Cracking auxiliary agent for increasing low-carbon olefin concentration

A technology of low-carbon olefins and catalytic cracking additives, applied in the direction of hydrocarbon cracking, cracking, catalytic cracking, etc., can solve the problem of low-carbon olefin concentration, achieve good wear resistance, improve heavy oil conversion capacity, and increase production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

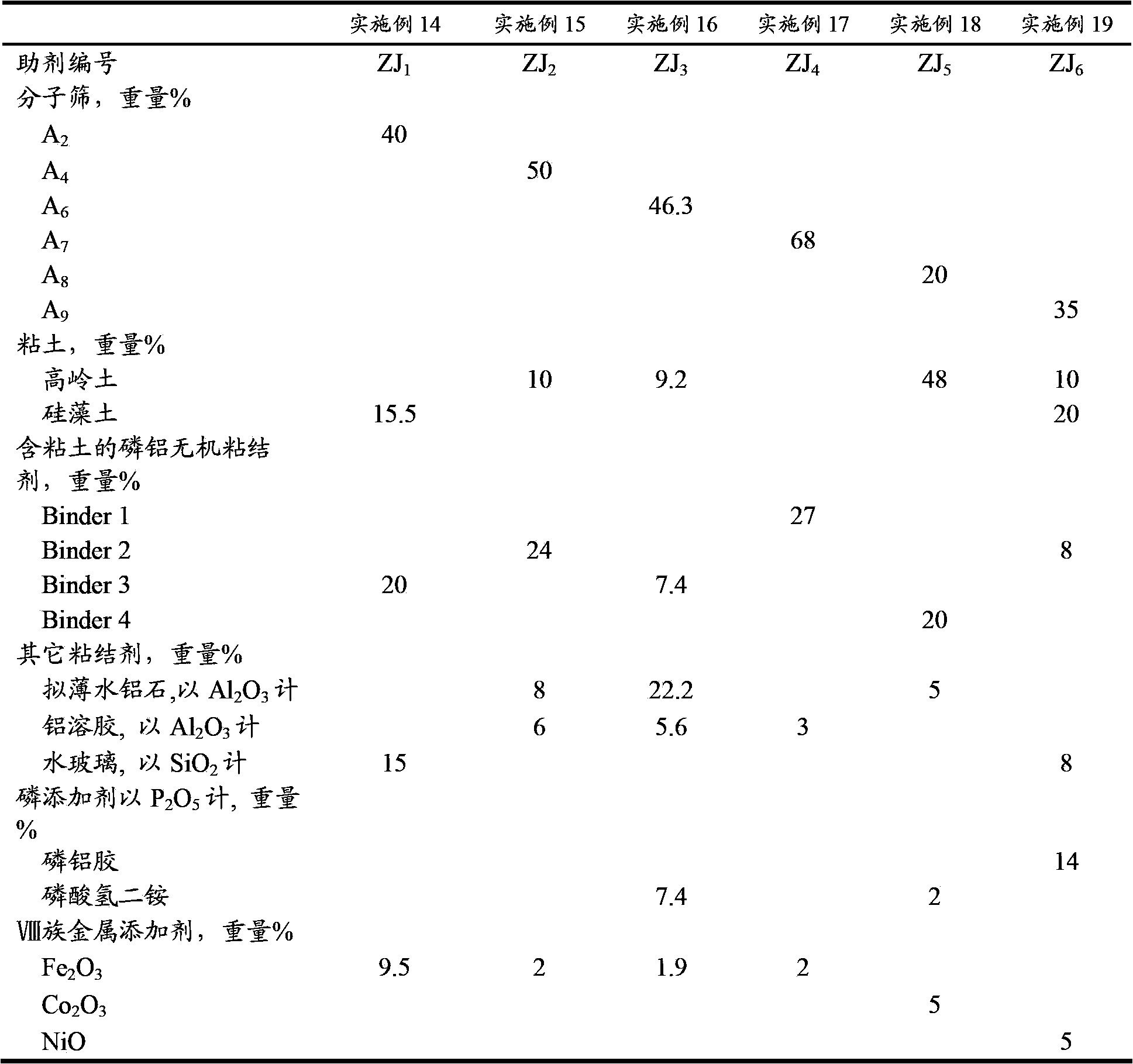

Examples

preparation example Construction

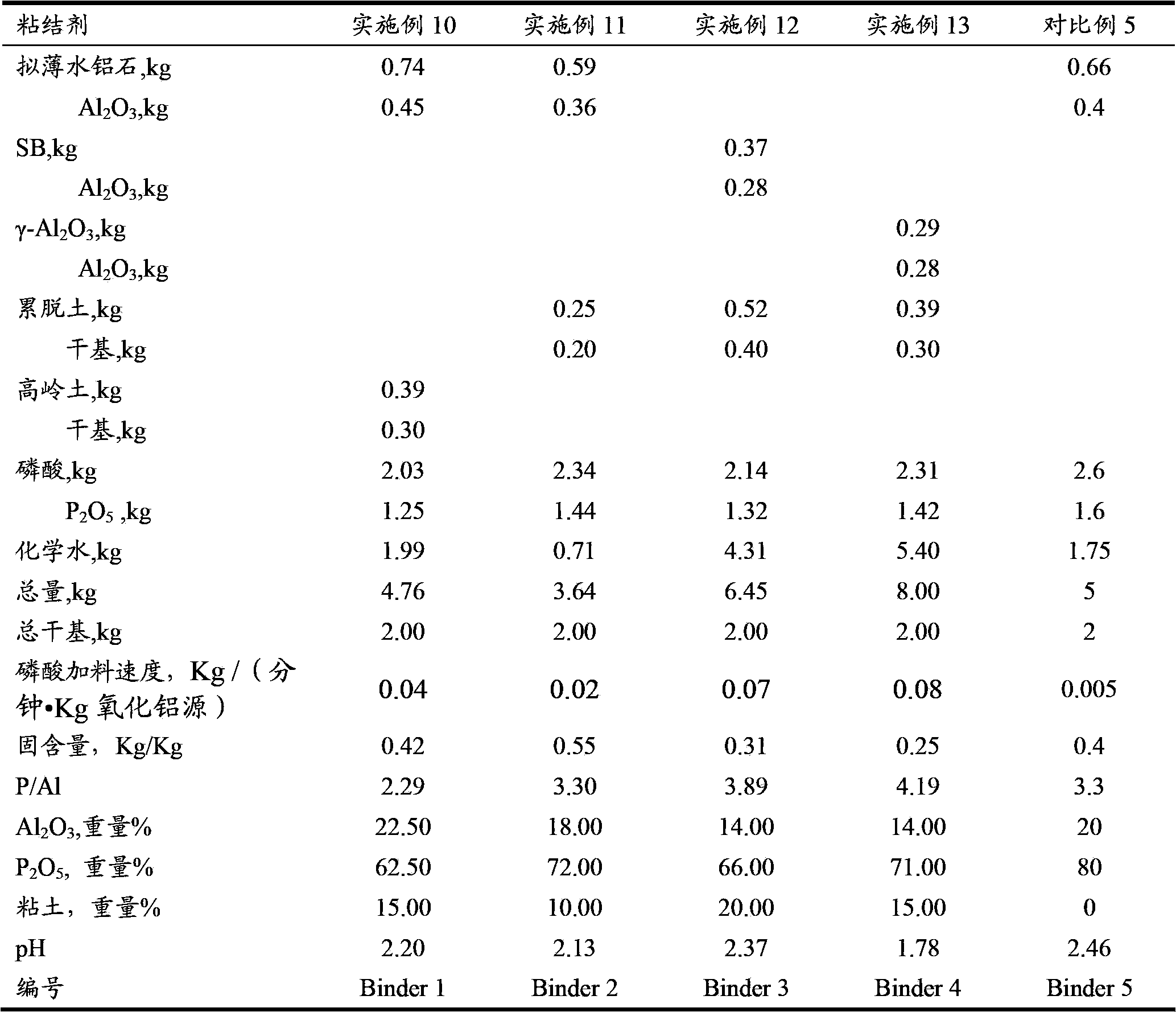

[0028] In the preparation method of the catalytic cracking aid provided by the present invention, the phosphorus-aluminum inorganic binder containing the first clay, based on its dry weight, contains Al 2 o 3 15-40% by weight aluminum component, with P 2 o 5 45-80% by weight of the phosphorus component and 1-40% by weight of the first clay on a dry basis, and does not contain chlorine, its P / Al weight ratio is 1.0-6.0, its pH is 1.0-3.5, and its solid content is 15-60% by weight. The preparation method of the phosphorus-aluminum inorganic binder containing the first clay comprises:

[0029] (1) Dispersing the alumina source, the first clay and water into a slurry with a solid content of 8-45% by weight; the alumina source is aluminum hydroxide and / or alumina that can be peptized by acid, and The dry basis of the first clay and Al 2 o 3 The weight ratio of the alumina source of meter is 1-40:15-40;

[0030] (2) under stirring, add concentrated phosphoric acid to the slur...

Embodiment 1

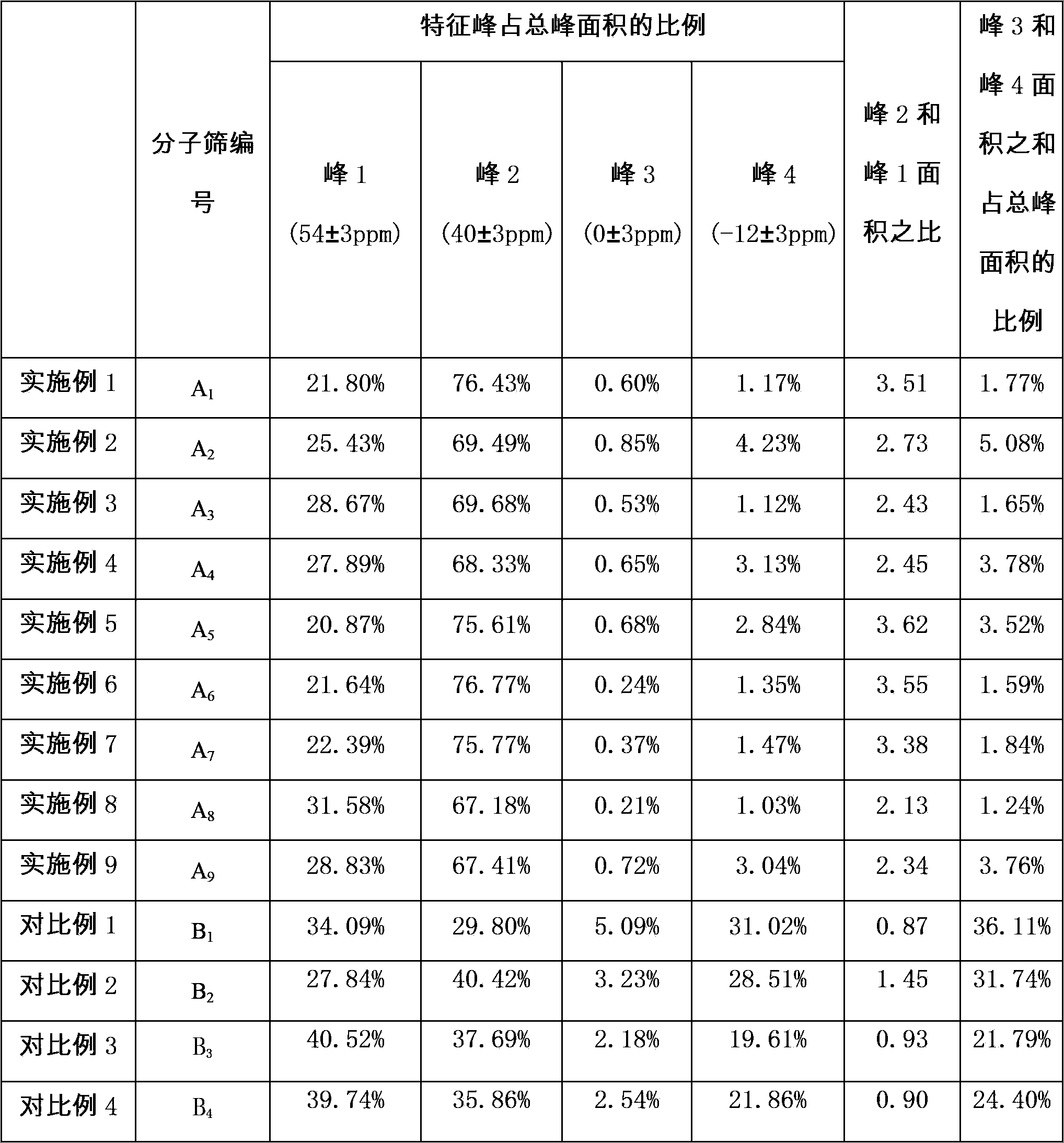

[0071] Beta zeolite (Naβ, produced by Qilu Catalyst Factory, SiO 2 / Al 2 o 3 =25, sodium oxide content 4.5% by weight, the same below) with NH 4 Cl solution exchange wash to Na 2 The O content is lower than 0.2% by weight, and the filter cake is obtained by filtration; dried, and the obtained sample is roasted at 350°C for 2 hours, and then heated to 550°C for 4 hours to remove the template agent; take 100g (dry basis) of the above-mentioned molecular sieve and add water Prepare a molecular sieve slurry with a solid content of 10% by weight, add 20g of oxalic acid during stirring, heat up to 80°C and stir for 1h, filter and wash until the filtrate is neutral; add water to the filter cake and beat to obtain a molecular sieve slurry with a solid content of 40% by weight, and mix 6.8gH 3 PO 4 (Concentration 85%) and 3.2gCu(NO 3 ) 2 ·3H 2 O was dissolved in 30 g of water, mixed with the molecular sieve slurry, impregnated and dried; the obtained sample was calcined at 550° ...

Embodiment 2

[0074] beta zeolite with NH 4 Cl solution exchange wash to Na 2 The O content is lower than 0.2% by weight, and the filter cake is obtained by filtration; dried, and the obtained sample is roasted at 150°C for 2 hours, then heated to 350°C for 2 hours for 30 minutes, and then heated to 500°C for 4 hours for 30 minutes. Template removal agent: Take 100g of the above-mentioned molecular sieve (dry basis) and add water to prepare a molecular sieve slurry with a solid content of 10% by weight, add 10g of fluosilicic acid during stirring, heat up to 60°C and stir for 1h, filter and wash until the filtrate is neutral; add water to the filter cake Beating to obtain a solid content of 40% by weight molecular sieve slurry, 11.8gH 3 PO 4 (concentration 85%) with 6.3gCuCl 2 Dissolved in 90g of water, mixed with filter cake, soaked and dried; the obtained sample was roasted at 550°C for 2 hours, namely the modified β molecular sieve provided by the present invention.

[0075] Elementa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com