Naphtha reforming catalyst and preparation method thereof

A technology for reforming catalyst and naphtha, applied in the direction of naphtha catalytic reforming, etc., can solve the problems of complex preparation process, rapid decrease of specific surface area, catalyst deactivation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

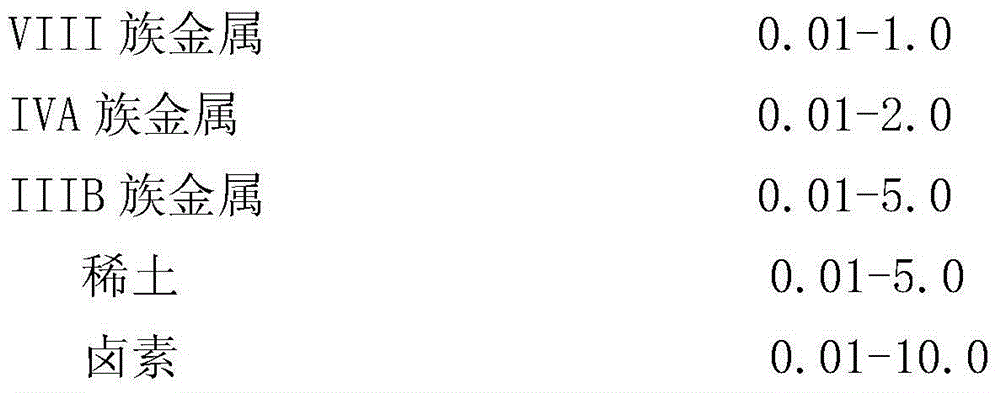

[0043] The preparation method of the catalyst of the present invention comprises introducing VIII group metals, IVA group metals, rare earth additives, and IIIB group metals into the inorganic oxide carrier, and can adopt the co-impregnation method or the distribution impregnation method to introduce the metal components, halogen Introduce the vector.

[0044] When the distributed impregnation method is adopted, the elements introduced first should be Group IVA metals, Ce, and Y, and the order of introduction can be arbitrary, that is, the Group IVA metals can be introduced into the carrier first, and then Ce and Y can be introduced successively or simultaneously, or vice versa. , that is, Ce and Y are introduced simultaneously or successively and then the IVA group metals are introduced. Ce, Y and IVA group metals can also be introduced at the same time. When Ce and Y are introduced in a distributed manner, the introduction order of Ce and Y can be arbitrary.

[0045] After e...

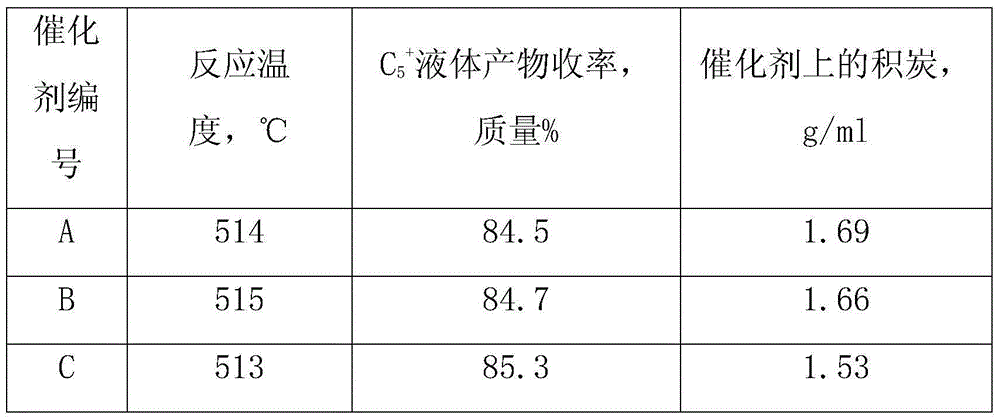

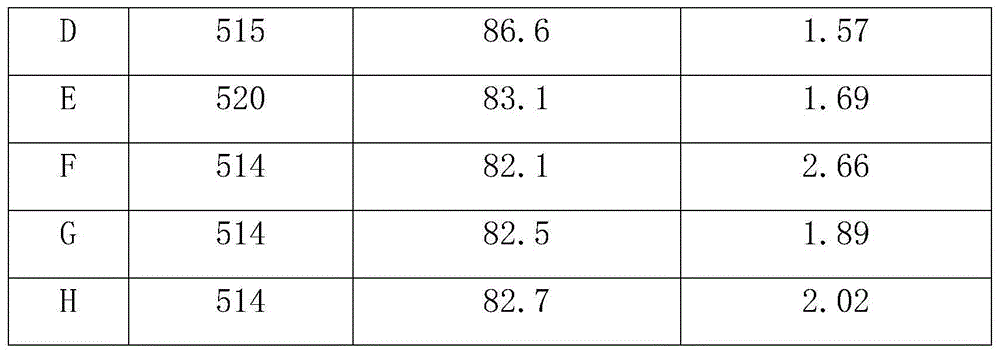

Embodiment 1

[0057] Preparation of Catalyst A: Pt-Sn-Ce-Y / Al 2 o 3 -Cl

[0058] The spherical alumina support was prepared by the oil drop method known to those skilled in the art. Firstly, the aluminum hydrosol is obtained by the reaction of metal aluminum and fatty alcohol under the action of an initiator, which is mixed with appropriate gelatin and dropped into a high-temperature oil bath until it solidifies and forms small balls. Put the pellets in the solution of oil and ammonia for aging treatment, dry at 50°C-300°C for 12 hours, and then roast at 400°C-600°C for 1 hour-24 hours to obtain spherical gamma -Al 2 o 3 carrier.

[0059] Take the above spherical γ-Al 2 o 3 Carrier 100g, put it in SnCl 2 In an ethanol solution, impregnate to obtain a Sn-containing carrier with a Sn content of 0.3%.

[0060] Take 100g of the carrier, and make hydrochloric acid, chloroacetic acid, cerium chloride, and yttrium chloride into an aqueous solution, so that the aqueous solution contains 1....

Embodiment 2

[0065] Preparation of Catalyst B: Pt-Sn-Ce-Y / Al 2 o 3 -Cl

[0066] Catalyst B was prepared in a manner similar to that of Example 1, except that the Ce content on the catalyst was 0.41%, and the rest of the active components had the same composition. The catalyst precursor after the impregnating solution was dried at 500°C, H 2 O: Cl 2 : HCl molar ratio of 50:5:1 in the air roasting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com