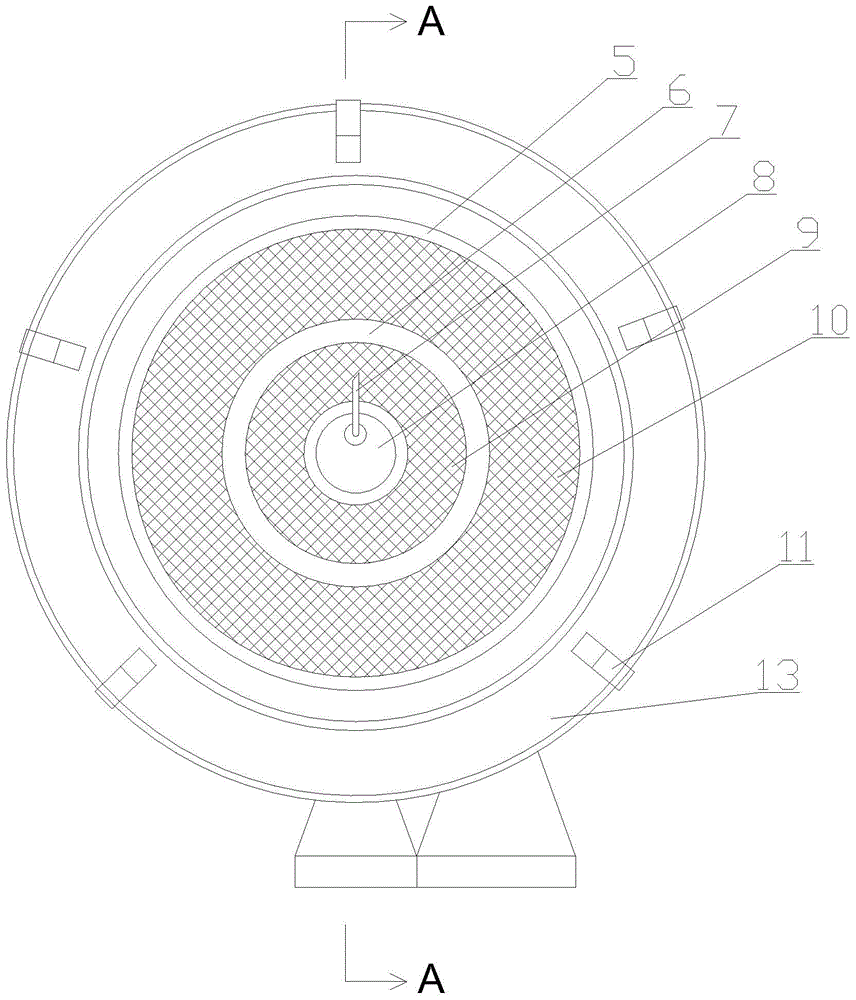

Flameless combustion organizational structure and flameless combustion chamber for realizing structure

InactiveCN101625130AAchieve flameless combustionImprove stabilityContinuous combustion chamberIndirect carbon-dioxide mitigationGas turbinesCombustion chamber

The invention discloses a flameless combustion organizational structure used in a combustion chamber of a gas turbine. In the structure, a plurality of coaxial ejector nozzles are evenly arranged at one end of the cylinder-shaped combustion chamber in a ring shape; the center of the ejector nozzles evenly arranged in the ring shape is provided with a cylinder-shaped reflux structure; secondary air does not take part in combustion in the cylinder-shaped combustion chamber; the air taking part in the reaction enters from one end provided with the ejector nozzles arranged on the cylinder-shaped combustion chamber, and a large amount of reflux high-temperature fume is mixed with the fresh air according to the position relationship between the nozzle evenly arranged in the ring shape and the cylinder-shaped reflux structure arranged in the center of the nozzles, so that the air temperature is increased, and the air is diluted; and the diluted high-temperature air spontaneously combusts when exposed to the fuel to form a high-temperature dispersing reaction area, so that the flameless combustion is achieved in the combustion chamber of the gas turbine. The invention simultaneously discloses the flameless combustion chamber for realizing the flameless combustion organizational structure. The flameless combustion organizational structure and the flameless combustion chamber realize flameless combustion and achieve the aims of extremely low pollutant emission and stable combustion of the combustion chamber of the gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

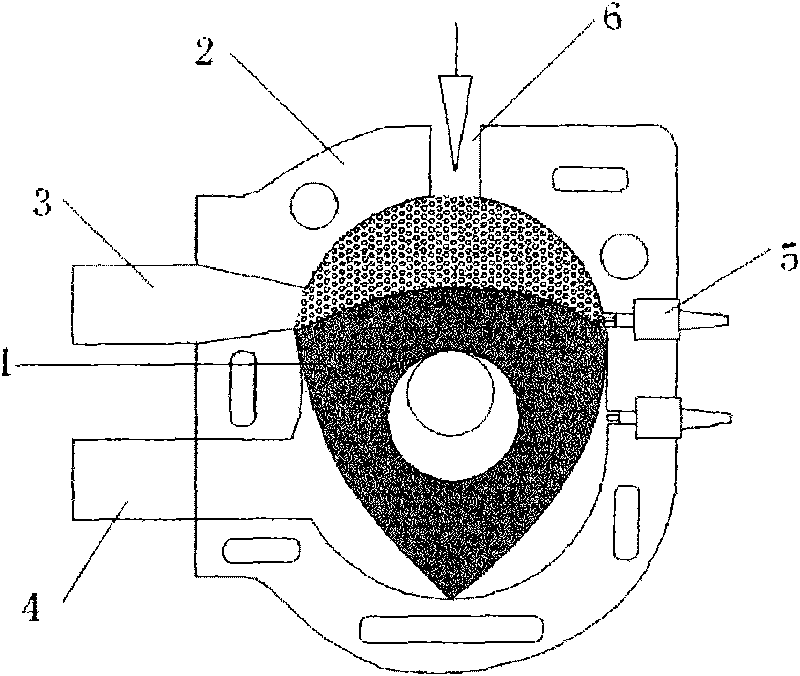

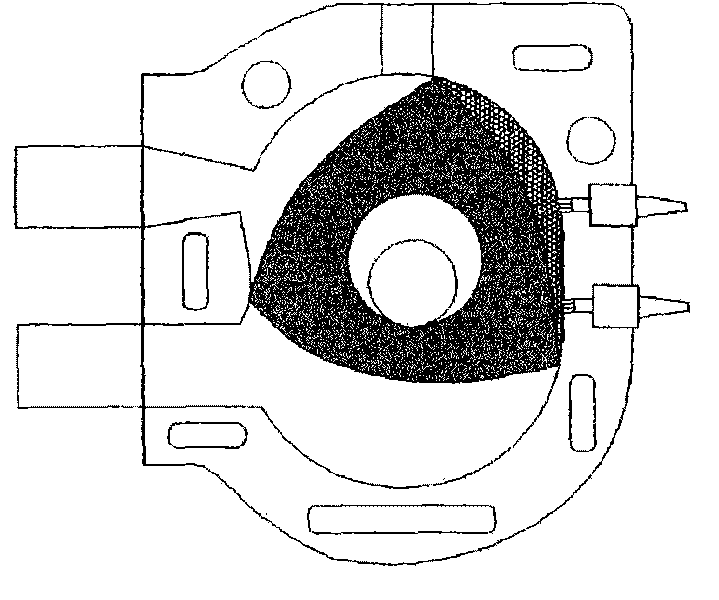

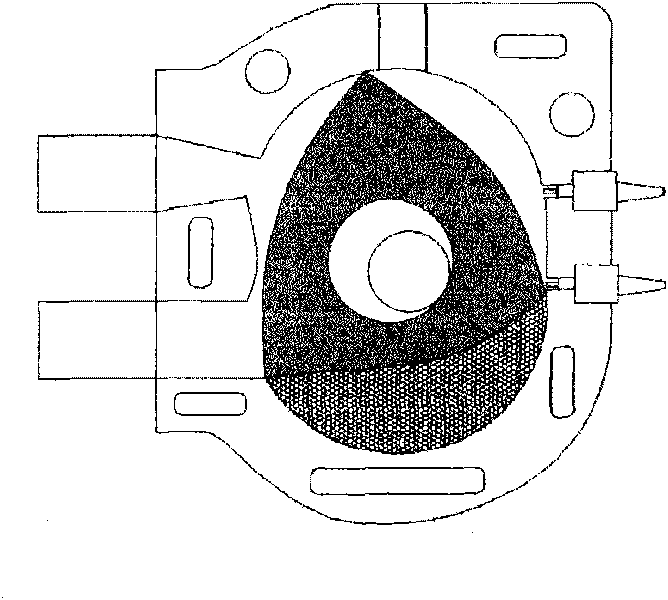

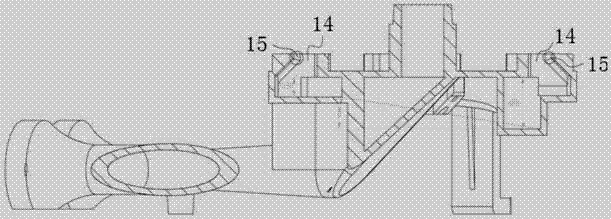

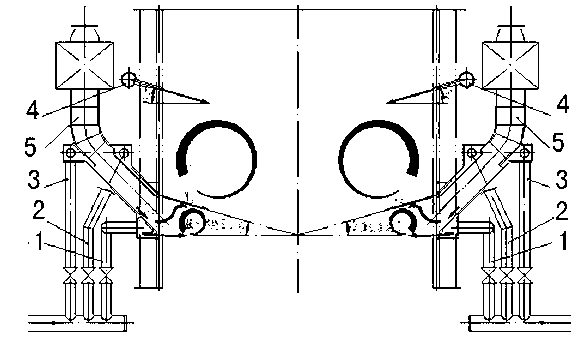

Application of hydrogen fuel and rotary engine thereof

InactiveCN101718221AUse technology to improveSolve backfire problemsInternal combustion piston enginesGaseous engine fuelsBack-fireRotary engine

The invention relates to application of hydrogen fuel and a rotary engine thereof; the hydrogen fuel can be effectively utilized and the problems of back fire, preignition and insufficient power of the hydrogen fuel engine; the technical proposal is that: the hydrogen fuel is used for the rotary engine, and the hydrogen fuel rotary engine is provided with a rotor and a shell, and an air inlet and an air outlet are arranged on the shell; the rotary engine is characterized in that: a hydrogen inlet is arranged on the shell.

Owner:CHERY AUTOMOBILE CO LTD

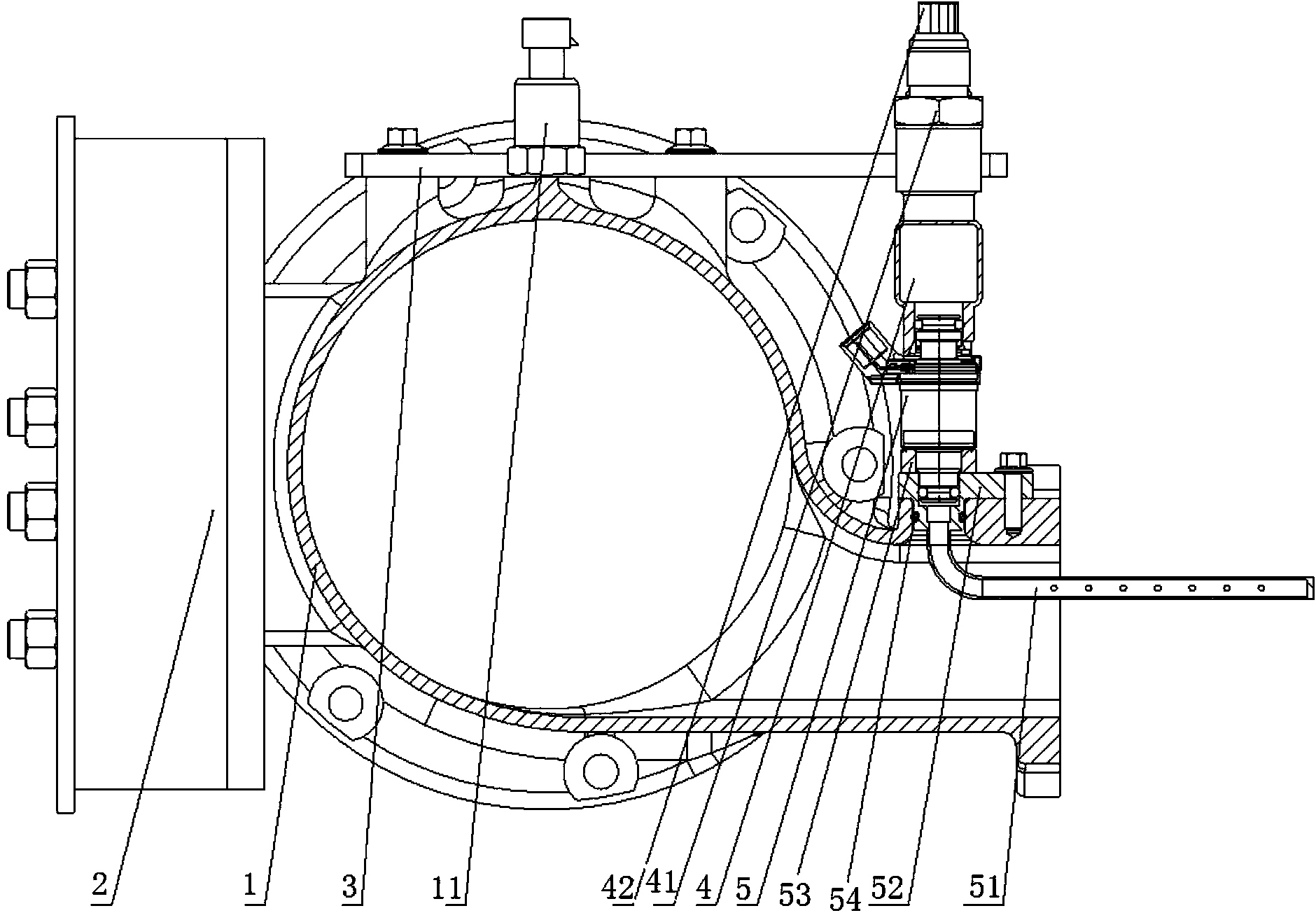

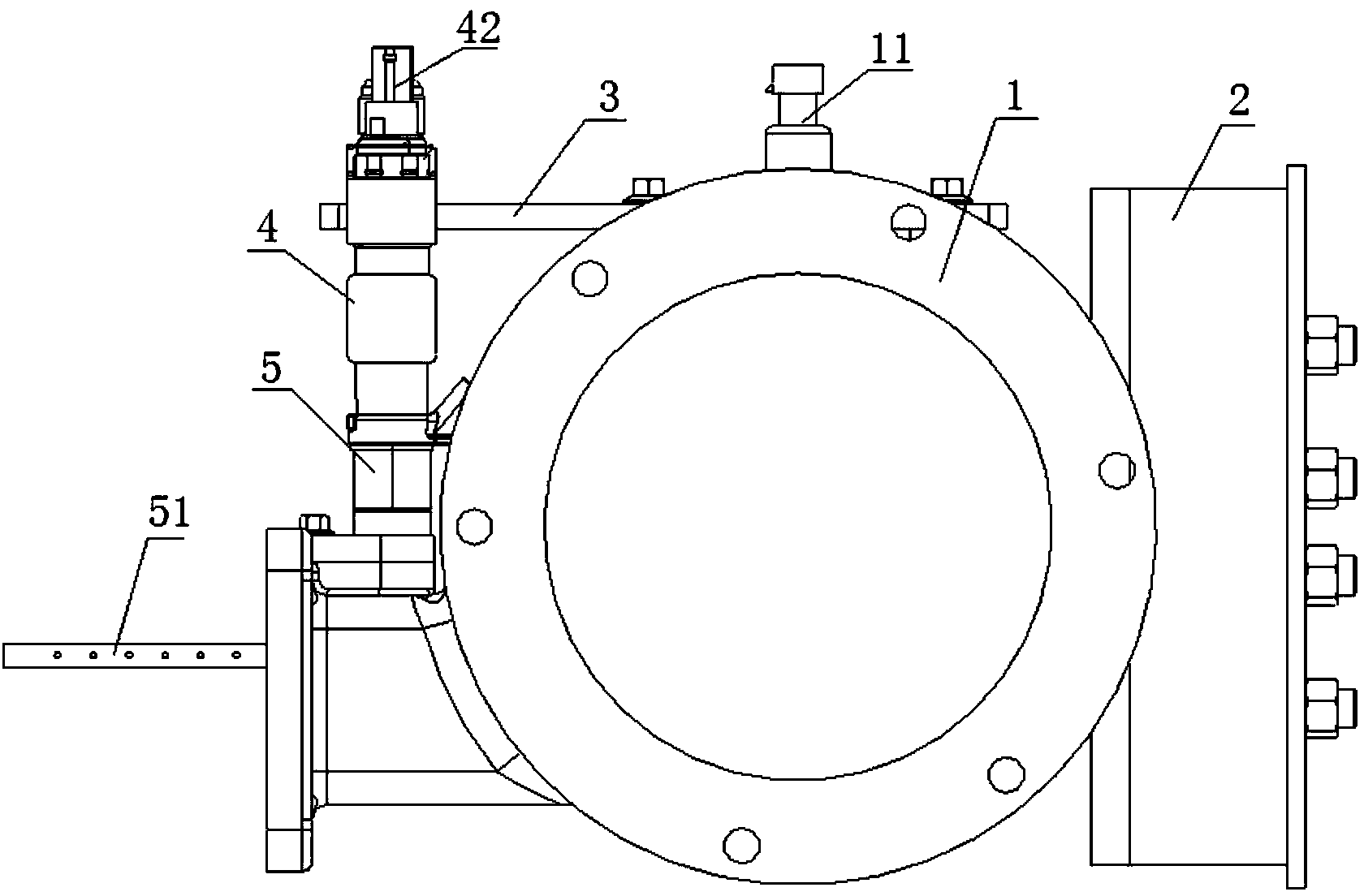

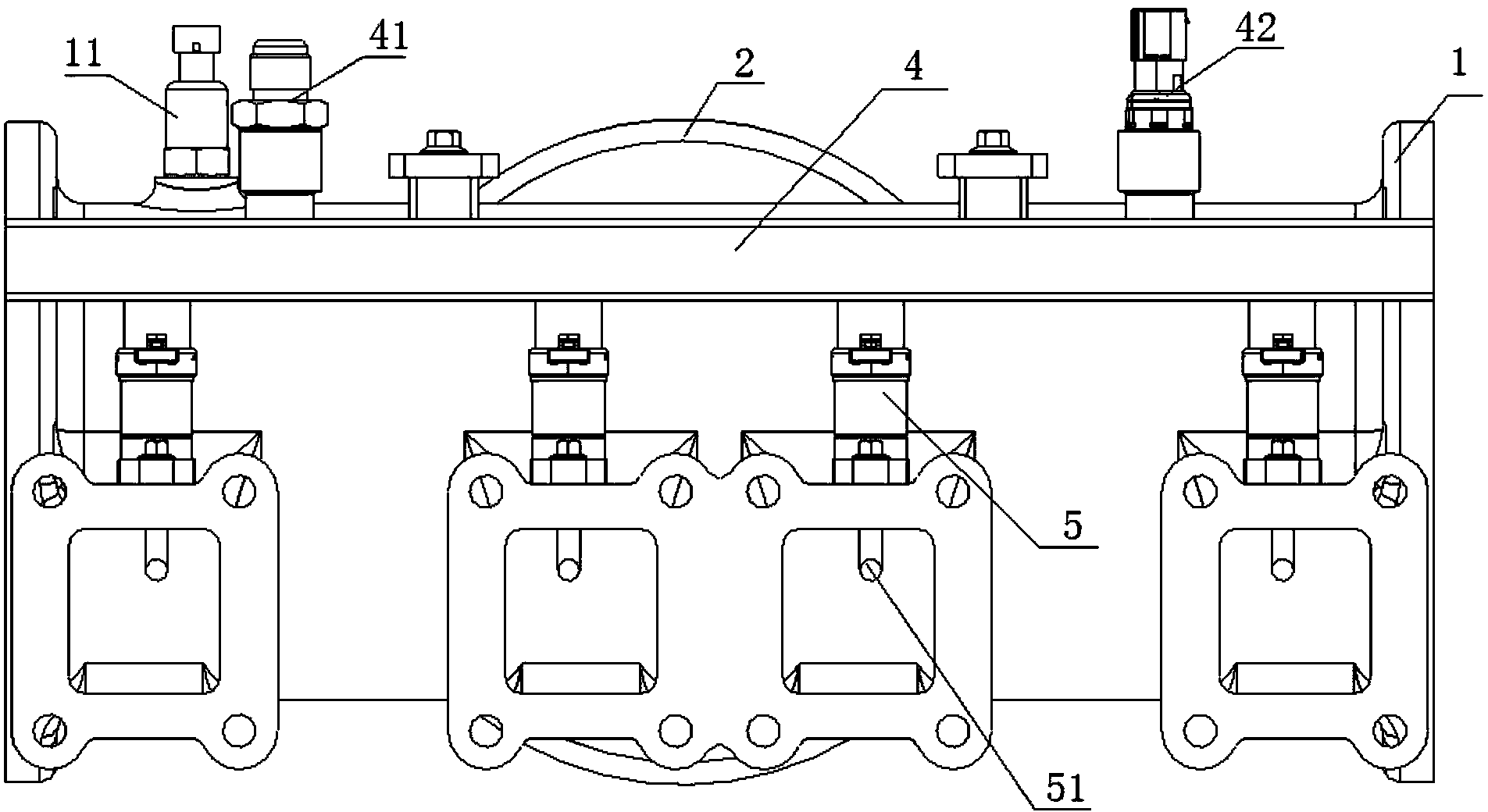

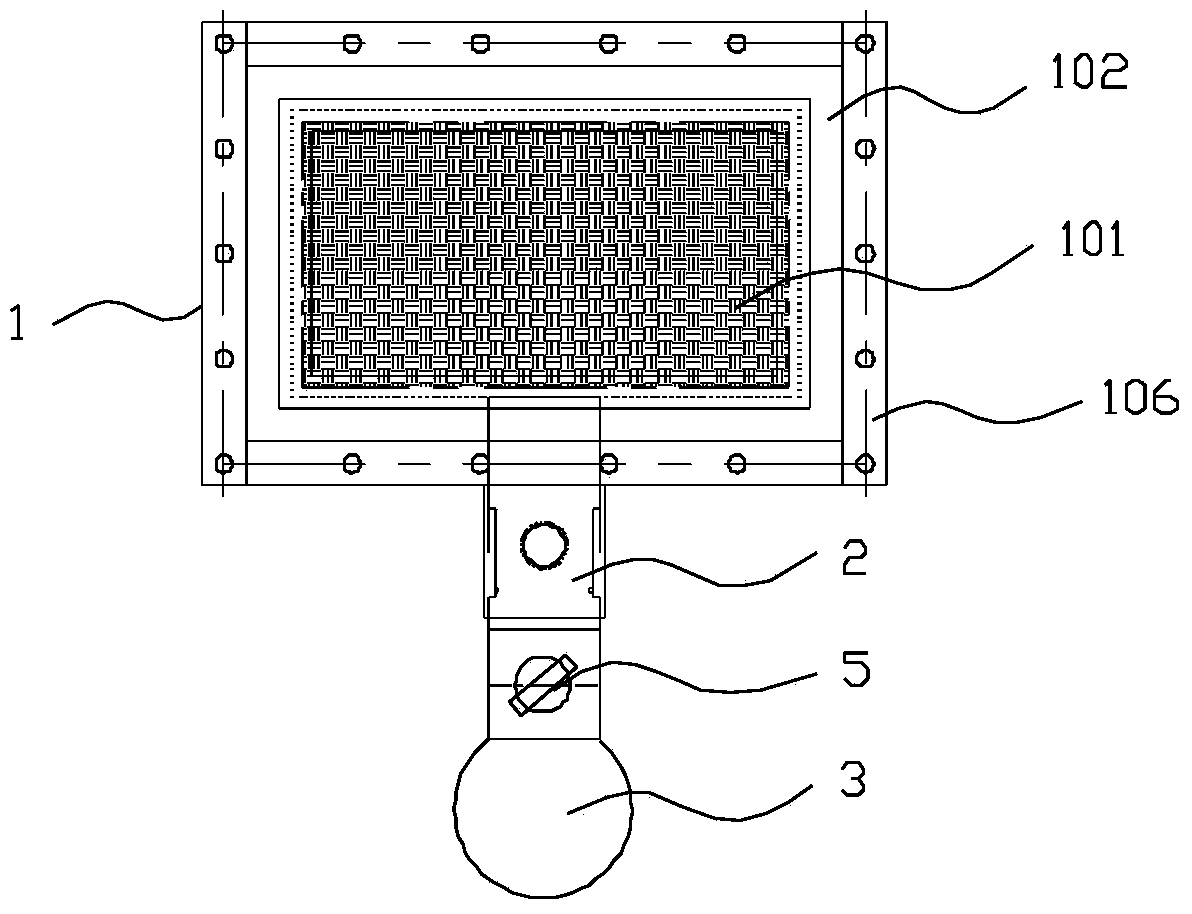

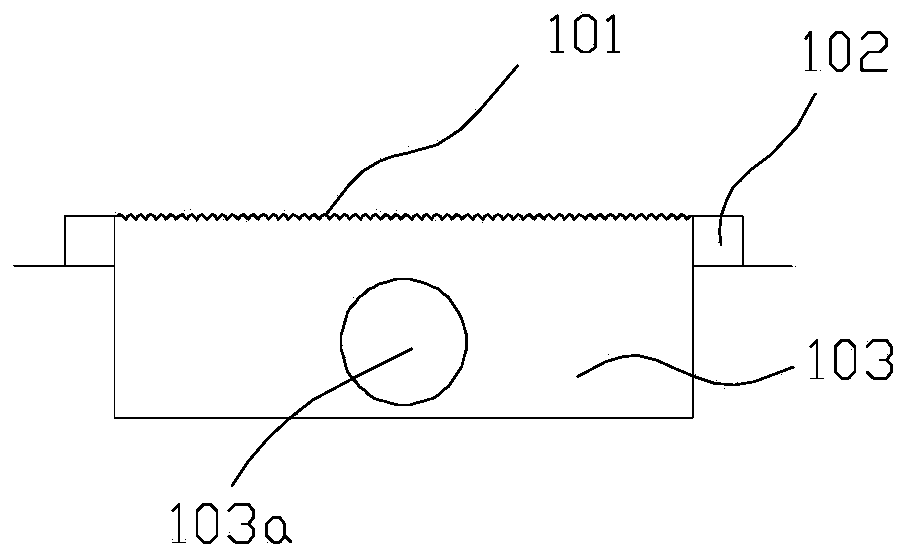

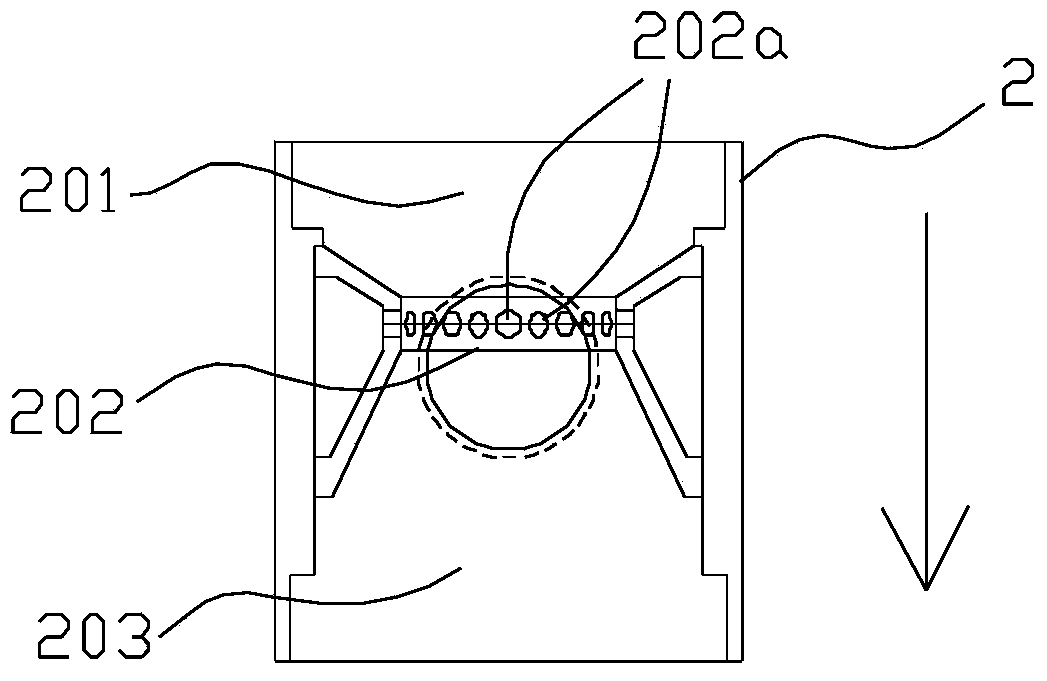

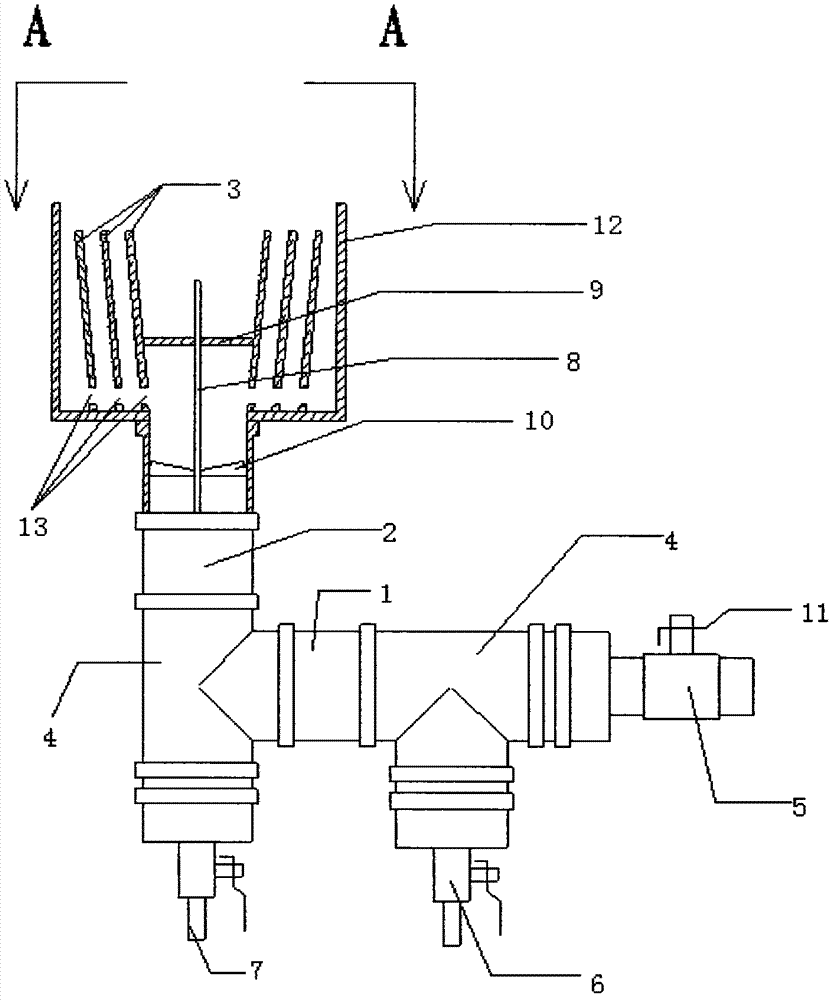

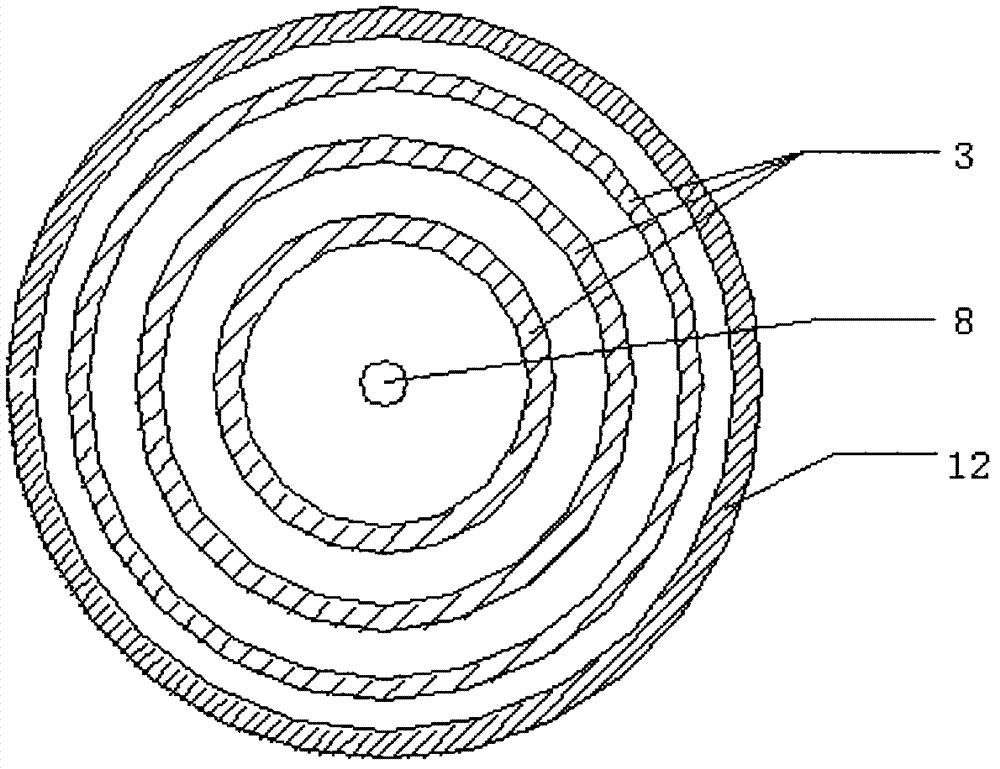

Fuel gas supply system of double-fuel diesel engine

ActiveCN103485944ACompact and reasonable structureSolve backfire problemsInternal combustion piston enginesFuel supply apparatusCommon railInlet pressure

The invention discloses a fuel gas supply system of a double-fuel diesel engine. The gas supply system comprises a gas inlet pipe, a pressure relief flame retardant device and a fuel gas common rail pipe, wherein the gas inlet pipe is provided with a gas inlet pressure sensor, the pressure relief flame retardant device is installed on the back sides of gas inlet manifolds of the gas inlet pipe, the fuel gas common rail pipe is fixedly arranged on the gas inlet pipe and is provided with a fuel gas inlet joint and a fuel gas common rail pipe pressure sensor, gas outlets are provided with fuel gas ejectors, and fuel gas jet tubes of the fuel gas ejector extend into the gas inlet manifolds of the gas inlet pipes corresponding to cylinders. The fuel gas supply system of the double-fuel diesel engine is compact and reasonable in structure, and the fuel gas jet tubes are arranged on the gas inlet manifolds corresponding to the cylinders, so that fuel gases are mixed in gas inlet passages of cylinder covers, and the response speed is high; each cylinder is capable of controlling the opening and closing of fuel gas through the corresponding fuel gas jet tube, so that scavenging loss in a valve overlapping time is eliminated.

Owner:GUANGXI YUCHAI MASCH CO LTD

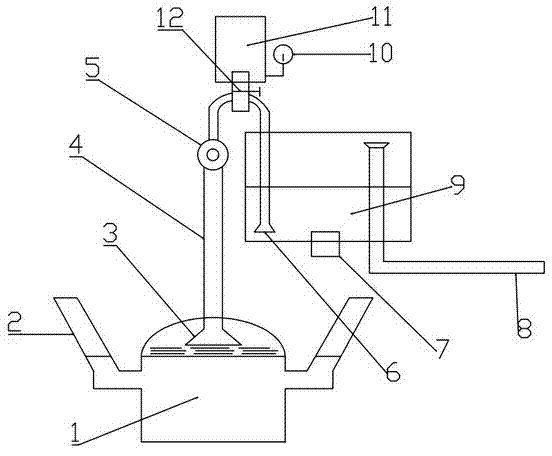

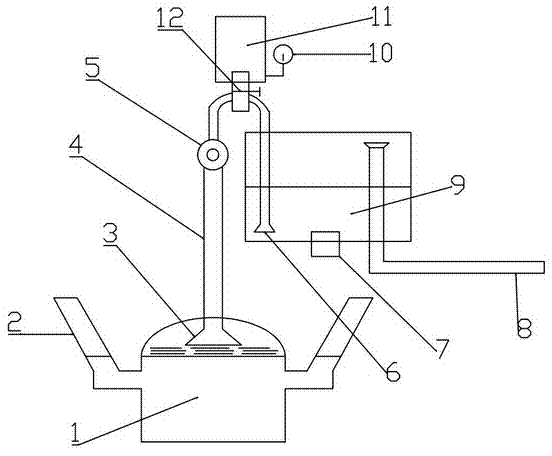

Commercial high-efficiency energy-saving gas burner

InactiveCN101619852AIncrease temperatureFierce firepowerIndirect carbon-dioxide mitigationGaseous fuel burnerGas burnerEngineering

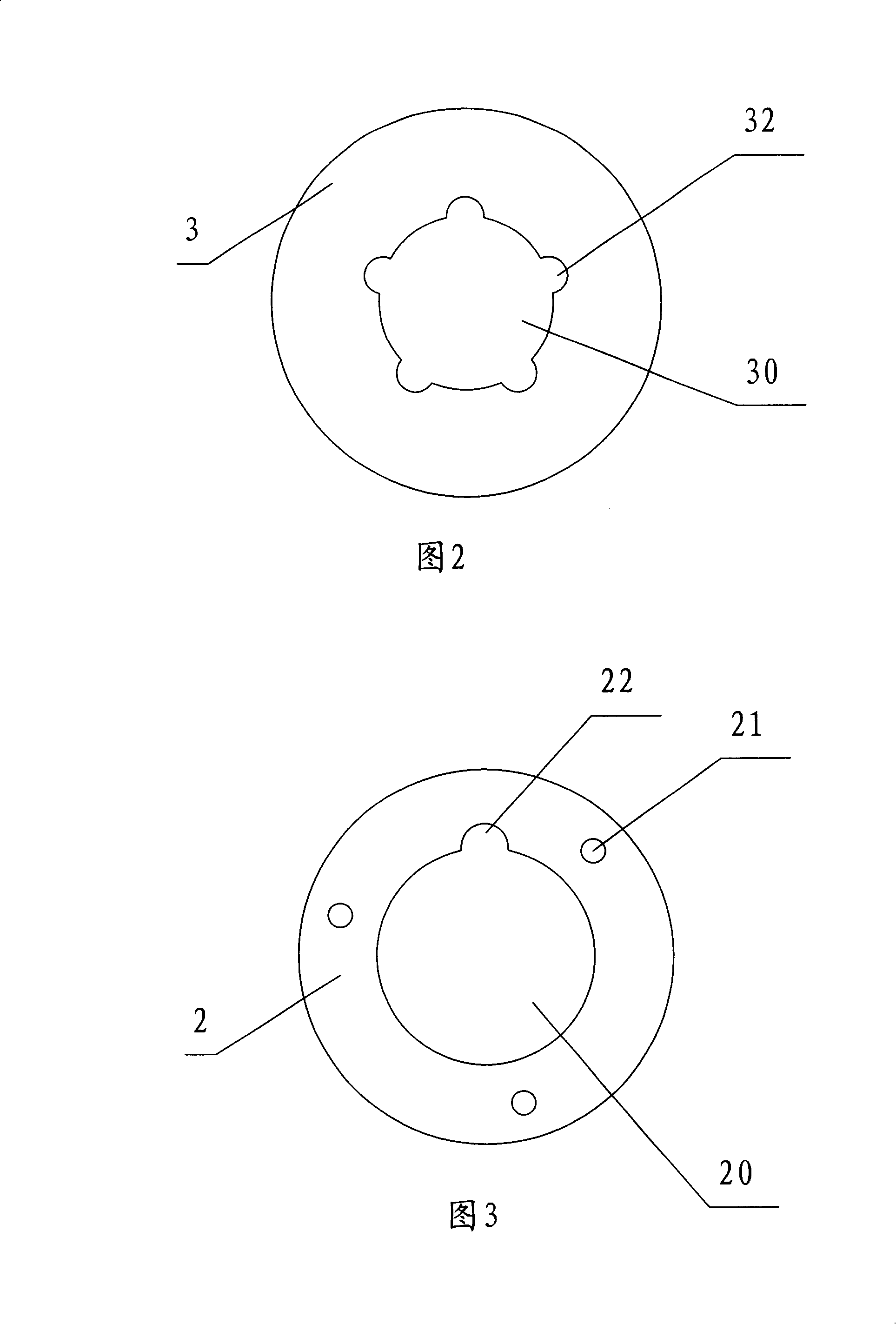

The invention discloses a commercial high-efficiency energy-saving gas stove head comprising a stove head outer sleeve, a stove ring, a stove core, a gas guiding cover, a gas nozzle, an air distributing disk, a gas cavity, an air inlet pipe, and the like. The commercial high-efficiency energy-saving gas burner is characterized in that the stove ring and the stove core which are supported by the gas guiding cover are integrally arranged in the stove head outer sleeve, the lower side wall of the gas guiding cover is provided with an air inlet hole, a stove core through hole which passes through the stove core is evenly arranged on the stove core, the upper part of the stove head outer sleeve is horizontally connected with the air inlet pipe, and the gas nozzle is evenly and vertically arranged on the upper end surface of the gas cavity, passes through the bottom of the stove head outer sleeve and is inserted into the stove core through hole upwards. The commercial high-efficiency energy-saving gas burner can lead cold air to sufficiently absorb heat of the stove ring and the stove core, divide gas into a plurality of blasts, use high-speed gas to roll high-temperature to burn, increase gas burning efficiency and thermal efficiency of the stove head and have strong firepower, does not have temper risks and is suitable for the catering industry.

Owner:HEFEI CENTURIES FIVE STAR CATERING EQUIP LIABILITY

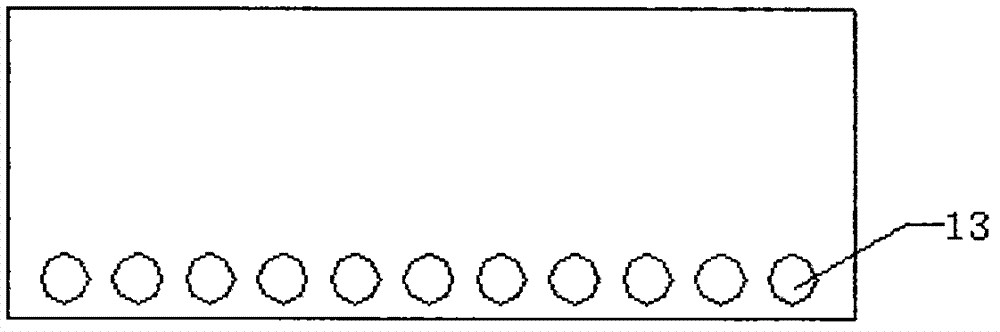

Industrial gas burner

ActiveCN102052677AOvercome temperingAvoid clogging and depositsGaseous fuel burnerProcess engineeringCombustion chamber

The invention discloses a burner for burning an industrial gas. The structure of the industrial gas burner is as follows: a gas chamber is arranged at the tail end of a gas supply pipe, the gas chamber is separated from an air chamber by a partition plate, a gas distribution pipe bundle is arranged on the partition plate and positioned inside the air chamber, guide vanes are arranged inside the individual gas distribution pipes, holes are formed on the walls of the individual gas distribution pipes and communicated with the air chamber, and the distance from the tail end on the downstream side of the gas distribution pipe bundle to the margin of the tail end of the air chamber ranges from 30 mm to 50 mm, which defines a space that serves as a gas and air mixing and combustion chamber.

Owner:兰州泰得燃烧设备工程有限公司

Micro-combustion thermoelectric generator based on porous medium micro-combustion

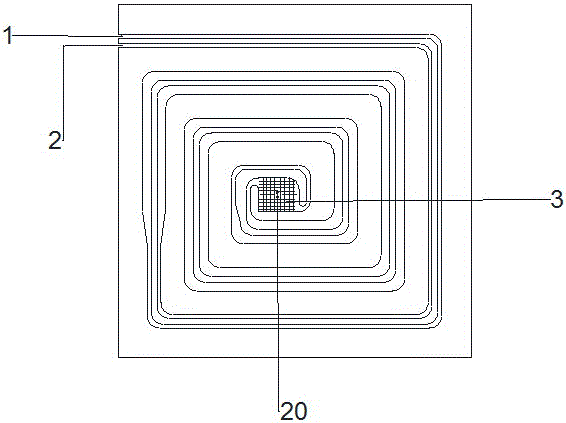

ActiveCN105827152AReduce volumeFix ignition problemsIndirect carbon-dioxide mitigationGenerators/motorsCombustion chamberPorous medium

The invention discloses a micro-combustion thermoelectric generator based on porous medium micro-combustion. The structure of the micro-combustion thermoelectric generator is displayed in a flake-shape, and is successively formed from top to bottom by a fuel storage layer, an upper thermoelectric generation sheet, an upper thermal insulation layer, a combustion module, a lower thermal insulation layer, a lower thermoelectric generation sheet, and an oxidant storage layer, wherein a combustion chamber is arranged at a hot end of each thermoelectric generation sheet; a gas preheating layer is arranged at a cold end of each thermoelectric generation sheet; the combustion module comprises an inlet channel, an outlet channel and a combustion chamber; the inlet channel is a square double helix parallel structure; the center combustion chamber is filled with porous mediums; and the upper and lower thermal insulation layers are filled by mixture of conduction oil and trace inert gas. The micro-combustion thermoelectric generator based on porous medium micro-combustion has the advantages of being high in energy, being small in volume, being light in weight, having no noise, being continuously stable and being low in discharge, and mainly aims at the mini electronic equipment field, and is suitable for the field and for power supply of mini precision portable equipment of the military and aerospace field.

Owner:HANGZHOU DIANZI UNIV

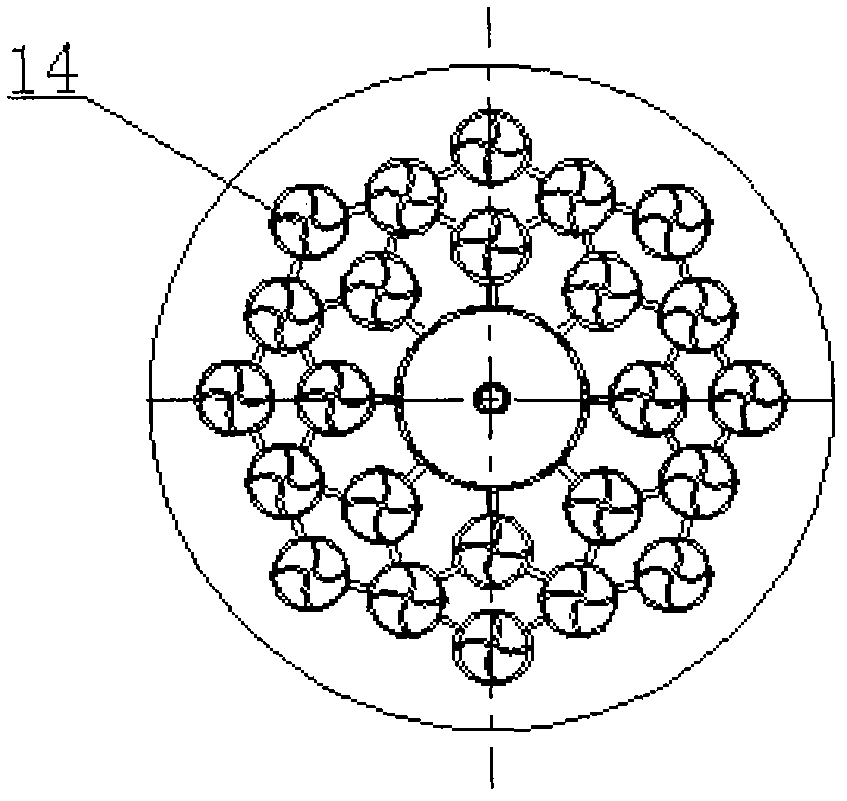

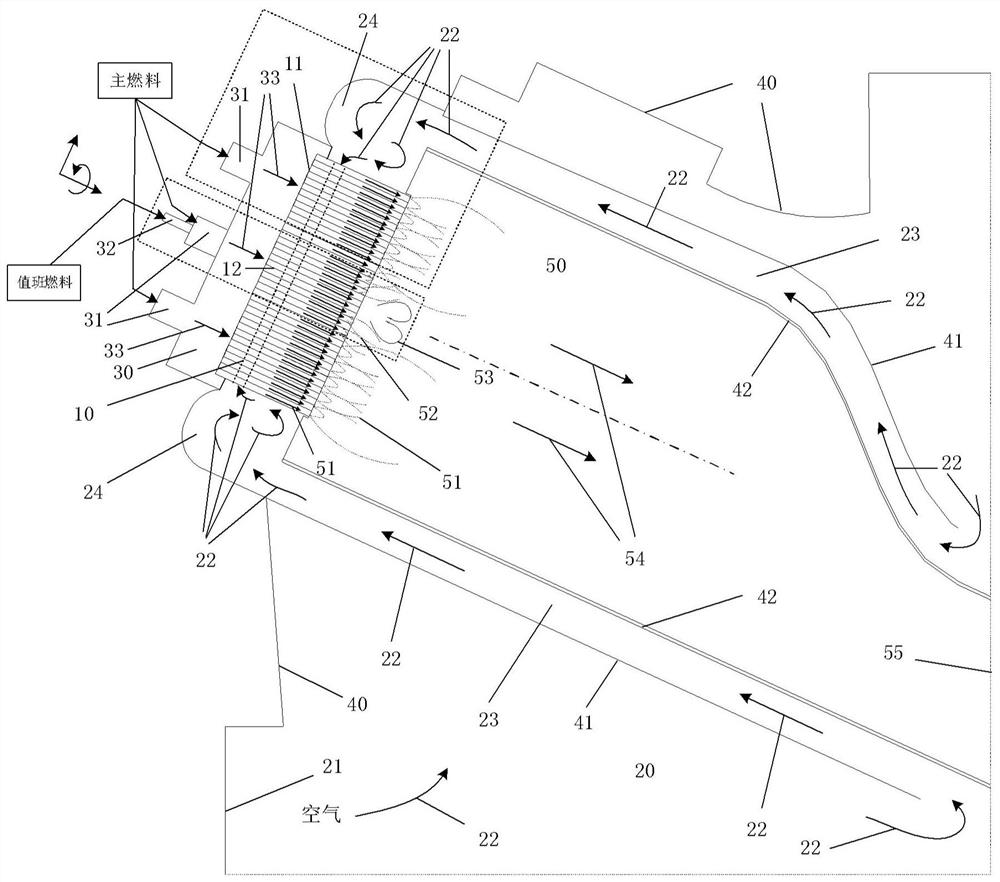

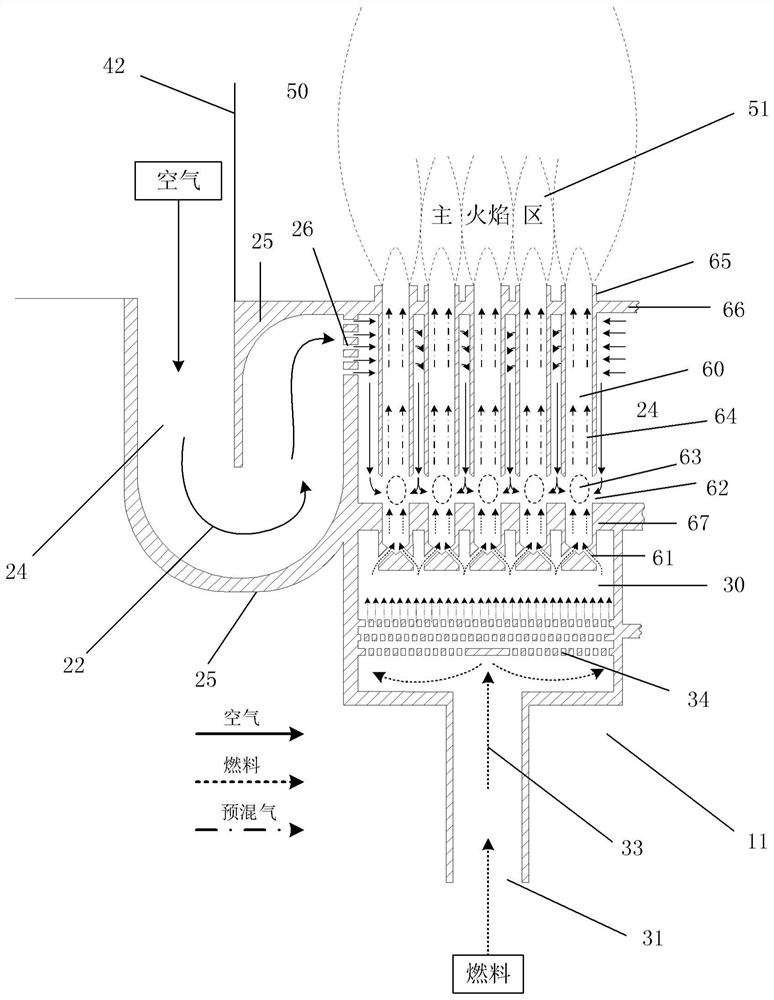

Micro-premixing combustion chamber used for natural gas turbine and applied to wet air circulation

PendingCN111765491AImprove scalabilityImprove blending uniformityContinuous combustion chamberAir cycleCombustion chamber

The invention discloses a micro-premixing combustion chamber used for a natural gas turbine and applied to wet air circulation. The micro-premixing combustion chamber used for the natural gas turbineand applied to wet air circulation comprises a combustor main body, a flame tube and a combustion chamber cartridge, wherein the combustor main body is arranged on the head part of the combustion chamber; the flame tube is arranged in the combustion chamber cartridge, and is a cylindrical wall surface wrapping the combustion chamber, and the inner side of the wall surface is a combustion area of the combustion chamber; a main fuel inlet and an on-duty fuel inlet are formed in the front end of the combustor main body, and the main fuel inlet is used for inputting a fuel into a main nozzle of acombustor; the on-duty fuel inlet is used for inputting the fuel into an on-duty nozzle of the combustor; and an air chamber is formed in the bottom of the combustion chamber, the air chamber is wrapped with a gas turbine cartridge, communicates to a gap which is formed by a lining of the combustion chamber and the flame tube, and feeds air which comes from an upstream air compressor outlet into an air bin of the combustor through the gap.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

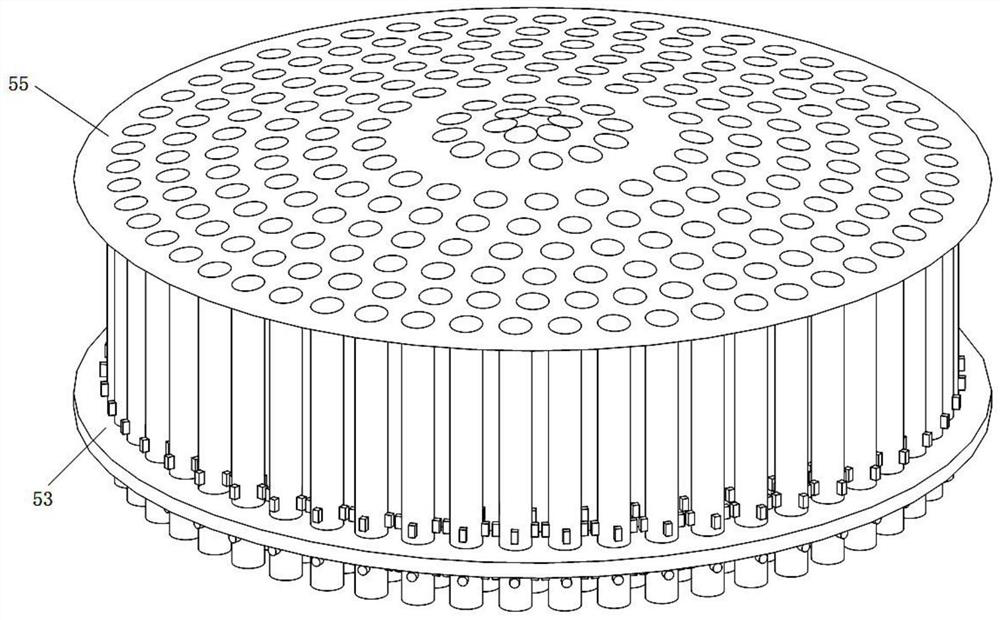

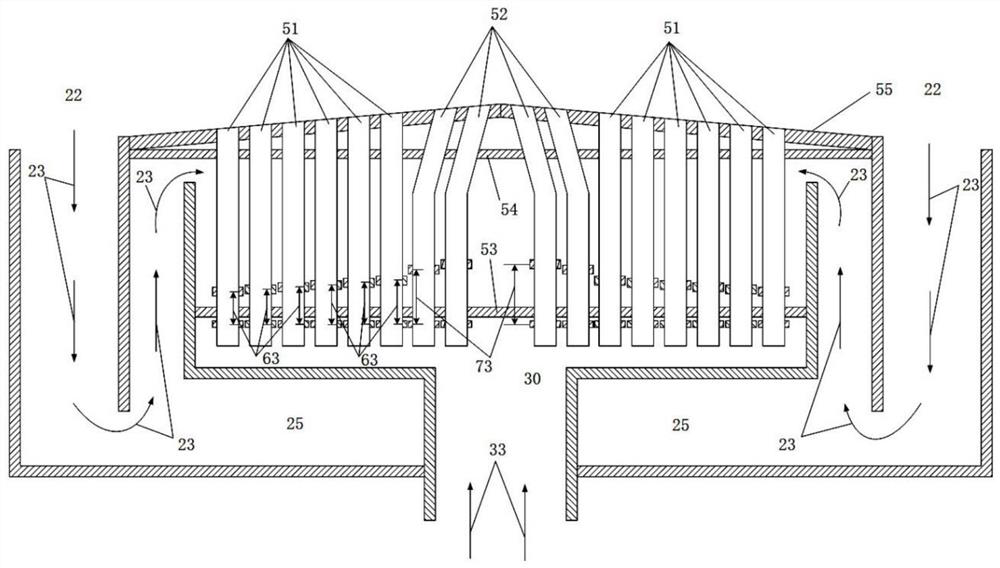

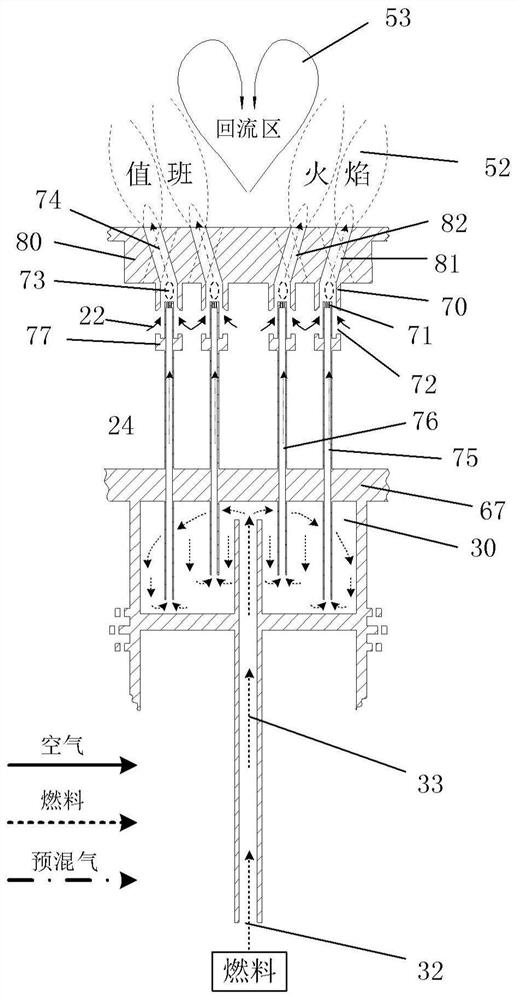

Micro-premixing on-duty nozzle assembly and micro-premixing combustion chamber of gas turbine

PendingCN111928295ARaise ignitionImprove flame transfer performanceContinuous combustion chamberCombustion chamberGas turbines

The invention discloses a micro-premixing on-duty nozzle assembly and a micro-premixing combustion chamber of a gas turbine. The micro-premixing combustion chamber of the gas turbine comprises a flametube and a combustor, the combustor is arranged at the end part of the flame tube; the combustor comprises a plurality of combustor main nozzle areas and a combustor on-duty nozzle area; the structure of the combustor on-duty nozzle area is the same as that of the micro-premixing on-duty nozzle assembly; wherein the plurality of combustor main nozzle areas are arranged around the circumference ofthe combustor on-duty nozzle area. Compared with a traditional combustion chamber of the gas turbine, the center on-duty nozzle enables a certain backflow area to be formed near an outlet of the on-duty nozzle through space angle arrangement, and therefore the flame stabilizing effect is achieved; and meanwhile, the lengths of fuel conveying pipes on an inner ring and an outer ring of the on-dutynozzle are different, each main nozzle micro-premixing pipe can adopt different structure schemes, inherent frequency difference is achieved, the thermo-acoustic coupling probability is reduced, andthe problem of unstable combustion can be effectively avoided.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

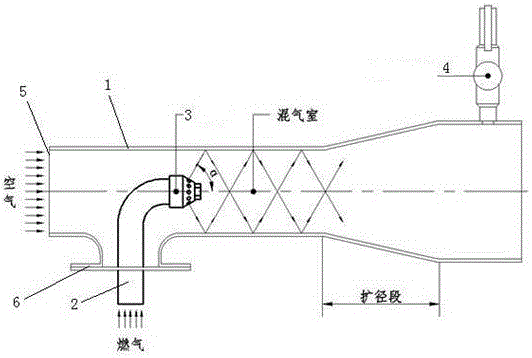

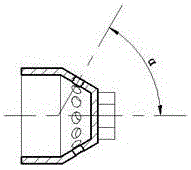

Mandatory all-over three-dimensional gas mixing chamber

The invention belongs to the technical field of gas mixture application, in particular to disclose a mandatory all-over three-dimensional gas mixing chamber. The gas mixing chamber comprises a pipeline, an air inlet placed on the pipeline, a gas duct mounted a flange, a gas duct placed inside the gas duct mounted a flange, and a nozzle placed at the end of the gas duct, wherein the nozzle is evenly provided with a plurality of spray orifices, and the connecting section of the gas duct and the nozzle is a curving structure. The mandatory all-over three-dimensional gas mixing chamber has the advantages of being reasonable in design structure, evenly and high efficient in mixing the gas and the air, meeting the burning gas requirement of the mandatory all-over static surface combustion system, low in CO and NOx emissions by evenly mixing and sufficiently burning, realizing the production requirement of energy-saving and emission reduction, effectively prolonging the service of the firing level, reducing the cost on businesses, effectively solving the problem of temper and guarantying the safety of mixed workloads by the increased overpressure air outlet valve.

Owner:XINGHUA ZIBANG GAS DEVICE TECH CO LTD

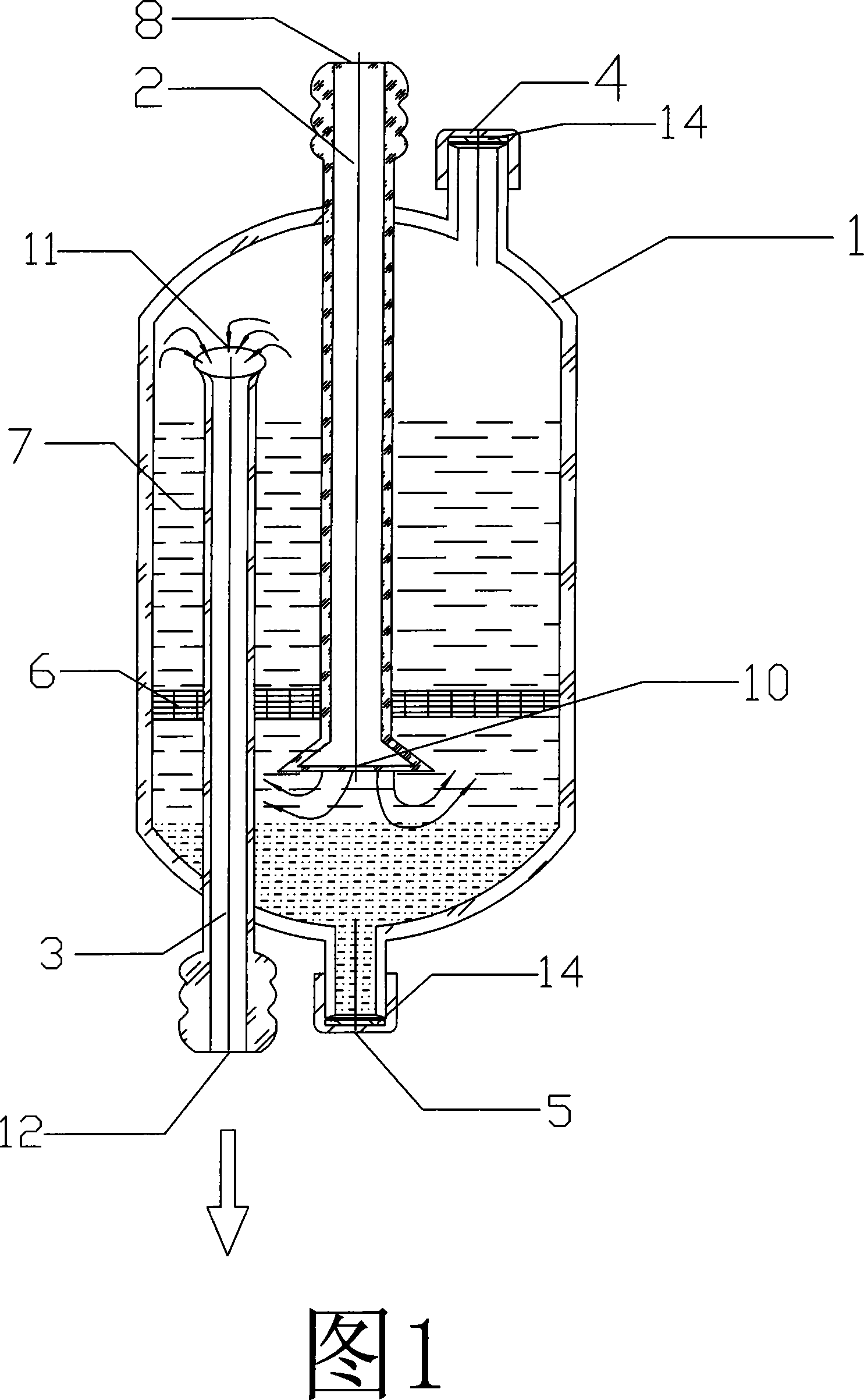

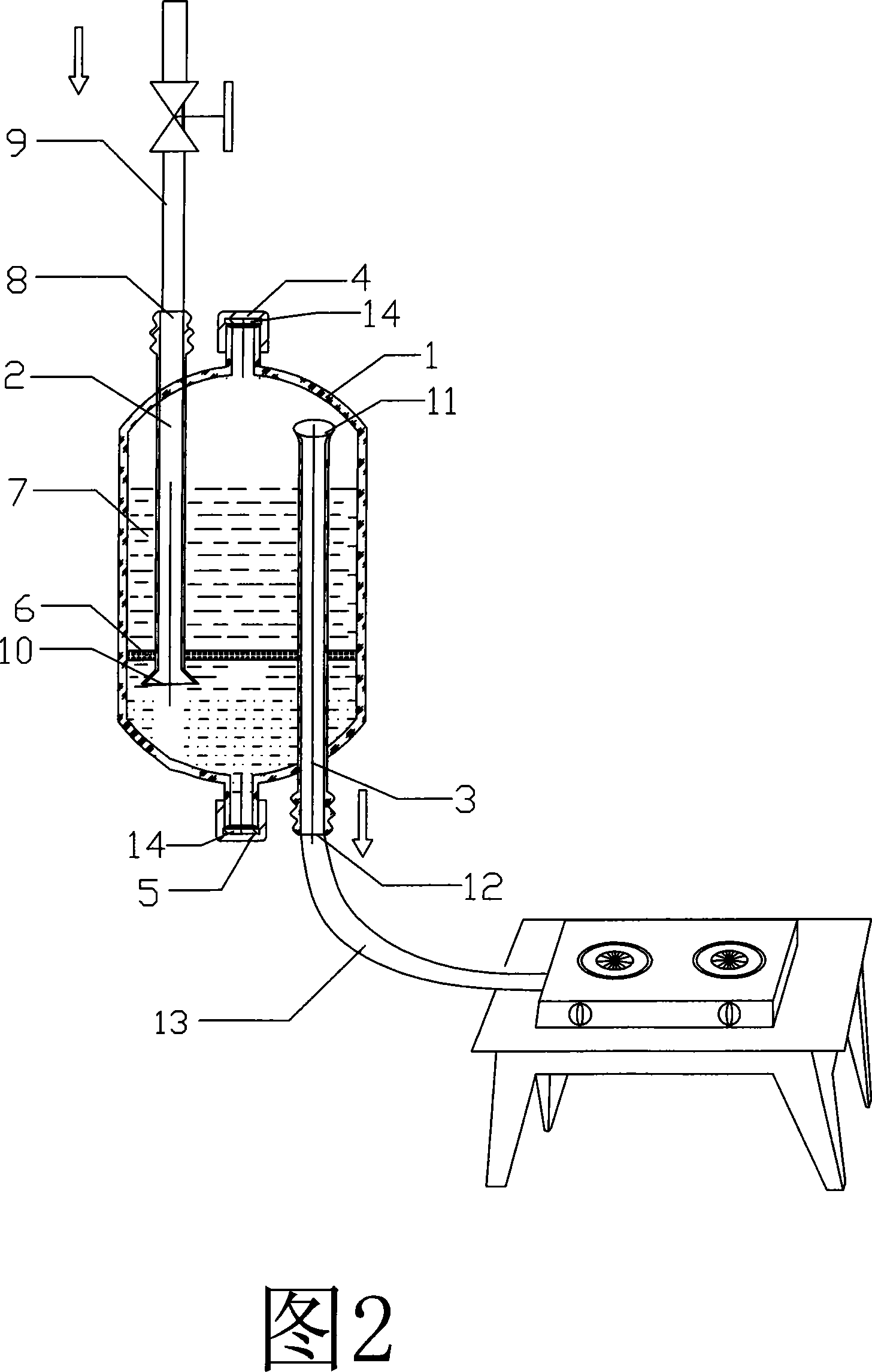

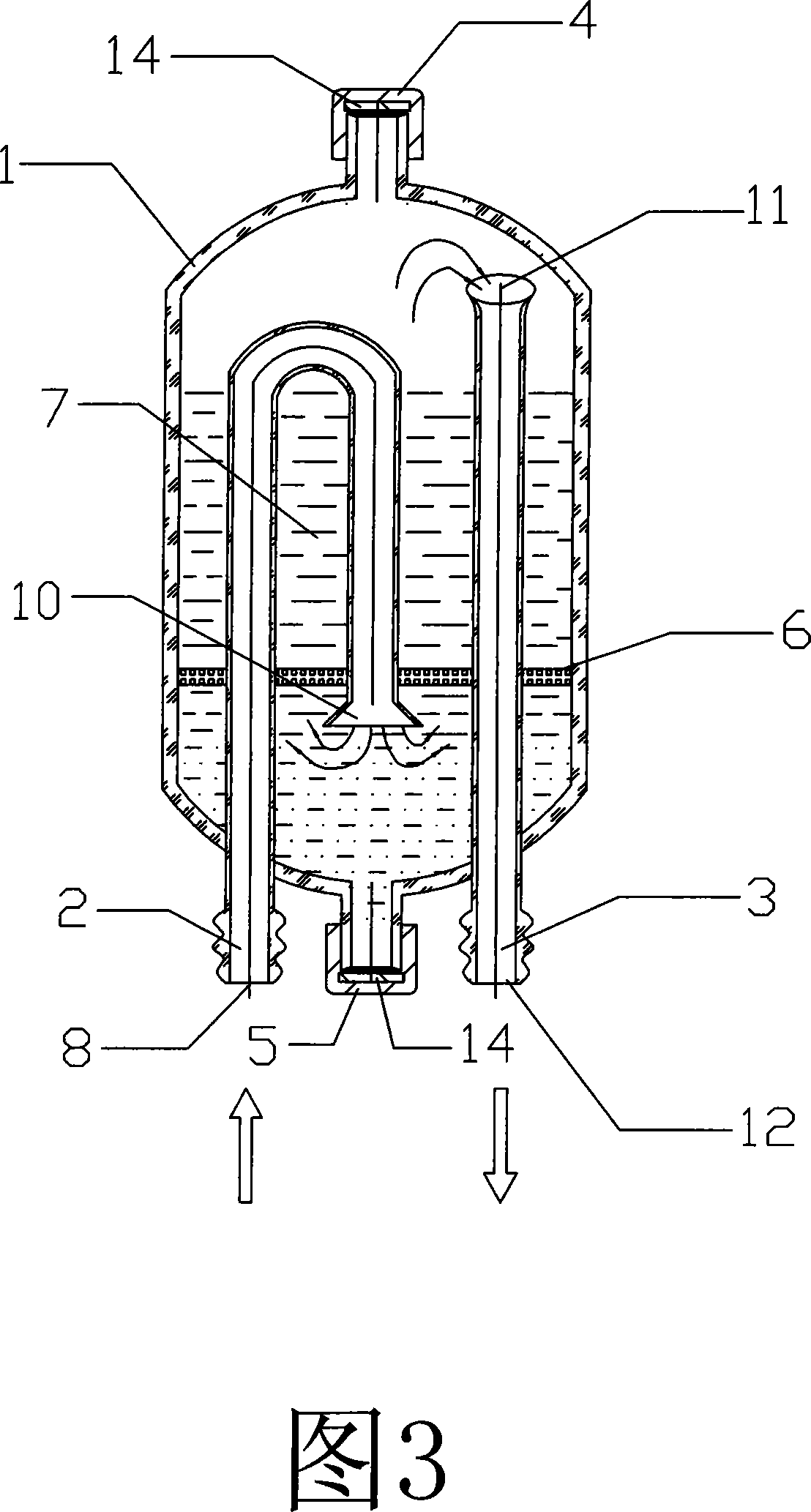

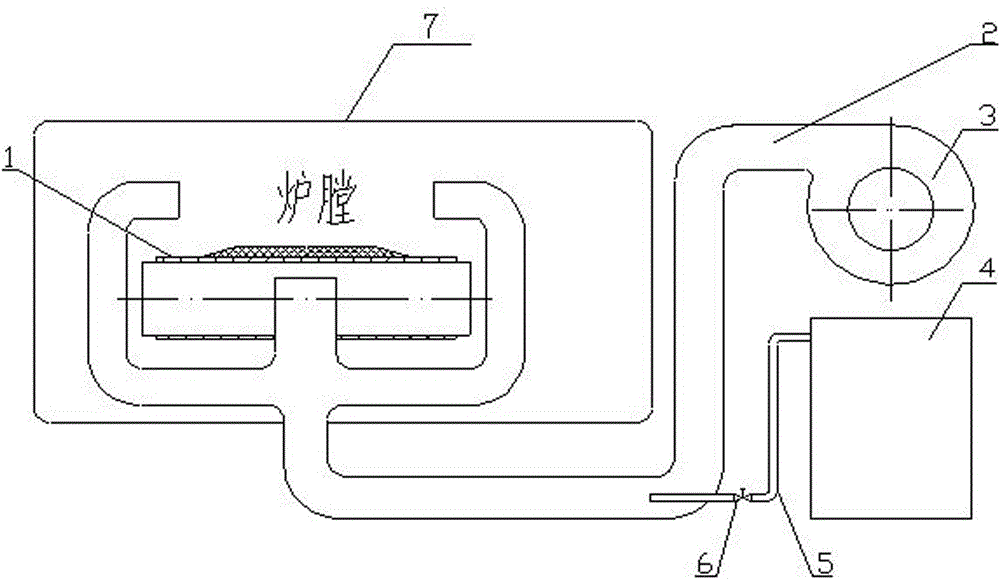

Protective system for methane tank

InactiveCN102304466AStop the explosionHigh purityGas production bioreactorsWaste based fuelFiltrationAir pump

The invention discloses a protective system for a methane tank, and belongs to the field of the building of methane tanks. The protective system consists of a methane tank, a material inlet and a protective system, and is characterized in that: a gas collection opening is formed on the upper part of the methane tank and is connected with a gas collection pipe, and the gas collection pipe is connected with a gas tank by a gas extracting pump; the gas extracting pump and the gas tank are controlled by a valve; the valve is also connected with the gas tank; a pressure gauge is arranged on the gas tank; a filter opening of the gas collection pipe is formed at the bottom of a water tank of the protective system; one end of a gas outlet pipe is exposed from the water surface of the water tank, and the other end of the gas outlet pipe extends to users for gas utilization; and a lower sealing cover is arranged at the bottom of the water tank. In the protective system, the explosion of methane in a gas storage tank and a pipeline due to backfire is prevented, and the problem of backfire is solved effectively by taking water as an isolation means. The purity of the methane can be improved, combustible gas contains a certain quantity of solid granules, and part of impurities can be filtered by water filtration conveniently, so the cost is low.

Owner:DALIAN NEW ENERGY IND

Anti-explosion device for combustible gas

InactiveCN101050841AStop the explosionPrevent leakageContainer filling methodsPipeline systemsCombustible gasProduct gas

An explosion-proof device of flammable gas is prepared for setting air inlet pipe air outlet pipe, top seal cover, bottom seal cover and filtering screen in tank body; and using water as isolation means to have backfire problem avoided effectively.

Owner:王景搏

Energy-saving burner for premixed fuel gas to be burnt at positive pressure and steam generator

ActiveCN103953928ARealize automatic flameout protectionOvercome the disadvantages of easy ignition and deflagrationBoiler cleaning apparatusEnergy industryFiberDetonation

The invention discloses an energy-saving burner for premixed fuel gas to be burnt at a positive pressure and a steam generator. According to the burner, a burning surface of the burner is made from aludirome fabric; cooling devices are arranged in the circumferential direction along the edge of the burning surface; the fuel gas and air are completely mixed through a mixer and a premixing cavity, and are burnt at the positive pressure on the surface of the aludirome fabric. The problems that tempering is easily caused in positive-pressure burning, and ignition detonation is easily caused in premixed and enclosed burning are solved, and the burning process is safe and reliable. The burner is adopted in the steam generator; the mixed gas is rapidly burnt out in minimal sealed space formed between a burning part and an inner container of the steam generator, steam is generated fast, and waste heat produced during the steam generating process is effectively utilized; the sealed and premixed burning manner and the reasonable connection of all components enable the size of the steam generator is much less than that of the conventional steam generator; meanwhile, automatic drainage control effectively depresses and relieves the formation of water scale after the conventional steam generator is used for a long time.

Owner:珠海歌林能源科技有限公司

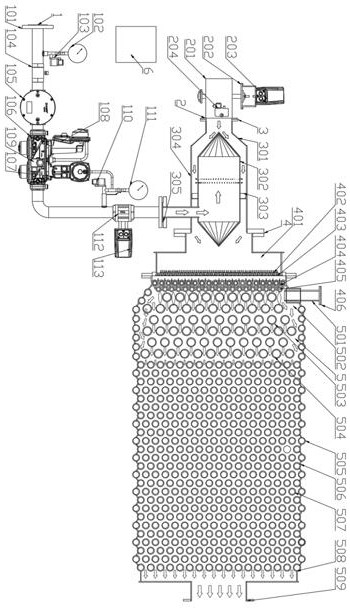

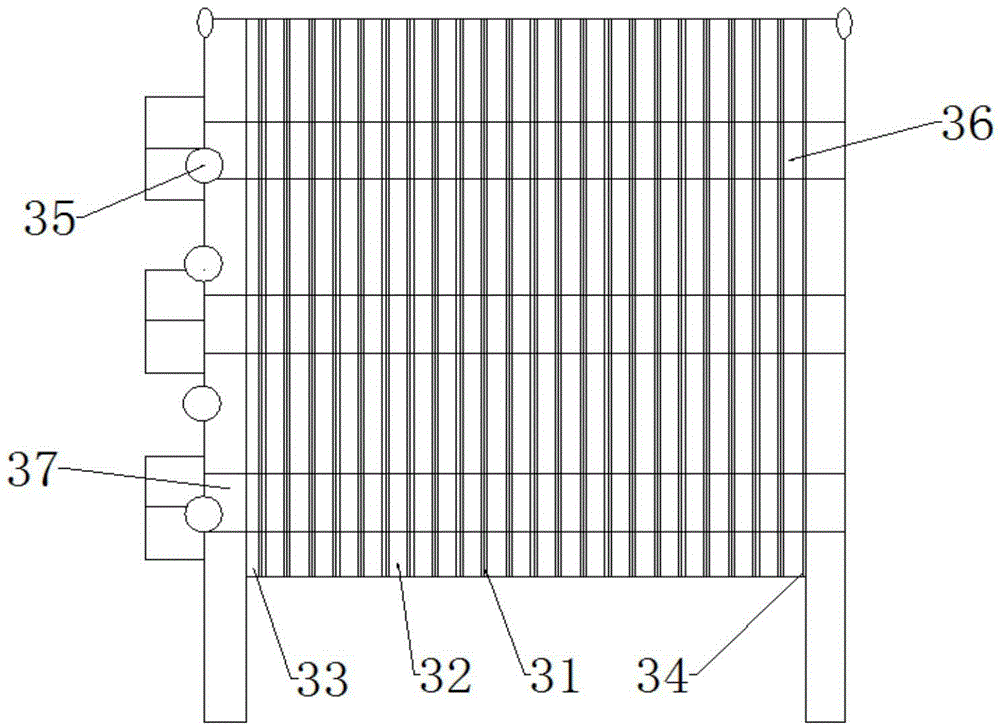

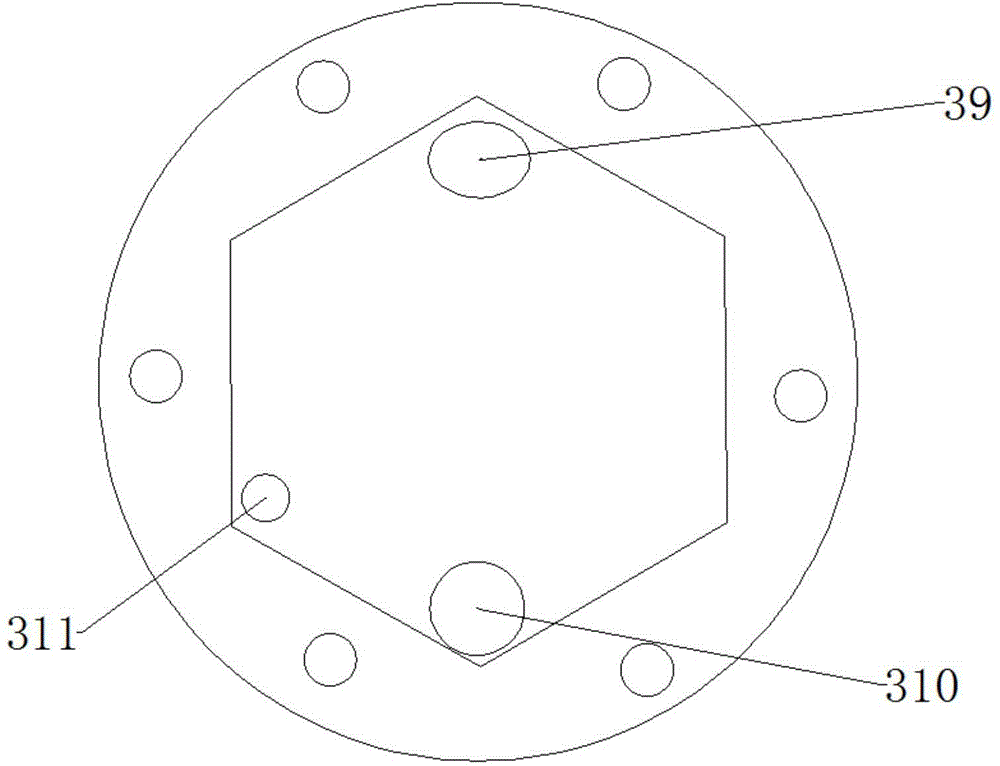

Ultra-low-nitrogen combustion equipment with post-premixing cold flame combustion coupling matrix tube mode wall structure

ActiveCN112815312AGuaranteed stabilityReduce the temperatureGaseous fuel burnerCombustion chamberAir volume

The invention relates to ultra-low-nitrogen combustion equipment with a post-premixing cold flame combustion coupling matrix tube mode wall structure. The ultra-low-nitrogen combustion equipment comprises a fuel gas regulation and control device, an air volume regulation and control device, an air-gas mixing device, a cold flame combustion device, a matrix tube and mode wall device and a comprehensive controller. The fuel gas regulation and control device provides fuel gas for the air-gas mixing device; the air volume regulation and control device provides combustion-supporting air for the air-gas mixing device; the air-gas mixing device conducts jet flow mixing on combustible gas provided by the fuel gas regulation and control device and the combustion-supporting air provided by the air volume regulation and control device, and the combustible gas and the combustion-supporting air are evenly mixed through the air-gas mixing device and then injected into the cold flame combustion device; the mixed gas sequentially passes through a double-layer rectifying plate, a hexagonal heat pipe type cooling fire-retardant tube nest and a flame cooling tube nest in the cold flame combustion device and then enters a combustion chamber for combustion; and after combustion, high-temperature flue gas is subjected to radiation and convective heat exchange in the combustion chamber, then exchanges heat with a medium in the matrix tube and mode wall device and then is discharged into a flue.

Owner:BEIJING BOOSTER BOILER

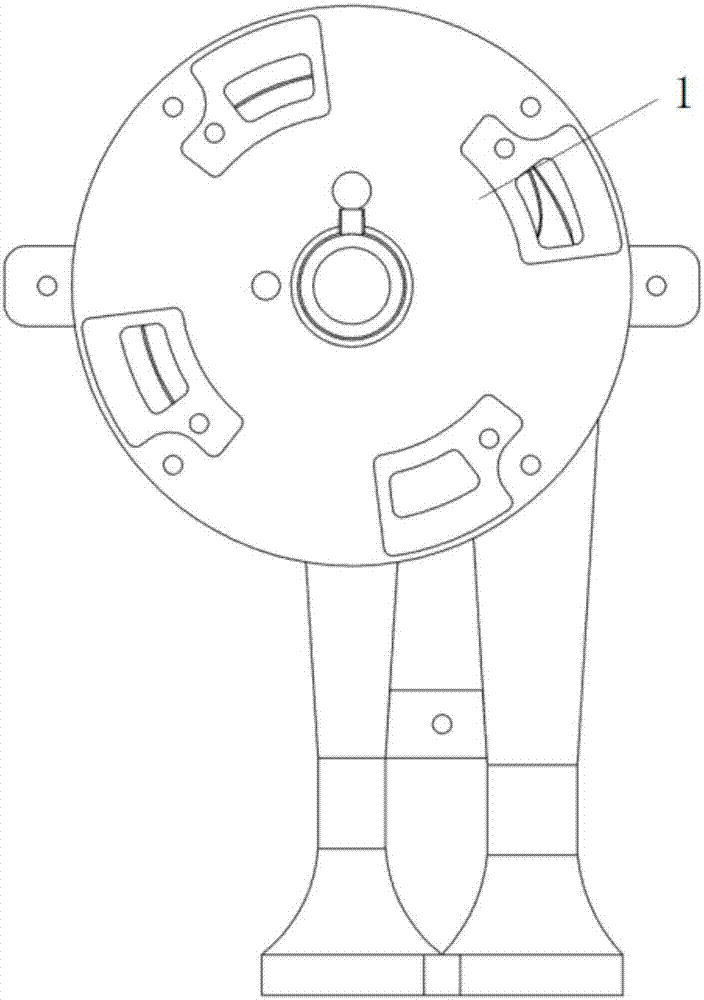

Dry low-emission combustor

The invention relates to the field of design of a dry low-emission combustion chamber of a gas turbine, in particular to a dry low-emission combustor. The dry low-emission combustor comprises a cartridge receiver, a rotatable flow device, a fuel nozzle and a flame cylinder; the rotatable flow device is provided with a body portion and a first boss portion, a first annular inner cavity with an opening in one end is formed between the inner wall of the cartridge receiver and the outer wall of the body portion, a first groove and a second groove which are formed in a side-by-side manner are formed in the outer wall of the body portion in the axis direction, a first through hole and a second through hole are formed in the first groove, a third through hole is formed in the second groove, the fuel nozzle is provided with a circular-ring second boss portion, a main fuel spraying rod, on-duty fuel spraying rods, a center cold air baffle and a conical sleeve, and the flame cylinder is coaxially arranged at one end, back onto the first boss portion, of the rotatable flow device body in a sleeving manner. According to the dry low-emission combustor, good mixing and stable combustion of fuel and air can be effectively achieved, and the common tempering problem in pre-mixing combustion can be prevented.

Owner:AECC SHENYANG ENGINE RES INST

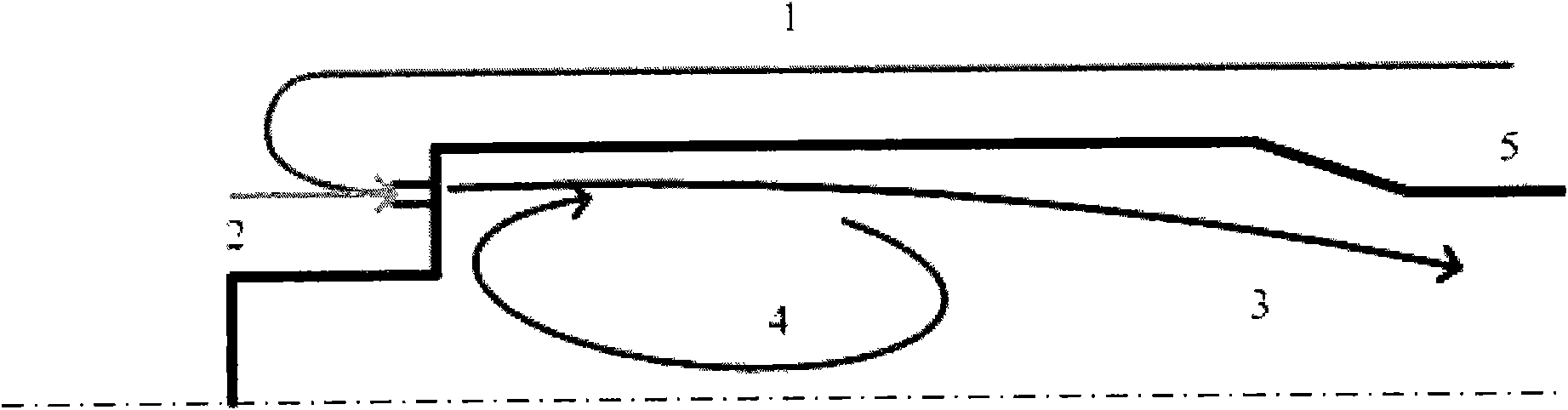

Low-emission environment-friendly vehicle-mounted hydrogen production device and control method

ActiveCN104791150AWon't flow backwardsReduce weightNon-fuel substance addition to fuelInternal combustion piston enginesEnvironmental resistanceHigh pressure

The invention provides a low-emission environment-friendly vehicle-mounted hydrogen production device and a control method. The vehicle-mounted hydrogen production device comprises an engine storage battery, a hydrogen and oxygen production machine, a hydrogen and oxygen production machine switch relay, a hydrogen and oxygen storage system and an electronic control unit. The electronic control unit is connected with the storage battery which is connected to the hydrogen and oxygen production machine through the hydrogen and oxygen production machine switch relay, and the hydrogen and oxygen storage system is connected to the hydrogen and oxygen production machine. The online hydrogen production and storage and hydrogen-oxygen mixture supply system suitable of vehicles is provided to solve the problems that hydrogen infrastructure construction is not enough, hydrogenation is difficult and hydrogen and oxygen storage is hard to achieve through existing hydrogen production systems. Hydrogen and oxygen storage pressure is low (about 3 bar), the strength of a hydrogen and oxygen storage tank can be greatly reduced compared with a traditional automotive high-pressure hydrogen and oxygen storage tank, the weight and manufacturing cost of a hydrogen production system are reduced, and economy and system practicability of a whole vehicle can be conveniently improved.

Owner:南通秀丽环保科技发展中心(有限合伙)

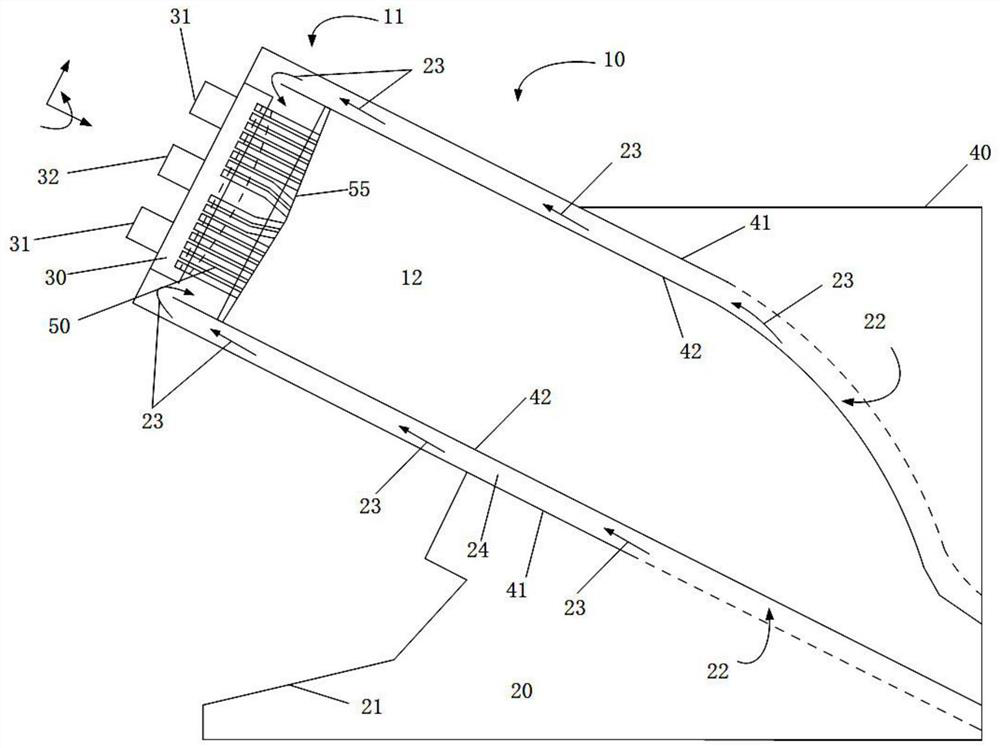

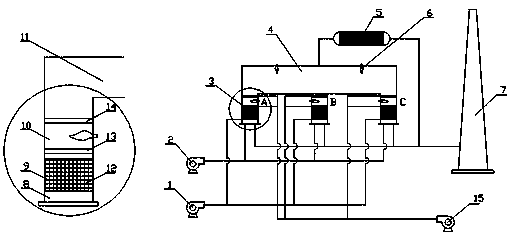

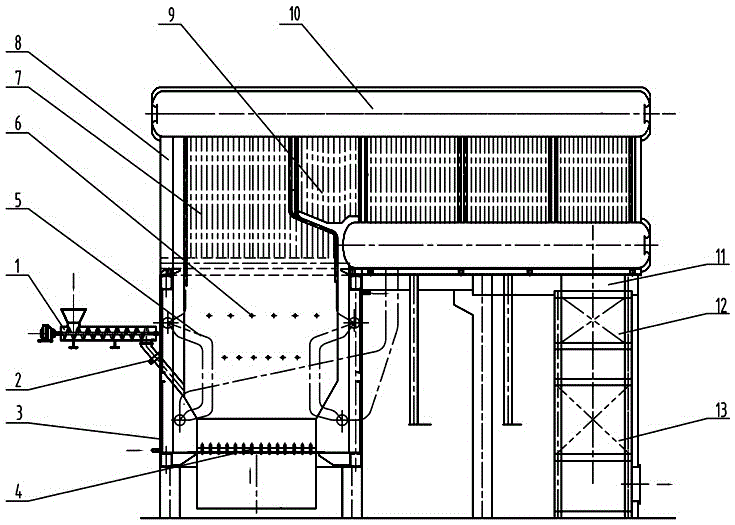

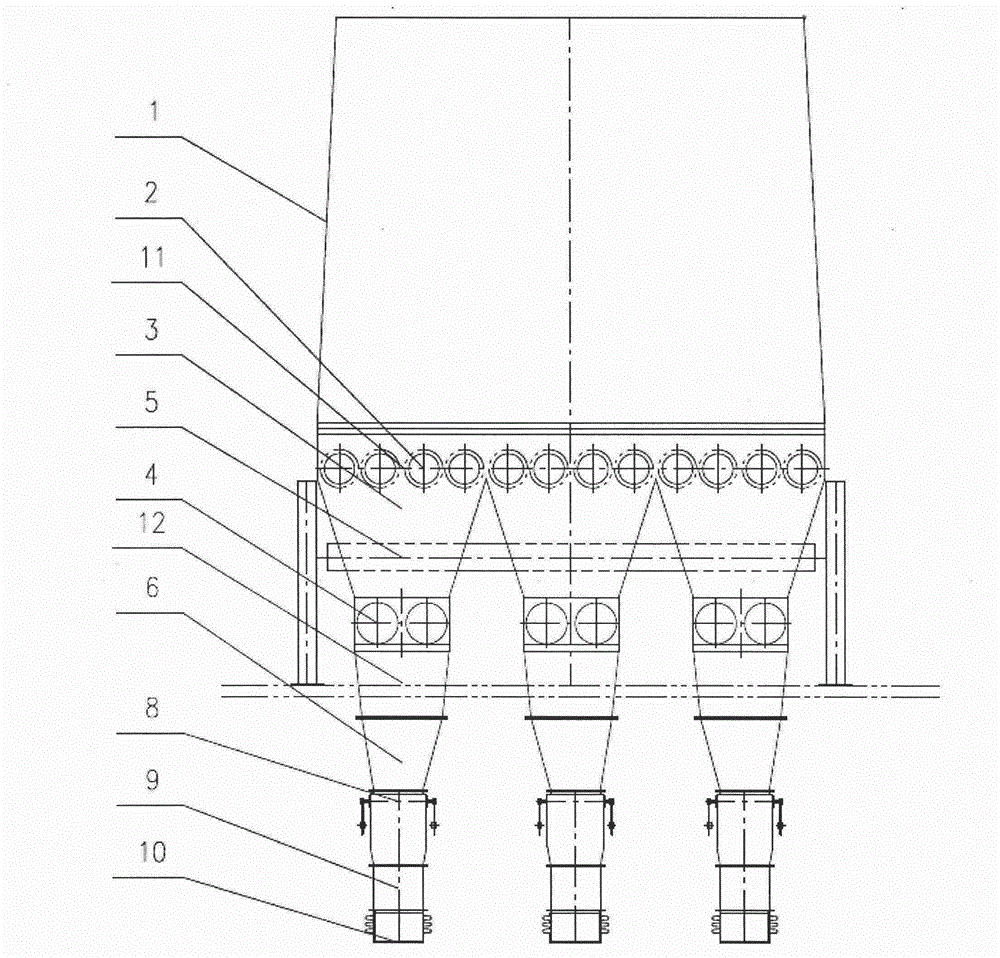

Grading air distribution type heat accumulating type incinerator

ActiveCN107642789AIncrease initial investmentImprove economyIncinerator apparatusEnvironmental resistanceProcess engineering

Provided is a grading air distribution type heat accumulating type incinerator which comprises a purging auxiliary fan, a main fan, a regenerative chamber, an oxidation chambers, an efficient waste heat boiler, energy-saving type pilot flame and a chimney. The regenerative chamber is internally provided with an air distribution section, a heat storage section, an air ring pipe, energy-saving pilotflame and a secondary air ring pipe. By adopting a combustion process of first performing preheating and then performing gradation air distribution incineration, medium and low concentration organicwaste gas containing oxygen (or containing a small amount of oxygen) can be treated. The waste gas cannot maintain the combustion. When the waste gas is treated by a conventional heat accumulating type incinerator, the waste gas needs to be diluted with plenty of air to below the deflagration limit of 25%, so that the waste gas treatment amount, equipment investment and application difficulty aregreatly increased. The grading air distribution type heat accumulating type incinerator is an innovation based on the conventional heat accumulating type incinerator, this type of organic waste can befully and efficiently treated, and the goals of cost reduction, high efficiency, economy and environmental protection are achieved.

Owner:JIANGSU SUNPOWER TECH

Equal-proportion channel combustor achieving uniform gas discharge and gas stove

InactiveCN108006636AStable pressureSolve backfire problemsStoves/ranges topsGaseous fuel burnerEngineeringChange Type

The invention provides an equal-proportion channel combustor achieving uniform gas discharge and a gas stove. The equal-proportion channel combustor comprises a burner, a base, a big burner cap and asmall burner cap. The burner is a gradual change type burner and comprises a venturi injection pipe, an outer ring equal-proportion gradual change type channel and an inner ring gas mixing cavity. Fuel gas passes through the venturi injection pipe, is pre-mixed in a primary air mixing cavity and then enters the outer ring equal-proportion gradual change type channel and the inner ring gas mixing cavity; wherein the gas in the inner ring gas mixing cavity enters the small burner cap via an inner ring channel, and outer ring gas enters a fuel gas channel of the base via the outer ring equal-proportion gradual change type channel and then enters the big burner cap. The channel combustor achieving uniform gas discharge and the gas stove have the beneficial effects that a straight pipe is additionally arranged on the venturi injection pipe, so that the purpose of stabilizing the gas pressure is achieved; the equal-proportion gradual change type spiral gas channel is adopted, so that the gascombustion speed and the gas flow speed achieve balance, and the backfire problem is solved; and double rows of fire holes are adopted, the upper row of fire holes are horizontal, the lower row of fire holes are inclined, and the backfire risk is lowered through the angle change.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

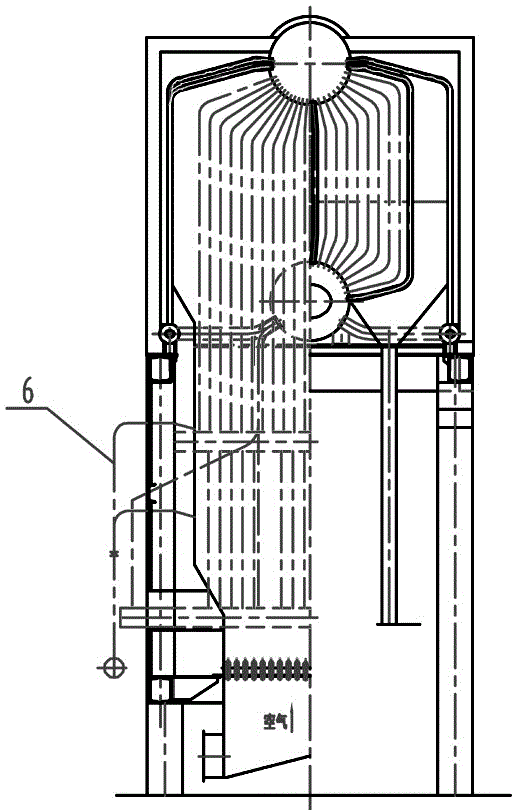

Combined fluidized bed biomass boiler

InactiveCN105066119AEasy to separateExtended burn timeFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEmission standard

The invention discloses a combined fluidized bed biomass boiler which comprises a hearth, a secondary air pipe, a water cooling pipe, a fluidized bed and a tempering preventing feeding device. The tempering preventing feeding device comprises a feeding pipe and a jacket, and an air supply interlayer is formed between the jacket and the feeding pipe. The combined fluidized bed biomass boiler is low in tempering accident rate, and multiple kinds of fuel can be combusted at the same time. The load adjusting range is wide, the environmental protection performance is excellent, emissions of NOx and SO2 are effectively controlled, and the national emission standard is met. Heat conduction in the boiler is even, high heat accumulation performance is achieved, the heat recovery efficiency is high, and a recovery heat source is stable. The recyclability of ash residues is high.

Owner:XIANGTAN BOILER

Injection type combustion nozzle

The invention discloses a spray burner body, which comprises a spray cylinder body, a steady burning tablet and a reverse-inject generator. The reverse-inject generator is shaped as a reversing pan, which is provided with a plurality of air blast burning ports on side edge and is fixed and connected with a supporting sheet at lower section of the side edge; the supporting sheet is internally provided with a spray cylinder fixing hole enabling the spray cylinder body to extend into; a plurality of semicircle breaches are arranged around the spray cylinder fixing hole; the steady burning tablet is provided with a fixing hole enabling the spray cylinder to extend into in the middle and also is arranged with convex points around the fixing hole on the upper surface; the upper end of the spray cylinder body penetrates through the steady burning tablet and extends into the reverse-inject generator, lower end of which is connected with fuel pipelines. Stable flare sheet connected with the air blast burning port is positioned below the air blast burning port to form a stable flare chamber. During utilizing, the air blast burning port and the stable flare chamber burn symmetrically to form double layer flares with upper big and lower small; therefore, the invention is able to effectively prevent unstable flame and tempering.

Owner:程敏

Energy-saving gas burner

The invention relates to an energy-saving gas burner which comprises a front mixing chamber, a rear mixing chamber and a burner body. The front mixing chamber is connected with an air intake control valve and a gas intake valve respectively through a three-way joint. One end of the rear mixing chamber is respectively connected with the front mixing chamber and a drain valve through a three-way joint, and the other end of the rear mixing chamber is connected with the burner body. The burner body comprises a burner shell, a gas distribution piece, a flame tube, a burner seal plate and at least two gas guide sleeves; the flame tube is disposed at the center of the burner body, the lower portion of the flame tube penetrates the gas distribution piece to be connected with the rear mixing chamber, the gas guide sleeves inside the burner body are distributed circular around the flame tube, the burner seal plate is arranged inside the circle formed by the gas guide sleeves, and the gas guide sleeves and the burner shell form the angle of 0.5-10 degrees. In addition, guide holes in volute arrangement are formed in the bottoms of the gas guide sleeves.

Owner:上海氢城新能源科技有限公司

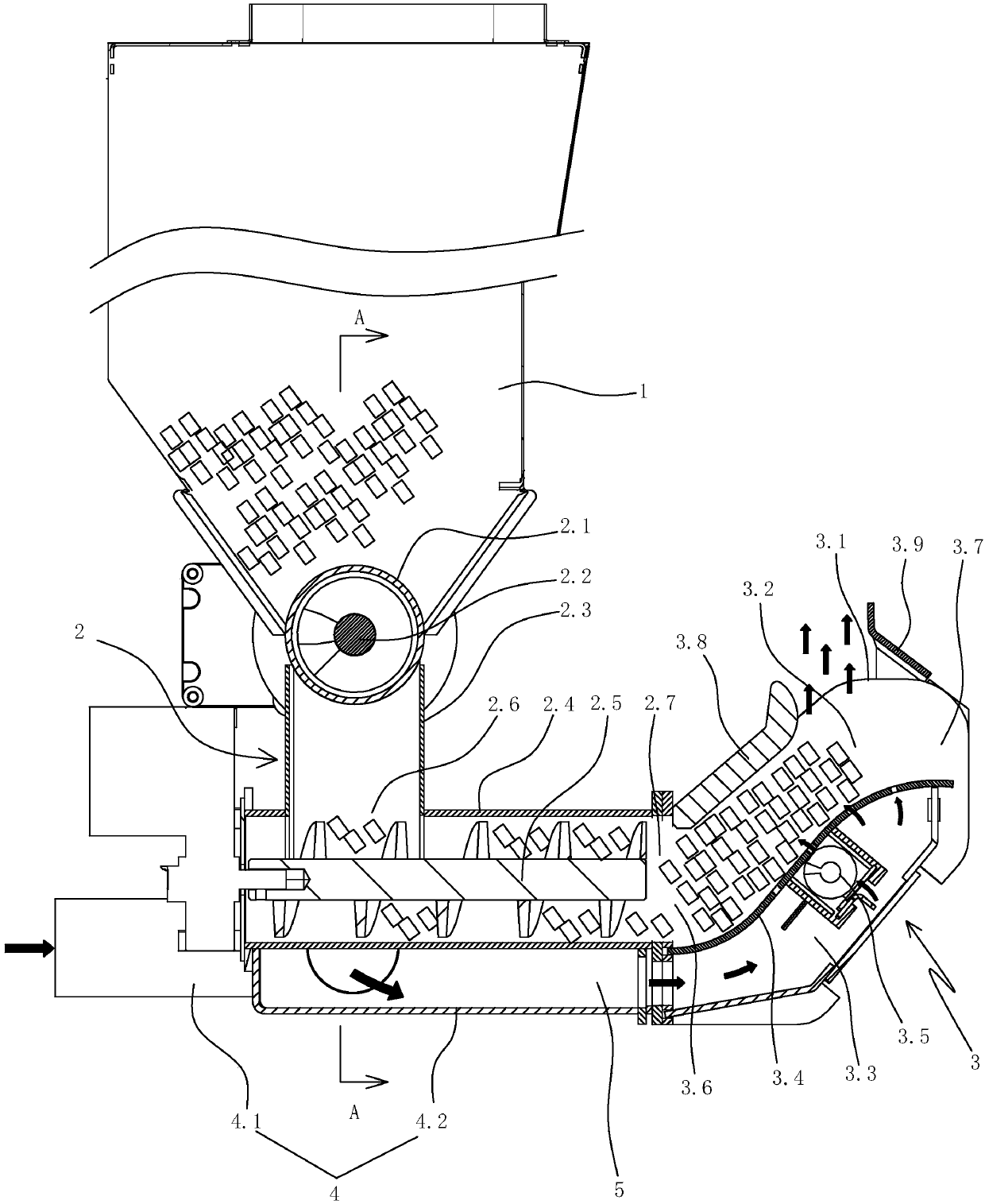

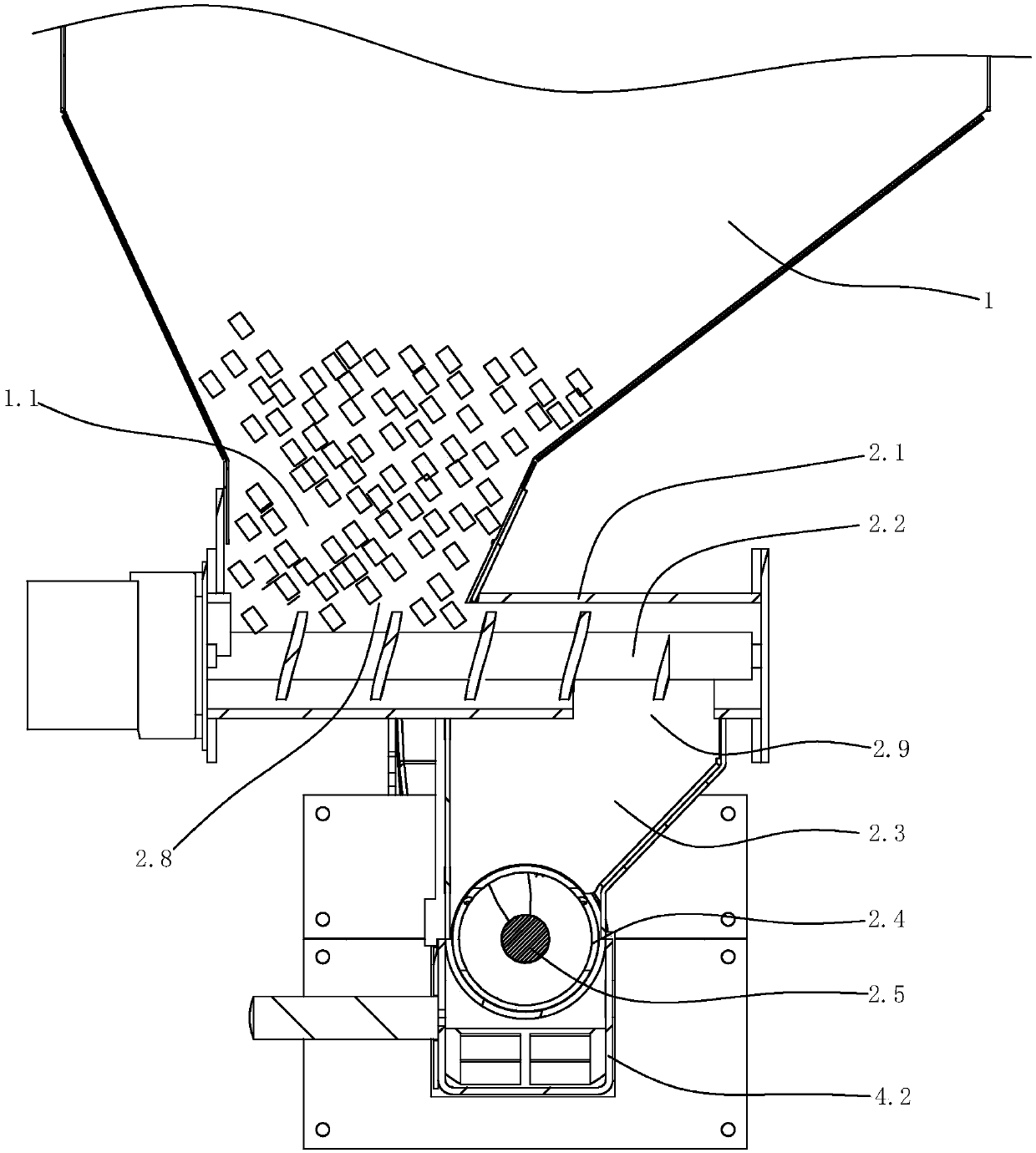

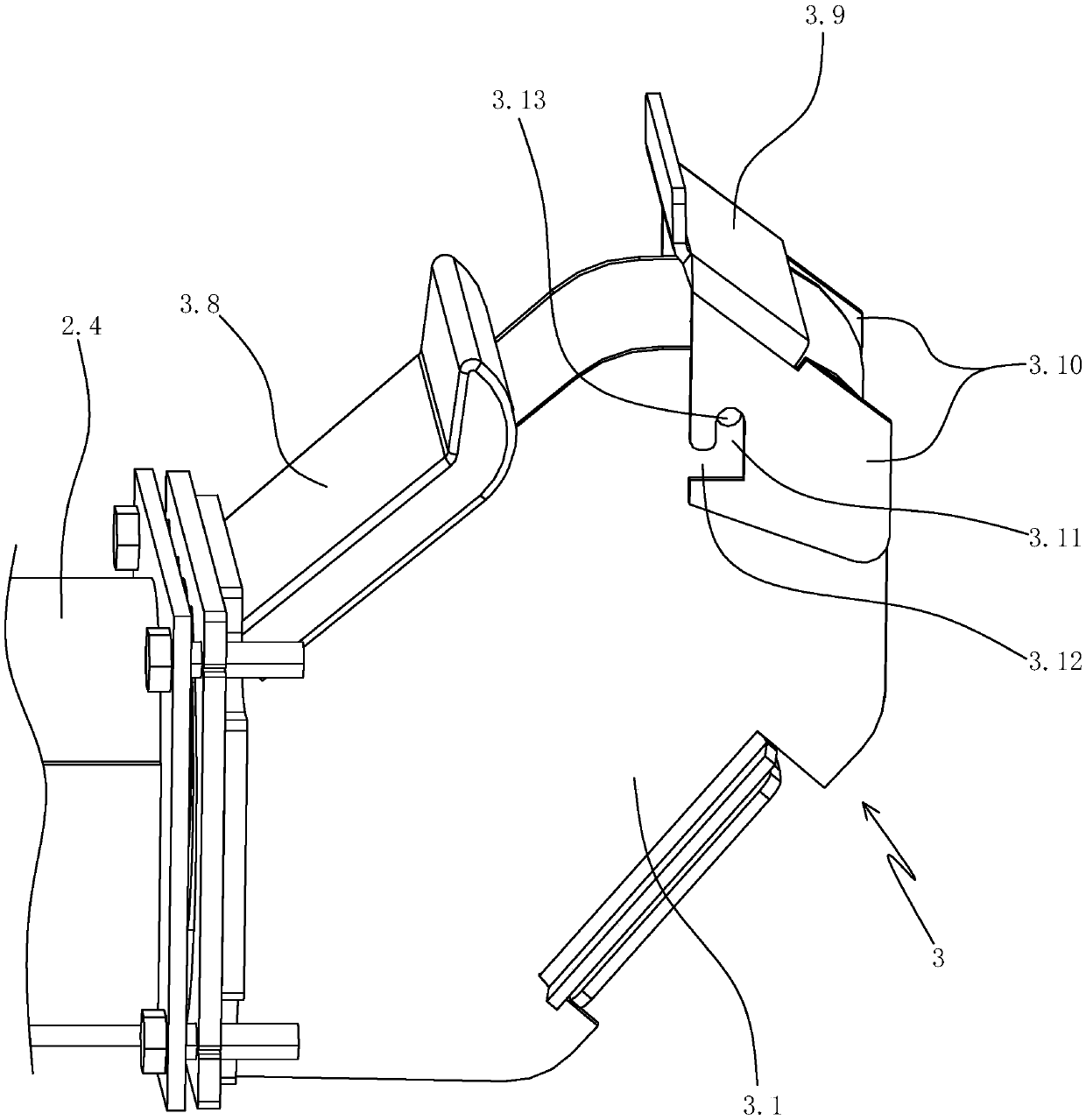

Two-stage screw feeding anti-tempering automatic slag removing burning device

ActiveCN109654478ASolve backfire problemsEfficient separationSolid fuel combustionLump/pulverulent fuel feeder/distributionSlagEngineering

Owner:ZHEJIANG ZHONGLI TOOL MFG

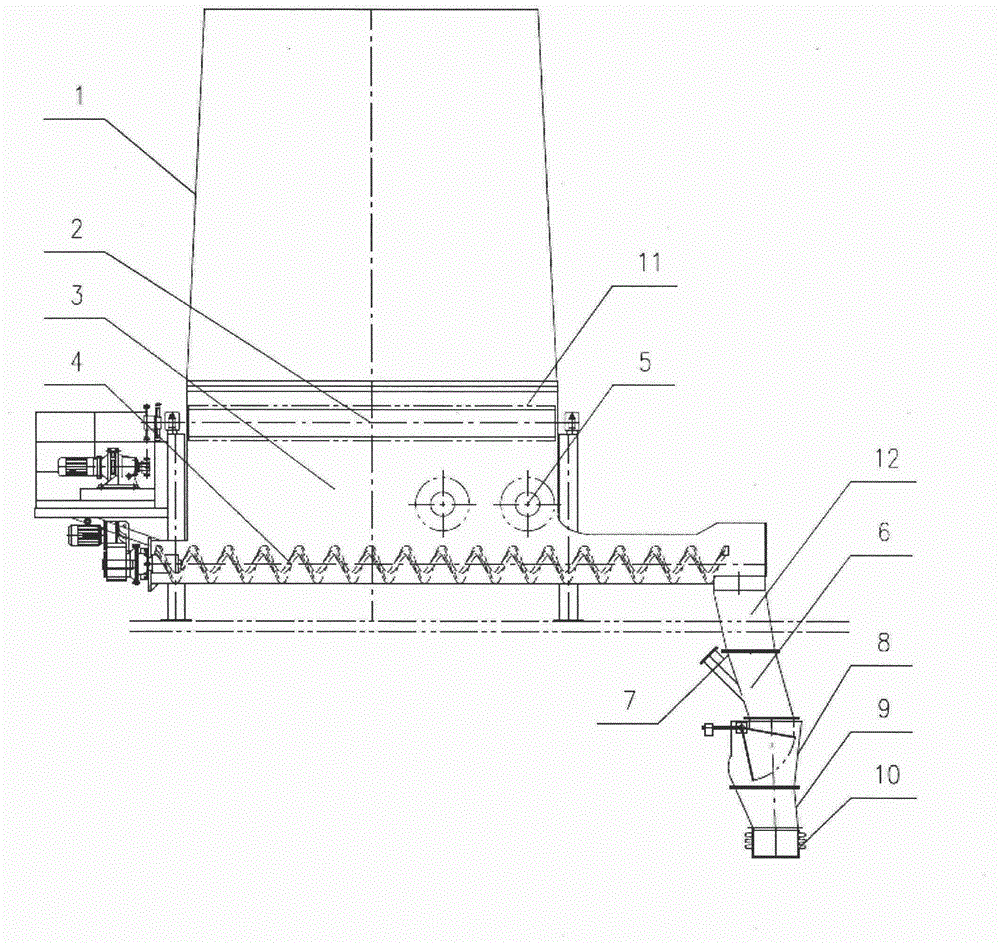

Feeding system of biomass boiler

InactiveCN102980180AImprove bridging problemSolving the Rollover BacklogFluidized bed combustionApparatus for fluidised bed combustionFlame arresterFluidized bed

The invention discloses a feeding system of a biomass boiler. The feeding system comprises a large storage hopper, a longitudinal kick-off device, a small storage hopper, a spiral conveyer, an articulated chute, a flame arrester, a transition pipe, an expansion joint and a transition blanking tube. The feeding system is characterized by also comprising a transverse kick-off device and an air hose; the air hose is tipsily inserted and welded into the articulated chute; the lower part of the articulated chute is directly connected with the flame arrester; the lower part of the flame arrester is directly connected with the transition pipe in a matching manner, and the transition pipe is connected with a feeding pipe of the boiler through the expansion joint. The feeding system has the beneficial effects that the fuel bridging problem in the storage hopper is improved; material kicking and controlling are even; the problem that the fuel at the end part of the spiral conveyer is rolled and overstocked is solved; and the problem that the fuel is easily accumulated at the bottom of the articulated chute is also solved. Meanwhile, the backfire problem when a hearth explodes or abnormally generates positive pressure suddenly can be effectively prevented by the flame arrester structure, and safe and continuous running period of the biomass boiler of a circulating fluidized bed is also prolonged.

Owner:南通万达能源动力科技有限公司

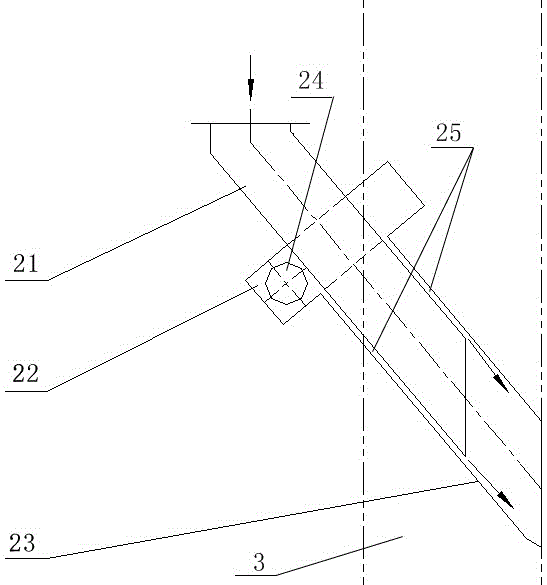

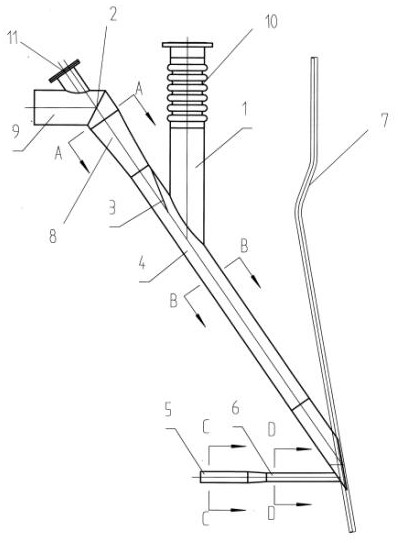

Anti-abrasion uniform coal feeding device for circulating fluidized bed

PendingCN112413576ASpread evenlySow fullyFluidized bed combustionApparatus for fluidised bed combustionFluidized bedSlag

The invention discloses an anti-abrasion uniform coal feeding device for a circulating fluidized bed. The problems of how to reduce impact and abrasion of coal particles on a uniform coal feeding pipeand how to reduce the too high concentration ratio when the coal particles enter a hearth are solved. A coal conveying air pipe (2) communicates with an upper port of a uniform coal feeding pipe (4),the cross section of an inclined downward pipe section (8) is gradually changed from round to oval, the cross section of a horizontal pipe section (9) is round, and the cross section of the uniform coal feeding pipe (4) is oval; a coal conveying air flow deflector (3) is arranged at the communication position of a coal falling pipe (1) and the uniform coal feeding pipe (4), and the coal conveyingair flow deflector (3) seals an upper half inner cavity, above a coal falling opening, of the uniform coal feeding pipe (4); and a uniform coal spreading air pipe (6) and a circular coal spreading air pipe (5) are arranged at the communication part of the uniform coal feeding pipe (4) and a water cooling film type wall (7) in a hearth, and coal particles are fully combusted, and the carbon content of bottom slag is reduced.

Owner:TAIYUAN BOILER GROUP

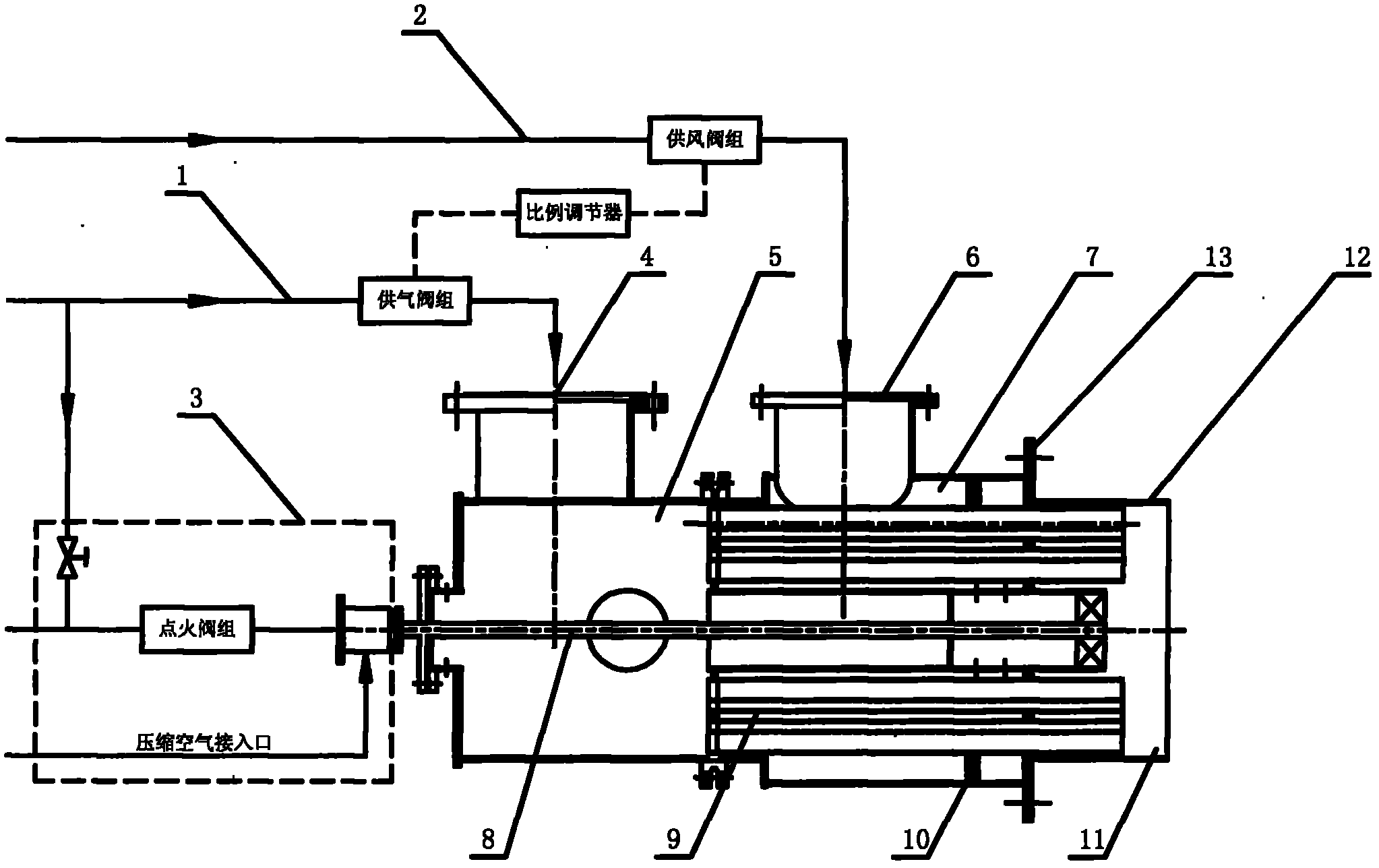

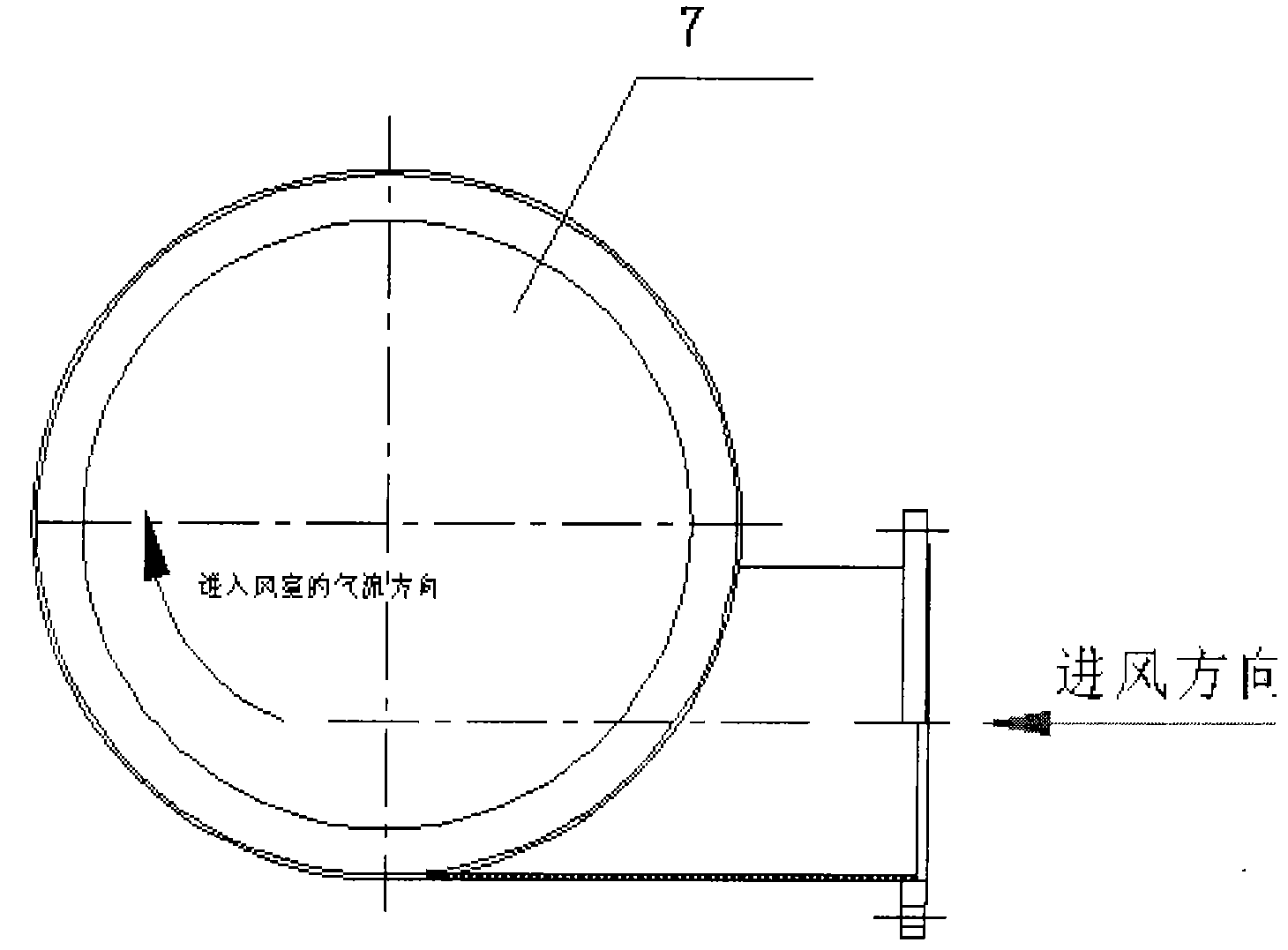

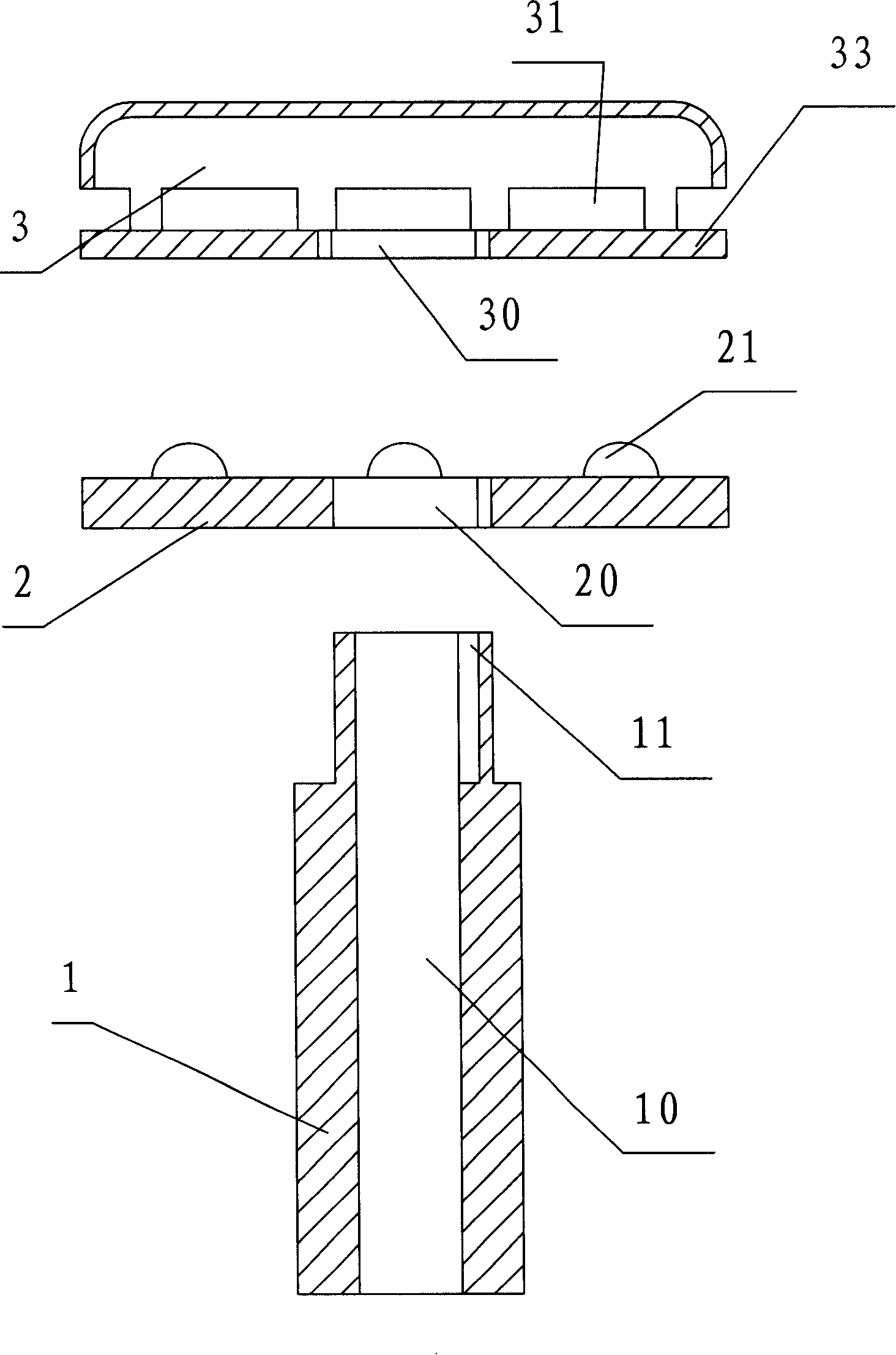

Dryness improving device and method for improving steam dryness of steam injection boiler

ActiveCN110486708AConducive to atomization combustionSo as not to damageBurnersBurner coolingSurface layerCombustion

The invention relates to a dryness improving device and method for improving steam dryness of a steam injection boiler. According to the technical scheme, a plurality of compressed air circulating holes perpendicular to a front end head are formed in a compressed air inlet channel from the middle of a flange bolt of the front end head; the compressed air inlet channel communicates with a fuel pipechannel through the compressed air circulating holes; a plurality of compressed air heat dissipating holes are formed in the front end surface of the front end head, are vertical to the compressed air circulating holes, and communicate with the compressed air circulating holes; an air heat dissipating nozzle is arranged at the tail ends of the compressed air heat dissipating holes; and a plurality of air heat dissipating spraying holes are uniformly formed in the circumference of the air heat dissipating nozzle. The dryness improving device and method have the beneficial effects that the front end head is well cooled, the compressed air is fully pre-heated in the process of cooling the front end head so as to be beneficial for atomization and combustion of fuel, and the air heat dissipating nozzle is designed on the front end surface of the front end head, so that an air cooling air film is generated on the front end surface layer of the front end head to sufficiently protect the front end surface of the front end head and various penetrating parts against high temperature damage, and the operation cost is greatly reduced.

Owner:北京华曦油服石油技术有限公司

Stove combustor assembly

InactiveCN104456561ASolve backfire problemsSolve quality problemsBurner safety arrangementsBurner material specificationsInfraredCombustion chamber

The invention relates to a stove combustor assembly, and belongs to the technical field of stoves. The stove combustor assembly comprises a combustion chamber, an ignition device, and a combustion disc and an insulation disc mounted at the ends of a combustor, wherein the combustion chamber is a double-ring structure, and an outer ring thereof is insulated from an inner ring space; the ignition device is positioned in the center position of the combustor; the combustion disc is a double-ring split porous ceramic disc; and the insulation disc is mounted at the end of the combustor. The stove combustor assembly solves the tempering problem of the stoves; the space of the combustion chamber is increased to enable the fuel combustion to become fuller; the service life of the combustion disc is prolonged; the insulation disc enables infrared rays radiated to the periphery to be reflected and concentrated to a pan bottom; and the heat efficiency of the stove combustor assembly is improved more than 30% compared with a traditional stove, so that peripheral staff cannot feel uncomfortable due to the infrared radiation.

Owner:宗吉林

Low-nitrogen combustor

The invention provides a low-nitrogen combustor. The combustor comprises a combustor barrel body, a combustor head cover and a fuel gas injection device; one end of the combustor barrel body is fixedly connected with the combustor head cover; the fuel gas injection device comprises a main fuel gas injection pipe and auxiliary fuel gas injection pipes, wherein the auxiliary fuel gas injection pipescommunicate with the main fuel gas injection pipe, the pipe diameter of the main gas injection pipe is greater than that of the auxiliary fuel gas injection pipes, auxiliary fuel gas nozzles are arranged at the tail ends of the auxiliary fuel gas injection pipes, and a plurality of small circulation holes are formed in the tail end of the main fuel gas injection pipe; and the end, away from the auxiliary fuel gas injection pipes, of the main fuel gas injection pipe is arranged in the combustor barrel body, and the end, close to the auxiliary fuel gas injection pipes, of the main fuel gas injection pipe and the auxiliary fuel gas injection pipes are all arranged in the combustor head cover. According to the technical scheme, the effects of high combustion efficiency and low NOx emission can be achieved.

Owner:HUAQIAO UNIVERSITY

Slight fuel accumulation ignition increasing mechanical feeding method

ActiveCN102997229AImprove burnout rateExtended stayFluidized bed combustionSolid fuel combustionBoiler furnaceRetention time

The invention discloses a slight fuel accumulation ignition increasing mechanical feeding method. The slight fuel accumulation ignition increasing mechanical feeding method comprises the following steps of: feeding a light biologic material or a fine powder fuel or recycled material fine powder on a negative pressure position in a boiler furnace, utilizing a boiler with a certain pressure and using a primary or secondary air special organization to form a special burning zone with accumulation and afterburning action, prolonging retention time of the light biologic material or fine powder fuel or returning fine powder on a secondary furnace bottom, and combining characteristics of different fuels. The technology can effectively solve the technological problems that the light biologic material or the returning fine powder can cause lower burning efficiency or higher water containing light fuel such as light weight straw, a plastic film in garbage and high fine powder bunker coal, and the slight fuel accumulation ignition increasing mechanical feeding method has the advantages of effectively improving burning efficiency and reducing attrition aspect.

Owner:JIANGLIAN HEAVY IND GRP CO LTD

Kiln catalytic combustion method and device

InactiveCN105783022AIncrease the speed of oxidation reactionIncrease burn rateIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyHydrogenFuel oil

The invention discloses a kiln catalytic combustion method and device which can be applied to kilns taking heavy oil, or pulverized coal or biomass as fuel. The method is characterized in that a water electrolyzing oxyhydrogen gas pipeline is additionally arranged on a blast pipeline of a kiln, oxyhydrogen gas generated by a water electrolyzing oxyhydrogen generator is mixed with air according to the proportion of 0.1% to 0.3%, and the mixture is blown into a kiln hearth to serve as a combustion catalyst from the bottom and one side surface of the kiln hearth. The device comprises the kiln hearth, wherein a grate is arranged in the kiln hearth; the blast pipeline is mounted under and on one side face of the grate; a blower is arranged at the tail end of the blast pipeline; the water electrolyzing oxyhydrogen gas pipeline is arranged in the middle section of the blast pipeline; a valve is arranged at the front end of the water electrolyzing oxyhydrogen gas pipeline; and the water electrolyzing oxyhydrogen generator is arranged at the tail end of the water electrolyzing oxyhydrogen gas pipeline. As the mixture obtained by mixing the oxyhydrogen gas generated by the water electrolyzing oxyhydrogen generator and air according to the proportion is added in the combustion process of the kiln to serve as the combustion catalyst, and enters the combustion space of heavy oil, or pulverized coal or biomass for mutual combustion, the combustion efficiency of the fuel can be improved.

Owner:湖南冠拓科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com