Patents

Literature

42results about How to "Improve circumferential uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

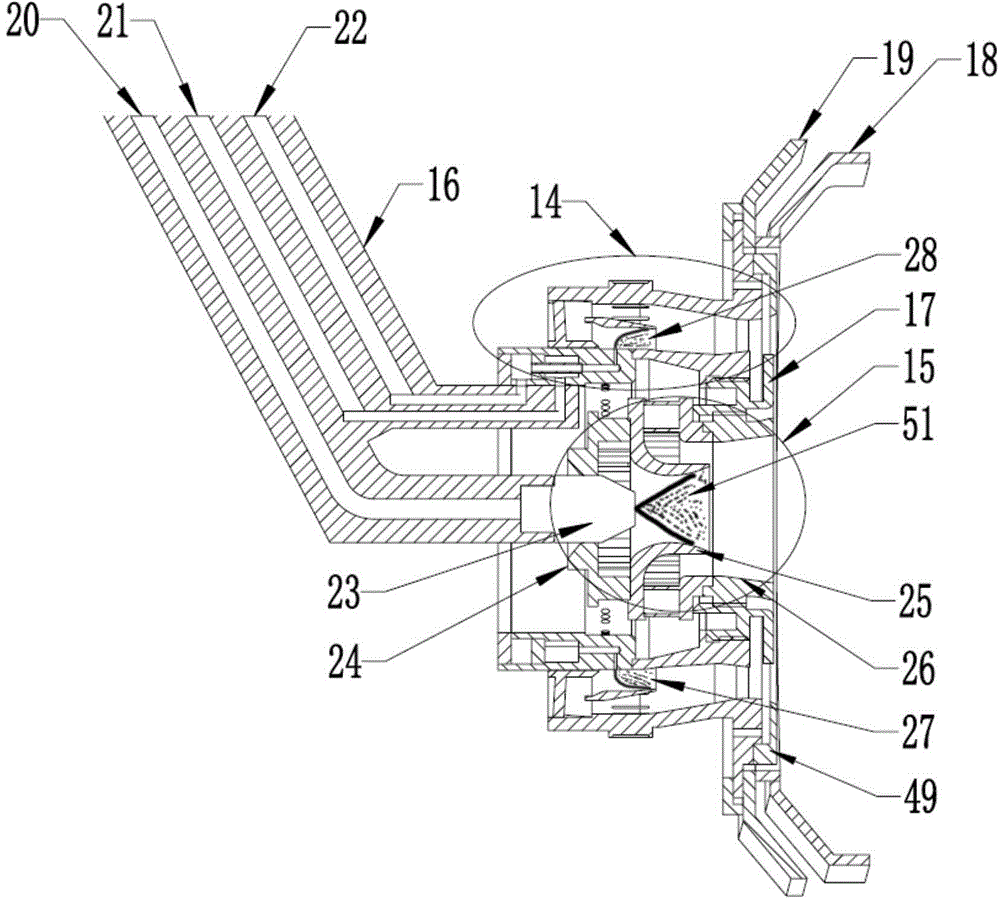

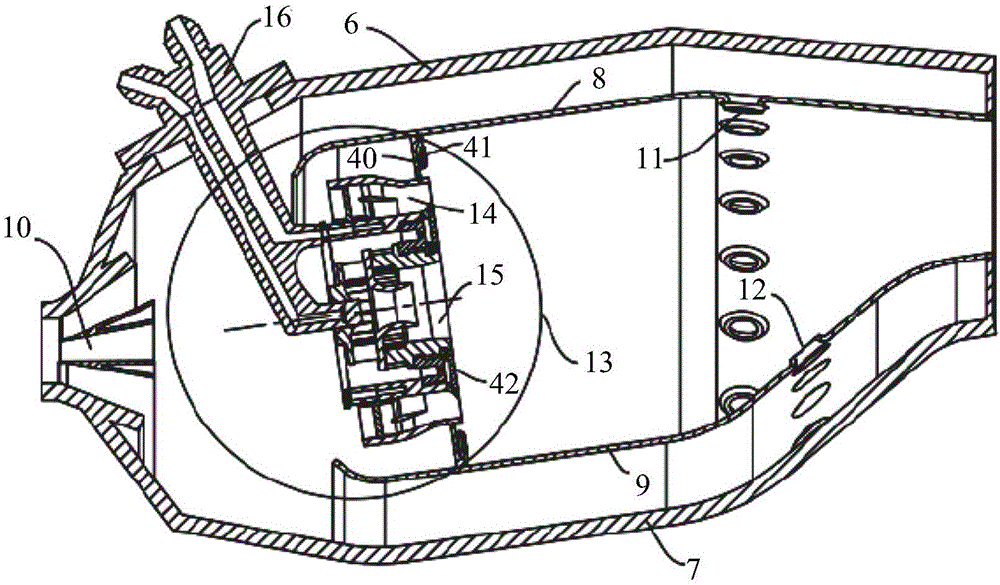

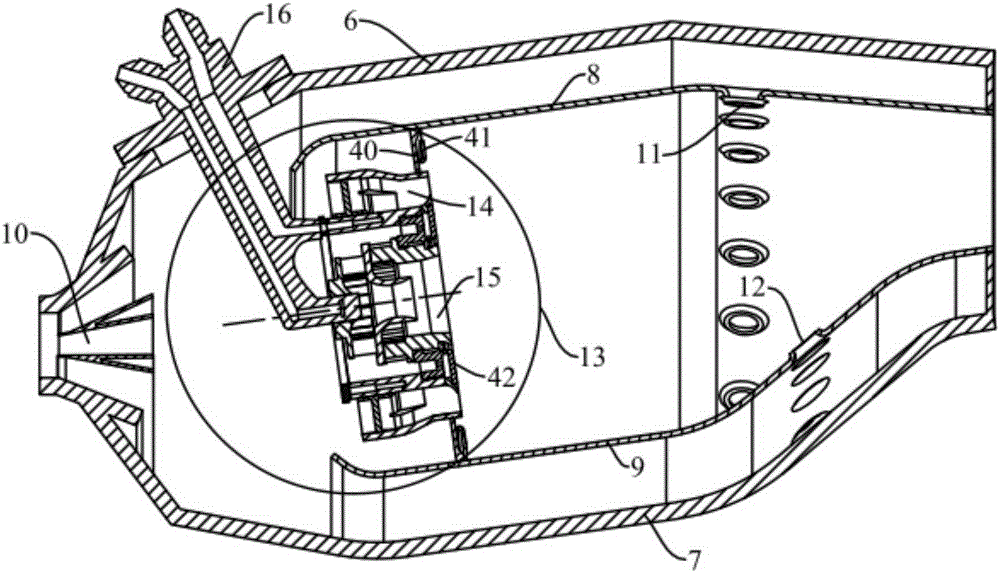

Lean oil premixing and pre-evaporating combustion chamber head structure with cyclone/pre-film plate integrated primary combustion stage

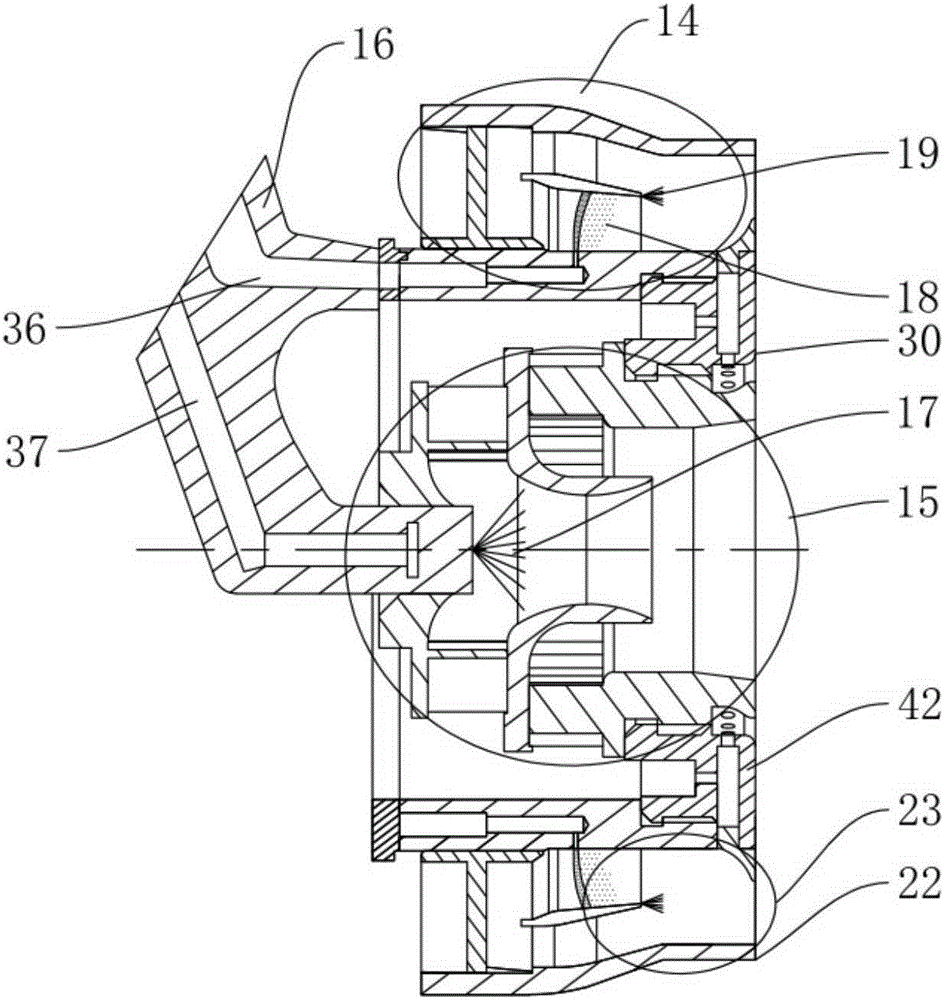

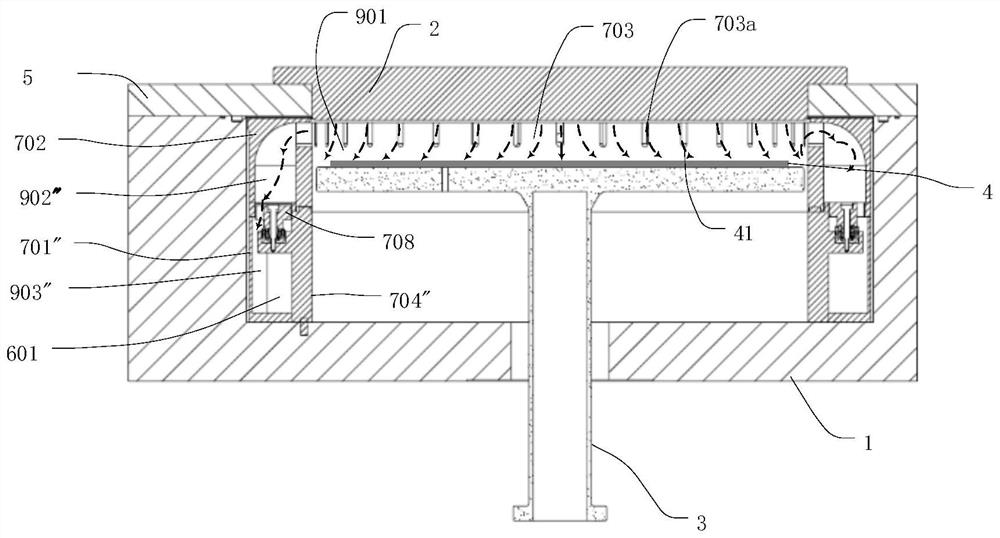

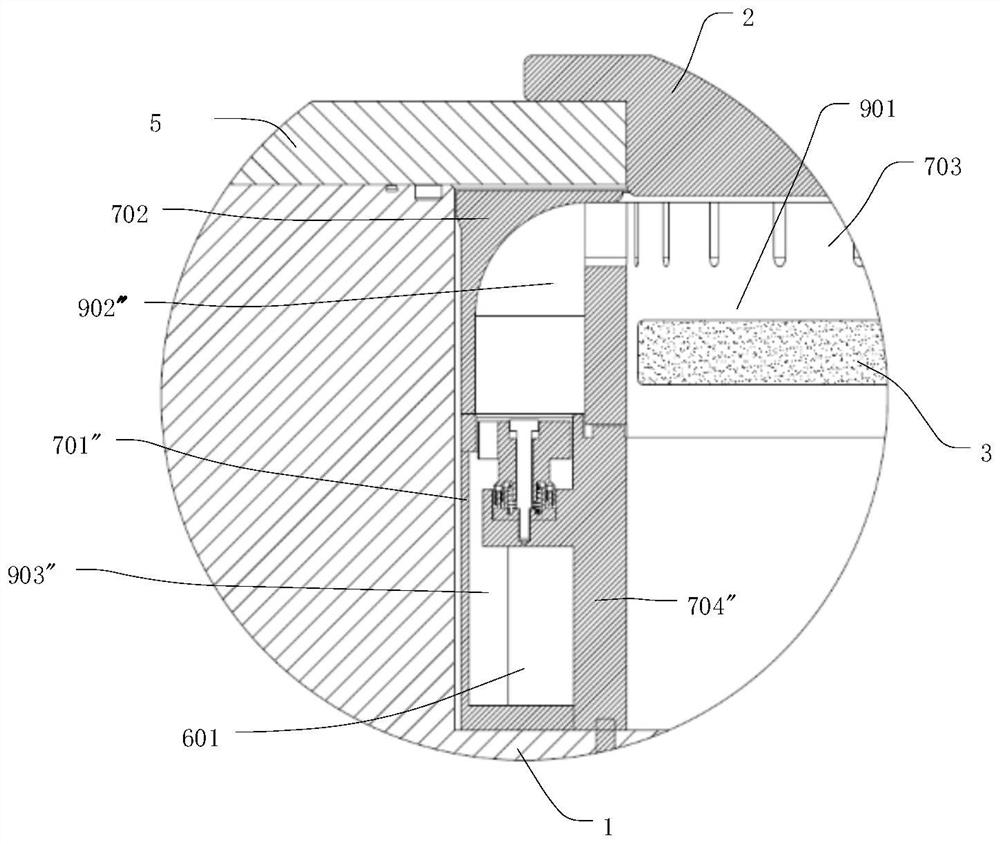

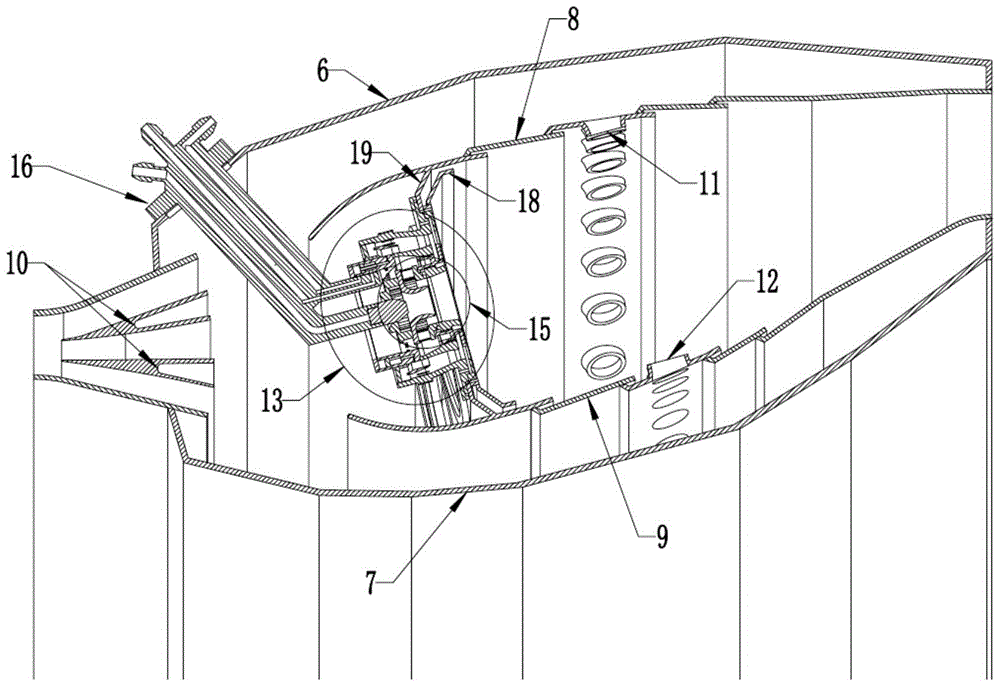

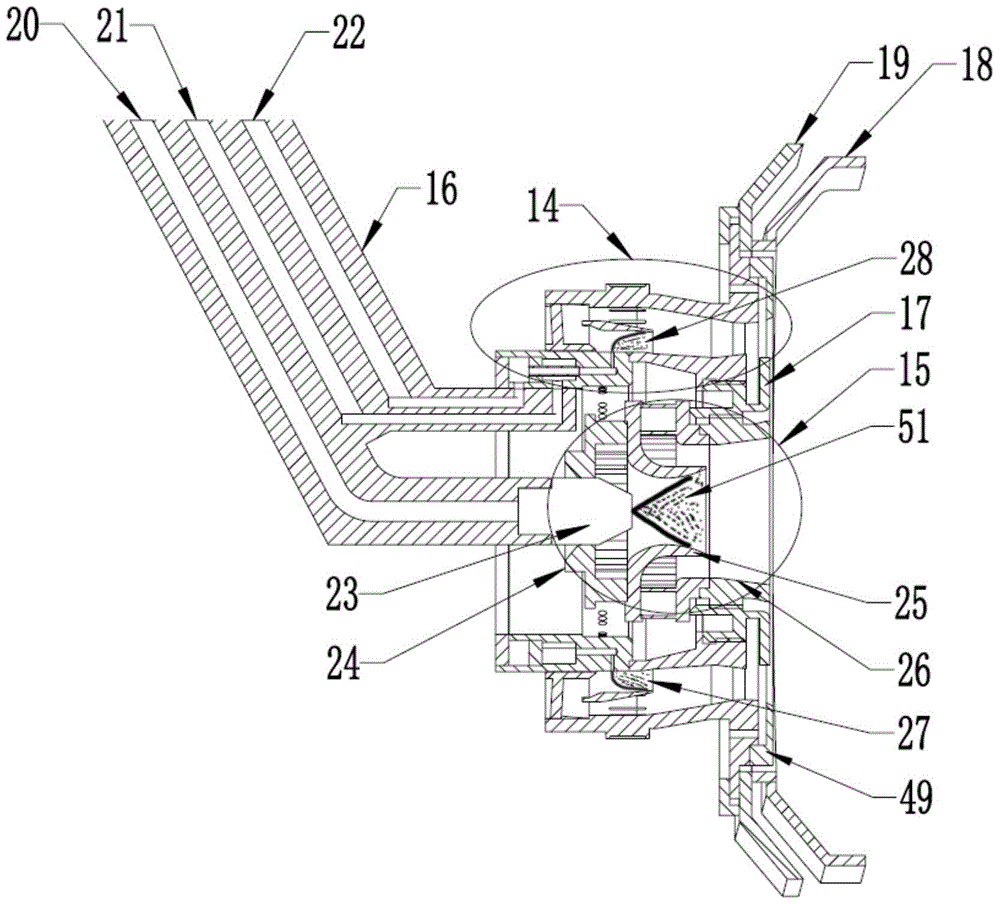

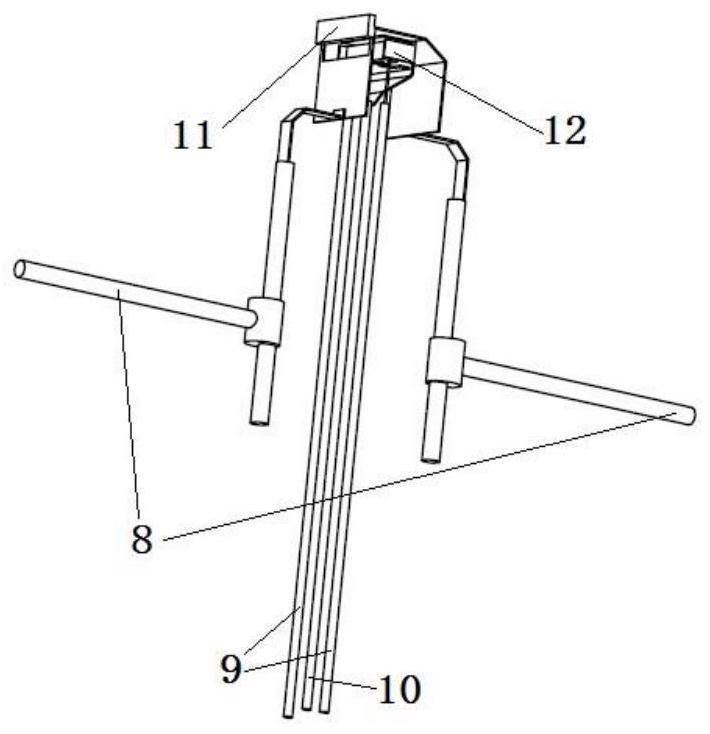

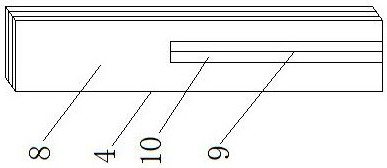

The invention relates to a lean oil premixing and pre-evaporating combustion chamber head structure with a cyclone / pre-film plate integrated primary combustion stage. A central staged combustion mode is adopted for the head structure and divided into a pre-combustion stage and the primary combustion stage, the mode of combining diffusive combustion and cyclone premixing combustion is adopted for the pre-combustion stage, the mode of premixing and pre-evaporating combustion mode is adopted for the primary combustion stage, and combustion pollutants can be effectively reduced. A cyclone / pre-film plate integrated structure is adopted for the primary combustion stage, the structure is simple and reliable, first-stage fuel and second-stage fuel form oil films on the same pre-film plate and are atomized, evaporated and mixed under the action of two strands of cyclones, an even oil and gas mixture can be easily formed at an outlet of the primary combustion stage, and the combustion pollutants are reduced. The design of dual oil paths of the primary combustion stage is beneficial to oil and gas matching of the combustion chamber under different working conditions, and the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aero-engine is further lowered. By means of the micro shrinkage type design of a primary combustion stage channel and the design of a backfire prevention ring, the backfire problem can be effectively solved, and the safety of the head of the combustion chamber is ensured.

Owner:BEIHANG UNIV +1

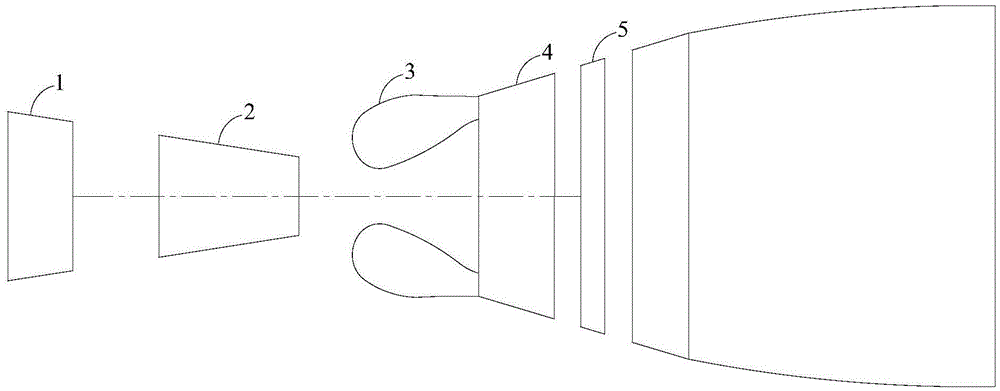

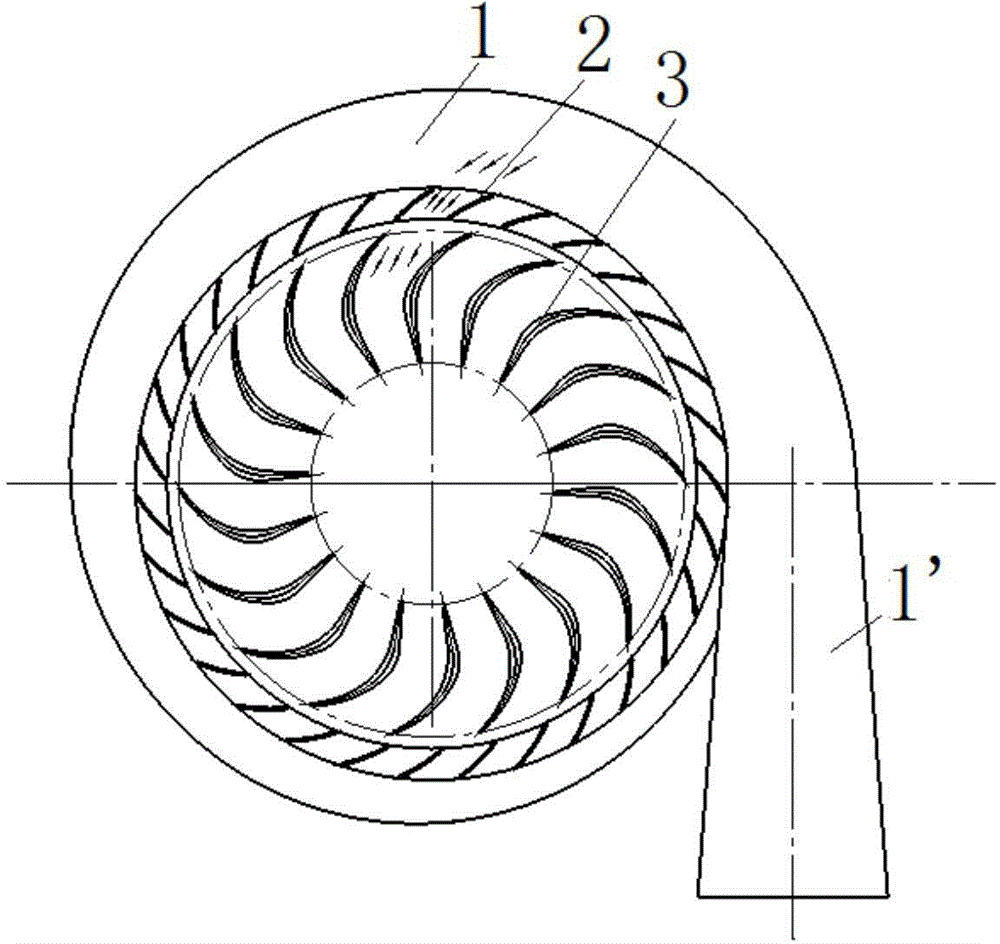

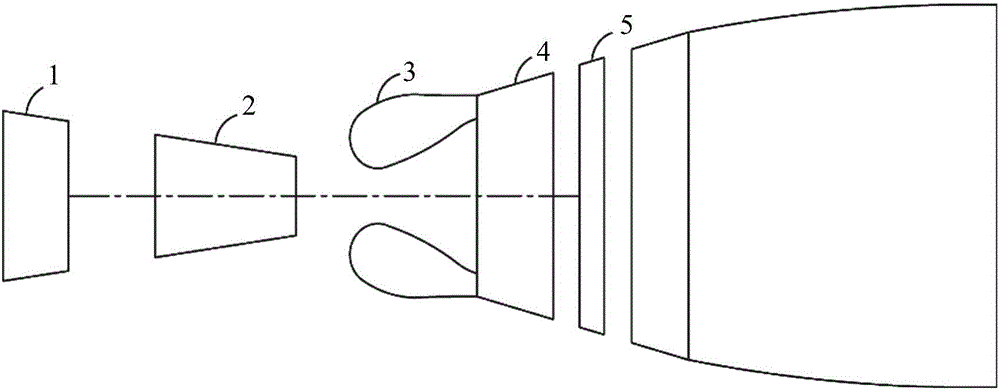

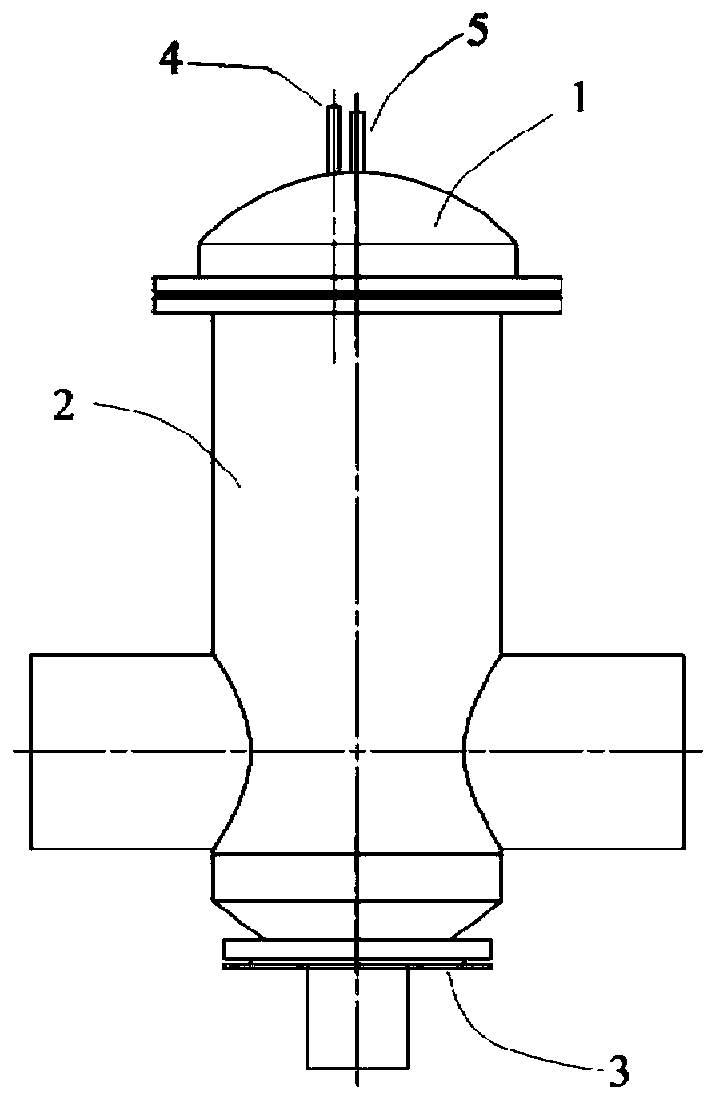

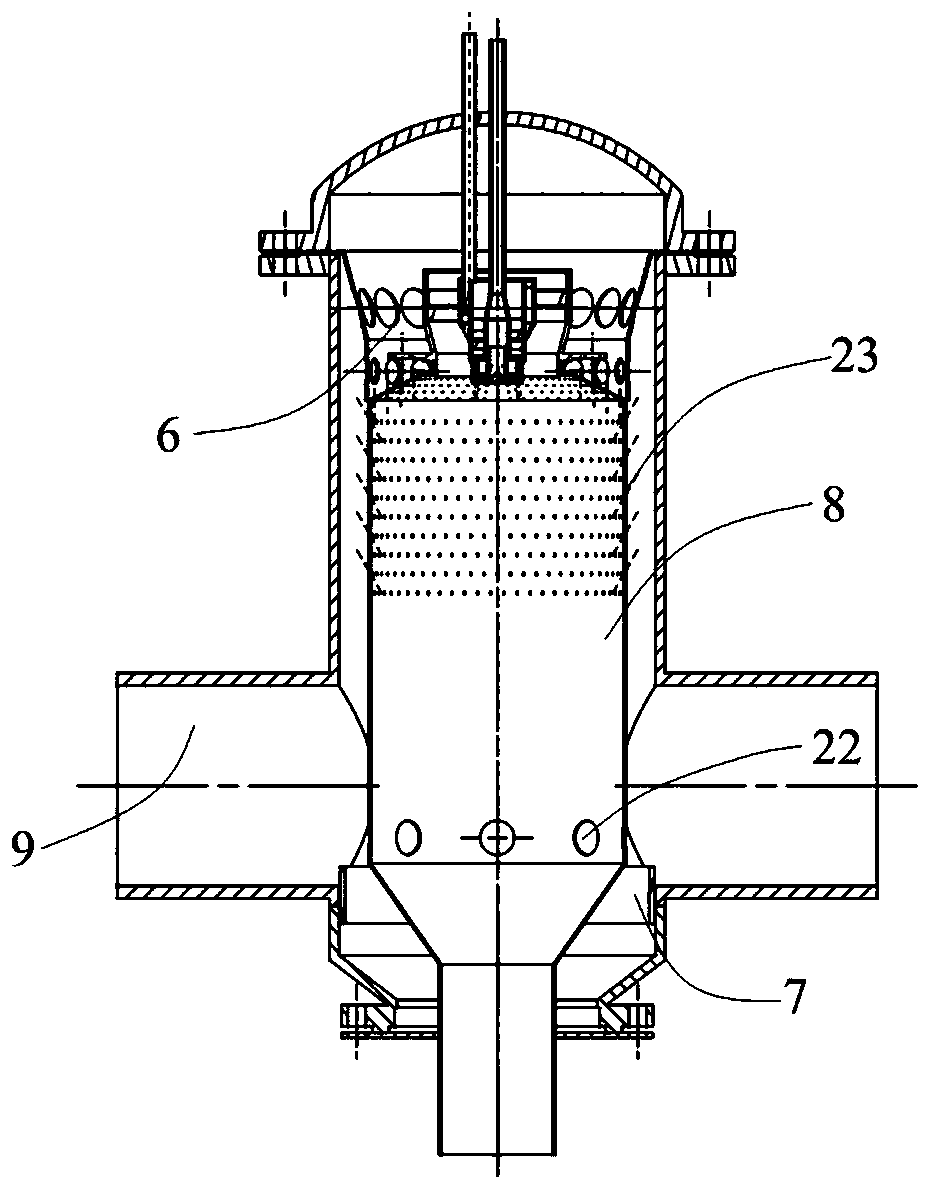

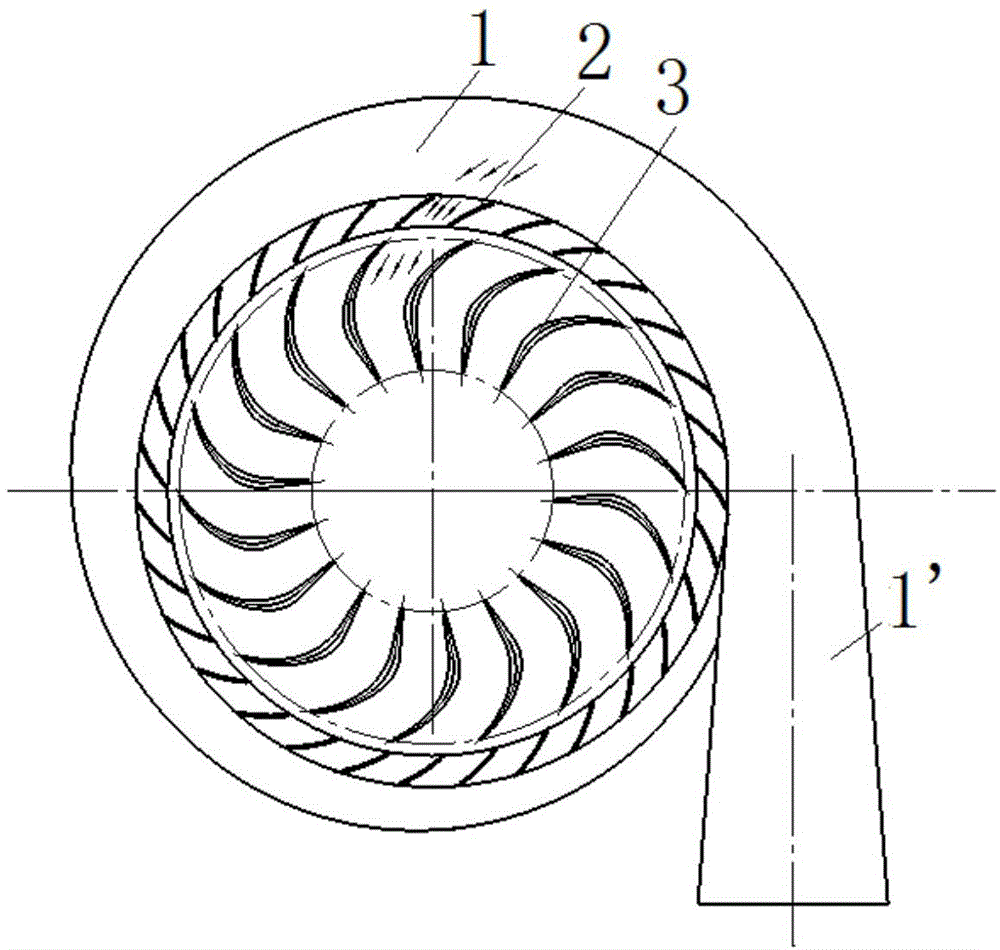

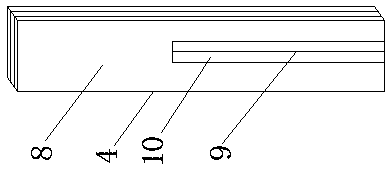

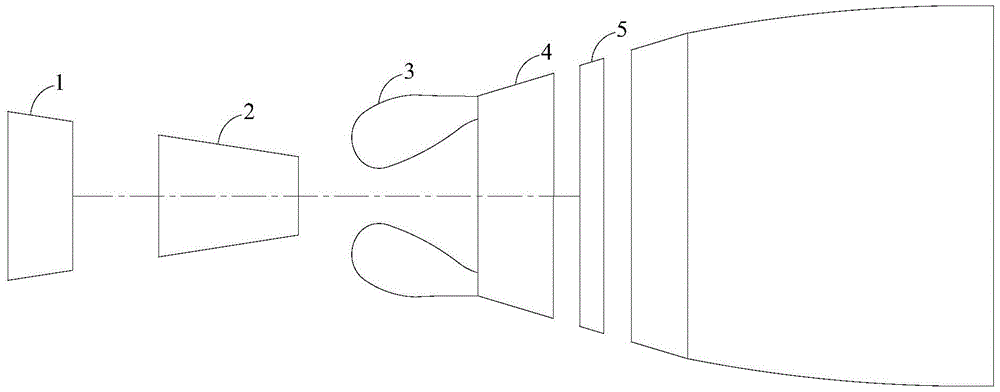

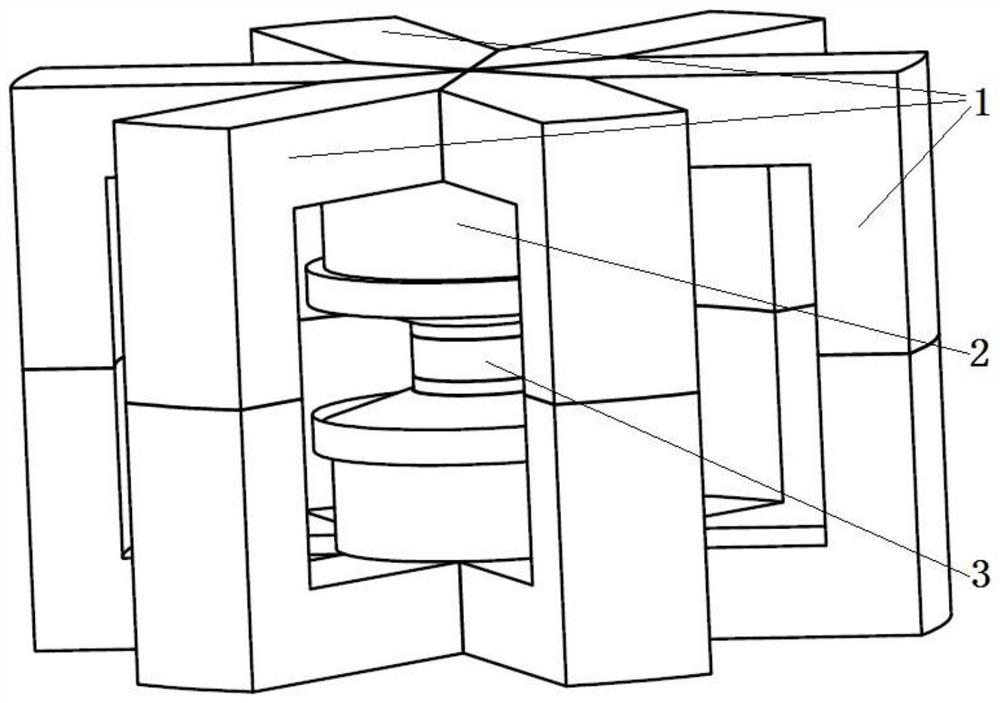

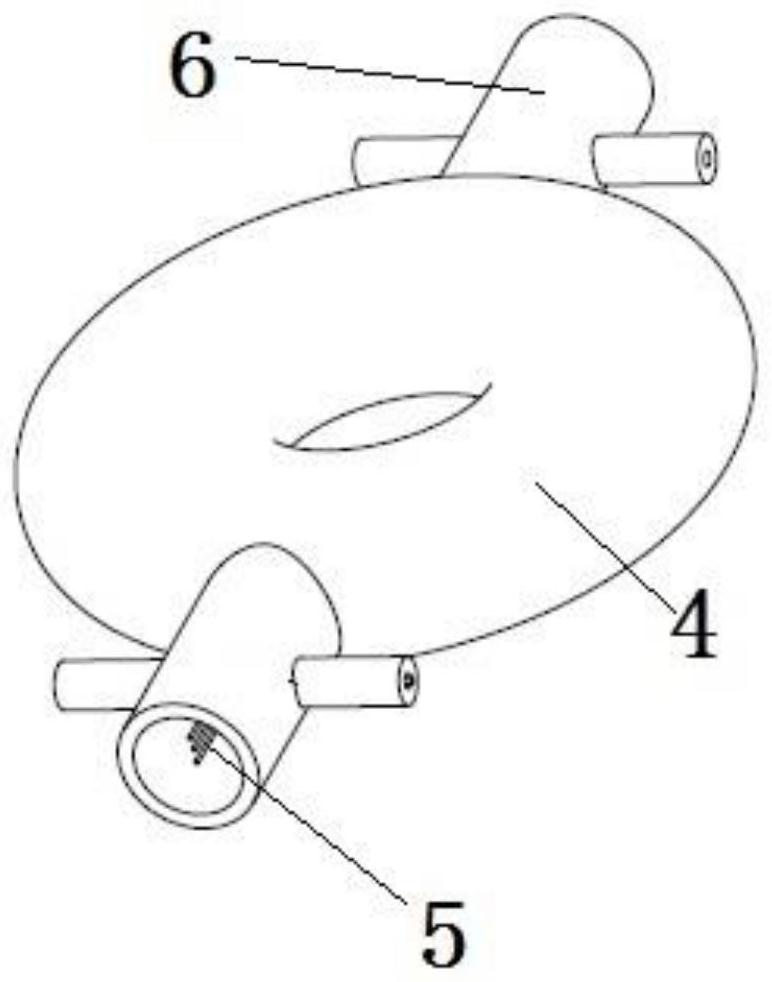

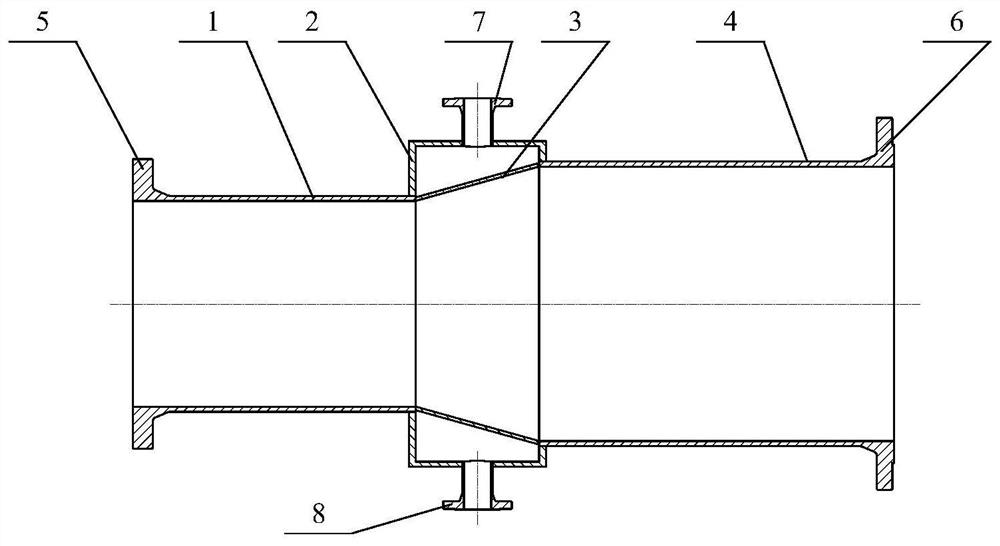

Inter-stage air feeding structure of centrifugal compressor and design method thereof

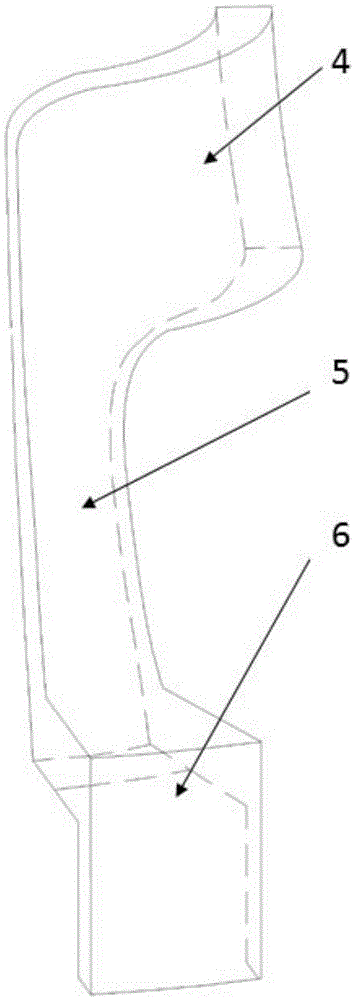

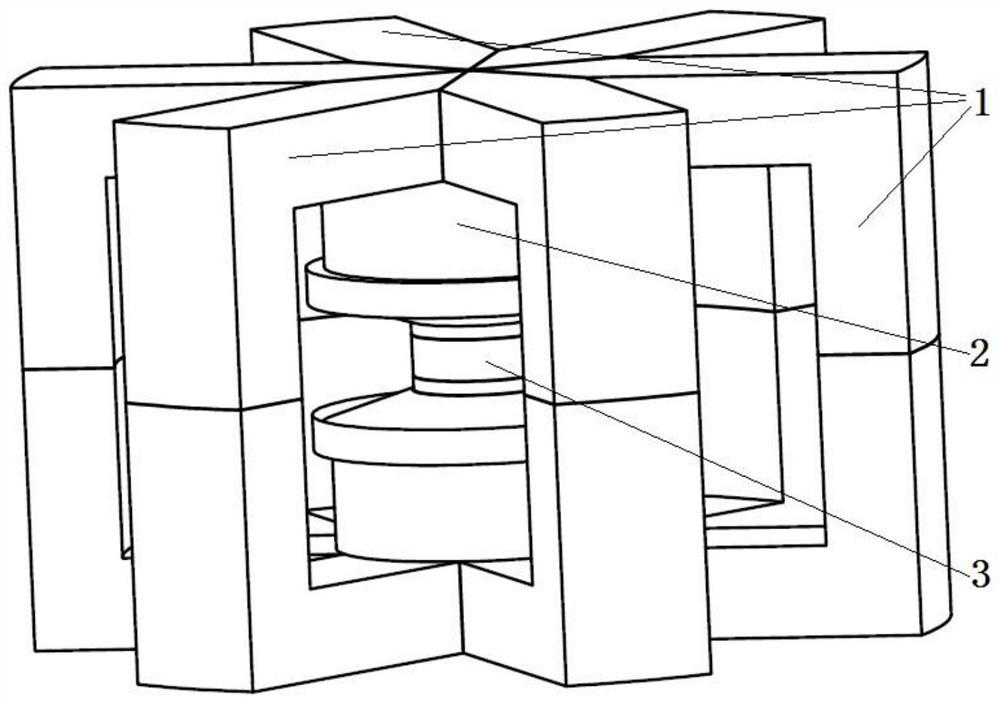

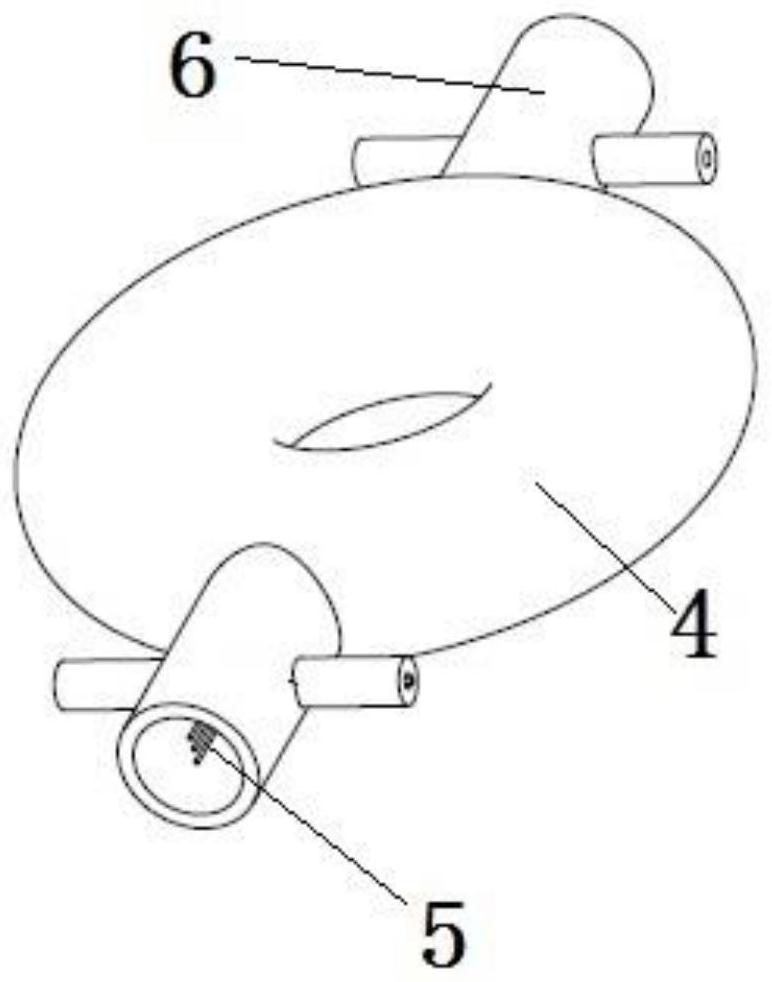

ActiveCN104533836AImprove circumferential uniformityChanging the gas flow anglePump componentsSpecial data processing applicationsCentrifugal compressorDesign methods

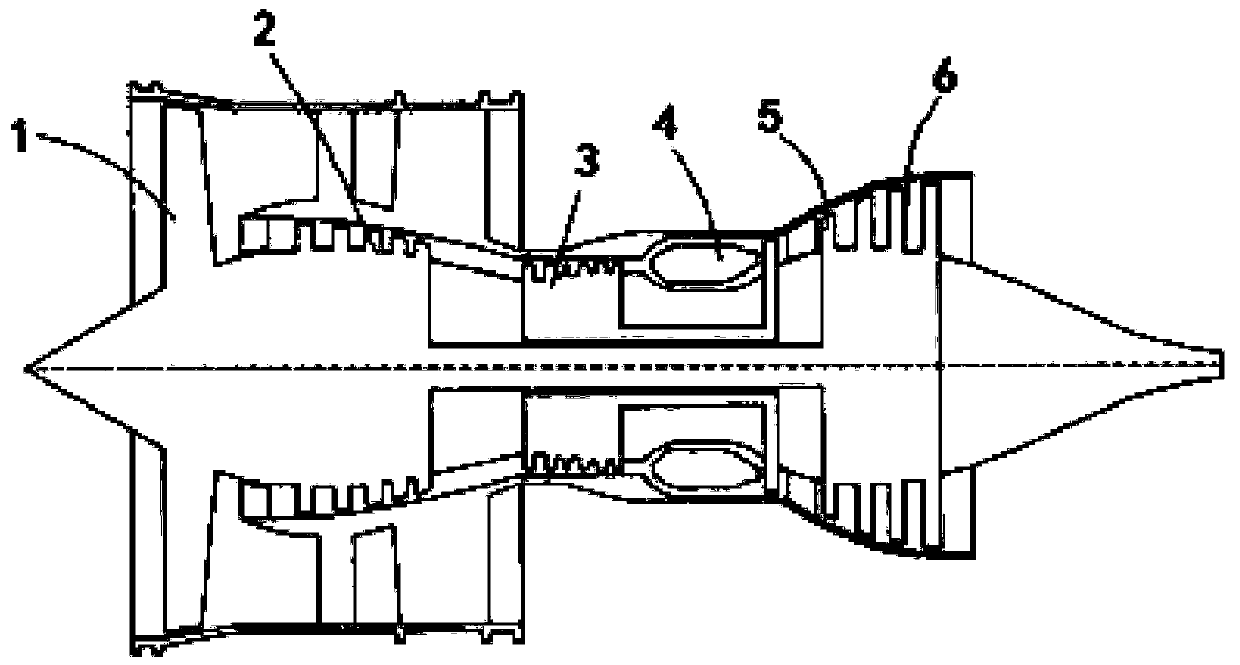

The invention provides an inter-stage air feeding structure of a centrifugal compressor. An air feeding port is formed in the bend of at least one stage of the centrifugal compressor, and the air feeding structure is additionally arranged at the air feeding port, so that fed airflow is led in for main airflow. The air feeding structure comprises an air feeding volute chamber and air feeding guide vanes. The air feeding vanes are circumferentially and uniformly distributed on a volute of the volute chamber in the same vane profile, so that the circumferential uniformity of the airflow is improved, the angle of the fed airflow is changed, and it is guaranteed that the fed airflow and the main airflow do not generate any large impact angle when flowing to a next-stage backflow device after being mixed. The invention further provides a design method of the inter-stage air feeding structure of the centrifugal compressor. By adopting the inter-stage air feeding structure of the centrifugal compressor and the design method of the inter-stage air feeding structure of the centrifugal compressor, when the number of the vanes is large, the axial span of the compressor can be reduced, and the requirement of the critical rotation speed of a set can be met more easily.

Owner:SHENYANG BLOWER WORKS GRP INSTALLATION MAINTENANCE FITTINGS

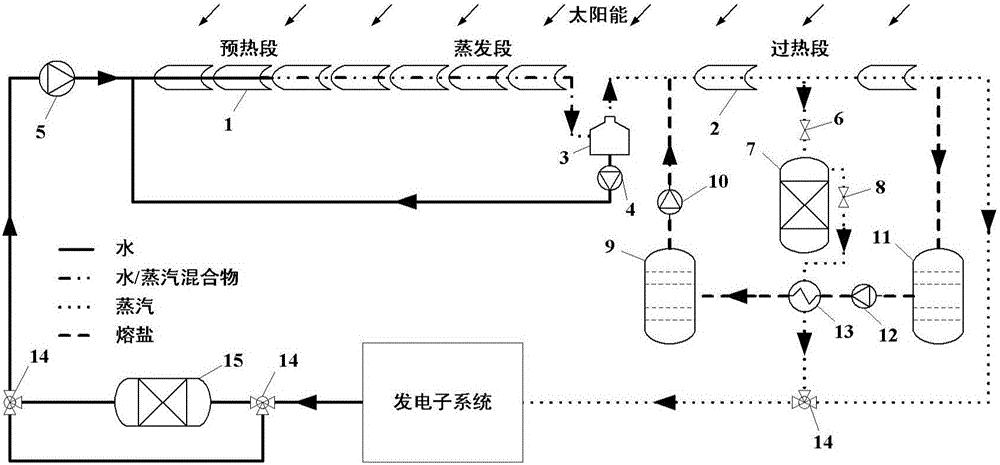

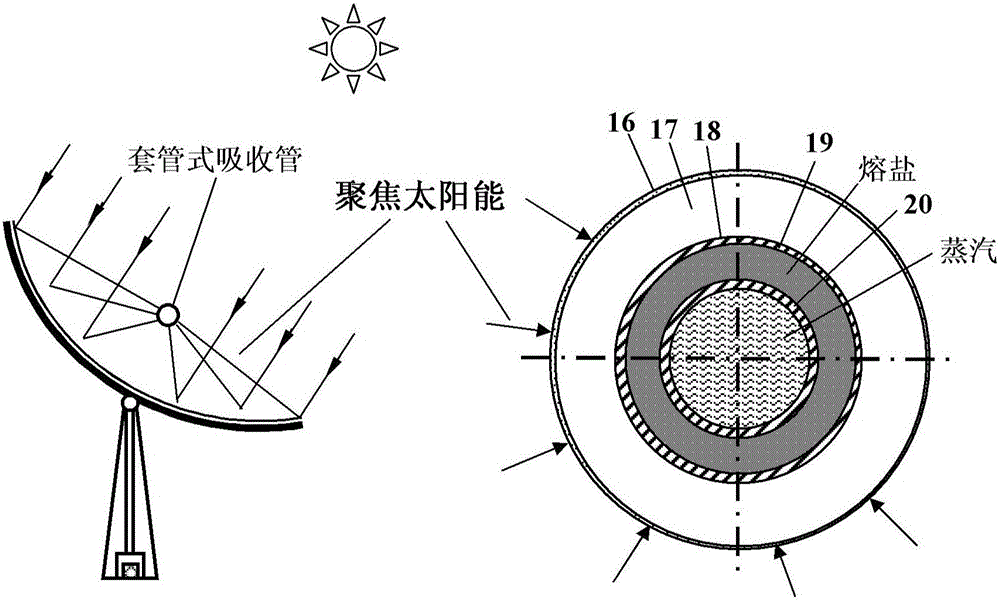

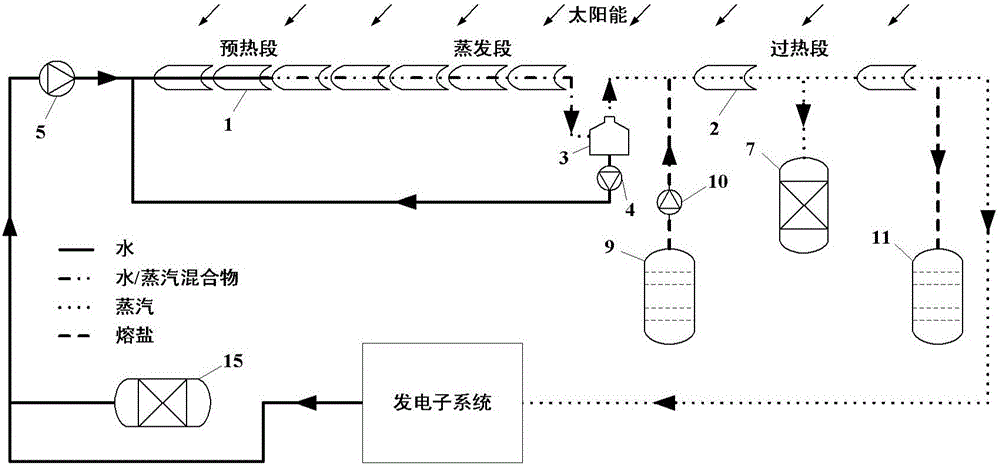

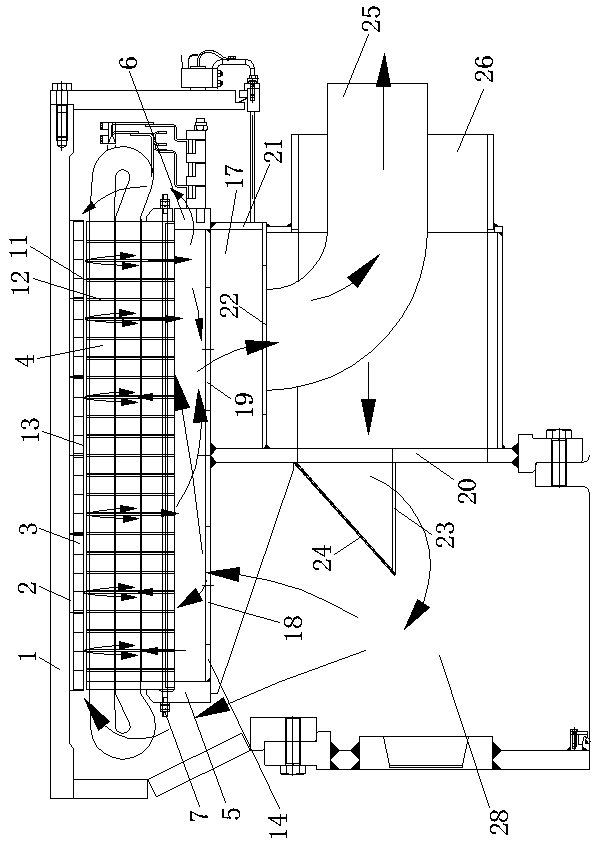

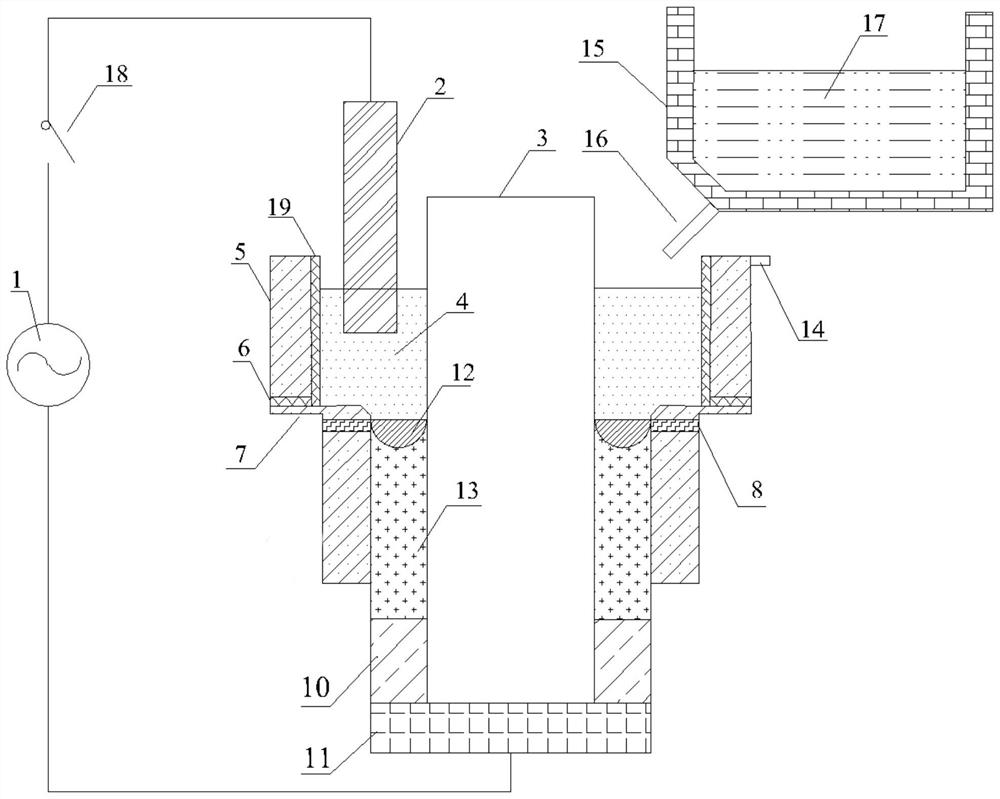

Solar steam direct power generation system with heat storage function

ActiveCN105756873AReduce investmentRealize uninterrupted continuous power generation day and nightSolar heating energyFrom solar energyMolten saltEngineering

The invention discloses a solar steam direct power generation system with a heat storage function. The solar steam direct power generation system comprises a heat collection subsystem, a heat storage subsystem and a power generation subsystem. Under irradiation conditions in the daytime, high-temperature and high-pressure saturated steam enters the inner pipe side of a sleeve type line focusing solar heat collector, and low-temperature molten salt enters the sleeve side. Focusing solar energy firstly heats the molten salt, and the steam is heated to an overheated state after the temperature rise of the molten salt. Part of the overheated steam enters a high-pressure storage tank for heat storage, and the rest of overheated steam enters the power generation subsystem for power generation. Meanwhile, the molten salt enters a high-temperature molten salt tank for heat storage. Under irradiation-free conditions in the nighttime, the molten salt in the high-temperature molten salt tank enters a low-temperature molten salt tank after heat release by an overheater; the high-pressure saturated steam flows out from the high-pressure storage tank and is heated by the overheater to form overheated steam to enter the power generation subsystem for power generation. The solar steam direct power generation system disclosed by the invention realizes the all-weather power generation by adopting a solar steam direct power generation technology through taking water / steam as not only a working medium but also a main heat storage medium and as an auxiliary heat storage medium with coordinate application of the small amount of molten salt.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

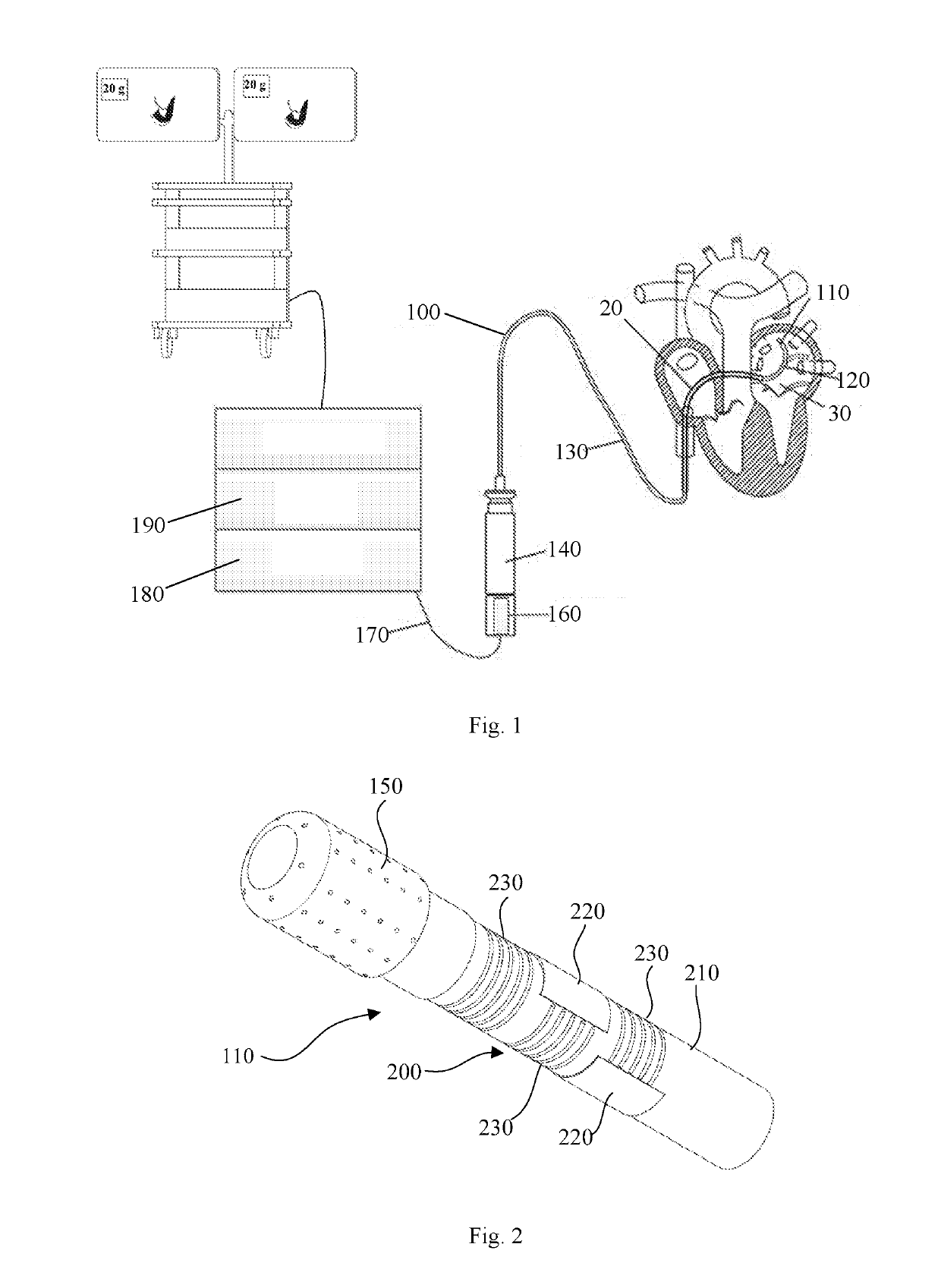

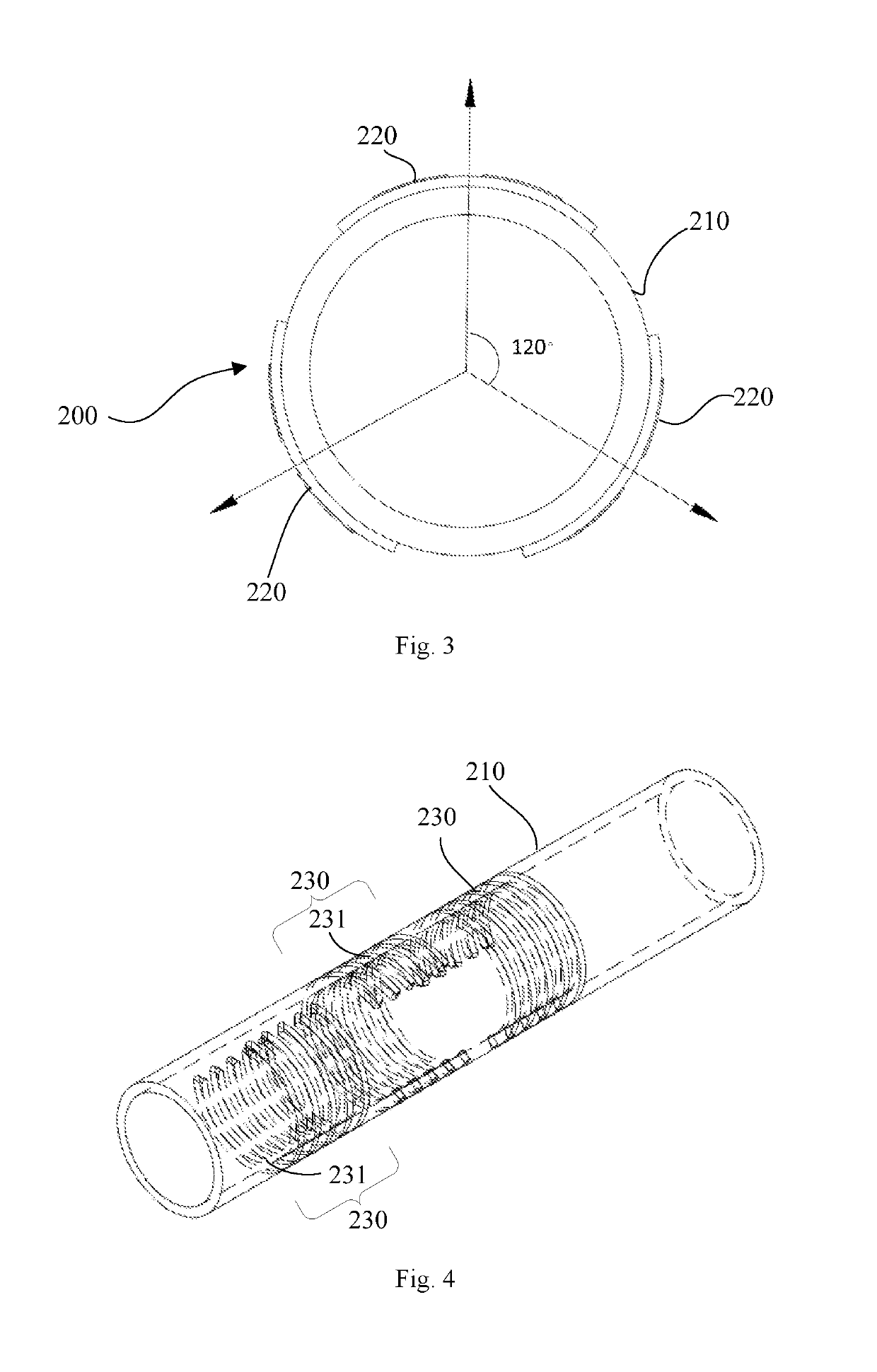

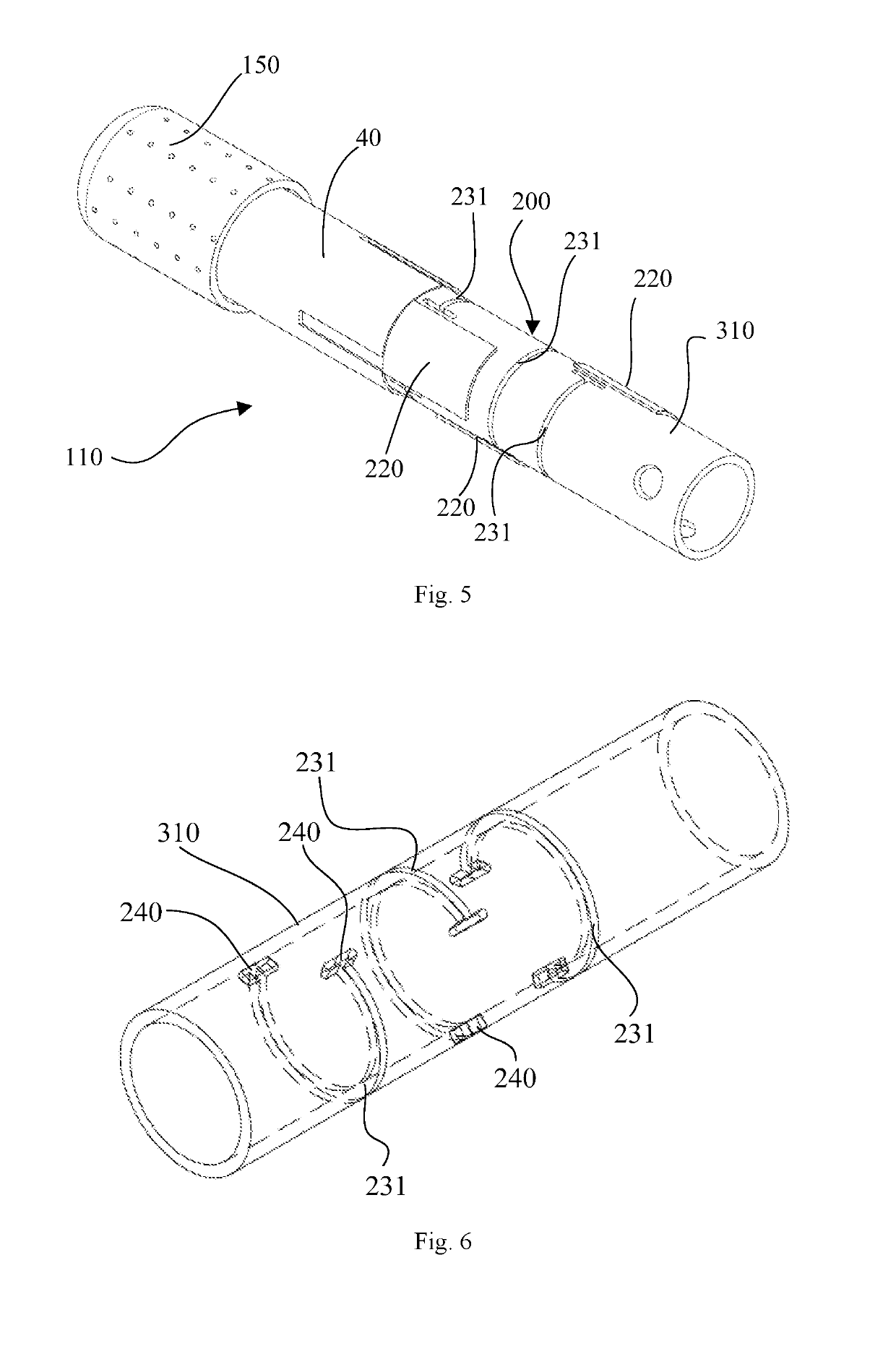

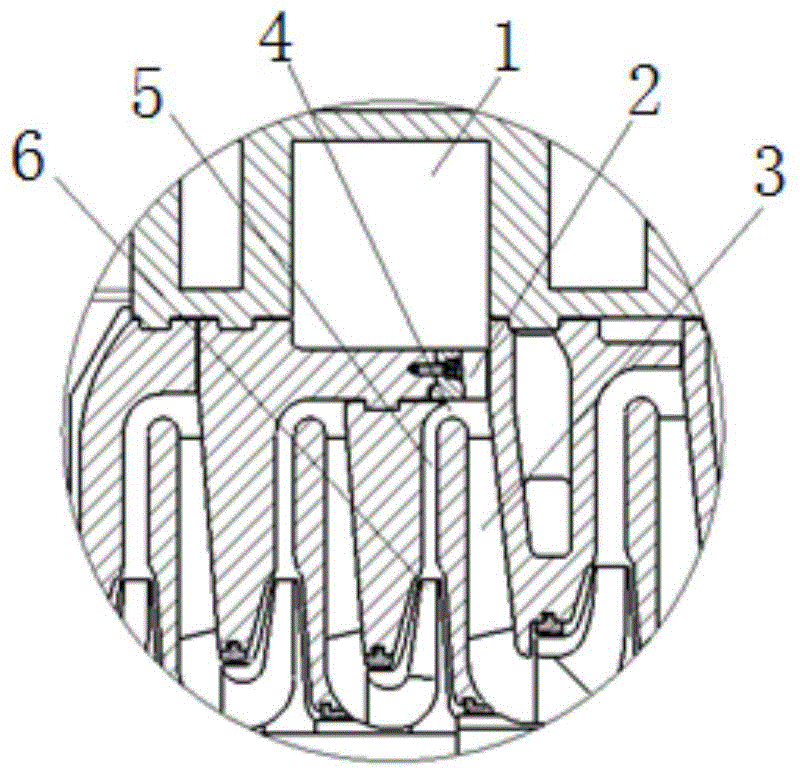

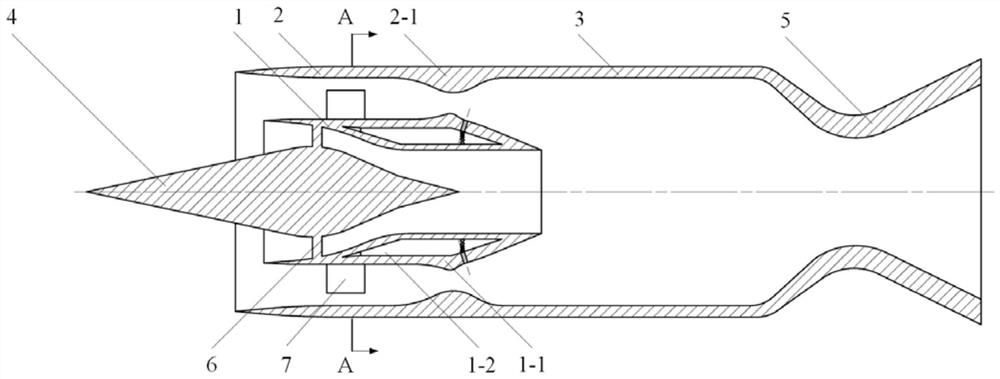

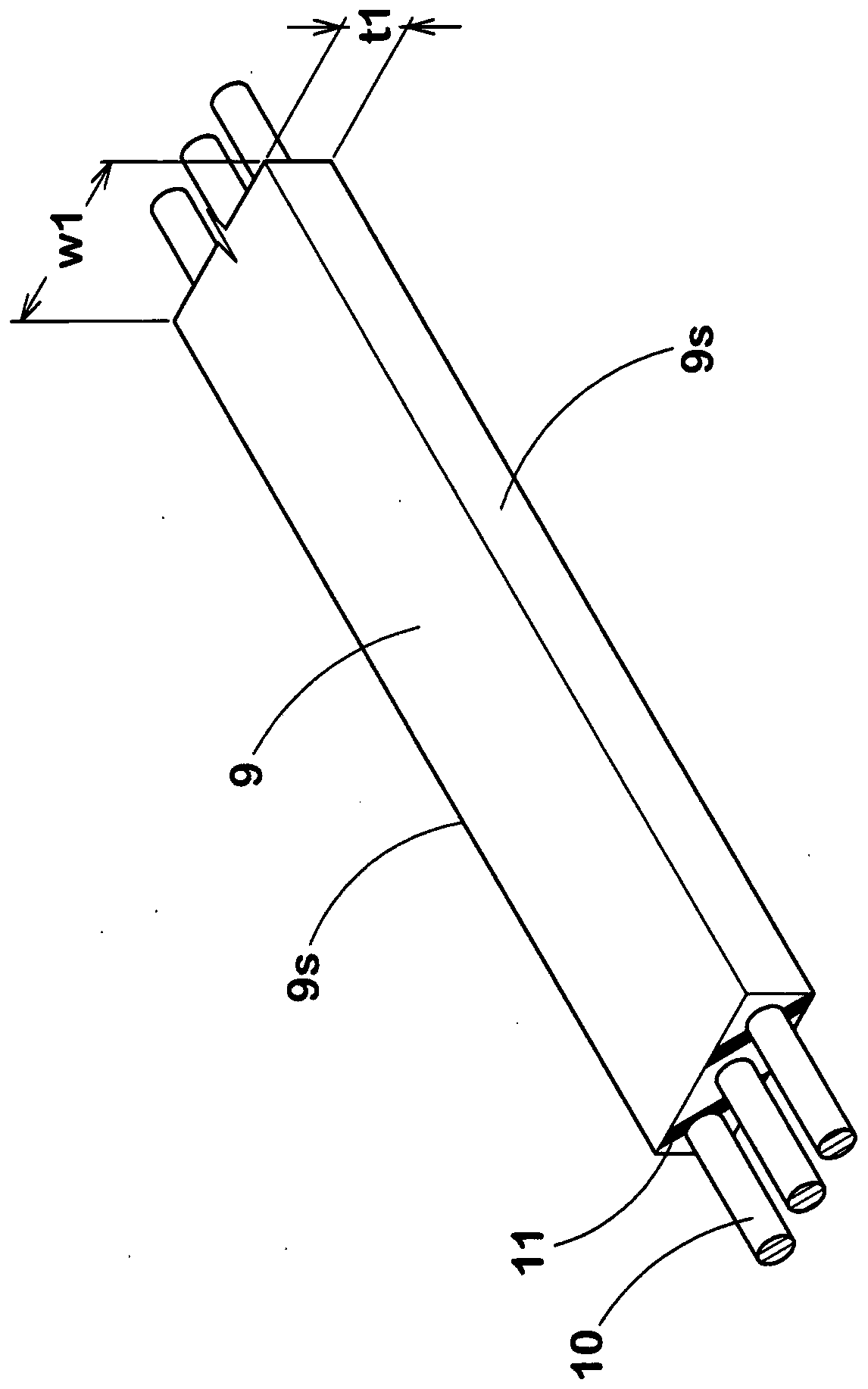

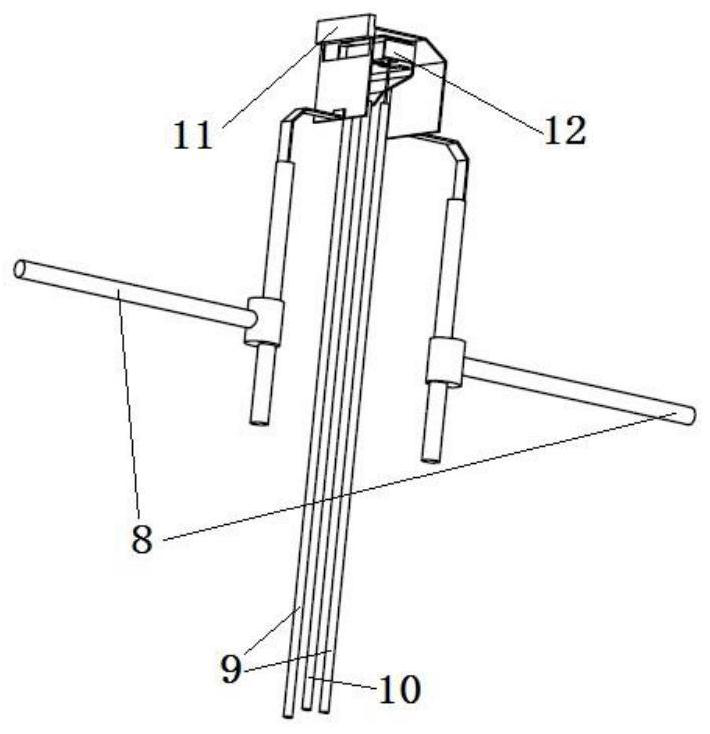

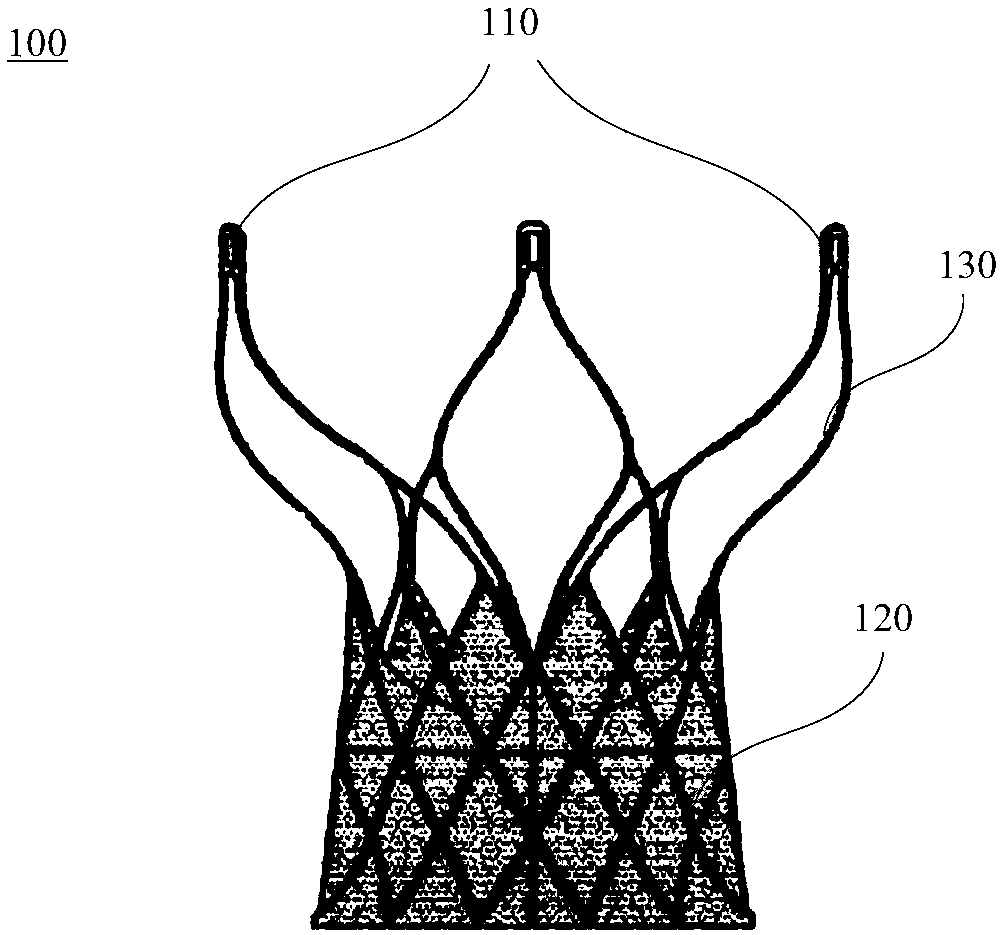

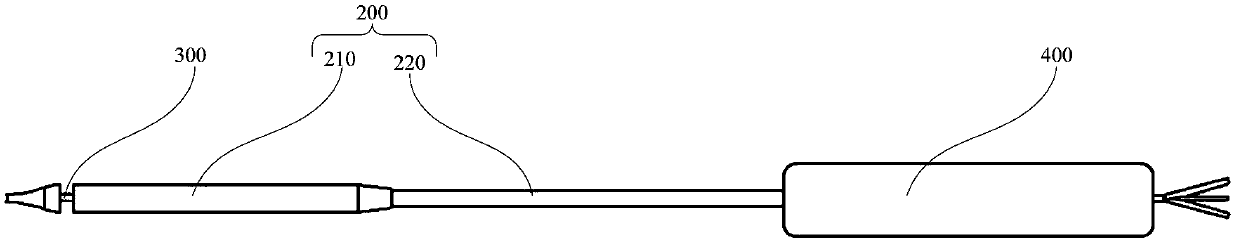

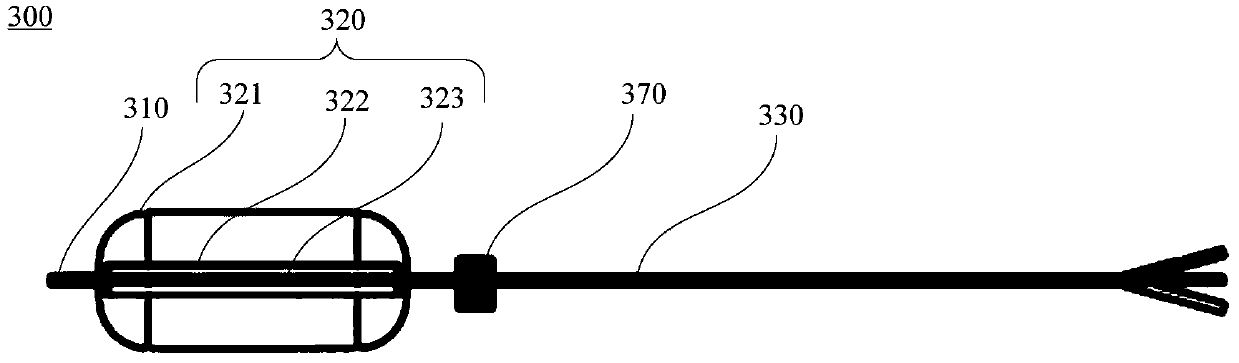

Electrophysiology catheter

ActiveUS20190307504A1Improve contact force measurement accuracyElectrical signal is accurateElectrocardiographyStrain gaugeDistal portionEngineering

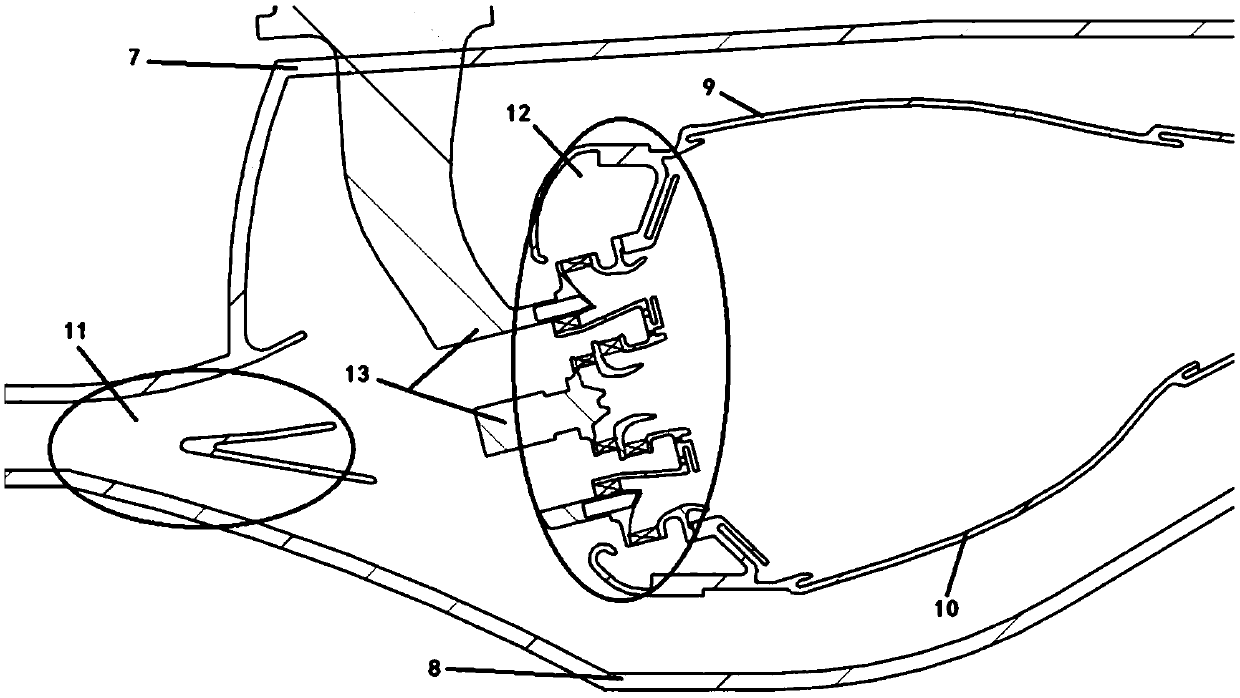

An electrophysiology catheter (100) includes a catheter distal portion (110) on which a force sensor (200) is arranged. The force sensor (200) includes an elastic tube (210) and strain gauges (220). The elastic tube (210) has a hollow portion in its wall, and the strain gauges (220) are disposed external to the hollow portion. Compared to the design with the strain gauges (220) overlapping the hollow portion, arranging them over solid portions of the elastic tube (210) allows the strain gauges (220) to collect more accurate electrical signals while suffering from less interference. This can result in a significant improvement in contact force measurement accuracy of the catheter distal portion (110).

Owner:SHANGHAI MICROPORT EP MEDTECH CO LTD

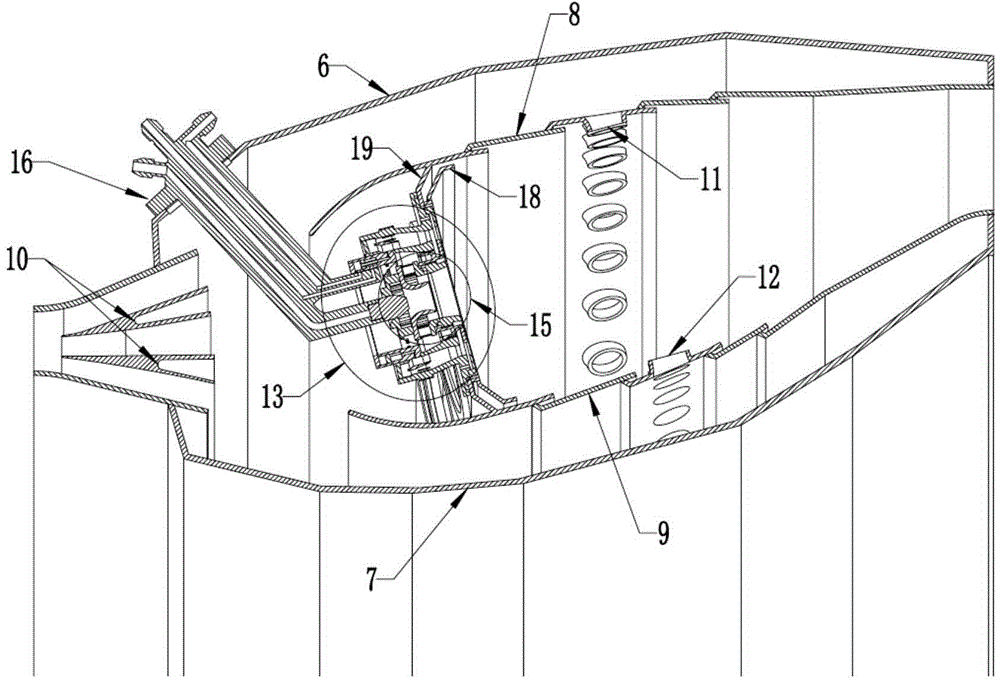

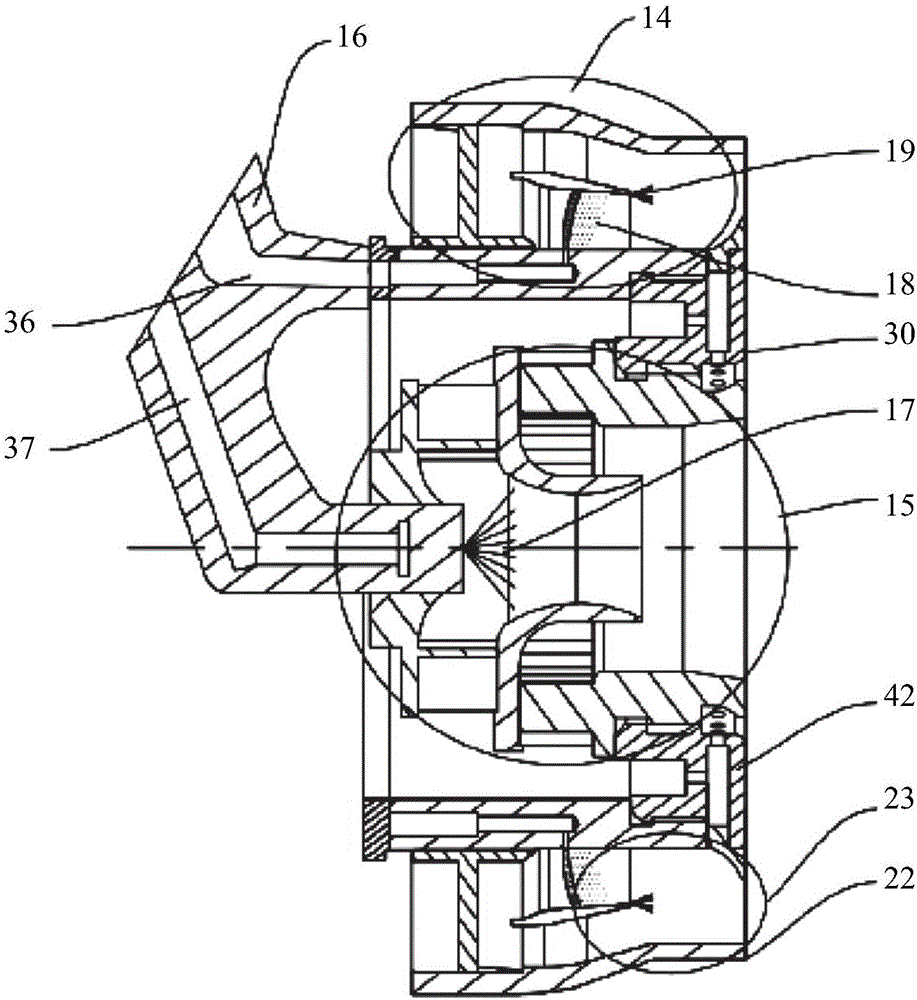

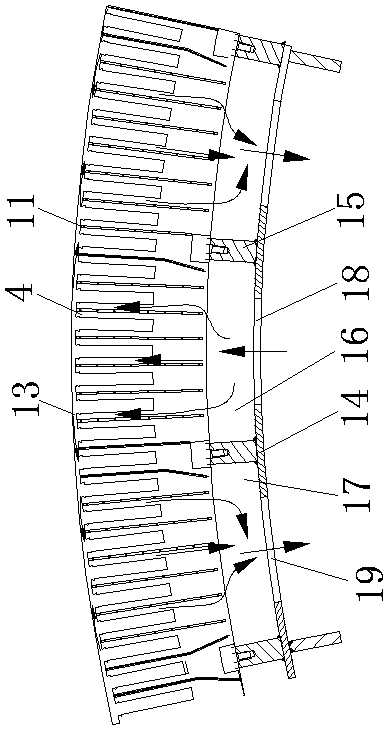

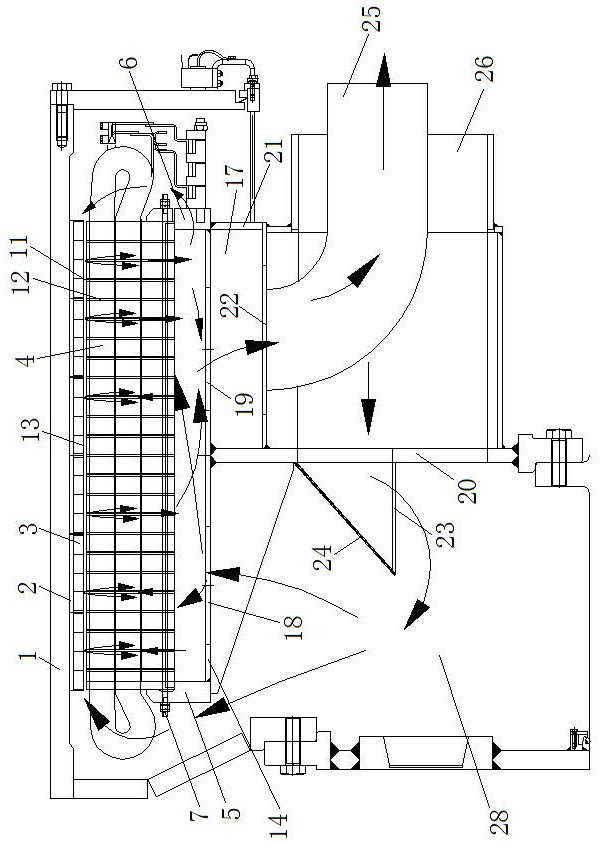

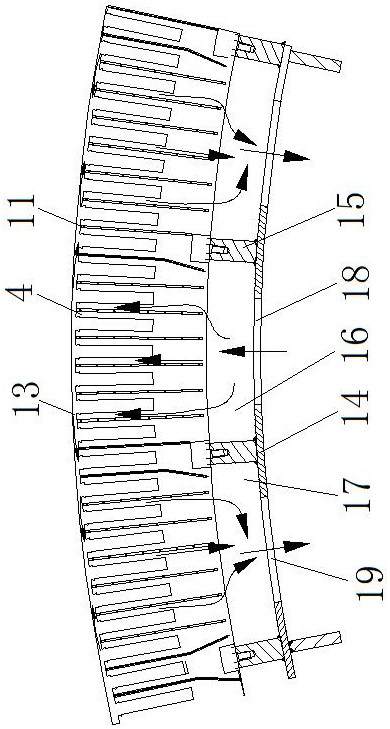

Low-pollution combustion chamber adopting forced diversion at main-combustion-stage outlet

ActiveCN106594801AImprove circumferential uniformityWell mixedContinuous combustion chamberCombustion chamberSpray nozzle

Provided is a low-pollution combustion chamber adopting forced diversion at a main-combustion-stage outlet. The emission level of LTO circulating pollutants can be lowered, and the ignition performance of the combustion chamber is improved. A fuel nozzle supplies all fuel to the combustion chamber, main-combustion-stage fuel is sprayed into an inner channel of a main-combustion-stage pre-film plate, part of fuel forms main-combustion-stage straight spray oil mist, part of fuel is sprayed to the main-combustion-stage pre-film plate to form an uniform oil film, breaking and atomization are conducted under the two-path rotational flow shear effect of the pre-film plate inner channel and a pre-film plate outer channel to from main-combustion-stage pneumatic atomized oil mist, the oil mist and the air are mixed to form an uniform oil-air mixture, and the oil-air mixture enters a flame tube for pre-mixing combustion; and a main-combustion-stage outlet diversion ring is mounted at the main-combustion-stage outlet, the longitudinal section of the outer side of the outlet diversion ring is in a smooth arc line, the arc line is inward in the radial direction and extends forwards in the axial direction, the radial height of the arc line is not larger than 1 / 2 of the penetration depth of the main-combustion-stage straight spray oil mist so that the main-combustion-stage air flow can form expanding flowing, and a full center backflow region is formed.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD +1

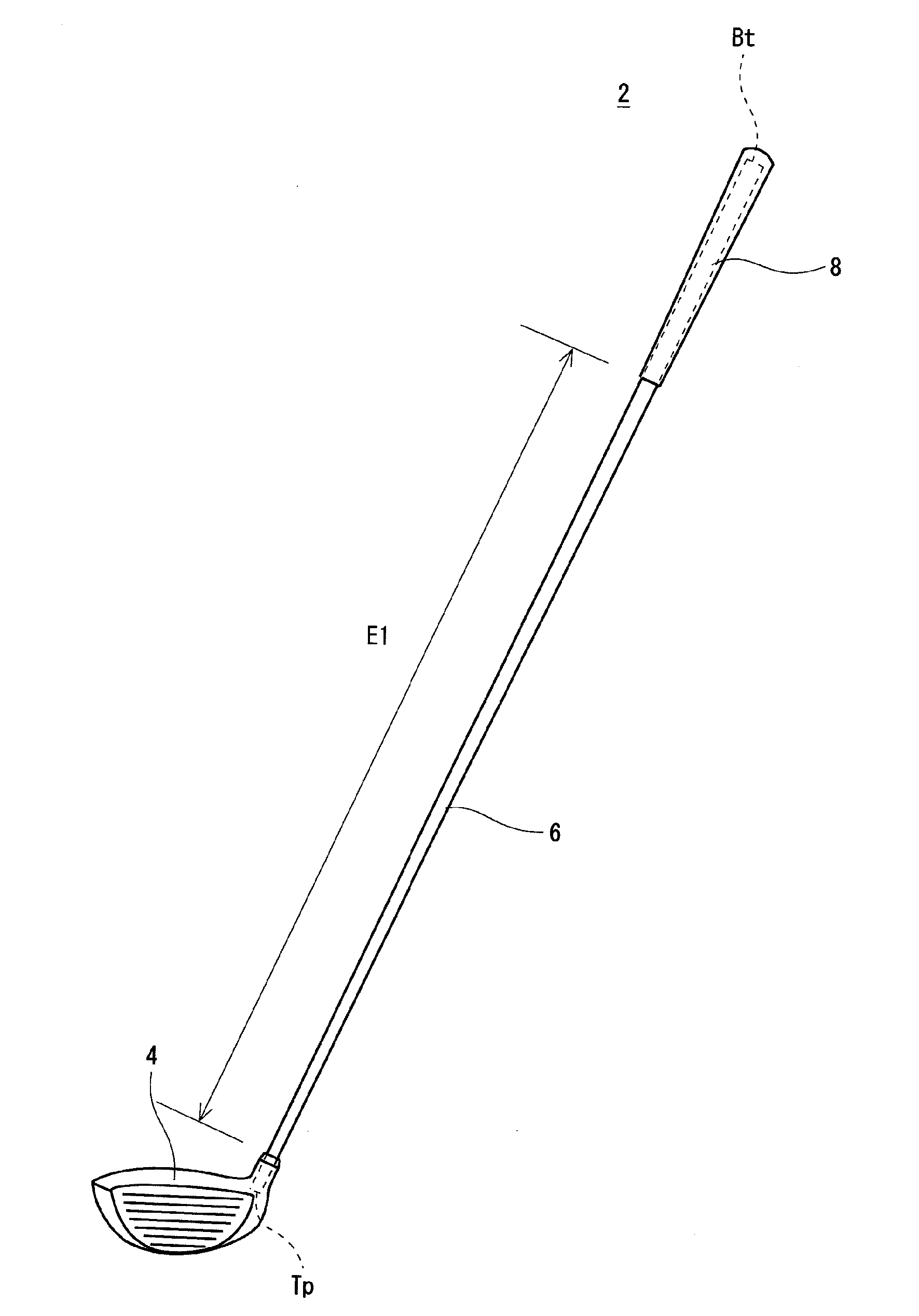

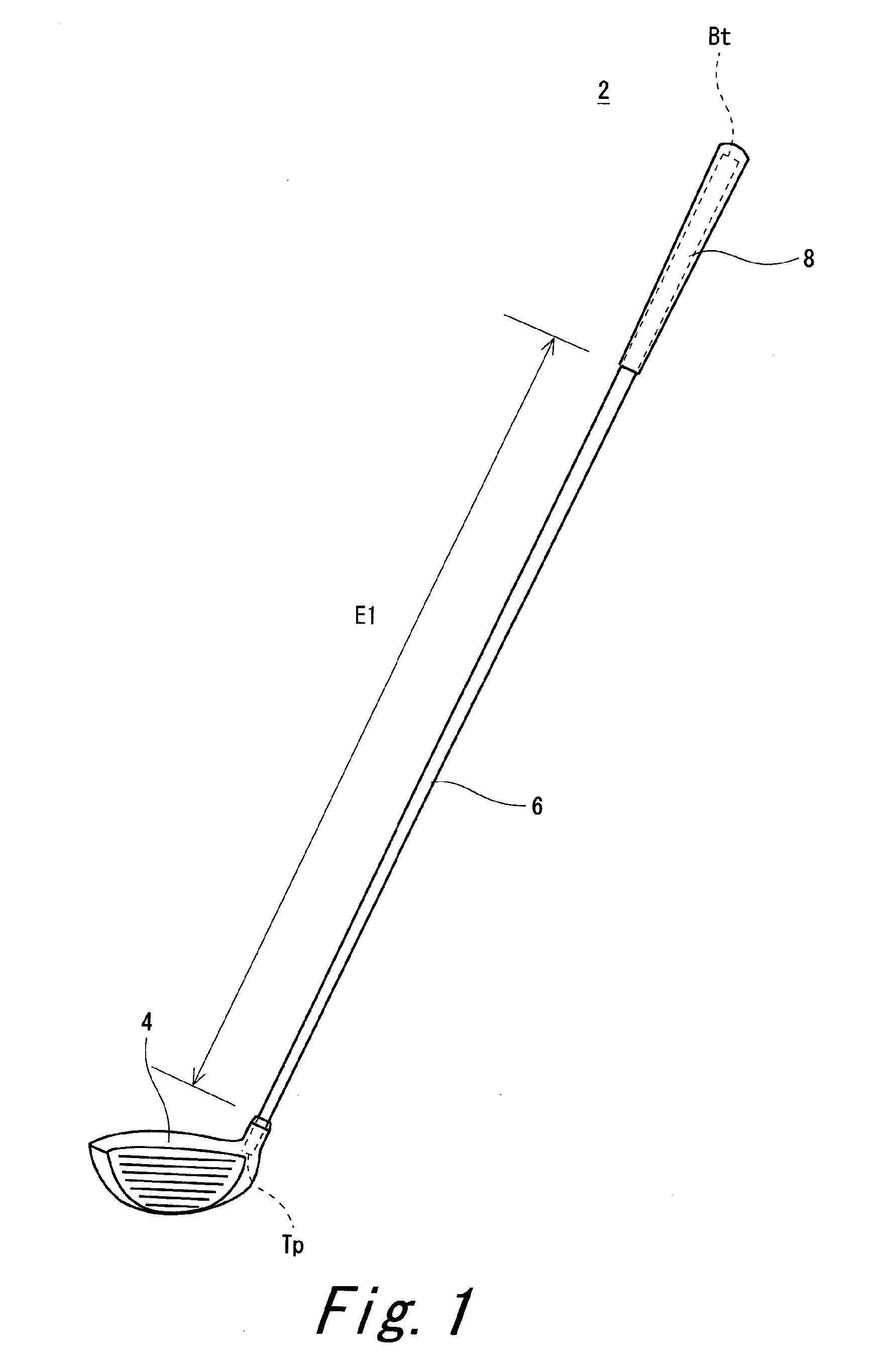

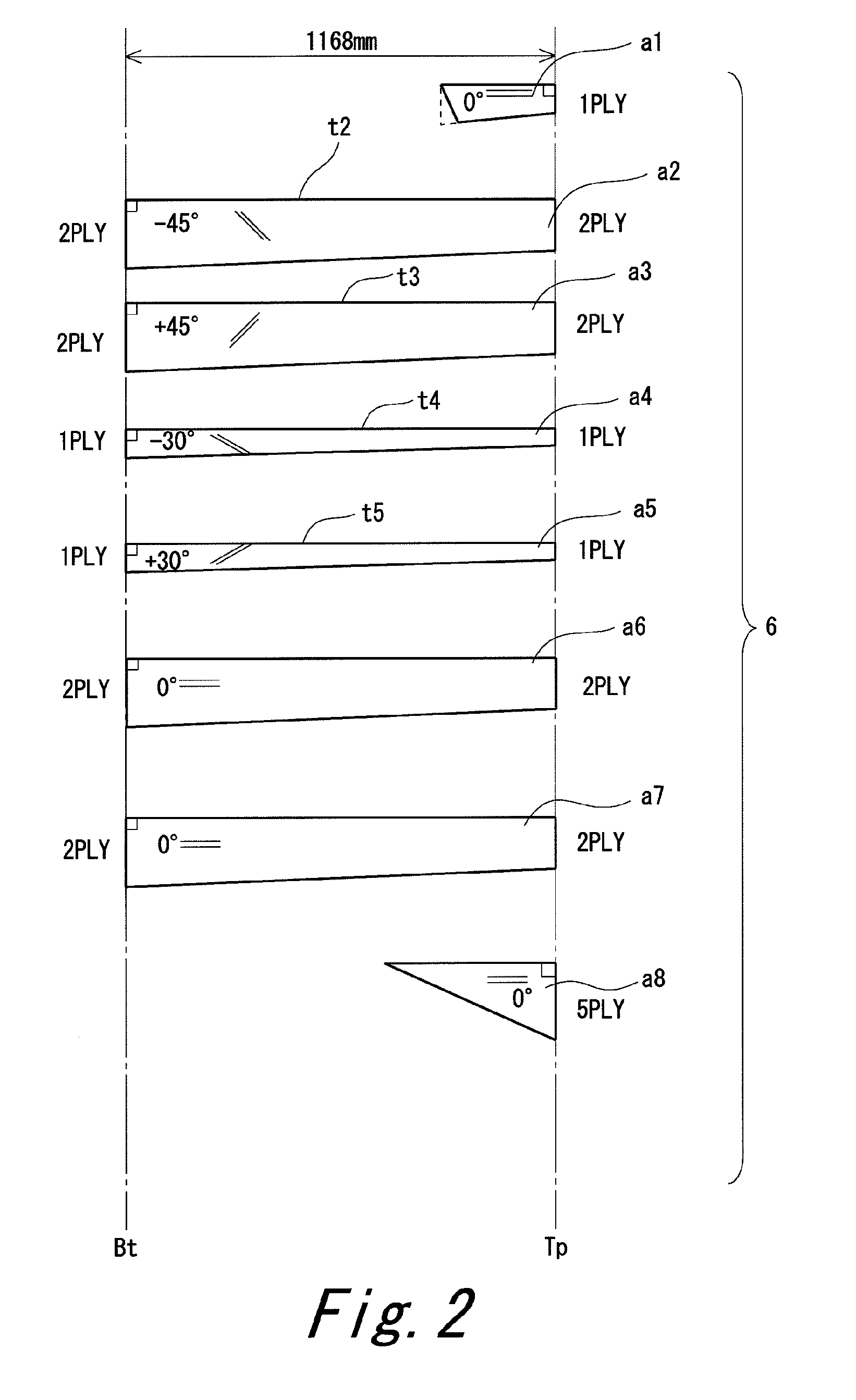

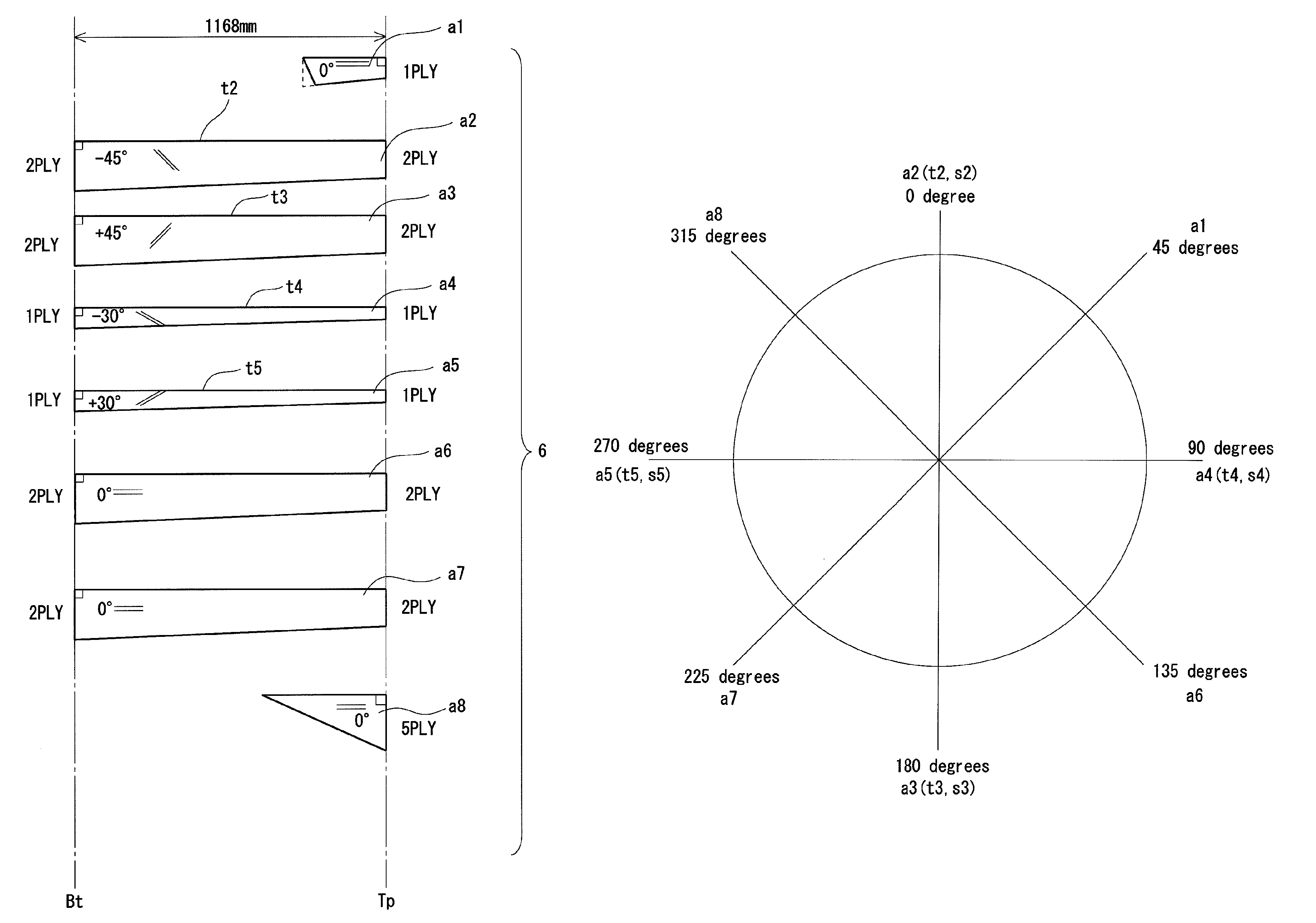

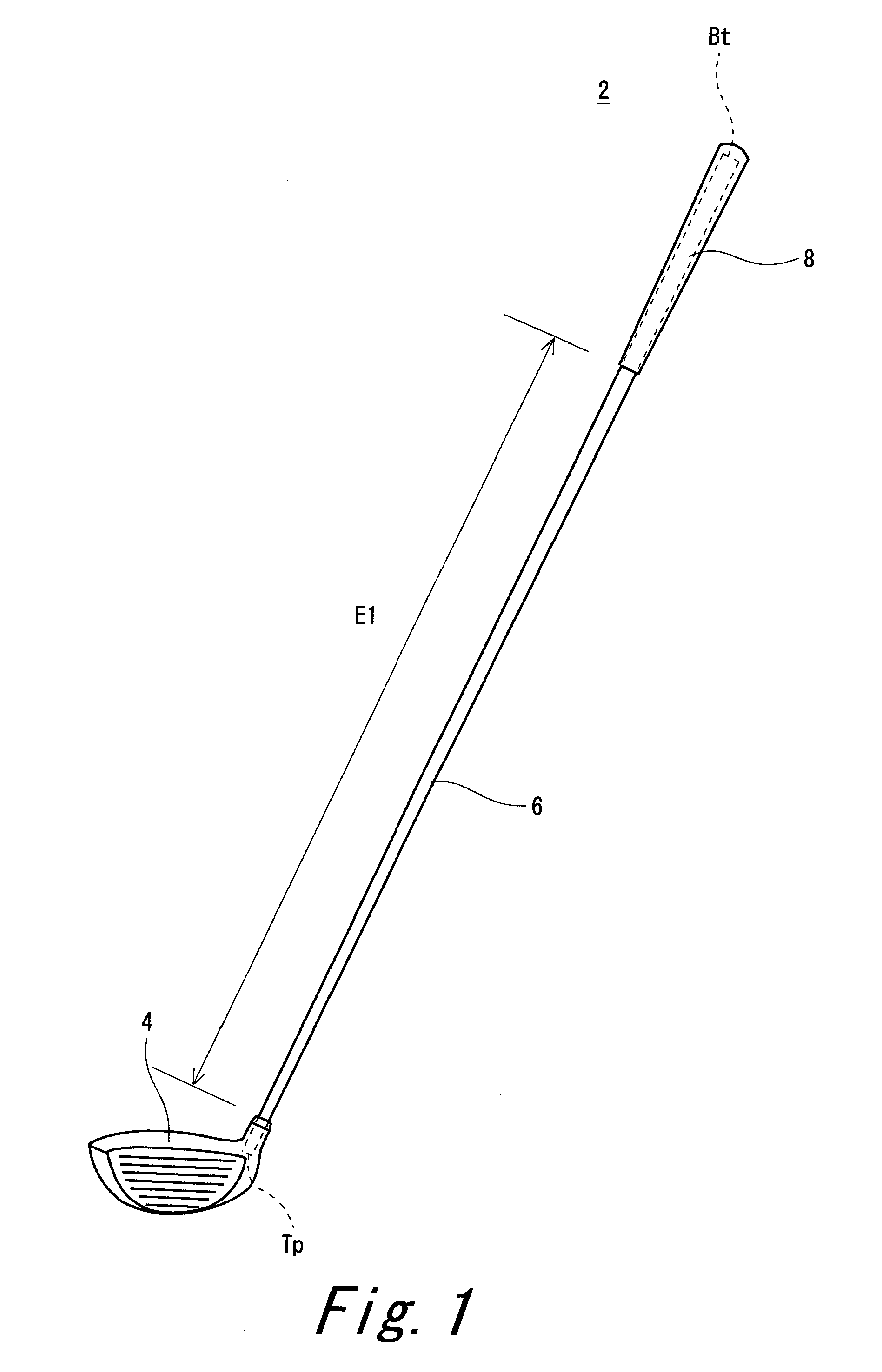

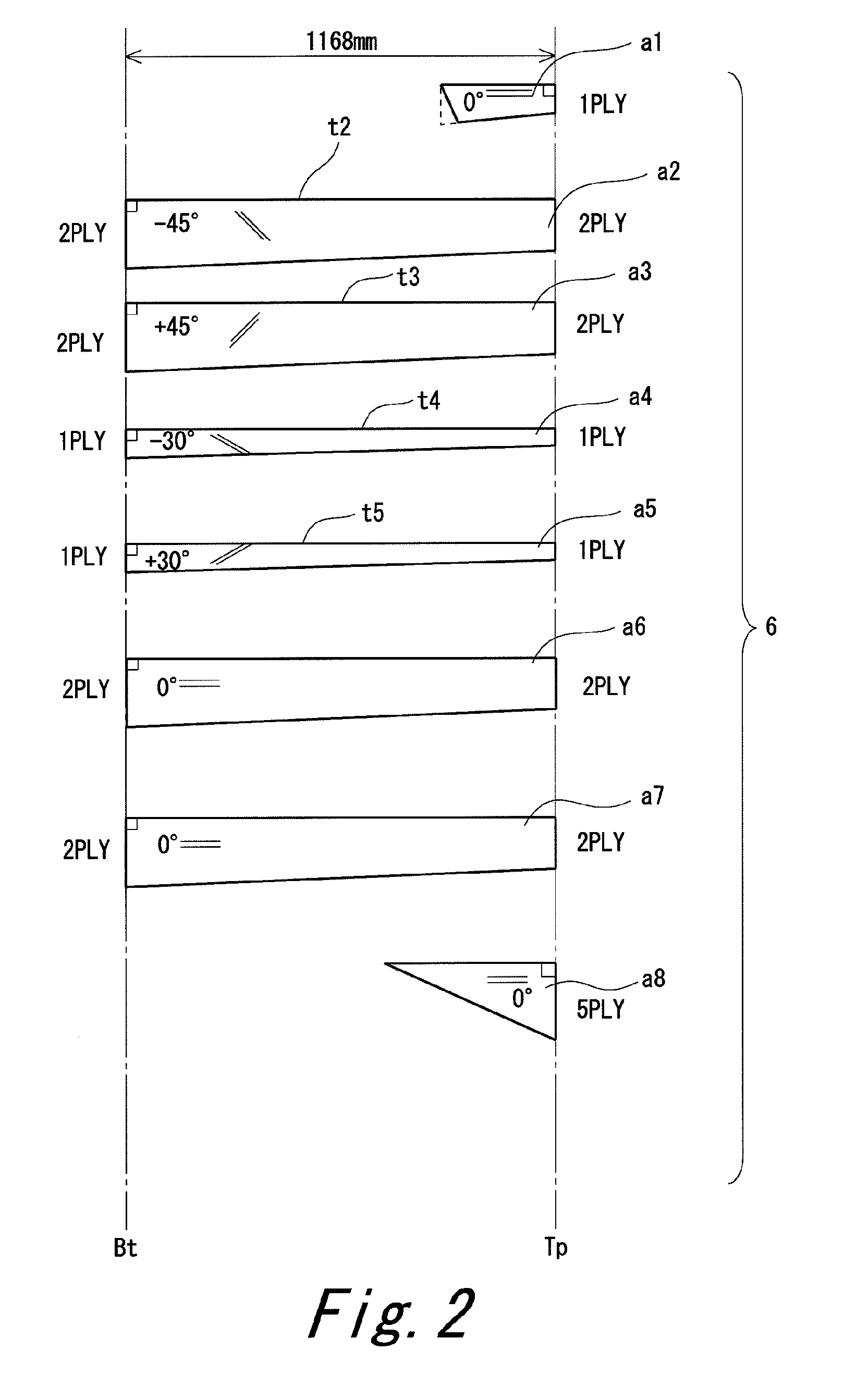

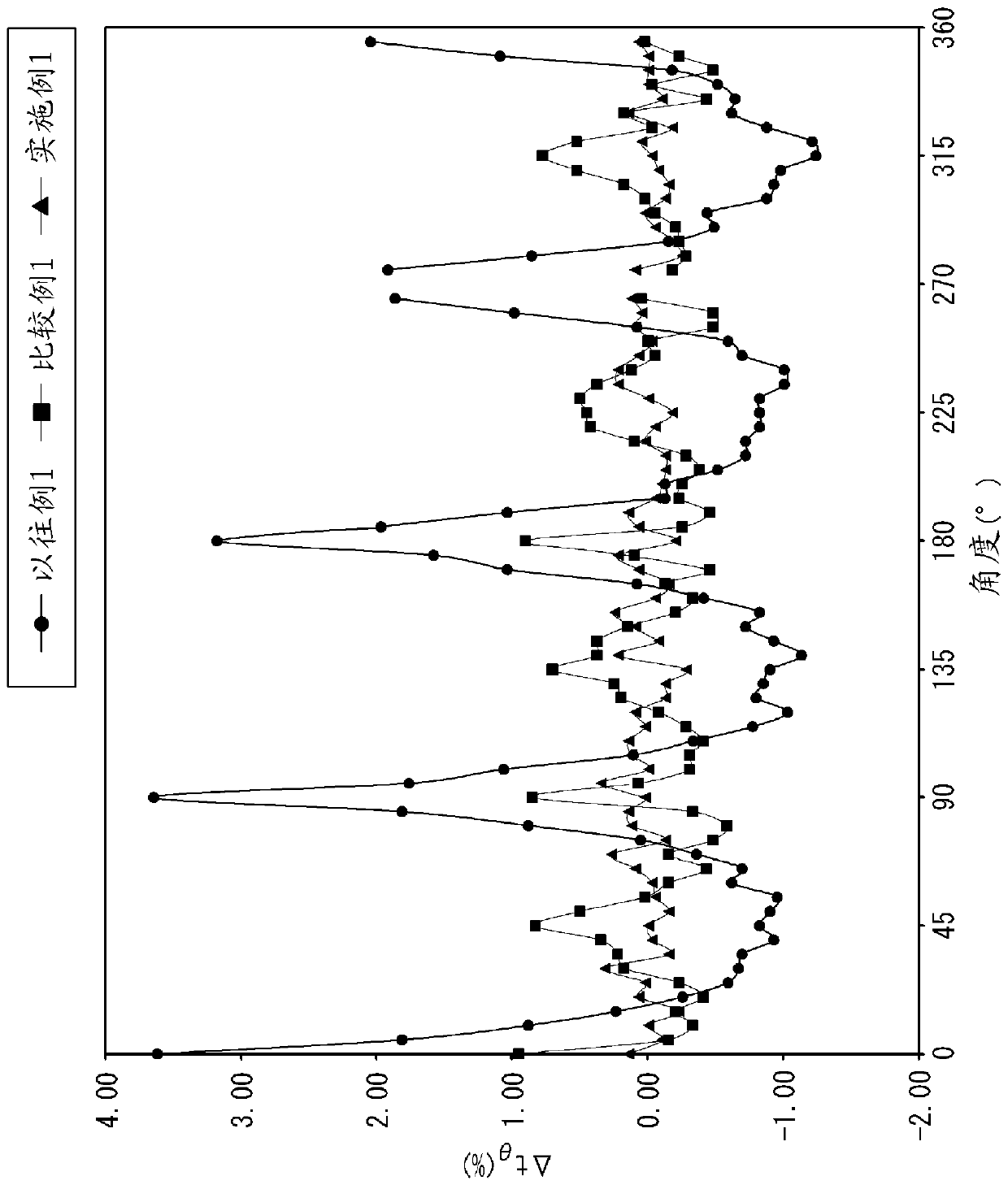

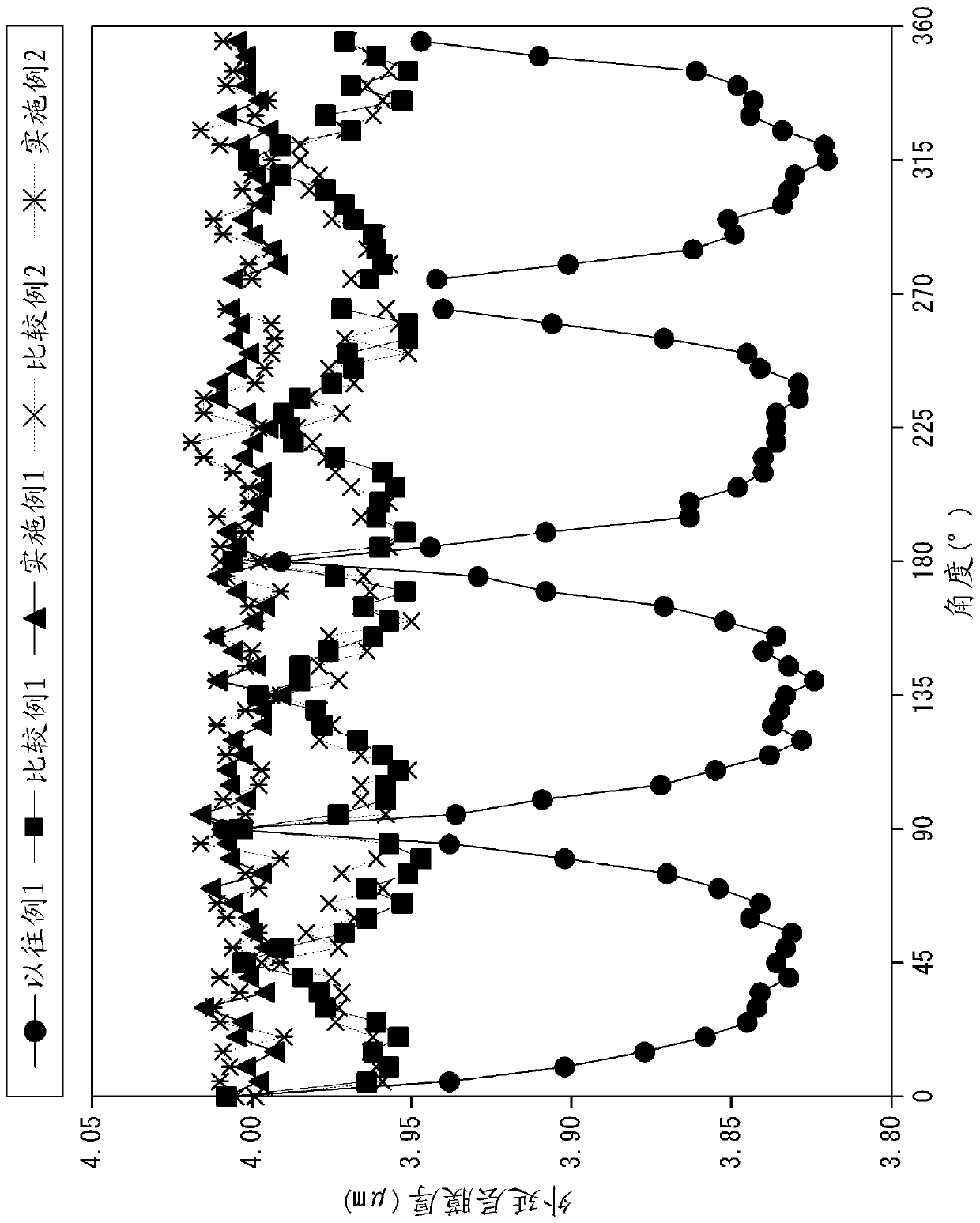

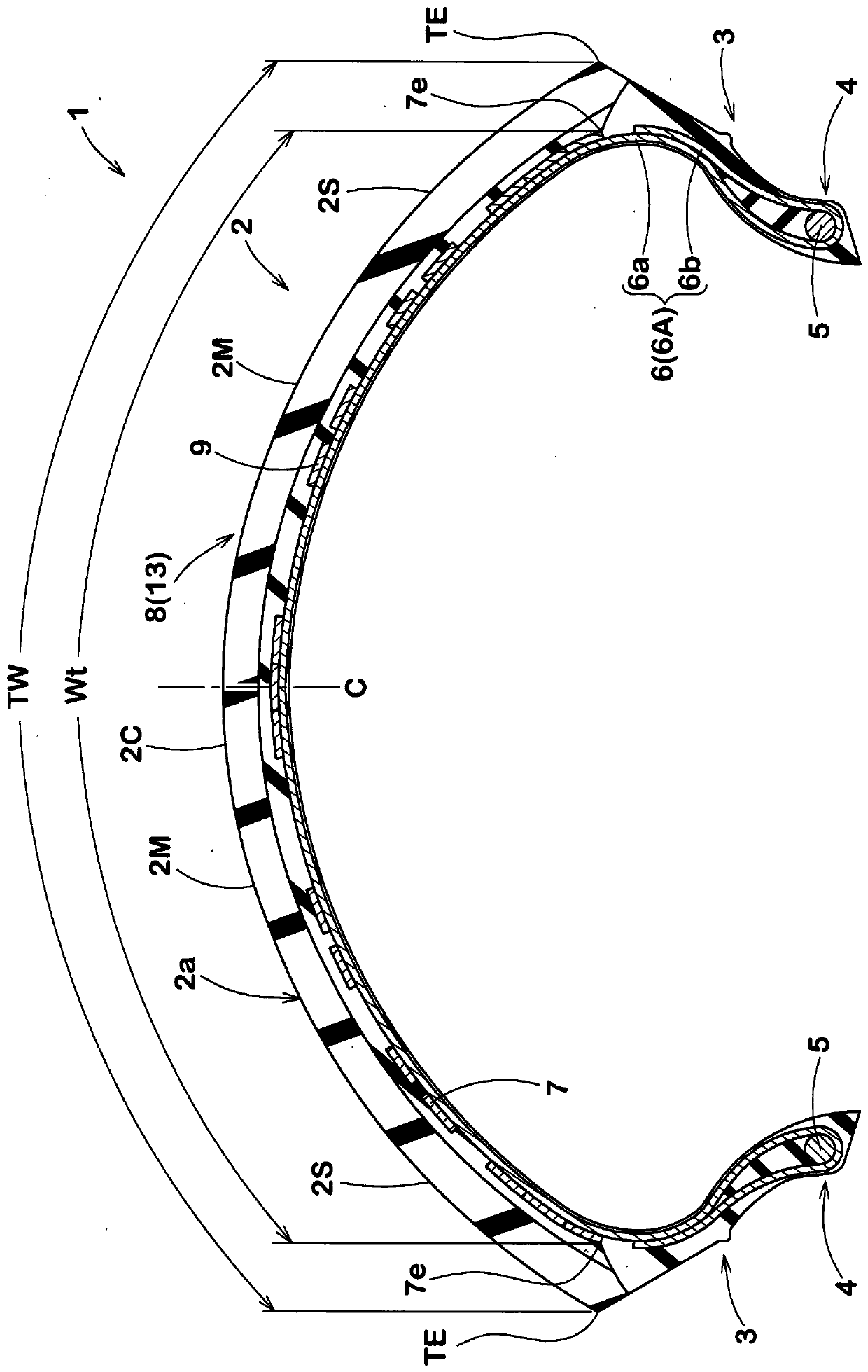

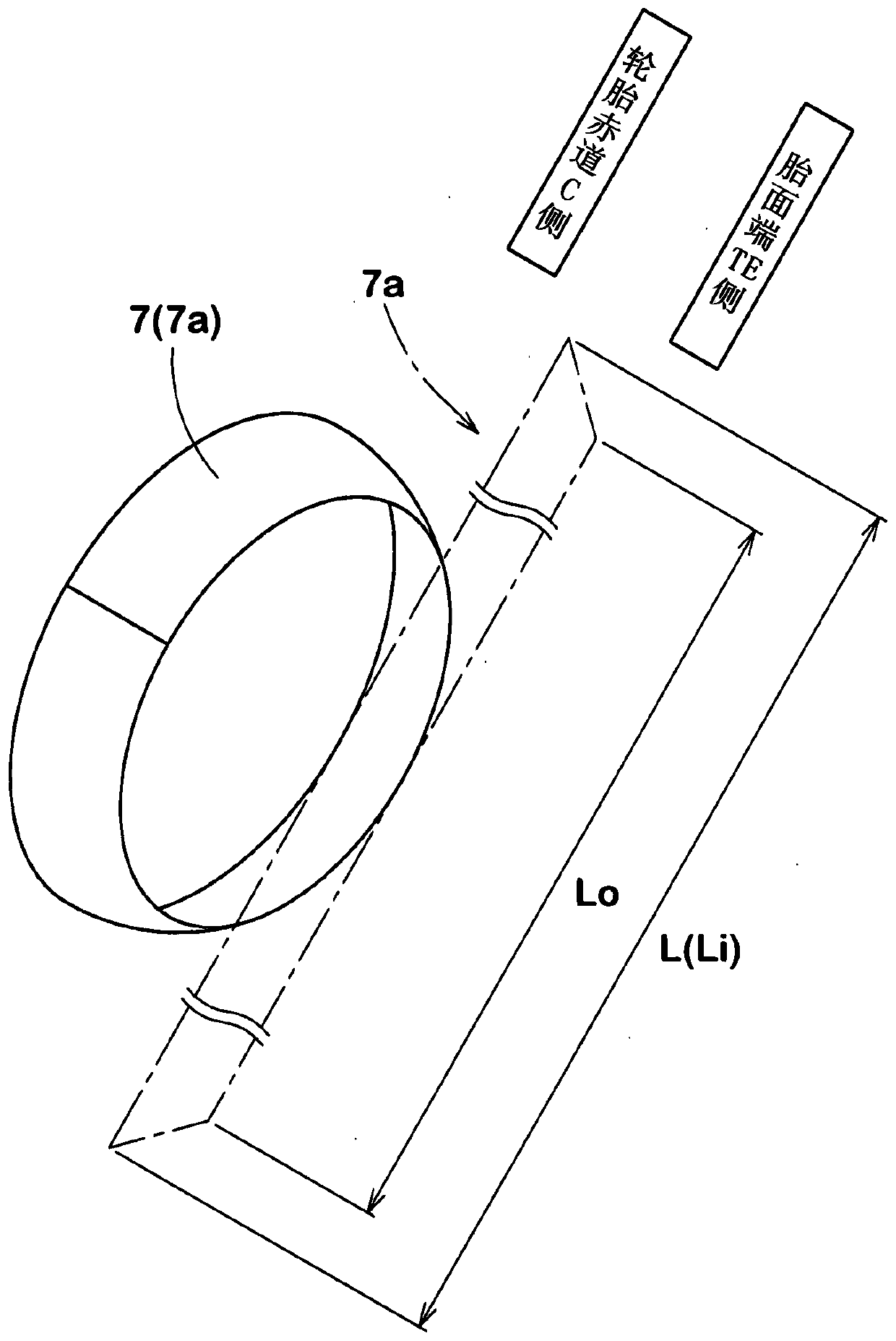

Golf club shaft

A golf club shaft is manufactured using a plurality of prepreg sheets a1 to a8. The plurality of prepreg sheets a1 to a8 includes full length sheets a2 to a7 disposed all over in a shaft axis direction and partial sheets a1 and a8 partially disposed in the shaft axis direction. The number of plies is substantially an integer in all the full length sheets a2 to a7. The full length sheets a2 to a7 include four or more bias sheets a2 to a5. Circumferential winding start positions of the bias sheets a2 to a5 are dispersed in four or more positions. Preferably, the circumferential winding start positions of the full length sheets a2 to a7 are dispersed in five or more positions.

Owner:SUMITOMO RUBBER IND LTD

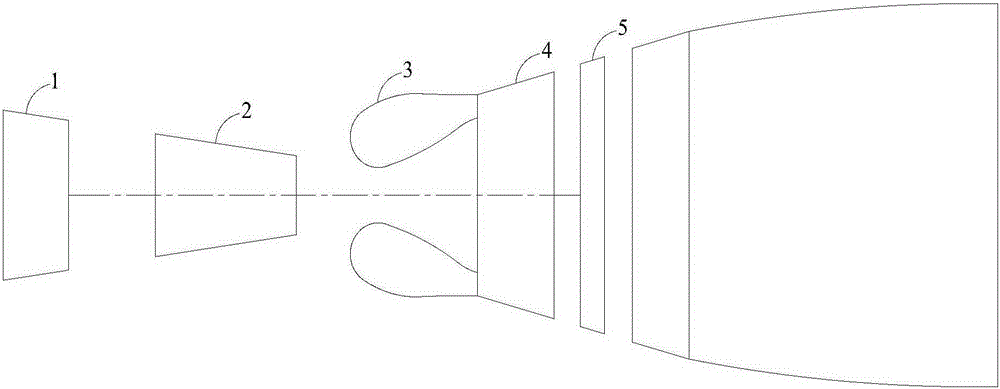

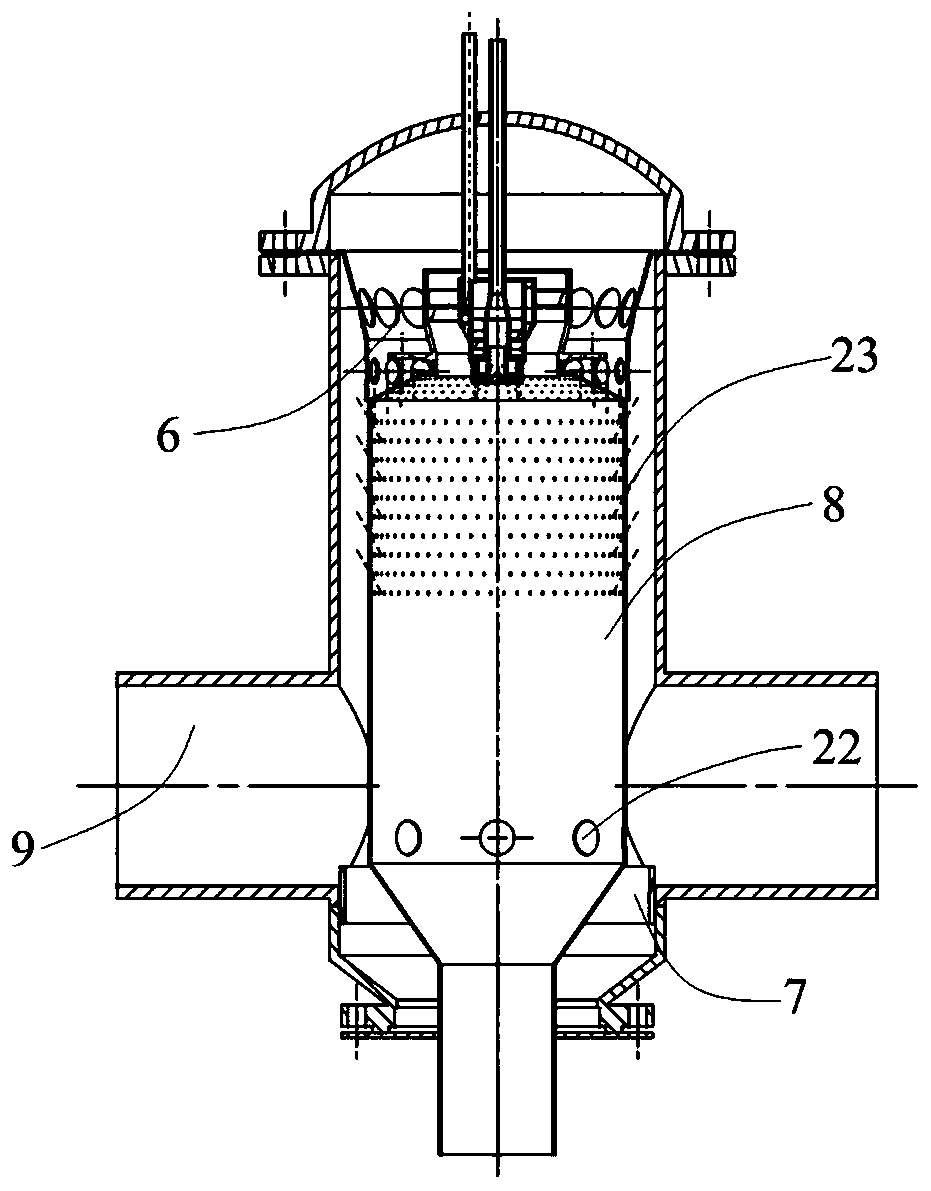

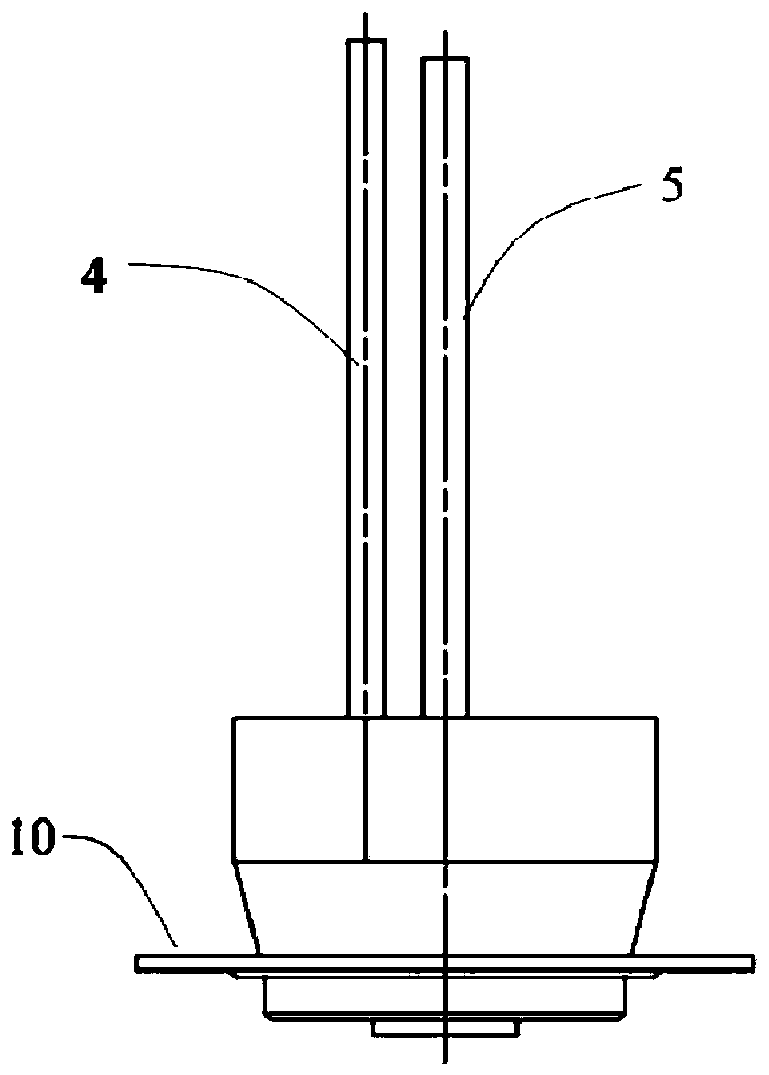

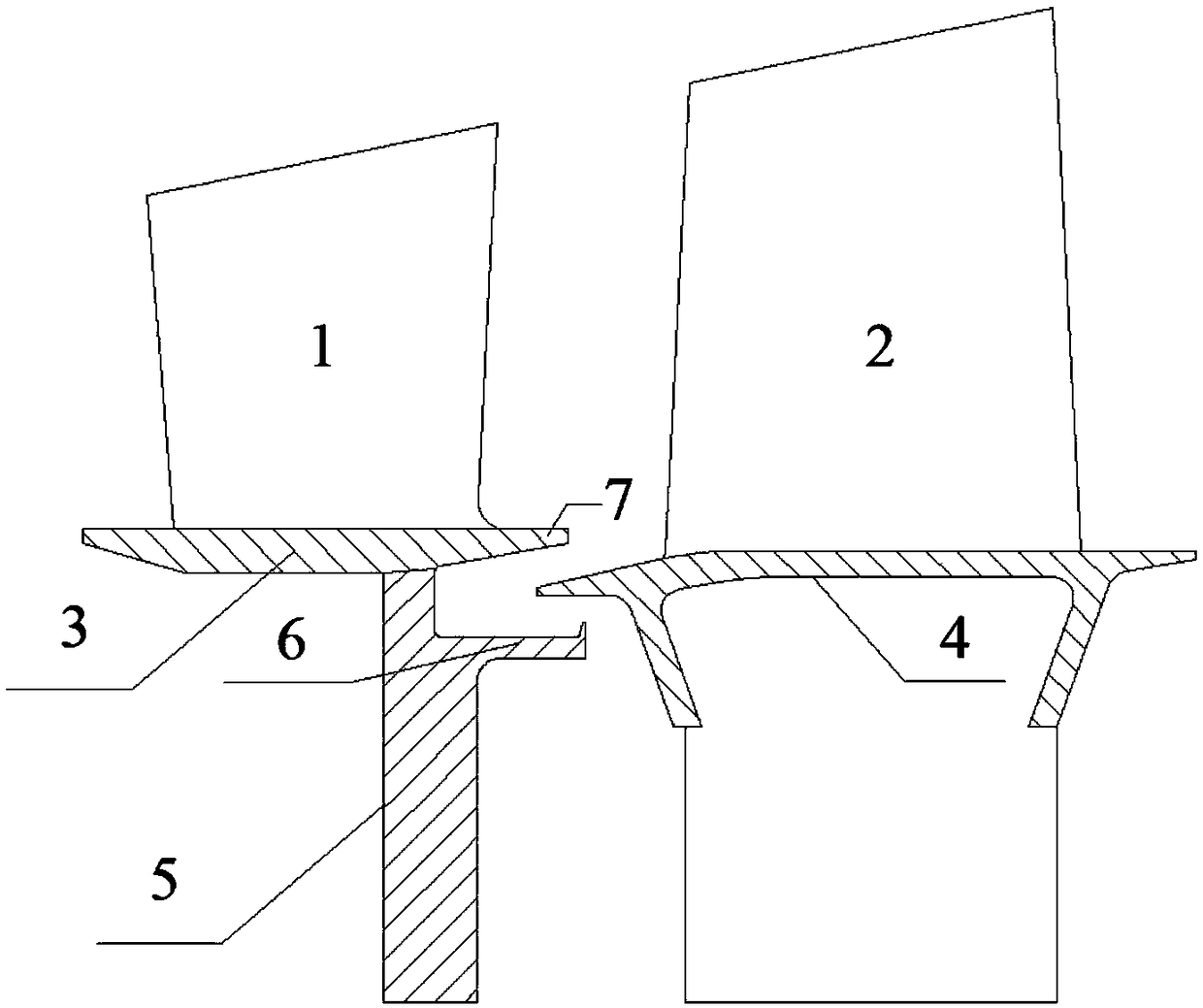

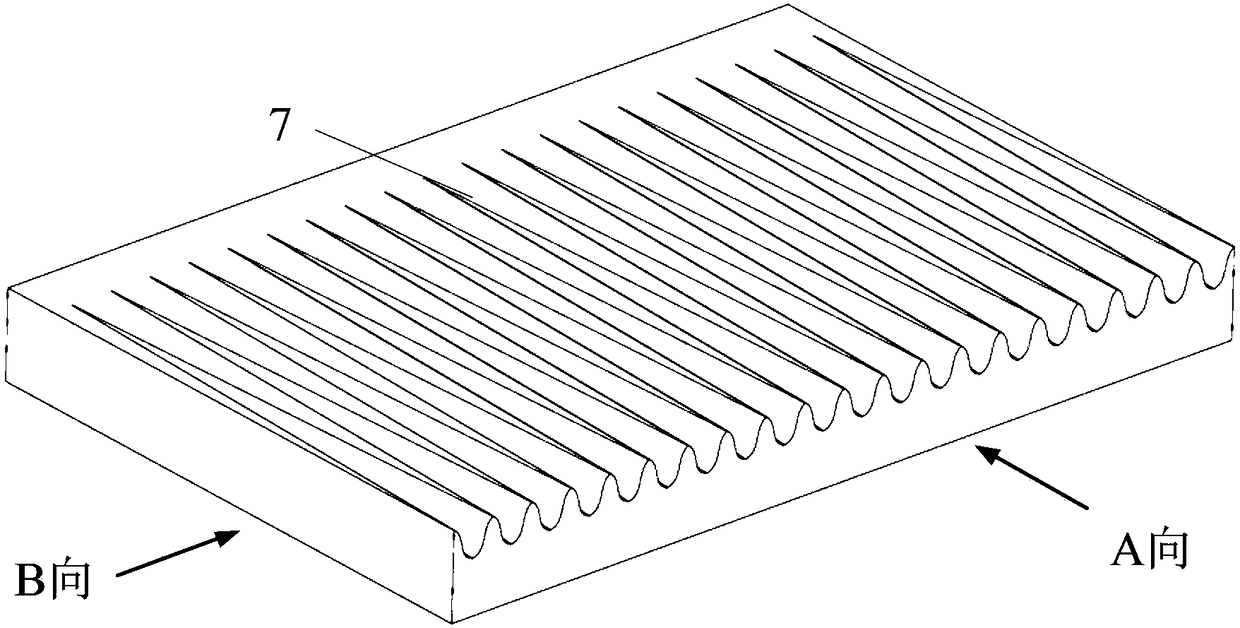

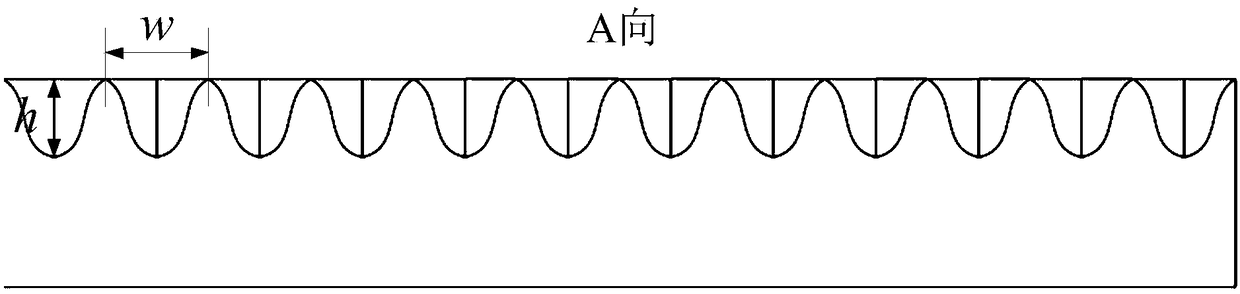

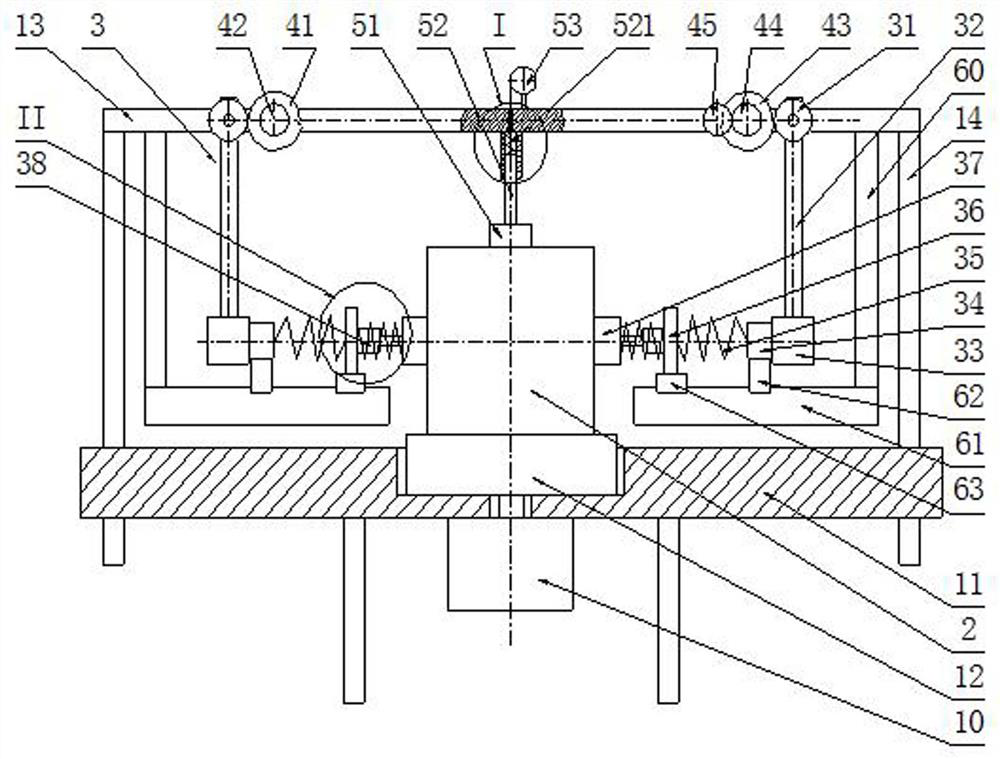

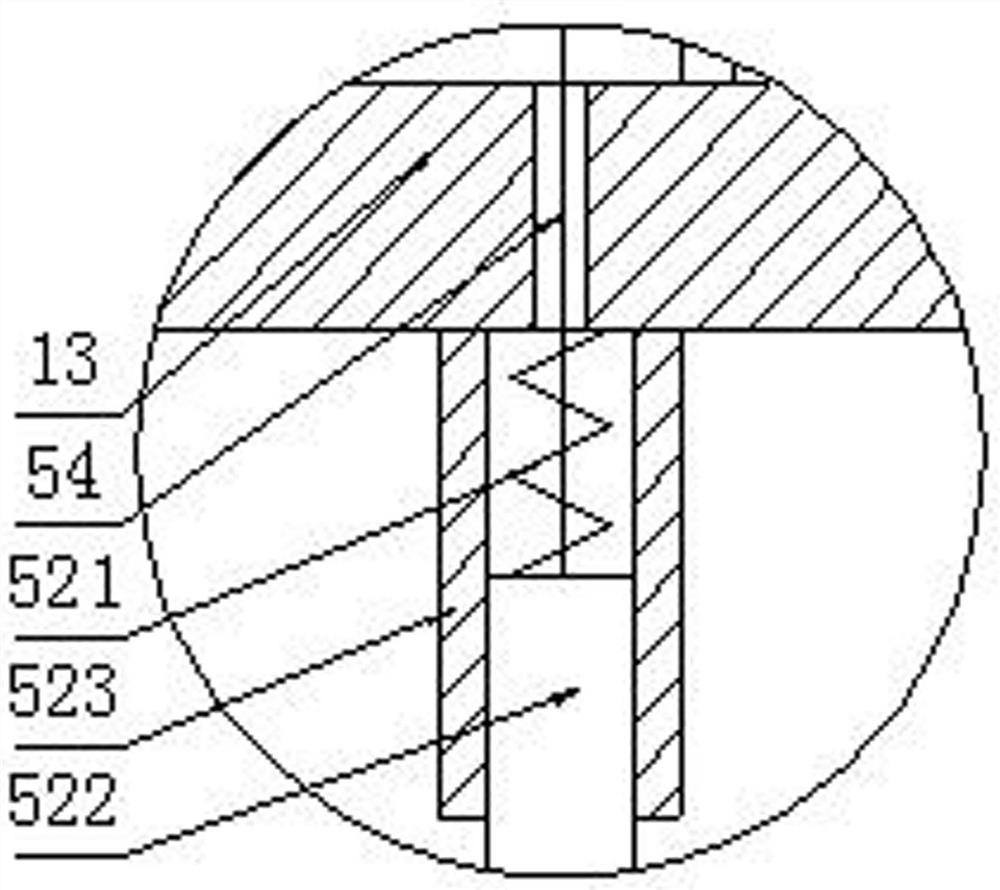

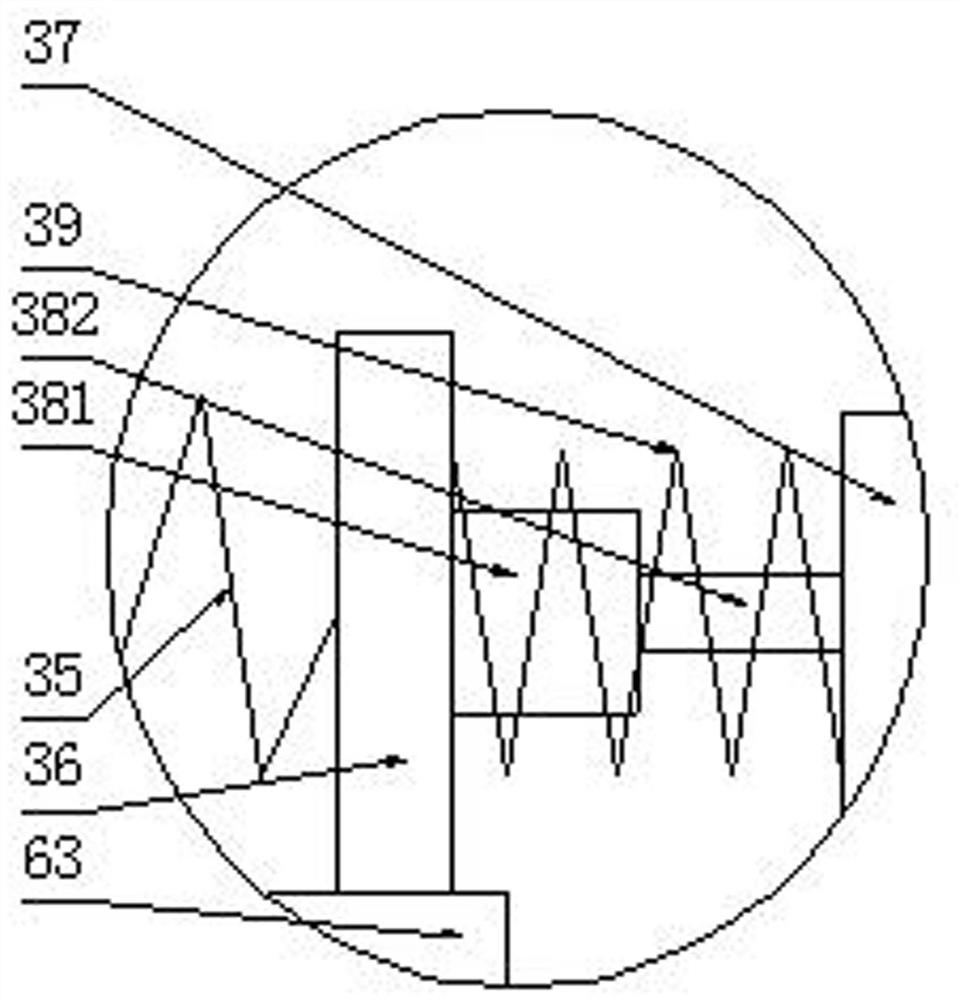

Low-pollution combustion chamber adopting forced diversion at primary combustion stage outlet

PendingCN105202580AImprove circumferential uniformityWell mixedContinuous combustion chamberCycloneCombustion chamber

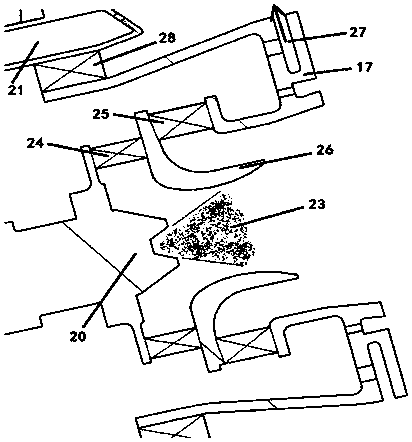

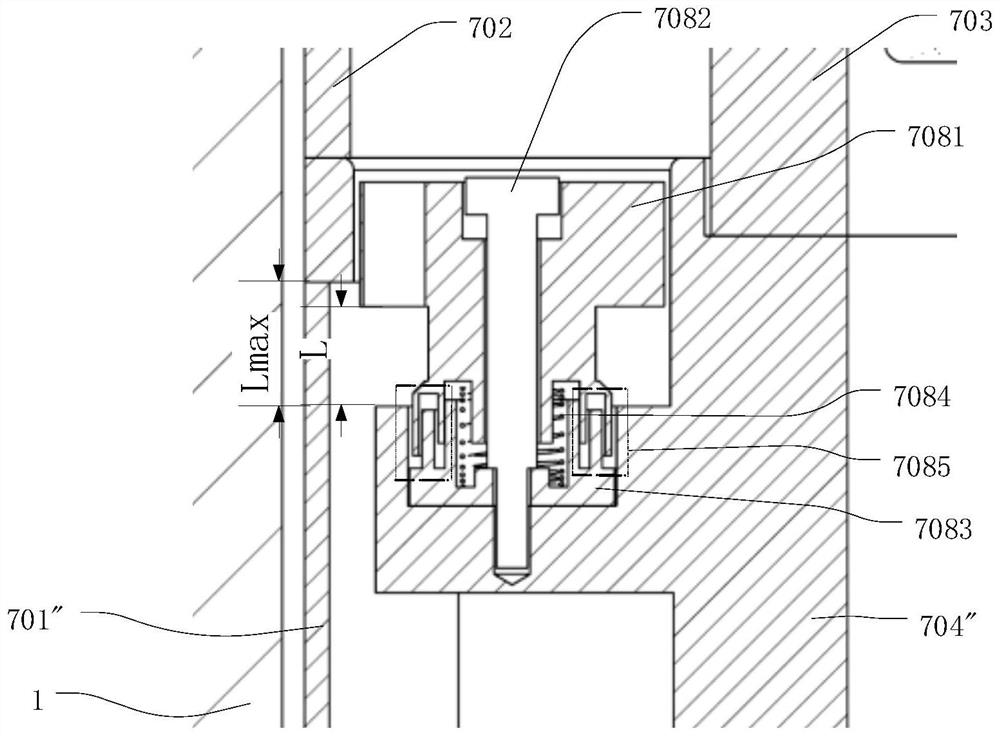

The invention discloses a low-pollution combustion chamber adopting forced diversion at the primary combustion stage outlet, which adopts a single ring cavity structure and comprises a diffuser, a combustion chamber outer casing, a combustion chamber inner casing, a flame tube outer wall, a flame tube inner wall and a combustion chamber head, wherein the combustion chamber adopts a staged combustion scheme, and is divided into a precombustion stage and a primary combustion stage; and the precombustion stage adopts a cyclone-stable diffusion combustion / cyclone premixed combustion combination mode. By adopting the central staged structure, the precombustion stage structure is simple. The primary combustion stage adopts the axial cyclone matched with the prefilming plate structure to enhance the fuel premixing and preevaporation, so that the pollution discharge of the whole landing-takeoff circulation of the aircraft engine combustion chamber is further lowered. Particularly, the primary combustion stage outlet is provided with an air forced diversion ring, so that the primary combustion stage air forms a divergent flow, and a full central backflow region is formed in the combustion chamber, thereby improving the ignition performance of the central backflow region.

Owner:BEIHANG UNIV

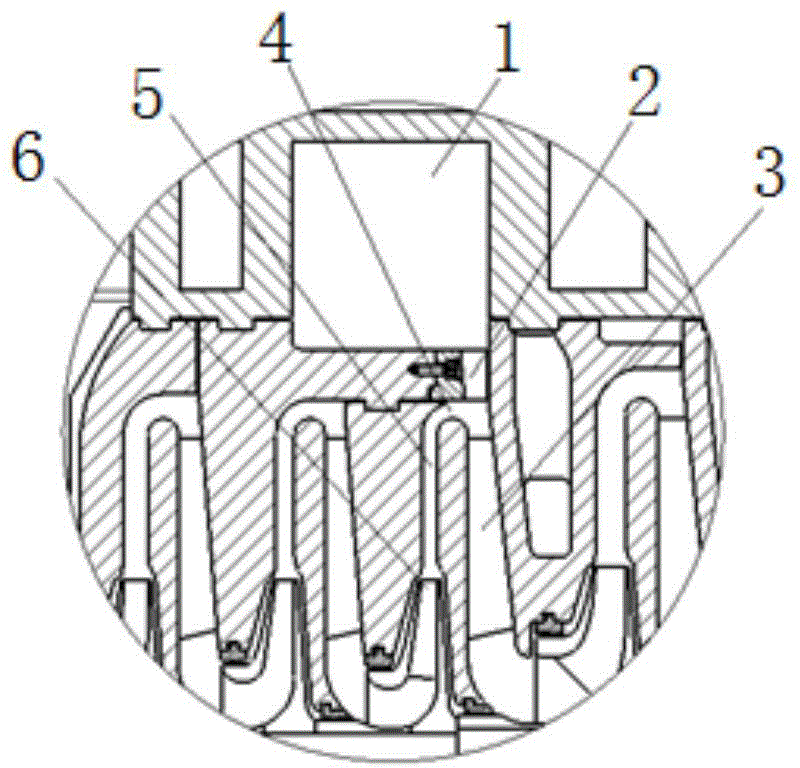

Combustion chamber

ActiveCN110657455AImprove circumferential uniformityImprove the mixing effectContinuous combustion chamberCombustion chamberEngineering

The invention aims to provide a combustion chamber. The combustion chamber adopts a single-ring-cavity flame tube structure, and the pollution emission of a whole LTO cycle of an engine is reduced onthe premise of ensuring the performance of the combustion chamber. In the combustion chamber, the main combustion stage involves an inner swirler, an outer swirler, an oil collecting ring and a premixing pre-evaporation section; the outer swirler adopts a radial swirler, the inner swirler adopts an axial swirler, and the oil collecting ring adopts direct fuel injection holes which are uniformly distributed in the circumferential direction, the fuel oil forms a direct spraying oil mist and forms the main combustion stage pneumatic atomizing oil mist by crushing and atomizing under the shearingaction of an inner swirling flow and an outer swirling flow; and the premixing pre-evaporation section adopts a nozzle structure and has a throat, the direct fuel injection holes are located in the 20%-80% range of the throat height relative to the radial position of the premixing pre-evaporation section of the main combustion stage, and the included angle between the injection direction of the direct fuel injection holes and the axis direction of the main combustion stage is negative 15 degrees to 60 degrees.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Combustion gas turbine low-emission combustion chamber and variable load air distribution adjusting method

ActiveCN110285447AImprove distribution uniformityAvoid local distributionContinuous combustion chamberCombustion chamberPollutant emissions

The invention relates to a combustion gas turbine low-emission combustion chamber and a variable load air distribution adjusting method. The combustion chamber comprises a casing, a casing top cover arranged on the top of the casing, an air inlet formed in the side face of the casing, a flame tube arranged inside the casing, a combustion chamber head arranged at the top of the flame tube and an air distribution mechanism arranged on the side face of the flame tube and matched with the air inlet; and the position of an air adjusting plate relative to the a doping hole is adjusted to adapt to unit load changes. Compared with the prior art, the combustion gas turbine low-emission combustion chamber can significantly improve the circumferential uniformity of main combustion stage premixed gas in the combustion chamber head, stabilize the pressure fluctuation of the main combustion grade gas and stabilize an on-duty stage flame, so that the pollutant emission of the combustion chamber is reduced. By changing the position of the air adjusting plate at different loads, the air intake ratio of the combustion chamber head is adjusted, so that the wide load adaptability of the combustion chamber is improved, and the pressure loss caused by structural changes is reduced.

Owner:TONGJI UNIV

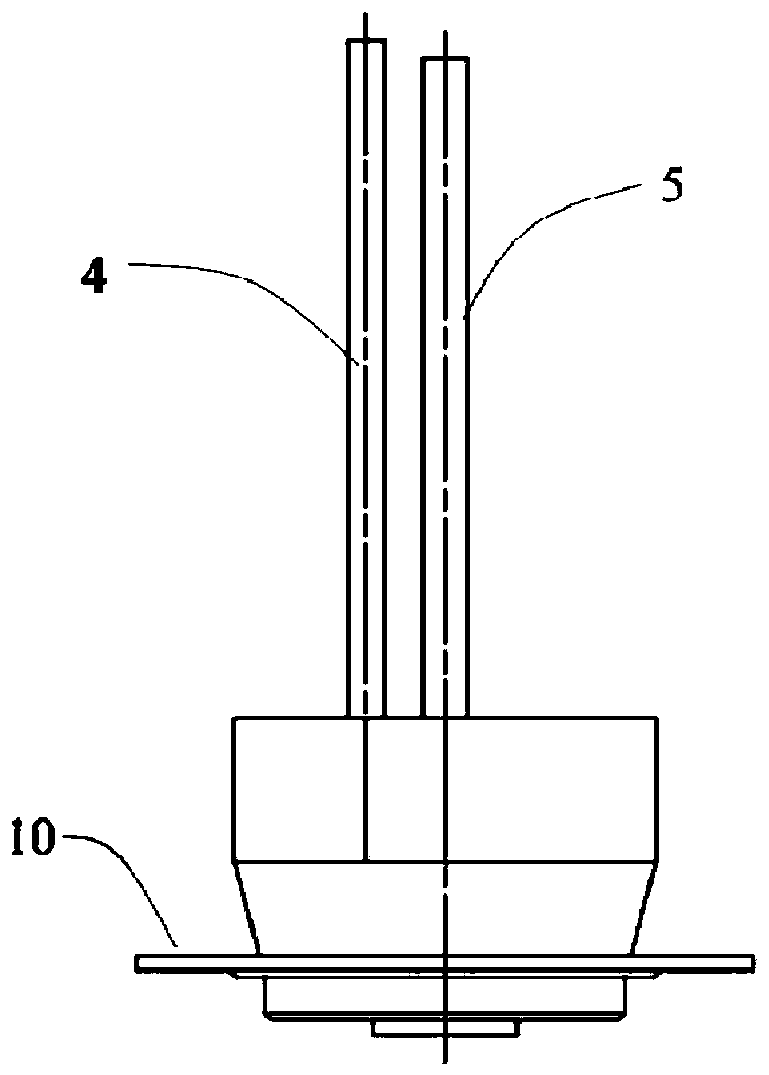

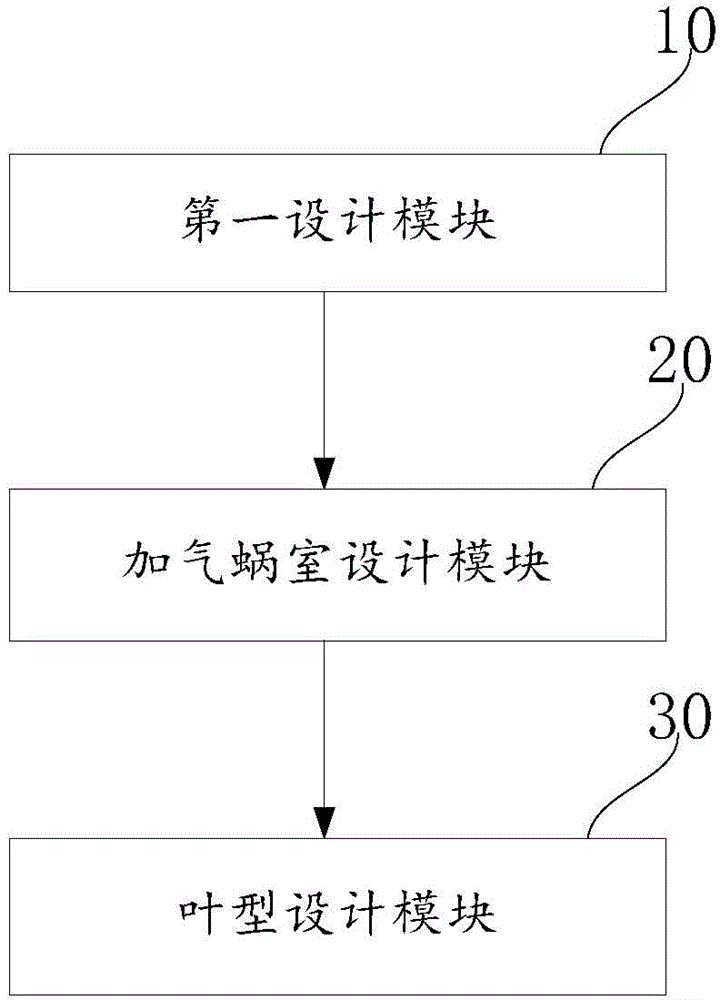

Design device of interstage air-entrapping structure of centrifugal compressor

ActiveCN104537173AImprove circumferential uniformityChanging the gas flow anglePump componentsSpecial data processing applicationsCentrifugal compressorAirflow

The invention provides a design device of an interstage air-entrapping structure of a centrifugal compressor. The design device of the interstage air-entrapping structure of the centrifugal compressor comprises a first design module. An air-entrapping hole is arranged on the curve of the centrifugal compressor with at least one stage. The air-entrapping hole is further provided with an air-entrapping structure so that air-entrapping airflow can be introduced. The air-entrapping structure comprises an air-entrapping spiral housing and an air-entrapping guiding vane. An air-entrapping spiral housing design module is used for designing a cross section of the air-entrapping spiral housing. A vane-shaped design module is used for designing a vane shape of the air-entrapping guiding vane. According to the design device of the interstage air-entrapping structure of the centrifugal compressor, when the number of a vane wheel is multiple, the spacing in the axial direction of the compressor is shortened, so that the critical speed of revolution of a machine set is easier to be exceeded.

Owner:SHENYANG BLOWER WORKS GRP INSTALLATION MAINTENANCE FITTINGS

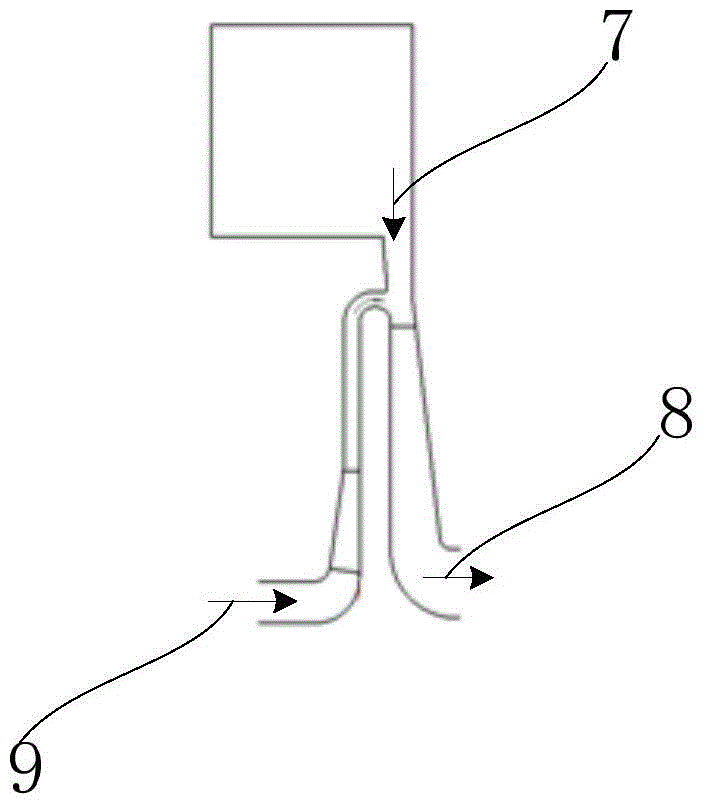

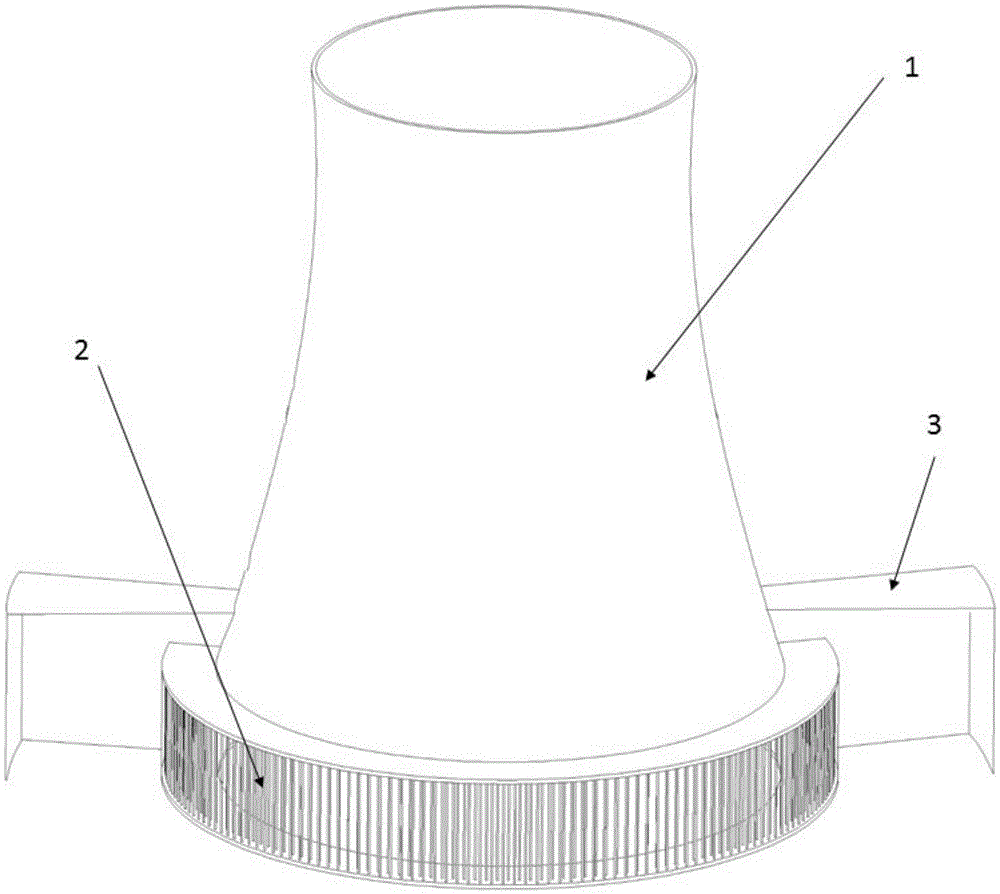

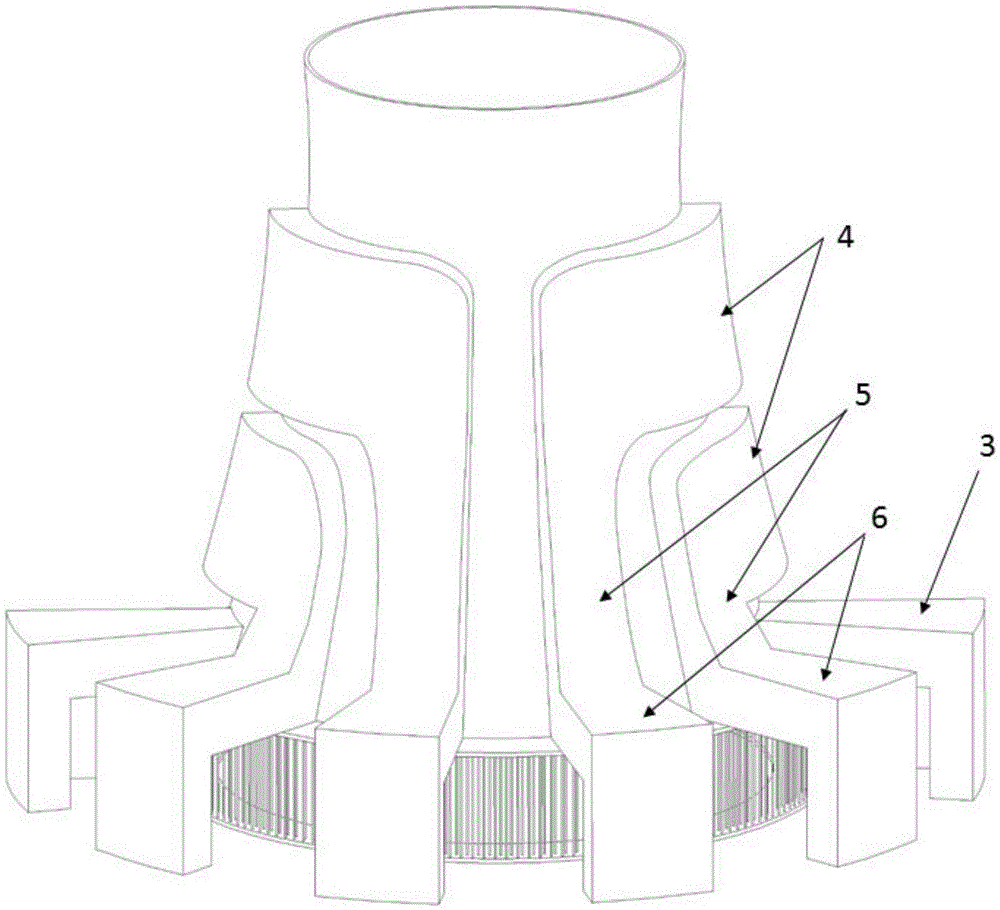

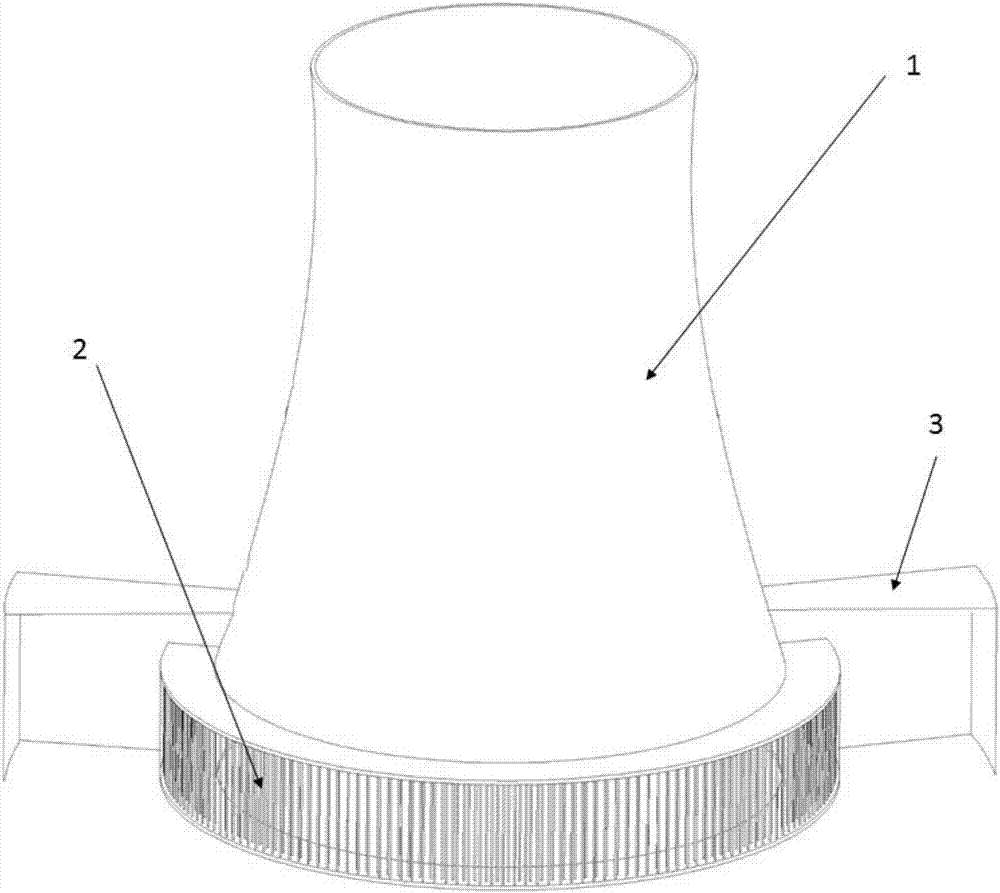

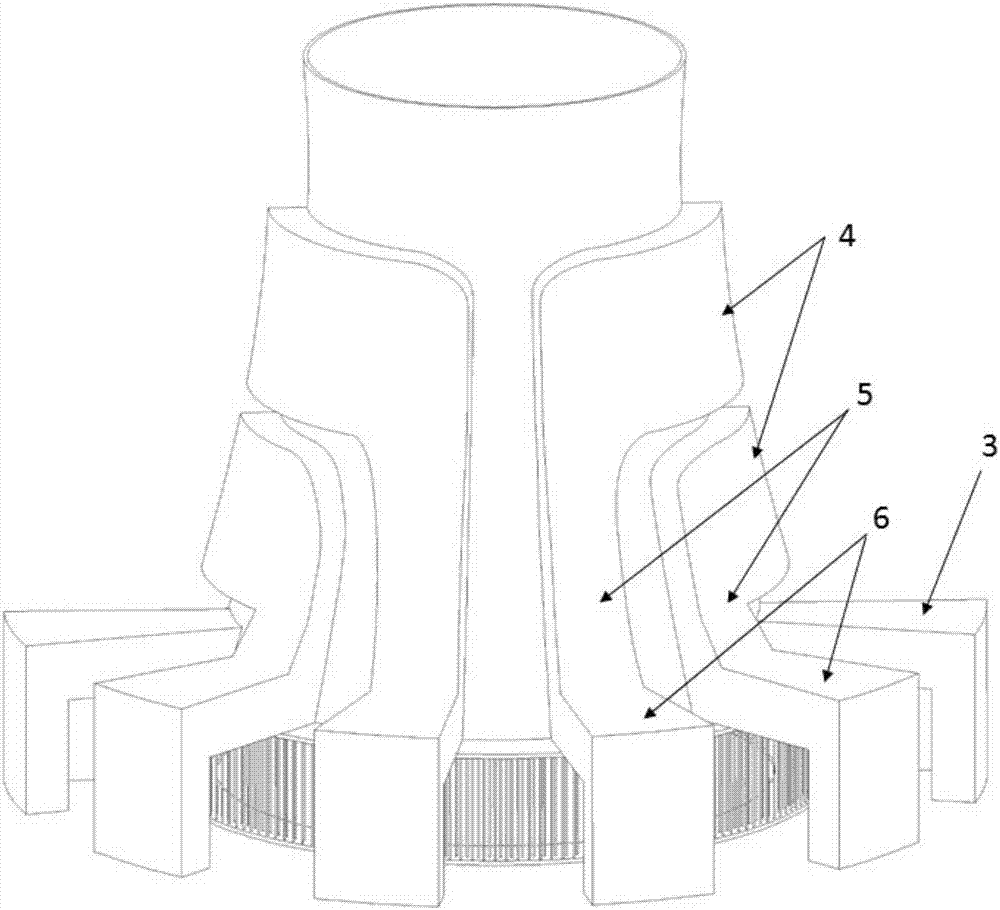

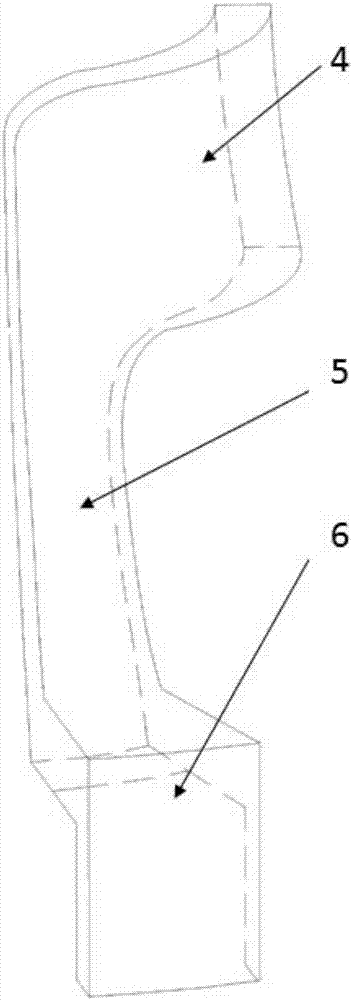

Cross wind recycling type wet cooling tower

InactiveCN105627782AImprove heat dissipationImprove circumferential uniformityHeat exchange apparatusTrickle coolersPower stationCooling Units

The invention discloses a cross wind recycling type wet cooling tower, in particular to a device for conducting flow guide utilization on environmental wind of a wet cooling unit of a power station. The wet cooling tower comprises a wet cooling tower shell, a bottom wind inlet and at least one wind collecting room arranged on the outer side of the bottom wind inlet. The wind collecting rooms are arranged in the circumferential direction of the wet cooling tower and are opened in the incoming flow direction of the environmental wind and are closed on the leeward side. At least one cross wind flow guide structure is arranged on the leeward side of the wet cooling tower. Each cross wind flow guide structure comprises an inlet wind flow guide section, a ventilation pipeline and a back outlet wind flow guide section, wherein the inlet wind flow guide section is opened in the incoming wind direction and is arranged on the upper side of the corresponding wind collecting room along the wet cooling tower shell. By means of the cross wind recycling tower wet cooling tower, due to the arrangement of the wind collecting rooms, the cross wind flow guide structures, wind blocking walls and the like, power sources of environmental cross wind are circumferentially arranged, the circumferential uniformity of inlet wind at the bottom of the wet cooling tower under the environmental wind condition is improved, a flow field structure in the wet cooling tower under the cross wind environment is improved, and therefore the ventilation characteristic and the cooling performance of the wet cooling tower are further enhanced.

Owner:TSINGHUA UNIV +2

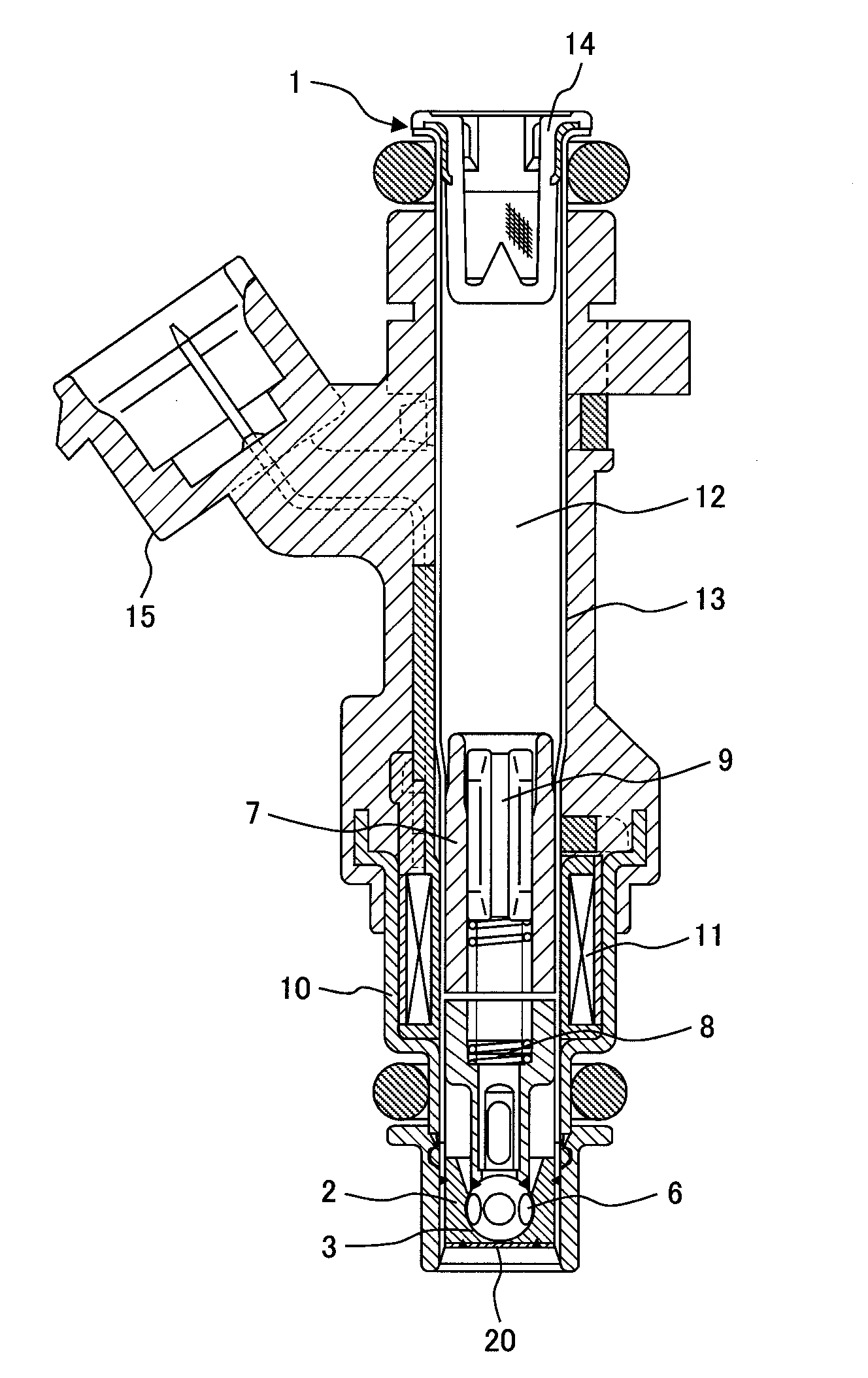

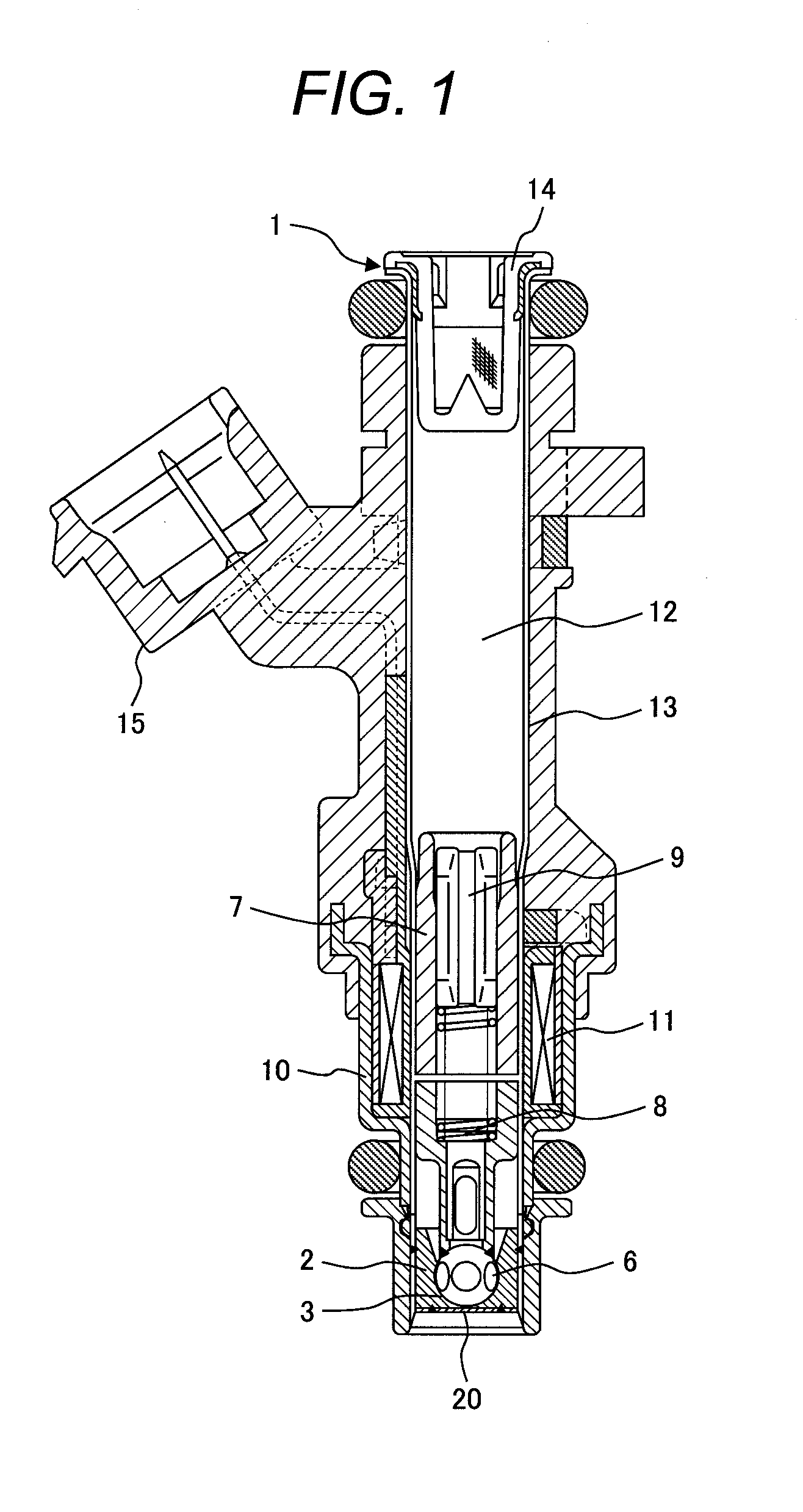

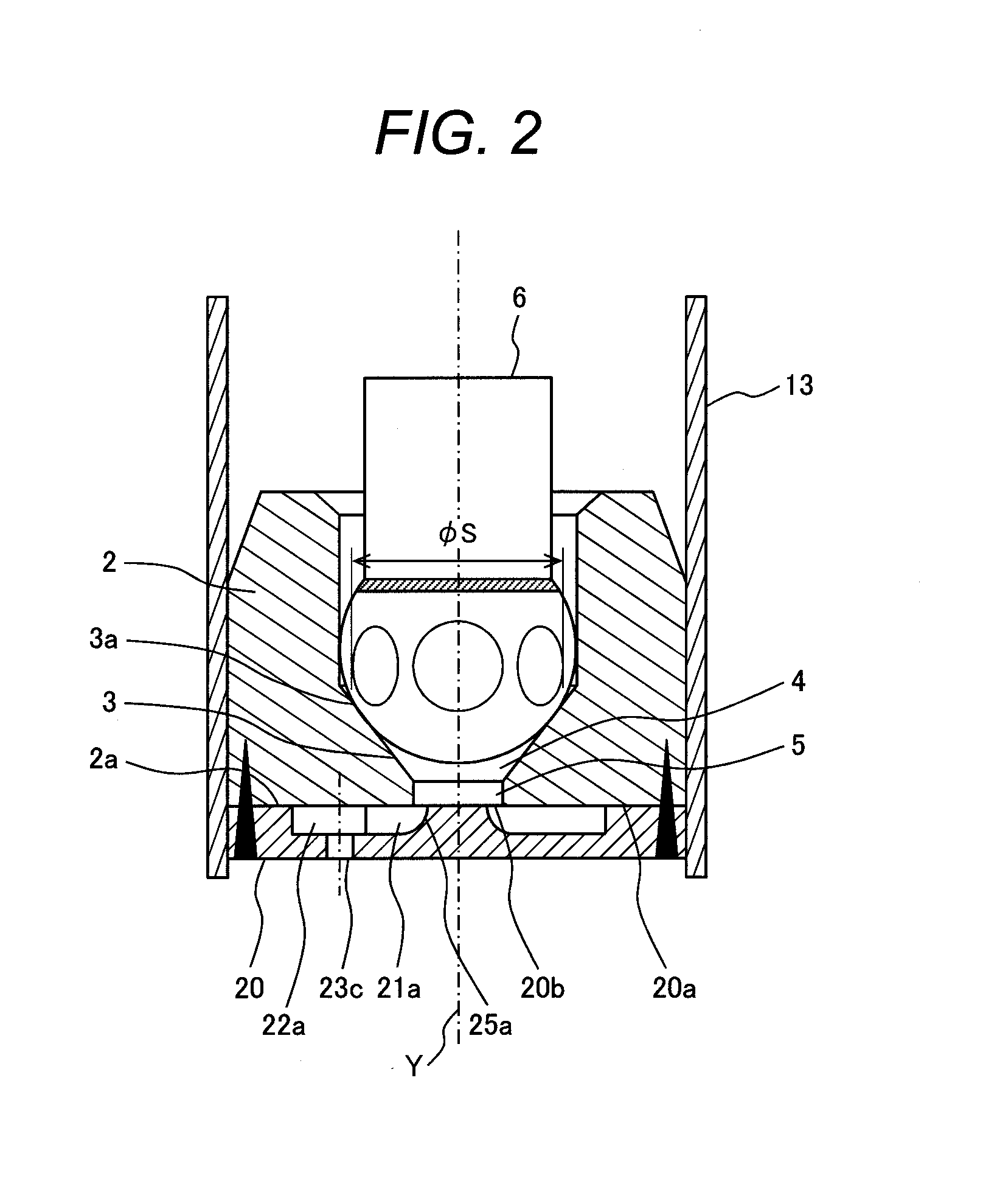

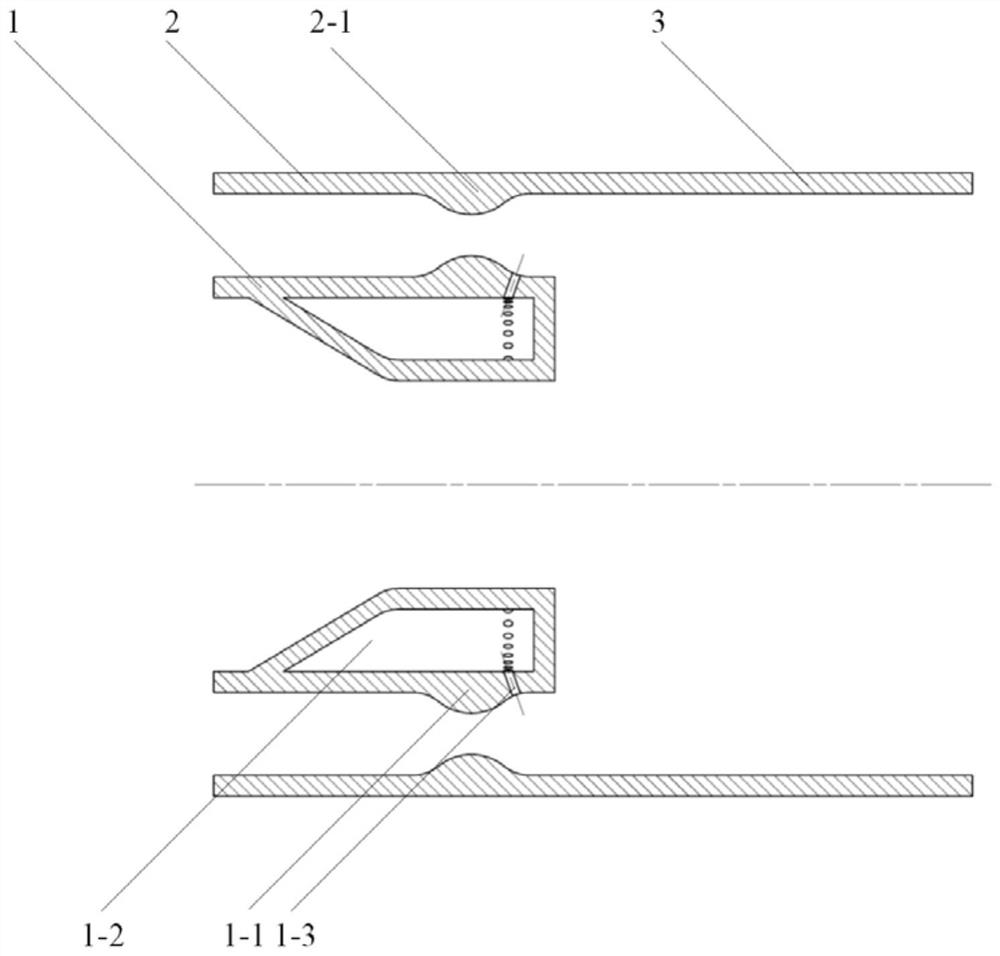

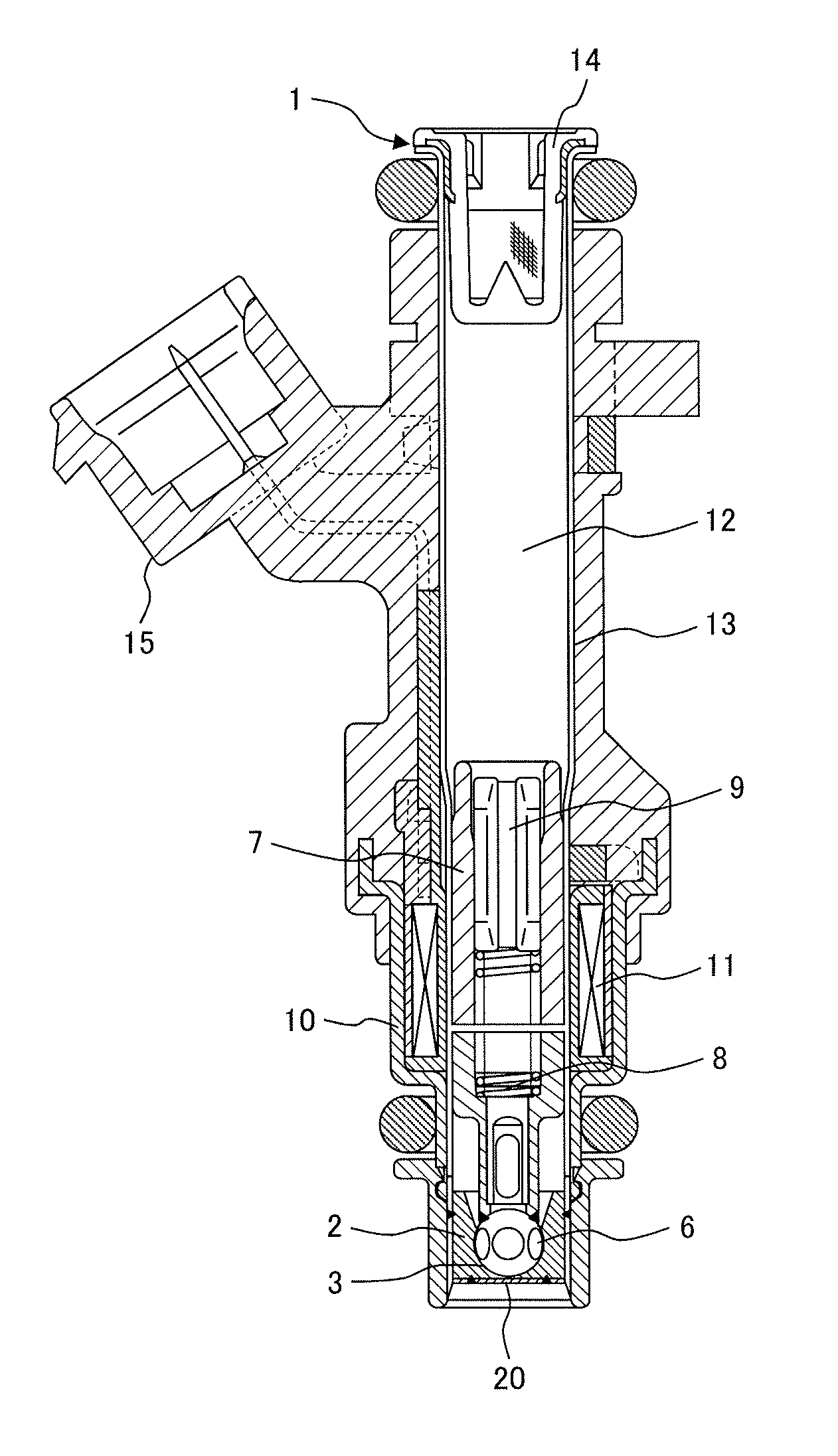

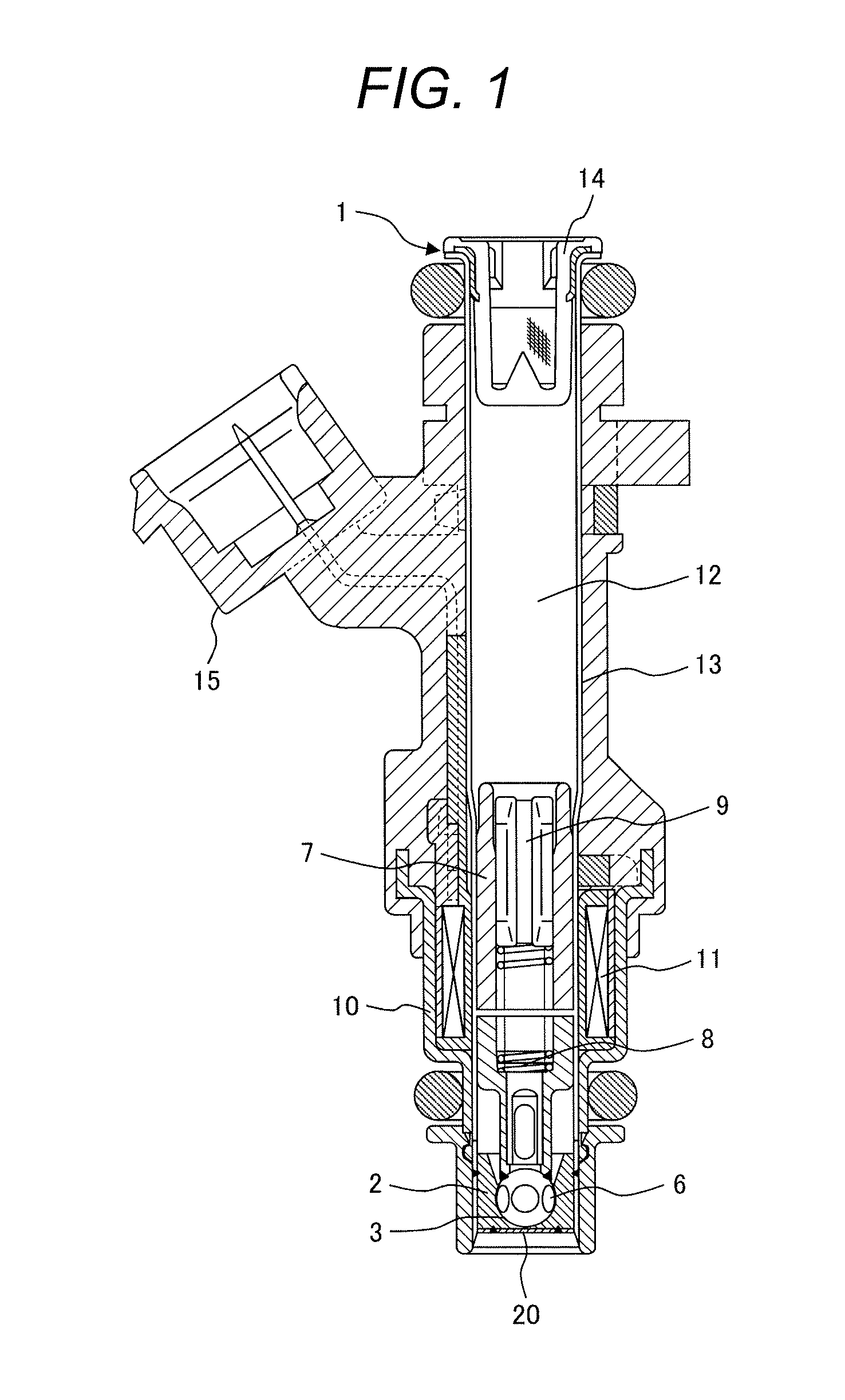

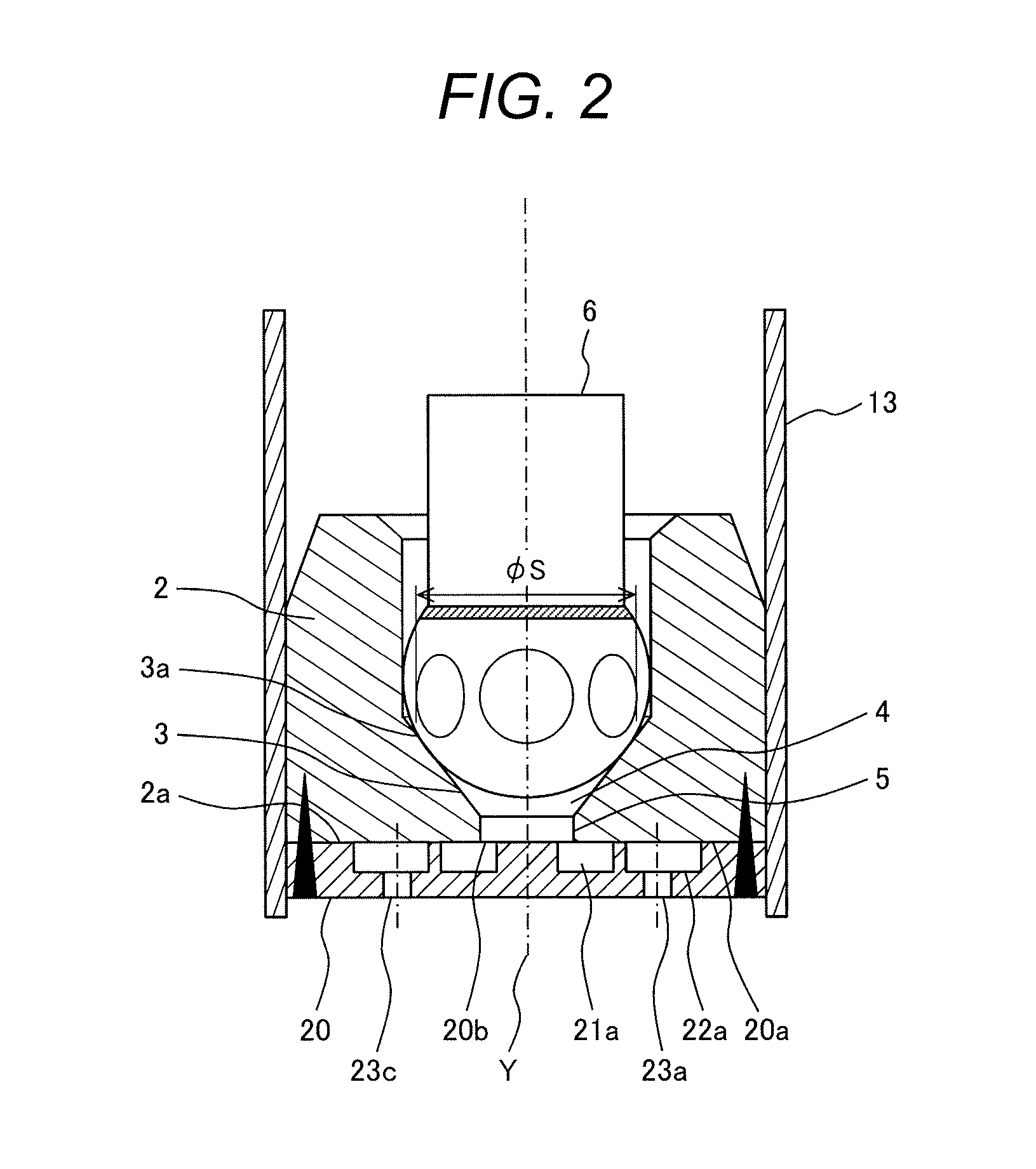

Fuel Injection Valve

ActiveUS20140251262A1Facilitate atomization of fuelImprove circumferential uniformityCombustion enginesFuel injection apparatusEngineeringVALVE PORT

A fuel injection valve realizing improved circumferential uniformity of swirling fuel is provided. The fuel injection valve includes swirling chambers each having an inner peripheral wall whose curvature is gradually larger from upstream to downstream, paths for swirling each of which, having a fuel flow-in region formed along a valve axis direction, guides fuel to the associated one of the swirling chambers, and fuel injection orifices open into the associated swirling chambers, respectively. In the fuel injection valve, a curved portion is formed on the bottom, in a sectional view along the valve axis direction, of an inlet portion of each of the paths for swirling so as to change the fuel flow in each of the paths for swirling.

Owner:HITACHI ASTEMO LTD

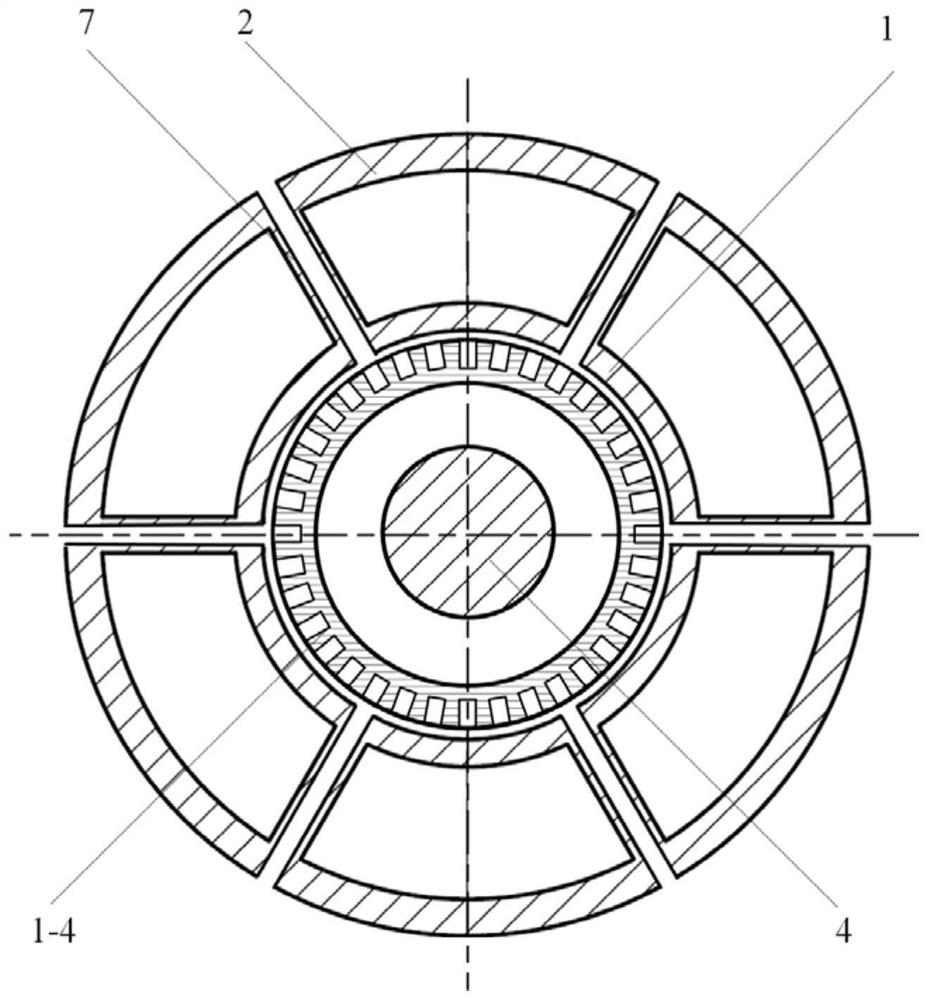

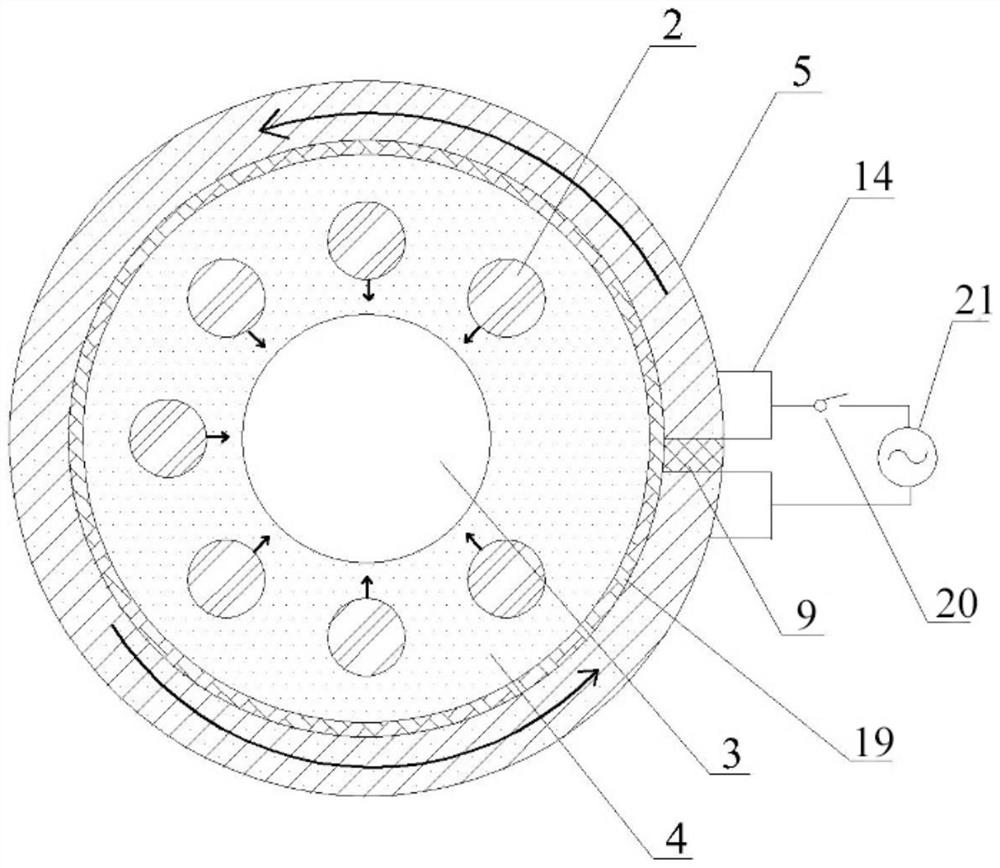

Method for reducing circumferential temperature difference between motor coil and iron core

ActiveCN110429747AReduce circumferential temperature differenceImprove circumferential uniformityMagnetic circuit rotating partsMagnetic circuit stationary partsAir volumeTemperature difference

The invention discloses a method for reducing the circumferential temperature difference between a motor coil and an iron core, which belongs to the technical field of wind driven generators and is characterized by comprising the following steps: a, installing a device for reducing the circumferential temperature difference between a large-diameter motor coil and an iron core on a wind driven generator; b, mounting an oblique wind shield at an outlet of an air inlet pipe, mounting an air volume adjusting plate on air inlet holes, and adjusting the air circumferential resistance through the airvolume adjusting plate; and c, enabling an air passing area of a near fan end close to the axis of the fan to be minimum and an air passing area of a far fan end far away from the axis of the fan tobe the maximum in one circumferential symmetric unit. The method is easy and flexible to operate and convenient to implement, and the airflow circumferential uniformity can be improved; the areas of different air inlet holes can be adjusted by adjusting the sizes of the air inlet holes shielded by the air volume adjusting plate according to actual needs so as to achieve uniform distribution of airspeed in the circumferential direction, and the circumferential temperature difference of the motor can be reduced by 10-20 K.

Owner:DONGFANG ELECTRIC MACHINERY

Rotary detonation combustion chamber adopting pneumatic inner column

ActiveCN113739207AAvoid enteringReduce the ratioContinuous combustion chamberCombustion chamberEngineering

The invention provides a rotary detonation combustion chamber adopting a pneumatic inner column. The rotary detonation combustion chamber comprises an injection head part and a combustion chamber body part. The injection head part comprises a flow divider and an injector shell, an annular oxidant airflow channel is defined by the outer wall of the flow divider and the injector shell, fuel injection holes are located in the downstream of a throat of an oxidant airflow channel, and fuel and an oxidant are mixed and then conduct rotary detonation combustion on the outer side of the combustion chamber body; and inert gas or the oxidant enters the combustion chamber body along the airflow channel defined by the inner wall of the flow divider, the pneumatic inner column flowing in the axial direction is generated, the central area of the combustion chamber body is occupied, rotating detonation products are prevented from flowing towards the center, and losses generated when rotating detonation waves expand towards the inner side are reduced. According to the rotary detonation combustion chamber adopting the pneumatic inner column provided by the invention, part of the rotating detonation products are prevented from being temporarily retained in the center area, the proportion of fresh mixed gas participating in slow combustion is reduced, the thermal cycle efficiency of the combustion chamber is improved, and meanwhile the pneumatic inner column does not need to be cooled. The rotary detonation combustion chamber can be applied to the technical field of rotary detonation propulsion.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Golf club shaft

Owner:SUMITOMO RUBBER IND LTD

Susceptor, epitaxial growth device, epitaxial silicon wafer manufacturing method, and epitaxial silicon wafer

ActiveCN111295737AImprove circumferential uniformityPolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingSusceptor

Owner:SUMCO CORP

Semiconductor process chamber

PendingCN114196942AGuaranteed Circumferential UniformityImprove circumferential uniformityChemical vapor deposition coatingFinal product manufactureGas passingEngineering

A semiconductor process chamber provided by the present invention comprises a cavity, a base and a gas guide structure, the gas guide structure comprises an upper gas guide part and a lower gas guide part, an upper gas guide cavity of the upper gas guide part is used for receiving gas from the periphery of the base, an annular opening is formed in the bottom of the upper gas guide part, and the bottom of the lower gas guide part is communicated with an exhaust port 601. A plurality of air guide through holes for communicating the upper air guide cavity with the lower air guide cavity of the lower air guide piece are formed in the top of the lower air guide piece, and a plurality of air guide assemblies in one-to-one correspondence with the air guide through holes are arranged in the lower air guide cavity; the gas guide assembly enables the minimum flow sectional area of gas flowing into the lower gas guide cavity from the upper gas guide cavity through the gas guide through hole to be reduced along with the increase of the pressure difference between the upper gas and the lower gas. In the invention, the upper gas guide cavity is connected with the lower gas guide cavity through the plurality of gas guide assemblies of which the opening degrees are reduced along with the increase of the pressure difference between the upper gas and the lower gas, so that the circumferential uniformity of a gas flow field above a wafer can be ensured under various working conditions, and the adaptability of the semiconductor process cavity is improved while the thickness uniformity of a film is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A lean-oil premixed pre-evaporation combustor head structure using a swirler/pre-diaphragm integrated main combustion stage

The invention relates to a lean oil premixing and pre-evaporating combustion chamber head structure with a cyclone / pre-film plate integrated primary combustion stage. A central staged combustion mode is adopted for the head structure and divided into a pre-combustion stage and the primary combustion stage, the mode of combining diffusive combustion and cyclone premixing combustion is adopted for the pre-combustion stage, the mode of premixing and pre-evaporating combustion mode is adopted for the primary combustion stage, and combustion pollutants can be effectively reduced. A cyclone / pre-film plate integrated structure is adopted for the primary combustion stage, the structure is simple and reliable, first-stage fuel and second-stage fuel form oil films on the same pre-film plate and are atomized, evaporated and mixed under the action of two strands of cyclones, an even oil and gas mixture can be easily formed at an outlet of the primary combustion stage, and the combustion pollutants are reduced. The design of dual oil paths of the primary combustion stage is beneficial to oil and gas matching of the combustion chamber under different working conditions, and the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aero-engine is further lowered. By means of the micro shrinkage type design of a primary combustion stage channel and the design of a backfire prevention ring, the backfire problem can be effectively solved, and the safety of the head of the combustion chamber is ensured.

Owner:BEIHANG UNIV +1

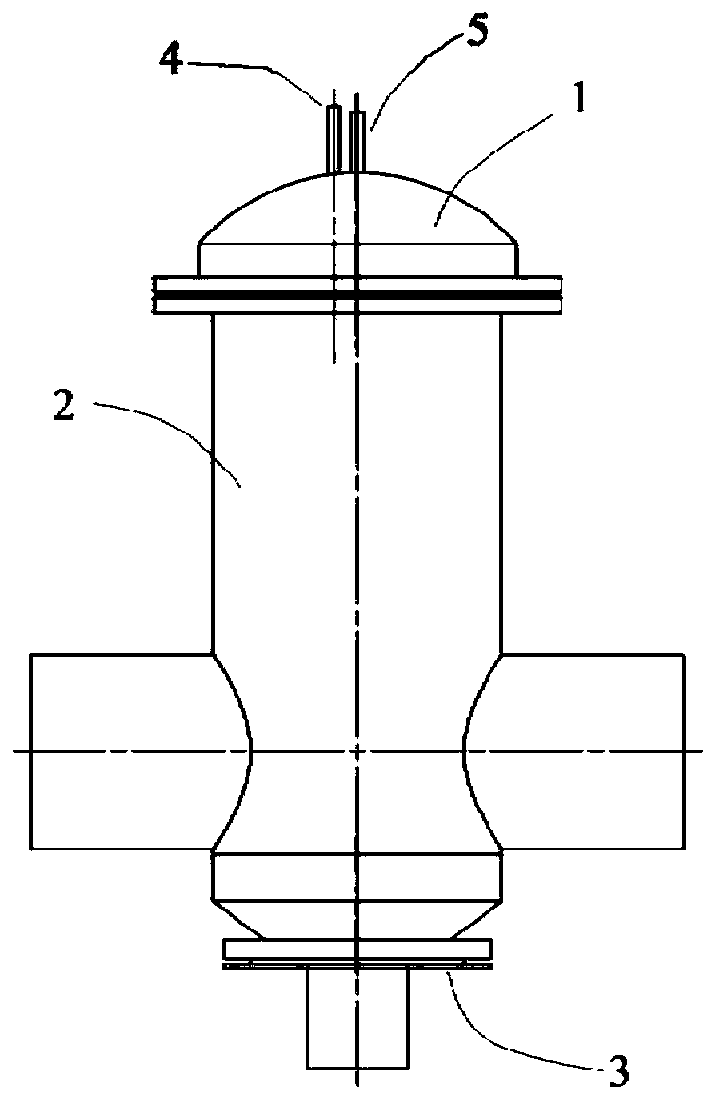

A small high-energy x-ray device and method

Owner:PAN CHINA DETECT TECH CO LTD

A Method for Reducing Circumferential Temperature Difference Between Motor Coil and Iron Core

ActiveCN110429747BReduce circumferential temperature differenceImprove circumferential uniformityMagnetic circuit rotating partsMagnetic circuit stationary partsWind drivenAir volume

The invention discloses a method for reducing the circumferential temperature difference between a motor coil and an iron core, which belongs to the technical field of wind driven generators and is characterized by comprising the following steps: a, installing a device for reducing the circumferential temperature difference between a large-diameter motor coil and an iron core on a wind driven generator; b, mounting an oblique wind shield at an outlet of an air inlet pipe, mounting an air volume adjusting plate on air inlet holes, and adjusting the air circumferential resistance through the airvolume adjusting plate; and c, enabling an air passing area of a near fan end close to the axis of the fan to be minimum and an air passing area of a far fan end far away from the axis of the fan tobe the maximum in one circumferential symmetric unit. The method is easy and flexible to operate and convenient to implement, and the airflow circumferential uniformity can be improved; the areas of different air inlet holes can be adjusted by adjusting the sizes of the air inlet holes shielded by the air volume adjusting plate according to actual needs so as to achieve uniform distribution of airspeed in the circumferential direction, and the circumferential temperature difference of the motor can be reduced by 10-20 K.

Owner:DONGFANG ELECTRIC MACHINERY

Fuel Injection Valve

ActiveUS20140251263A1Improve circumferential uniformityEasy to shapeCombustion enginesFuel injection apparatusFuel injection

A fuel injection valve realizing improved circumferential uniformity of swirling fuel is provided. The fuel injection valve includes a swirling chamber having an inner peripheral wall whose curvature is gradually larger from upstream to downstream, a path for swirling which, having a fuel flow-in region formed along a valve axis direction, guides fuel to the swirling chamber, and a fuel injection orifice open into the swirling chamber. In the fuel injection valve, the path for swirling is inclined toward the fuel injection orifice formed on a downstream side of the swirling chamber.

Owner:HITACHI ASTEMO LTD

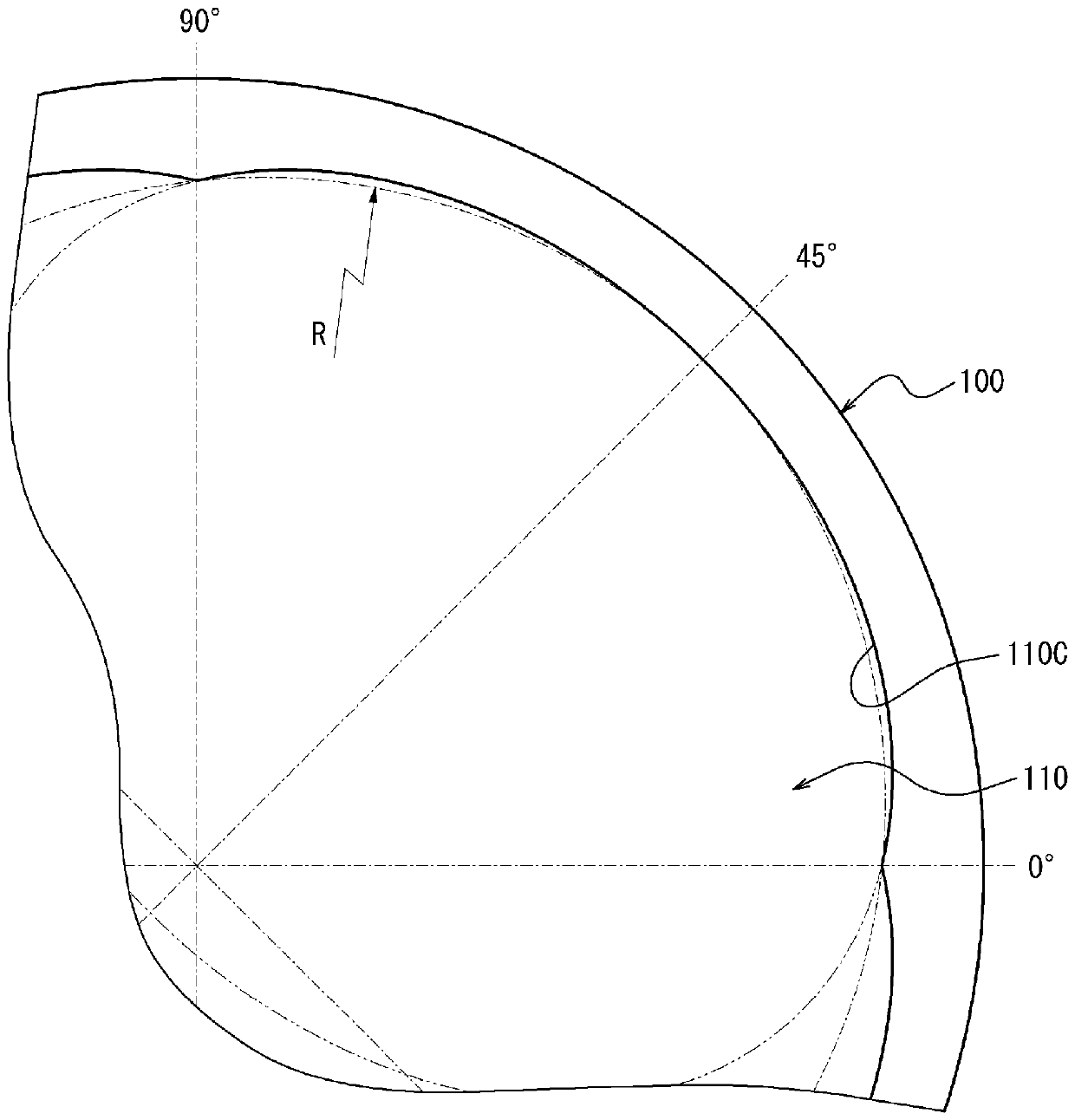

Tire

ActiveCN110254139AImprove uniformityAvoid deformationPneumatic tyre reinforcementsMotorcycle tyresControl theoryMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Device and method for preparing composite roller through electroslag remelting method of crystallizer additional magnetic field

PendingCN114653926AImprove axial uniformityImprove circumferential uniformityElectrically conductiveEngineering

The invention discloses a device and a method for preparing a composite roller by an electroslag remelting method of a crystallizer additional magnetic field. The device comprises a remelting power supply, a crystallizer power supply, a dummy ingot plate, an upper crystallizer and a lower crystallizer, a notch is formed in the upper crystallizer and is filled with an insulating block; two conductive interfaces are assembled on the upper portion of the outer wall of the upper crystallizer, located on the two sides of the insulating block and connected with the two electrodes of a crystallizer power source respectively. The method comprises the following steps: (1) placing the mandrel in an electroslag furnace crystallizer; (2) arranging a coating layer; (3) putting the ladle molten pool into an electroslag furnace crystallizer to form a liquid slag pool; (4) descending the consumable electrode to a liquid slag pool; the remelting switch is switched on; (5) connecting two conductive interfaces with two electrodes of a crystallizer power supply; and (6) starting an ingot pulling system. A conductive loop in the crystallizer is additionally arranged in the composite system, and the temperature field of a slag bath, especially the temperature field near a slag-metal interface, is reasonably optimized by adding an axial extra magnetic field in a remelting composite area.

Owner:NORTHEASTERN UNIV

A side wind recovery type air cooling tower

The invention discloses a cross wind recycling type air cooling tower and relates to a device for conducting flow guide utilization on environmental wind of an air cooling unit of a power station. The air cooling tower comprises an air cooling tower shell, a bottom wind inlet and at least one wind collecting room arranged on the outer side of the bottom wind inlet. The wind collecting rooms are arranged in the circumferential direction of the air cooling tower and are opened in the incoming flow direction of the environmental wind and are closed on the leeward side. At least one cross wind flow guide structure is arranged on the leeward side of the air cooling tower. Each cross wind flow guide structure comprises an inlet wind flow guide section, a ventilation pipeline and a back outlet wind flow guide section, wherein the inlet wind flow guide section is opened in the incoming wind direction and is arranged on the upper side of the corresponding wind collecting room along the air cooling tower shell. By means of the cross wind recycling tower air cooling tower, due to the arrangement of the wind collecting rooms, the cross wind flow guide structures, wind blocking walls and the like, power sources of environmental cross wind are circumferentially arranged, the circumferential uniformity of inlet wind at the bottom of the air cooling tower under the environmental wind condition is improved, a flow field structure in the air cooling tower in the cross wind environment is improved, and therefore the ventilation characteristic and the cooling performance of the air cooling tower are further enhanced.

Owner:TSINGHUA UNIV +2

A gas turbine low-emission combustor and variable load air distribution adjustment method

ActiveCN110285447BImprove distribution uniformityAvoid local distributionContinuous combustion chamberThermodynamicsCombustion chamber

The invention relates to a combustion gas turbine low-emission combustion chamber and a variable load air distribution adjusting method. The combustion chamber comprises a casing, a casing top cover arranged on the top of the casing, an air inlet formed in the side face of the casing, a flame tube arranged inside the casing, a combustion chamber head arranged at the top of the flame tube and an air distribution mechanism arranged on the side face of the flame tube and matched with the air inlet; and the position of an air adjusting plate relative to the a doping hole is adjusted to adapt to unit load changes. Compared with the prior art, the combustion gas turbine low-emission combustion chamber can significantly improve the circumferential uniformity of main combustion stage premixed gas in the combustion chamber head, stabilize the pressure fluctuation of the main combustion grade gas and stabilize an on-duty stage flame, so that the pollutant emission of the combustion chamber is reduced. By changing the position of the air adjusting plate at different loads, the air intake ratio of the combustion chamber head is adjusted, so that the wide load adaptability of the combustion chamber is improved, and the pressure loss caused by structural changes is reduced.

Owner:TONGJI UNIV

Small high-energy X-ray device and method

The invention relates to a small high-energy X-ray device, and the device comprises an X-ray source magnet system, an X-ray tube and a power supply system; the X-ray source magnet system comprises six iron core yokes, two magnetic pole heads, two to four magnetic pole pads, two expansion coils and two circular excitation coils, and the six iron core yokes are distributed in a hexagonal star radial shape to form a cylindrical inner space; the two circular excitation coils are arranged in a cylindrical inner space formed by the two magnetic pole heads and the six iron core yokes and are coaxial with the magnetic pole heads; and the two expansion coils are arranged on the conical surfaces of the two magnetic pole heads and are coaxial with the magnetic pole heads. On the one hand, the size of the magnet can be reduced, the circumferential uniformity of magnet field distribution is improved, and the purpose of reducing the size of equipment is achieved, and on the other hand, electrons are injected through the falling edge of the current of the expansion coil, electrons are led out through the rising edge of the current of the expansion coil, and the X-ray yield is improved.

Owner:PAN CHINA DETECT TECH CO LTD

Rim sealing structure comprising wave-shaped hollows and turbine using rim sealing structure

InactiveCN108798794AImprove circumferential uniformityImprove aerodynamic efficiencyLeakage preventionMachines/enginesWave shapeEngineering

The invention provides a rim sealing structure comprising wave-shaped hollows and a turbine using the rim sealing structure. A stationary blade is installed on a stationary blade hub margin plate; a movable blade is installed on a movable blade hub margin plate; the edge of a partition plate below the rear side of the stationary blade hub margin plate is provided with stationary blade side sealingteeth; the top ends of the sealing teeth protrude upwards in the radial direction to form a sickle shape; a wave-shaped hollow structure is arranged at the rear side of the stationary blade hub margin plate; hollows are toward an air outlet angle of the stationary blade; the depth of the hollows is gradually increased along the flow direction; the front side of the movable blade hub margin plateis inserted between the stationary blade hub margin plate and the stationary blade side sealing teeth in a staggered manner so as to form the rim sealing structure which is provided with the wave-shaped hollows. The rim sealing structure provided by the invention has the advantages of improving the circumferential uniformity of air flow at the position, close to the end wall of a rim, of the outlet of the stationary blade, reducing the requirements of the rotary disc of the movable blade on the minimum cooling and sealing flow, also straightening the air flow, close to the end wall of the rim,of the outlet of the stationary blade, reducing the probability of invasion of gas under full conditions, and improving the aerodynamic efficiency of the turbine.

Owner:HARBIN ENG UNIV

A kind of air flow mixer used in the high-altitude flow simulation device of planar cascade

ActiveCN112964448BCircumferential uniformShorten the lengthGas-turbine engine testingAerodynamic testingStraight tubeEngineering

The invention discloses an air flow mixer for a plane blade cascade high-altitude flow simulation device. The airflow mixer includes an intake pipe, an annular straight pipe, a rectifier pipe and an exhaust pipe; the intake pipe and the exhaust pipe are straight pipes, and the rectifier pipe is an annular cone pipe; the intake pipe, the rectifier pipe and the exhaust pipe are sequentially welded along the airflow direction from front to back Fixed, the annular straight pipe is sheathed outside the rectifier pipe, the front end of the annular straight pipe is welded with the intake pipe and reinforced with a rib plate, and the rear end of the annular straight pipe is welded with the air outlet pipe and reinforced with a rib plate; between the annular straight pipe and the rectifier pipe The space is the airflow mixing chamber; the wall surface of the rectifier tube is opened with holes, and the opening rate is 45% to 70%. The airflow mixer has a simple structure, significantly shortens the length of the intake pipe, improves the circumferential uniformity of the mixed airflow, provides a stable and uniform inflow for the cascade test section, and improves the flow field quality and test accuracy of the cascade test section. Spend.

Owner:中国空气动力研究与发展中心空天技术研究所

Resonance type radial forging machine and forging application thereof

ActiveCN114850372AReasonable structureHigh quality forging effectPower hammersHammer drivesGear wheelMachine

The invention discloses a resonance type radial forging machine and forging application thereof, and belongs to the technical field of forging equipment. The lifting device comprises a lower frame plate, an upper frame plate which can ascend and descend and is parallel to the lower frame plate, and two lifting guide rods which are fixedly arranged on the upper frame plate, a platform counter bore is formed in the lower frame plate, a rotating platform is mounted in the platform counter bore, and a hammer excitation device, an axial locking device and two hammer resonance devices are mounted on the upper frame plate; the two hammerhead resonance devices are the same in structure, and each hammerhead resonance device comprises a driving gear, a swing rod, a pendulum bob, a resonance hammerhead, a sliding telescopic rod, a hammerhead locking spring, a quasi-static base and a mass block. The resonance type radial forging machine is reasonable in structure, the radial forging acting force is remarkably improved through the resonance effect, the circumferential and axial forging uniformity of forge piece blanks can be remarkably improved, and the high-quality forging effect is achieved.

Owner:JIANGSU SUNSHINE FORGING

Stent conveying device and stent loading method

PendingCN111374813AReduce stress unevennessImprove circumferential uniformityStentsBiomedical engineeringCatheter

The invention provides a stent conveying device which comprises a sheath tube and an inner catheter, wherein the sheath tube is arranged outside the inner catheter in a sleeving manner; the inner catheter has a first expansion state; at the first expansion state, a stent is pressed and held in the sheath tube; the inner catheter is at a ball state; the outer surface of the inner catheter is adhered to the inner wall of the stent at the pressed and held state; and the outer diameter of the inner catheter is smaller than the inner diameter of the sheath tube. By adopting the stent conveying device, the stent is expanded through the inner catheter, so that the state of the stent pressed and held in the sheath tube can be adjusted, the phenomenon that the stent pressed and held in the sheath tube has non-uniform stress can be reduced, the loading uniformity of the stent can be improved, and furthermore, the risks that the release quality is affected, peripheral tissue is damaged, valve fatigue can be affected, even conveying systems are damaged and a retracement function is affected as twisting and sinking are caused in the release process because of the phenomena of the stent can be reduced, that is, the stent release success rate can be increased.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com