Anthracene oil hydrogenation method

An anthracene oil and hydrofining technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of low hydrogenation liquid yield, low circulating hydrogen partial pressure, and incomplete hydrogenation reaction, etc., and achieve conversion High efficiency, increased hydrogen partial pressure, improved reaction depth and hydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

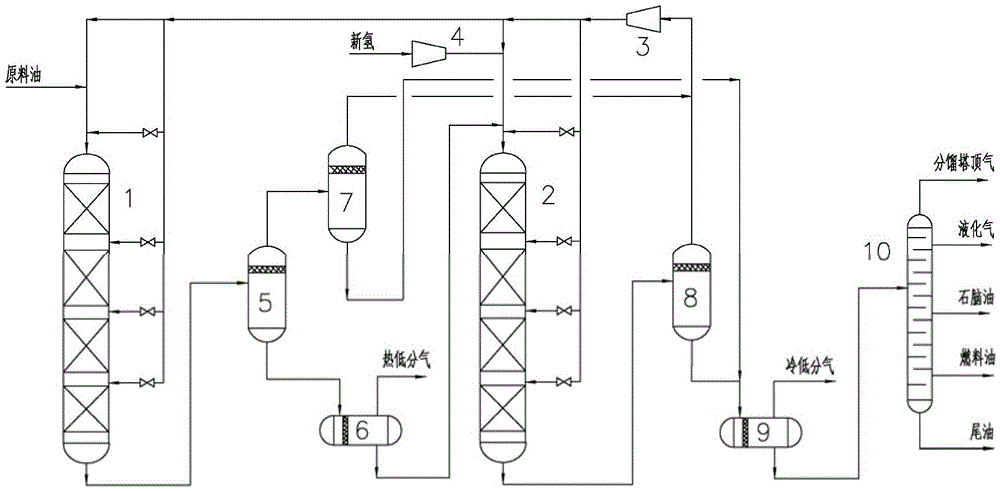

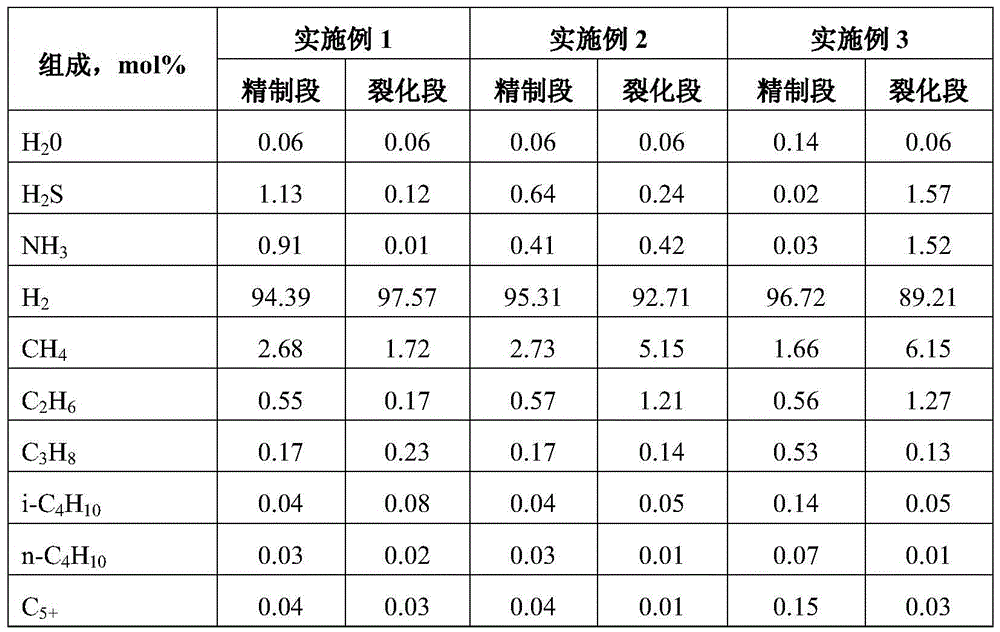

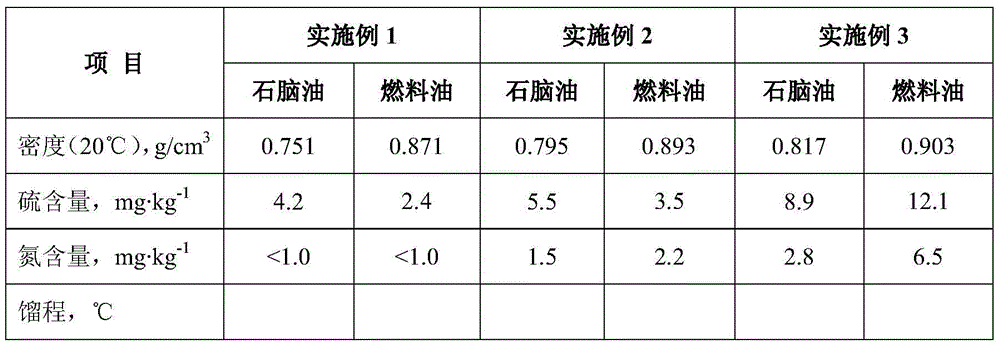

[0033] In this example, fixed-bed hydrorefining and hydrocracking are used in series, the refining and cracking hydrogen circulation systems are connected in parallel, and new hydrogen is added from the cracking section to treat anthracene oil.

[0034] Process flow diagram as figure 1 Shown: the anthracene oil is diluted with hot low fraction oil, pressurized, heated and mixed with inlet hydrogen, and then enters the hydrofining reactor 1; the hot low fraction oil used for dilution can be pre-stored hot low fraction oil or the first The stored hot low-separation oil generated by the first start-up, after the cycle is started, the hot low-separation oil is refined hot low-separation oil.

[0035]The hydrofinishing product from the bottom of the refining reactor enters the hot high-pressure separator 5 after taking heat, and is separated into hot high-fraction steam and hot high-fraction oil. After heat extraction and injection of desalinated water, the hot high-separation ste...

Embodiment 2

[0041] In this example, fixed bed hydrofining and hydrocracking are used in series, and the refining and cracking hydrogen circulation systems are connected in parallel. The difference from Example 1 is that the new hydrogen is supplied by the cracking section and the refining section respectively, and other parts are the same as in Example 1. .

[0042] Among them, the conditions of hydrofining reaction are total pressure of 18MPa, standard volume ratio of hydrogen to oil of 800:1, reaction temperature of 350°C, volume space velocity of 1.0h -1 , The composition and properties of the hydrogenation refining catalyst are: molybdenum oxide 22wt%, nickel oxide 8wt%, and the carrier is alumina. The pore volume of the catalyst is 0.40ml / g, and the specific surface area is 150m 2 / g, the catalyst dosage is 80μg / g.

[0043] The total pressure of the hydrocracking reaction system is 18MPa, the reaction temperature is 260°C, and the reaction space velocity is 1.0h -1 , The standard ...

Embodiment 3

[0045] In this example, fixed-bed hydrofining and hydrocracking are used in series, the refining and cracking hydrogen circulation systems are connected in series, and new hydrogen is added from the refining section to process anthracene oil. The difference from Example 1 is the refining refrigeration of hydrofining The high-fraction gas is used as the circulating hydrogen in the hydrocracking section for hydrocracking reaction without introducing new hydrogen. The cold high-fraction gas in the cracking section is boosted and circulated through the circulating hydrogen compressor, and other parts are the same as in Example 1.

[0046] Among them, the conditions of hydrofining reaction are total pressure of 18MPa, standard volume ratio of hydrogen to oil of 800:1, reaction temperature of 350°C, volume space velocity of 1.0h -1 , The composition and properties of the hydrogenation refining catalyst are: molybdenum oxide 22wt%, nickel oxide 8wt%, and the carrier is alumina. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com