Small high-energy X-ray device and method

An X-ray and X-ray tube technology, applied in the field of X-ray sources produced by high-energy electrons bombarding heavy metals, can solve the problems of complex structure, high construction and operation costs, and low penetration ability of electron linear accelerators, and achieve simplified power supply design and system Complexity, low construction and operation costs, and improved circumferential uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further explained in detail below in conjunction with the accompanying drawings.

[0027] A small high-energy X-ray device, including an X-ray source magnet system, an X-ray tube and a power supply system;

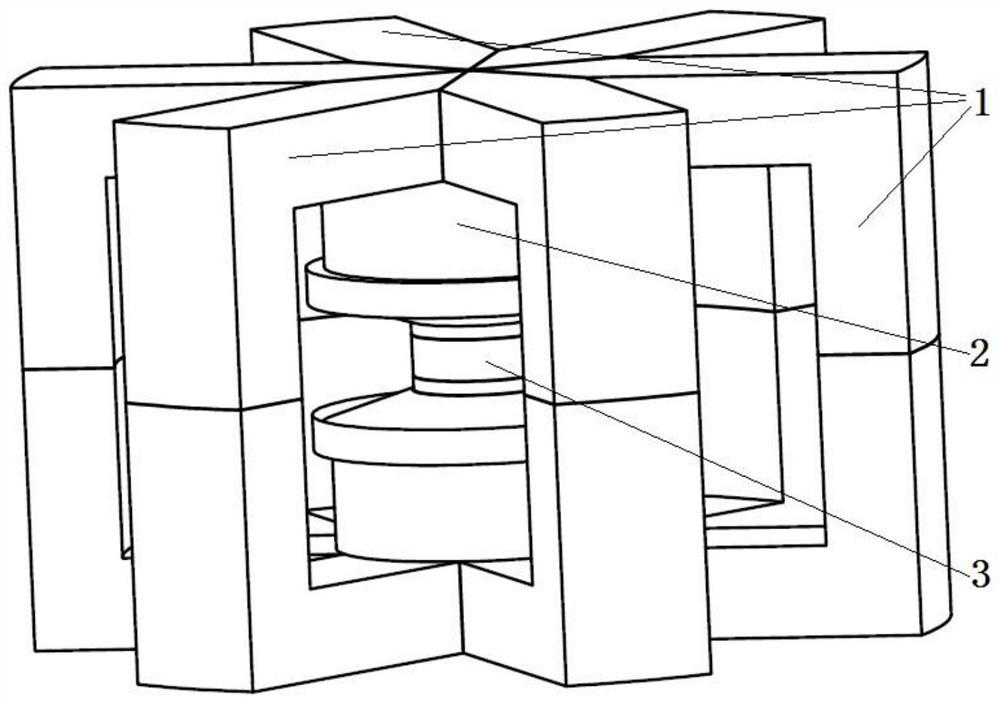

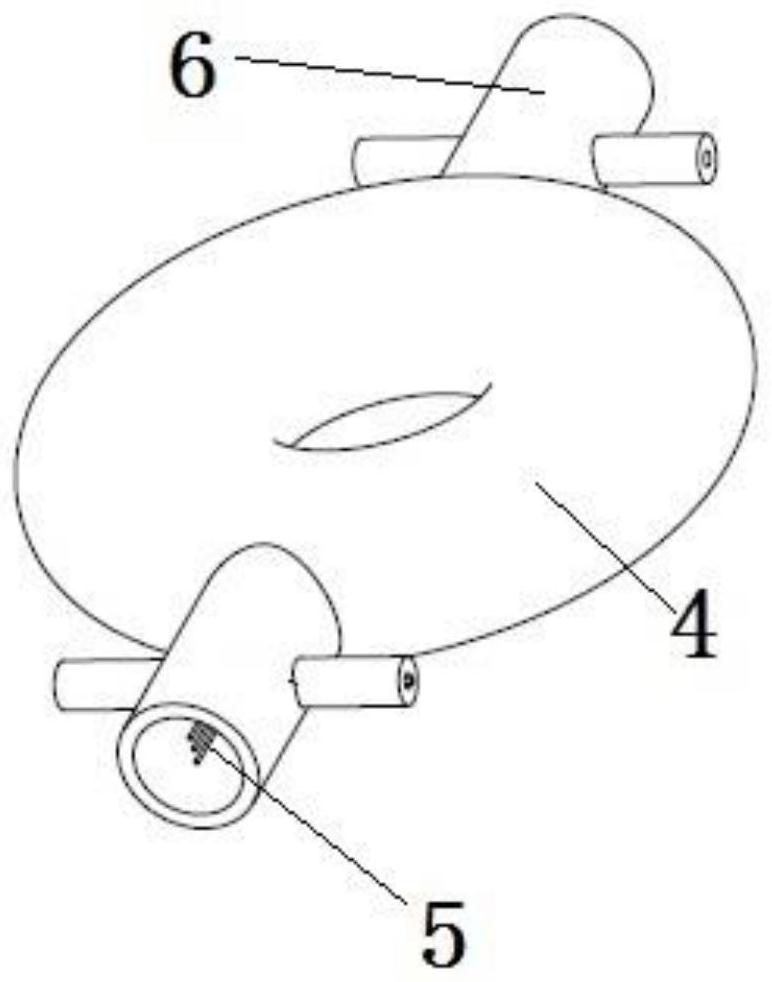

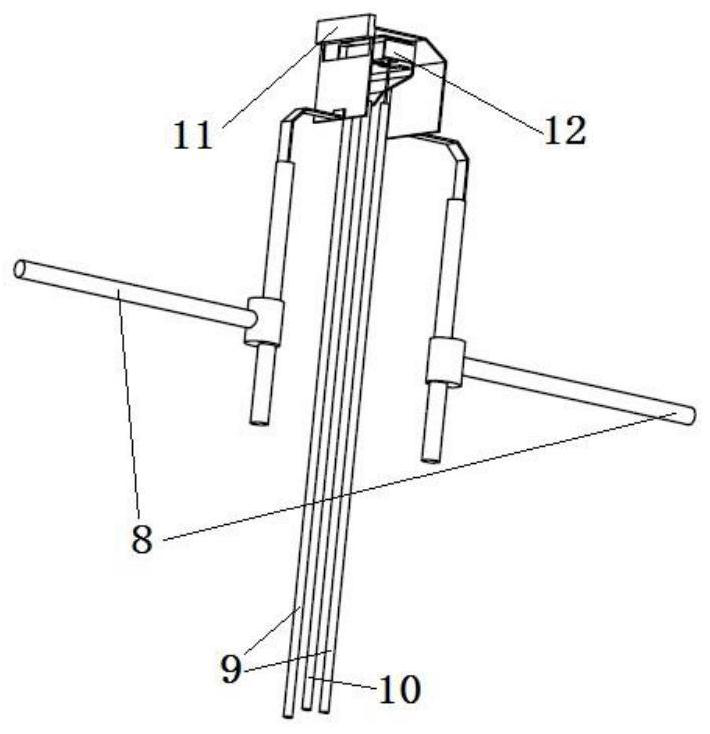

[0028] refer to figure 1 , Figure 4 and Figure 5, the X-ray source magnet system includes six iron core yokes 1, two magnetic pole heads 2, two to four magnetic pole pads 3, two expansion coils 13 and two annular excitation coils 7, and the six iron core yokes 1 are The hexagonal stars are radially distributed to form a cylindrical inner space; the bottom planes of the two magnetic pole heads 2 are connected with the upper and lower bottom surfaces of the cylindrical inner space formed by the iron core and yoke 1, and are connected with the iron core and yoke 1 to form a magnetic circuit; the magnetic pole pads 3 are placed Between the two magnetic pole heads 2 and coaxial with the magnetic pole heads 2, it is used to adjust the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com