Resonance type radial forging machine and forging application thereof

A radial forging and forging technology, which is applied in the resonant radial forging machine and its forging application field, can solve problems such as uneven stress on metal blanks, achieve improved circumferential and axial forging uniformity, and improve axial uniformity Sexual, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

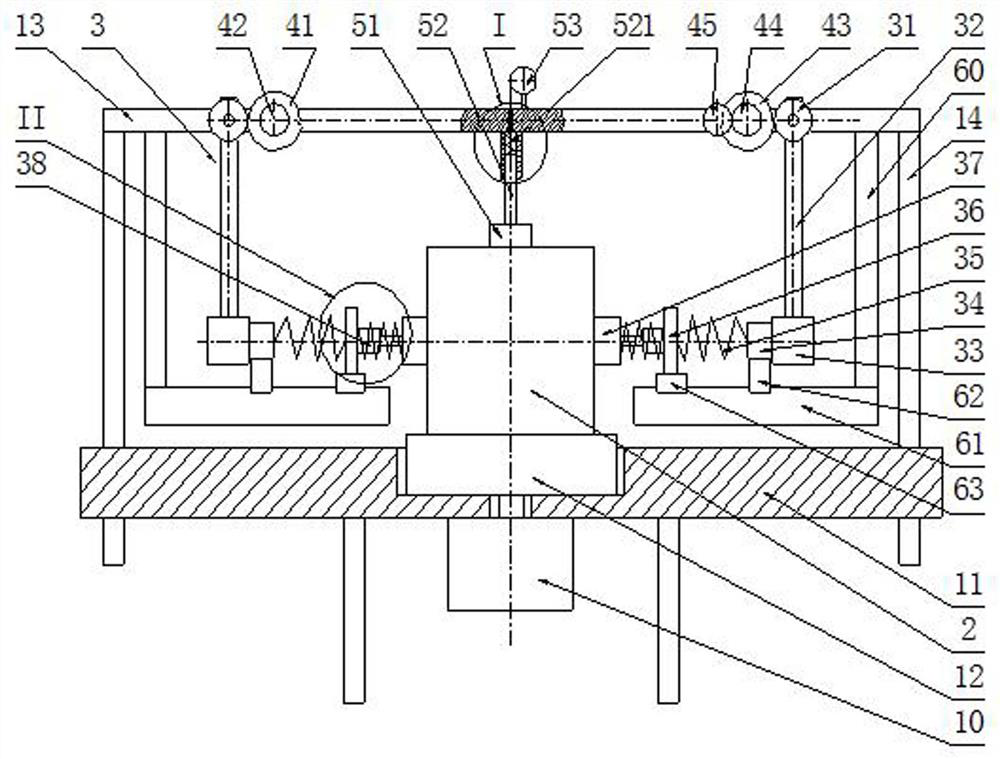

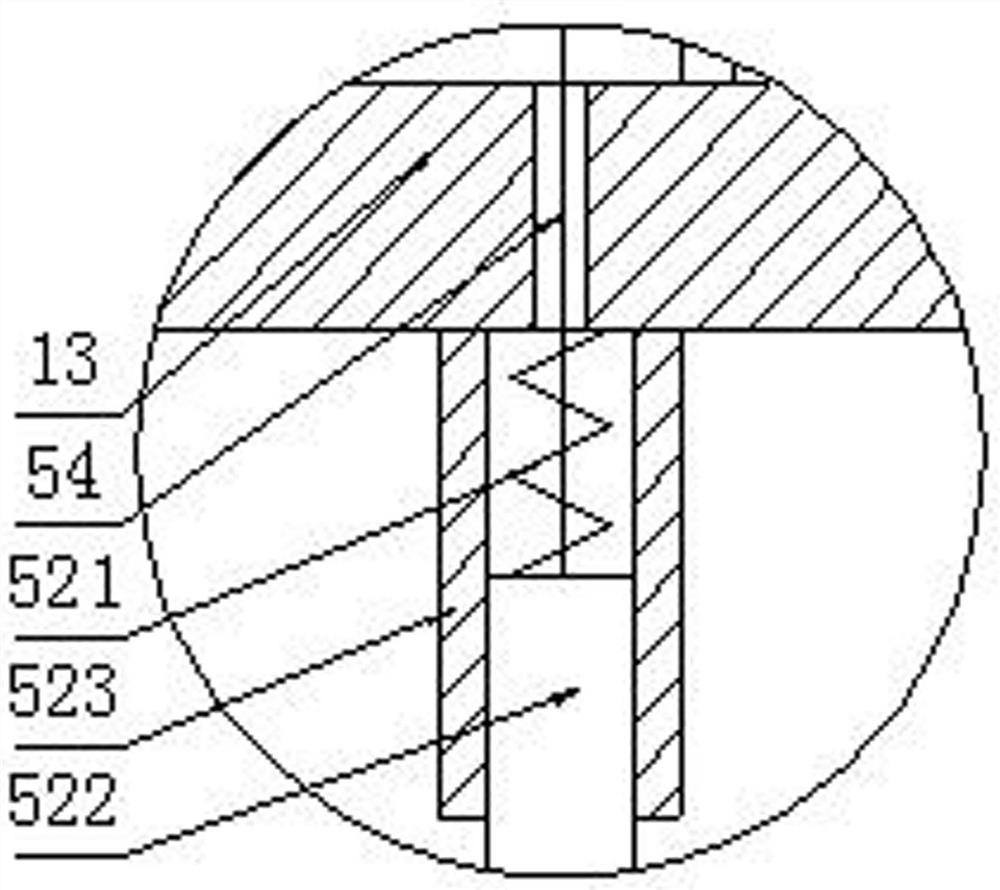

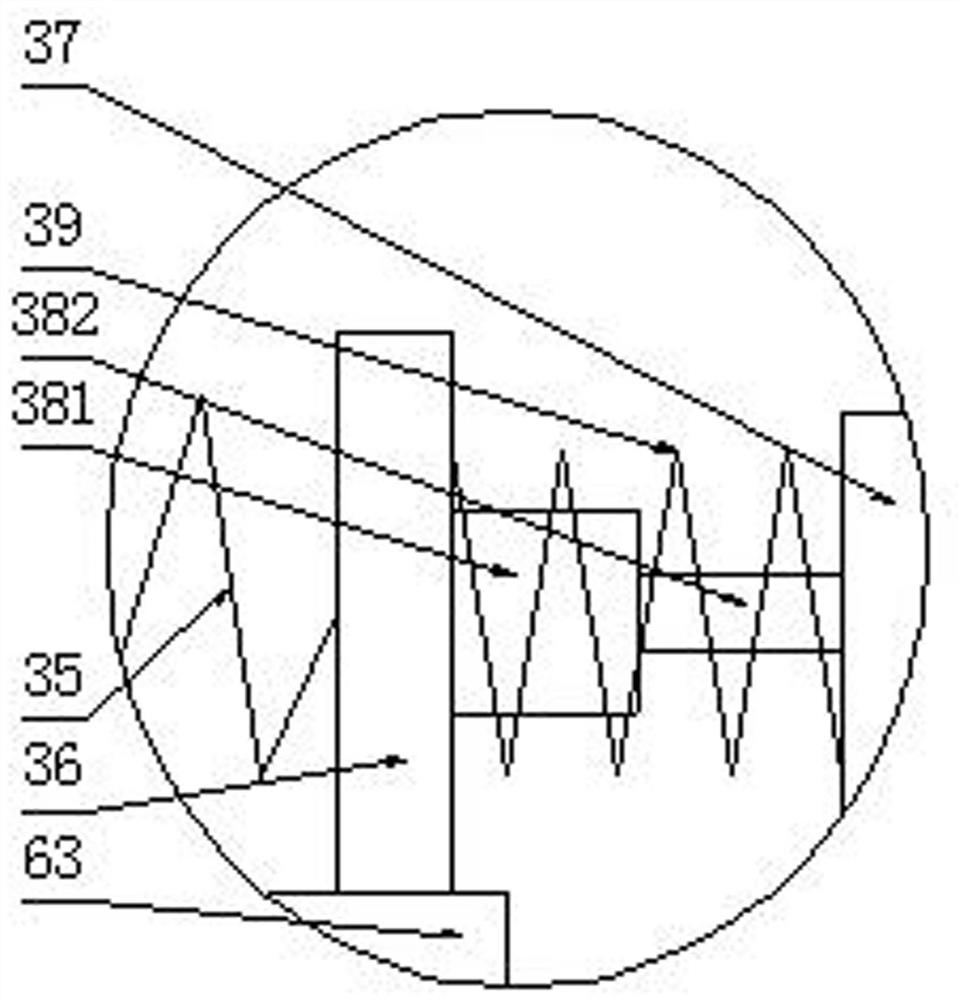

[0026] see figure 1 , a resonance type radial forging machine of the present invention, which includes a lower frame plate 11, an upper frame plate 13 and a lifting guide rod 14, the upper frame plate 13 is installed parallel to the lower frame plate 11 above the lower frame plate 11; the lifting guide rod The number of 14 is two, installed along the vertical direction, the upper end of which is fixedly connected to the upper frame plate 13, and the lower end slides through the lower frame plate 11 to ensure that the upper frame plate 13 moves vertically relative to the lower frame plate 11. The lower frame plate 11 is provided with a platform counterbore 110 for accommodating the rotating platform 12. The inner diameter of the platform counterbore 110 is slightly larger than the outer diameter of the rotating platform 12, and the depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com