Patents

Literature

168results about How to "Increase liquid collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbent for reducing sulfur content of light hydrocarbon oil

ActiveCN101434854AHigh desulfurization activityEvenly distributedHydrocarbon oils refiningSorbentRare earth

The invention provides a sorbent used for reducing the content of sulfur in light hydrocarbon oil. According to weight percentage, the sorbent comprises 1-30 percent of phosphorus-modified rare earth faujasite, 5-40 percent of active metal oxide and 30-94% of carrier; wherein, the carrier comprises alumina and zinc oxide; the rare earth faujasite is modified by phosphorus and is pre-formed into porous heat-resistance solid grains together with carrier mixture; subsequently, the active metal oxide is led into the solid grains, thus preparing the sorbent; the light hydrocarbon oil raw material containing the sulfur and hydrogen donor enter a reactor filled with the sorbent; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated after reaction is stripped, burned and regenerated; and the regenerated sorbent is reduced by the hydrogen donor and subsequently returns to the reactor so as to be circularly used. The sorbent realizes that the sulfur of light hydrocarbon oil is deeply removed, and simultaneously, the octane number of the outcome gasoline is higher, while thebenzene content is lower and the strength is higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

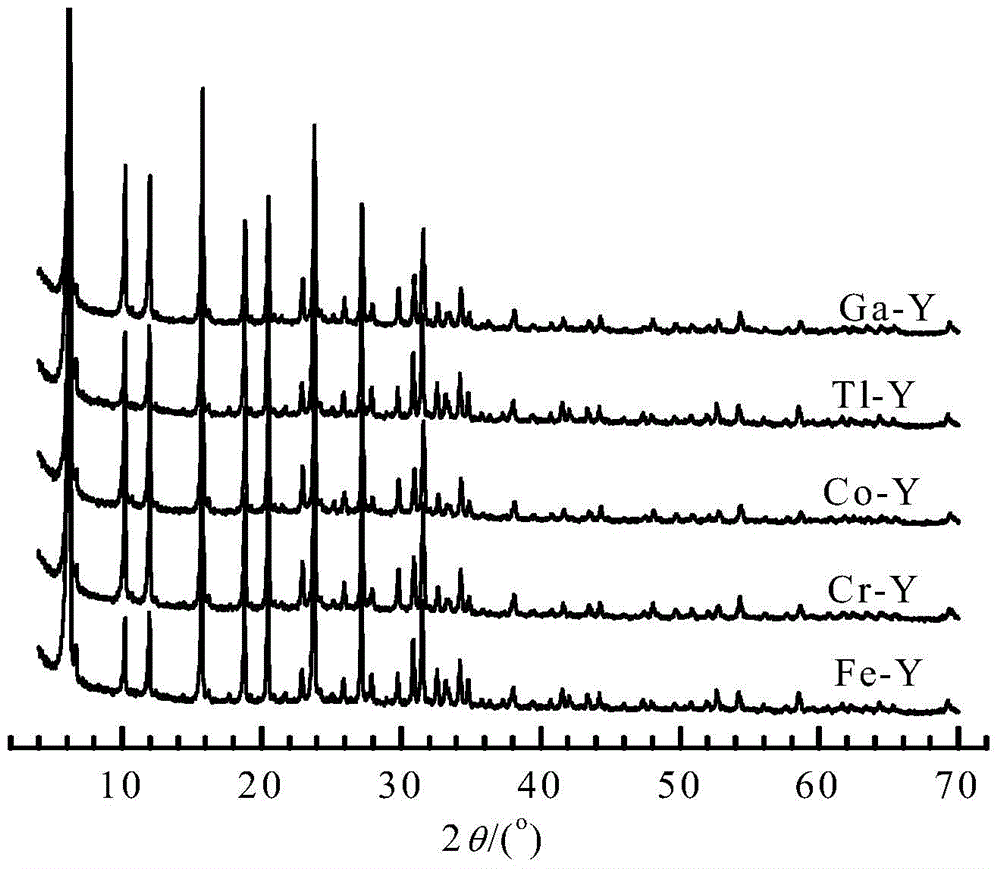

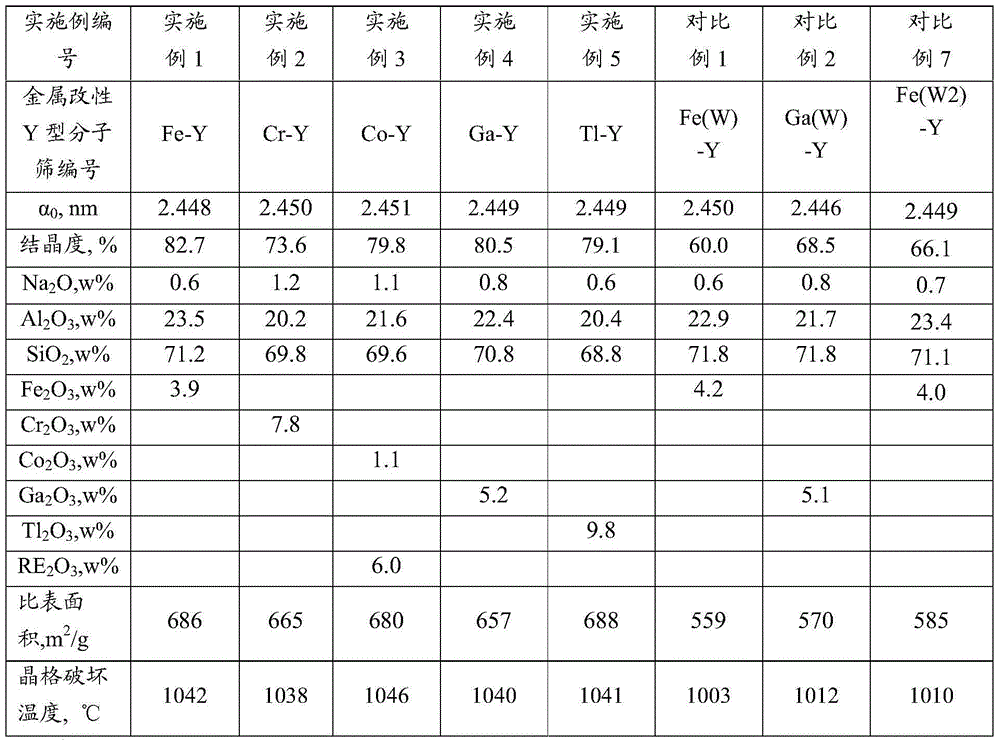

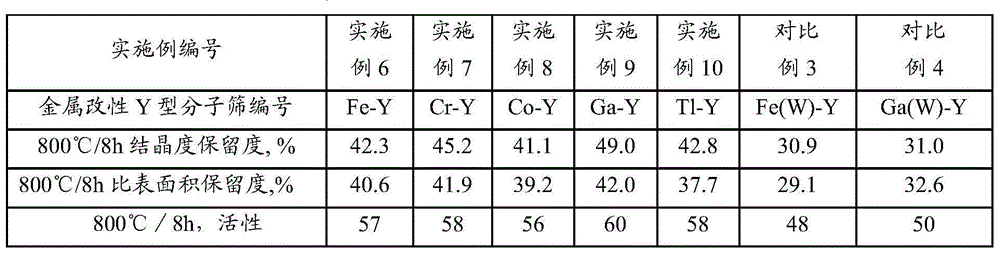

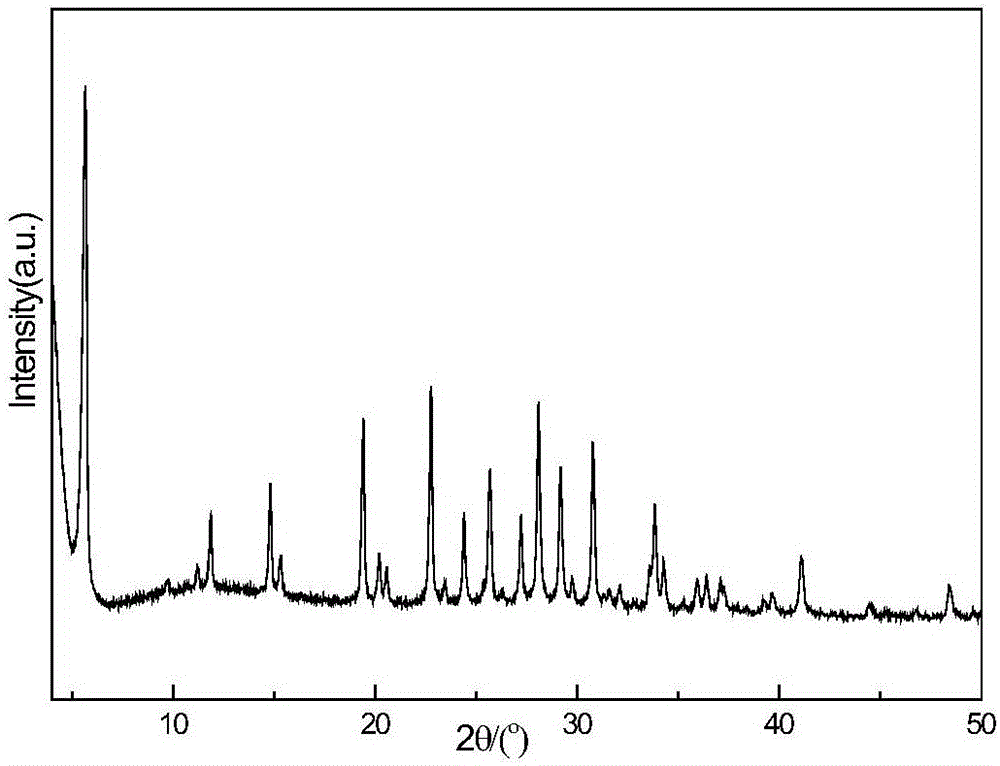

Preparation method of metal modified Y type molecular sieve

ActiveCN104556120AHigh crystallinityHigh hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveAlcohol

The invention discloses a preparation method of a metal modified Y type molecular sieve. The preparation method comprises the following steps: (1) treating the Y type molecular sieve with an acid solution; (2) dehydrating the treated Y type molecular sieve; (3) then dissolving a compound of modified metal elements in a buffer solution of ethyl alcohol-ammonium acetate-water so as to prepare impregnation liquid, mixing and impregnating the impregnation liquid and the molecular sieve obtained in the step (1), and calcining. Wherein modified metal is one or more of Fe, Cr, Ga, In, Tl, Sn and Co. The metal modified Y type molecular sieve obtained by the method is high in hydrothermal stability, and the productive rate for gasoline by cracking hydrocarbon oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

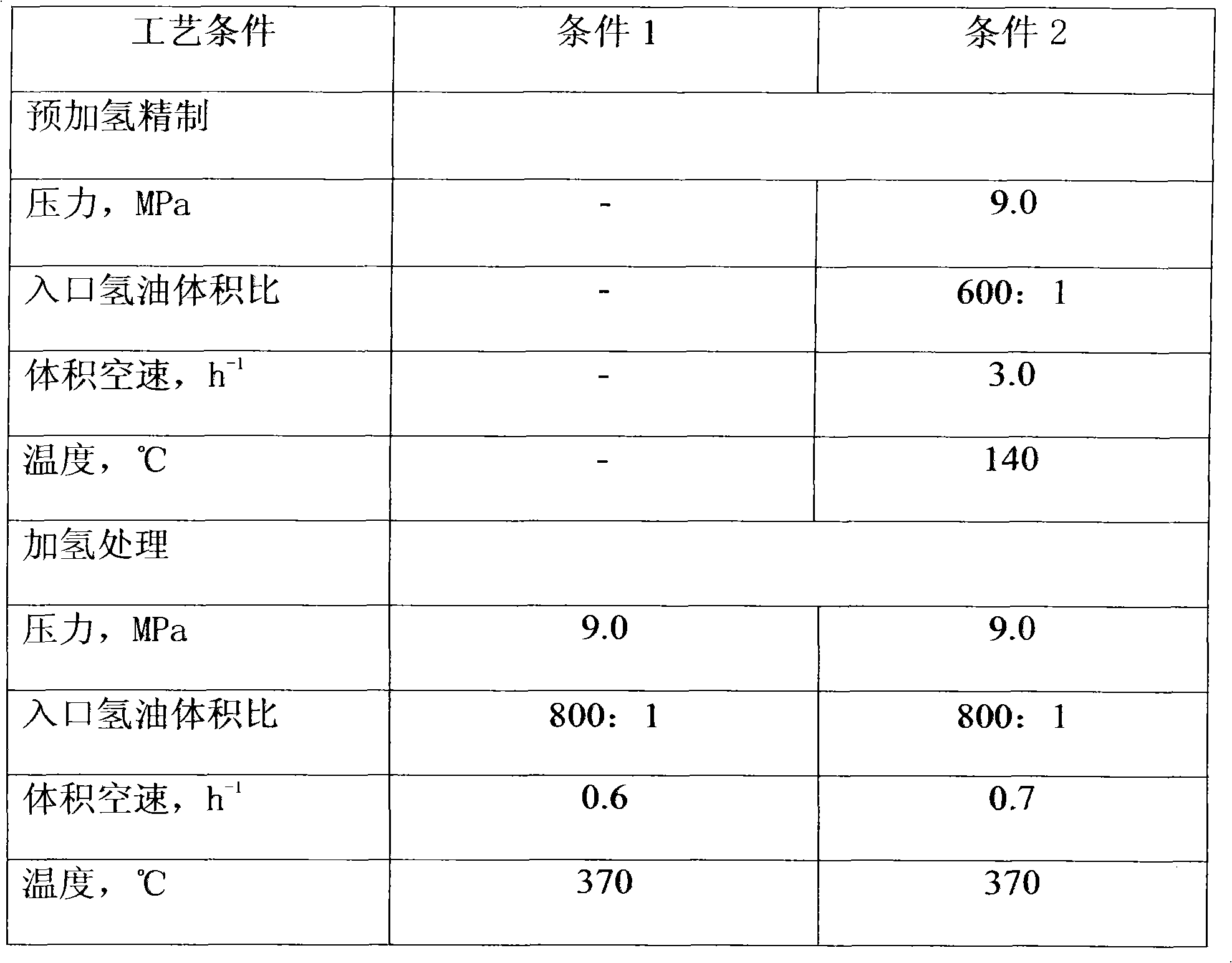

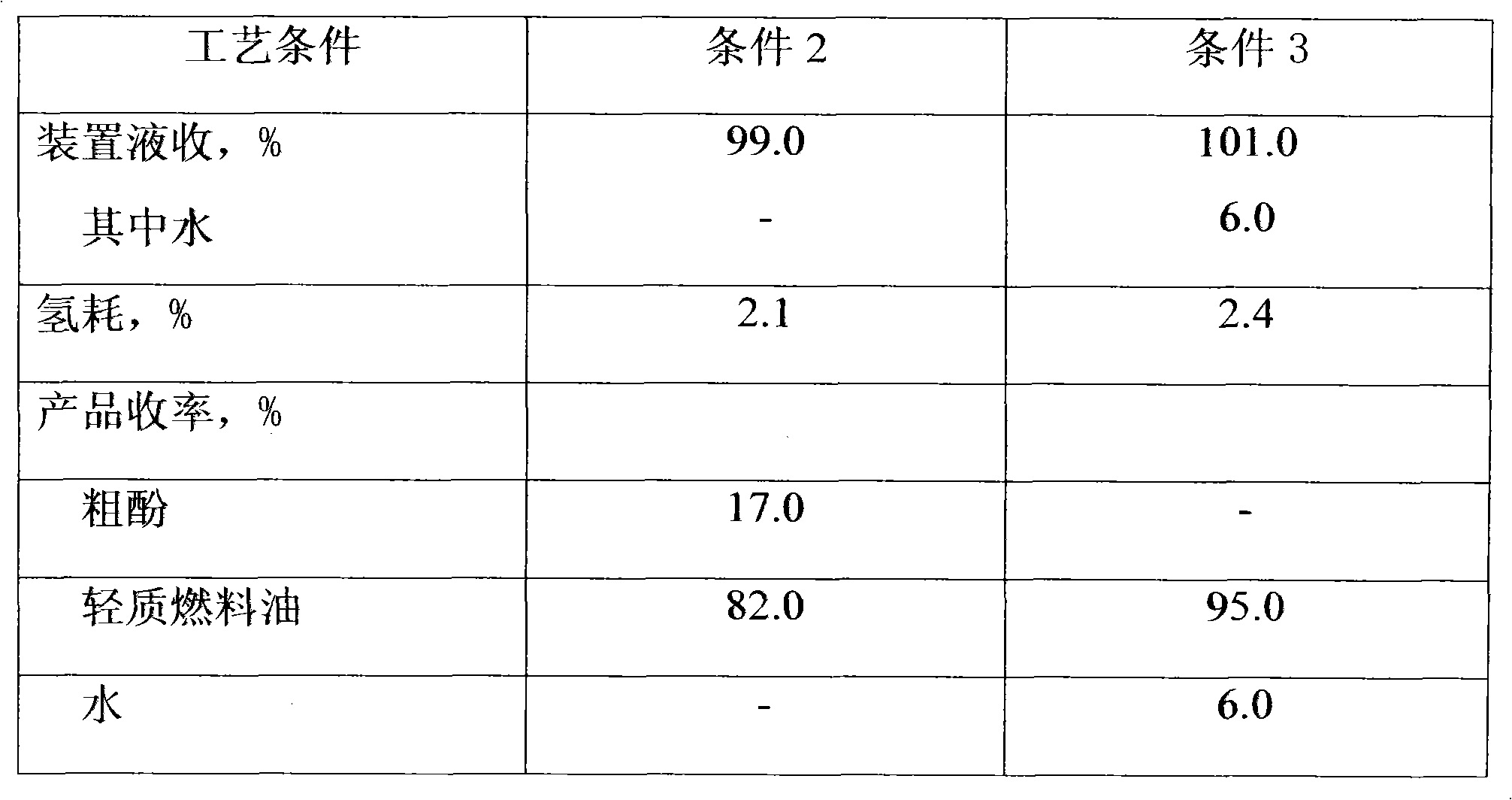

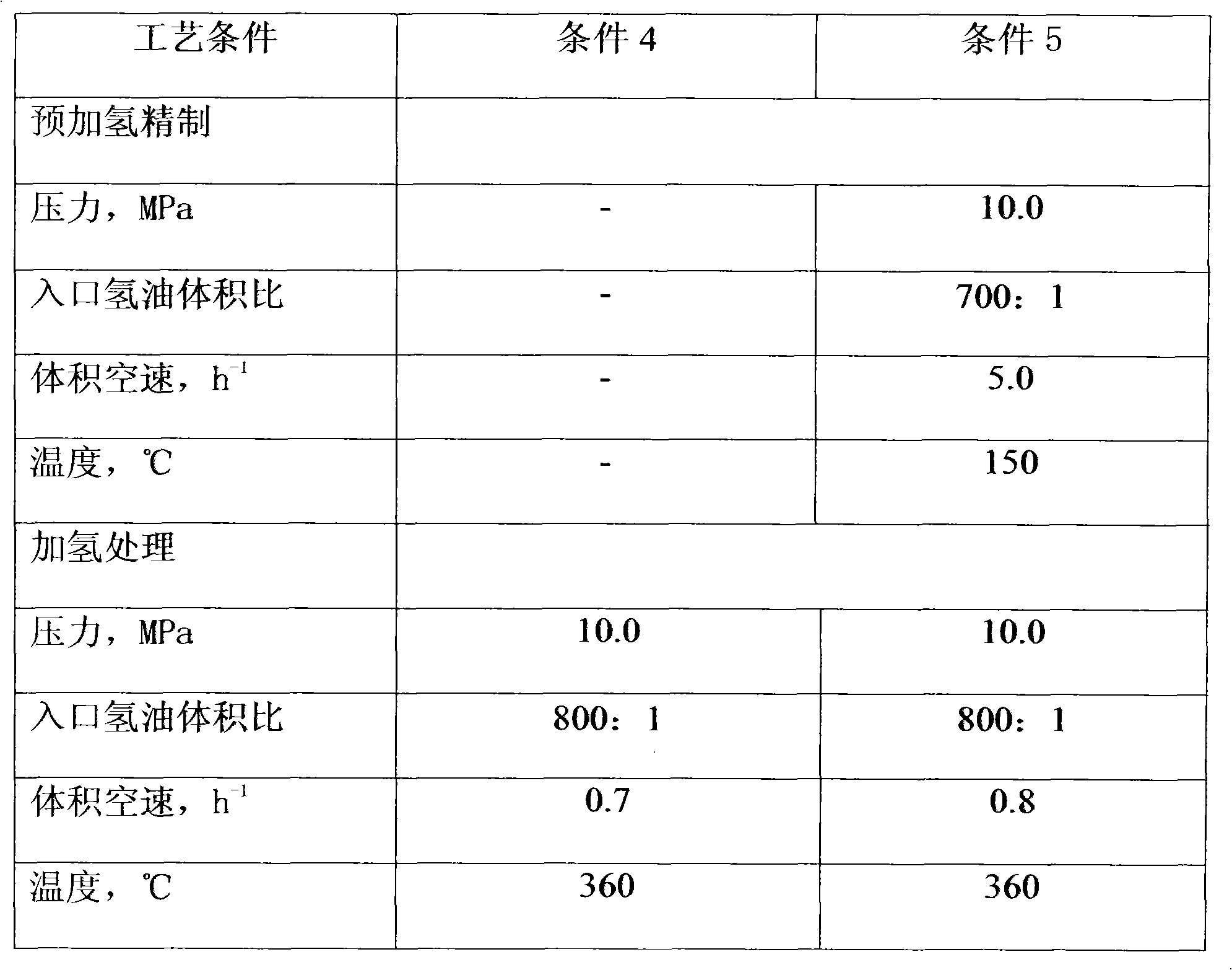

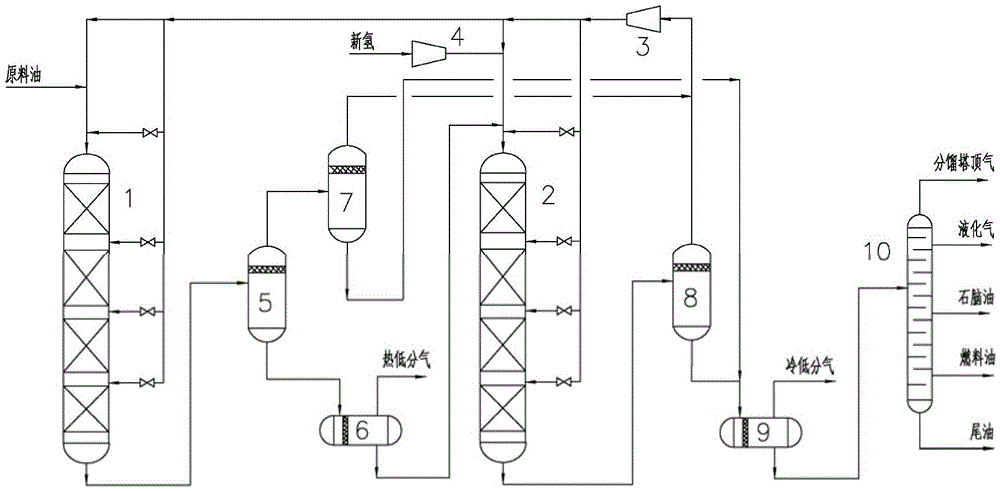

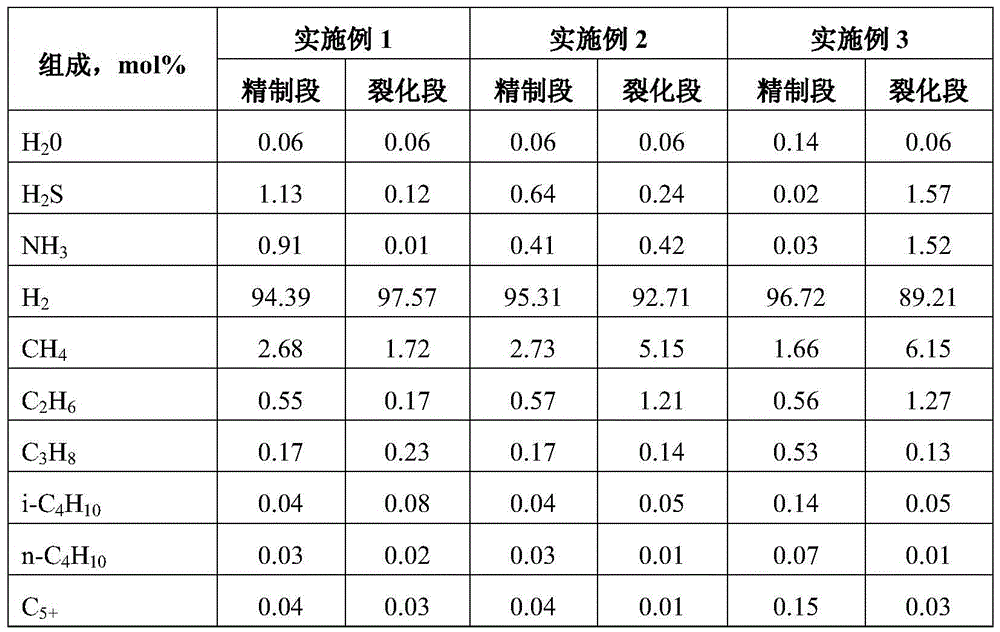

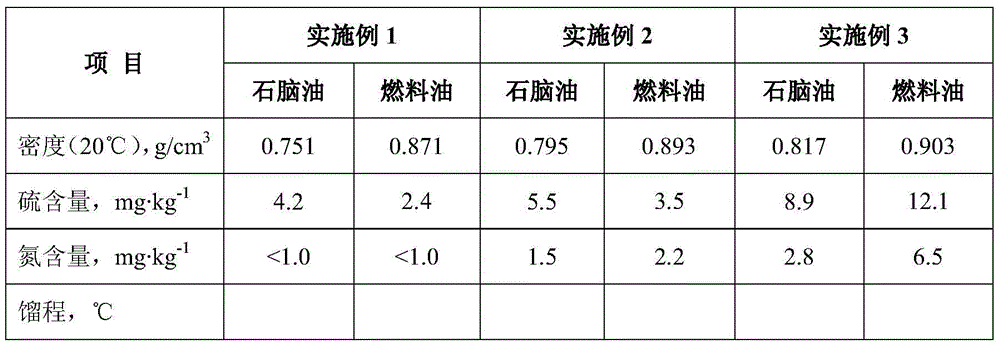

Processing method of medium-low temperature coal tar

ActiveCN102465033AImprove economyOperation cycle solutionOrganic chemistryOrganic compound preparationSlagFuel oil

The invention discloses a processing method of medium-low temperature coal tar. According to the method, whole fraction of the medium-low temperature coal tar which has been undergone dehydration and slag removal is firstly distilled to obtain a light fraction and a heavy fraction. The heavy fraction is used as modified asphalt or heavy fuel oil and the like. A phenolic compound is separated from the light fraction by an acid-base extraction method so as to obtain a crude phenol product. Hydrogenation saturation of alkene from dephenolized raw oil is carried out by a hydro-pretreating method. The prehydrogenation raw oil contacts with a main hydrofining catalyst for desulphurization, nitrogen removal, aromatic saturation and other reactions. In comparison with the prior art, by the adoption of the method provided by the invention, components which influence long-term operation of a hydrogenation device can be fundamentally removed; the operation period of the device can be obviously prolonged; the crude phenol product can be obtained; and the utilization rate of raw materials and the whole economy of a processing device can be raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

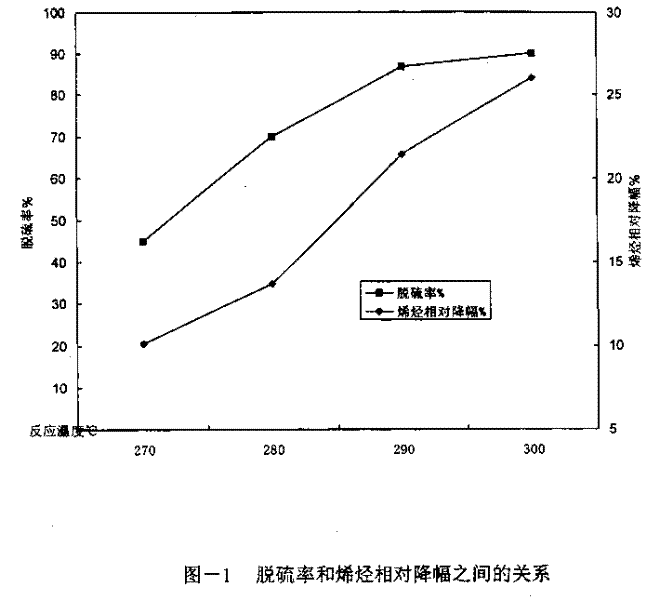

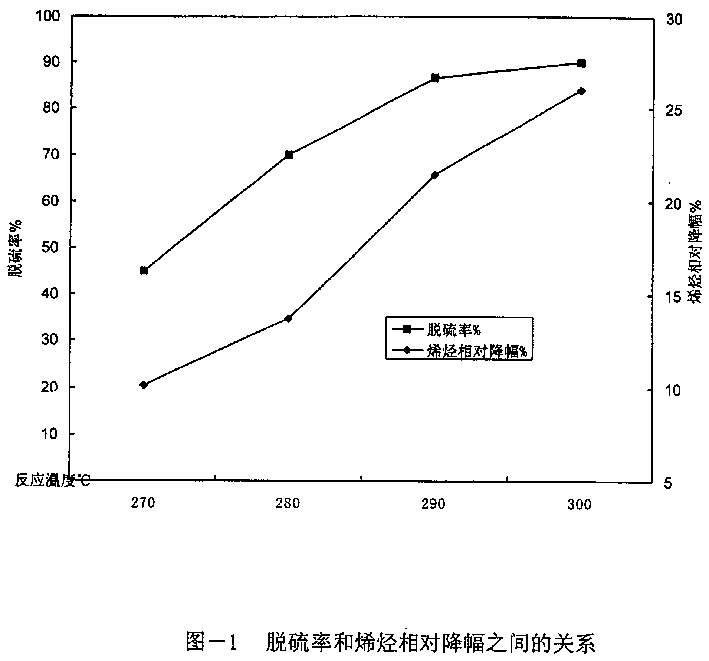

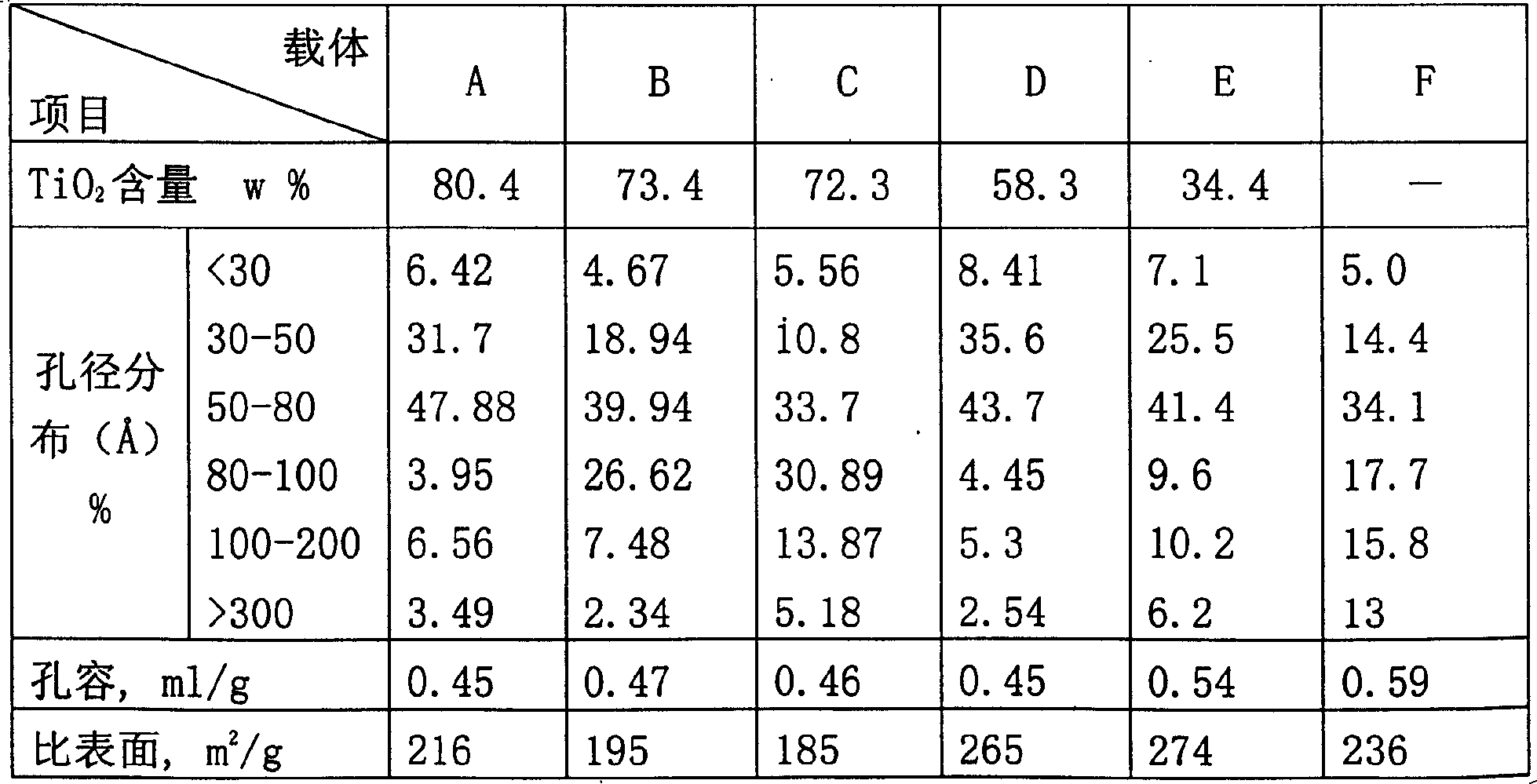

Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

InactiveCN1448471AImprove anti-coking performanceHigh activityRefining to eliminate hetero atomsLiquid productActive component

The gasoline hydrogenating catalyst includes the components of carrier with TiO2 in 20-90 wt%; active component A of VIII metal oxide in 0.1-8 wt%; active component B of VIB metal oxide in 1-13 wt%; and adhesive in the rest content. After being pre-sulfurized, the catalyst of the present invention is used to process FCC gasoline in condition of mild hydrogenation and exhibits very high hydrodesulfurization activity and selectivity. Compared with traditional hydrogenation catalyst, the catalyst of the present invention has less loss of gasoline octane number and higher liquid product yield, up to 99 wt%, in the condition of same hydrodesulfurization level.

Owner:BEIJING HAISHUNDE TITANIUM CATALYST

Normal-paraffin isomerization catalyst, preparation method and application thereof

ActiveCN104117369ALow reaction temperatureReaction conditions are easy to controlHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneLow activity

The invention provides a normal-paraffin isomerization catalyst, a preparation method and application of the normal-paraffin isomerization catalyst, and relates to the technical field of the paraffin-isomerization catalyst, and is used for solving the problems of low activity, poor stability and low conversion rate in the existing isomerization catalyst. The normal-paraffin isomerization catalyst comprises the following components in percentage by mass: 0.1-1.0% of metal component Pt and 2.0-5.0% of halogen Cl and the balance of carrier gamma-Al2O3. The normal-paraffin isomerization catalyst provided by the invention is prepared by dipping, reduction, inorganic chlorination and organic chlorination; the metal elementary substance Pt is loaded on the multi-porous carrier gamma-Al2O3, and after chlorination treatment, the Pt-Al2O3-Cl normal-paraffin low-temperature isomerization catalyst is formed; and the normal-paraffin isomerization catalyst has the advantages of high liquid absorption, high isomerization rate, high reaction activity and good stability.

Owner:JIANGSU YANGZI CATALYST CO LTD +1

Desulphurization sorbent

ActiveCN101433817AEvenly distributedHigh strengthOther chemical processesHydrocarbon oils refiningAdditive ingredientSorbent

The invention discloses a desulfurization adsorbent, which comprises 1 to 30 weight percent of rare earth-zeolite mixture, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide; the rare earth-zeolite mixture and a carrier mixture are preformed into porous heat-resistant solid particles, and then active metal ingredients are introduced on the solid particles to obtain the adsorbent; and a light hydrocarbon oil raw material containing sulfur and a hydrogen donor enter a reactor filled with the adsorbent, materials remained after the reaction are separated, a reaction product is sent into a subsequent separation system for product separation, a spent adsorbent after the reaction is steam-stripped and then is subject to coke-burning regeneration, and the regenerated adsorbent is reduced by the hydrogen donor and is returned to the reactor for cyclic use. The adsorbent realizes the deep removal of sulfide in light hydrocarbon oil, and the produced gasoline has higher octane number, lower benzene content, and higher strength at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of recovering light hydrocarbon from byproduct gas of Fischer-Tropsch synthesis

ActiveCN103626898ASimple compositionHigh yieldLiquid hydrocarbon mixture productionPolyolefinPolymer science

The invention discloses a method of recovering light hydrocarbon from byproduct gas of Fischer-Tropsch synthesis. The method includes exhaust gas treatment, light hydrocarbon recovery, olefin conversion and polyolefin synthesis. The exhaust gas treatment includes decarburization and crude separation of a C1 stream and a C2 stream. The light hydrocarbon recovery includes separating the C2 stream, cracking gas and a portion of mixed C4 to obtain a stream comprising ethane, ethylene, propane, propylene, the mixed C4 and light naphtha. The olefin conversion includes reacting C4 olefins with the ethylene to produce the propylene. The polyolefin synthesis includes subjecting the obtained ethylene and the obtained propylene to polymerization to obtain polyethylene and polypropylene. The method is capable of increasing the yield of effective products of Fischer-Tropsch synthetic products, increasing the product kinds, improving the added valve of the products and increasing benefit.

Owner:CHINA PETROCHEMICAL CORP +1

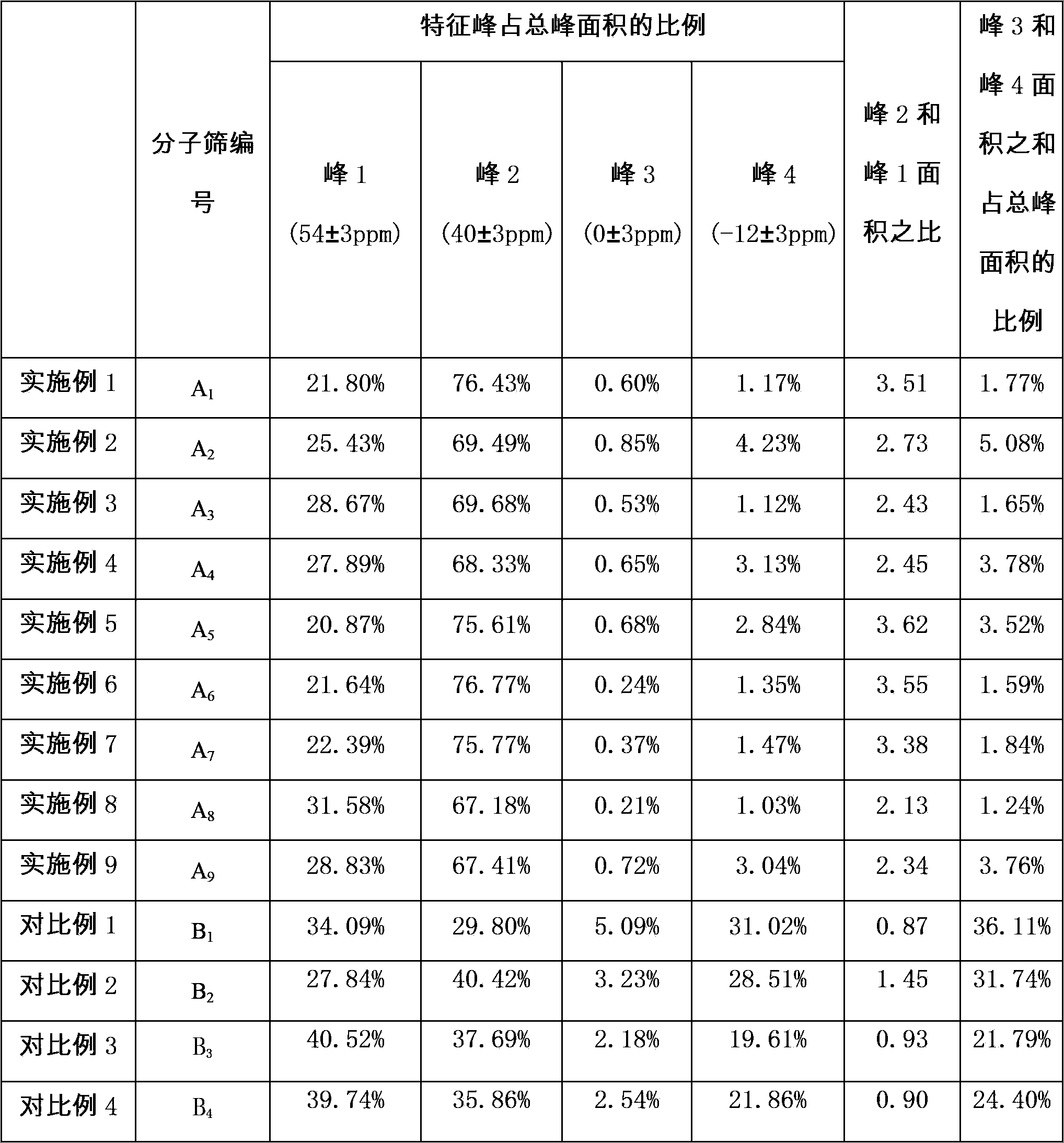

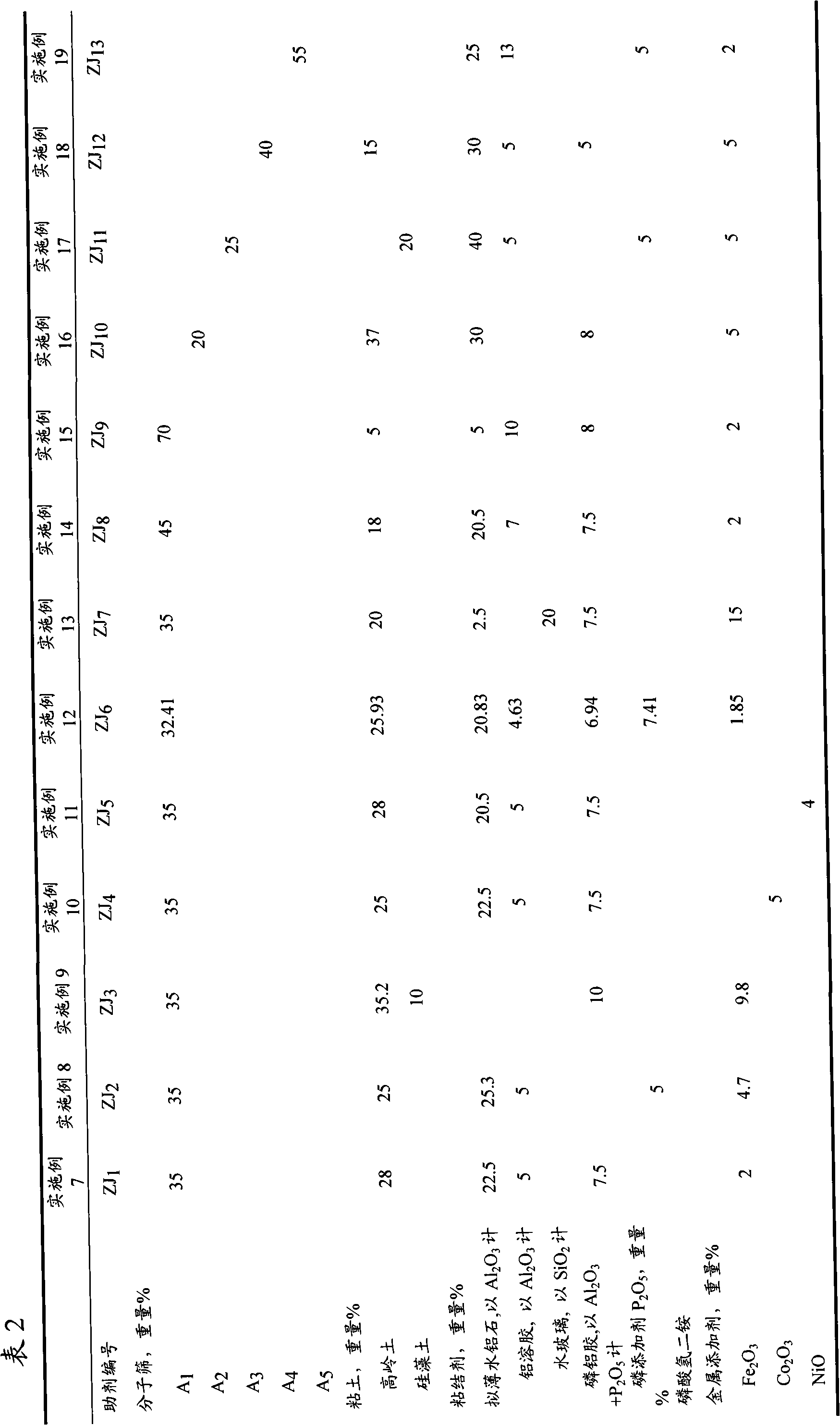

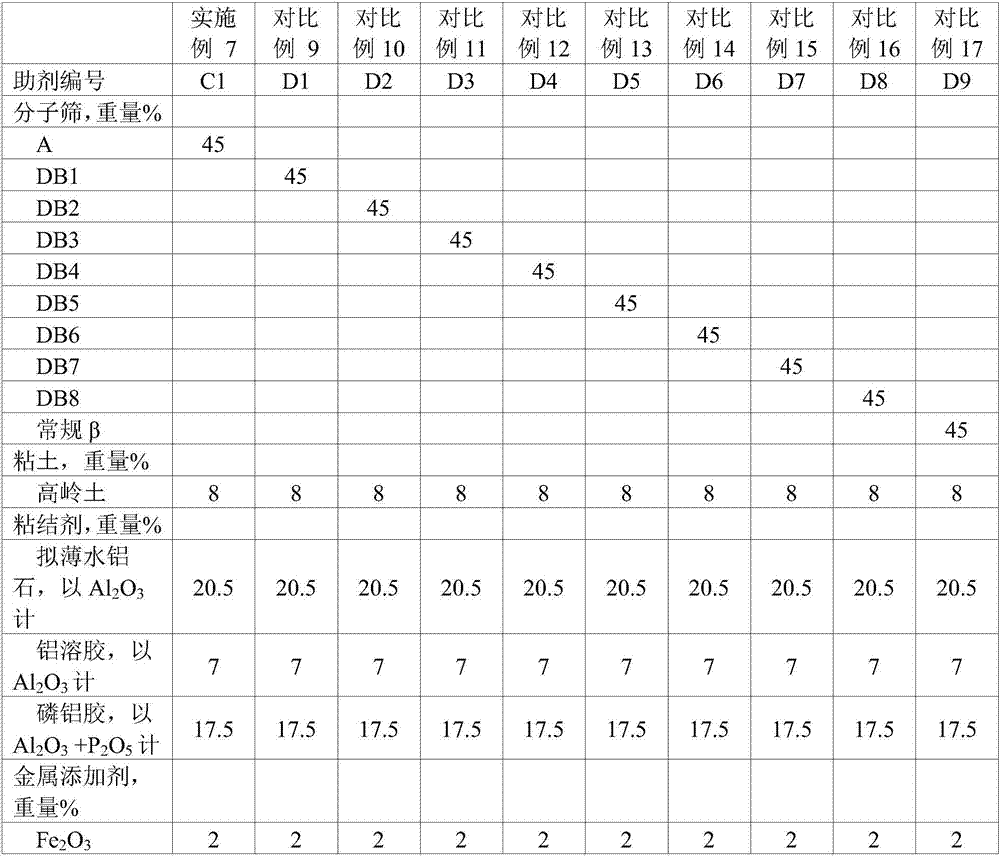

Cracking auxiliary agent for increasing low-carbon olefin concentration

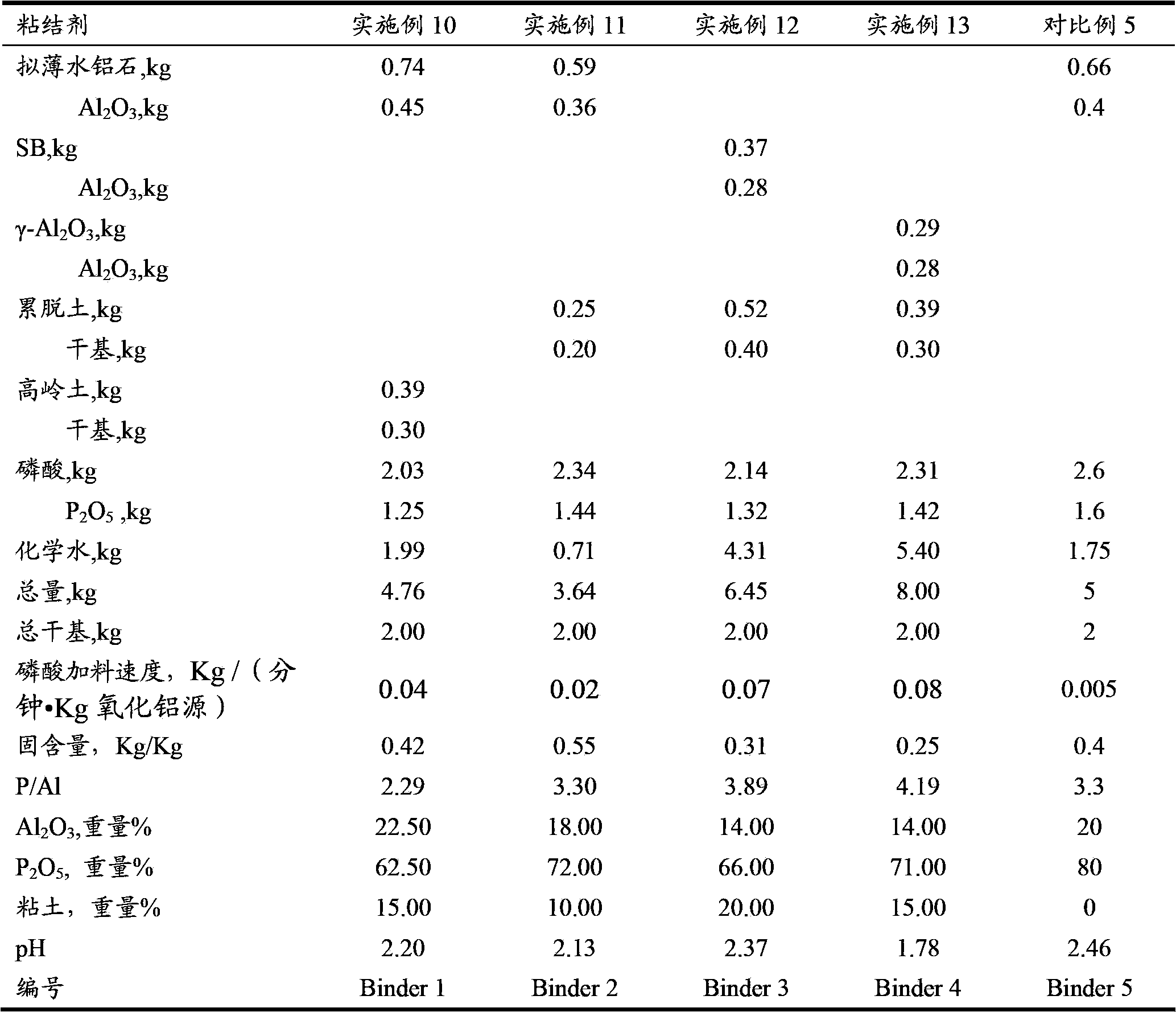

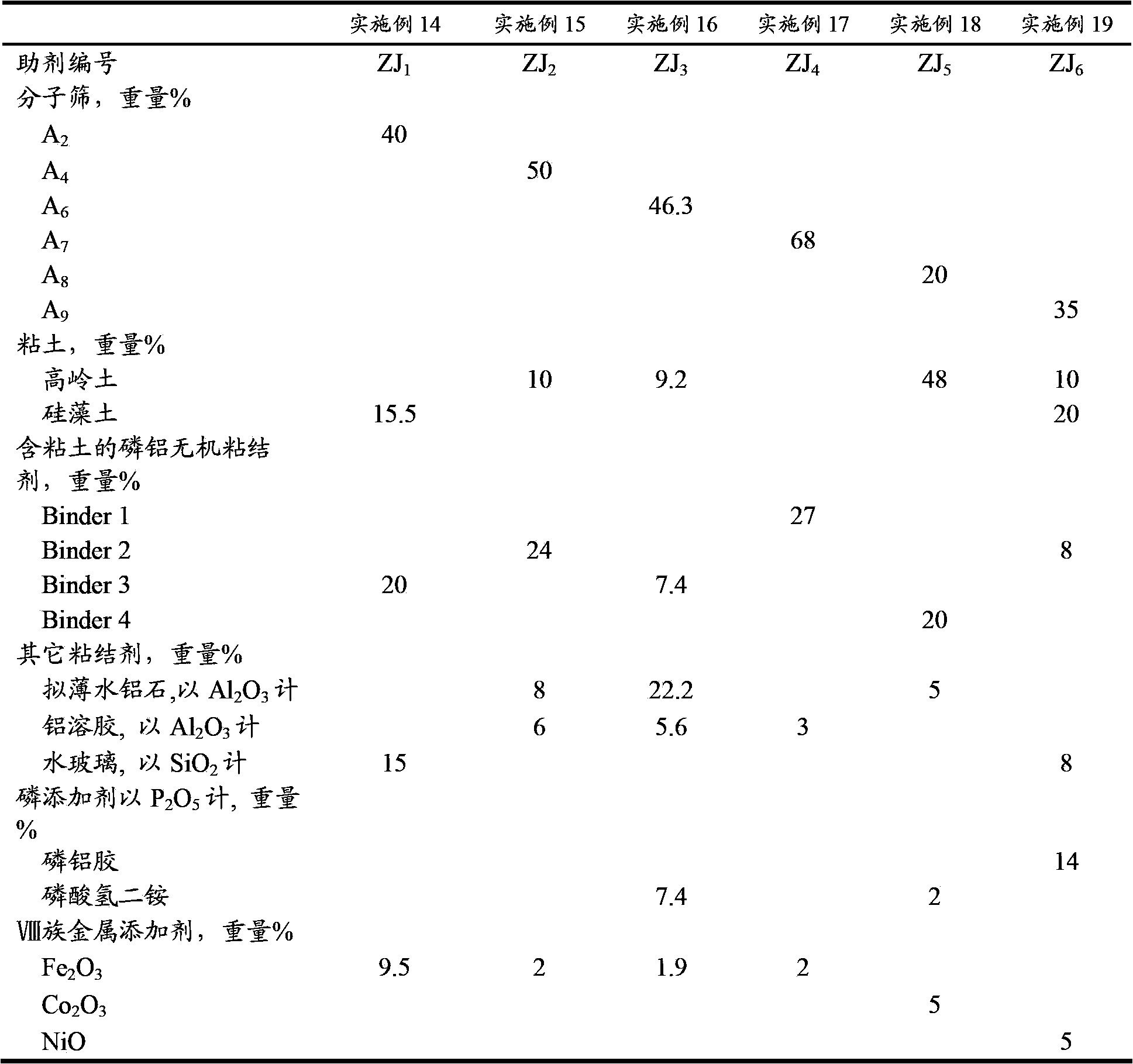

ActiveCN103785456AImprove wear resistanceGood catalytic cracking performanceCatalytic crackingMolecular sieve catalystsFuel oilPeak area

The invention relates to a cracking auxiliary agent for increasing low-carbon olefin concentration. The cracking auxiliary agent contains a modified beta molecular sieve, a first clay-containing phosphorus-aluminum inorganic binder, and other inorganic binders and VIII group metal additives, and contains or does not contain second clay, wherein the first clay-containing phosphorus-aluminum inorganic binder comprises an aluminum component, a phosphorus component and first clay, the modified beta molecular sieve containing the phosphorus and the transition metal comprises 1-10 wt% (calculated as P2O5) of the phosphorus and 0.5-10 wt% (calculated as metal oxide) of the metal, and in the 27Al MAS NMR of the molecular sieve, a ratio of the resonance signal peak area at the chemical shift of 40+ / -3 ppm to the resonance signal peak area at the chemical shift of 54+ / -3 ppm is more than or equal to 1, and the sum of the resonance signal peak areas at the chemical shifts of 0+ / -3 ppm and -12+ / -3 ppm accounts for less than or equal to 10% of the total peak area. According to the present invention, the cracking catalyst composition is used for catalytic cracking of petroleum hydrocarbons, and can be provided for increasing the catalytic cracking liquefied gas yield, increasing the concentration of the low-carbon olefin in the liquefied gas, especially the concentration of isobutene, increasing the ratio of ethylene to dry gas, and increasing the gasoline octane number, and the heavy oil conversion capacity of the main catalyst is not affected when the auxiliary agent is blended in the large proportion manner.

Owner:CHINA PETROLEUM & CHEM CORP +1

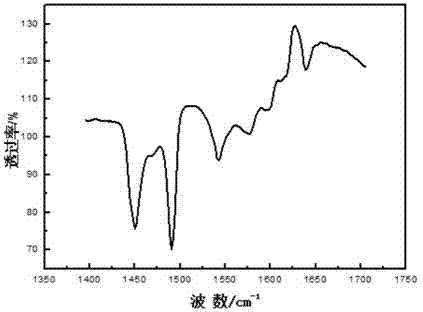

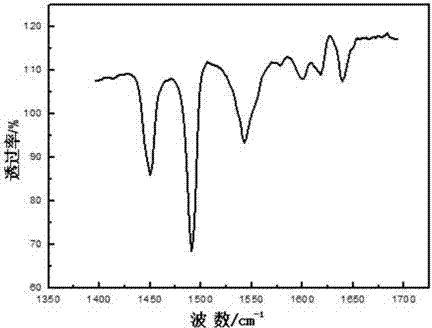

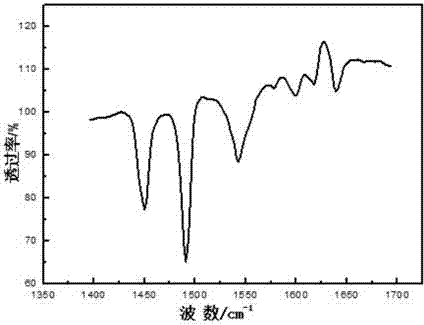

Cracking auxiliary agent for improving catalytic cracking low-carbon olefin concentration

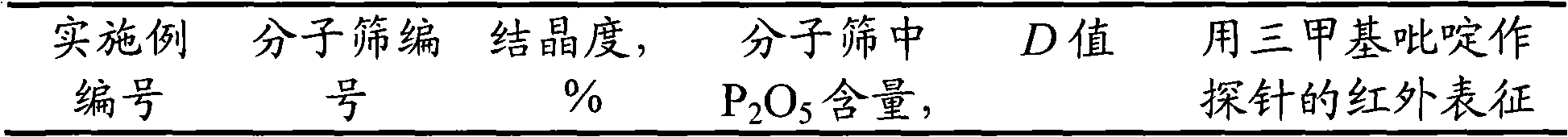

ActiveCN103007986AIncrease concentrationHigh yieldCatalytic crackingMolecular sieve catalystsLiquid gasInorganic oxide

The invention provides a cracking auxiliary agent used for improving propylene concentration. The auxiliary agent comprises 10-75wt% of phosphorus and transition metal-modified MFI molecular sieve, 0-60wt% of clay, 15-60wt% of an inorganic oxide binder, 0.5-15wt% of a VIII-family metal additive, and 2-25wt% of a phosphorus additive. The phosphorus and transition metal-modified MFI-structured molecular sieve has no absorption peak at 1633cm<-1> on an infrared spectrum obtained with trimethylpyridine as probe molecules, and has a phosphorus distribution of 0-0.8. D is a ratio of the phosphorus content from the edge to a 1 / 5 position of the center of molecular sieve crystal to the phosphorus content at the center of molecular sieve crystal, which is characterized by using a TEM-EDX method. The transition metal is one or more selected from Fe, Co, Ni, Cu, Mn, Zn, Sn and Bi. The auxiliary agent is used in catalytic cracking, and assists in improving catalytic cracking liquefied gas yield, and improving yields of low-carbon olefins such as ethylene, propylene, isobutylene, and the like. With the catalyst, low-carbon olefin concentration in catalytic cracking liquefied gas is improved, heavy oil conversion capacity of catalyst combination is improved, dry gas and coke selectivity is improved, and gasoline octane number is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking multifunctional strengthened additive

The invention provides multifunctional catalytic cracking strengthening additive which comprises a rare earth organic compound, heteropoly acid (and salt thereof), chemical inhibitor, solvent, and the like and has the functions of resisting oxidation and preventing from scorch, dispersing, increasing the acid center, passivating the metal, and the like. When being added into a catalytic cracking lifting pipe reactor, the multifunctional catalytic cracking strengthening additive can inhibit the generation of secondary reaction such as thermal cracking reaction, dehydrogenation condensation reaction, and the like, reduces the generation of side products of net gas, coke, hydrogen, and the like, and improves the yield coefficients of products with high added values, such as liquid gas (especially propylene), gasoline and diesel. The catalytic cracking strengthening additive has the function of metal deactivator and can replace the metal deactivator, therefore, the metal deactivator needs not to be added after the catalytic cracking strengthening additive is added. The invention has the function of resisting oxidation and preventing from scorch, can inhibit a lifting pipe and a settling vessel from being coked and prevent a reaction system from scale deposit, thereby being multifunctional catalytic cracking strengthening additive.

Owner:河北鑫泰精细化工有限公司

Method for reducing sulfide in light hydrocarbon oil

The invention provides a method used for reducing the content of sulfide in light hydrocarbon oil, which comprises the steps as follows: after being preheated, a hydrocarbon oil raw material containing sulfur, and hydrogen donor enter a reactor filled with a sorbent and a zeolite additive so as to react under the conditions as follows: temperature of 300-500 DEG C, pressure of 0.5-3.5MPa, weight hourly space velocity of raw material oil at 0.5-10h<-1> and weight ratio between total amounts of the sorbent and the hydrocarbon oil raw material at 1-20; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated and the zeolite additive to be regenerated after reaction are stripped, burned and regenerated; and the regenerated sorbent and the zeolite additive are reduced by the hydrogen donor and subsequently returned to the reactor so as to be circularly used. The method adds the zeolite additive during the adsorption desulfurization process, realizes deep desulfurization, leads the removal rate of the sulfur to achieve more than 96wt percent when disposing the gasoline, reduces the olefin of the gasoline, improves the octane number of the outcome gasoline simultaneously, keeps high liquid recovery and has low benzene content in the outcome gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline deep etherification modification method

ActiveCN103509591AIncrease the etherification contentIncrease liquid collectionTreatment with hydrotreatment processesHydrocarbon oils refiningAlcoholHeat resistance

The invention relates to a gasoline deep etherification modification method which comprises the following steps: an olefin-containing raw material and methanol are mixed; and in the presence of a solid strongly-acidic catalyst under the olefin etherification reaction condition of 95 DEG C above, secondary carbon olefin and tertiary carbon olefin in the gasoline and methanol are subjected to etherification reaction to obtain etherified gasoline, wherein the solid strongly-acidic catalyst is a high-temperature-resistant strongly-acidic catalyst, of which the heat resistance temperature is 125-250 DEG C and the acid core strength is greater than H0=-8.According to the method provided by the invention, the tertiary carbon olefin participates in the etherification reaction, and the secondary carbon olefin also participates in the etherification reaction, thereby greatly enhancing the etherified substance content in the gasoline, lowering the olefin content, enhancing the octane number, indirectly adding more cheap alcohols into the gasoline in a mode of etherified substances, increasing the liquid yield of the gasoline and lowering the gasoline cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulphurization sorbent composition

ActiveCN101433819AHigh desulfurization activityEvenly distributedOther chemical processesHydrocarbon oils refiningSorbentRare earth

The invention discloses a desulfurization adsorbent composition, which comprises 1 to 30 weight percent of phosphorus-modified rare earth-zeolite mixture, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide; a rare earth-zeolite mixture is modified by phosphorus and then is preformed with a carrier mixture into porous heat-resistant solid particles, and then active metal components are introduced on the solid particles to obtain an adsorbent; and a light hydrocarbon oil raw material containing sulfur and a hydrogen donor enter a reactor filled with the adsorbent, materials remained after the reaction are separated, a reaction product is sent into a subsequent separation system for product separation, a spent adsorbent after the reaction is steam-stripped and then is subject to coke-burning regeneration, and the regenerated adsorbent is reduced by the hydrogen donor and is returned to the reactor for cyclic use. The adsorbent realizes the deep removal of sulfide in light hydrocarbon oil, and the produced gasoline has higher octane number, lower benzene content, and higher strength at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

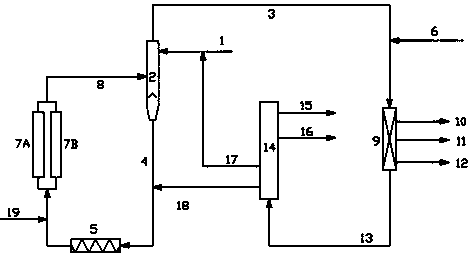

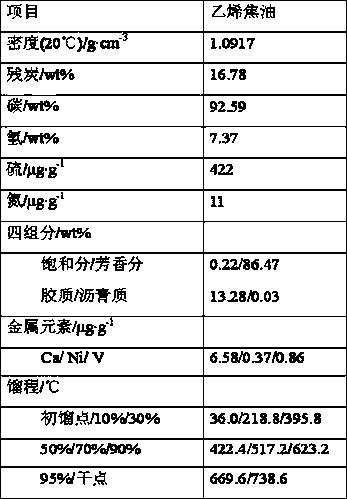

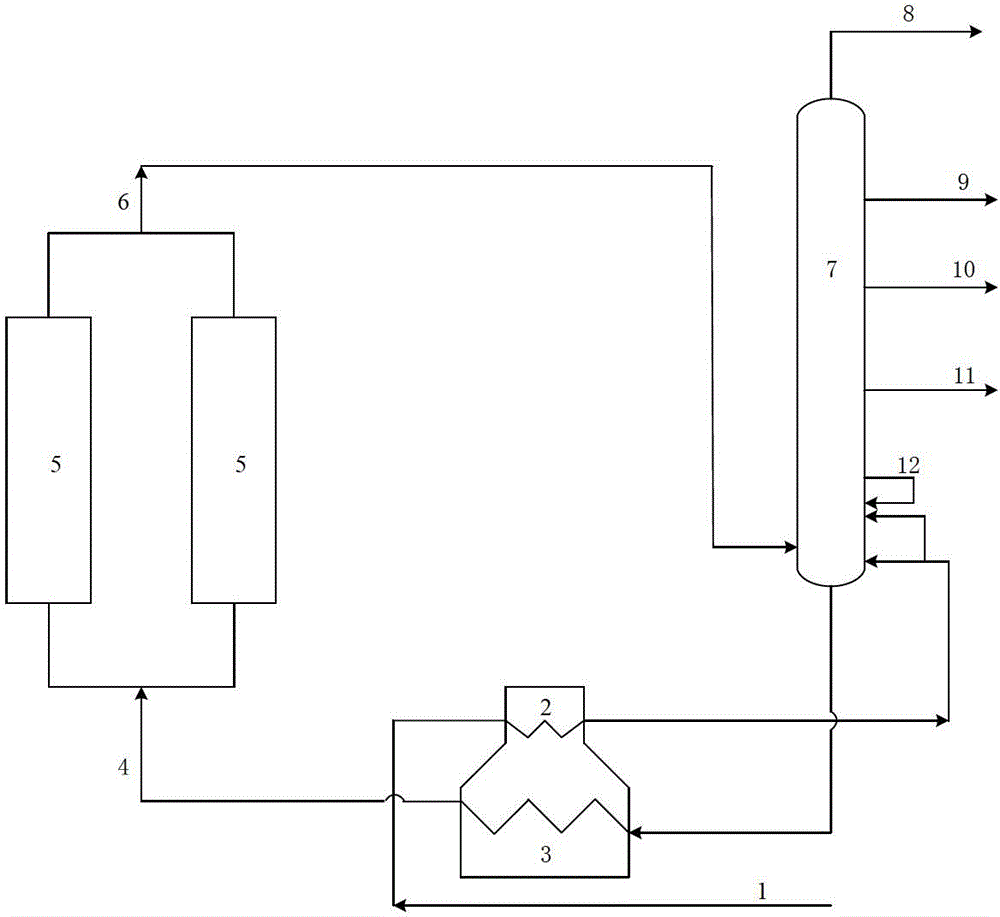

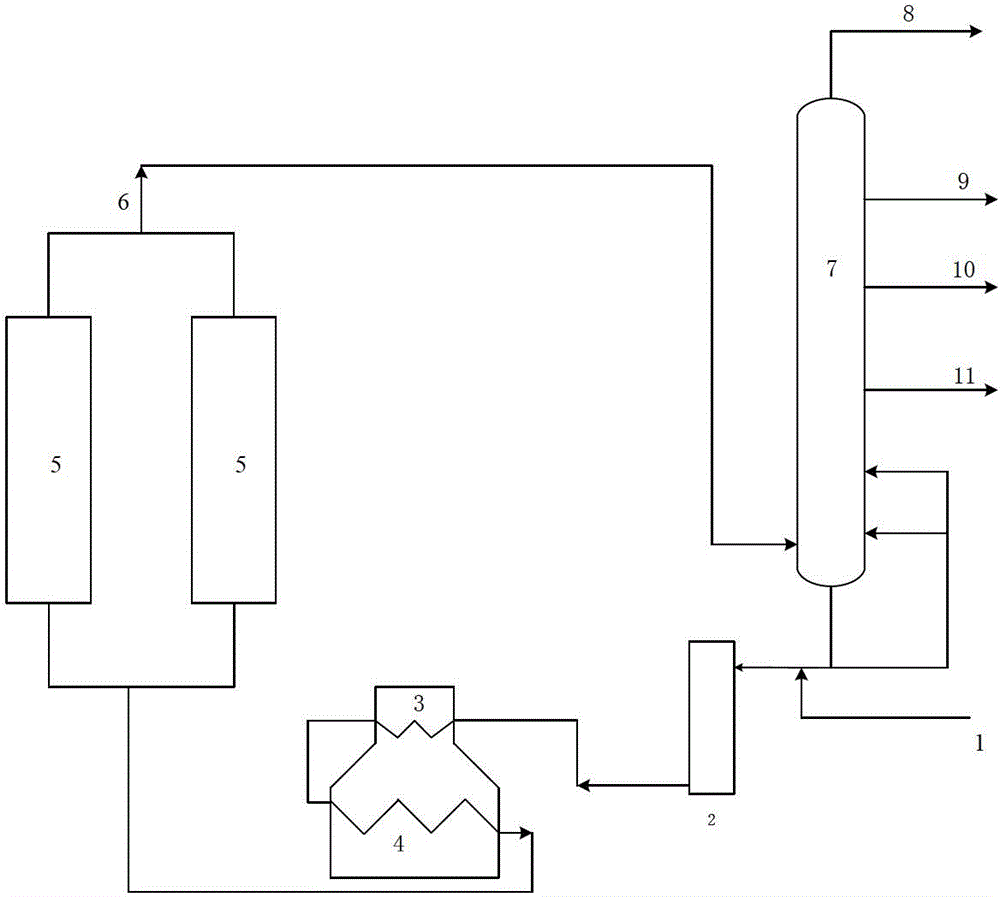

Process and system for treating ethylene tar

ActiveCN109929592APlay a role in strippingRestricted accessTreatment with hydrotreatment processesCracking reactionTreatment system

The invention discloses a process and a system for treating ethylene tar. According to the process, preheated ethylene tar contacts a coking reaction effluent from a delayed coking reaction system ina pretreatment reactor, and a light component and a heavy component are obtained after separation; the heavy component enters the delayed coking reaction system, and the generated coking reaction effluent enters the pretreatment reactor; the light component and hydrogen enter a hydrogenation reaction system, and the reaction effluent is separated to obtain gas, gasoline distillate, diesel oil distillate and heavy oil distillate; and the heavy oil distillate enters a catalytic cracking reaction system, and the catalytic diesel oil obtained after separation enters the pretreatment reaction. Thetreatment system comprises the pretreatment reactor, the coking reaction system, the hydrogenation reaction system, and the catalytic cracking reaction system. With the process and the system of the present invention, the stable long-cycle operation of the whole treatment system can be ensured, and the yield of the light oil product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bimetal reforming catalyst and its preparing process

InactiveCN1393513AGood choiceImprove anti-coking performanceCatalyst activation/preparationNaphtha reformingCatalytic reformingGasoline

A reforming bimetal catalyst for gasoline fraction contains VIII-family metal (0.1-1.0 wt.%), VIIB-family metal (0.1-1.0), phosphorus (0.1-5.0), chlorine (0.6-3.0) and gamma-Al2O3 as carrier (90-99.1). Its advantages are low carbon depositing speed, high stability of activity and high selectivity of arylhydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

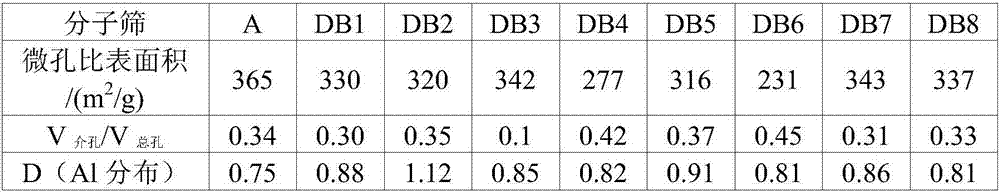

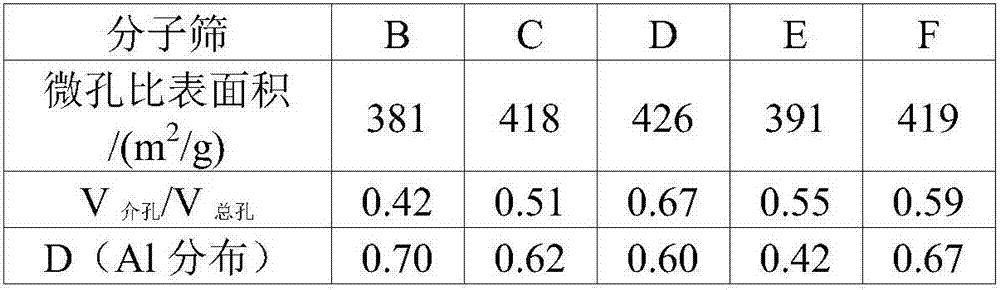

Catalytic cracking aid containing Beta molecular sieve rich in mesopores, and preparation method thereof

ActiveCN107971001AHigh yieldHigh selectivityCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

The invention discloses a catalytic cracking aid containing a Beta molecular sieve rich in mesopores, and a preparation method thereof. The catalytic cracking aid comprises, on the basis of the dry base weight of the aid, 10 to 75 wt% of the Beta molecular sieve rich in mesopores in terms of a dry base, 0 to 60 wt% of clay in terms of a dry base, 15 to 60 wt% of an inorganic oxide binder in termsof a dry base, 0 to 25 wt% of a phosphorus additive in terms of P2O5 and 0 to 15 wt% of a group-VIII metal additive in term of oxide, wherein the distribution parameter D of Al in the molecular sieveis no less than 0.4 and no more than 0.8; the micropore specific area of the molecular sieve is 350 to 500 m<2> / g; the mesopore volume of the molecular sieve accounts for 30 to 70% of total pore volume. The aid can improve the yield of isobutene and propylene and the octane number of gasoline when applied to catalytic cracking.

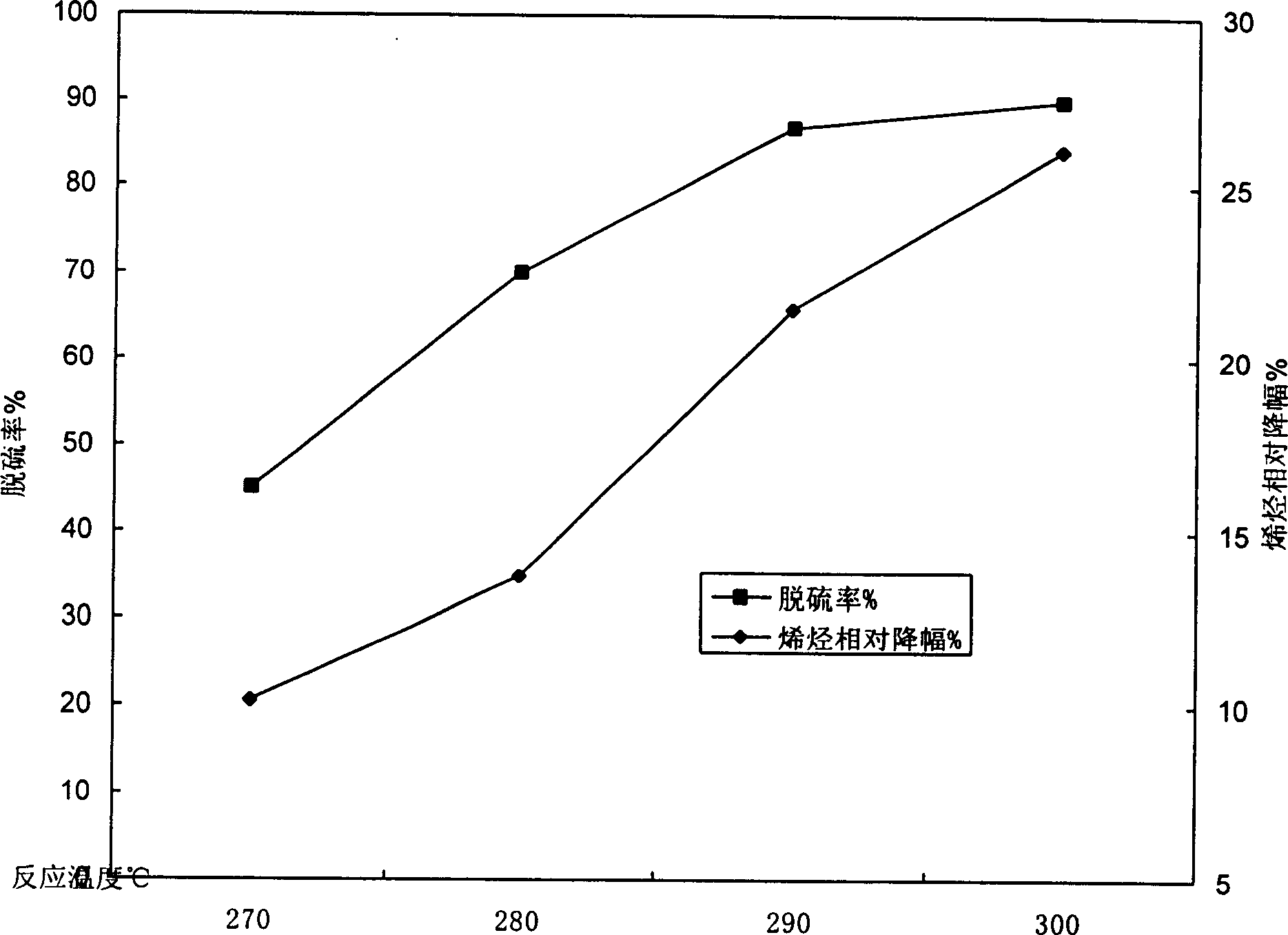

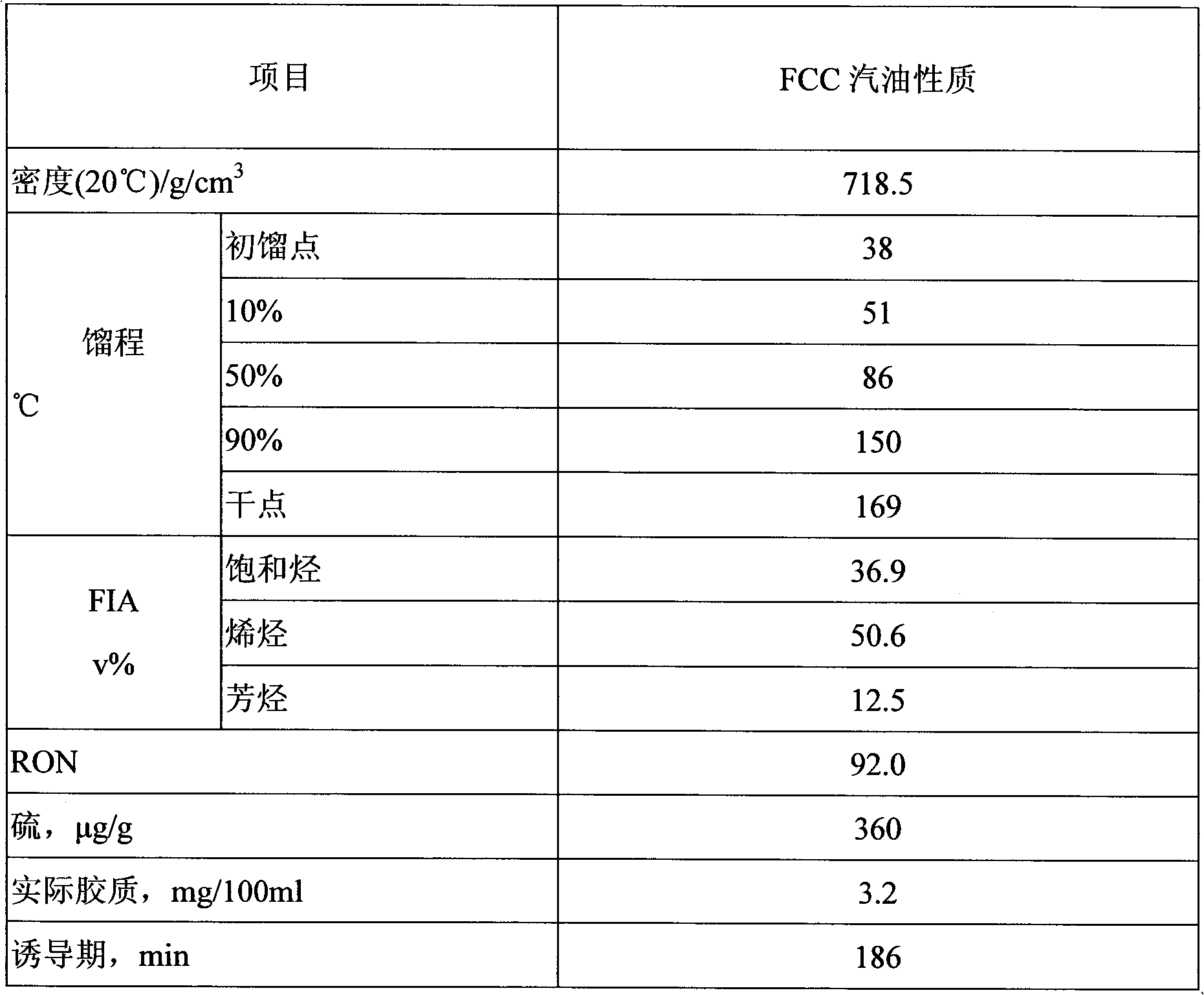

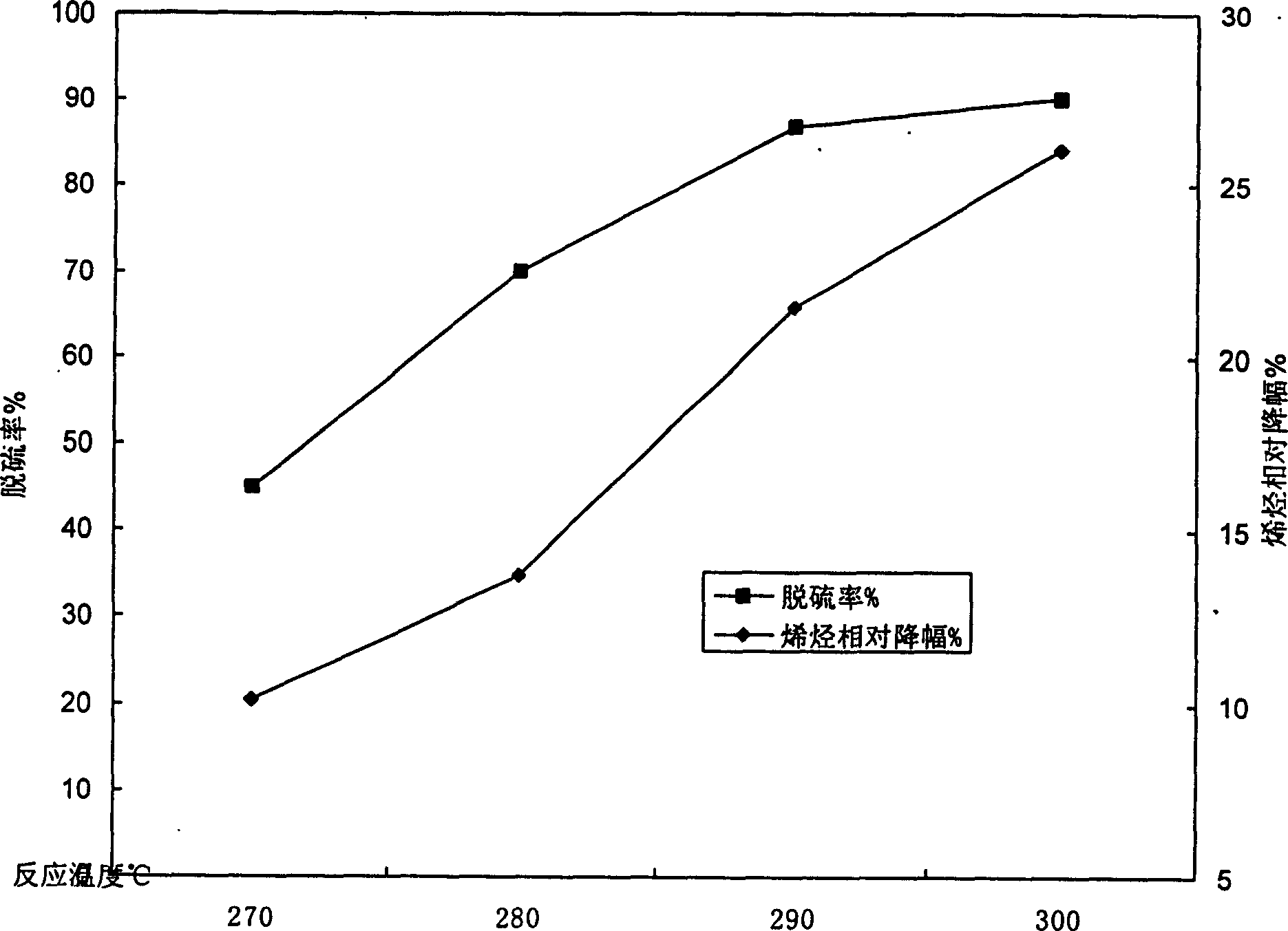

Catalytic process for selective hydrodesulfurization of gasoline

ActiveCN101845321AReduce sulfur contentIncrease liquid collectionTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention relates to a catalytic process for selective hydrodesulfurization of gasoline, which comprises the following steps of: performing hydrodesulfurization reaction on heavy gasoline obtained by cutting and fractionating catalytic gasoline under a hydrogenation condition through a catalyst bed, mixing the heavy gasoline and light gasoline subjected to alkaline cleaning, and removing mercaptan to obtain a blended gasoline product, wherein reaction conditions of hydrodesulfurization of the heavy gasoline are that: the temperature is between 150 and 450 DEG C, the pressure is between 1.0 and 5.0MPa, the liquid hourly space velocity is between 1.0 and 6.0 h<-1>, and the hydrogen-gasoline ratio is between 50 and 1,000v / v; and the catalyst takes monomers of Al2O3, TiO2, MgO, SiO2 or composite oxides as a carrier, takes Mo or W and Co or Ni metal as active ingredients and takes P, B or Mg as a modifier. The method can greatly reduce the sulfur content of the catalytic gasoline, wherein the desulfurization rate is no less than 80 percent; and the method can make the octane number loss of gasoline products less, wherein the octane number loss is no more than 1.5 units.

Owner:PETROCHINA CO LTD

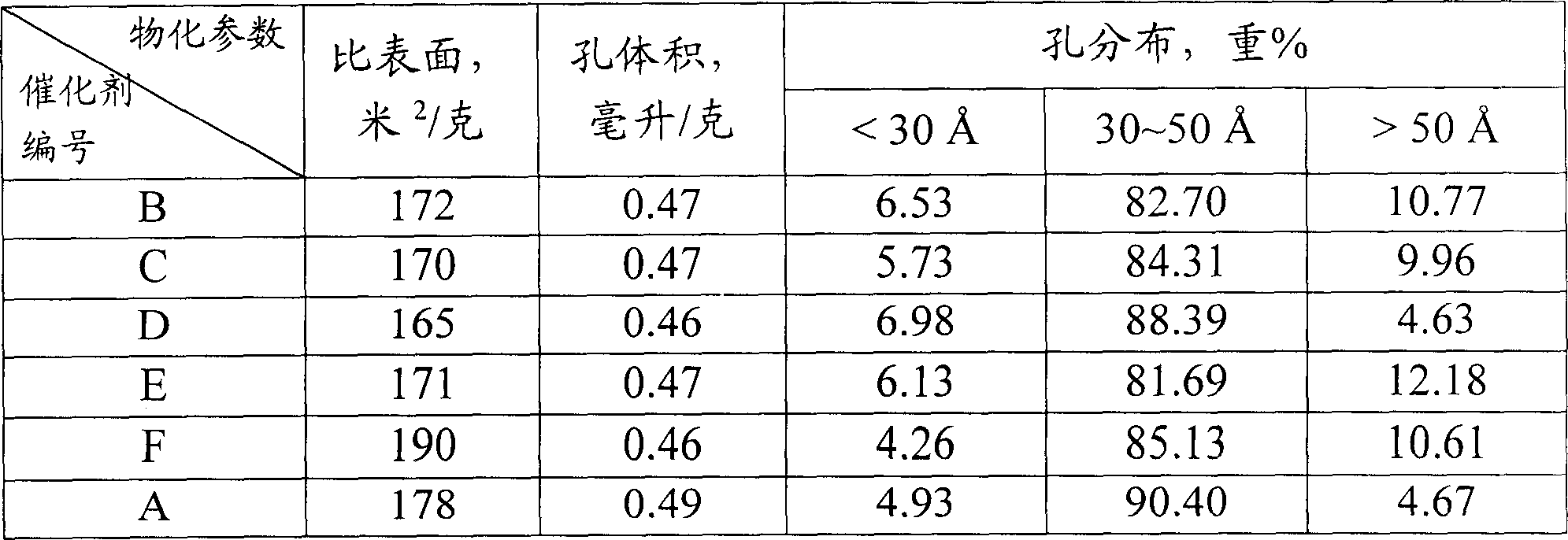

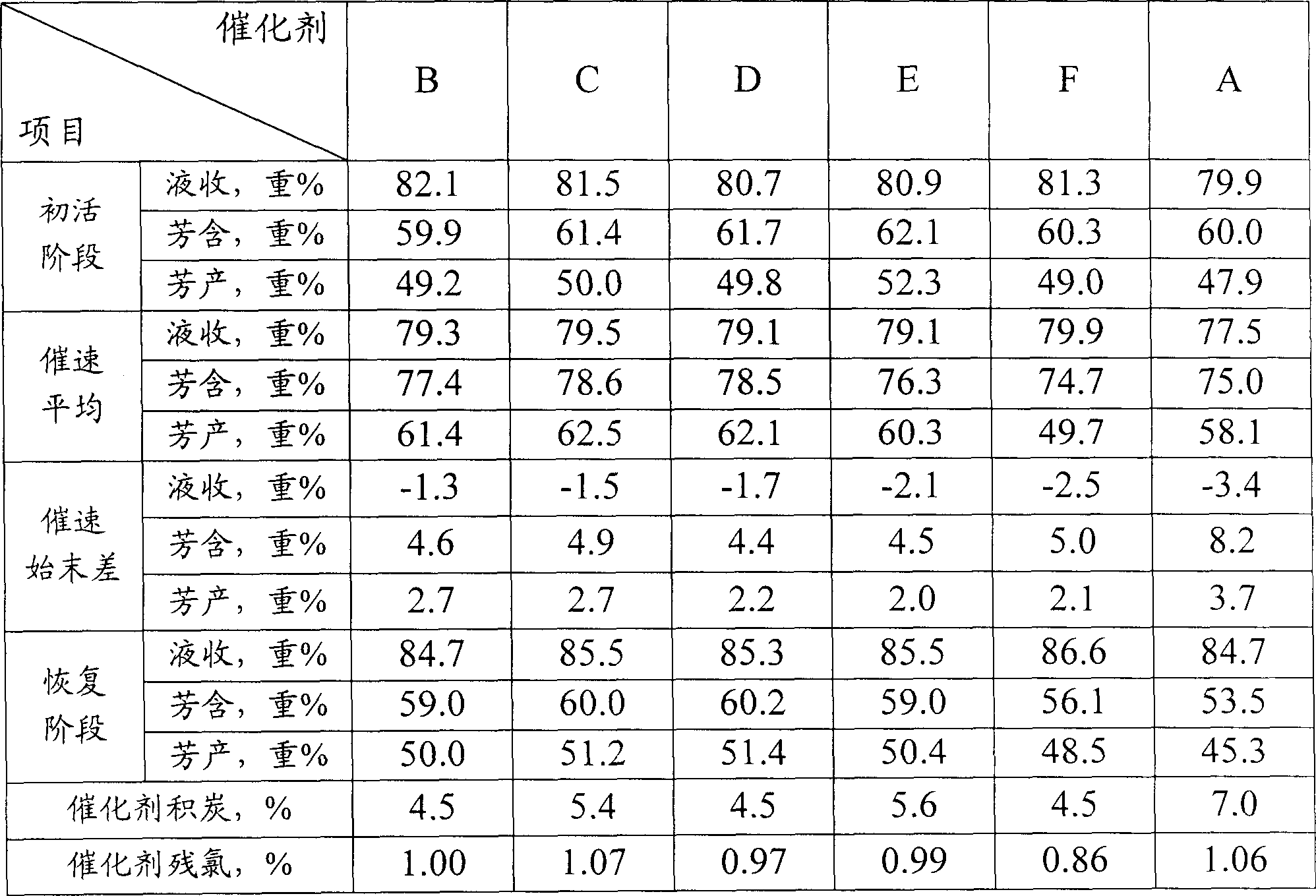

Naphtha reforming catalyst and preparation method thereof

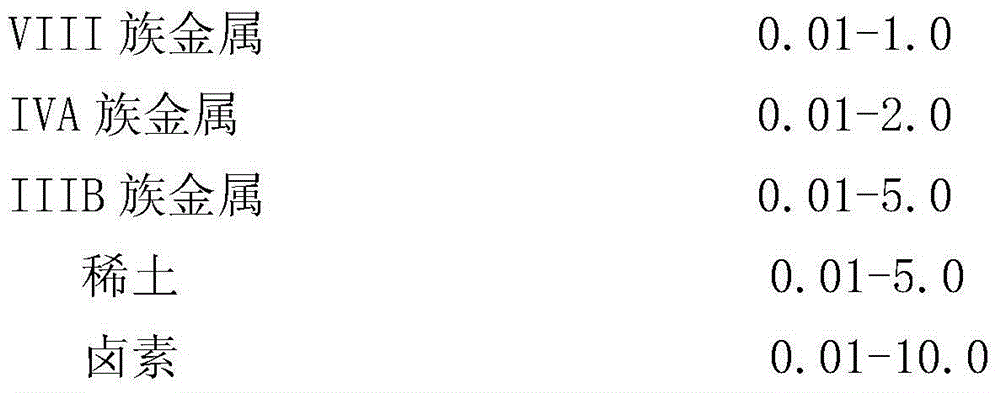

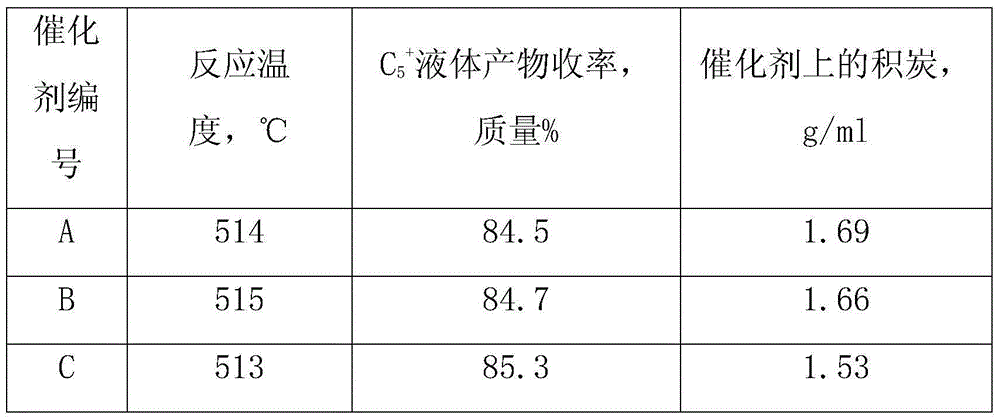

InactiveCN105771981AHigh activityHigh selectivityCatalytic naphtha reformingMetal/metal-oxides/metal-hydroxide catalystsHalogenNaphtha

The invention belongs to the technical field of catalyst and relates to a naphtha reforming catalyst and its preparation method. The catalyst comprises a carrier and VIII group metal, IVA group metal, rare-earth metals Ce and Y and a halogen component. The method comprises the following steps: gamma-alumina is respectively contacted with solutions containing Ce and Y to make the carrier adsorb Ce and Y and is then contacted with VIII group metal, and the carrier needs to be dried and roasted after each time of contact. The invention has the following advantages: the catalyst has high aromatics selectivity, liquid yield and stability and low carbon deposit rate.

Owner:PETROCHINA CO LTD

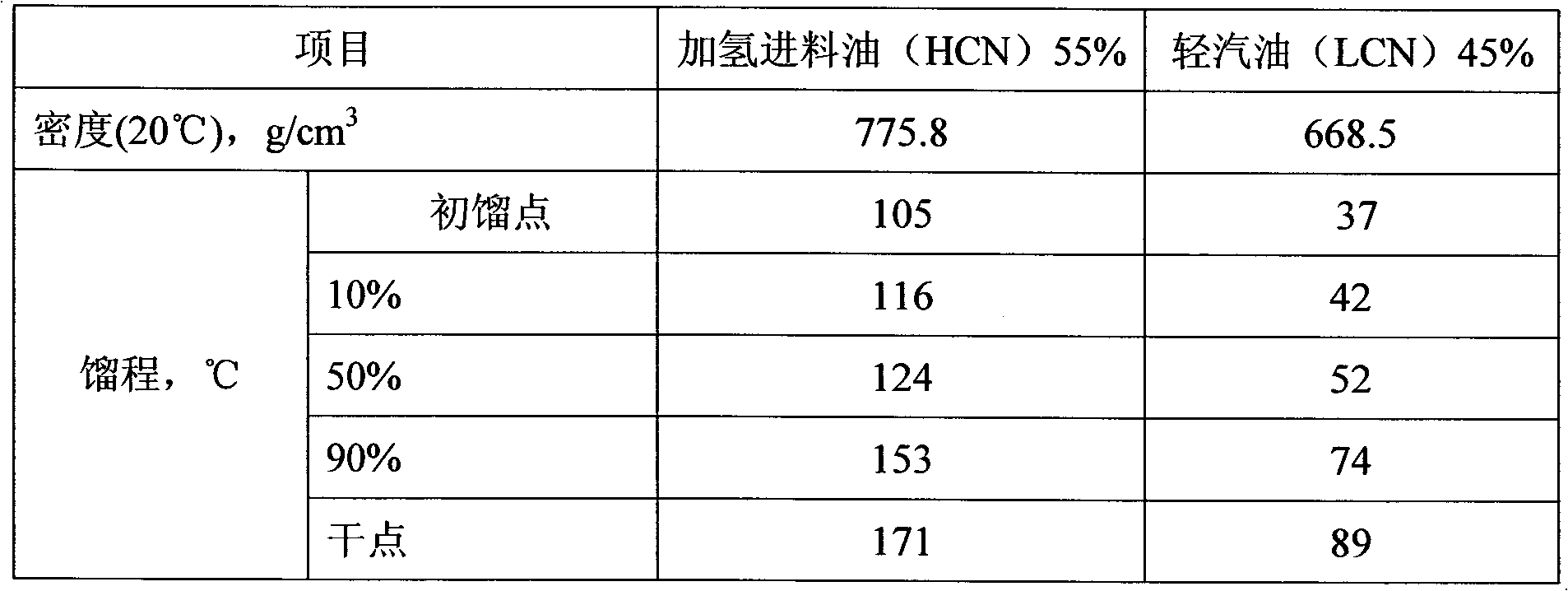

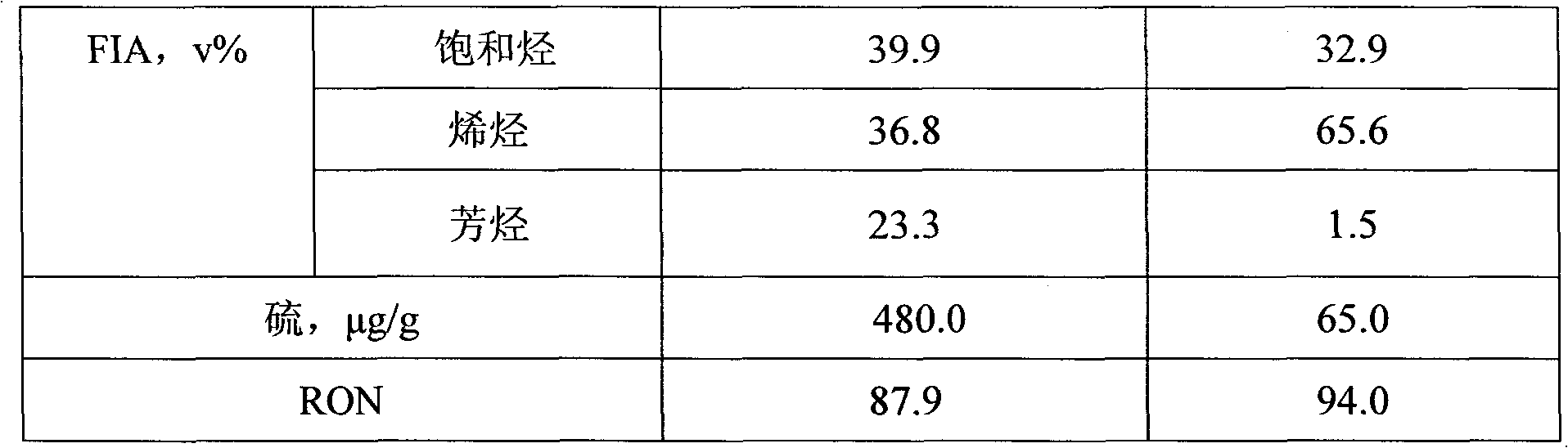

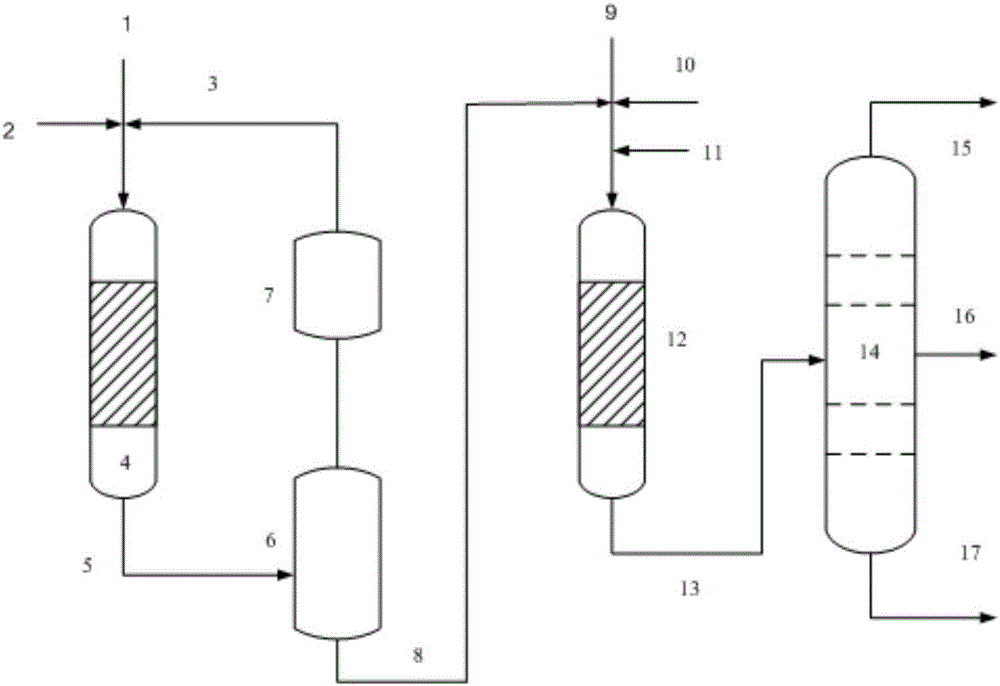

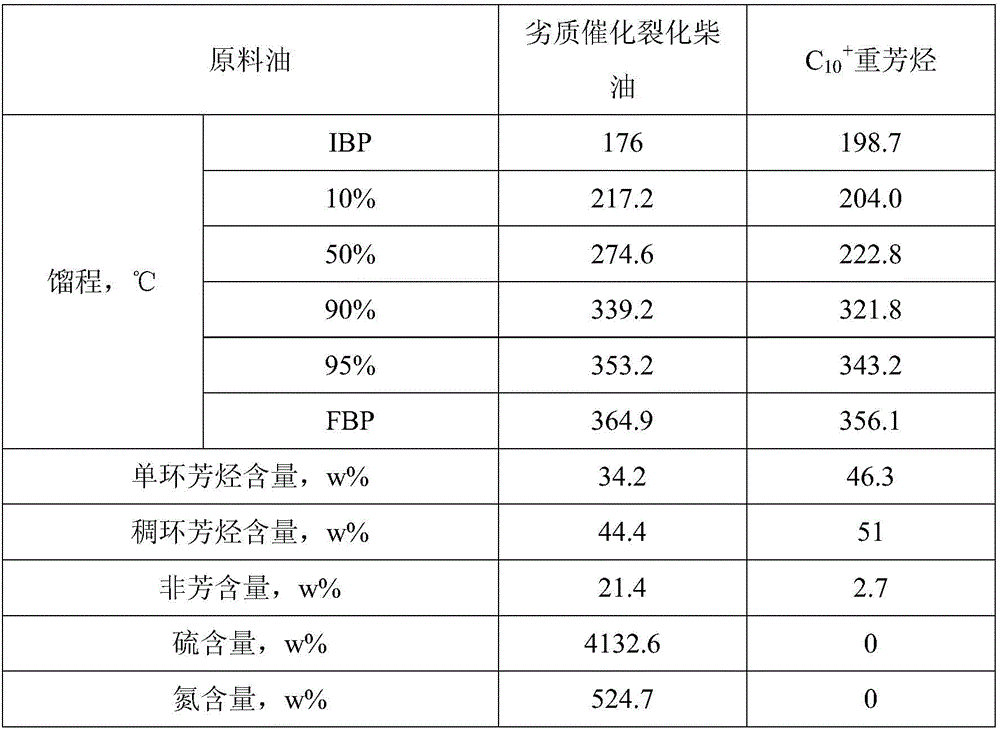

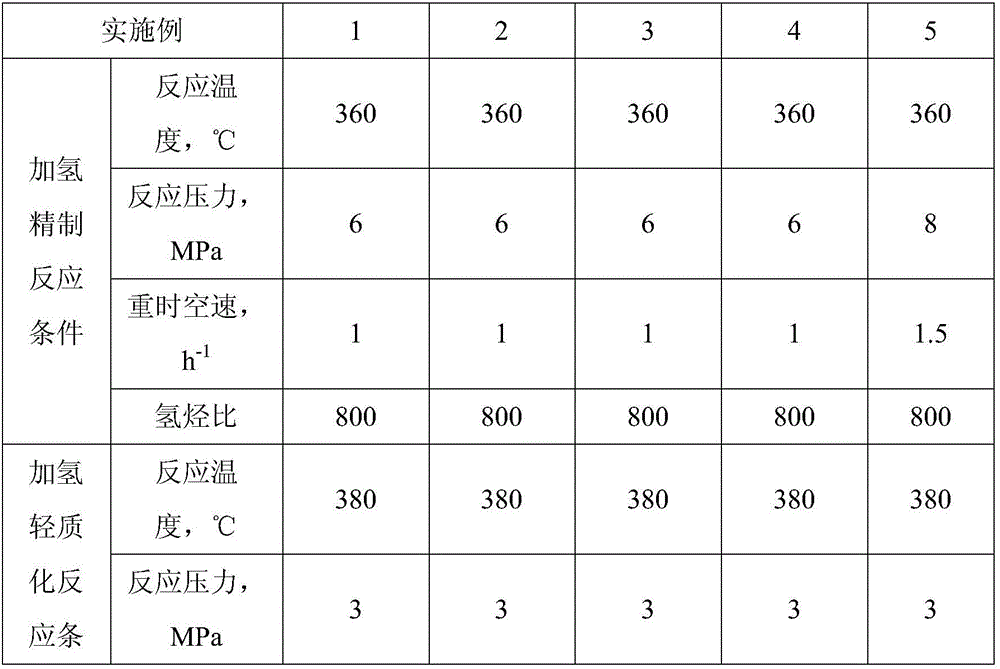

Combined technique for improving yield of high-octane gasoline by using inferior catalytic cracking diesel

ActiveCN106047404AAchieve ultra-deep removalAchieve maximum retentionTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonHydrogen atmosphere

The invention relates to a combined technique for improving yield of high-octane gasoline by using inferior catalytic cracking diesel. The combined technique comprises the following steps: firstly, carrying out polycyclic aromatic hydrocarbon selective hydrogenation, desulfurization and denitrification reaction on the inferior catalytic cracking diesel through a hydrofining reactor at a hydrogen atmosphere and under a relatively gentle refining condition; feeding a refined liquid-phase product into a reactor for conversion to light fraction and filled with a noble metal catalyst and carrying out hydrogenation conversion to light fraction; and finally, achieving the purpose of increasing the yield of the high-octane gasoline. By the technique, the inferior catalytic cracking diesel can be treated, and meanwhile, reforming C10+ heavy aromatics are converted to light fraction; the combined technique has relatively high gasoline fraction yield, gasoline fraction aromatics selectivity and liquid yield, and meanwhile, the inferior catalytic cracking diesel and the C10+ heavy aromatics are utilized effectively at high value.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Nobel metal hydrogen cracking catalyst and its preparing method

The present invention discloses a kind of noble metal hydrogen cracking catalyst and its preparation process. The catalyst contains one carrier component, one modified Y-type zeolite, and one or two kinds of noble metal components. The catalyst features that the hydrogenating noble metal component is loaded onto the carrier component and that the modified superhydrophobic Y-type zeolite containing no hydrogenating component is deep treated to possess great specific surface area, great pore volume, proper acid distribution and high Si / Al ratio. The catalyst has high metal dispersivity, powerful carbon deposition resistance and certain sulfur resistance, and may be used in hydrogen cracking, hydrogenation, hydrogen modification, etc. of fraction oil with high selectivity to middle fraction oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

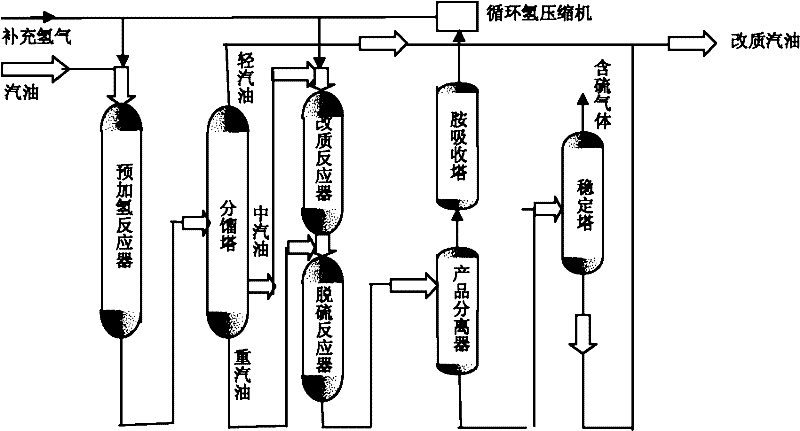

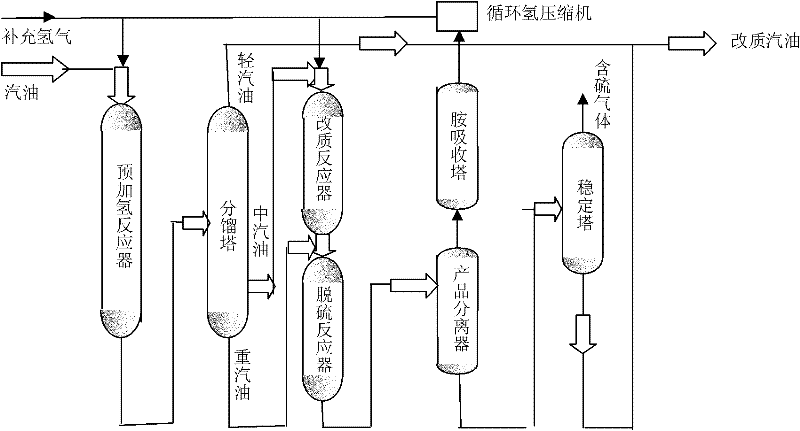

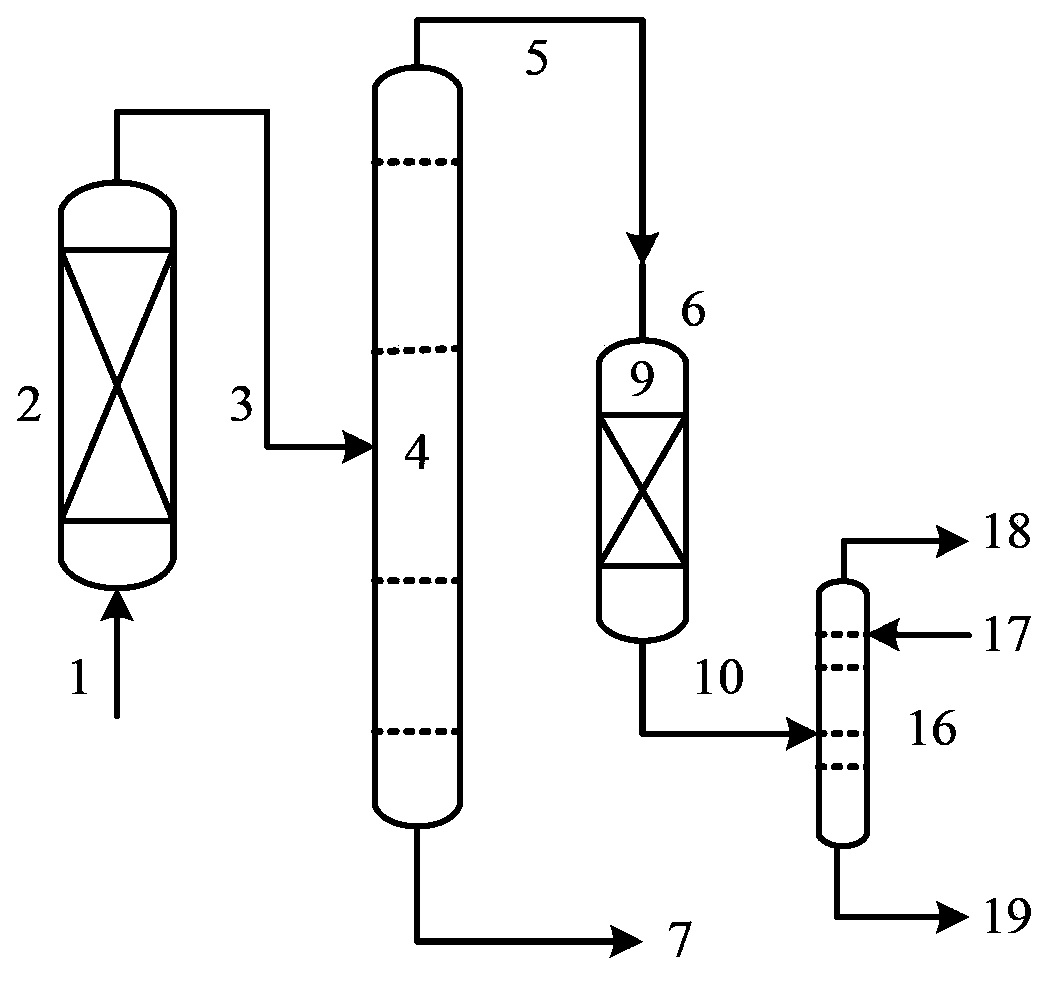

Method for inferior gasoline modification

ActiveCN102634368AReduce olefin contentReduced mercaptan contentTreatment with hydrotreatment processesLiquid productIsomerization

The invention relates to a method for inferior gasoline modification; gasoline raw materials and hydrogen are mixed, and the mixture is allowed to enter a prehydrogenation reactor for dialkene removal; the prehydrogenation products are allowed to enter a fractionating tower so as to cut the gasoline into light, medium, and heavy components; light gasoline from the tower top is directly used as a clean gasoline blending component; the medium gasoline component from the lower section of the fractionating tower is allowed to enter a hydrogenation modification reactor firstly for reactions such as aromatization, isomerization, and the like, then to mix with heavy gasoline from the bottom of the fractionating tower and to enter a hydrodesulfurization reactor; materials from the hydrodesulfurization reactor is cooled, and is allowed to enter a product separation device for gas-liquid separation; hydrogen from the gas-liquid separation device is treated by desulphurization and then recycled; liquid products enter a product stabilization tower to remove light hydrocarbon and hydrogen sulfide generated during the reaction, and then are mixed with the light gasoline to obtain the modified gasoline products; the method of the invention can greatly reduce sulfur and alkene contents in gasoline, and can reduce octane number loss due to the modification process.

Owner:PETROCHINA CO LTD

Anthracene oil hydrogenation method

ActiveCN105462610AAdd depthIncrease liquid collectionTreatment with hydrotreatment processesAnthraceneHydrogen purity

The invention discloses an anthracene oil hydrogenation method. According to the method, anthracene oil is diluted with hot low-pressure segregator oil, and then the diluted oil and inlet hydrogen are mixed to undergo hydrofining so as to obtain a hydrofining product; the hydrofining product is separated to obtain refined hot low-pressure segregator oil; part of the refined hot low-pressure segregator oil and inlet hydrogen are mixed, and new hydrogen is supplemented to carry out hydrocracking so as to obtain a hydrocracking product; the hydrocracking product is separated to obtain cracked cold high-pressure segregator oil; the cracked cold high-pressure segregator oil and refined cold high-pressure segregator oil are mixed and separation is then carried out to obtain cold low-pressure segregator oil; and the cold low-pressure segregator oil undergoes fractionation so as to obtain a product. by the method of introducing inlet hydrogen in the hydrofining stage and supplementing new hydrogen in the hydrocracking stage, the hydrogen circulatory system and new hydrogen joint point are adjusted, hydrogen purity and hydrogen partial pressure in the hydrogen circulatory system are guaranteed, hydrofining and hydrocracking depth is enhanced, liquid yield of the product is raised, and tail oil quantity is reduced. The method has advantages of simple technological flow, high conversion rate and stable plant operation.

Owner:HUADIAN HEAVY IND CO LTD

Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

InactiveCN1218021CImprove anti-coking performanceHigh activityRefining to eliminate hetero atomsLiquid productActive component

The gasoline hydrogenating catalyst includes the components of carrier with TiO2 in 20-90 wt%; active component A of VIII metal oxide in 0.1-8 wt%; active component B of VIB metal oxide in 1-13 wt%; and adhesive in the rest content. After being pre-sulfurized, the catalyst of the present invention is used to process FCC gasoline in condition of mild hydrogenation and exhibits very high hydrodesulfurization activity and selectivity. Compared with traditional hydrogenation catalyst, the catalyst of the present invention has less loss of gasoline octane number and higher liquid product yield, up to 99 wt%, in the condition of same hydrodesulfurization level.

Owner:BEIJING HAISHUNDE TITANIUM CATALYST

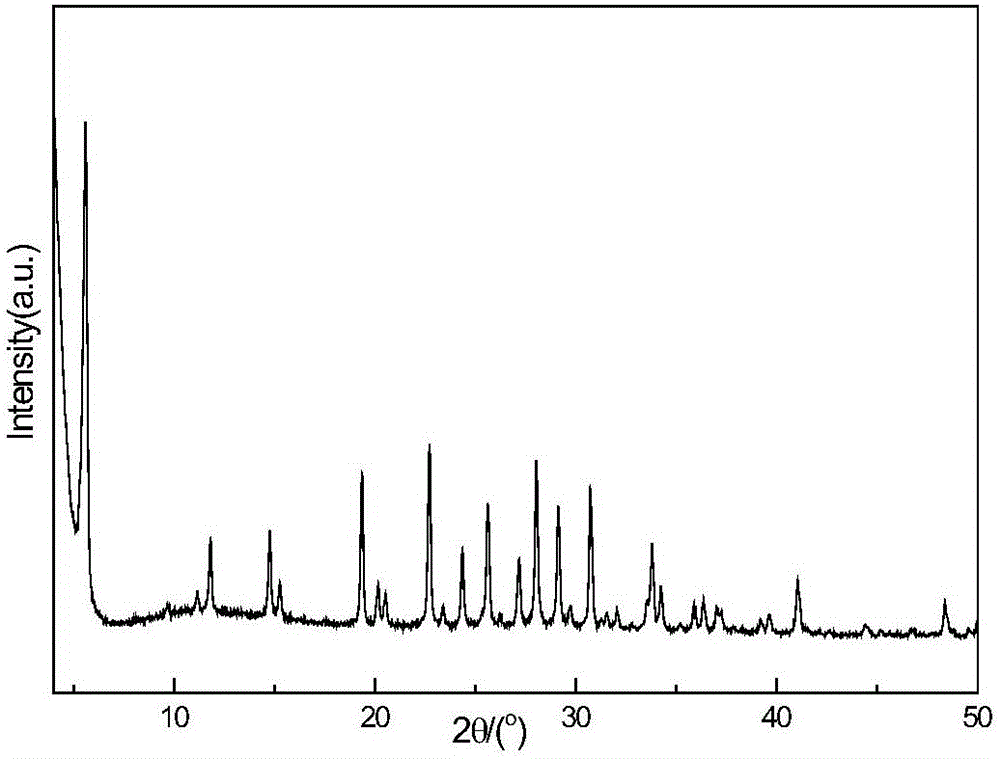

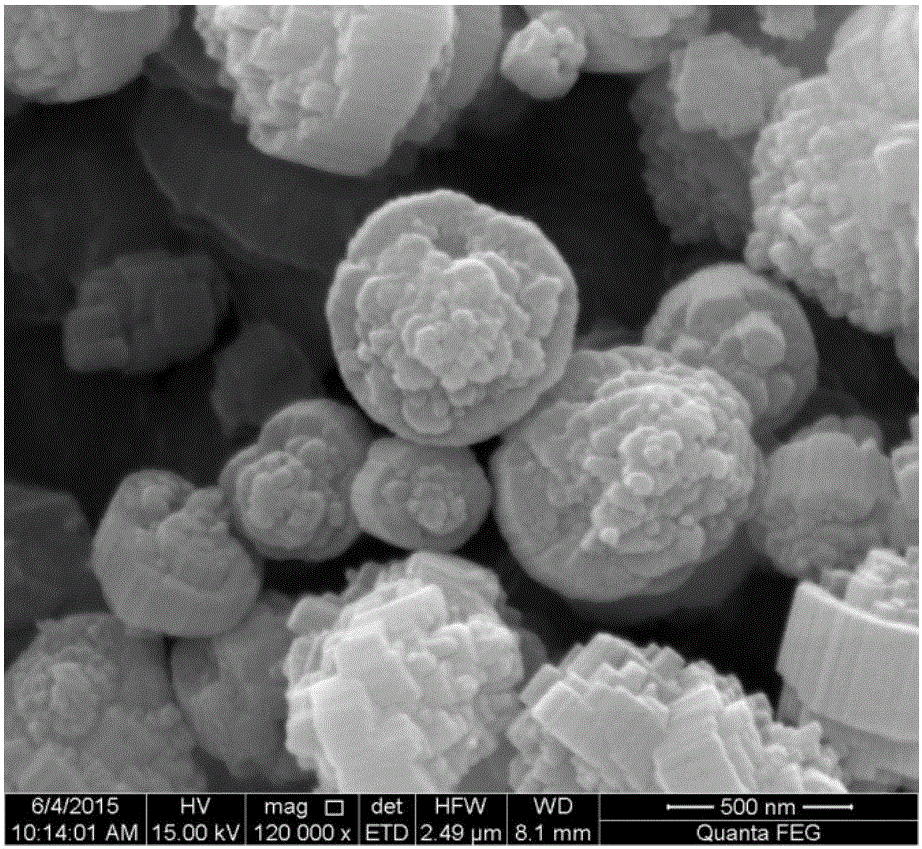

Ba hetero atom-containing LTL molecular sieve as well as preparation method and application thereof

ActiveCN106395851AThe synthesis method is simpleHigh yield in one potMolecular sieve catalystsHydrocarbonsMolecular sieveParaffin oils

The invention discloses Ba hetero atom-containing LTL molecular sieve and a preparation method thereof. The preparation method of the molecular sieve comprises the following steps: a barium source, inorganic base, an aluminium source, a silicon source, water and alcohol are mixed according to a mol ratio in order to obtain sol, aging and crystallization are carried out in order, obtained solid is separated, washing and drying are carried out, and after roasting, the molecular sieve is obtained. The molecular sieve is advantageous in that: 1. the synthetic method is simple, single kettle yield is high, and synthesis and operation cost are low; 2. the product has good degree of crystallization, purity, and structured morphology; 3. the Ba hetero atom-containing LTL molecular sieve is used in an aromatization reaction of normal paraffins, and can obviously improve yield of aromatic hydrocarbons, especially yield of C8 aromatic hydrocarbons, and the molecular sieve has good application prospects.

Owner:SYNFUELS CHINA TECH CO LTD

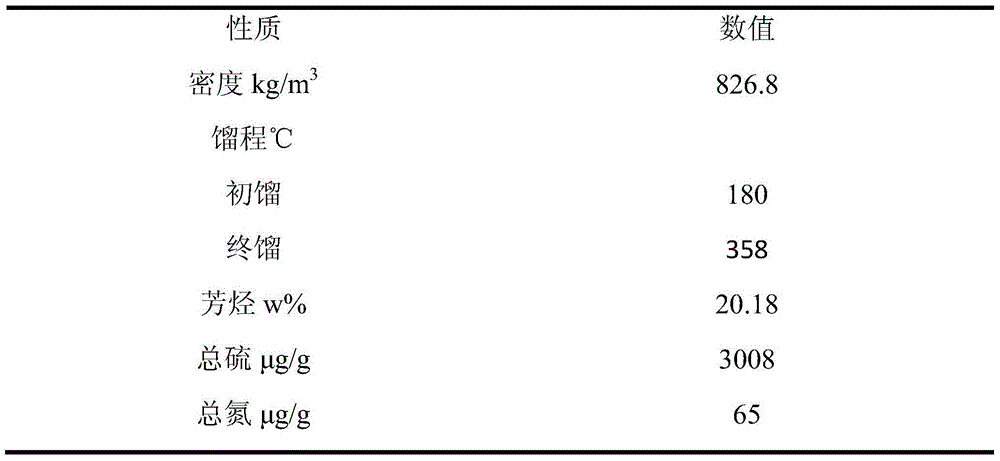

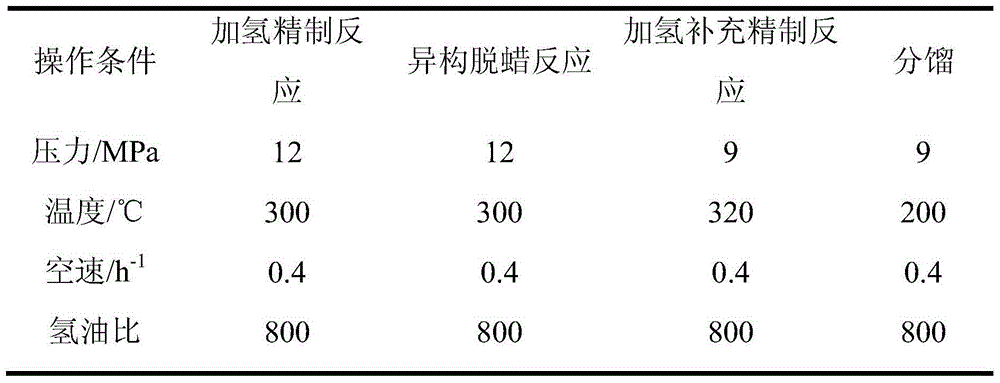

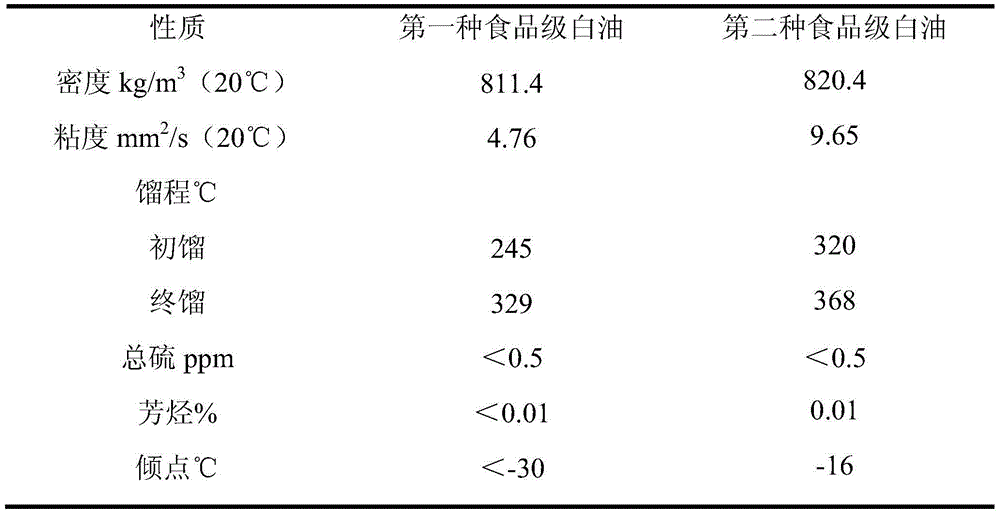

Method for producing food-grade white oil with atmospheric-vacuum extraction oil

ActiveCN104910963AWide distillation rangeExtended service lifeTreatment with hydrotreatment processesIsomerizationVacuum extraction

The invention discloses a method for producing food-grade white oil with atmospheric-vacuum extraction oil. According to the invention, the raw material atmospheric-vacuum extraction oil is heated; the oil is delivered into two serially connected reactors respectively loaded with a catalyst I and a catalyst II, and contacts the catalysts; under the effect of a hydro-refining catalyst, a hydro-treating reaction is carried out, and de-S, de-N and aromatic saturation reactions are carried out; a refined product is subjected to gas-liquid separation, stripping and fractionation, such that produced H2S is removed; a component with a boiling point higher than 230 DEG C is cut from a distillate, and is adopted as a feed of an isomerization dewaxing reaction; the isomerization dewaxing reaction is carried out with a catalyst III; an oil product produced through the isomerization dewaxing reaction is cooled, and is subjected to a hydro-finishing reaction with a catalyst IV; an oil product obtained after the reaction is subjected to product cutting in a fractionation system, such that the food-grade white oil with an aromatic hydrocarbon content lower than 0.01% w / w, a sulfur content lower than 1ppm, and a solidifying point lower than -30 DEG C is obtained.

Owner:洛阳金达石化有限责任公司

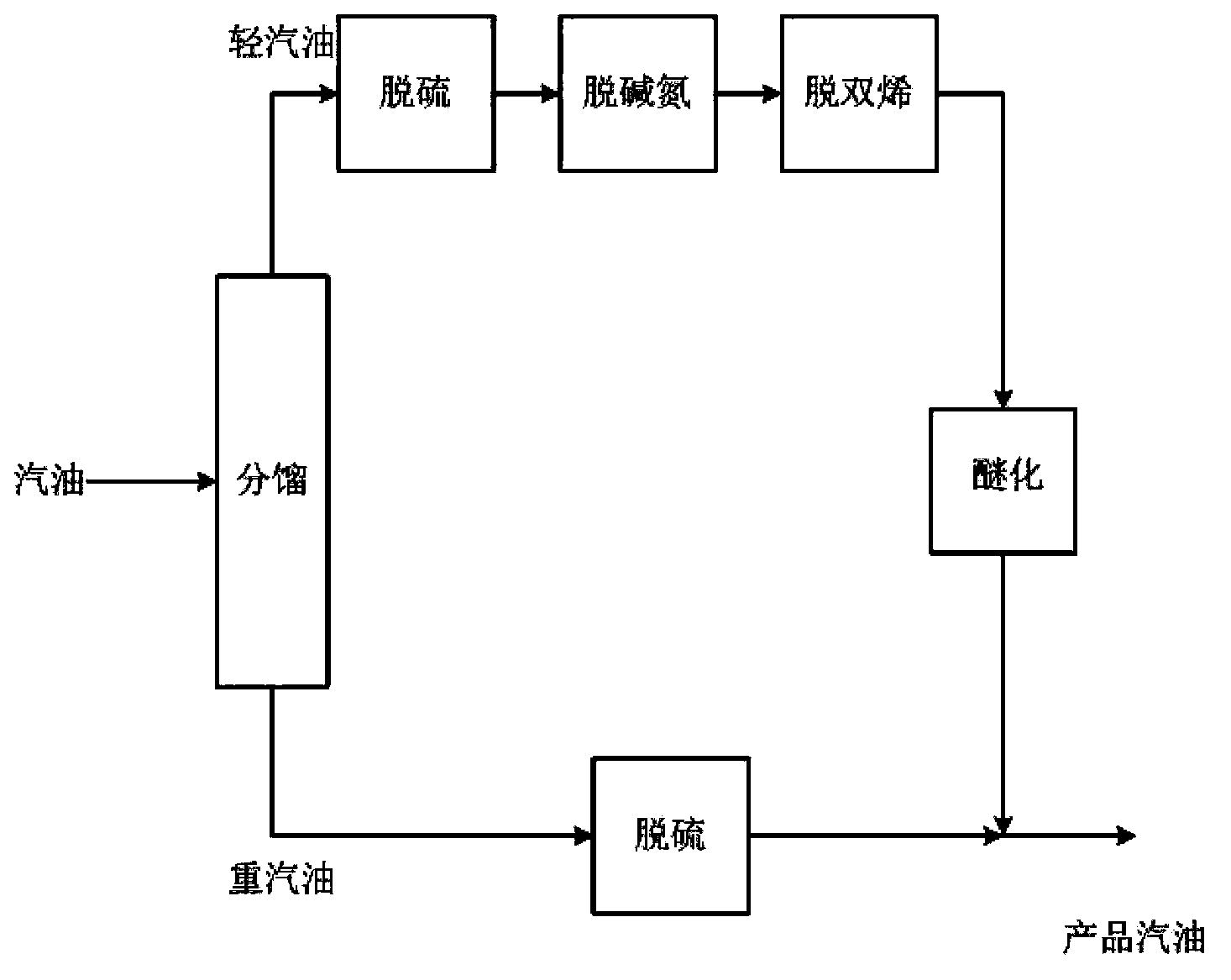

Method for producing clean gasoline

ActiveCN103773479AIncrease the content of etherification productsIncrease liquid collectionTreatment with hydrotreatment processesSulfideEther

The invention discloses a method for producing clean gasoline. The method comprises the following steps: (1) making a gasoline raw material contact an adsorption desulfurization catalyst in a refining reactor in the presence of hydrogen, adsorbing and removing sulfides from the gasoline, and meanwhile, performing selective hydrogenation to remove diene from the gasoline;(2) introducing the gasoline refined in the step (1) into an etherification reactor, reacting olefin in the gasoline with alcohol to generate ether to obtain an etherified gasoline product in the presence of a solid high-acid catalyst at the temperature of higher than 95 DEG C, wherein the solid high-acid catalyst is a high-temperature-resistant high-acid catalyst with the heat-resistance temperature of 125 DEG C to 250 DEG C and the acid site strength H0 greater than minus 8. According to the method provided by the invention, sulfur and the diene are removed from the gasoline, the etherate content of a gasoline product is greatly improved, and a clean gasoline product with high octane rating can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dewaxing catalyst for lubricant oil distillate and its uses

The invention disclosed a kind of lubricating oil deparaffinage catalyst as well as its application during the deparaffinage process. The mentioned catalyst contains TON and / or MTT molecular sieve, at least one VIII group precious metal and zinc, the ratio of zinc and VIII group precious metal is 0.1-50. According to the invention, the zinc can regulate the catalyst's acidifying function and hydrogenating function so as to improve the activity and selectivity of the catalyst. If the catalyst is used in the deparaffinage process of lubricating oil to get the base oil of the same pour point, it can increase the liquid yield and base oil yield by 1.5wt%-5wt% and 2wt%-10wt% respectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

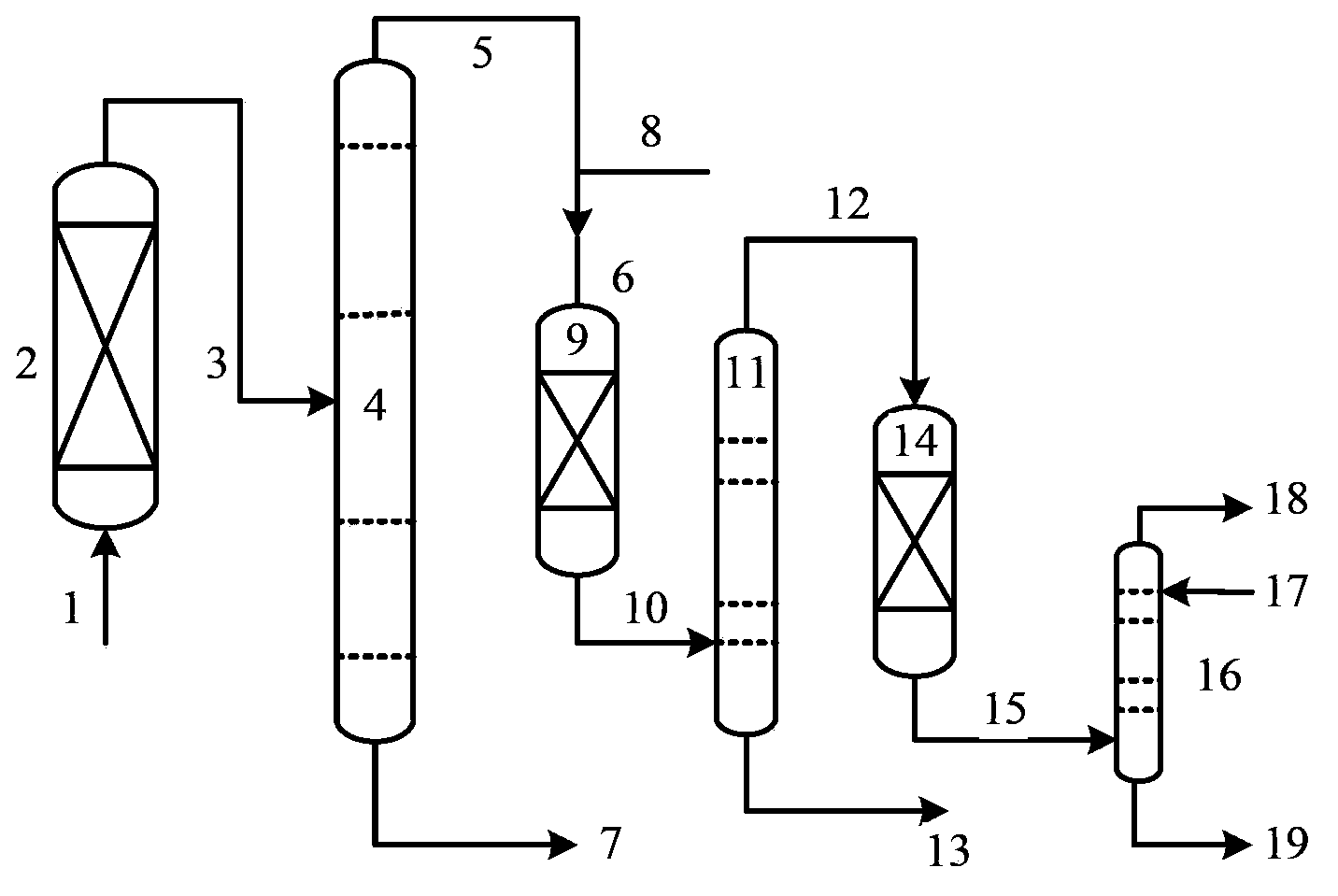

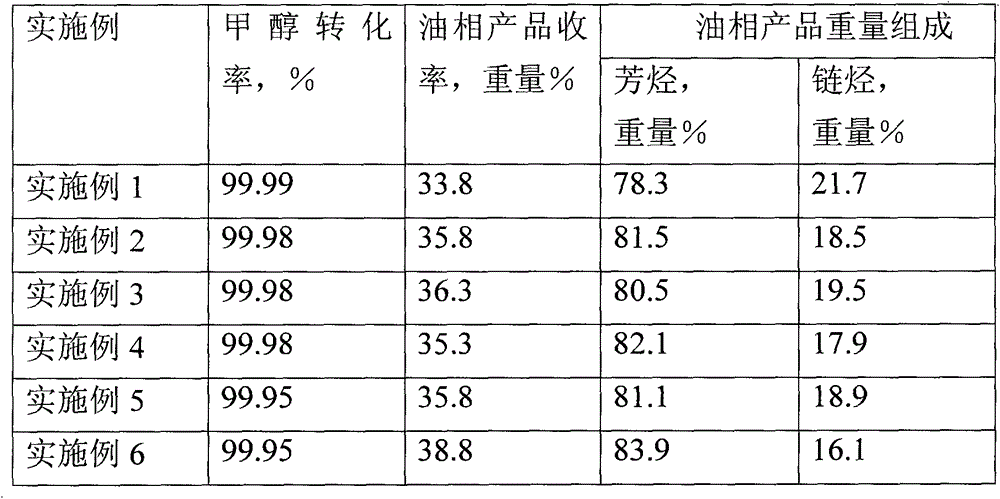

Methanol aromatization technology

ActiveCN104098418AImprove stabilityLong life one wayHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionLiquid productLiquid gas

The invention disclose a methanol aromatization technology which includes following steps: 1) feeding methanol into a tube side of a reactor to enable the methanol to contact with a tube-side catalyst with an operation temperature being 400-450 DEG C and an operation pressure being 0.1-5 Mpa, wherein a liquid space velocity of the raw material methanol is 0.5-7.0 h<-1>; 2) feeding a reaction product out of the tube side into a shell side of the reactor to enable the reaction product to contact with a shell-side catalyst with an operation temperature being 330-380 DEG C, an operation pressure being 0.1-3.5 Mpa and an operation space velocity being 0.4-4.0 h<-1>; performing a catalytic convention reaction in the shell side to obtain C5+ hydrocarbon liquid products and performing a rectification separation process to obtain aromatic hydrocarbons and non-aromatic hydrocarbons; and performing a separation process to gas products in shell-side products, wherein low-carbon olefins are fed back to the shell side of the reactor for being subjected to a reaction continuously. By means of the technology, utilization of the methanol can be increased, a complex reaction can be simplified, selectivity of the low-carbon olefins is enhanced and generation of dry gas and liquefied gas can be reduced.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

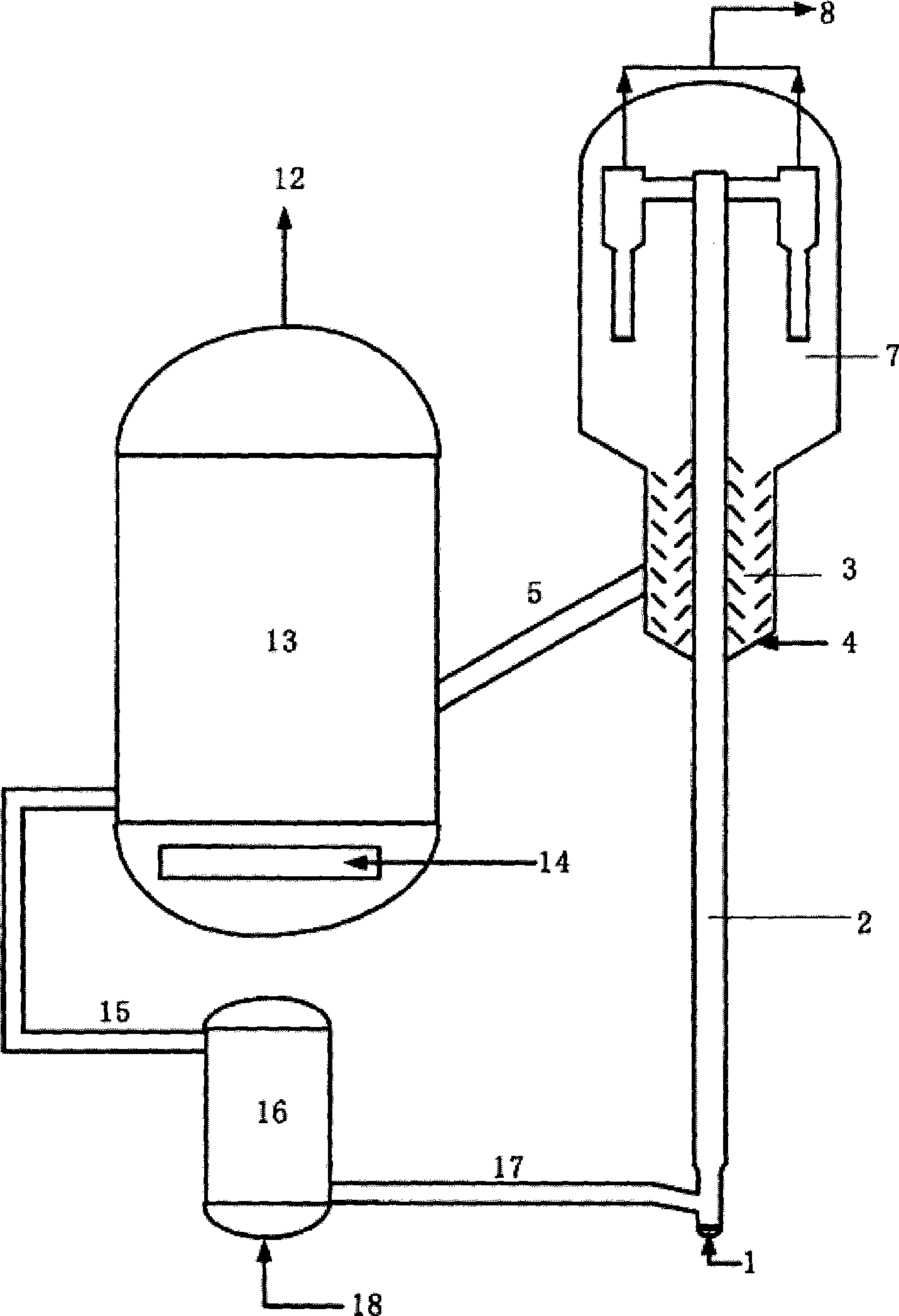

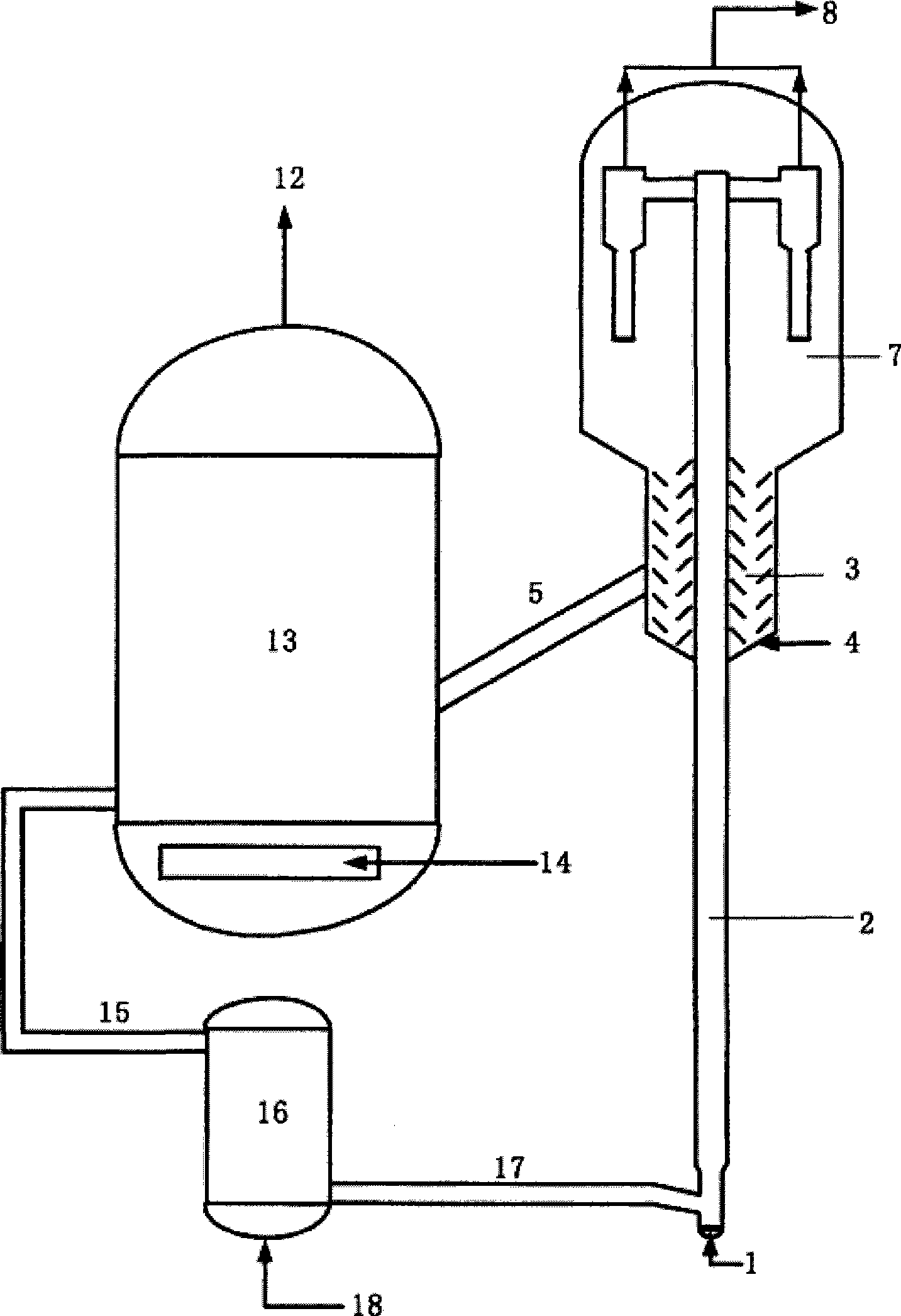

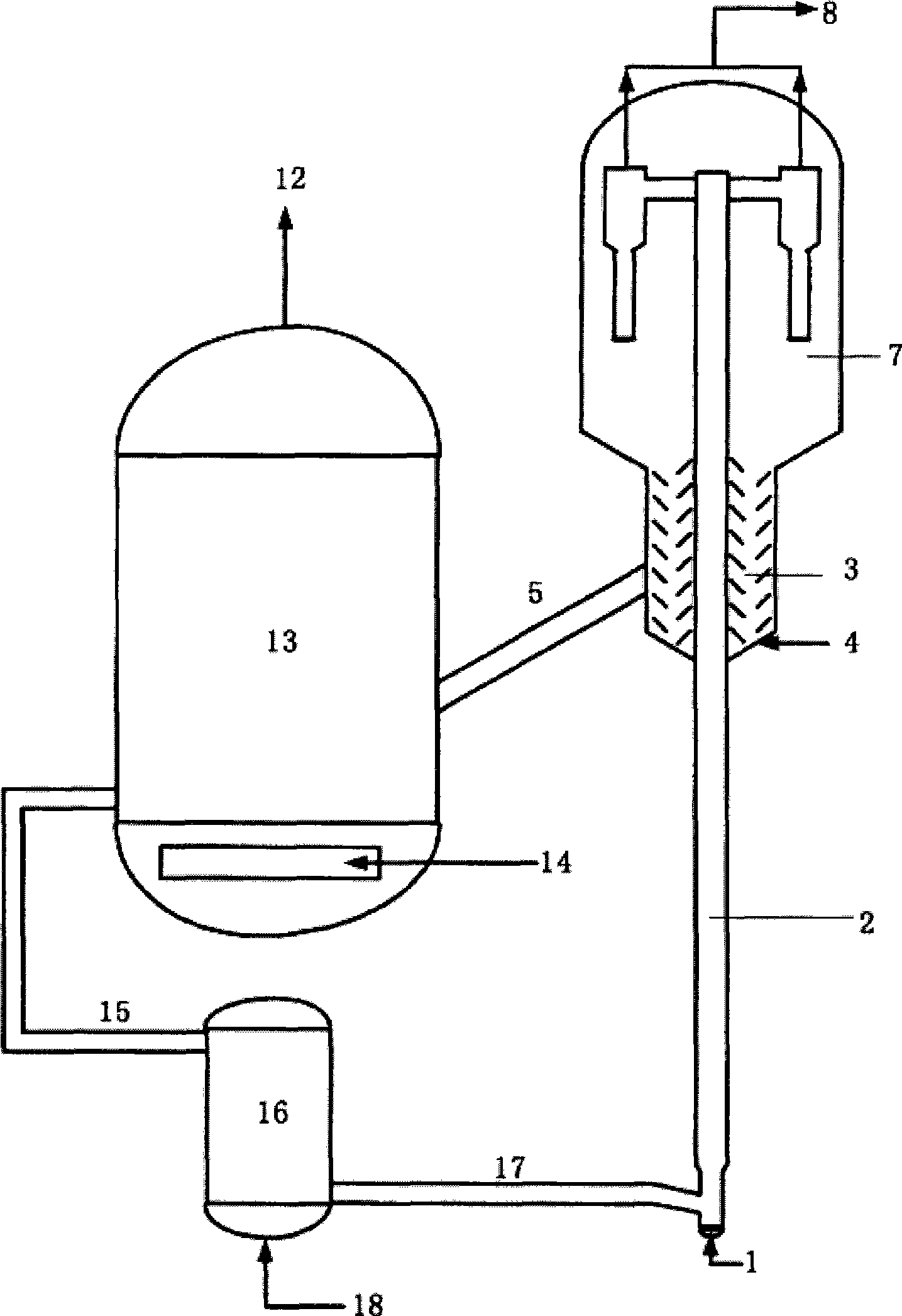

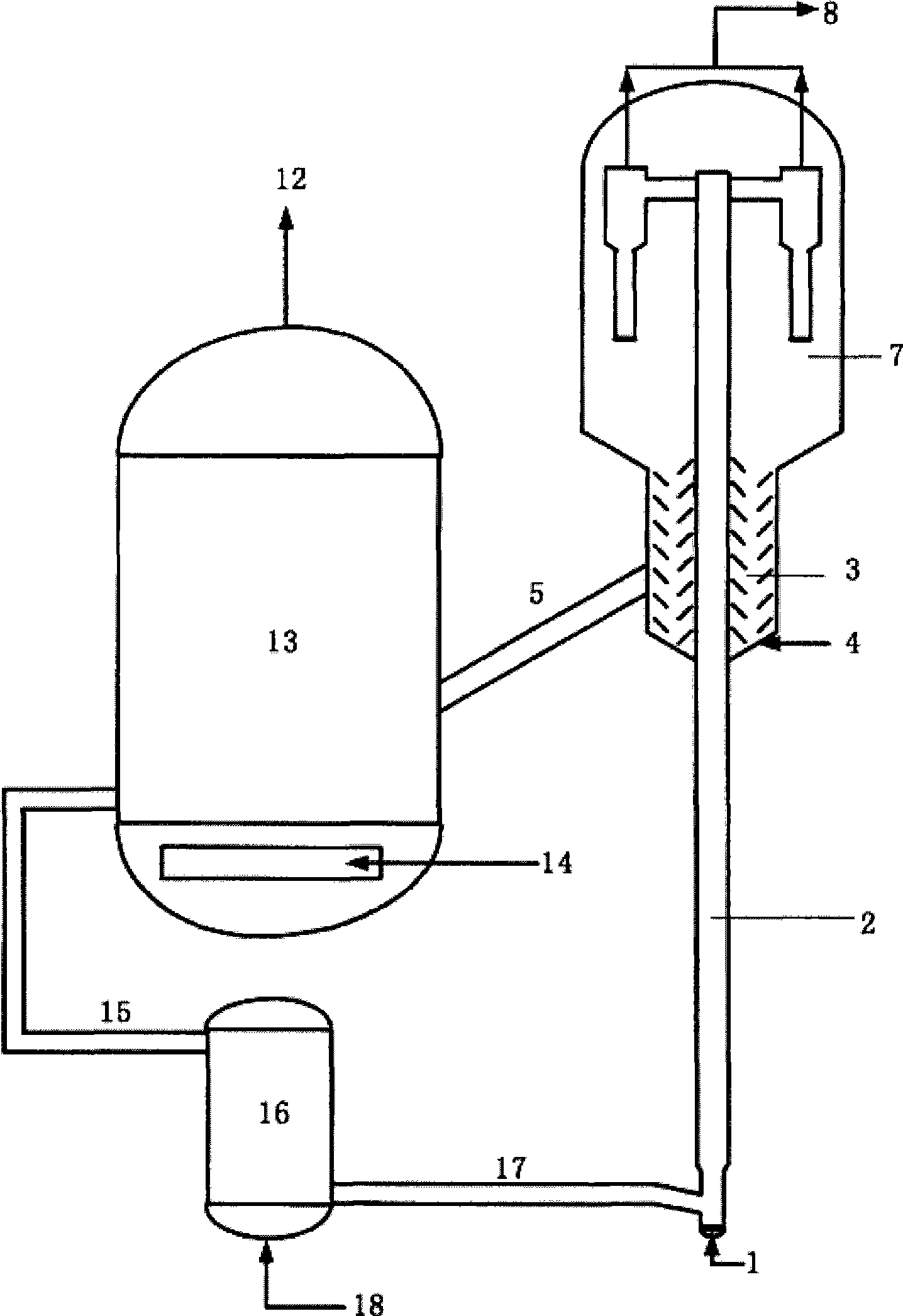

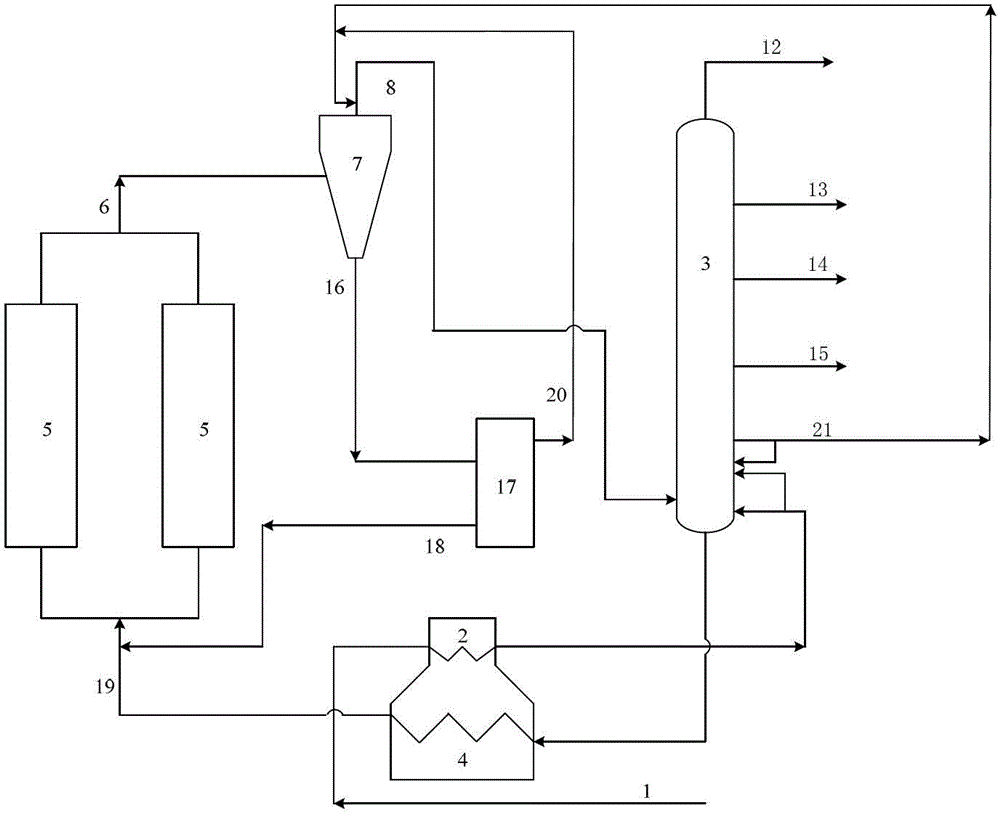

A kind of process method and device of delayed coking

ActiveCN104046386BQuality improvementReduce adverse effectsHydrocarbon distillationTreatment with plural serial stages onlyLiquid productEngineering

The invention relates to a delayed coking process which comprises the following steps: high-temperature oil gas coming from a coke tower top enters a cyclone separator in a tangent manner; flushing oil is injected into the top of the cyclone separator; oil gas on the top of the cyclone separator enters a fractionating tower to separate coke products; oil at the bottom of the cyclone separator is divided through gravity or rotational flow sedimentation into a flow containing much coke powder and a flow containing less coke powder; the flow containing much coke powder and a flow at an exit of a heating furnace are mixed and then the mixture enters a coke tower to react; and the flow containing less coke powder or an oil mixture composed of the flow containing less coke powder and coking distillate oil is used as flushing oil of the cyclone separator. By the method and the device provided by the invention, quality of a coking product can be raised; influence of coke powder on downstream processes is reduced; yield of a liquid product can be raised; and operational cycle of the device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrogenation aromatization catalyst

InactiveCN1621496AImprove hydrodesulfurization activityStrong aromatization abilityHydrocarbon oils refiningTungstateSulfide

The preparation process of hydrogenating and aromatizing catalyst includes: modifying titanian and SB aluminum hydroxide with two or three of ammonium tungstate, ammonium molybdenate, cobalt nitrate and nickel nitrate; modifying ZSM-5 molecular sieve with one or two of zinc nitrate, zirconium nitrate and ammonium dihydrogen phosphate; mixing modified titanian and SB aluminum hydroxide and modified ZSM-5 molecular sieve to form the mixture; and adding sesbania powder in the amount of 2-5 wt% of the mixture, citric acid of 1-3 wt% and expanding agent of 5-15 wt% to obtain the catalyst. The catalyst can eliminate impurity sulfide in catalytic cracked gasoline effectively, lowering the olefin content in gasoline and raise octane number of gasline in hydroforming condition.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com