Rim sealing structure comprising wave-shaped hollows and turbine using rim sealing structure

A technology of sealing structure and concave structure, which is applied in the field of turbines, can solve the problems of limited effect and achieve the effects of convenient processing, increased circumferential uniformity, and enhanced fluid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

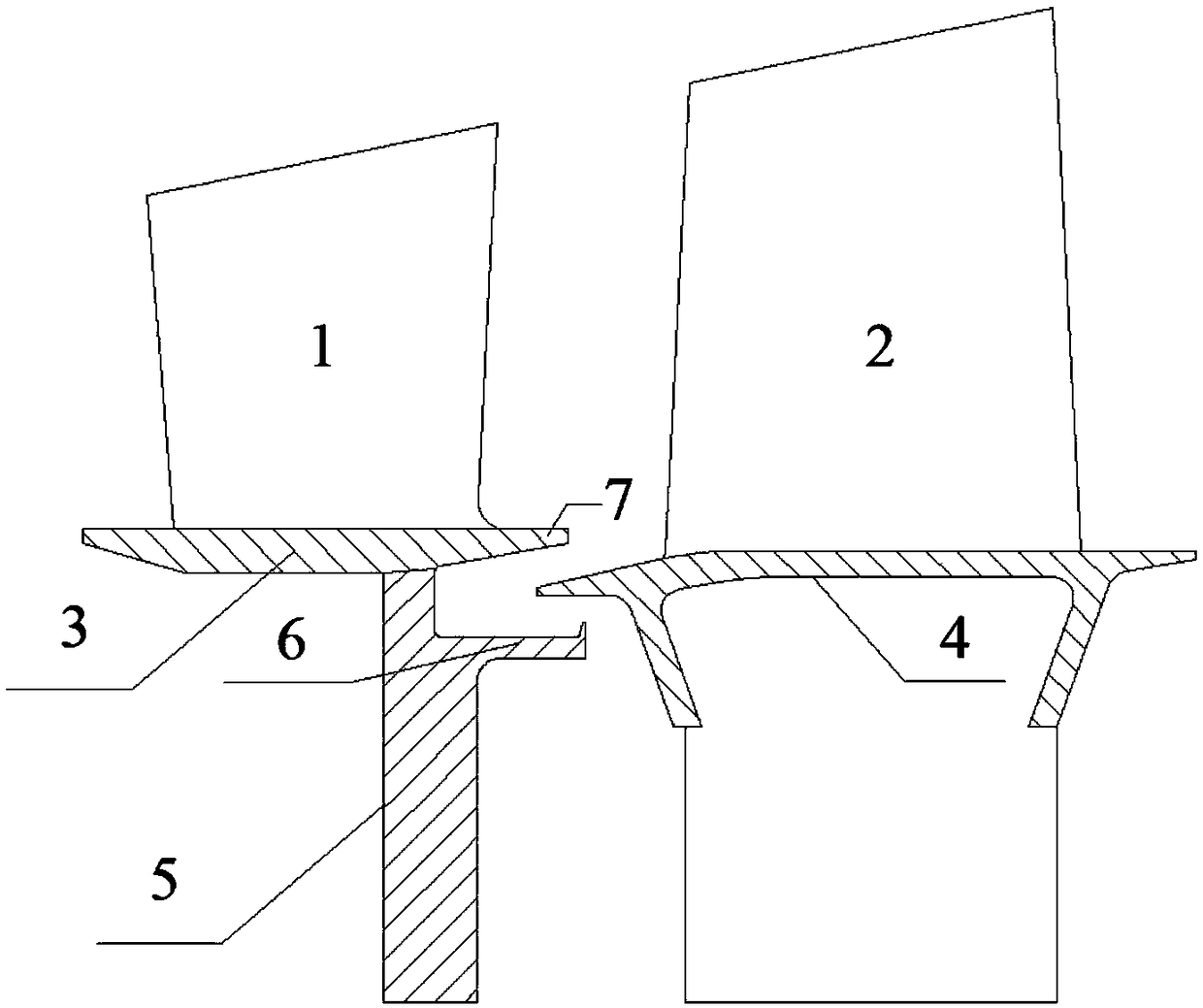

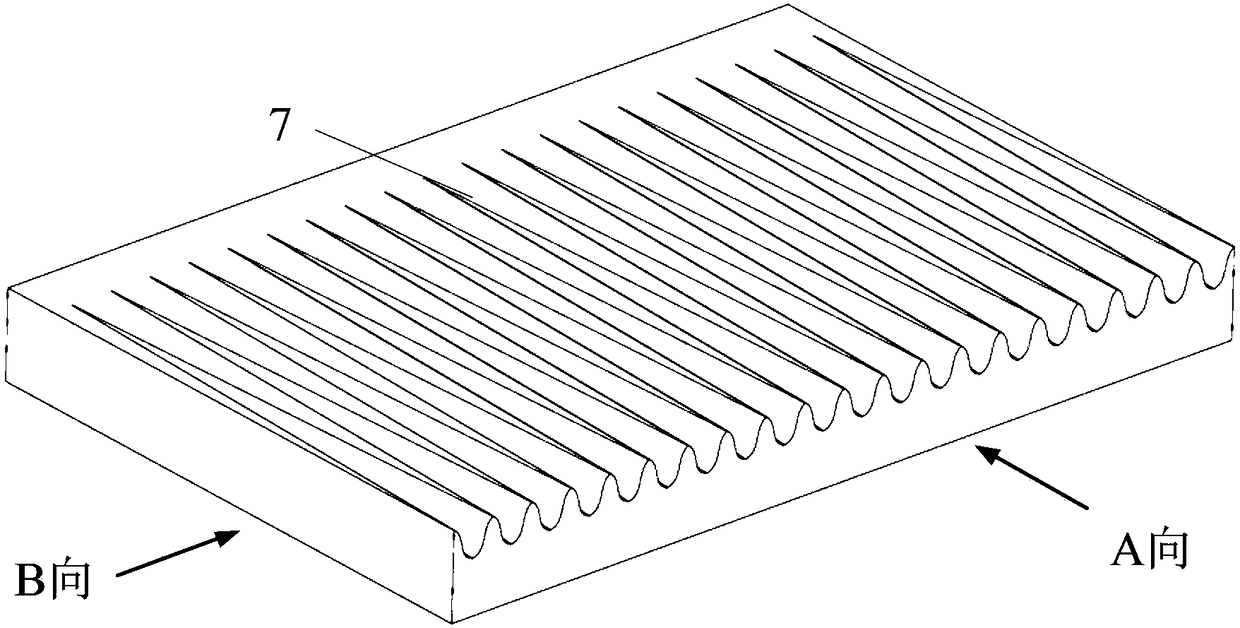

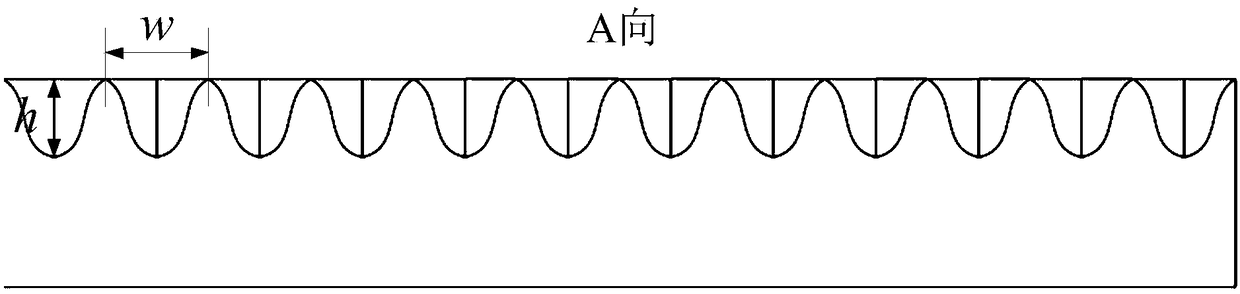

[0017] to combine Figure 1~4 , the present invention is made up of hub (comprising stationary blade hub flange 3 and moving blade hub flange 4), stationary blade 1, moving blade 2 and casing (not shown in the figure), between the hub and the casing along the circumference Install the stationary blade 1 and the moving blade 2 evenly in the direction, the stationary blade 1 is in the front, and the moving blade 2 is behind. On the rotor hub flange plate 4 and connected with the rotor blade rotating disc, a cold flow channel is formed between the stationary blade partition plate 5 and the rotor blade rotating disc, and is set at the edge of the partition plate below the rear side of the stator hub flange plate 3 The sealing teeth 6 on the side of the stator blade, the tops of the sealing teeth protrude radially upwards in a sickle shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com