Integrated injector

An injector and main body technology, which is applied in the field of integrated injectors, can solve the problems that the oxidant and the fuel are not mixed evenly, the service life of the injector is affected, the injector is abnormally high temperature, etc., and the processing cycle is shortened and the weight is light. , the effect of avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

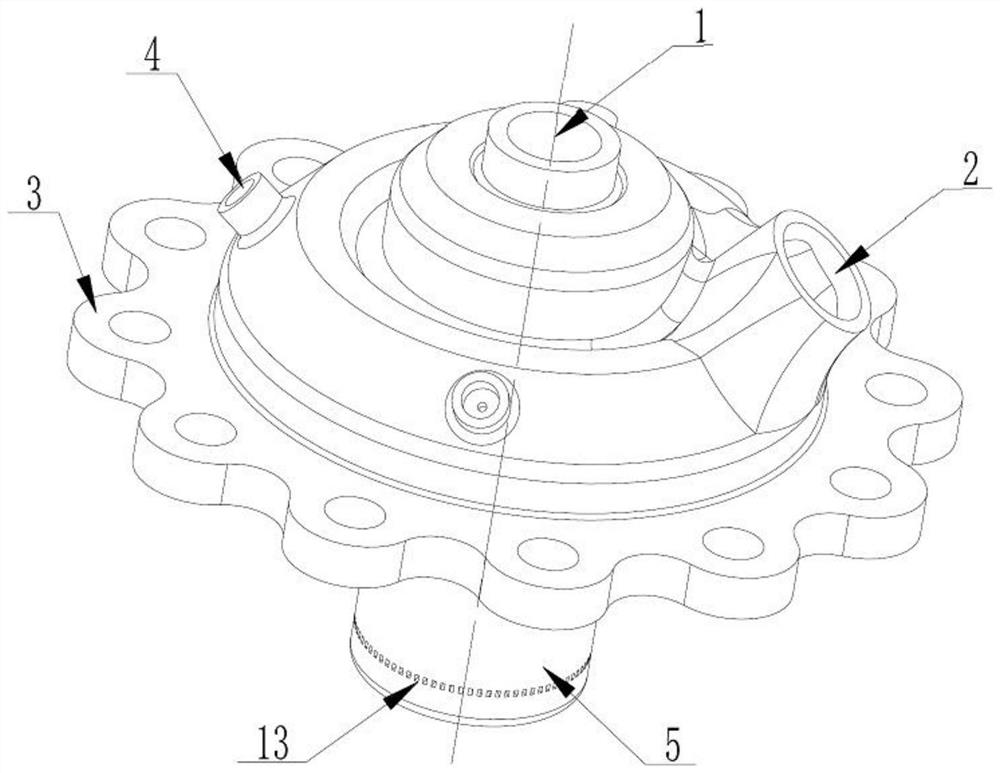

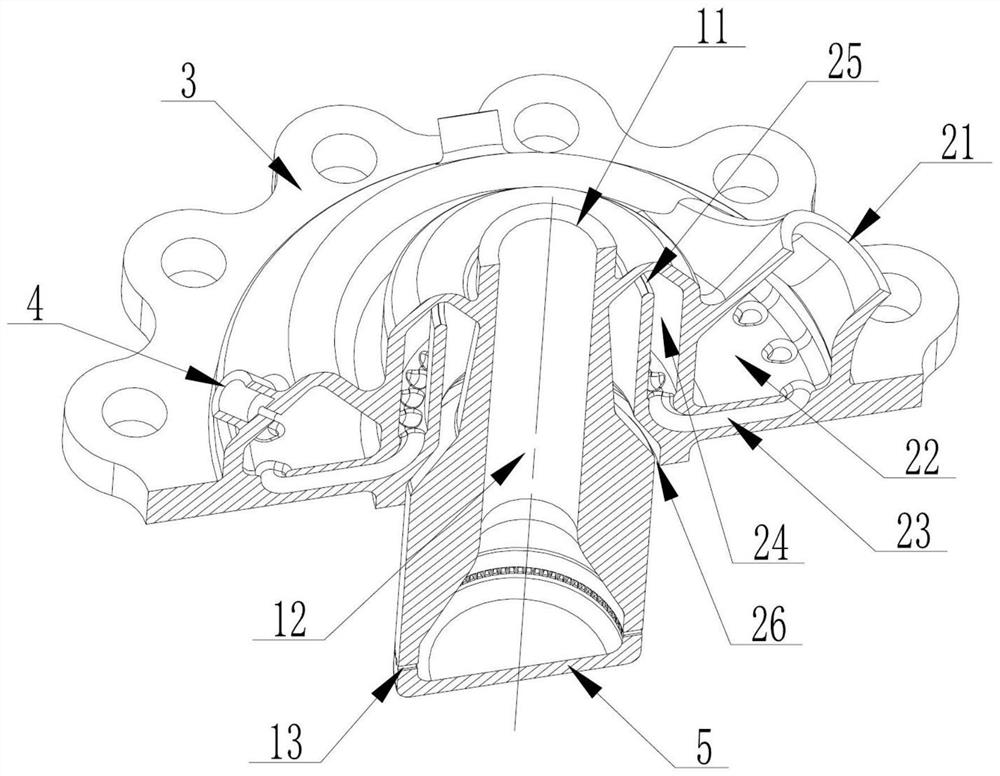

[0035] Figure 1-2 An embodiment of the present invention: an integrated injector, including an injector body 1, a mounting flange 3 located on the outer edge of the injector body 1, a test interface 4 on the outer wall of the injector body 1, and The injector head 5 located in the central area of the bottom of the injector body 1 is added in the injector body 1 to improve the circumferential uniformity of the oxidant flow rate and effectively cool the lower wall surface of the injector body 1. The oxidant flow channel part 2, In the present invention, since the oxidant flow channel part is added in the main body of the injector, the circumferential uniformity of the oxidant flow rate can be ensured through the complex oxidant channel arrangement, and at the same time, the oxidant is used to effectively cool the lower wall of the injector, which can improve the injection efficiency. life of the injector.

[0036] The oxidant flow channel part 2 includes an oxidant inlet 21 ...

Embodiment 2

[0053] The cooling channel 23 includes a total of 30 sub-channels, and the cross-sectional shape of each sub-channel is raindrop-shaped, which is beneficial to 3D printing.

Embodiment 3

[0055] The width of the buffer slit 25 should be small enough, in this embodiment, the width is 4 mm, and its pressure holding effect makes the oxidant in the buffer chamber 24 evenly distributed in the circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com