Catalytic cracking aid containing Beta molecular sieve rich in mesopores, and preparation method thereof

A technology of molecular sieves and additives, which is applied in the field of catalytic cracking additives and their preparation, can solve the problems of molecular sieve pore structure damage, long preparation process, and no adjustment of aluminum distribution on the surface, so as to increase liquid absorption and octane number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

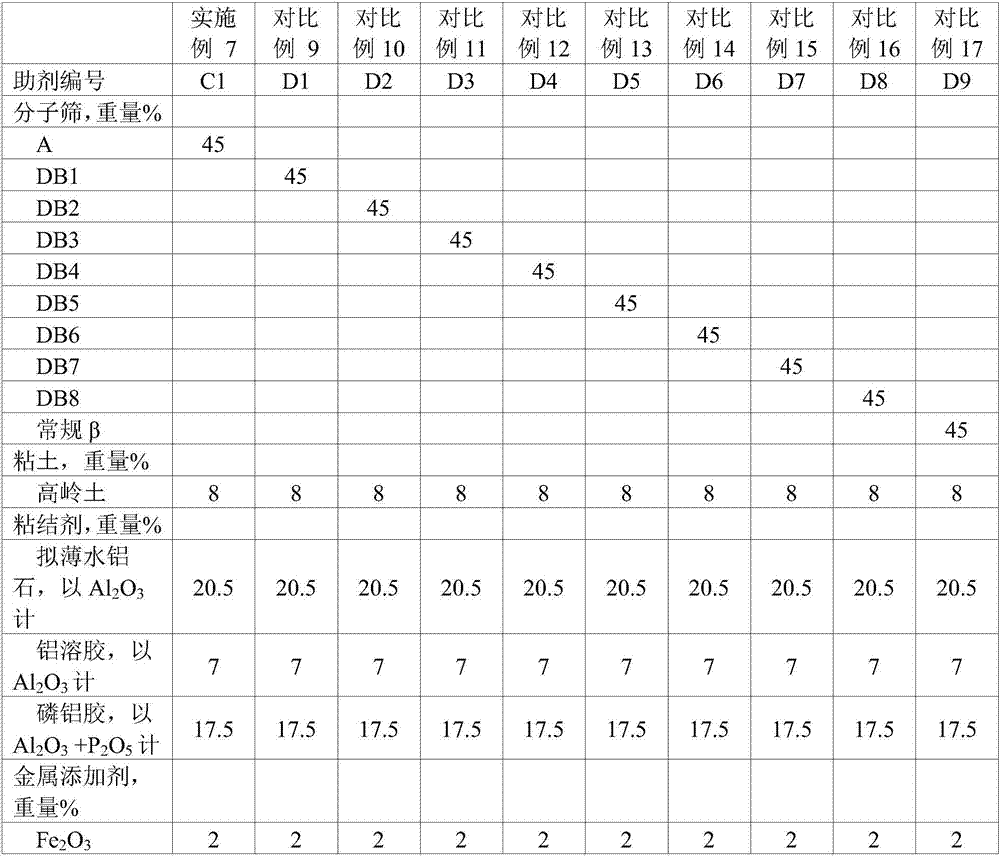

[0064] The present invention also provides a preparation method of catalytic cracking additive, the preparation method comprising: mixing Beta molecular sieve rich in mesoporous, inorganic oxide binder and water, adding or not adding clay, beating, and spray drying; wherein , introducing or not introducing phosphorus additives, introducing or not introducing Group VIII metal additives; by weight and based on the dry basis weight of the preparation raw materials of the auxiliary agent, the preparation raw materials of the auxiliary agent contain 10 - 75% by weight of mesoporous-rich Beta molecular sieve, 0-60% by weight of clay on a dry basis, 15-60% by weight of an inorganic oxide binder on a dry basis, expressed as P 2 o 5 0-25% by weight of phosphorus additives and 0-15% by weight of group VIII metal additives in terms of oxides; the Al distribution parameter D of the molecular sieve satisfies: 0.4≤D≤0.8, wherein, D=Al(S ) / Al(C), Al(S) means the aluminum content in any regi...

Embodiment 1

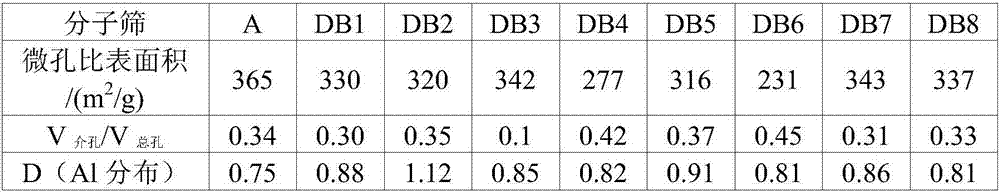

[0086] With 100gBeta molecular sieve (catalyst Qilu branch production, SiO 2 / Al 2 o 3 =25, the sodium oxide content is 4.5% by weight, the same below; dry basis mass) is added with water and beaten to obtain a molecular sieve slurry with a solid content of 10% by weight, and 11.4g of high alkali sodium metaaluminate solution (Na 2 O is 290g / L, Al 2 o 3 40g / L, the solution density is 1.353g / mL), heated to 50°C and stirred at a constant temperature for 0.5h, filtered and washed until neutral; the filter cake was beaten with water to obtain a molecular sieve slurry with a solid content of 20% by weight, and 5.3g Oxalic acid, then slowly add 51g hydrochloric acid (mass fraction 10%) and 17g fluosilicic acid (concentration 20%) dropwise at the same time, raise the temperature to 50°C and stir at a constant temperature for 1h, filter, wash and dry to obtain molecular sieve sample A, the physical and chemical properties of molecular sieve sample A are listed in Table 1.

Embodiment 2

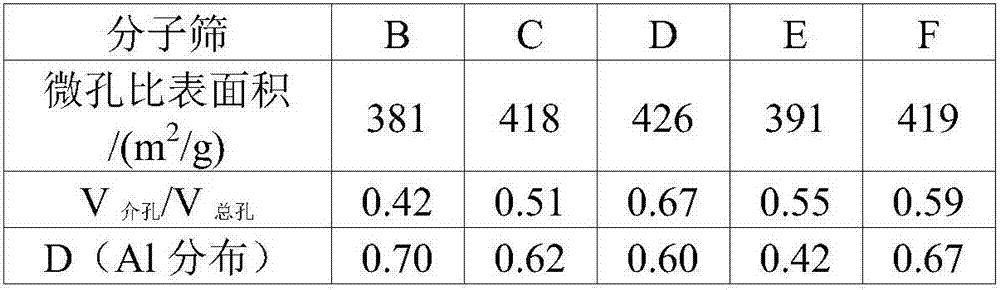

[0104]Add water to 100g Beta molecular sieve (mass on dry basis) to prepare a molecular sieve slurry with a solid content of 10% by weight, add 16g NaOH (purity 96%), heat up to 50°C and stir at a constant temperature for 0.5h, filter and wash until neutral; add water to beat the filter cake to obtain a solid Molecular sieve slurry with a content of 20% by weight, 16g of oxalic acid was added during stirring, and then 108g of hydrochloric acid (mass fraction 10%) and 26g of fluosilicic acid (concentration of 20%) were slowly added dropwise at the same time, the temperature was raised to 50°C and stirred at a constant temperature for 1 hour, filtered, washed and dried Molecular sieve sample B was obtained, and the physicochemical properties of molecular sieve sample B are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com