Patents

Literature

77results about How to "Uniform radial distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

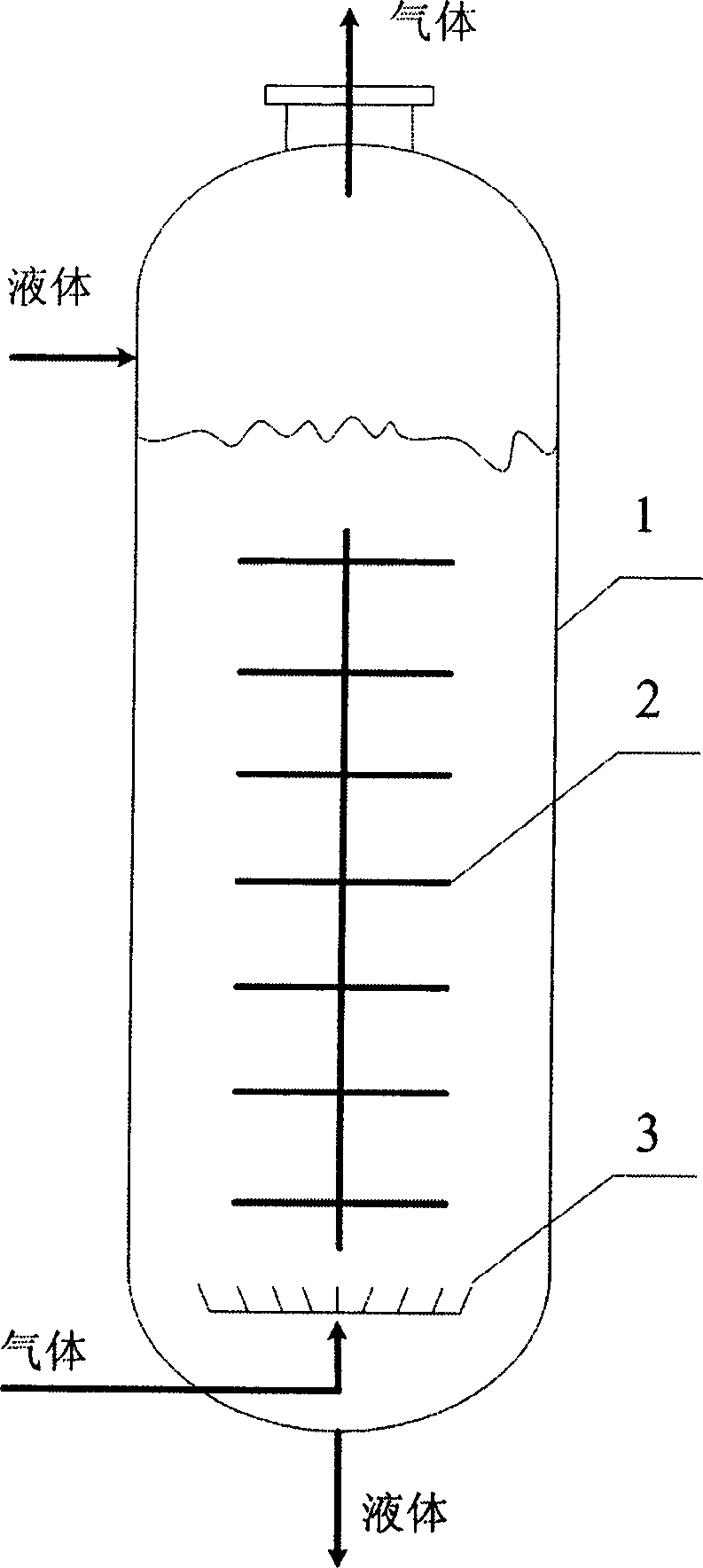

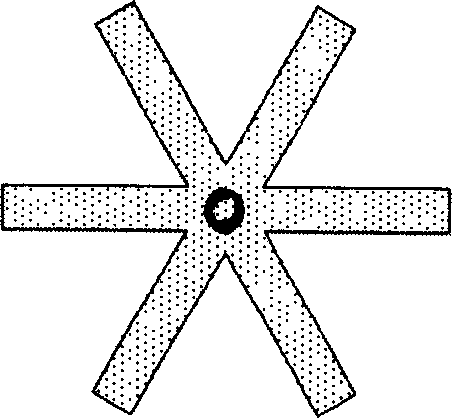

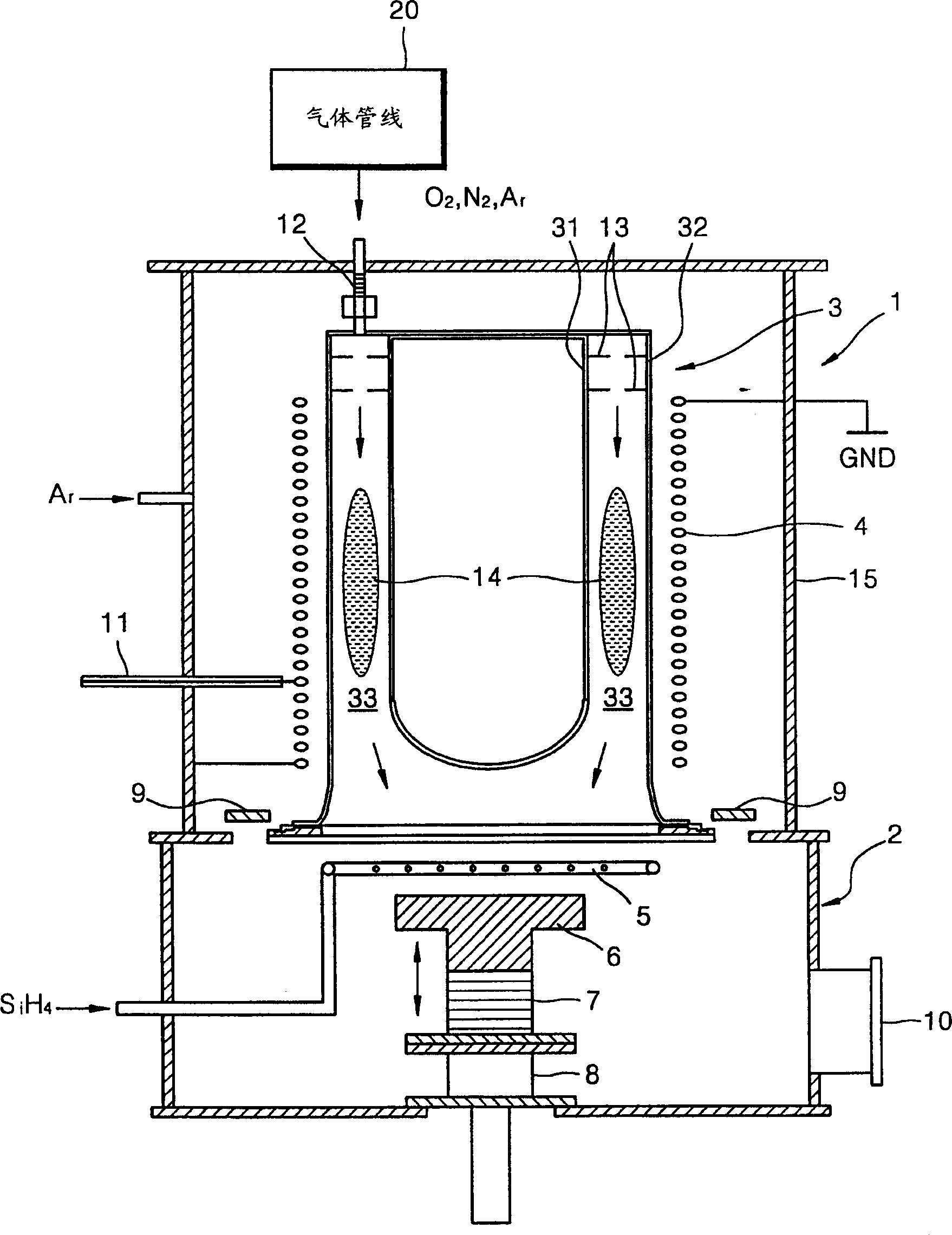

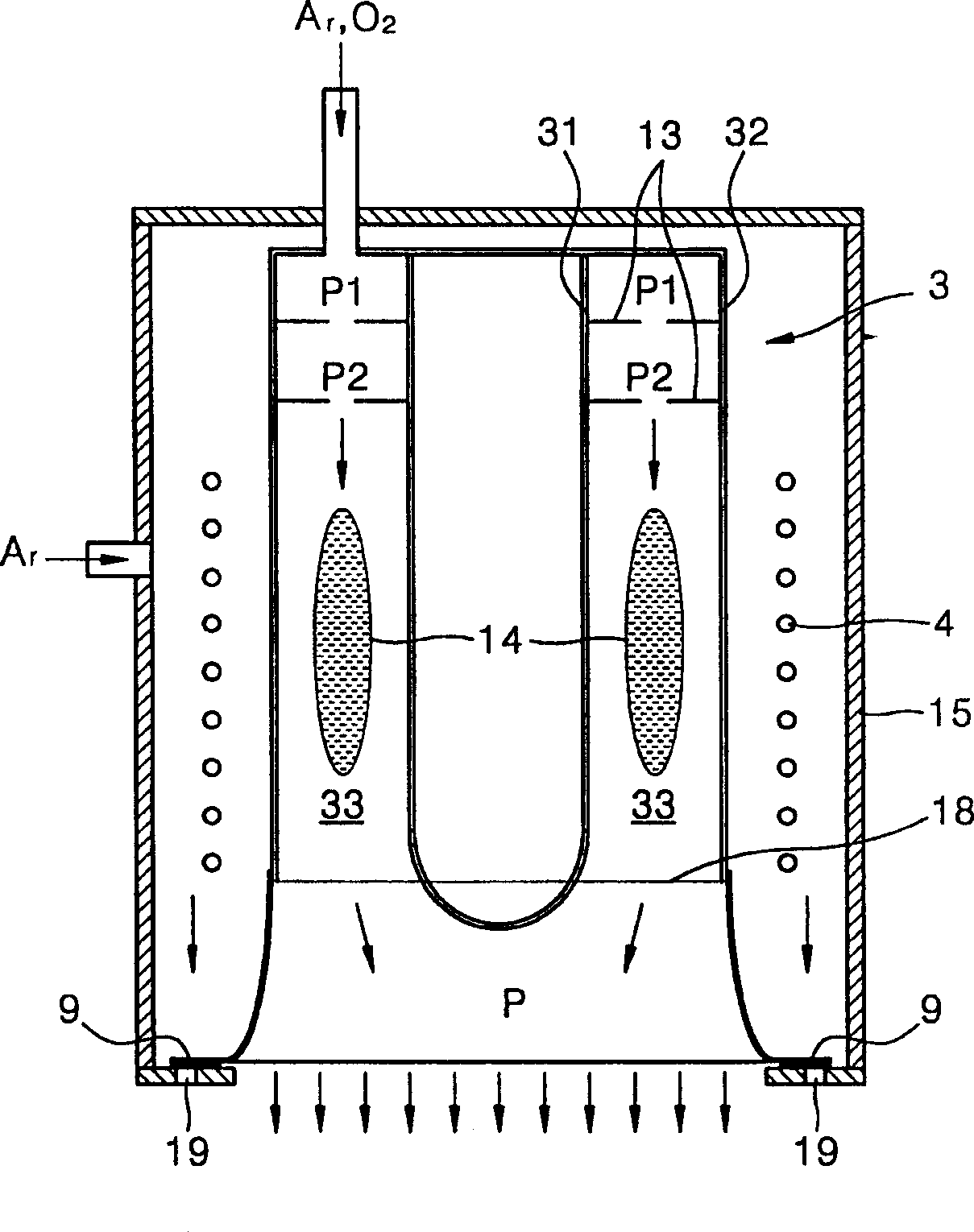

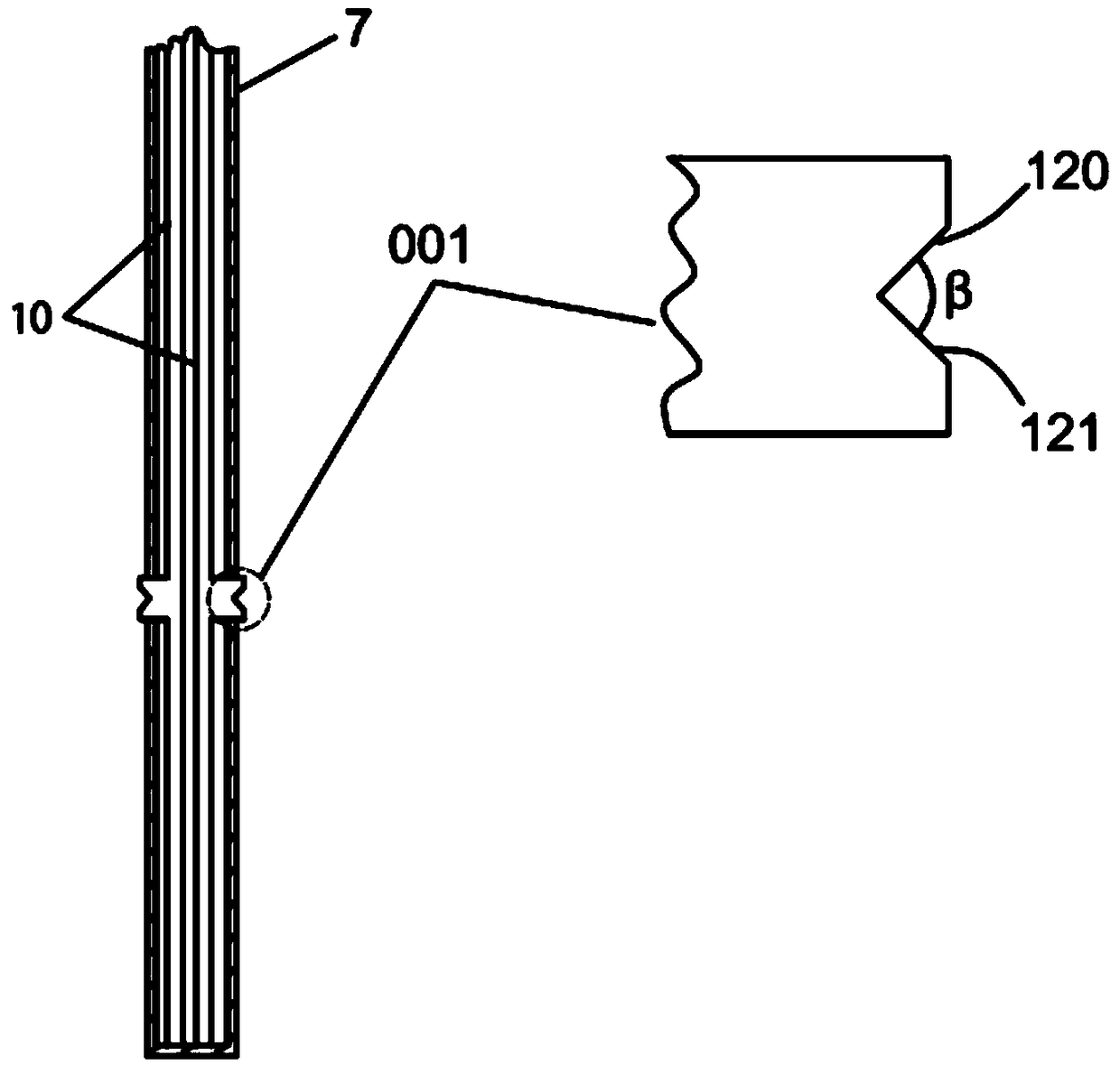

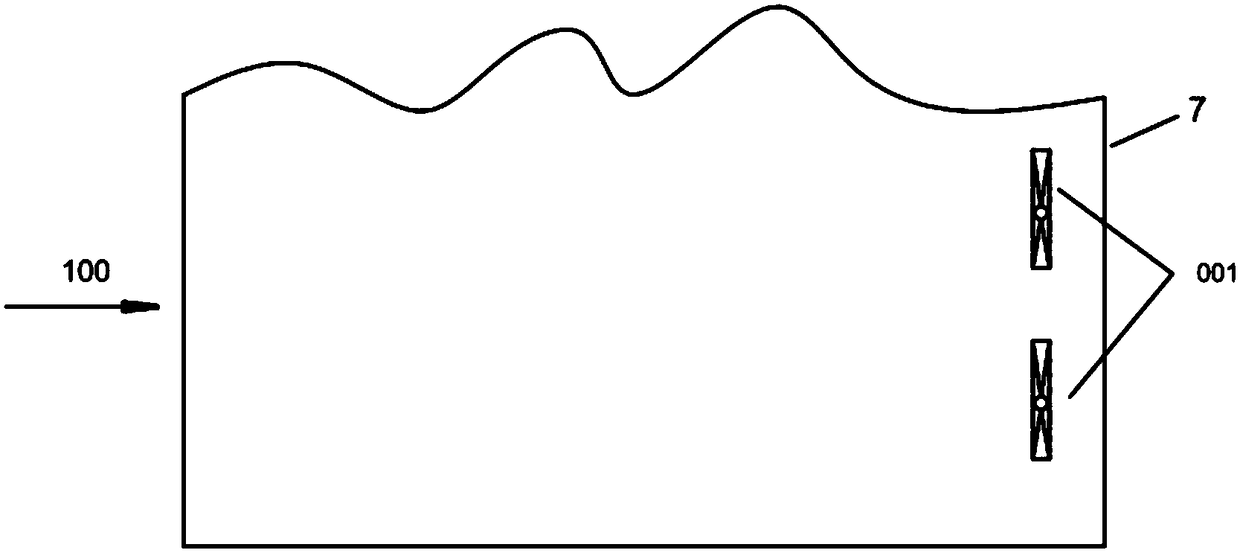

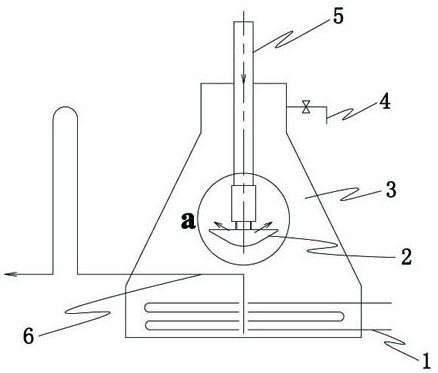

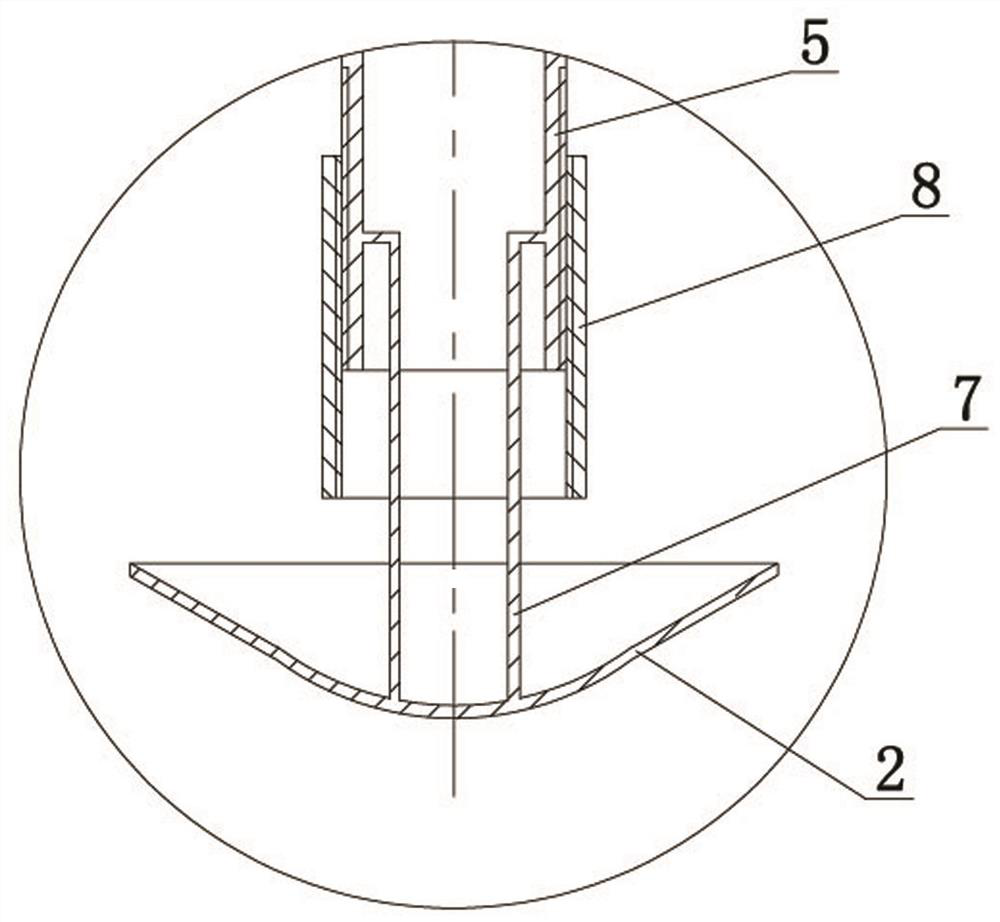

Bubbling tower reactor having damping internal construction member

InactiveCN1785495AIncrease mass transfer rateInhibit flow rateLiquid-gas reaction processesEngineeringTower

A bubbling column reactor with internal damping member features that said internal damping member is coaxially installed in the reaction region above gas distributor for suppressing the flow speed in central region to make the radial speed distribution more uniform and interferring the flow field to promote local turbulence and increase gas-liquid mass transfer speed.

Owner:ZHEJIANG UNIV

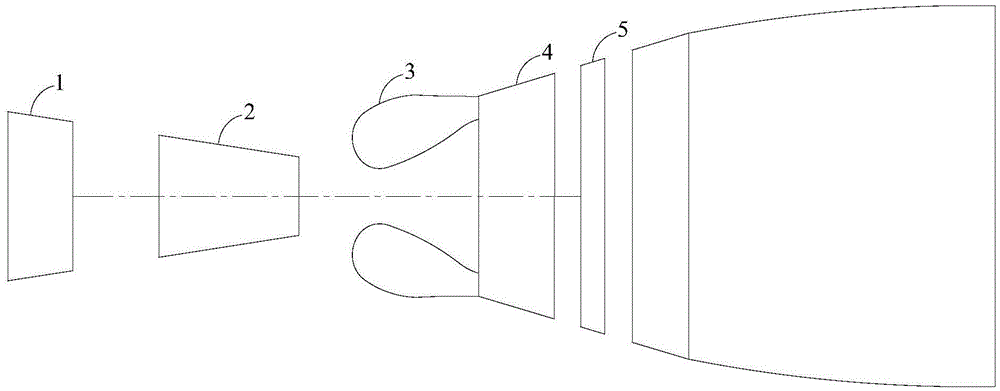

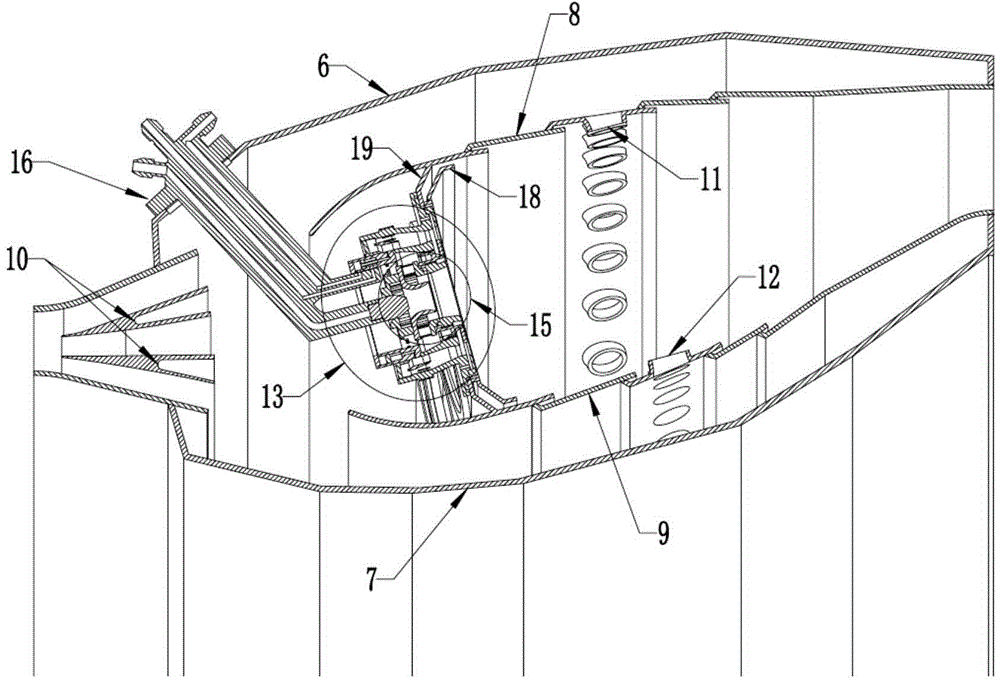

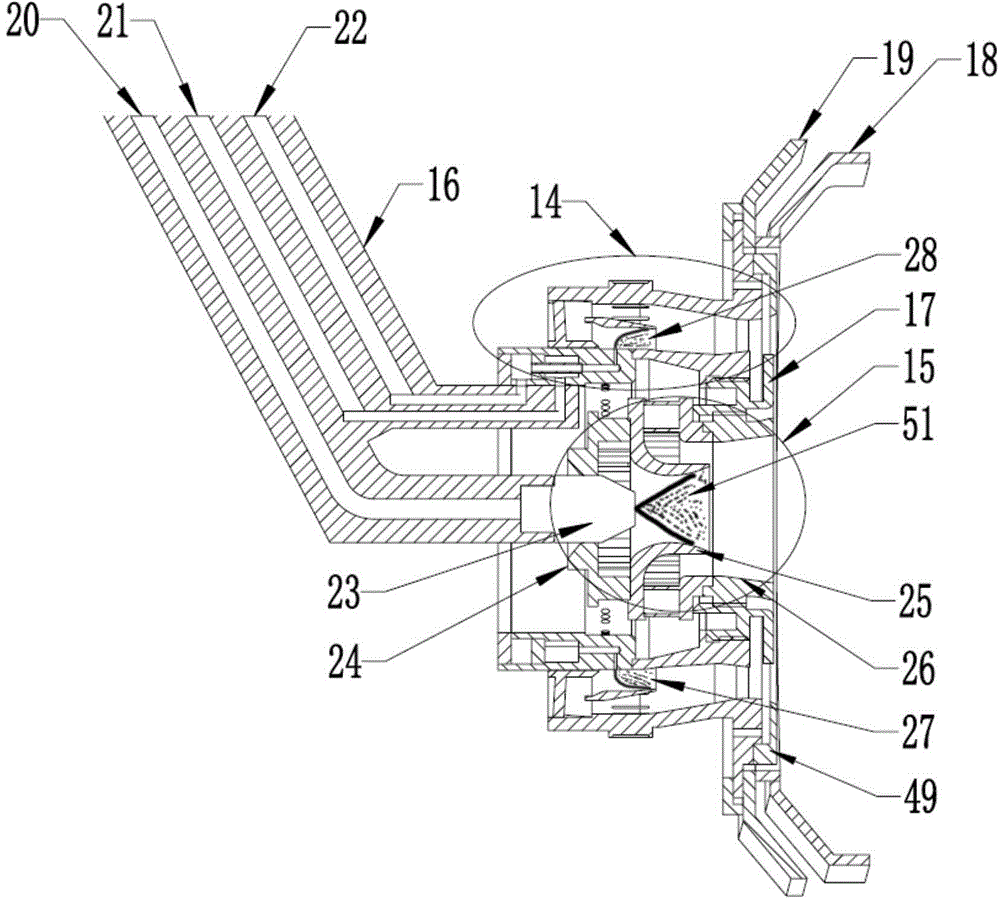

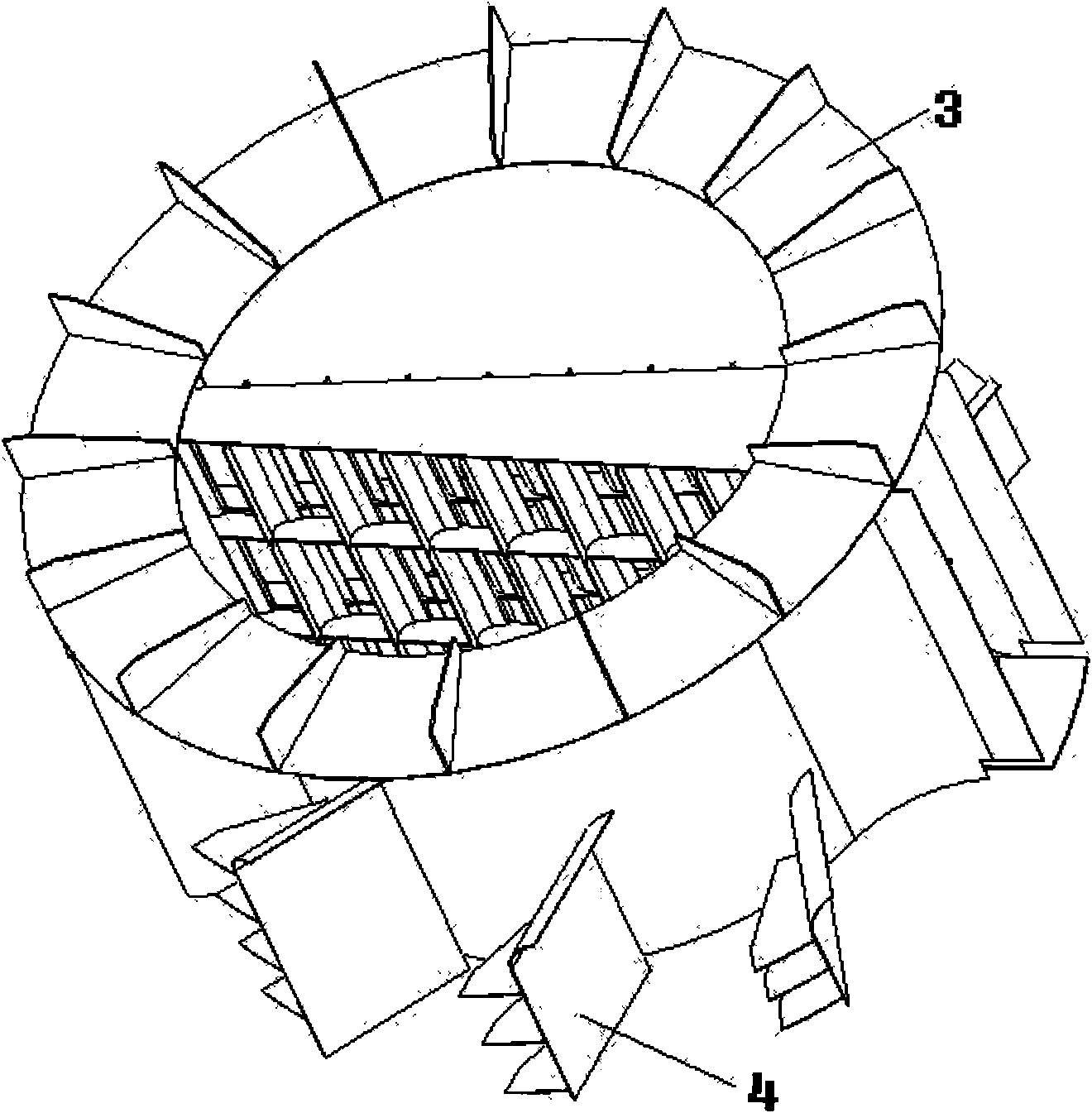

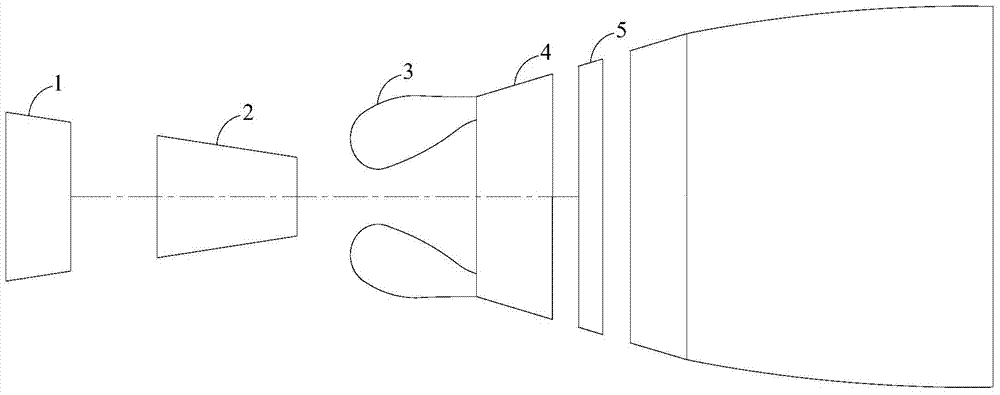

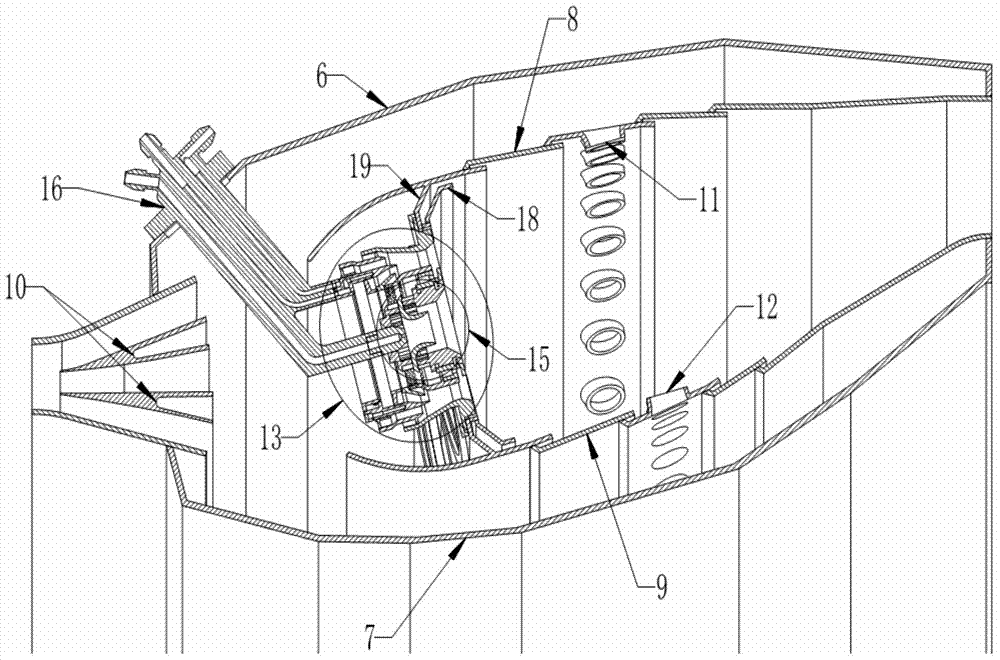

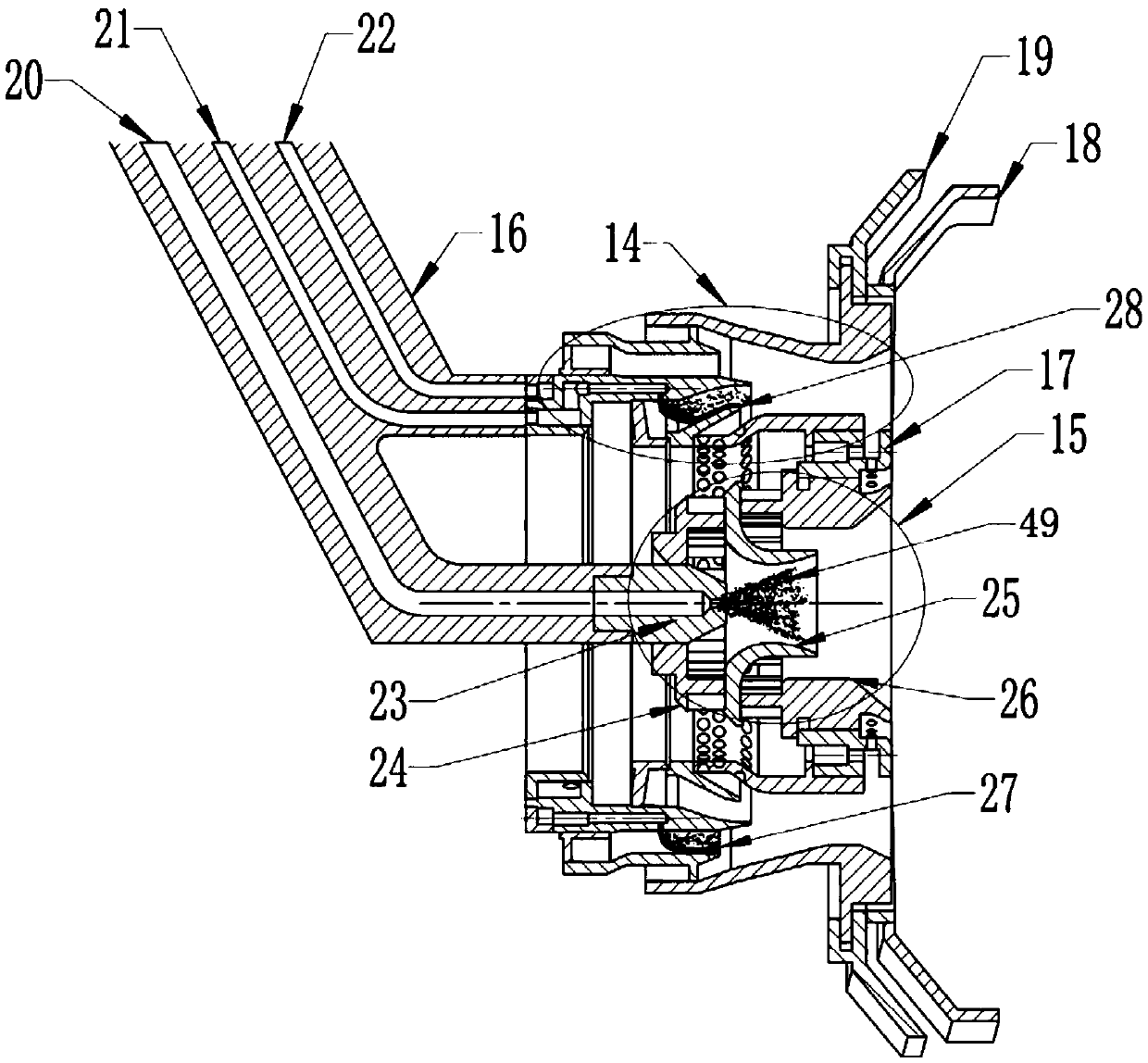

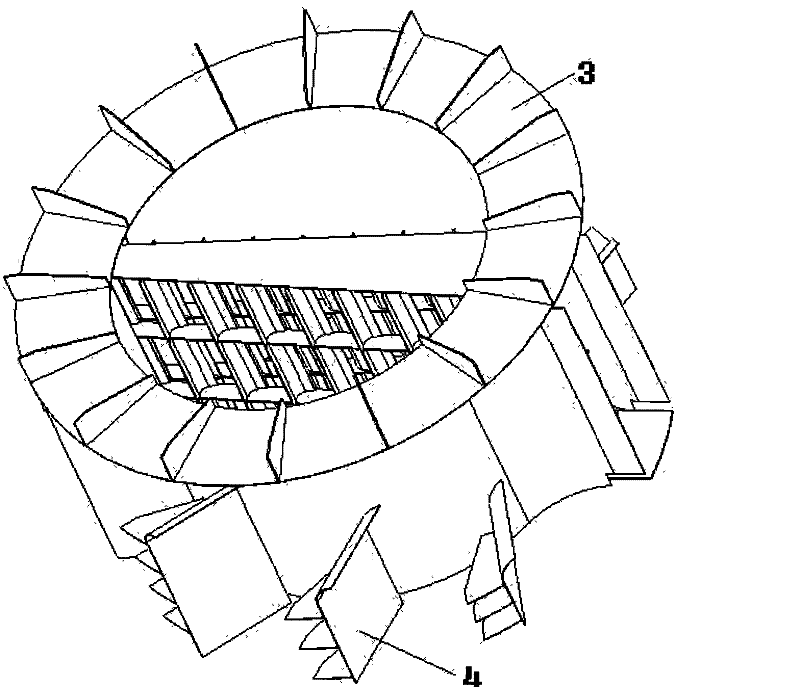

Lean oil premixing and pre-evaporating combustion chamber head structure with cyclone/pre-film plate integrated primary combustion stage

The invention relates to a lean oil premixing and pre-evaporating combustion chamber head structure with a cyclone / pre-film plate integrated primary combustion stage. A central staged combustion mode is adopted for the head structure and divided into a pre-combustion stage and the primary combustion stage, the mode of combining diffusive combustion and cyclone premixing combustion is adopted for the pre-combustion stage, the mode of premixing and pre-evaporating combustion mode is adopted for the primary combustion stage, and combustion pollutants can be effectively reduced. A cyclone / pre-film plate integrated structure is adopted for the primary combustion stage, the structure is simple and reliable, first-stage fuel and second-stage fuel form oil films on the same pre-film plate and are atomized, evaporated and mixed under the action of two strands of cyclones, an even oil and gas mixture can be easily formed at an outlet of the primary combustion stage, and the combustion pollutants are reduced. The design of dual oil paths of the primary combustion stage is beneficial to oil and gas matching of the combustion chamber under different working conditions, and the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aero-engine is further lowered. By means of the micro shrinkage type design of a primary combustion stage channel and the design of a backfire prevention ring, the backfire problem can be effectively solved, and the safety of the head of the combustion chamber is ensured.

Owner:BEIHANG UNIV +1

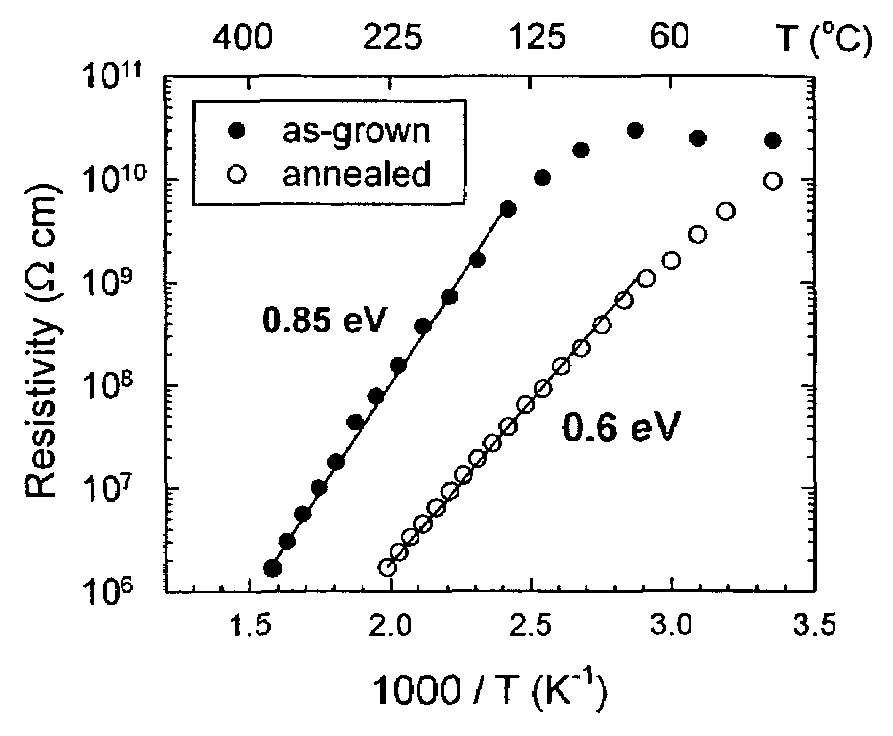

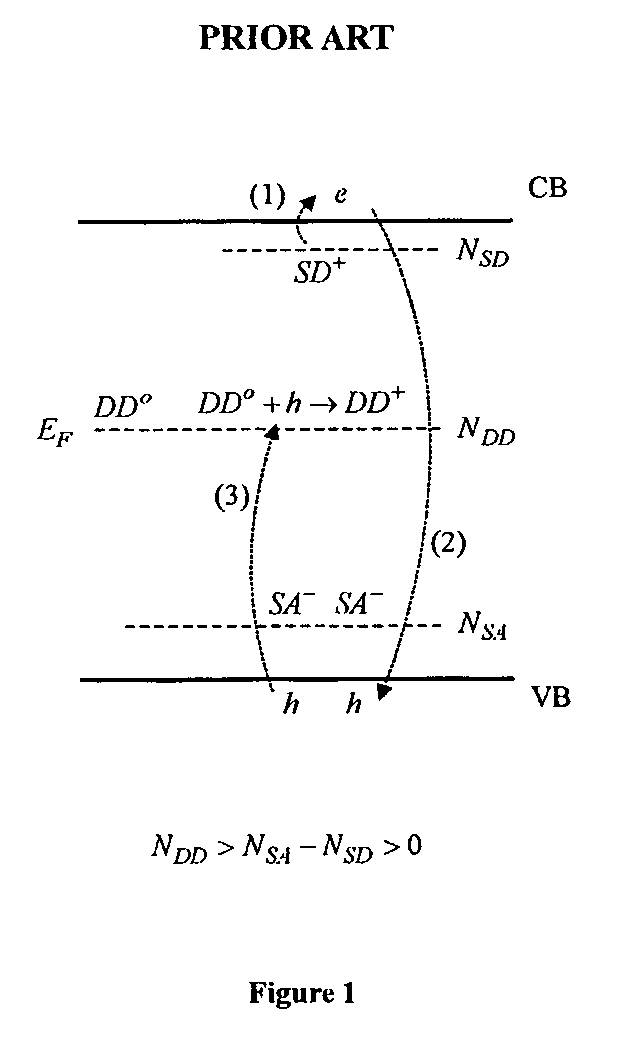

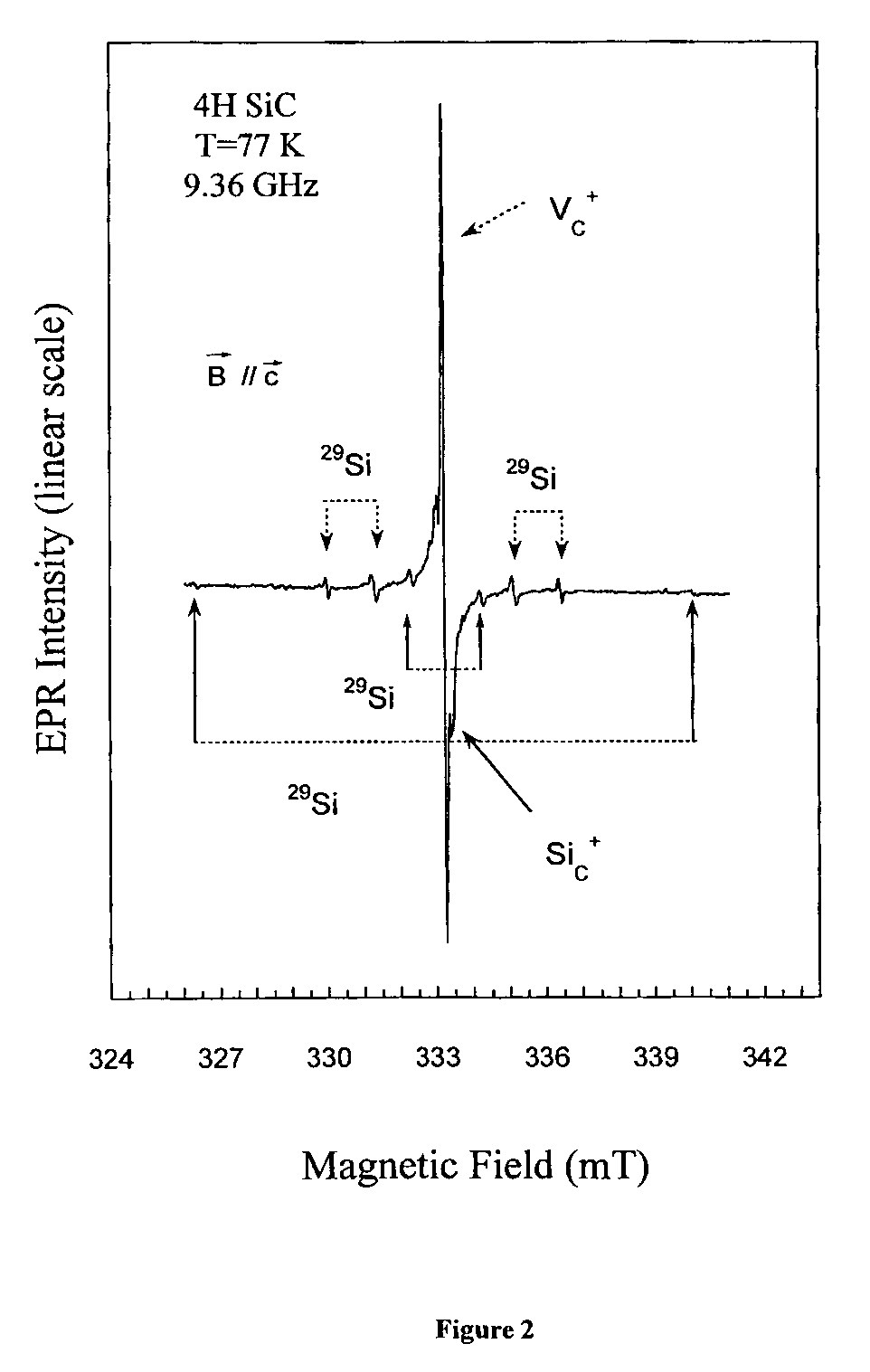

High resistivity silicon carbide single crystal

InactiveUS7018597B2Stable and linear characteristicHigh resistivityPolycrystalline material growthSemiconductor/solid-state device manufacturingHigh resistivity siliconCarbide

The purpose of the invention is to provide a high resistivity silicon carbide substrate with electrical properties and structural quality suitable for subsequent device manufacturing, such as for example high frequency devices, so that the devices can exhibit stable and linear characteristics and to provide a high resistivity silicon carbide substrate having a low density of structural defects and a substantially controlled uniform radial distribution of its resistivity.

Owner:OKMETIC OY

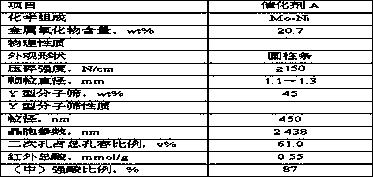

Noble metal catalyst used in hydrocracking and isomerization of Fischer-Tropsch synthetic wax and preparation method therof

ActiveCN101698148AHigh activityGuaranteed thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentIsomerizationPore distribution

The invention provides a noble metal catalyst used in hydrocracking and isomerization of Fischer-Tropsch synthetic wax and a preparation method thereof. The a catalyst carrier comprises the following components: 70 to 85 weight percent of amorphous silicon aluminum and 15 to 30 weight percent of alumina adhesive, wherein active components are selected from noble metal Pt and Pd elements (in a molar ratio of 0.1 to 0.6) and the noble metal active components account for 0.1 to 1 weight percent of the carrier; the specific surface area of the catalyst is 150 to 400m2 / g, while the pore volume is 0.3 to 1.4ml / g and the NH3-TPD total acidity is between 0.5 and 1.5mmol / g; and 4 to 15nm pore distribution accounts for 60 to 90 percent of total pore volume respectively. The preparation method comprises the following steps: (1) adding the alumina adhesive, 1 to 5 weight percent pore-forming agent CMC of the amorphous silicon aluminum and 1 to 3 weight percent extrusion-aid agent sesbania powder into the amorphous silicon aluminum of required weight, extruding the mixture on an extruder after mixed kneading and roller compaction, and drying and baking to obtain the carrier; and (2) loading active components Pt and Pd noble metal elements by a common dipping method and then carrying out vacuum drying to obtain the catalyst through calcination.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

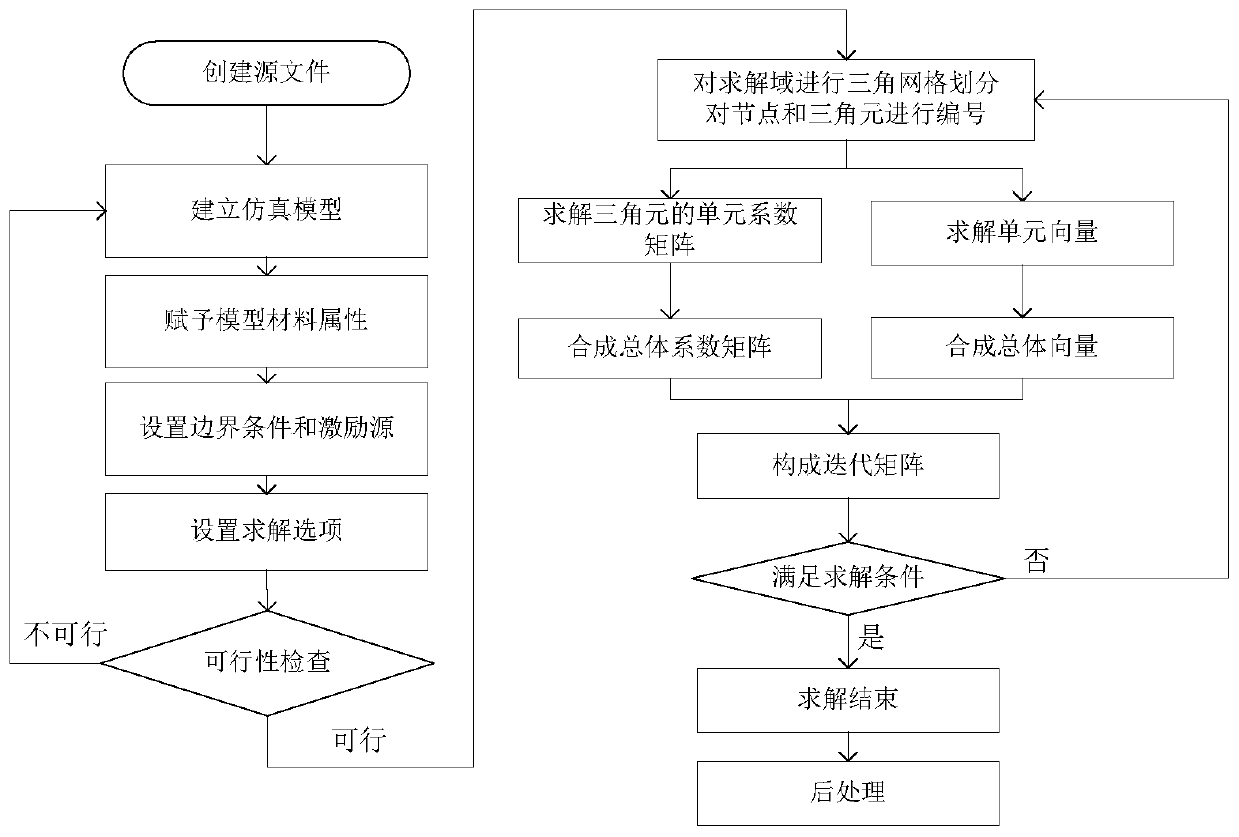

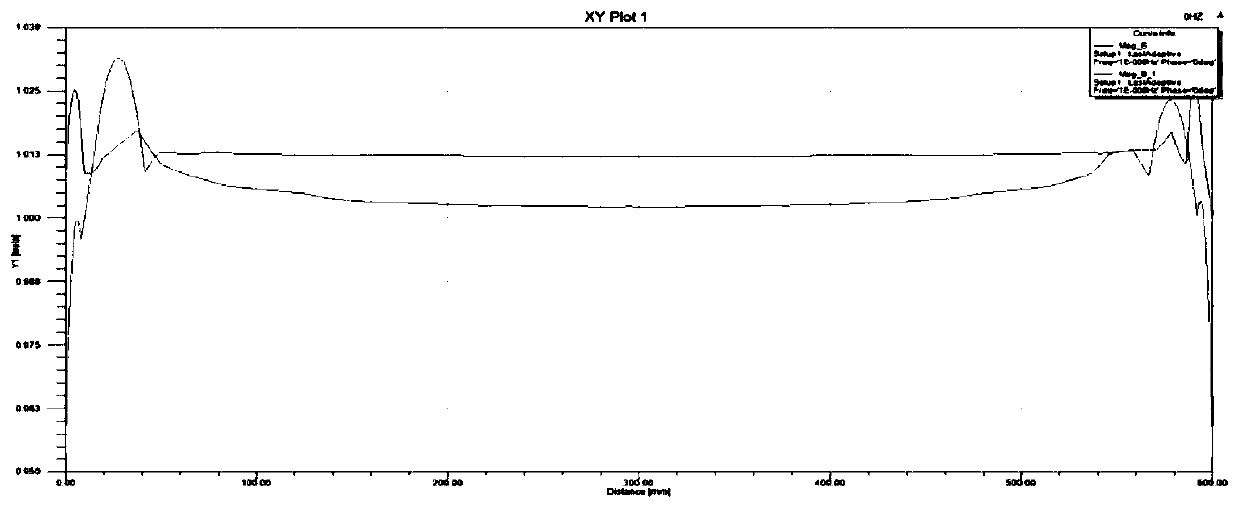

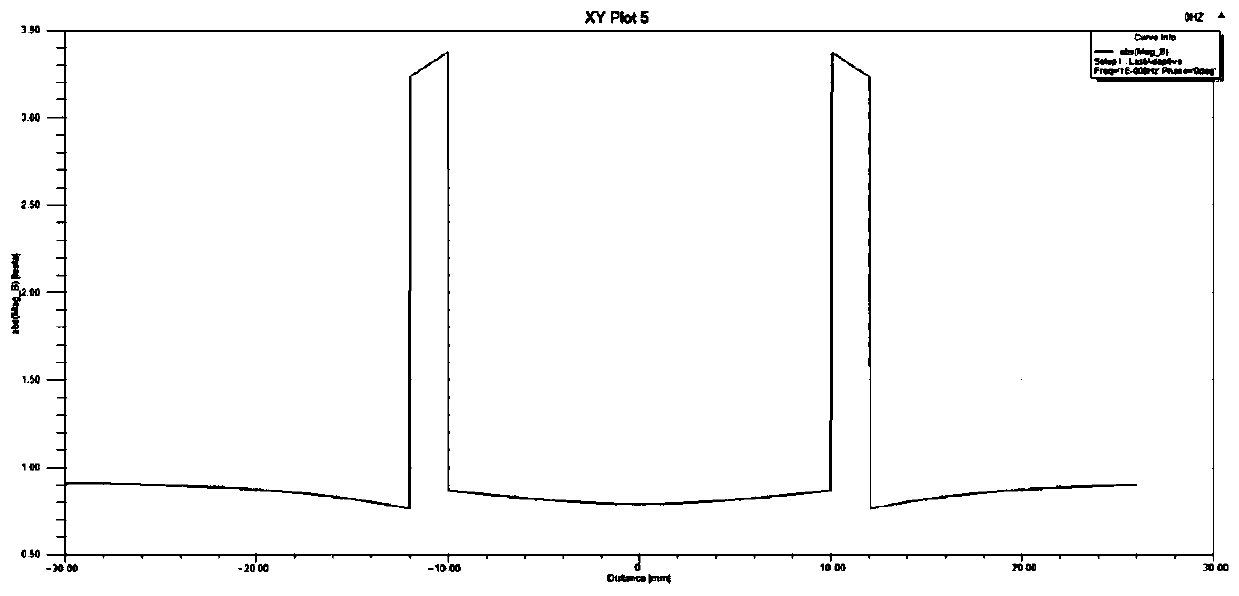

Finite element analysis method for metal cylinder electromagnetic field in close-wound solenoid

PendingCN109933911AUniform radial distributionSpecial data processing applicationsMetal cylinderAngular frequency

The invention discloses a finite element analysis method for a metal cylinder electromagnetic field in a close-wound solenoid, which comprises the following steps: S1, pretreatment: defining a geometric area of a problem, enabling plasma in a barrel to form a magnetized plasma sheath layer on the surface of an inner bore under the action of a magnetic field and generate three effects, S2, final assembly solving, and S3, post-treatment. The analysis method disclosed by the invention is more scientific and reasonable. According to the analysis method, the nonuniform radial distribution of the alternating magnetic field in the long straight solenoid can be intuitively obtained. The influence of the changed angular frequency is avoided. The magnetic field of the central part is larger than theedge part under the influence of the alternating magnetic field in the absence of the conductor, and on the contrary, when the conductor exists, the magnetic field of the central part is smaller thanthe edge part, and when the frequency is small, the influence of the two situations tends to zero, and the situation that the magnetic field is changed into a constant value along with time can be seen.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

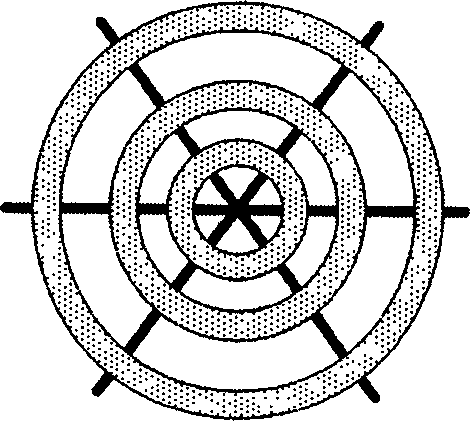

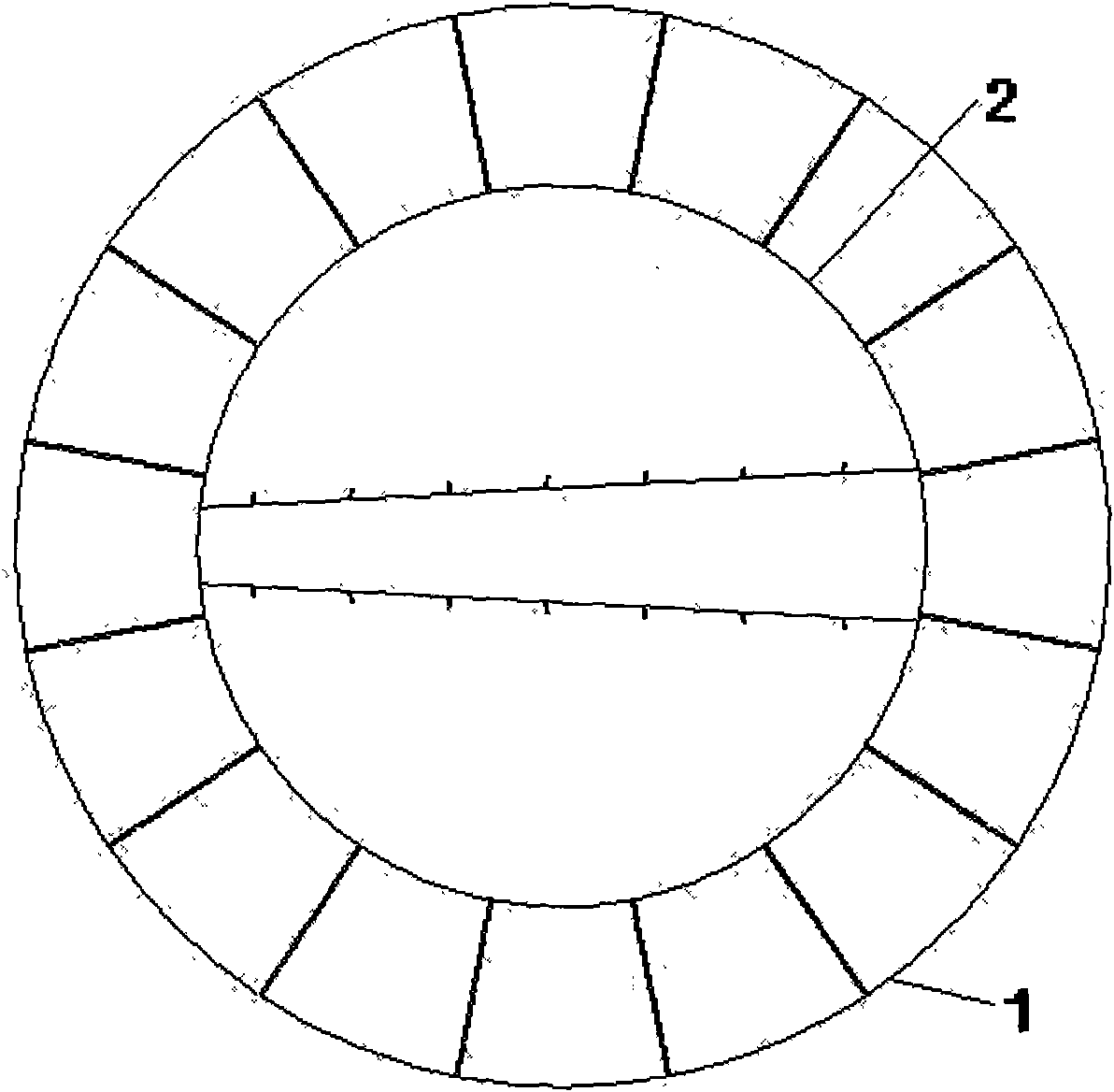

Combined type gas distributor

InactiveCN101607184ASmall pressure dropUniform radial distributionDispersed particle separationChemical/physical/physico-chemical processesDistributorVertical axis

The invention discloses a combined type gas distributor which comprises an inner cylinder, a top ring-shaped plate and a trapezoidal double-line vane diversion device, wherein the side wall of the inner cylinder is provided with a feed inlet along the radial direction, the top ring-shaped plate is welded on the top of the inner cylinder, the trapezoidal double-line vane diversion device which has the cross section changed from large to small is arranged inside the inner cylinder along the direction of the feed inlet, and the double-line vane diversion device comprises a left line and a right line of at least one layer of guide vanes that are symmetrically arranged by taking a vertical axis section of the feed inlet as symmetrical plane; the upper and the lower guide vanes of the adjacent layers are connected with each other by a left and a right connecting plates, the guide vanes arranged at the top layer and the bottom layer are respectively connected with an upper and a lower cover plate, the upper and the lower cover plates as well as the left and the right connected plates are connected with the top ring-shaped plate by bolts, a plurality of whirl plates are symmetrically connected on the outer wall of the inner cylinder by taking a central section of the inner cylinder as the symmetrical plane. By changing the flow direction of gas, the combined type gas distributor achieves the aims of reducing intensity of pressure and evenly distributing the gas.

Owner:TIANJIN UNIV

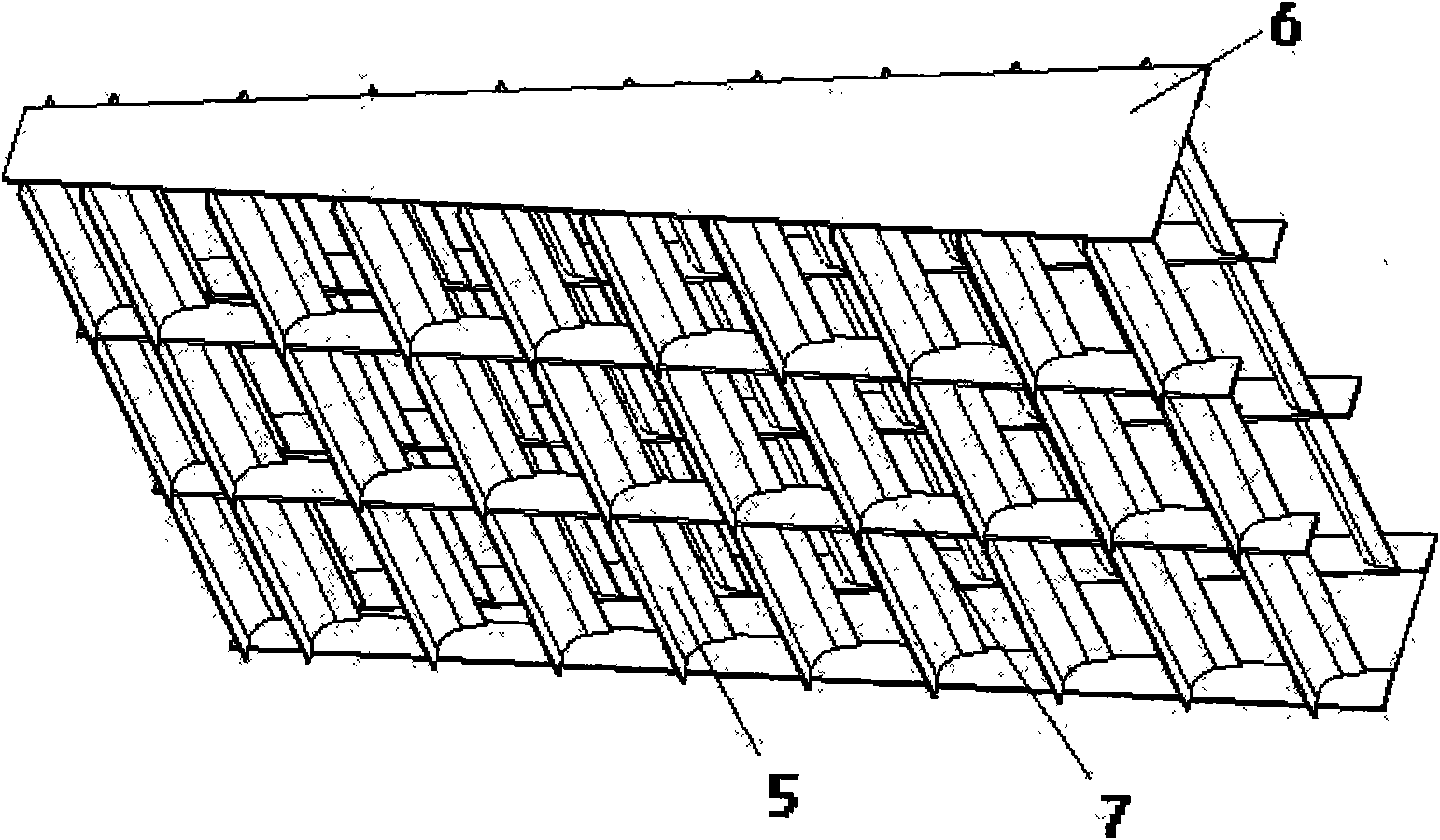

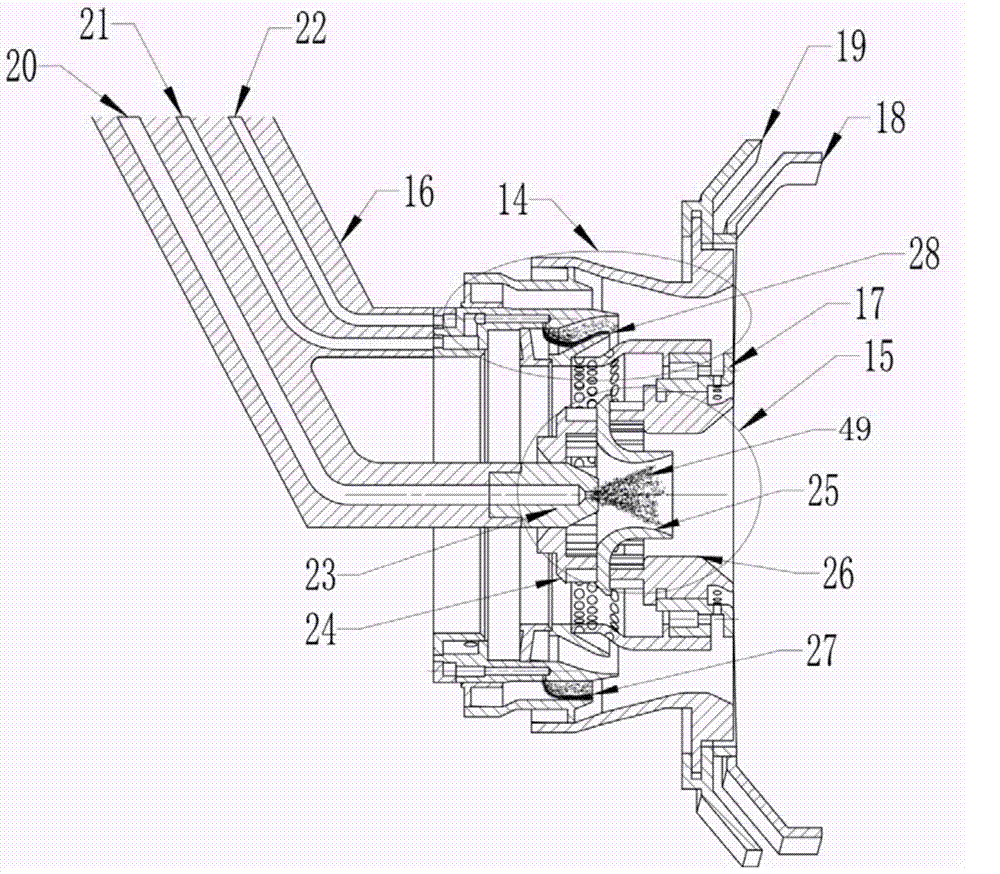

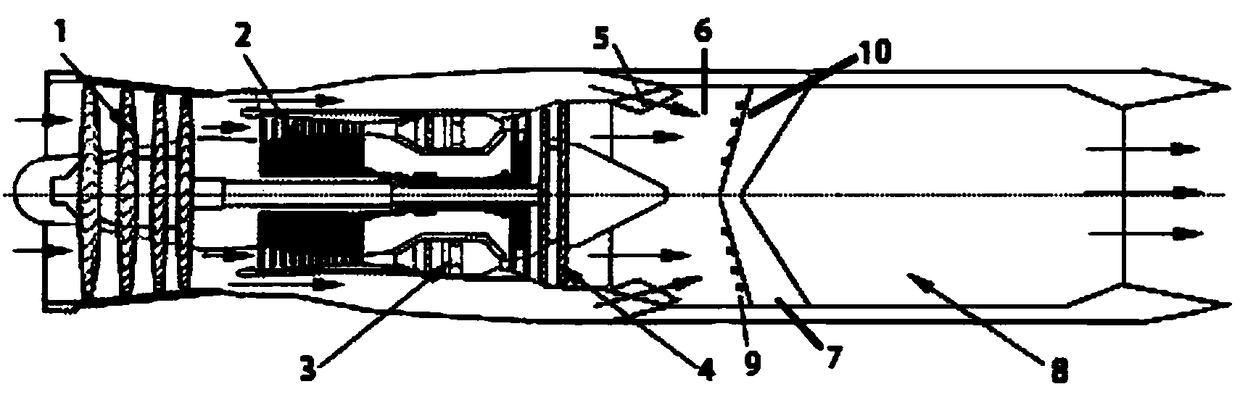

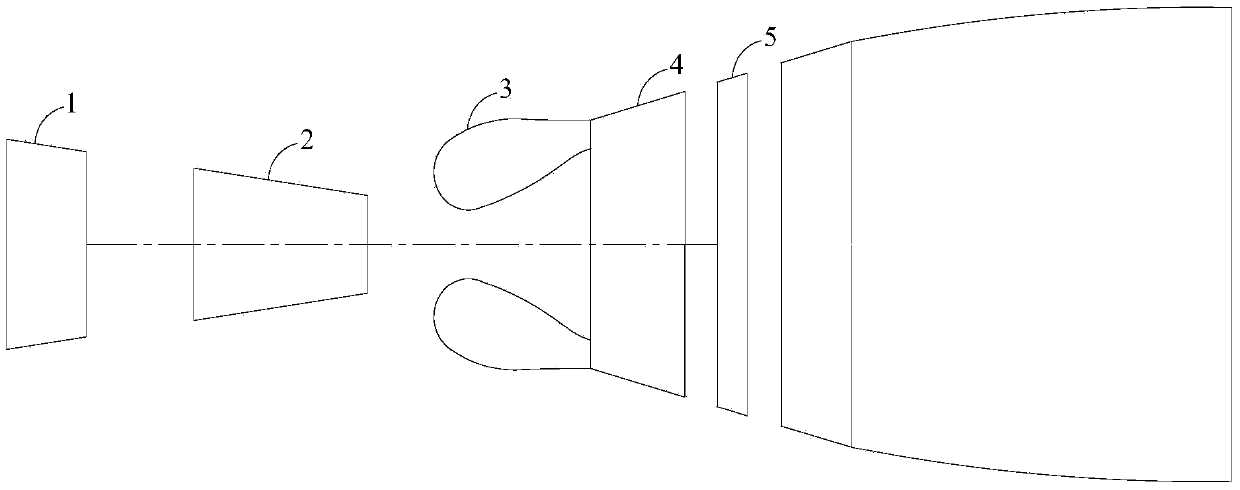

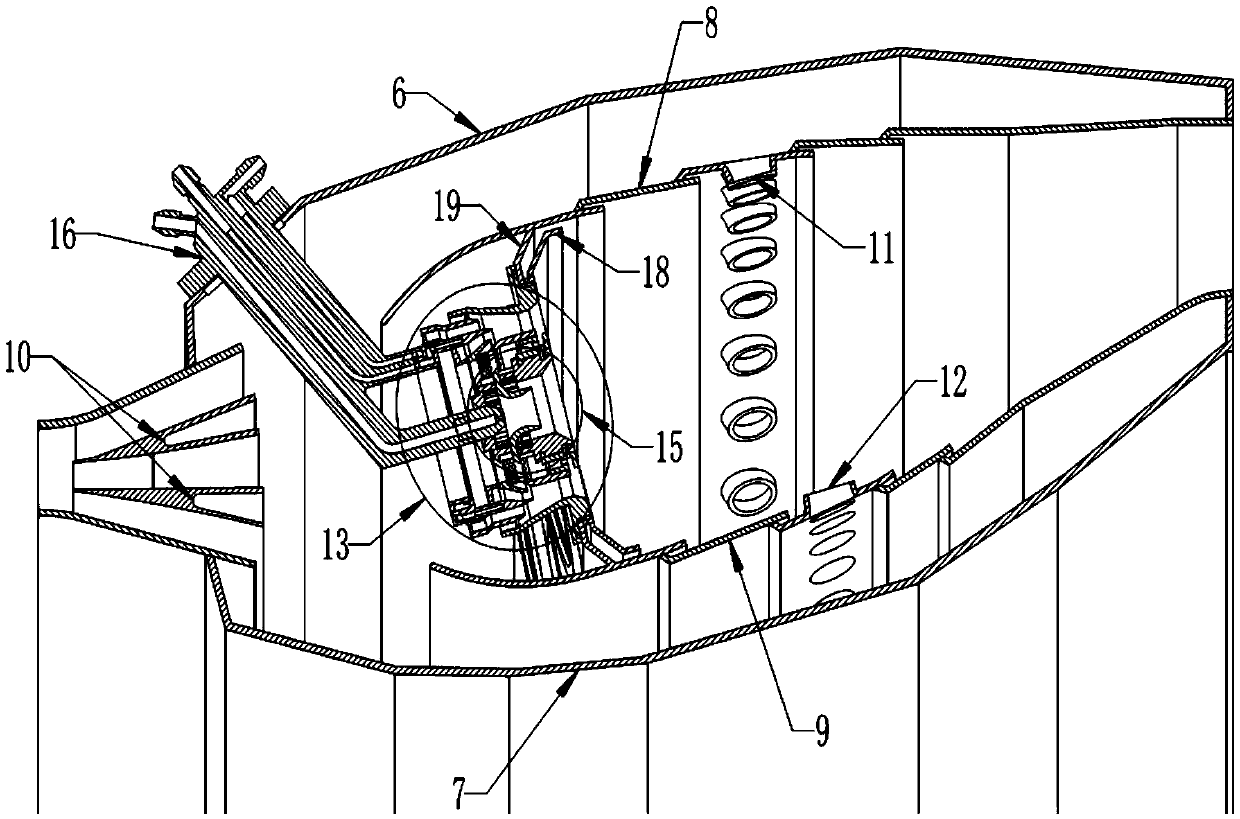

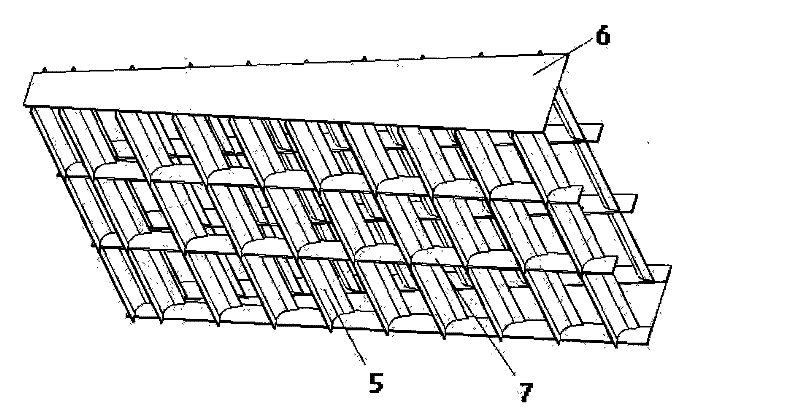

Pre-mixing and pre-evaporation low-pollution combustion chamber with double-oil-way four-rotational-flow pre-film type main combustion stage

ActiveCN103697500AEasy to adjustReduce pollutionContinuous combustion chamberCombustion chamberEvaporation

The invention relates to a pre-mixing and pre-evaporation low-pollution combustion chamber with a double-oil-way four-rotational-flow pre-film type main combustion stage. The combustion chamber is of a single-ring-cavity structure, and adopts a central staged combustion mode, wherein the head of the combustion chamber is divided into a preliminary combustion stage and a main combustion stage, the preliminary combustion stage adopts a mode of combining diffusive combustion with rotational-flow pre-mixing combustion, and is capable of reducing pollutant discharge under low-flow working conditions while ensuring combustion stability; the main combustion stage adopts a mode of pre-mixing and pre-evaporation combustion, and is capable of effectively reducing combustion pollutants. The oil way of the main combustion stage is divided into two stages, fuel oil in each stage forms an oil film on a pre-film plate, and the oil films are atomized, evaporated and blended under the action of two rotational flows to form a uniform oil-gas mixture, thus facilitating reduction for the combustion pollutants; due to the double-oil-way design, the one-stage working of the main combustion stage under low-flow and medium-flow working conditions such as entrance, and the two-stage working of the main combustion stage under high-flow working conditions such as take-off can be met, thus facilitating the oil-gas matching of the combustion chamber under different working conditions, and further reducing the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aeroengine.

Owner:BEIHANG UNIV +1

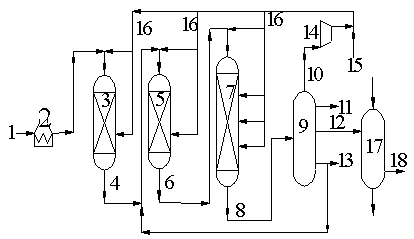

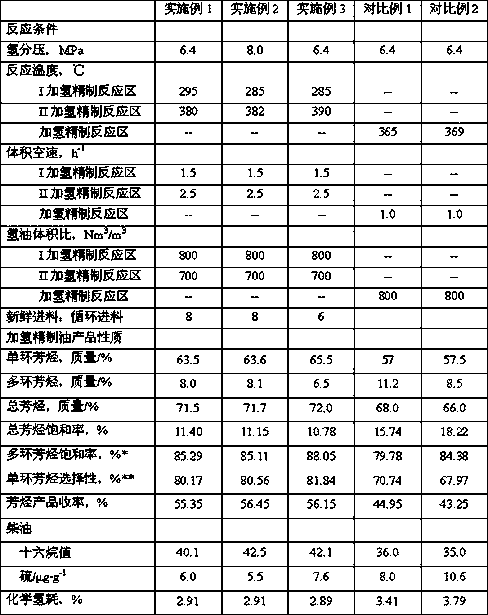

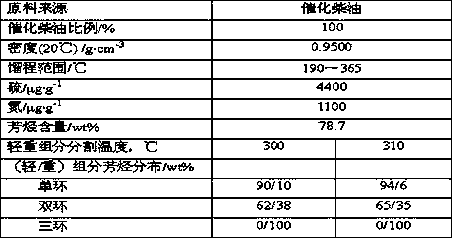

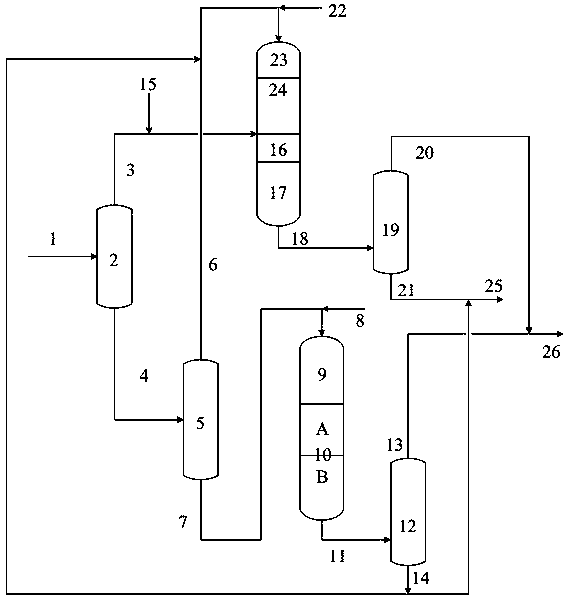

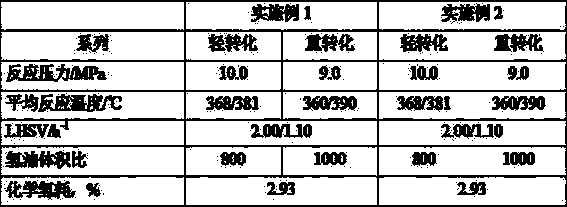

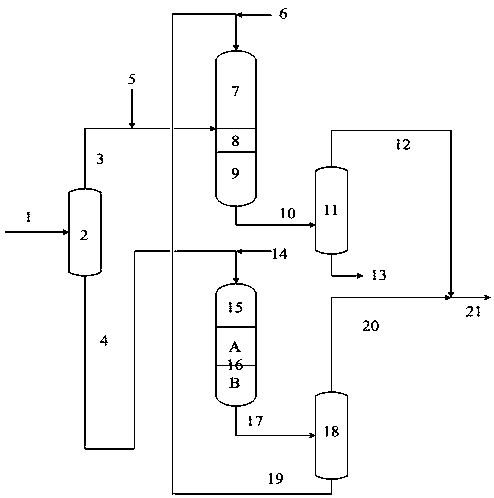

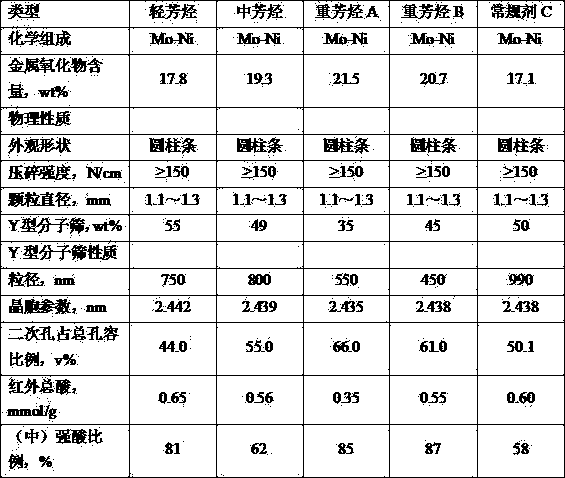

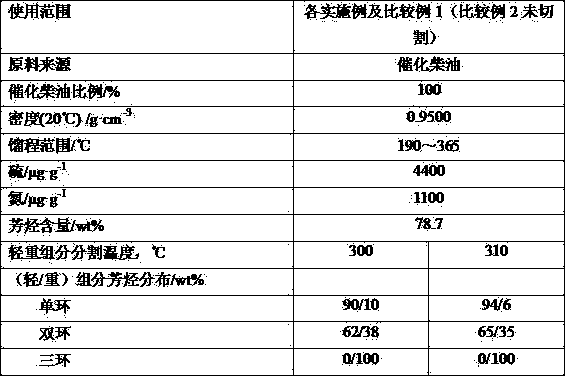

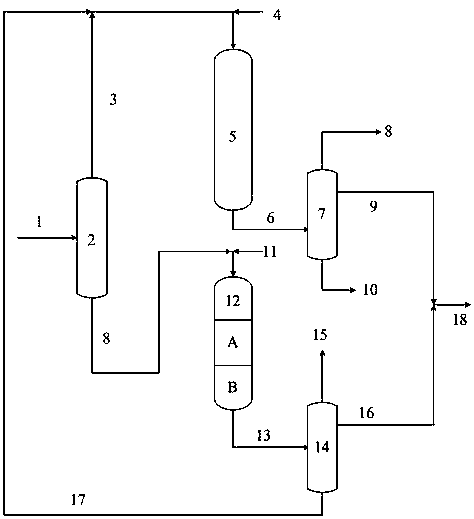

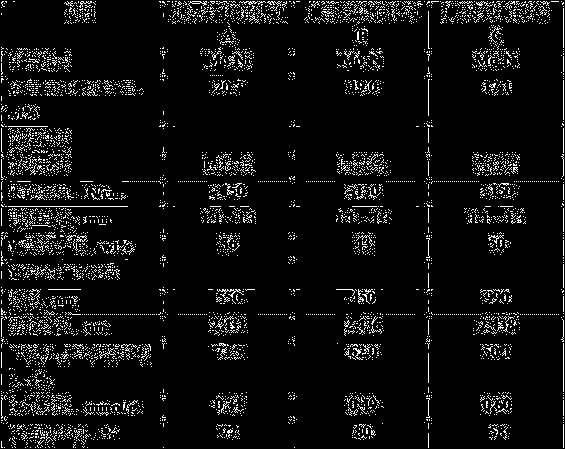

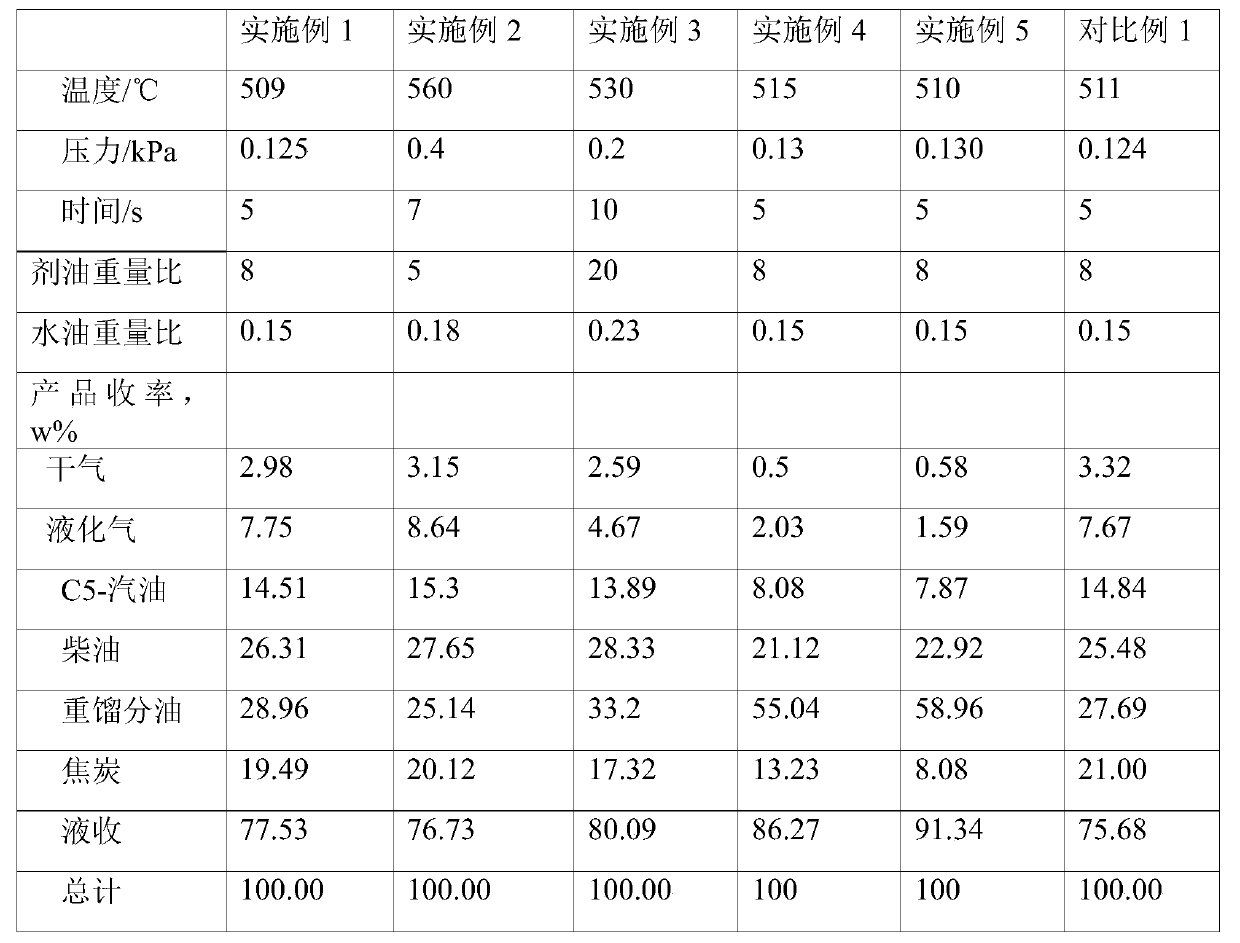

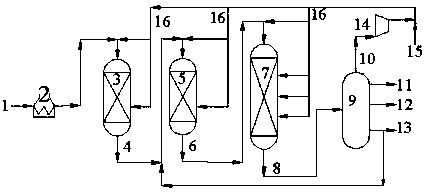

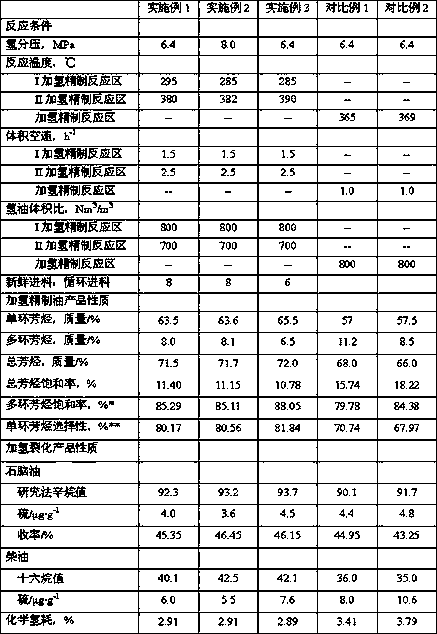

Method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion

ActiveCN109777514AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion. The method comprises the following steps: (1) mixing high aromatic hydrocarboncatalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, andfeeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen and feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to a hydrofining reaction zone II, and discharging the other part of the diesel oil from a device; and (5) feeding theheavy naphtha fraction obtained in the step (4) into an aromatic hydrocarbon extraction system to obtain an aromatic hydrocarbon product. By the coupling hydrocracking-aromatic hydrocarbon extractionprocess method for processing catalytic diesel oil raw materials, the yield of the aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

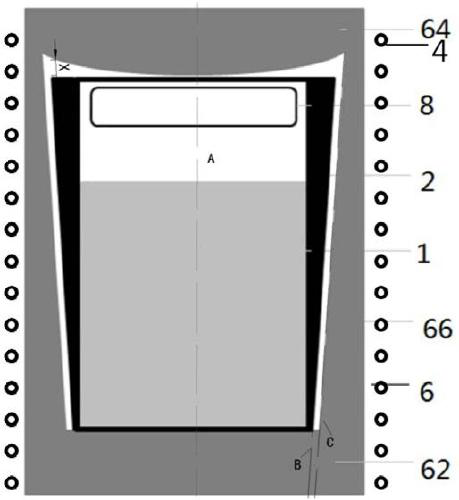

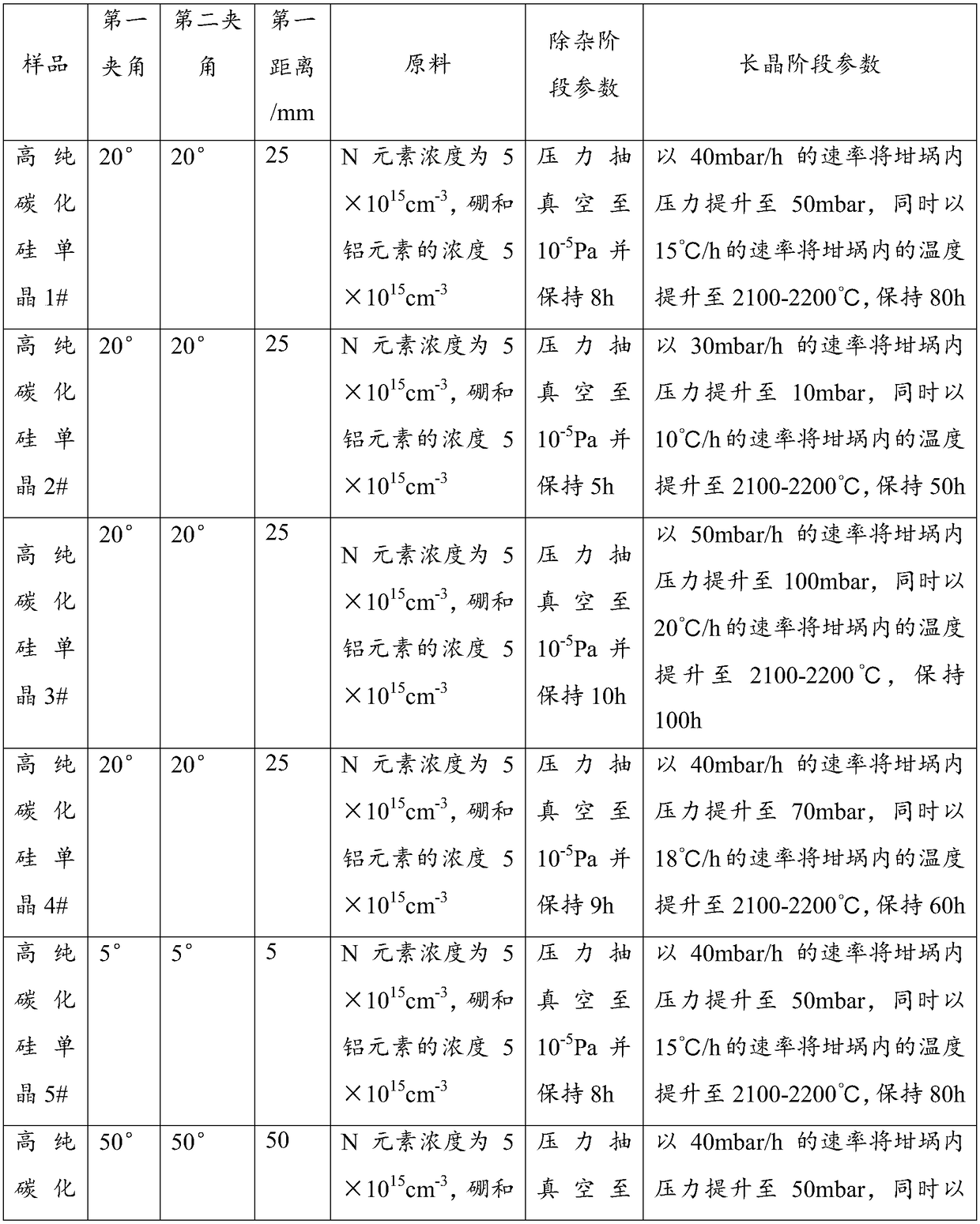

Large-sized high-purity silicon carbide single crystal, single crystal substrate and preparation methods thereof

ActiveCN109280976AUniform radial distributionUniform radial resistivityPolycrystalline material growthFrom condensed vaporsThermal insulationCrucible

The invention discloses a large-sized high-purity silicon carbide single crystal, a single crystal substrate and preparation methods thereof, and belongs to the field of silicon carbide single crystals and single crystal substrates. The preparation method of the large-sized high-purity silicon carbide single crystal comprises the following steps: after a seed crystal unit is installed at a crucible filled with a silicon carbide powder, placing the crucible in a cavity of a closed thermal-insulation structure, transferring the whole system into a crystal growth device; and then conducting impurity removal and crystal growth, so as to prepare a high-purity semi-insulating silicon carbide single crystal. A semi-insulating silicon carbide single crystal substrate is obtained by conducting cutting, grinding and polishing on the high-purity semi-insulating silicon carbide single crystal. In the preparation methods of the large-sized high-purity silicon carbide single crystal and single crystal substrate, an axial temperature gradient is created by using different thicknesses of crucibles and different thicknesses of thermal insulation structures, and a thermal insulation structure at theupper side of a crucibles is changed, so that a thermal field with uniform radial temperature distribution is created, and thus a large-sized silicon carbide single crystal and single crystal substrate of 4 to 12 cun can be obtained, and the prepared large-sized high-purity silicon carbide single crystal and single crystal substrate have uniform electric resistivity and small inner stress.

Owner:SICC CO LTD

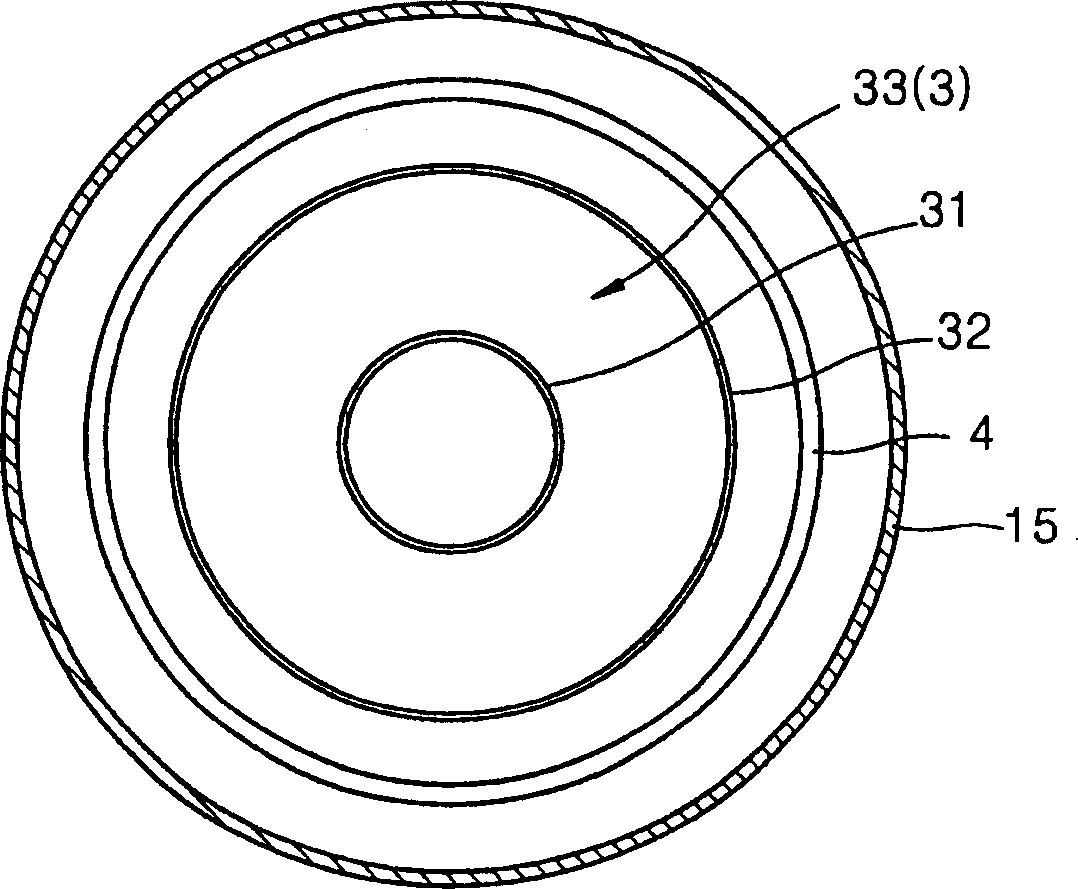

Inductive coupling type plasma device

InactiveCN1426090AUniform radial distributionEliminate sputteringElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorNuclear engineering

An inductively coupled plasma apparatus is provided, wherein the inductively coupled plasma apparatus includes a process chamber having a wafer susceptor on which a substrate is installed, a top plasma source chamber which is installed on the process chamber, a reactor, which is installed in the top plasma source chamber, having a channel through which a gas flows, wherein the reactor supplies plasma reaction products to the process chamber, an inductor, having two ends, is installed between the top plasma source chamber and the reactor and is wound around the reactor, an opening which is positioned within a circumferential space in which the inductor is installed between the reactor and the process chamber, and a shutter operable to open and close the opening. Thus, a uniform radial distribution of radicals emanating from a plasma source can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Catalyst for splitting decomposition of biomass tar and preparation method thereof

InactiveCN103551182AGood dispersionHigh activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a catalyst for splitting decomposition of biomass tar. The catalyst comprises the following components according to weight percent: 0.1-1% of RuO2, 5-15% of NiO, 1-6% of CuO, 5-20% of CeO2, and the balance of catalyst carrier. The invention also discloses a preparation method for the catalyst. The method comprises steps of adding an HZSM-5 molecular sieve into an aluminum oxide binder, adding a pore former and an assisting extrusion agent, kneading and grinding into balls, extruding into strips, drying, and roasting to obtain the catalyst carrier; then respectively loading metallic elements through a saturated impregnation method, drying, and roasting to obtain the catalyst. The catalyst has high activity in tar splitting decomposition, and has strong stability and anti-carbon accumulation performance; the catalyst carrier is of a hollow strip shape, so that the device is guaranteed to run smoothly; the catalyst is obtained by reduction of feed gas generated by biomass gasification, so that the processes are greatly simplified, and the catalyst is applicable to industrial production.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI +1

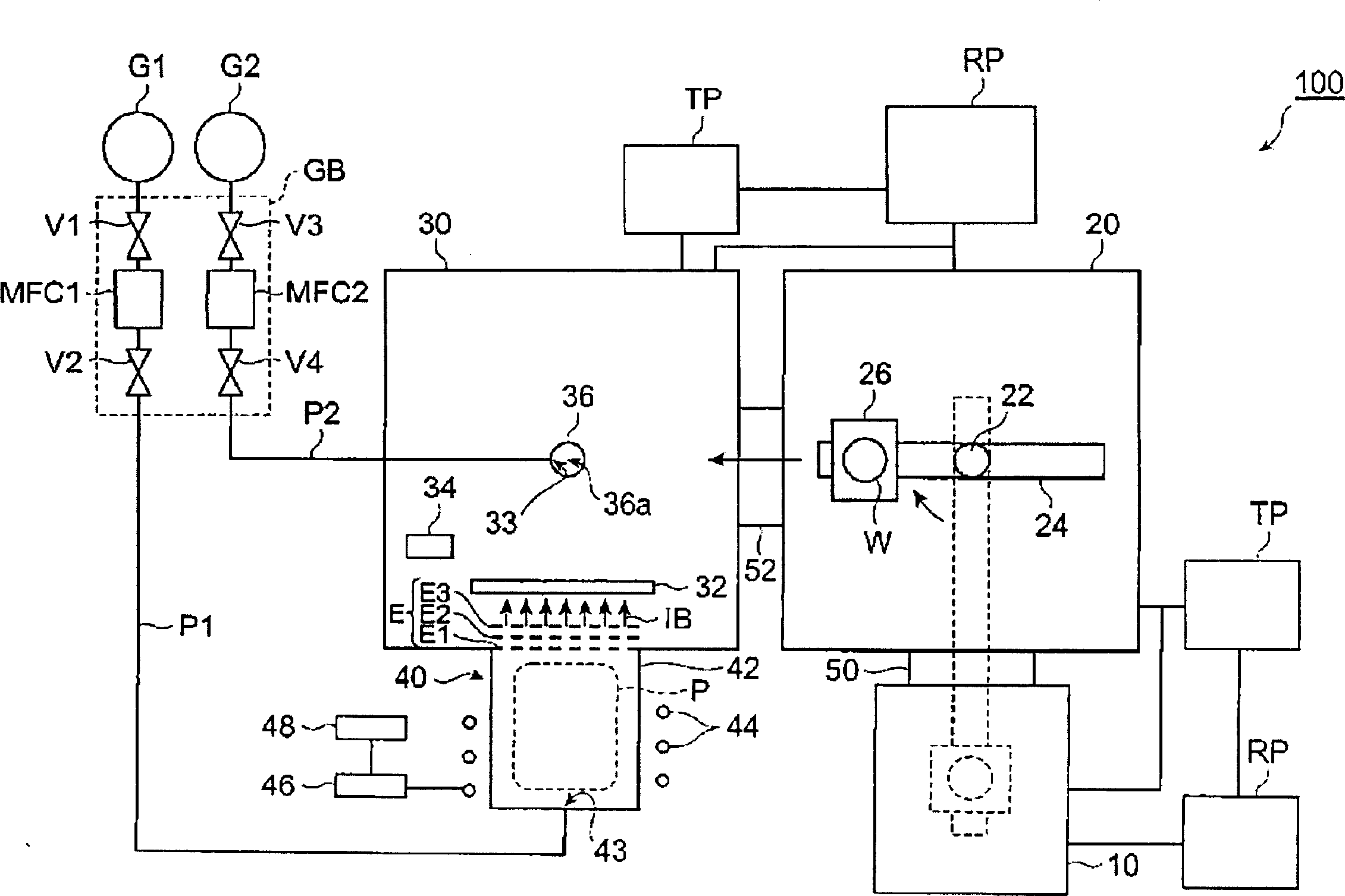

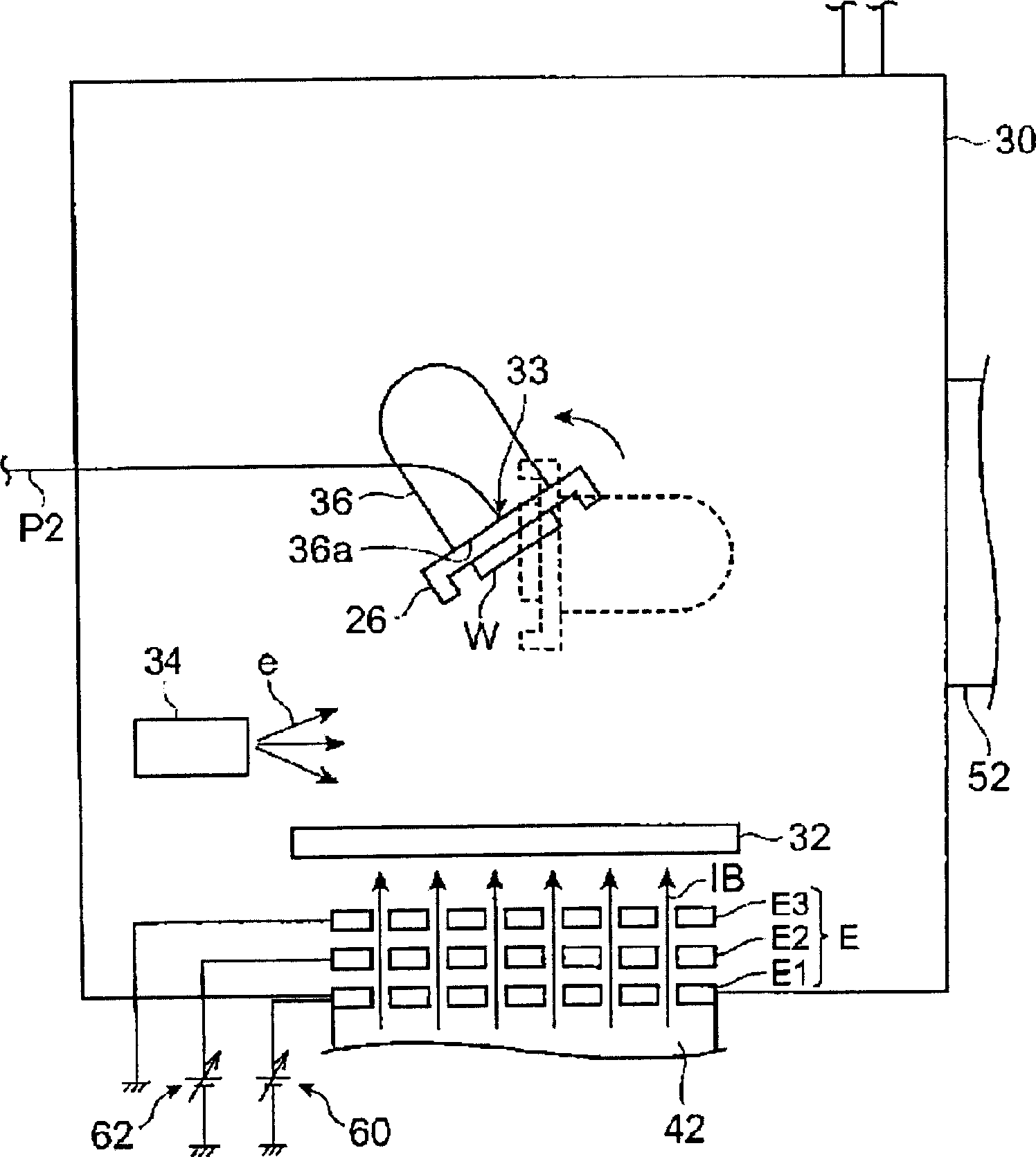

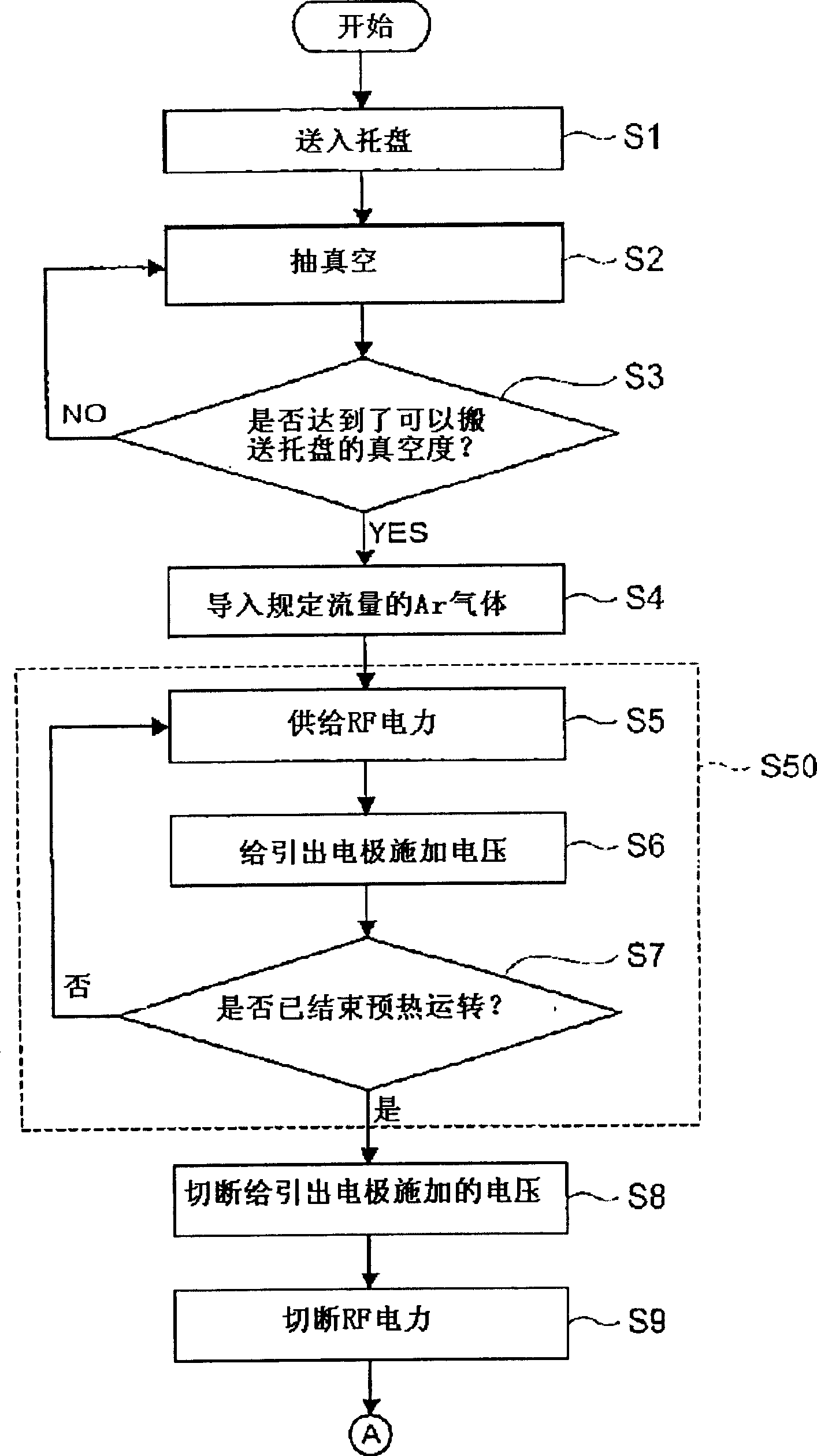

Ion beam etching method and ion beam etching apparatus

InactiveCN1896315AImprove extraction efficiencyUniform radial distributionNanoinformaticsRecord information storageAtomic physicsIon beam etching

Owner:TDK CORPARATION

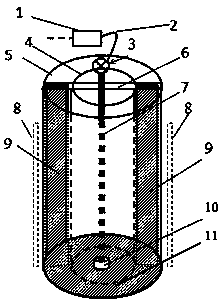

Alga cultivation device with indoor controllable cultivation condition

InactiveCN103756874ARealize temperature controlRealize light controlBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlEngineering

The invention discloses an alga cultivation device with indoor controllable cultivation conditions. A bottom plate is arranged at the bottom of an annular tank; a bearing is vertically connected with a rotating shaft; a rotating transverse arm is horizontally connected to the top of the rotating shaft; the rotating shaft is connected with an adjustable motor; the adjustable motor is connected with a speed regulator through a connection line; thrust blades are respectively vertically connected with two ends of the rotating transverse arm; the thrust blades are arranged inside a tank chamber of the annular tank; light sources are symmetrically arranged on two sides of the annular tank. The alga cultivation device has the advantages that temperature control and light control are achieved, and hydrodynamic condition experiments under different cultivation conditions are provided. In the alga cultivation process, the blades of the device rotate in a uniform speed, so that the problems that the flow speed is not stable, not uniform and the like are effectively solved.

Owner:JIANGXI NORMAL UNIV

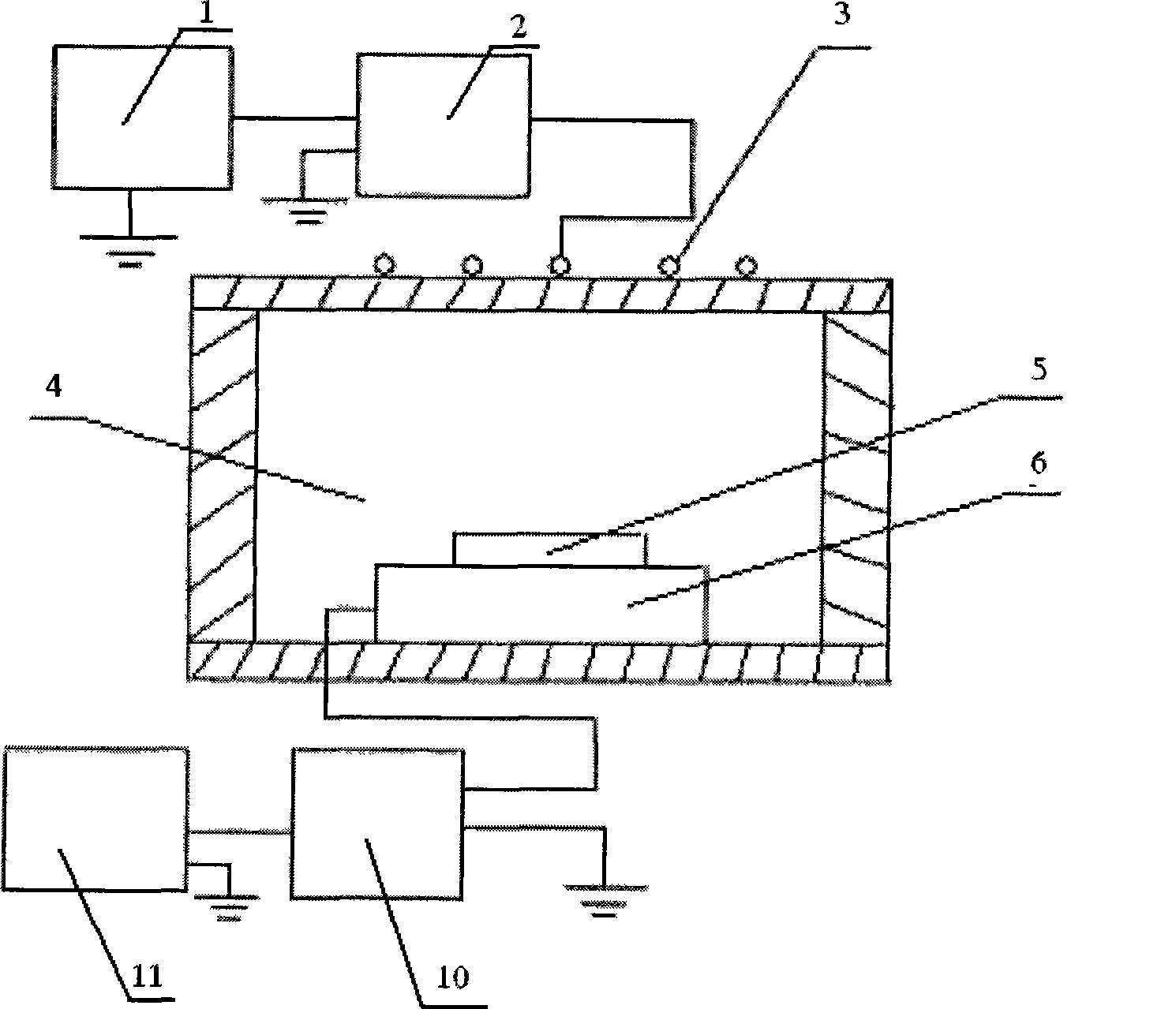

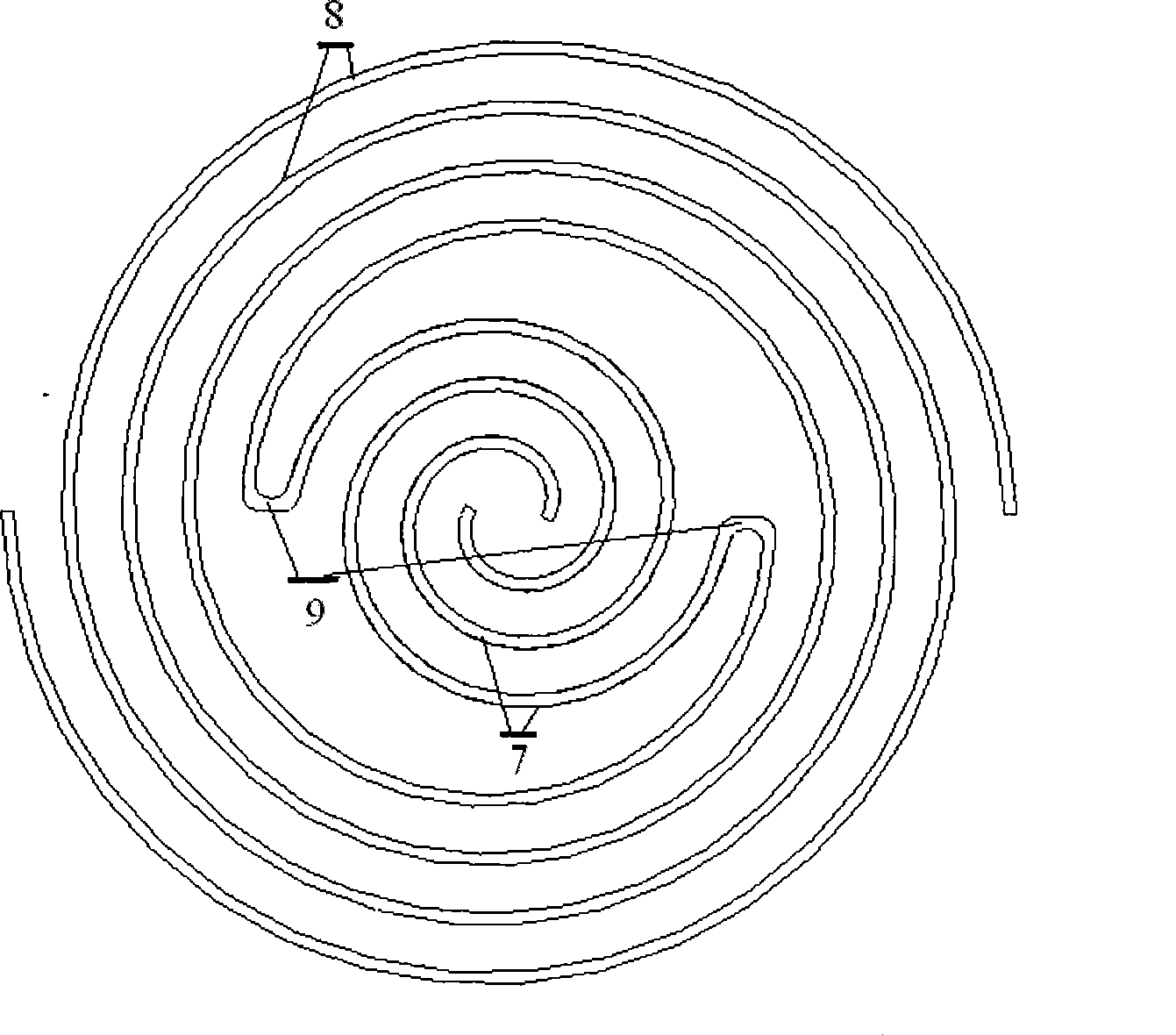

Inductance coupling coil and plasma device

ActiveCN101465189AReduce intensityUniform radial distributionTransformersSemiconductor/solid-state device manufacturingChemical reactionReaction rate

The invention relates to an inductively coupled coil used in the semiconductor machining process, and a plasma device which uses the inductively coupled coil. The key design points lie in that the inductively coupled coil at least comprises two identical branches, and each branch comprises an inner coil (7) and an outer coil (8); the coiling directions of the inner and outer coils are opposite; the tail end of the inner coil (7) is connected with the initial end of the outer coil (8) in series through a connecting segment (9); and the inner and outer coils of each branch are symmetrically nested respectively and are coplanar. When in work, the RF current flowing through the inner coil and the RF current flowing through the outer coil are opposite in direction, so that uniformly distributed electromagnetic fields are generated in a reaction chamber so as to obtain uniformly distributed plasmas; according to the wafer size, a large area of plasmas can be easily obtained through the increase of coil length and number to improve the uniformity of plasmas in the large-area process, so as to achieve less chemical reaction rate differences on the wafer surface and improve the quality of wafer products.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

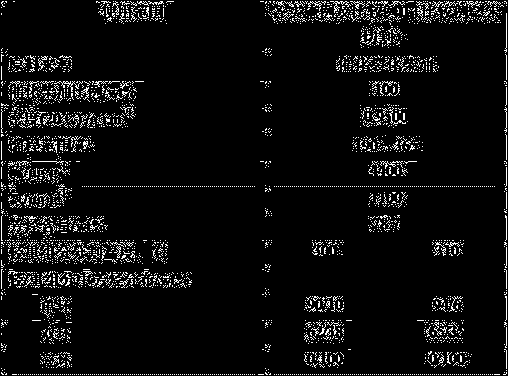

Processing treatment method of catalytic diesel

ActiveCN108102709AEasy to handleImprove targetingHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjectedto hydrofining and hydro-conversion reactions, and gasoline and diesel components are obtained; the heavy components are separated, and a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained; the non-triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, the triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, and gasoline components and diesel components are obtained; a gasoline product is obtained after gasoline from all parts is mixed, and a diesel product is obtained after diesel components from all parts are mixed. Through the reasonable separation and processing process, different types of raw materials can be selectively and independently processed, so that qualified gasoline and dieselproducts can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

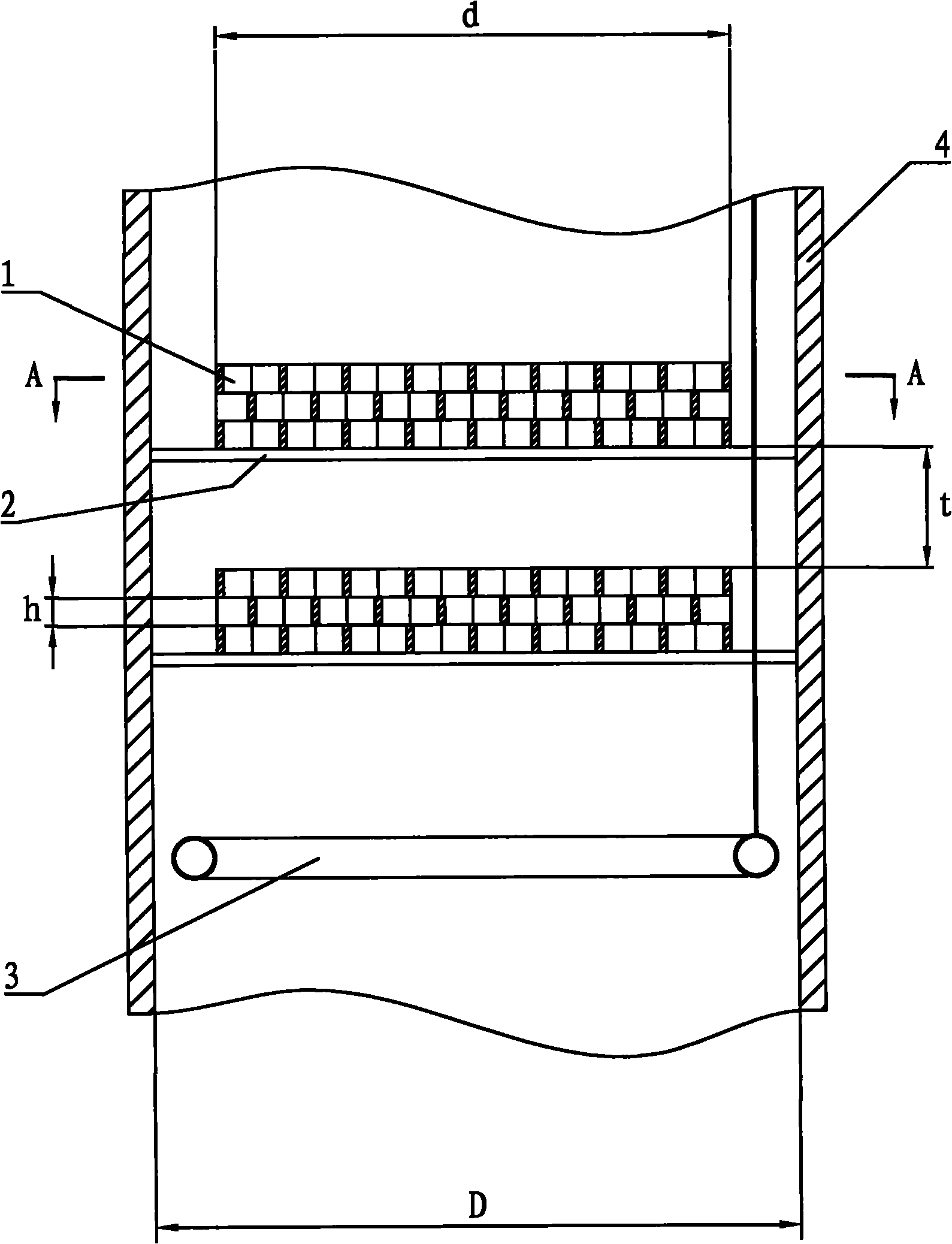

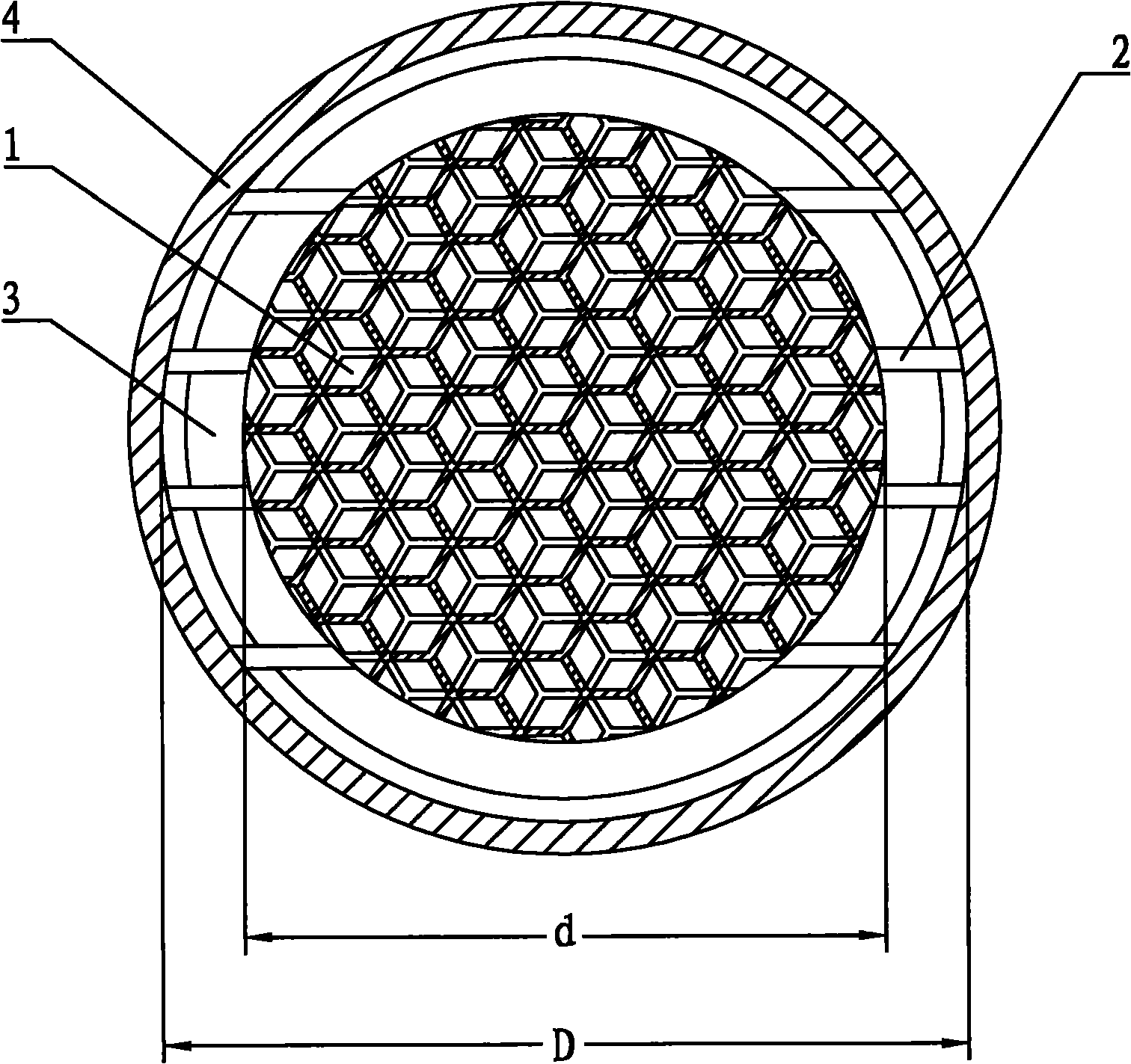

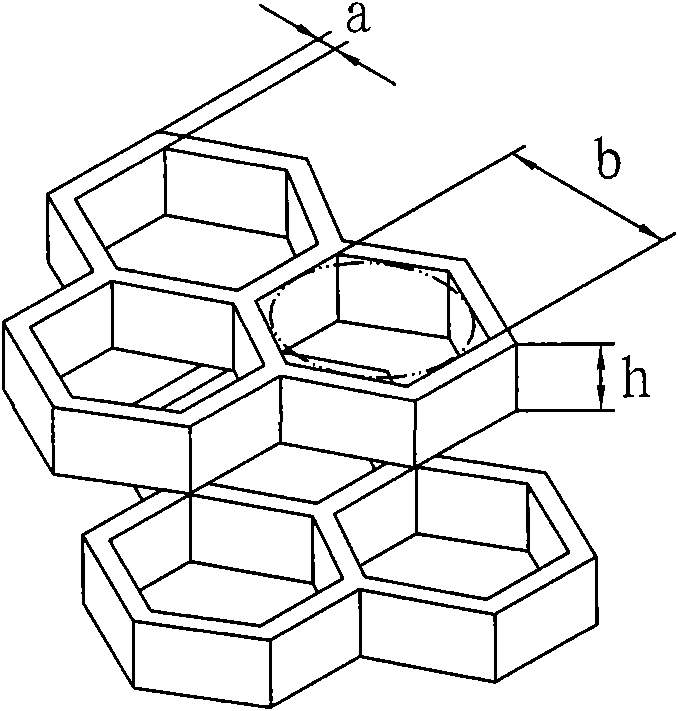

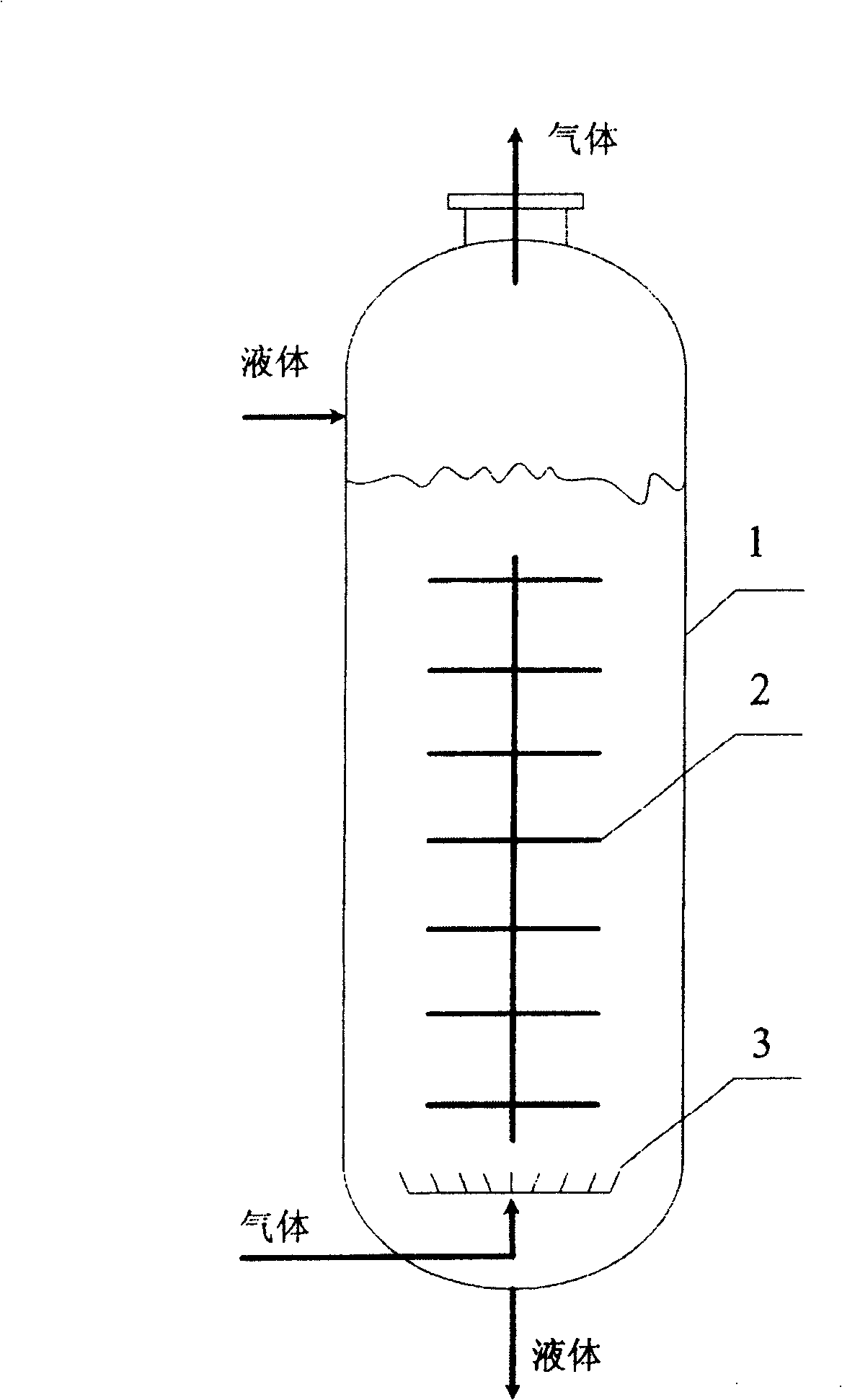

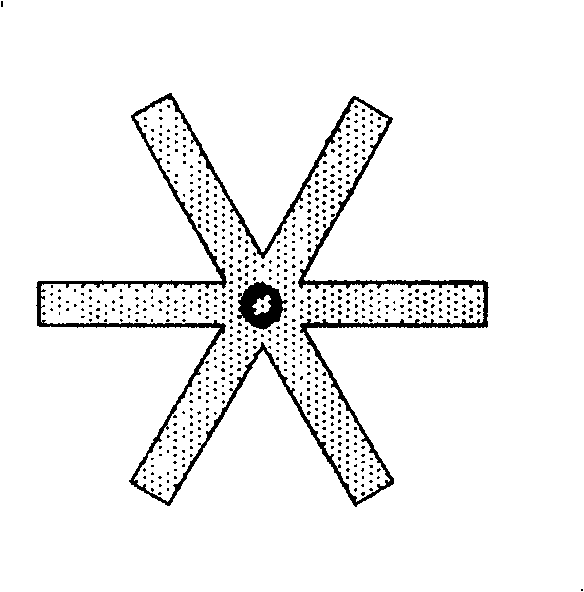

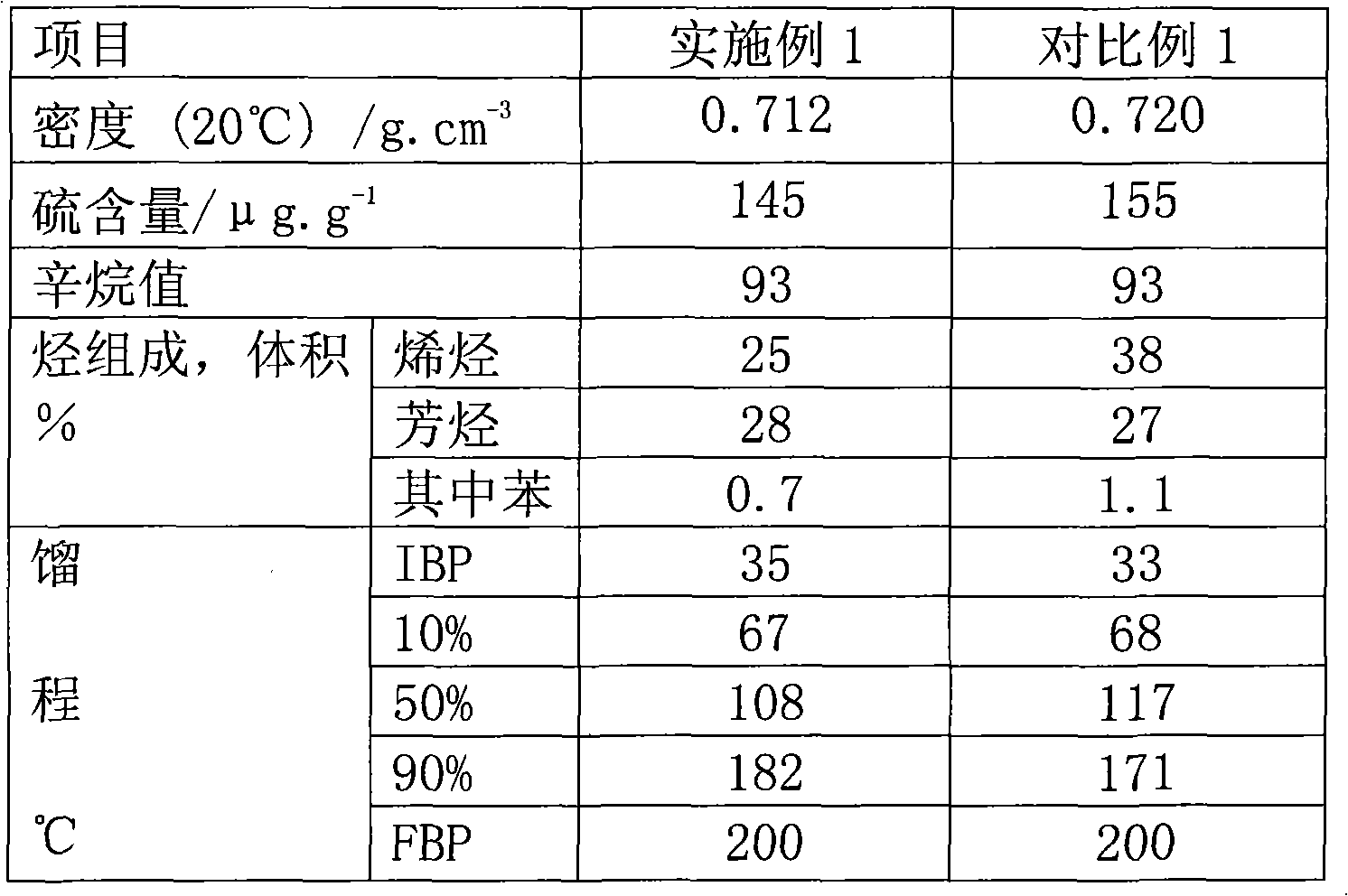

Gas-solid contact equipment for fluidized bed

ActiveCN101879432AImprove efficiencySimple structureCatalyst regeneration/reactivationChemical/physical/physico-chemical processesGas solidFluidized bed

The invention discloses gas-solid contact equipment for a fluidized bed, which is used for catalytic conversion devices in petroleum refining, petrochemical industry and other industries so as to solve the problems of non-flowing region, local slugging of gas or local solid bridging and the like which are easy to generate respectively when the conventional contact equipment is provided with a corresponding tray-type inner component or a filler, and the problems that the inner component or filler is difficult to install, overhaul and maintain. The contact equipment is at least provided with two groups of fillers (1) along the axial direction of a cylinder body (4), and a space is reserved between the two groups of fillers; each group of filler consists of a plurality of filler layers which are overlapped along the vertical direction, each filler layer is provided with a vertical hexagonal channel formed by strip plates, and the cross section shape of the hexagonal channel is a regular hexagon shape; and in each group of filler, the hexagonal channels on two adjacent filler layers are alternately arranged. The equipment can be used as a stripper to strip oil gas, hydrocarbon or gas impurities carried in the catalyst, and also can be used as a regenerator to regenerate the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

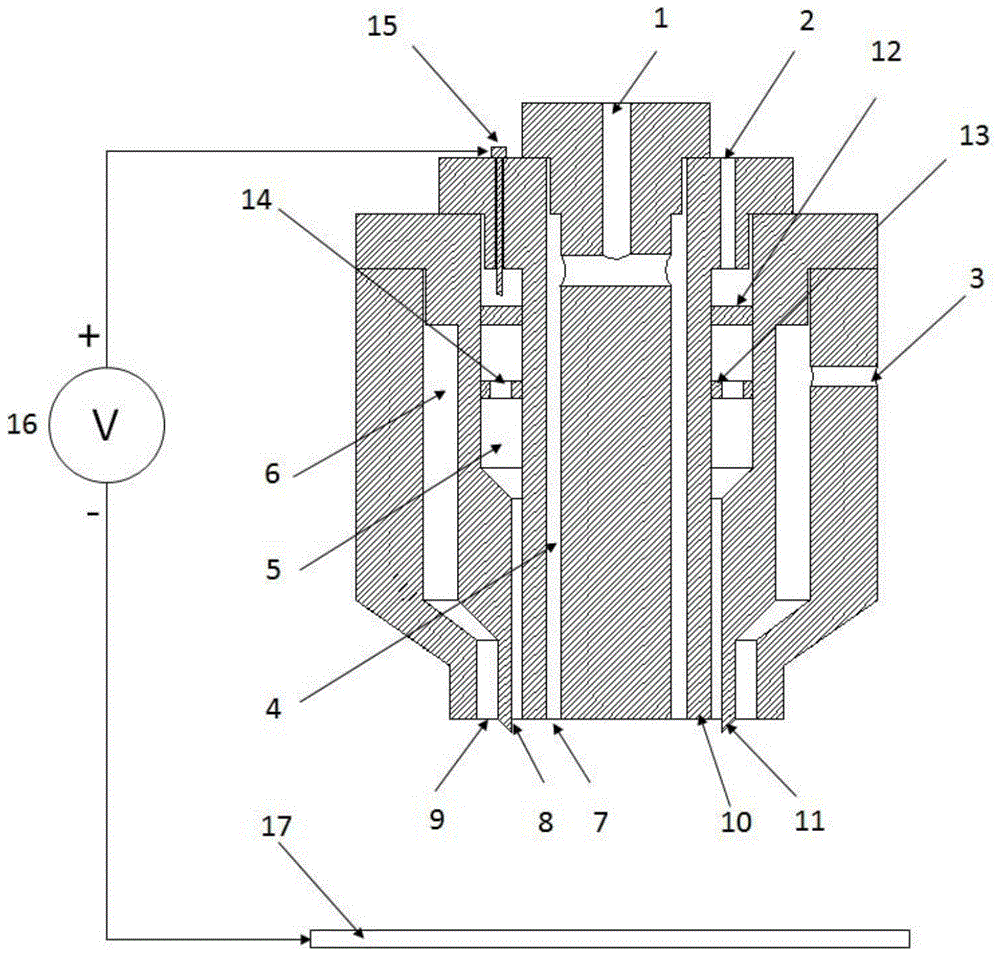

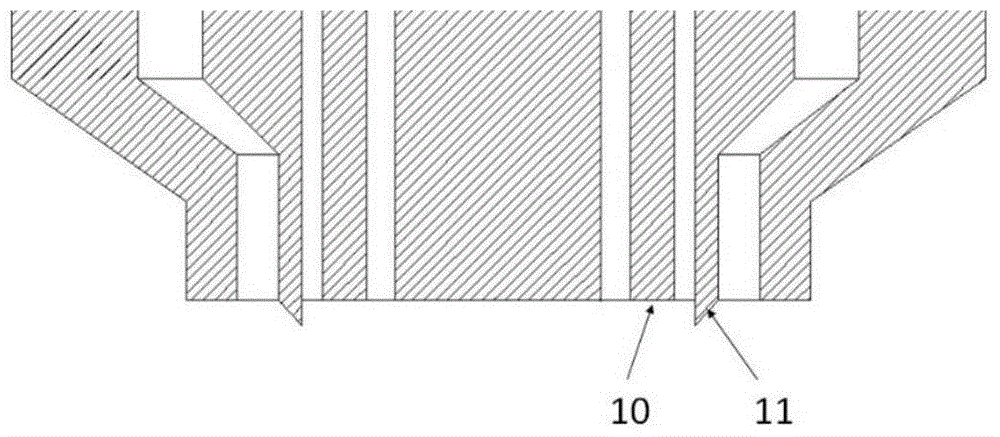

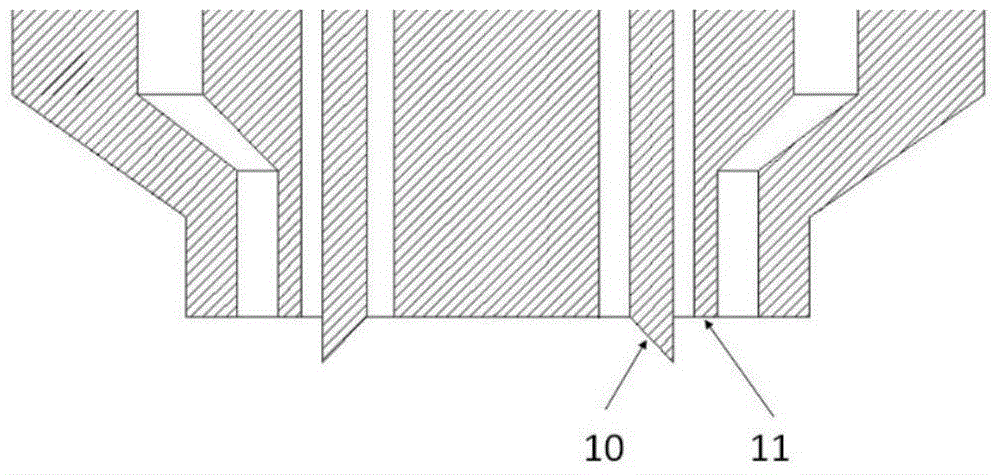

Internal and external circular air assisted electrospinning nozzle unit

ActiveCN104928768AEvenly distributedPrevent volatilizationFilament/thread formingElectrospinningNanofiber

The invention belongs to the field of electrospinning and relates to an internal and external circular air assisted electrospinning nozzle unit, comprising a nozzle body and a positive electrode. The nozzle body is composed of a first component, a second component, a third component and a fourth component nested to one another and detachably arranged from inside to outside. The four components of the nozzle body form an internal circular air passage, an external circular air passage, a middle circular liquid passage and an internal circular air inlet; an external circular air outlet and an external circular liquid outlet are concentrically circular; a guide plate is disposed within the middle circular liquid passage. The positive electrode extends into the middle circular liquid passage and contacts liquid. The nozzle unit is assisted by both internal and external air flows, is simple in structure, high in controllability and good in airtightness, helps avoid volatilizing of solvents in the liquid during spinning, has the yield up to ten times as high as the needle type, roller type or spiral type electrospinning unit, and is suitable for continuous industrial production of nanofibers.

Owner:烟台森森环保科技有限公司 +1

Nano-scale low carbon alkane aromatization catalyst

InactiveCN101108364AHigh activityActive components, so that the catalyst has a higher catalytic activityMolecular sieve catalystsHydrocarbonsAlkaneMolecular sieve

The invention relates to a Nami grade low carbon alkane aromatization catalyst, each component is counted by the occupying weight per centage in molecular sieve, make Nami HZSM-5 molecular sieve as carrier, the load occupies 0.3 to 10 per cent of Zn in Nami HZSM-5 molecular sieve, and one or tow of Te, Tm, Eu, Er which occupies 0.1 to 5 per cent of Nami HZSM-5 molecular sieve. The catalyst has the advantages of high catalyzing activity and selectivity and long service life.

Owner:DAQING PETROLEUM ADMINISTRATION

Afterburner adopting planar fan nozzles for oil supply

ActiveCN108844094AStable and reliable combustionAchieve atomizationContinuous combustion chamberSpray nozzlePerpendicular direction

The invention discloses an afterburner adopting planar fan nozzles for oil supply, and belongs to the field of aero-engines. The afterburner adopting the planar fan nozzles for oil supply is characterized in that supporting plates are arranged on an oil supply device in the afterburner, and are uniformly arranged along the circumference of the afterburner in the perpendicular direction; and oil spraying rods are arranged on the inner sides of the supporting plates in the radial direction, the planar fan nozzles are arranged on the side walls of the oil spraying rods in the radial direction, and the opening cross section of each planar fan fuel nozzle is V-shaped. According to the design of the afterburner adopting the planar fan nozzles for oil supply, the fuel spray extending angle is enlarged, the number of the nozzles is reduced, the diameter of each nozzle is increased, and meanwhile, the fuel radial and circumferential concentration distribution is more uniform, so that reliable and stable combustion of the afterburner is facilitated, and the problems in the prior art are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

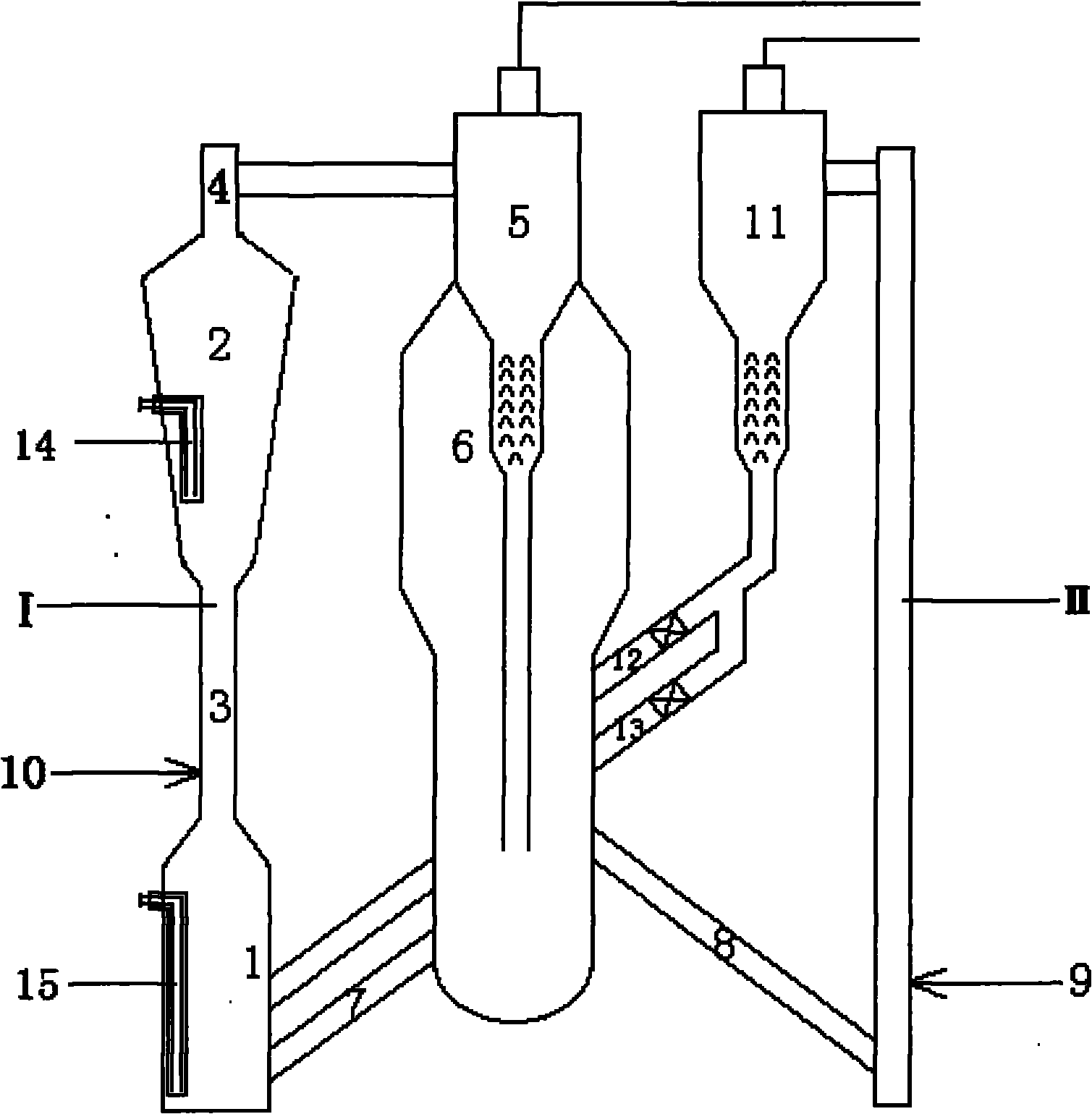

Processing method of catalytic diesel

ActiveCN108102702AHigh Yield High OctaneReduced activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsContact reactionGasoline

The invention discloses a processing method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjected to a conversion reaction in a bed layer containing a light aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and converted diesel are obtained; the heavy components are subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and diesel fractions are obtained; the diesel fractions obtained through conversion of heavy componentsare subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, a reaction effluent is then subjected to a contact reaction with a light component hydro-conversion catalyst; the converted gasoline obtained from each part is mixed, and high-quality gasoline is obtained. Through the reasonable separation and processing process, different types of raw materials can beselectively and independently processed, so that the qualified gasoline product with high octane value can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of catalytic diesel oil

ActiveCN108102713AGreat suitability and pertinenceImprove product qualityTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryGasoline

The invention discloses a processing method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected to hydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is subjected to hydrofining and hydroconversion, and a gasoline component and a dieseloil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that qualified gasoline and diesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil .

Owner:CHINA PETROLEUM & CHEM CORP +1

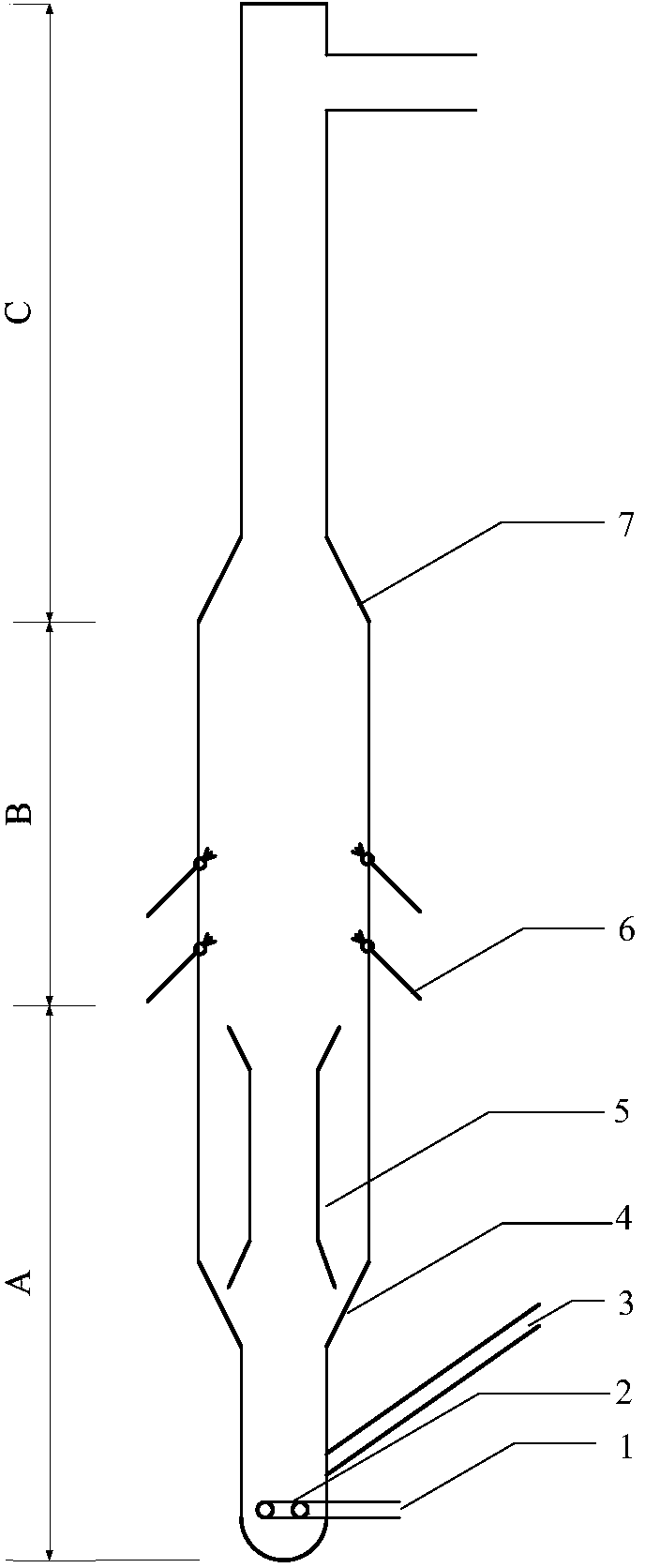

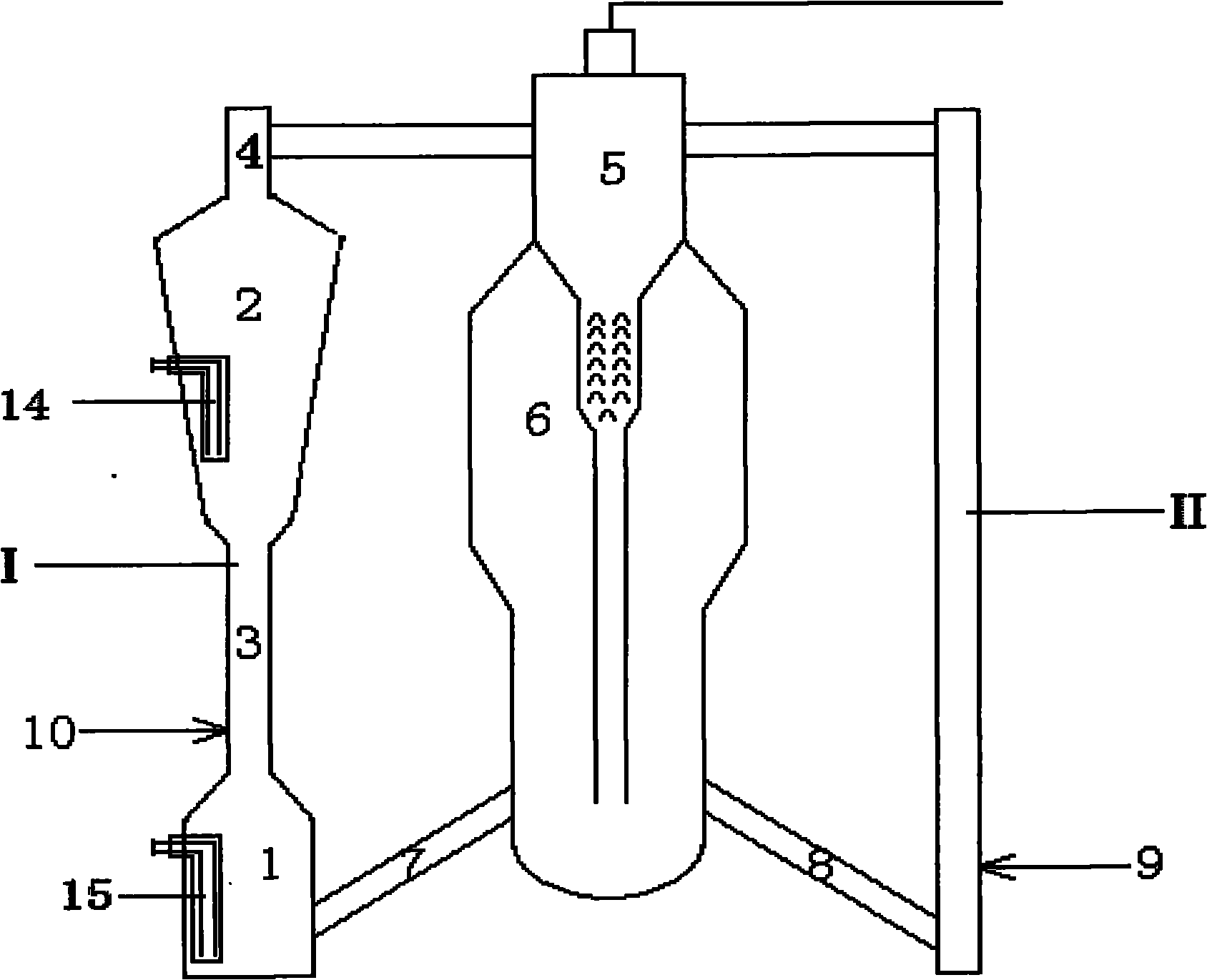

Heavy oil contact cracking method

ActiveCN105505438AImprove contact effectUniform radial distributionThermal non-catalytic crackingFuel oilCracking reaction

A heavy oil contact cracking method is performed in a cracking reactor. The cracking reactor comprises a pre-lifting section, an oil agent contact reaction area, and an outlet area from bottom to top. The diameter of the outlet area is smaller than the diameter of the oil agent contact reaction area. A sleeve pipe is arranged in the pre-lifting section, the diameter of the center of the sleeve pipe is the smallest, and the diameter of the sleeve pipe increases from the center to two ends. The method comprises the following steps: adding a contact agent into the pre-lifting section, making the contact agent enter the oil agent contact reaction area through the pre-lifting section, making heavy oil and the contact agent carry out contact cracking reactions in the oil agent contact reaction area; and discharging the products obtained in contact reactions out of the cracking reactor from the outlet area. The provided method can carry out a cracking treatment on heavy oil, and has the advantages that the coking on the wall of the reactor is reduced, the generation of coke is reduced, and the yield of light oil products is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

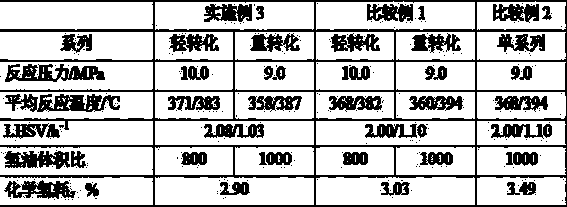

Catalytic diesel oil hydro-conversion method

ActiveCN109777511AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a catalytic diesel oil hydro-conversion method. The catalytic diesel oil hydro-conversion method comprises the following steps: (1) mixing high aromatic hydrocarbon catalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, and feeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen, feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to the hydrofining reaction zone II, and discharging the other part of the diesel oil from the device. By the catalytic diesel oil hydro-conversion method, the yield of aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

A pre-mixed pre-evaporation low-pollution combustor with dual oil channels and four swirl flow pre-film main combustion stages

ActiveCN103697500BReduce pollutionCircumferential uniformContinuous combustion chamberCombustion chamberEvaporation

The invention relates to a pre-mixing and pre-evaporation low-pollution combustion chamber with a double-oil-way four-rotational-flow pre-film type main combustion stage. The combustion chamber is of a single-ring-cavity structure, and adopts a central staged combustion mode, wherein the head of the combustion chamber is divided into a preliminary combustion stage and a main combustion stage, the preliminary combustion stage adopts a mode of combining diffusive combustion with rotational-flow pre-mixing combustion, and is capable of reducing pollutant discharge under low-flow working conditions while ensuring combustion stability; the main combustion stage adopts a mode of pre-mixing and pre-evaporation combustion, and is capable of effectively reducing combustion pollutants. The oil way of the main combustion stage is divided into two stages, fuel oil in each stage forms an oil film on a pre-film plate, and the oil films are atomized, evaporated and blended under the action of two rotational flows to form a uniform oil-gas mixture, thus facilitating reduction for the combustion pollutants; due to the double-oil-way design, the one-stage working of the main combustion stage under low-flow and medium-flow working conditions such as entrance, and the two-stage working of the main combustion stage under high-flow working conditions such as take-off can be met, thus facilitating the oil-gas matching of the combustion chamber under different working conditions, and further reducing the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aeroengine.

Owner:BEIHANG UNIV +1

Noble metal catalyst used in hydrocracking and isomerization of Fischer-Tropsch synthetic wax and preparation method thereof

ActiveCN101698148BHigh activityGuaranteed thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentIsomerizationPore distribution

The invention provides a noble metal catalyst used in hydrocracking and isomerization of Fischer-Tropsch synthetic wax and a preparation method thereof. The a catalyst carrier comprises the following components: 70 to 85 weight percent of amorphous silicon aluminum and 15 to 30 weight percent of alumina adhesive, wherein active components are selected from noble metal Pt and Pd elements (in a molar ratio of 0.1 to 0.6) and the noble metal active components account for 0.1 to 1 weight percent of the carrier; the specific surface area of the catalyst is 150 to 400m2 / g, while the pore volume is 0.3 to 1.4ml / g and the NH3-TPD total acidity is between 0.5 and 1.5mmol / g; and 4 to 15nm pore distribution accounts for 60 to 90 percent of total pore volume respectively. The preparation method comprises the following steps: (1) adding the alumina adhesive, 1 to 5 weight percent pore-forming agent CMC of the amorphous silicon aluminum and 1 to 3 weight percent extrusion-aid agent sesbania powder into the amorphous silicon aluminum of required weight, extruding the mixture on an extruder after mixed kneading and roller compaction, and drying and baking to obtain the carrier; and (2) loading active components Pt and Pd noble metal elements by a common dipping method and then carrying out vacuum drying to obtain the catalyst through calcination.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Oil-water separation device with flow guide plate

PendingCN112300866AEasy to separateSolve efficiency problemsEssential-oils/perfumesLiquid separationOil waterSteam distillation

The invention discloses an oil-water separation device with a flow guide plate, which comprises a conical oil-water separator, wherein the flow guide plate is arranged at the outlet end of an ingresspipe of the oil-water separator, the flow guide plate is segment-shaped and is fixedly connected with the ingress pipe through a rod-shaped body, an adjusting pipe is arranged at the lower part of theingress pipe, the adjusting pipe is screwed or clamped with the ingress pipe, an oil outlet is formed in upper part of oil-water separator, and a condensation pipe and a return pipe are arranged at the bottom of the oil-water separator. The flow direction of the mixed liquid can be impacted vertically and downwards by the flow guide plate, the mixed liquid is guided to be uniformly distributed onthe whole section along the radial direction of the flow guide plate and slowly moves downwards, direct impact on the oil-water mixed liquid in the separator is eliminated, and part of the oil-watermixed liquid is prevented from returning to a distillation device or entering fresh flower dew without being separated. The device can continuously and efficiently separate and collect volatile oil, has the characteristics of high separation efficiency and good continuity for oil-water mixed liquid with low volatile oil content, is easy to disassemble and replace, is low in manufacturing cost, canbe universally compatible with water vapor distillation equipment used in current production, and is suitable for popularization and application.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

Bubbling tower reactor having damping internal construction member

InactiveCN100417437CIncrease mass transfer rateInhibit flow rateLiquid-gas reaction processesEngineeringTower

A bubbling column reactor with internal damping member features that said internal damping member is coaxially installed in the reaction region above gas distributor for suppressing the flow speed in central region to make the radial speed distribution more uniform and interferring the flow field to promote local turbulence and increase gas-liquid mass transfer speed.

Owner:ZHEJIANG UNIV

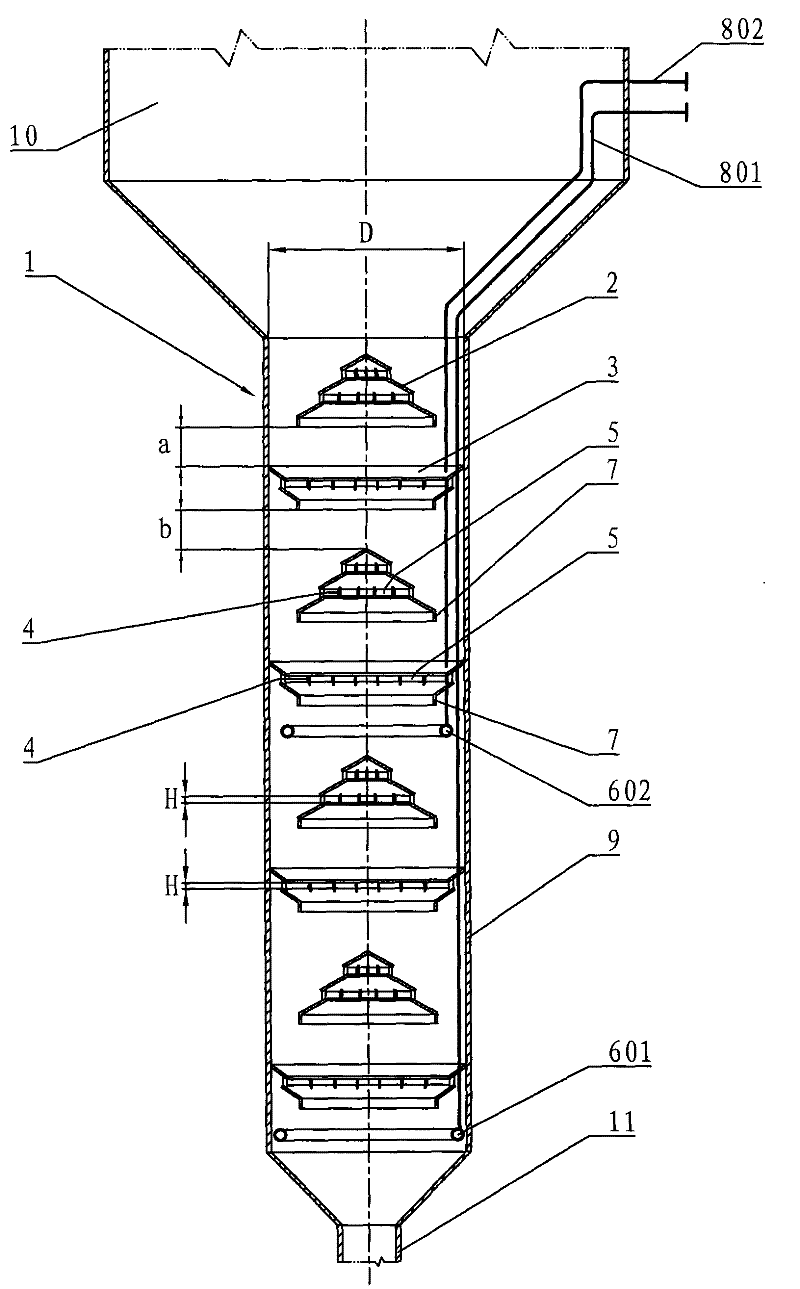

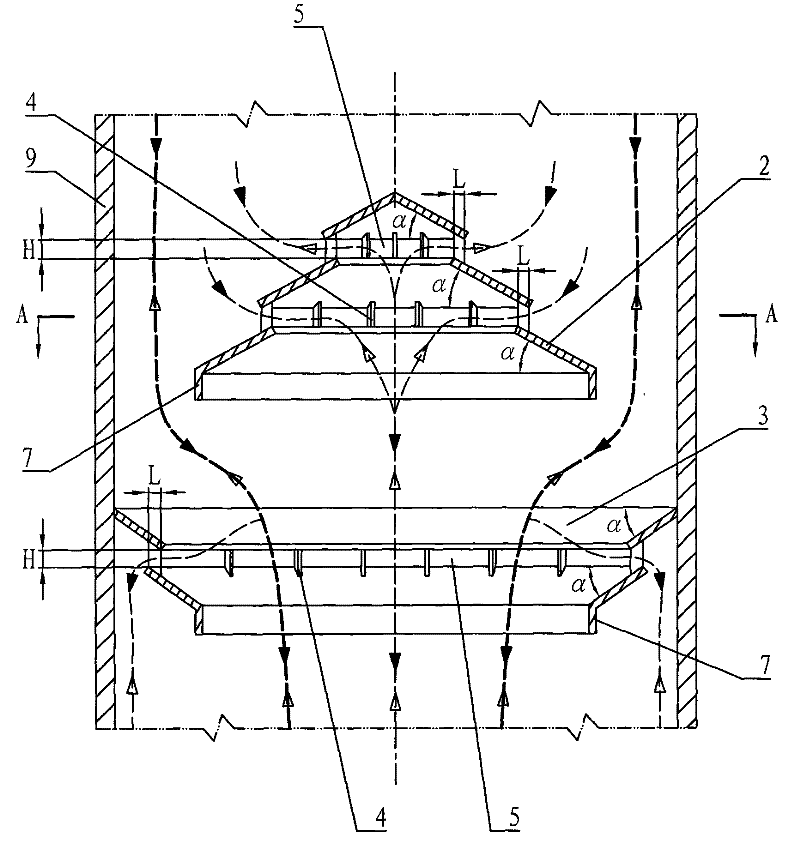

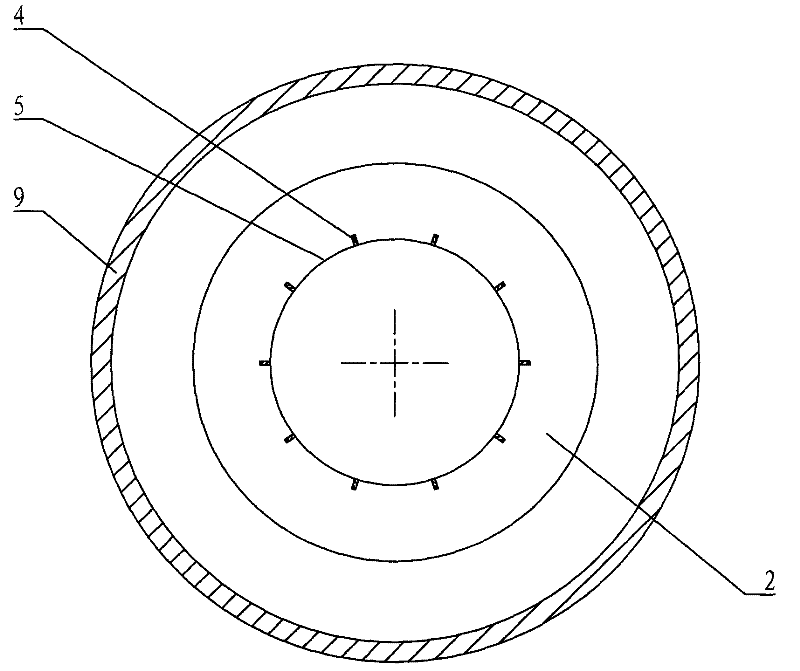

A catalytic conversion stripper

ActiveCN101711962BImprove stripping efficiencyEasy to handleCatalytic crackingChemical/physical processesPetrochemicalPetroleum

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Catalytic cracking method and device thereof

InactiveCN101993709AUniform radial distributionImprove contact effectCatalytic crackingGasolineChemistry

The invention discloses a catalytic cracking method and device. The method comprises the following steps of extracting the heat of a catalyst from a regenerator at a mixing section, mixing the catalyst subjected to heat extraction with heavy raw oil, entering a riser reactor, an isokinetic bed reactor and a precipitator of a reactor I, entering a fractionator by oil gas, and entering the regenerator by the catalyst for regeneration; mixing the other part of the catalyst from the regenerator with light raw oil, entering a reactor II, entering the precipitator by a compound of reaction oil gas and the catalyst, entering the fractionator by the oil gas, entering the regenerator by the catalyst for regeneration, producing qualified gasoline by the reactor I, and producing olefin by the reactor II, and thus, a set of devices is utilized to satisfy the needs for producing the gasoline and a chemical material.

Owner:CHINA PETROCHEMICAL CORP +1

Combined type gas distributor

InactiveCN101607184BSmall pressure dropUniform radial distributionDispersed particle separationChemical/physical/physico-chemical processesEngineeringDistributor

The invention discloses a combined type gas distributor which comprises an inner cylinder, a top ring-shaped plate and a trapezoidal double-line vane diversion device, wherein the side wall of the inner cylinder is provided with a feed inlet along the radial direction, the top ring-shaped plate is welded on the top of the inner cylinder, the trapezoidal double-line vane diversion device which hasthe cross section changed from large to small is arranged inside the inner cylinder along the direction of the feed inlet, and the double-line vane diversion device comprises a left line and a right line of at least one layer of guide vanes that are symmetrically arranged by taking a vertical axis section of the feed inlet as symmetrical plane; the upper and the lower guide vanes of the adjacent layers are connected with each other by a left and a right connecting plates, the guide vanes arranged at the top layer and the bottom layer are respectively connected with an upper and a lower cover plate, the upper and the lower cover plates as well as the left and the right connected plates are connected with the top ring-shaped plate by bolts, a plurality of whirl plates are symmetrically connected on the outer wall of the inner cylinder by taking a central section of the inner cylinder as the symmetrical plane. By changing the flow direction of gas, the combined type gas distributor achieves the aims of reducing intensity of pressure and evenly distributing the gas.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com