Semiconductor process chamber

A process chamber and semiconductor technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of inconsistent wafer exhaust pressure, exhaust uniformity of exhaust system, film thickness and uniformity , Affect the film thickness and uniformity and other issues to achieve the effect of ensuring circumferential uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

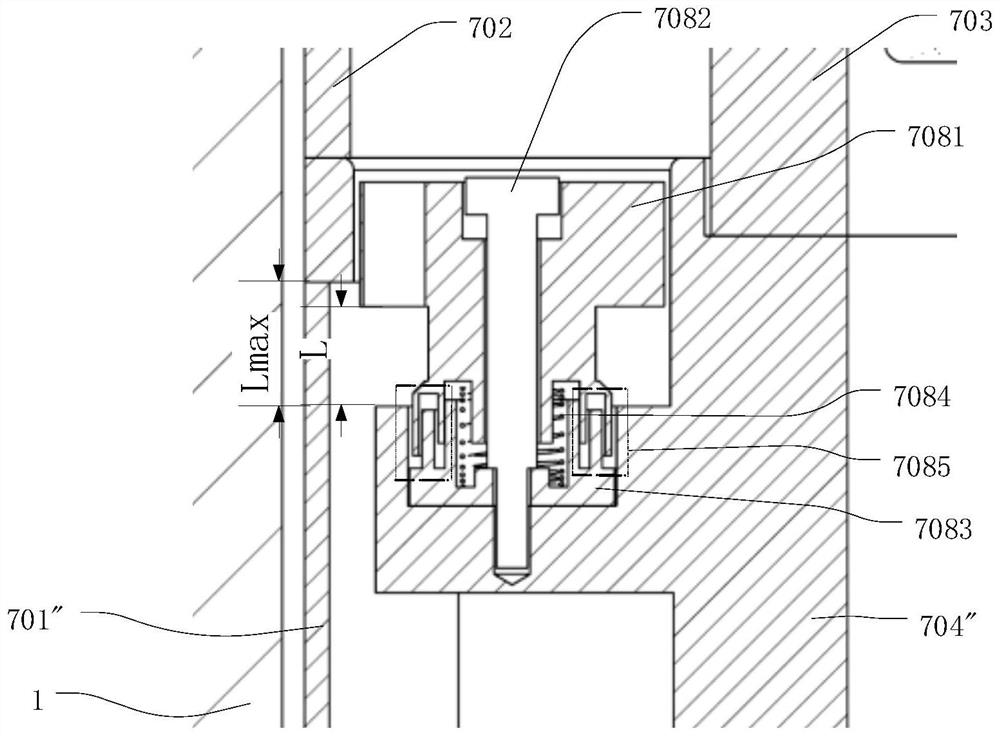

[0046] As an optional embodiment of the present invention, the thickness of the top wall (the baffle ring 7045) of the lower air guide is 5-15mm, and 12-36 air guide through-holes 7043 are formed on the top wall of the lower air guide. , preferably 18 air guide through holes 7043 are formed. The thickness of the plugging portion 7081d corresponds to the thickness of the top wall (baffle ring 7045) of the lower air guide, and each plugging portion 7081d is formed with 4 to 12 air guide holes 7081a, preferably 6 air guide holes 7081a. The diameter of the pores 7081a is 2 mm to 5 mm, preferably 3 mm.

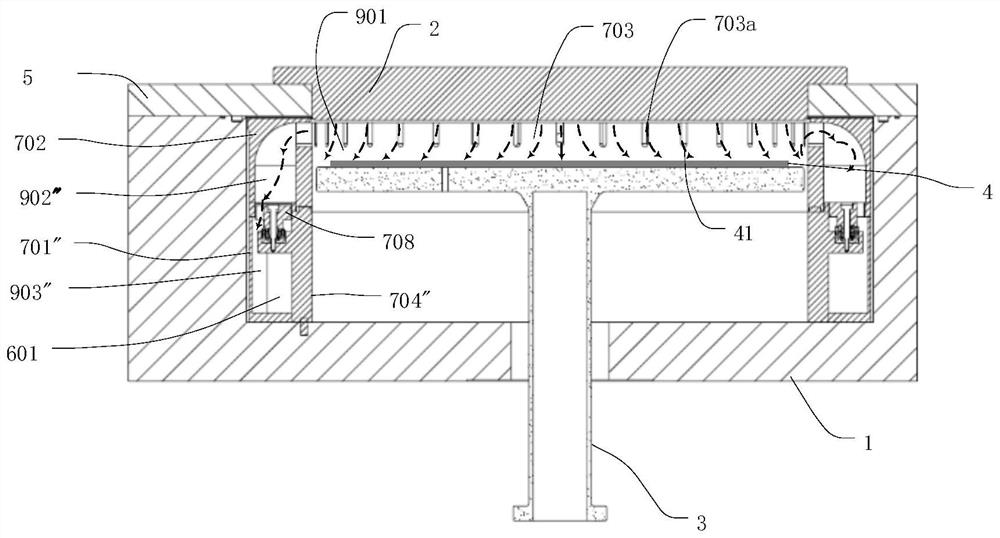

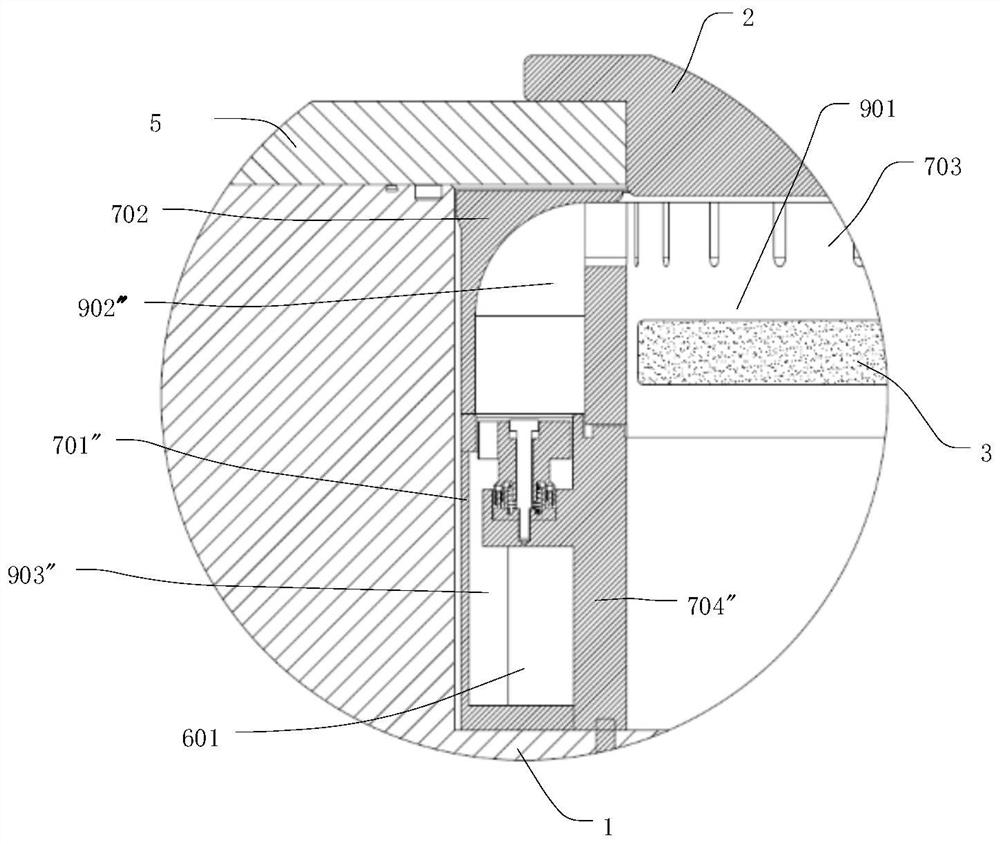

[0047] As an optional embodiment of the present invention, such as Figure 1 to Figure 6 As shown, the lower air guide includes a baffle ring 7045, an annular bottom plate, a component support ring 704" and a lower shield ring (Lower shield) 701", and the lower shield ring 701" is coaxially sleeved on the outside of the component support ring 704", The outer edge (that is, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com