Heavy oil contact cracking method

A contact cracking, heavy oil technology, applied in cracking, non-catalytic thermal cracking, petroleum industry and other directions, can solve the problems of increased coke yield, difficult to control the temperature in the bed, flying temperature, etc., achieve uniform radial distribution, improve oil Agent contact effect, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

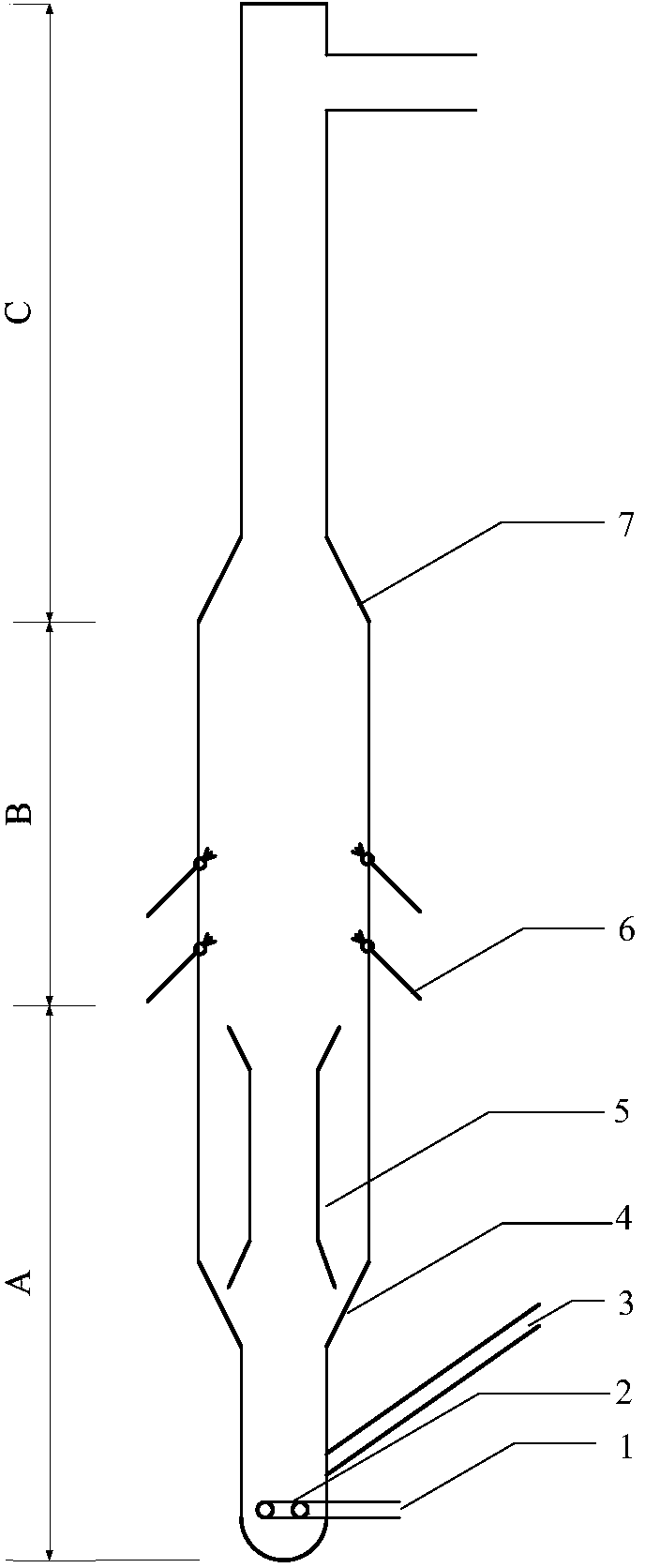

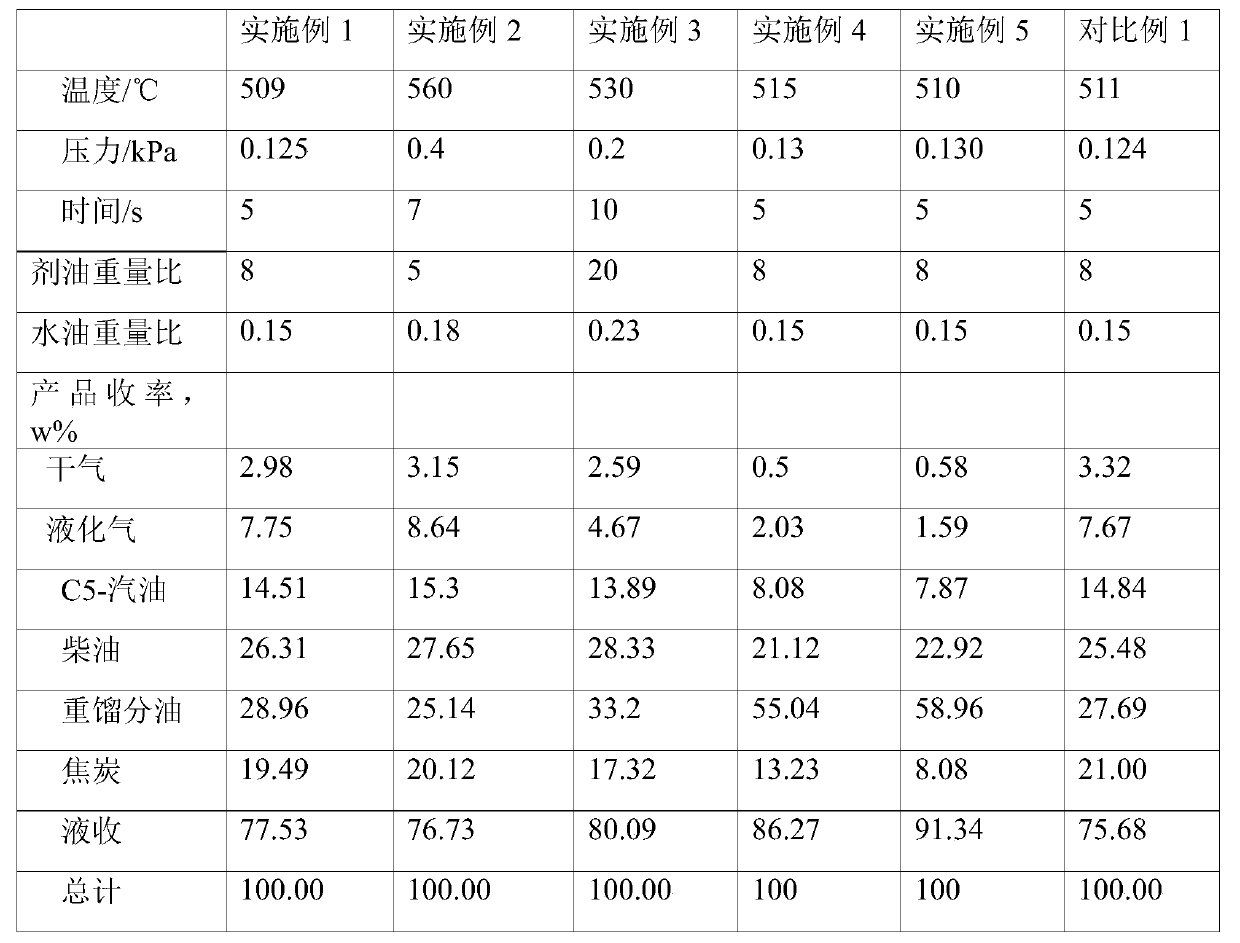

[0059] use figure 1 In the cracking reactor shown, the total height of the pre-lift section A, the oil agent contact reaction zone B, and the outlet zone C of the cracking reactor is 12m, the diameter of the lower part of the pre-lift section A is 0.15m, and the height is 0.5m. The height of the middle part 4 of A is 0.5m, the diameter of the upper part of the pre-lifting section A is 0.5m, and the height is 2m, the height of the oil contact reaction zone B is 5m, and the diameter is 0.5m, and the height of the exit zone C is 4m, and the diameter is 0.1m. The middle and upper part of the pre-lifting section A is provided with a casing 5, the casing 5 is thin in the middle, and the diameter of both ends is enlarged, and the height ratio of the three parts of the casing 5 from top to bottom is 1:3:0.2, and the middle The diameter ratio of the section to the upper part of the pre-lift section A is 0.4:1, the acute angle at the top of the longitudinal section of the casing 5 is 40...

Embodiment 2

[0063] use figure 1 In the cracking reactor shown, the total height of the pre-lift section A, the oil agent contact reaction zone B, and the outlet zone C of the cracking reactor is 30m, the diameter of the lower part of the pre-lift section A is 0.3m, and the height is 1m, and the pre-lift section A The height of the middle part 4 is 1.2m, the upper part of the pre-lifting section A has a diameter of 1m and a height of 4m, the height of the oil agent contact reaction zone B is 10m, and the diameter is 1m, and the height of the exit zone C is 13.8m, and the diameter is 0.5m. The middle and upper part of the section A is provided with a casing 5, the casing 5 is thin in the middle, and has a shape of enlarged diameter at both ends, and the height ratio of the three parts of the casing 5 from top to bottom is 1:2:1, and the middle section and The diameter ratio of the upper part of the pre-lift section A is 0.8:1, the top acute angle of the longitudinal section of the casing 5 ...

Embodiment 3

[0066] use figure 1 In the cracking reactor shown, the total height of the pre-lift section A, the oil agent contact reaction zone B, and the outlet zone C of the cracking reactor is 10m, the diameter of the lower part of the pre-lift section A is 0.1m, and the height is 0.4m, and the pre-lift section A middle part 4 has a height of 0.5m, the upper part of the pre-lift section A has a diameter of 0.4m and a height of 1.1m, the oil agent contact reaction zone B has a height of 4m and a diameter of 0.4m, and the outlet zone C has a height of 4m and a diameter of 0.1m , the middle and upper part of the pre-lifting section A is provided with a casing 5, the casing 5 is thin in the middle, and has a shape of enlarged diameter at both ends, and the height ratio of the three parts of the casing 5 from top to bottom is 1:3:1, The diameter ratio of the middle section to the upper part of the pre-lift section A is 0.2:1, the acute angle of the top of the longitudinal section of the casi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com