Susceptor, epitaxial growth device, epitaxial silicon wafer manufacturing method, and epitaxial silicon wafer

A technology of epitaxial growth and silicon wafers, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of slow growth rate and achieve the effect of improving the circumferential uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0099] First, bases related to Conventional Example 1, Comparative Example 1, and Example 1 described below were produced. Then, using these three types of susceptors, a silicon epitaxial layer was epitaxially grown on the surface of a silicon wafer with a diameter of 300 mm doped with boron and the wafer growth plane was the (100) plane, to obtain an epitaxial silicon wafer.

[0100] In addition, when manufacturing a silicon epitaxial wafer, the silicon wafer is introduced into an epitaxial film forming chamber, and placed on a susceptor using lift pins. Next, hydrogen gas was supplied at 1130° C., and after hydrogen baking was performed, a silicon epitaxial film was grown to 4 μm at 1130° C. to obtain an epitaxial silicon wafer. Here, trichlorosilane gas was used as the source gas, diborane gas was used as the dopant gas, and hydrogen gas was used as the carrier gas.

[0101] (Previous Example 1)

[0102] Prepare to set the radial distance L from the center of the base to ...

Embodiment 1)

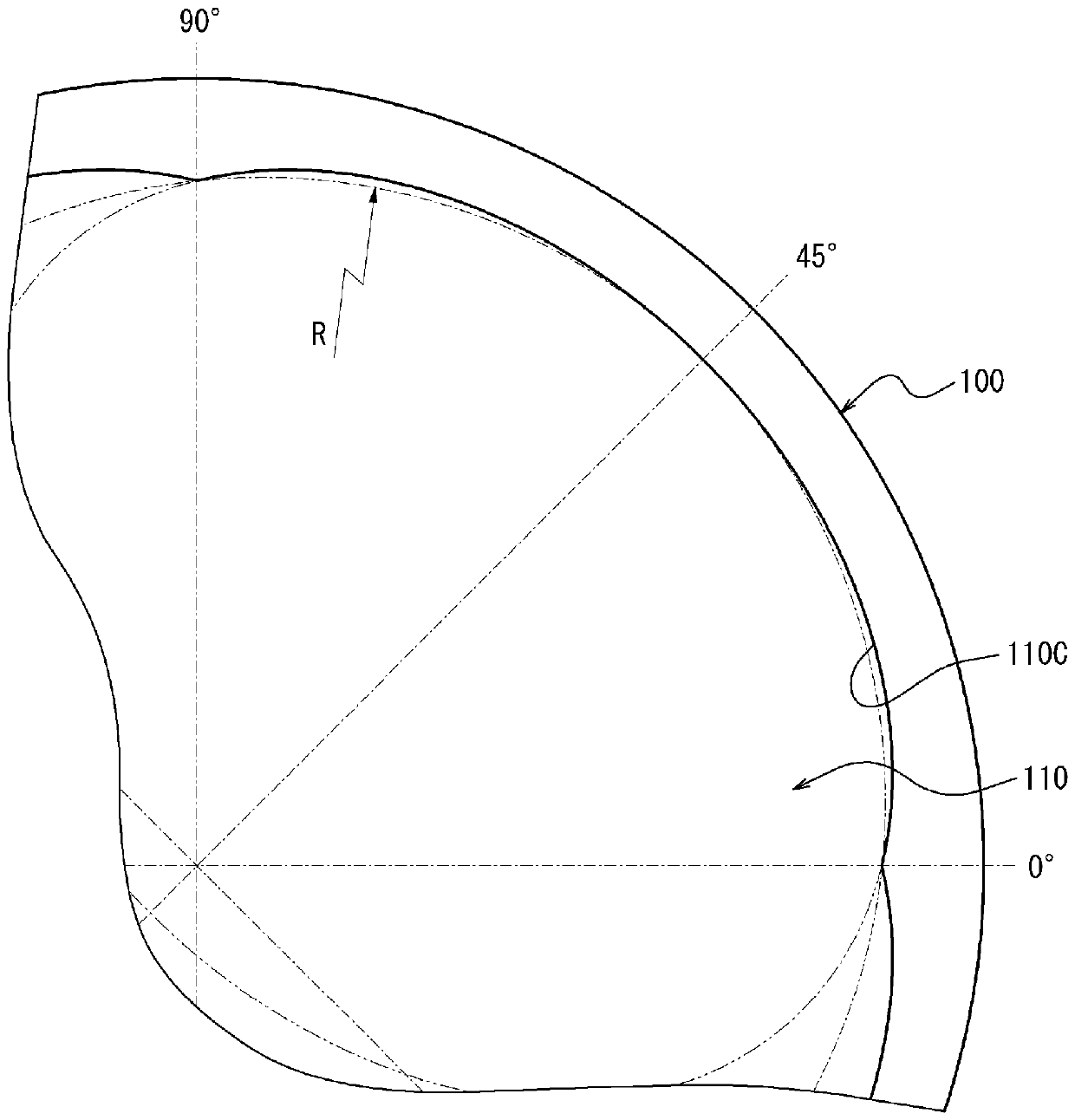

[0106] Prepare the radial distance L from the center of the base to the opening edge of the countersink according to Table 1 and Figure 8A A base whose variation shown varies in 90-degree cycles. When the base of Comparative Example 1 is viewed from above, the opening edge draws four elliptical arcs. Also, set the spot facing depth to be constant (difference in height H and shoulder height H W is also constant), and as in Conventional Example 1, the shoulder height Hw was set to 0.80 mm.

[0107] [Table 1]

[0108]

[0109]

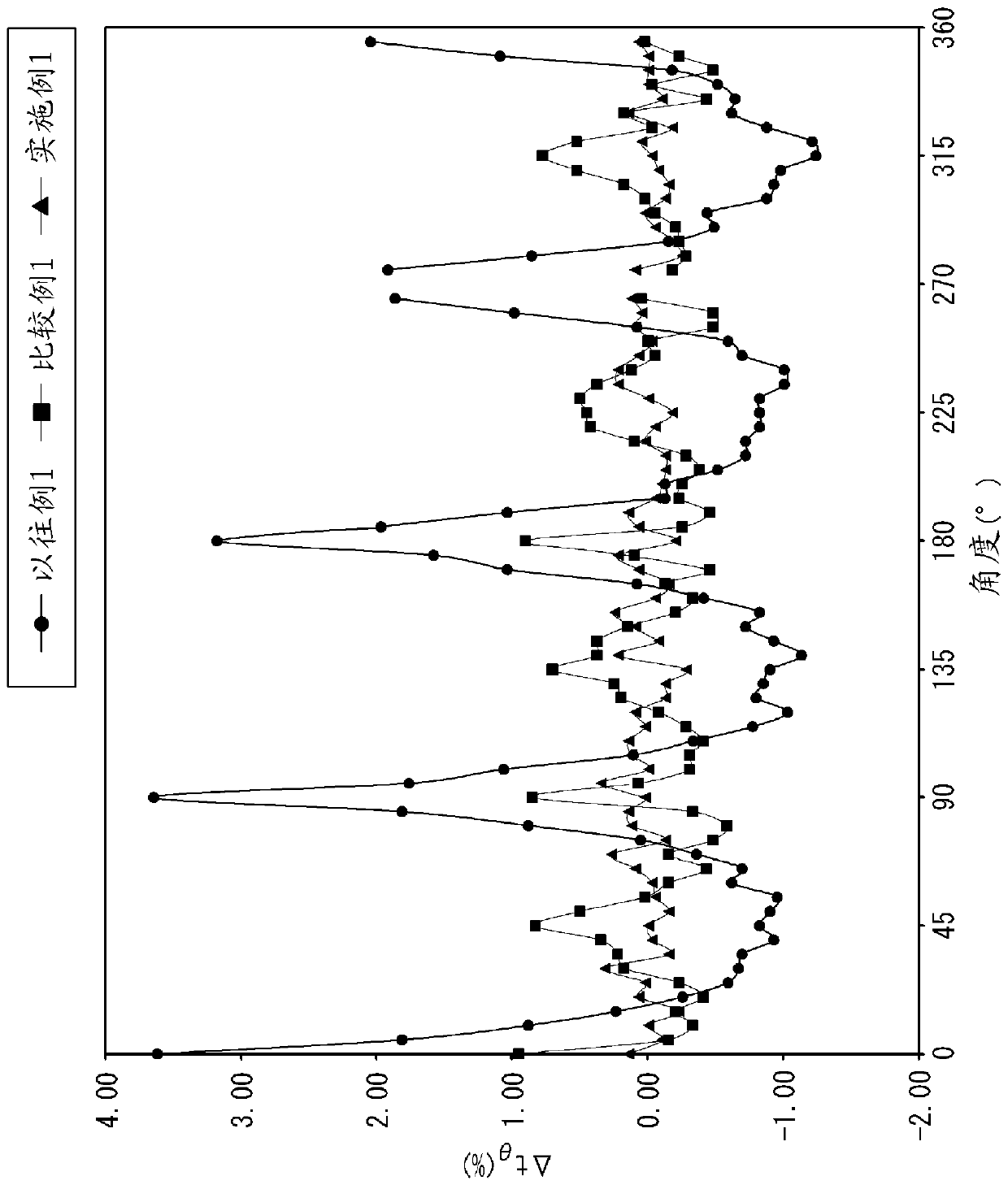

[0110] The film thickness distribution in the circumferential direction at a position 1 mm from the wafer edge of the epitaxial silicon wafer produced using the susceptors of Conventional Example 1, Comparative Example 1, and Example 1 was measured using a film thickness measuring device (manufactured by Nanometrics: QS3300). express the result in Figure 8B in the graph of . As is clear from this graph, it can be confirmed that the uniformity ...

experiment example 2

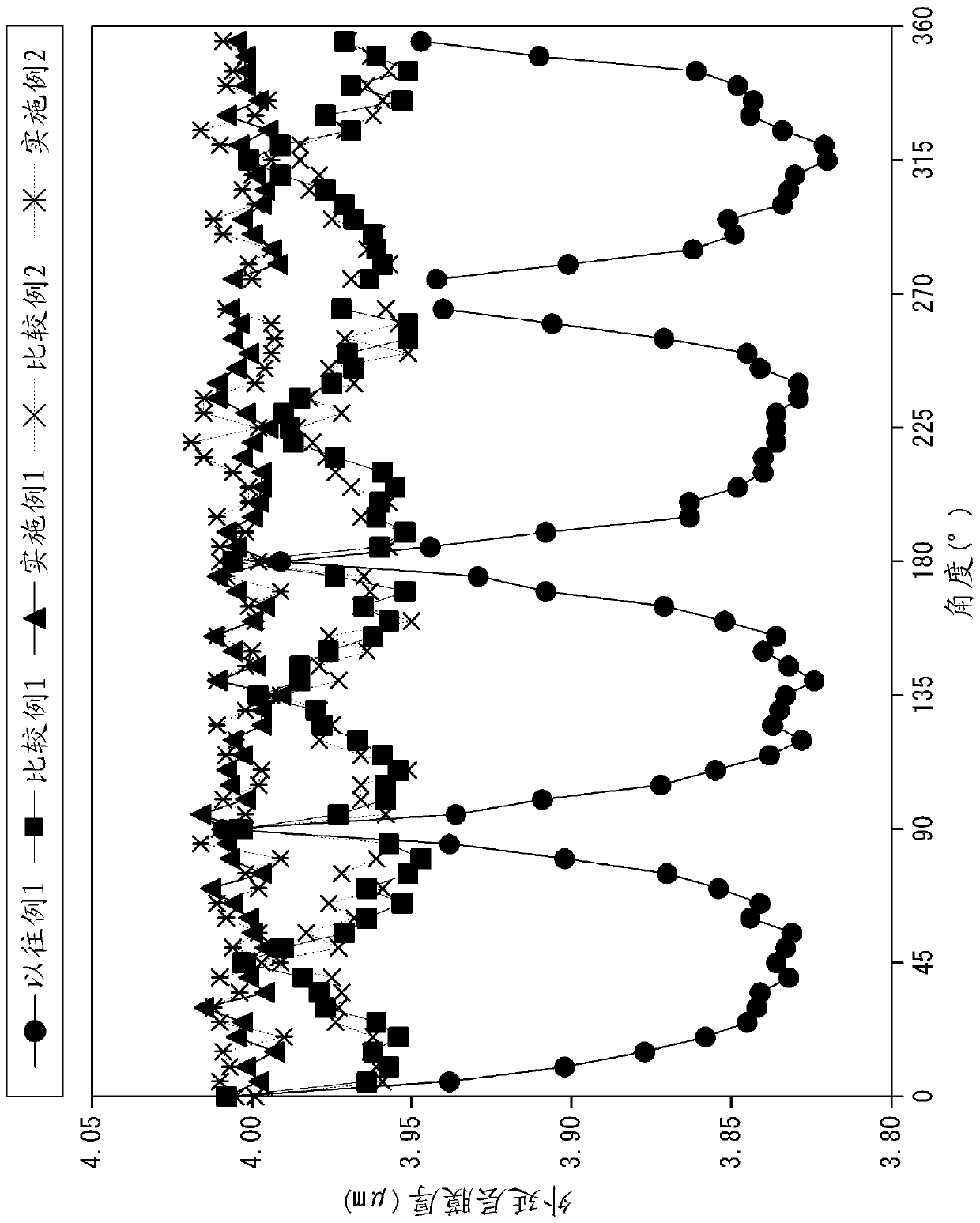

[0118] In addition to the base of Conventional Example 1 used in Experimental Example 1, bases of Comparative Example 2 and Example 2 described below were produced. Then, using these three types of susceptors, a silicon epitaxial layer was epitaxially grown on the surface of a boron-doped silicon wafer with a diameter of 300 mm in the same manner as in Experimental Example 1 to obtain an epitaxial silicon wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com