Bimetal reforming catalyst and its preparing process

A technology for reforming catalysts and catalysts, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as increased carbon deposition, reduced hydrogen-oil ratio, and reduced hydrogen partial pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] In this example, the co-impregnation method was used to prepare the catalyst.

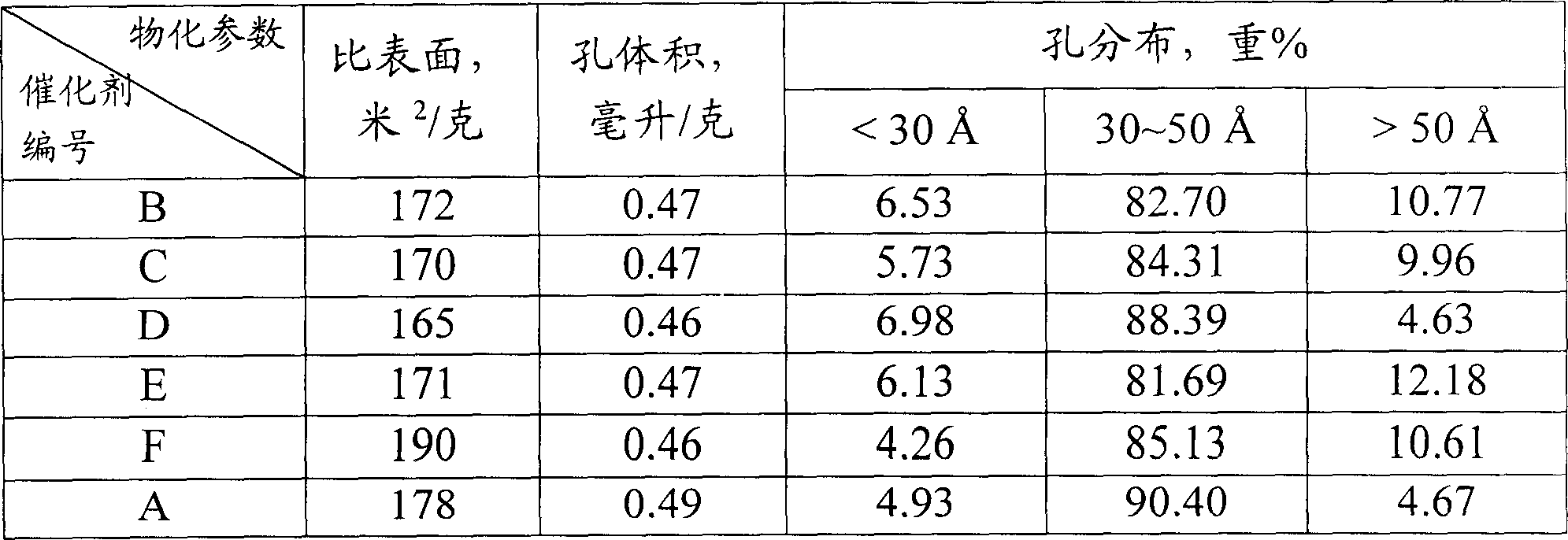

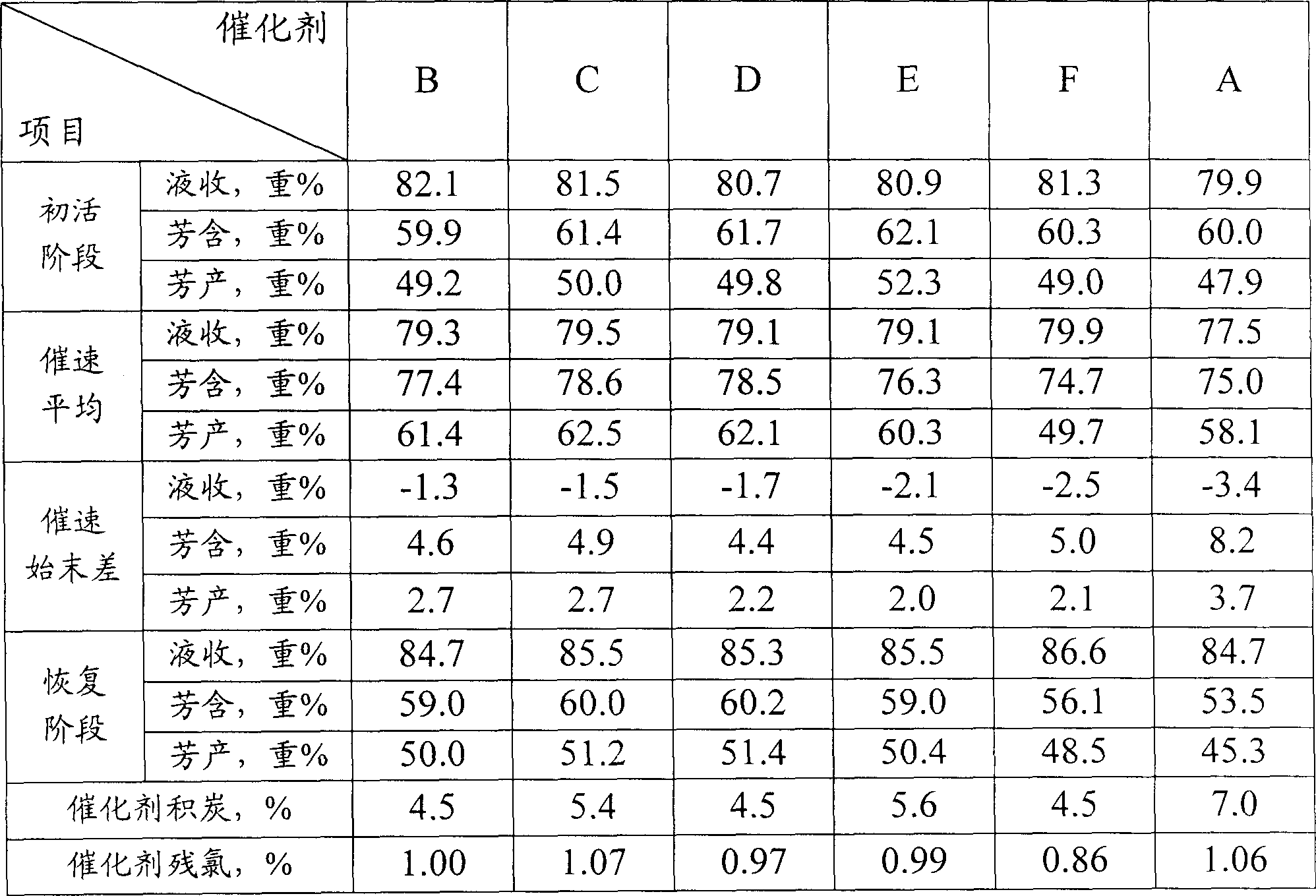

[0030] Weigh 60 grams of bar-shaped γ-Al 2 o 3 Carrier (prepared with SB oxy-alumina powder produced by Germany Condea Company), chloroplatinic acid (Changling Catalyst Factory, analytically pure), perrhenic acid, phosphoric acid and hydrochloric acid (analytical pure) were made into impregnating solution, and the impregnating solution was It contains 0.22% of Pt, 0.50% of Re, 0.2% of P, and 1.8% of Cl (relative to the weight of alumina on a dry basis), and the liquid-solid volume ratio is 1.9. After immersing at room temperature for 24 hours, filter, dry at 120°C for 12 hours, and activate it by roasting for 4 hours in dry air at 500°C and an air-to-agent volume ratio of 700, then use H at 480°C and an air-to-agent volume ratio of 500 2 Reduction for 4 hours to prepare phosphorus-containing Pt-Re / γ-Al 2 o 3 Catalyst B. Then add 0.10% by weight (to catalyst weight) of hydrogen sulfide i...

example 2

[0032] Get the γ-Al described in 60 grams of example 1 2 o 3For the carrier, use a predetermined amount of chloroplatinic acid (analytical pure), perrhenic acid (analytical pure), phosphoric acid (analytical pure) and hydrochloric acid (analytical pure) to prepare an impregnation solution, which contains Pt0.22%, Re0. 58%, P0.8%, Cl1.8% (all relative to the weight of alumina on a dry basis), and the liquid-solid volume ratio is 1.9. After immersing at room temperature for 24 hours, filter, dry at 120°C for 12 hours, activate for 4 hours in dry air at 500°C, and the volume ratio of gas to agent is 700, H 2 Catalyst C was obtained by reducing for 4 hours at a temperature of 480°C and an air-to-agent volume ratio of 500. at 425°C H 2 The stream was presulfided by adding 0.10% (to catalyst weight) hydrogen sulfide. The composition of the catalyst is shown in Table 1, and the physicochemical properties are shown in Table 2.

example 3

[0034] The catalyst was prepared by stepwise impregnation.

[0035] Get the γ-Al described in 60 grams of example 1 2 o 3 The carrier is prepared with a predetermined amount of phosphoric acid to make an impregnation solution, so that the impregnation solution contains 2.0% phosphorus P (relative to the weight of alumina on a dry basis), and the liquid-solid ratio is 1.5. After soaking at room temperature for 24 hours, filter, dry at 120°C for 12 hours, and bake at 650°C for 4 hours. Then use a predetermined amount of chloroplatinic acid (analytical pure), perrhenic acid (analytical pure), hydrochloric acid (analytical pure) to make an impregnation solution, so that it contains Pt0.22%, Re0.56%, Cl1.8% (relatively Based on the weight of alumina on a dry basis), the liquid-solid volume ratio is 1.5. After impregnating at room temperature for 24 hours, filter, dry at 120°C for 12 hours, and activate by roasting for 4 hours at 500°C in dry air with an air-agent volume ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com