Patents

Literature

122results about How to "High purity hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

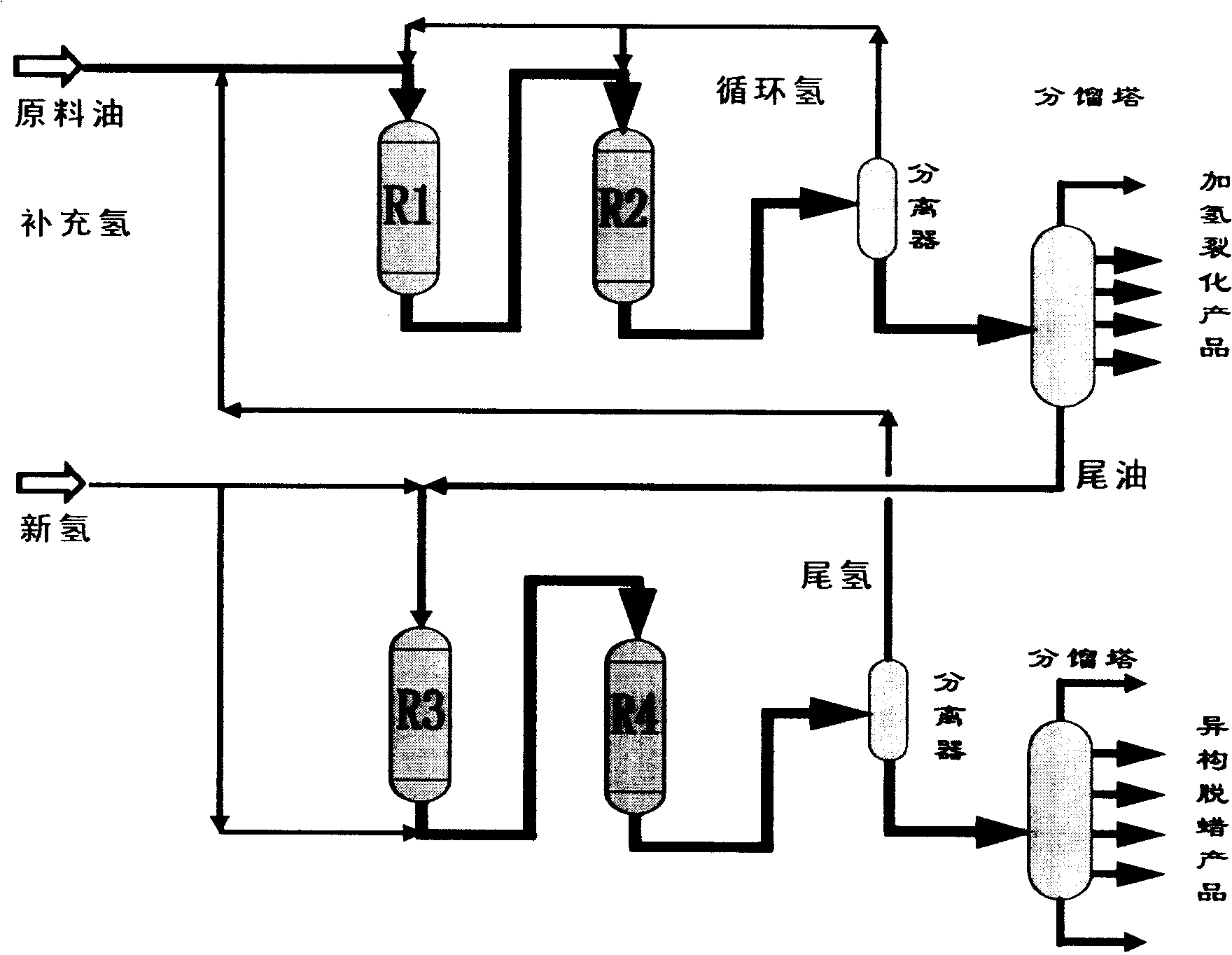

Combined technological process for producing lube oil base stock

ActiveCN101333460ASimple processLow operating costTreatment with hydrotreatment processesPetroleum wax recoveryHydrogenIsomerization

The invention discloses a production method of lubricating oil basic oil. The method takes distillate oil or refined oil, etc. as raw materials, and adopts the combined process of hydrogen cracking-isomerization dewaxing to produce the lubricating oil basic oil. The tail oil of a hydrogen cracking unit is directly supplied to a tail oil isomerization dewaxing unit for serving as a raw material, the new hydrogen passes through the tail oil isomerization dewaxing unit at a time, and the tail hydrogen directly returns to the hydrogen cracking unit for serving as compensation hydrogen. Only one hydrogen circulation system is arranged due to the deep combination of the two units, the construction investment of apparatus and the operating cost are obviously reduced, and the product quality is somewhat improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

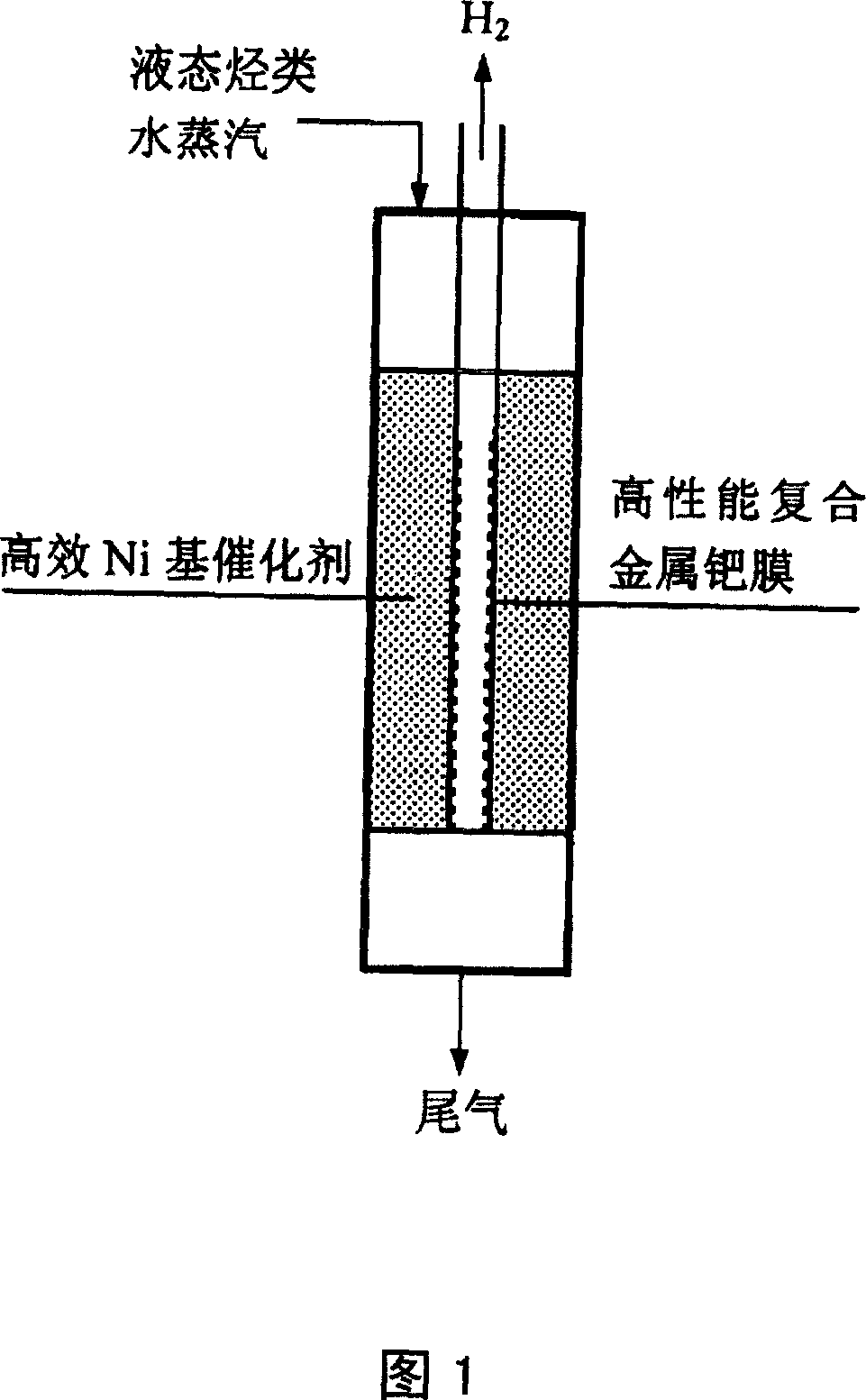

Process of preparing high purity hydrogen with liquid hydrocarbon in a palladium film reactor

The process of preparing high purity hydrogen with liquid hydrocarbon in a palladium film reactor adopts Ni base catalyst with high activity at low temperature to obtain liquid hydrocarbon converting rate near 100 % at the conditions of 450-550 deg.c temperature and carbon space velocity as high as 30,000 / hr, and uses high performance composite metal palladium film simultaneously at the conditions of 500-600 deg.c temperature and carbon space velocity as high as 2000 / hr for timely separating hydrogen generated through water vapor reformation of liquid hydrocarbon to avoid methanation reaction, so as to obtain methane selectivity lower than 3 % and hydrogen selectivity higher than 97 % and obtain high pure hydrogen in the permeation side of the palladium film. The present invention has low hydrogen producing cost and may be used widely in hydrogen refilling station and small dispersed power station.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

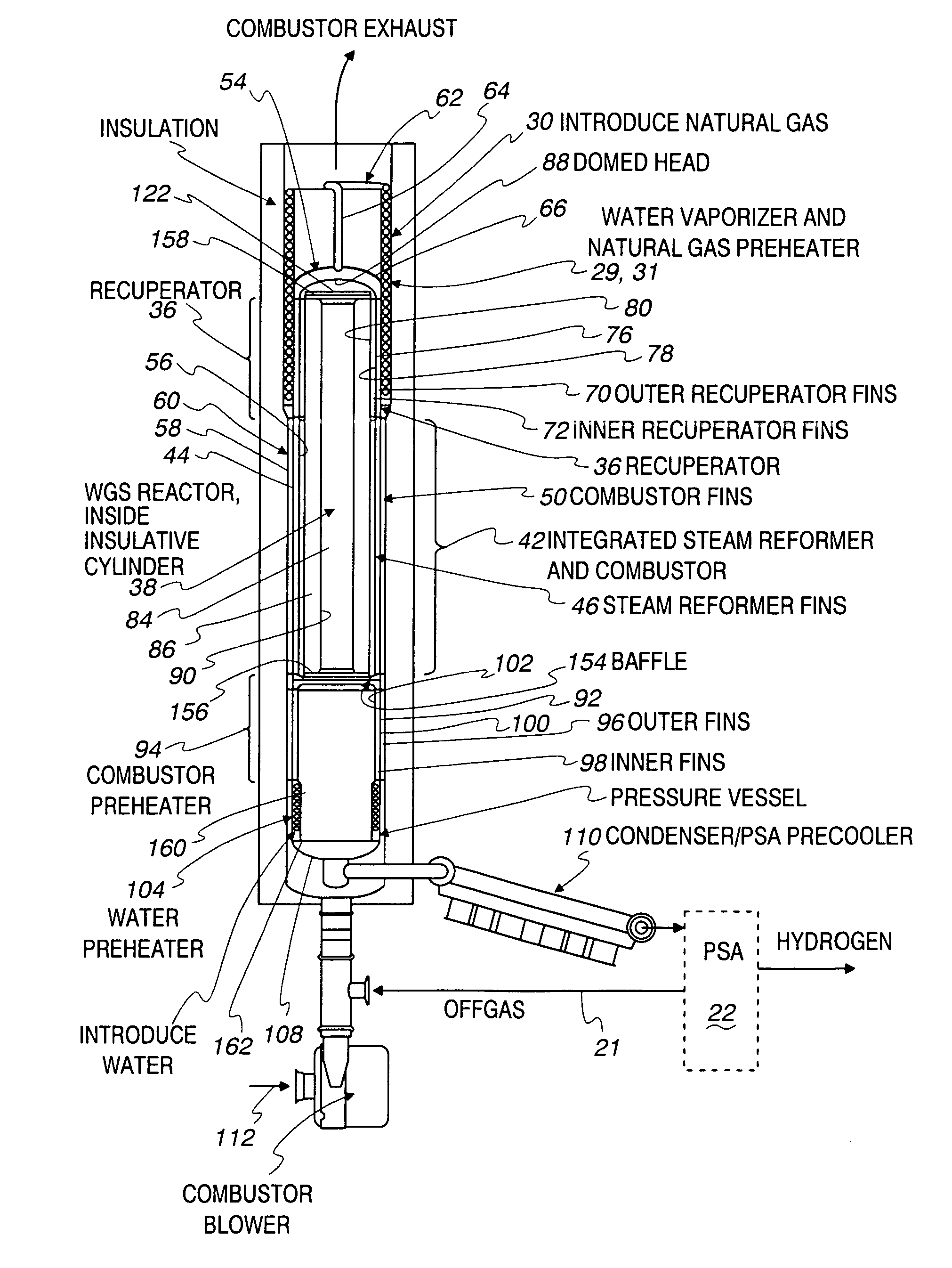

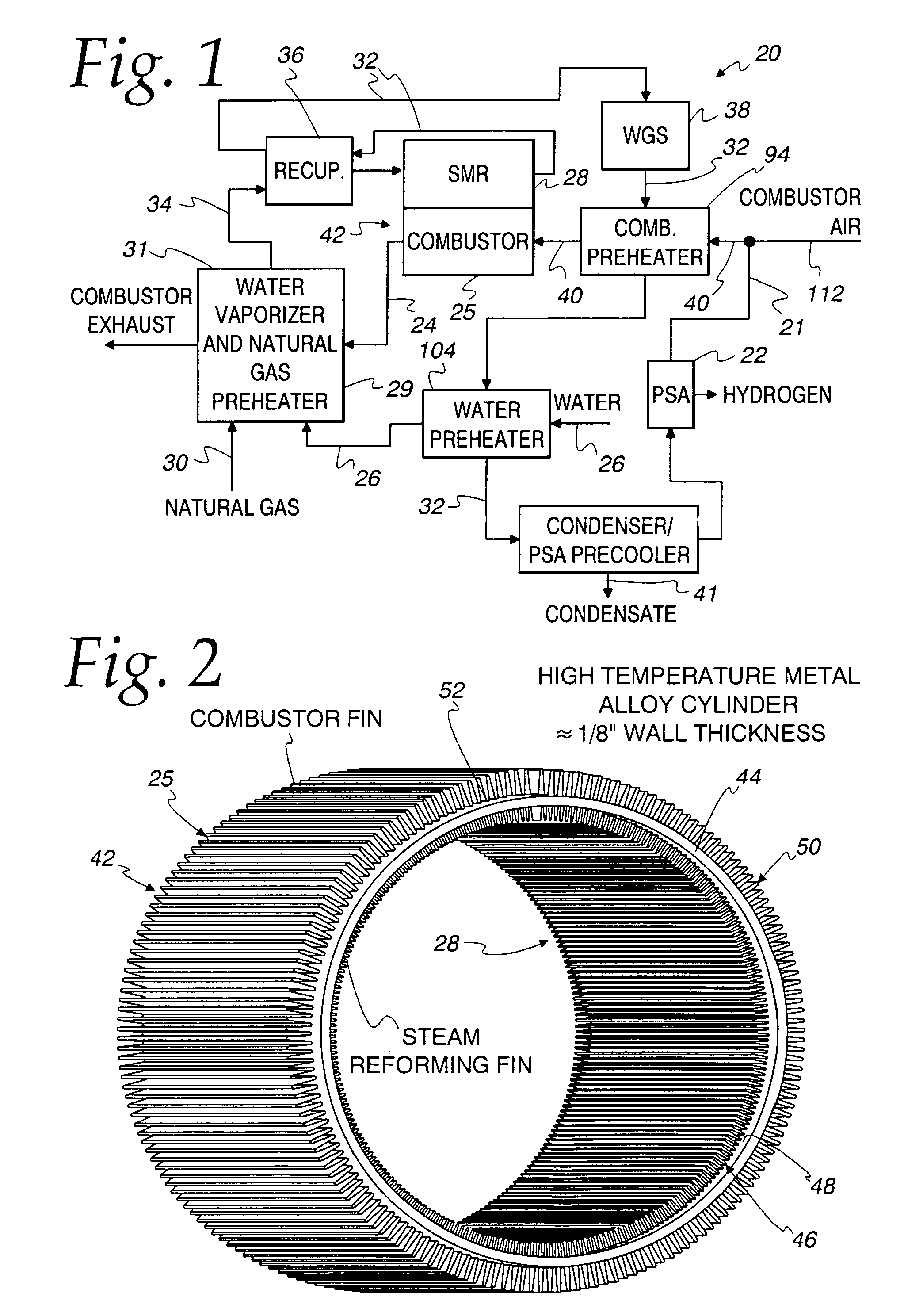

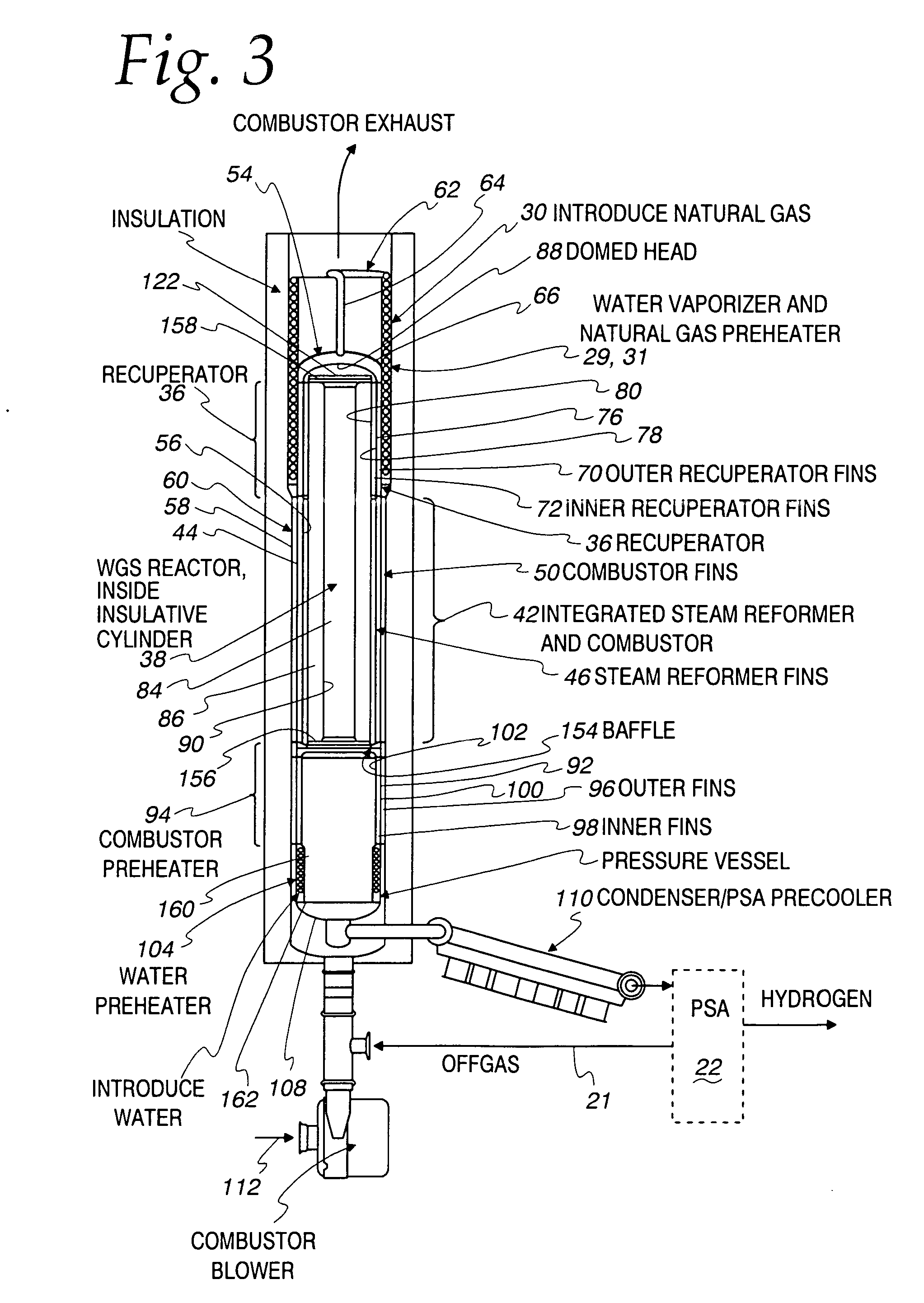

Highly integrated fuel processor for distributed hydrogen production

InactiveUS20050178063A1High purity hydrogenHigh level of hydrogen product efficiencyMuffle furnacesFuel cell auxillariesSteam reformingCombustor

A fuel processing system is provided wherein heat is transferred from a reformate flow (32) downstream from a water-gas shift (38) to both a) a combustor feed flow (40) that is supplied to a combustor (25); and b) a water flow (26) that is supplied to a reformer feed mix (34) for a steam reformer (28).

Owner:MODINE MFG CO

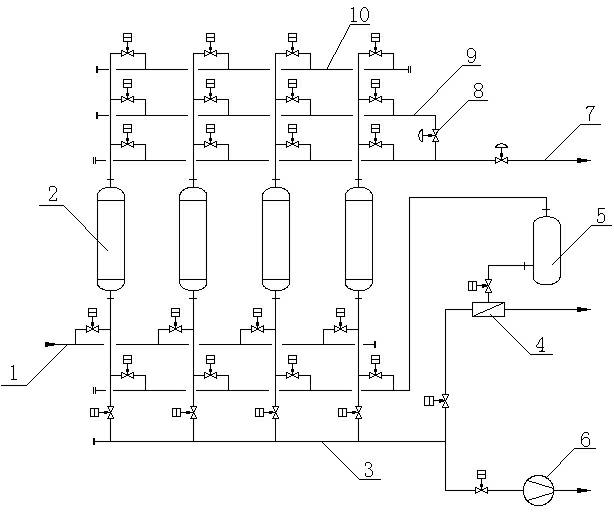

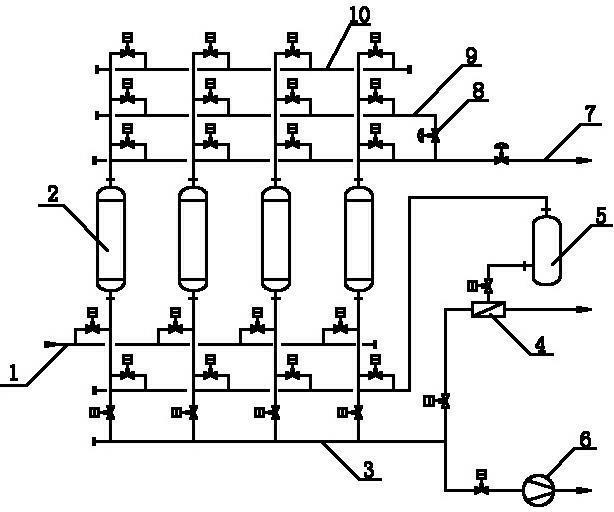

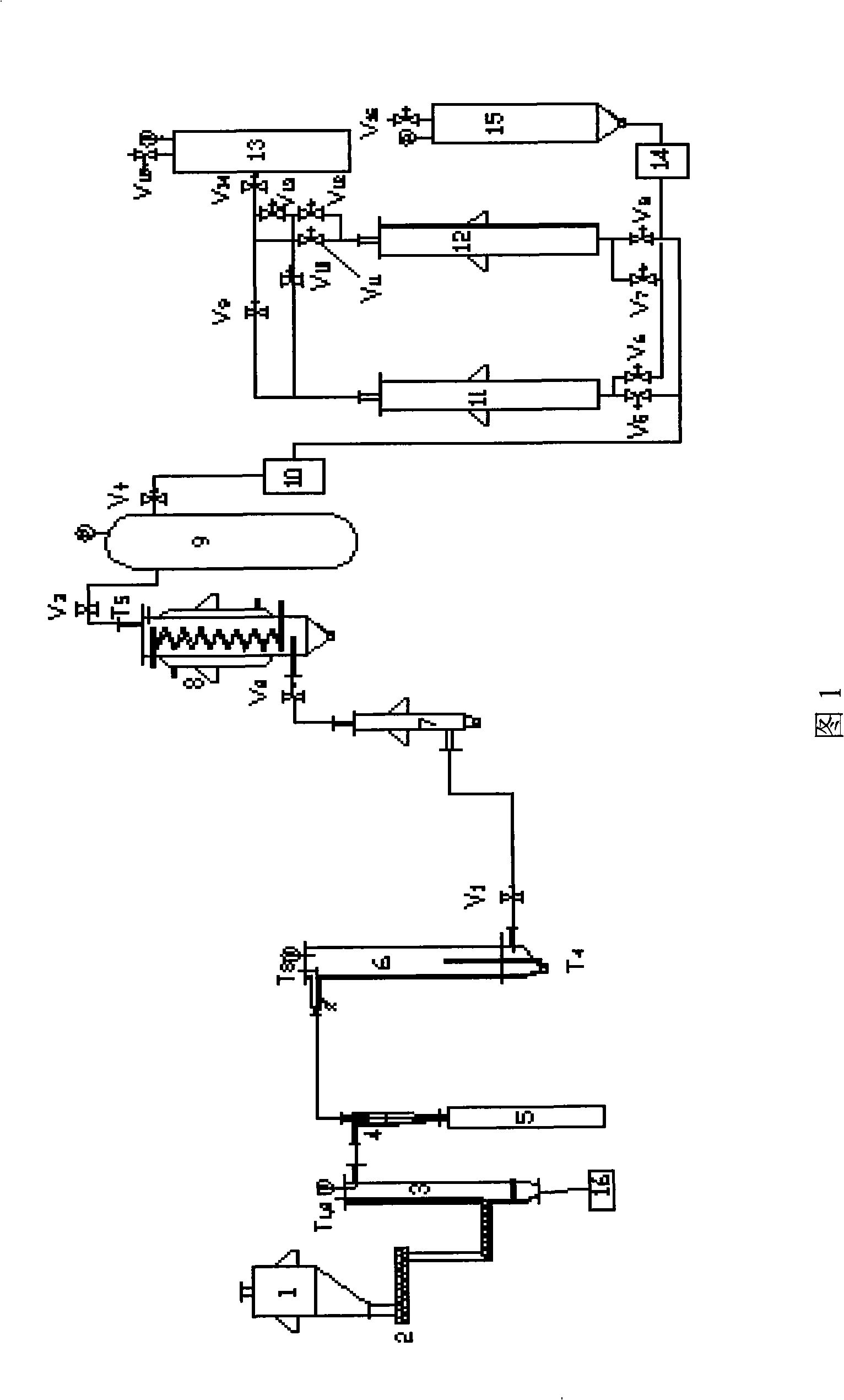

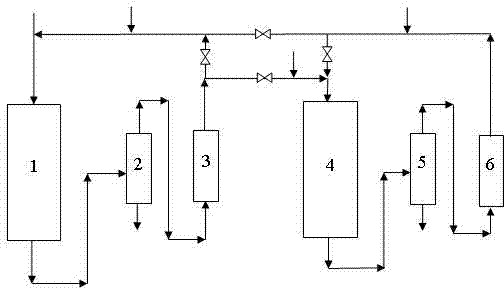

One-stage hydrogen separating and purifying method based on pressure swing adsorption membrane and device for realizing same

ActiveCN102674249ASmall scaleLarge amount of processingHydrogen separation using solid contactSorbentBuffer tank

The invention discloses a one-stage hydrogen separating and purifying method based on a pressure swing adsorption membrane and a device for realizing the same. The method comprises the following steps of: a, adsorption, wherein feed gas with hydrogen content of 75%, carbon dioxide content of 24.5%, carbon monoxide content of 0.5% and pressure of 1.2Mpa is fed into an adsorption tower, a hydrogen purification adsorbent filled in the adsorption tower adsorbs the carbon dioxide and the carbon monoxide in the feed gas, effective gas component hydrogen is output from the top of the adsorption tower, and the product hydrogen is sent to a user from the device through an outlet valve; and b, regeneration, wherein after the feed gas is adsorbed in the adsorption tower, equalized pressure drop and inverse discharge are performed on the adsorption tower, inversely discharged gas enters into a membrane separation unit, infiltration gas is stored in a buffer tank and then returned into the evacuated adsorption tower, and finally equalized pressure increasing and final charge are performed on the adsorption tower. By utilizing the process, the size of a pressure swing adsorption device can be reduced, the hydrogen yield is improved, and the cost is lowered.

Owner:SICHUAN TECHAIRS

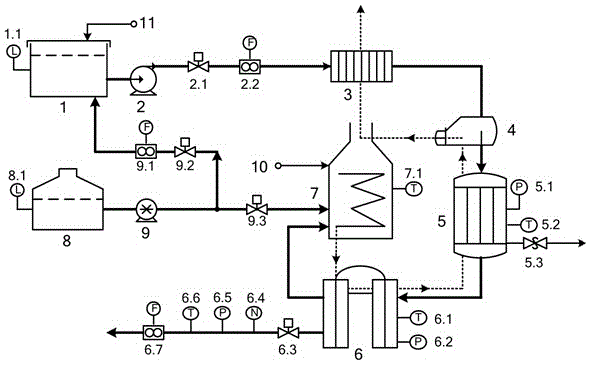

Online high-purity hydrogen preparation system for fuel cell and control method of online high-purity hydrogen preparation system

ActiveCN105152133AReduce energy consumptionLower requirementHydrogenSolid electrolyte fuel cellsHydrogen purityOxygen

The invention discloses an online high-purity hydrogen preparation system for a fuel cell. The online high-purity hydrogen preparation system comprises a methyl alcohol box as well as a raw material box and a catalytic burner which are connected with the methyl alcohol box through a methyl alcohol metering pump, wherein a fuel cell discharge water inlet is formed in the raw material box, an oxygen inlet is formed in the catalytic burner, an ethanol water metering pump and a heat exchanger are sequentially connected onto the raw material box, a vaporizer is connected onto the heat exchanger, a reforming reactor is connected onto the vaporizer, a palladium film purifier is connected onto the reforming reactor, and the palladium film purifier is connected with the catalytic burner; the invention further discloses a control method of the system. According to the system provided by the invention, online hydrogen supplying is performed through a manner of using a methanol water reforming reaction to produce hydrogen, the yield of pure hydrogen is controlled through adjusting the flow of an ethanol water mixture; the method has the characteristics of high hydrogen storage density, high hydrogen purity, low energy consumption, compact structure, simpleness and convenience in start-stop controlling, easiness in implementing modular design and the like.

Owner:武汉氢能与燃料电池产业技术研究院有限公司

Electrochemical zinc-water hydrogen making and storing method

InactiveCN1854063AImprove controllabilityEasy to startHydrogenElectrolysis componentsHydrogen fuel cellOxygen

A method for producing and storing hydrogen by electrochemical zinc-water is carried out by connecting electrode and zinc electrode external circuit when releasing hydrogen, water reduction reacting on electrode, releasing hydrogen, zinc oxidation reacting on zinc electrode, generating zinc oxide, supplementing water to enclosed system, connecting power supply negative electrode onto zinc electrode external circuit, connecting power supply positive electrode onto electrode external circuit, inducing DC, zinc reduction reacting on zinc electrode, reducing zinc oxide into zinc, restoring zinc electrode, oxidation reacting, generating oxygen and discharging. It is an enclosed system consisted of electrode electrolyte and zinc electrode, electrode and zinc are connected with external circuit. It is simple and can be used to provide hydrogen source and generation.

Owner:黄潮 +1

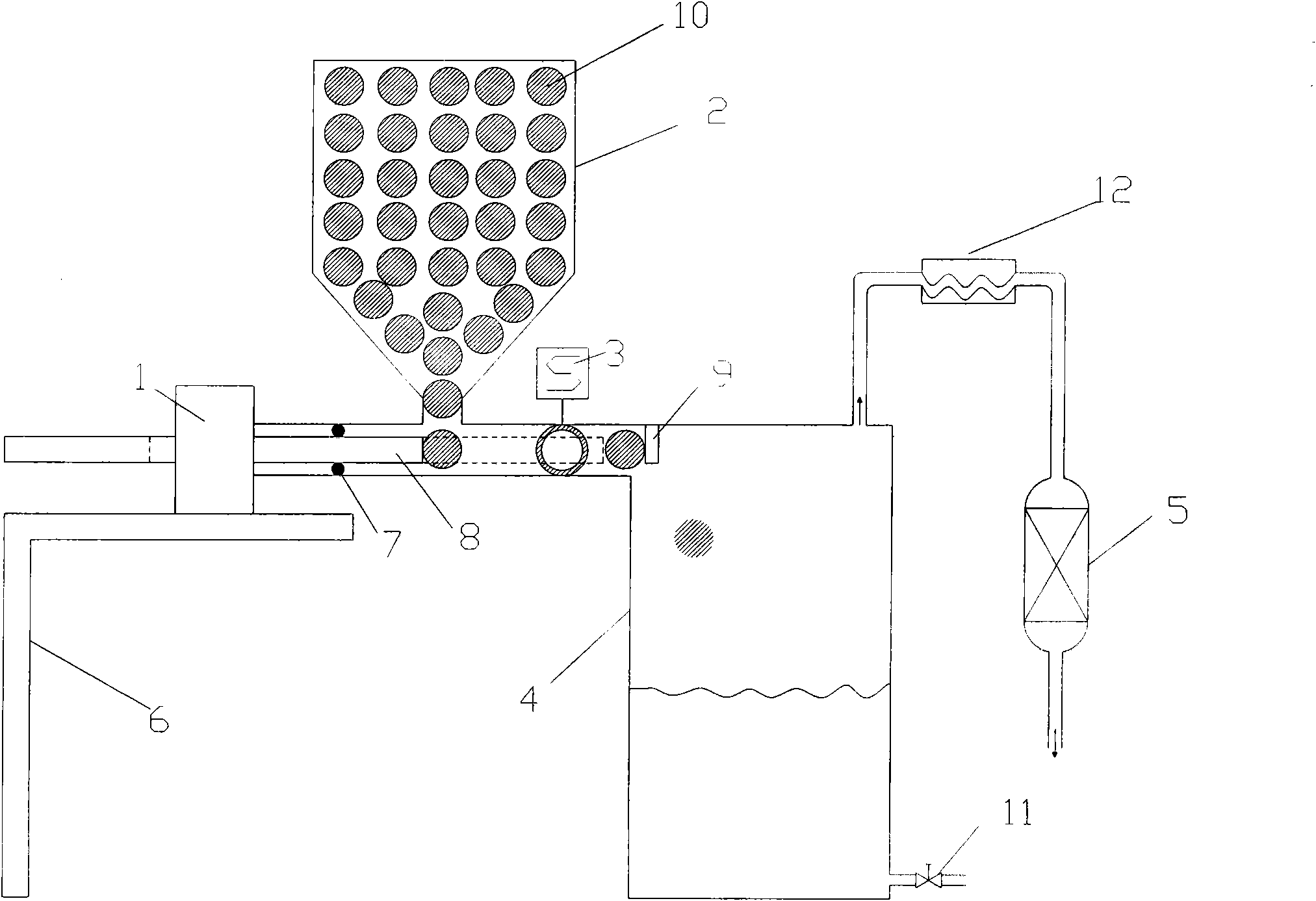

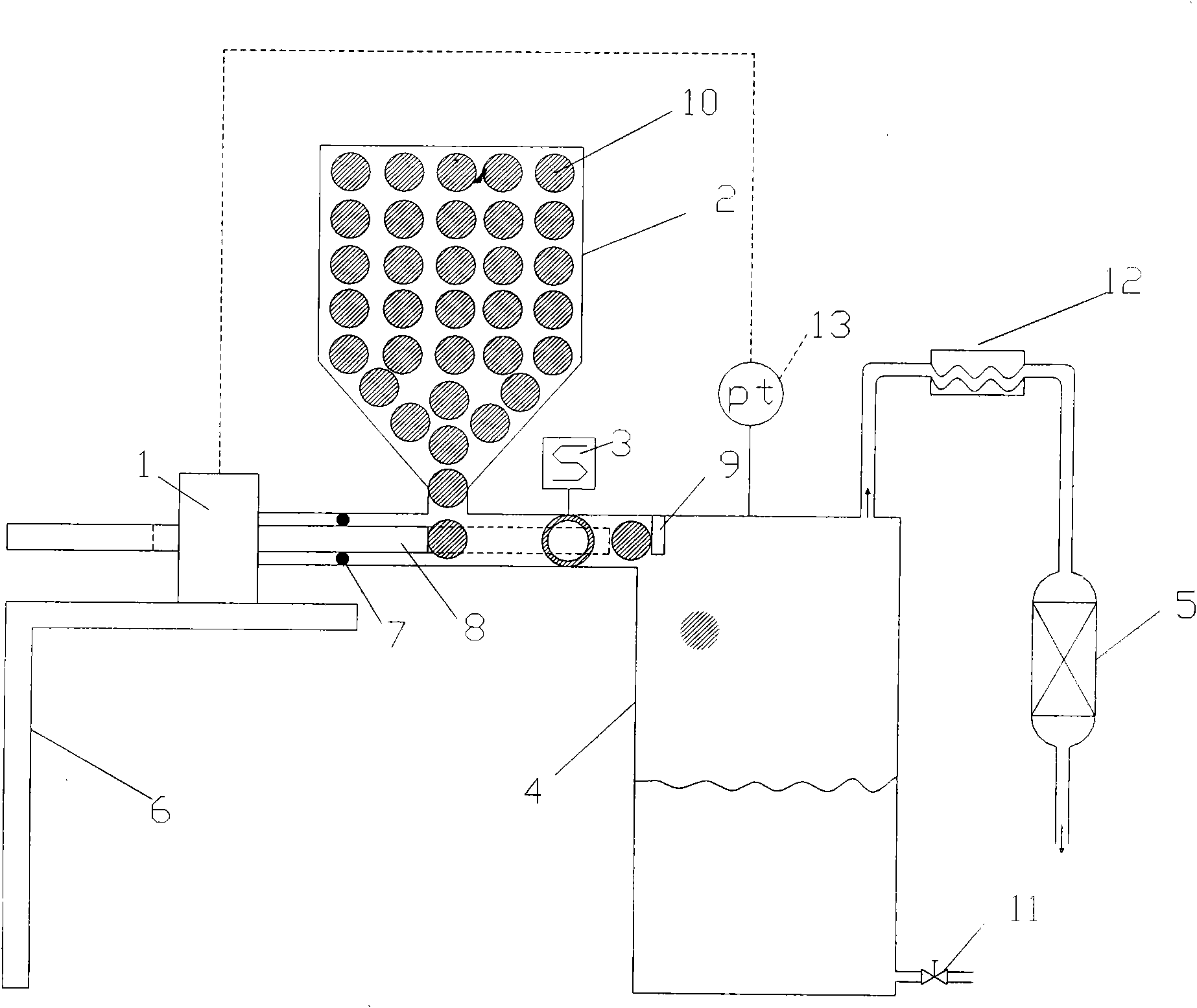

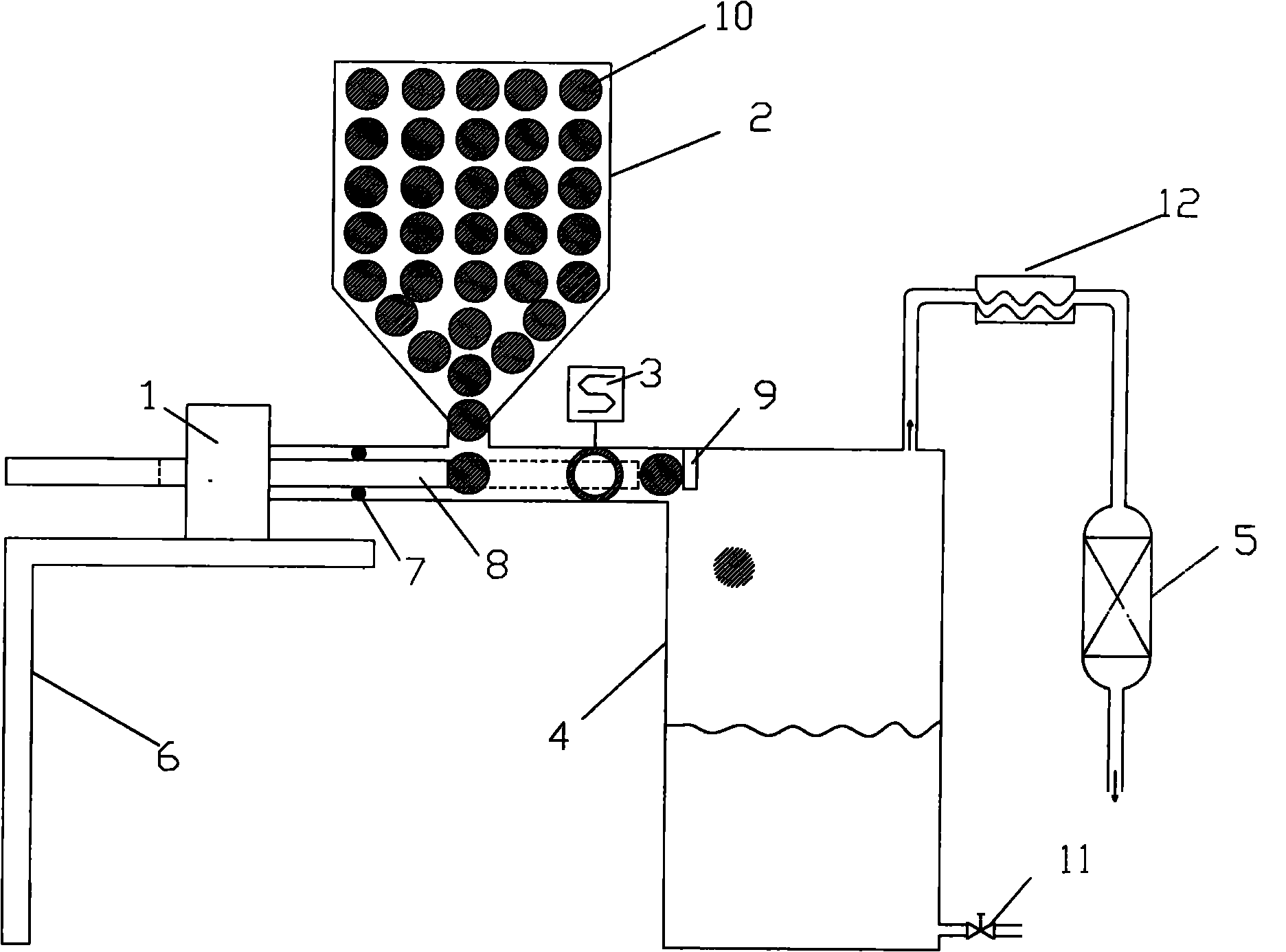

Device for preparing hydrogen through hydrolysis

InactiveCN101786603ASimple structureFast hydrogen productionHydrogen productionHydrogen purityHydrogen

The invention relates to a device for preparing hydrogen through hydrolysis and belongs to the technical field of hydrogen preparation. The device comprises a storage tank, a reactor, a condenser and a drier and is characterized in that the storage tank is used for storing solid reactant and connected to a driving mechanism; the driving mechanism is communicated with a hydrolysis reactor provided with a hydrogen outlet; and the hydrogen outlet is provided with a pipeline sequentially communicated with the condenser and the drier. The device of the invention has the advantages of simple structure, rapid hydrogen preparation, controllable rate, high hydrogen purity, low pollution level, low manufacturing cost, high safety and reliability, good controllability wide applicable range, convenient popularization and application and the like.

Owner:天津海蓝德能源技术发展有限公司

System and method of preparing hydrogen rich gas and carbon monoxide from synthesis gas

The invention relates to a system and a method of preparing hydrogen rich gas and carbon monoxide from synthesis gas. The system mainly comprises a synthesis gas purifying unit, a low-temperature liquefying separation unit and a CO product compressor, wherein the low-temperature liquefying separation unit is composed of a first plate-fin heat exchanger, a second plate-fin heat exchanger, a flash separator, a high-pressure rectification tower and a low-pressure rectification tower; a first evaporator is arranged at the bottom of the high-pressure rectification tower; a second evaporator is arranged at the bottom of the low-pressure rectification tower; and a first condenser is arranged at the top part of the low-pressure rectification tower. The system and the method are strong in adaptability to raw gas, little in equipment and small in investment, lower the requirement for impurities of the synthesis gas, eliminate a nitrogen compressor and an expander, increase the hydrogen recovery rate of a device and reduce the processing load of PSA or a membrane separation system.

Owner:KAIFENG AIR SEPARATION GROUP

Supported type nickel catalyst for producing hydrogen via decomposition of ammonia and preparation method

InactiveCN101352686APromote resource utilizationLess investmentHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen purityCatalytic reforming

The invention relates to a catalyst applied to catalyst hydrogen generation and a method of the catalyst hydrogen generation. The catalyst comprises industrial catalyst YWC-95 and CaO. The catalyst is used in steam catalytic reforming reaction of the catalyst hydrogen generation, the technical process of the catalyst hydrogen generation is shortened, hydrogen purity and production rate are improved and no secondary pollutant is generated in the production process.

Owner:EAST CHINA UNIV OF SCI & TECH

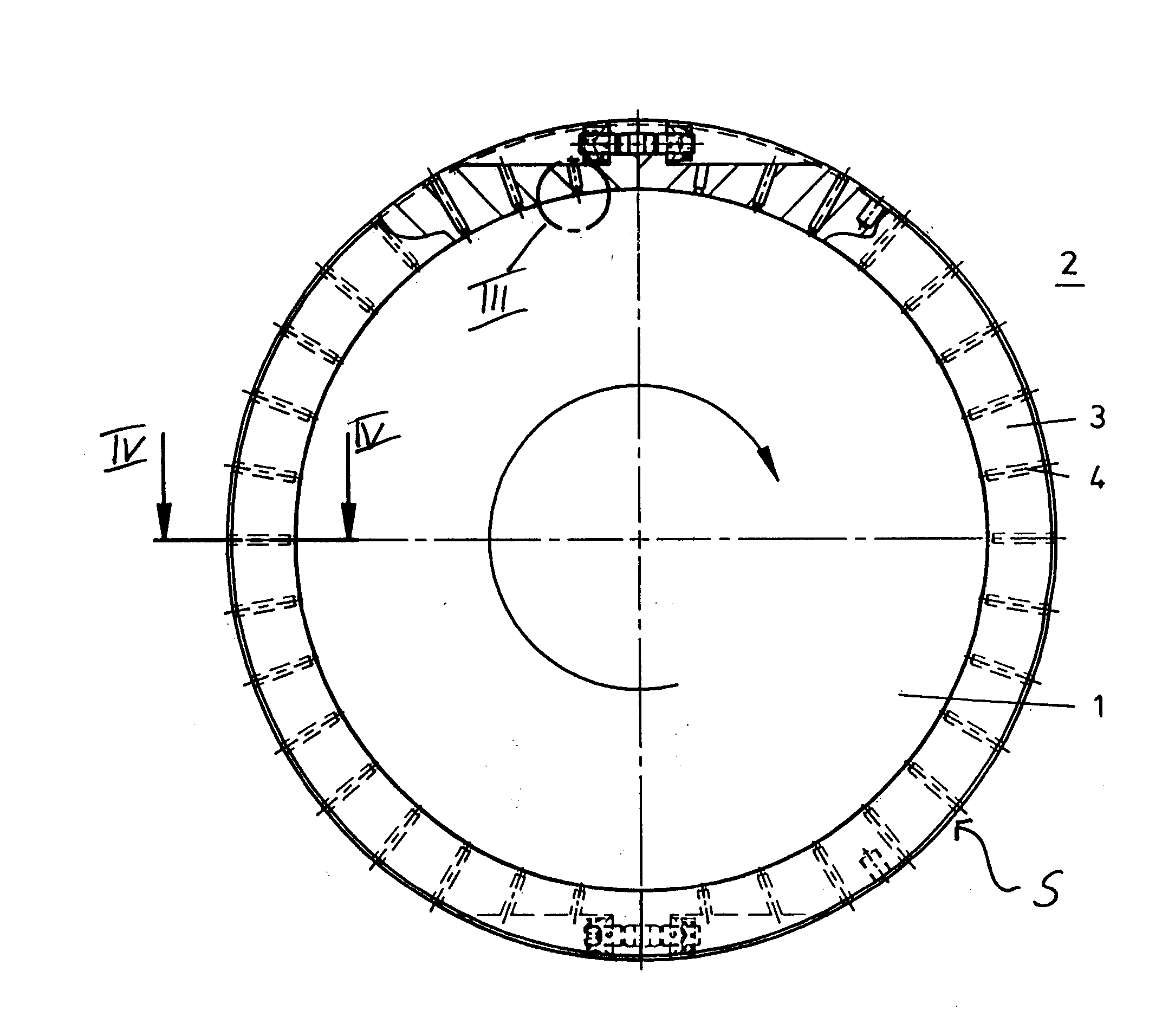

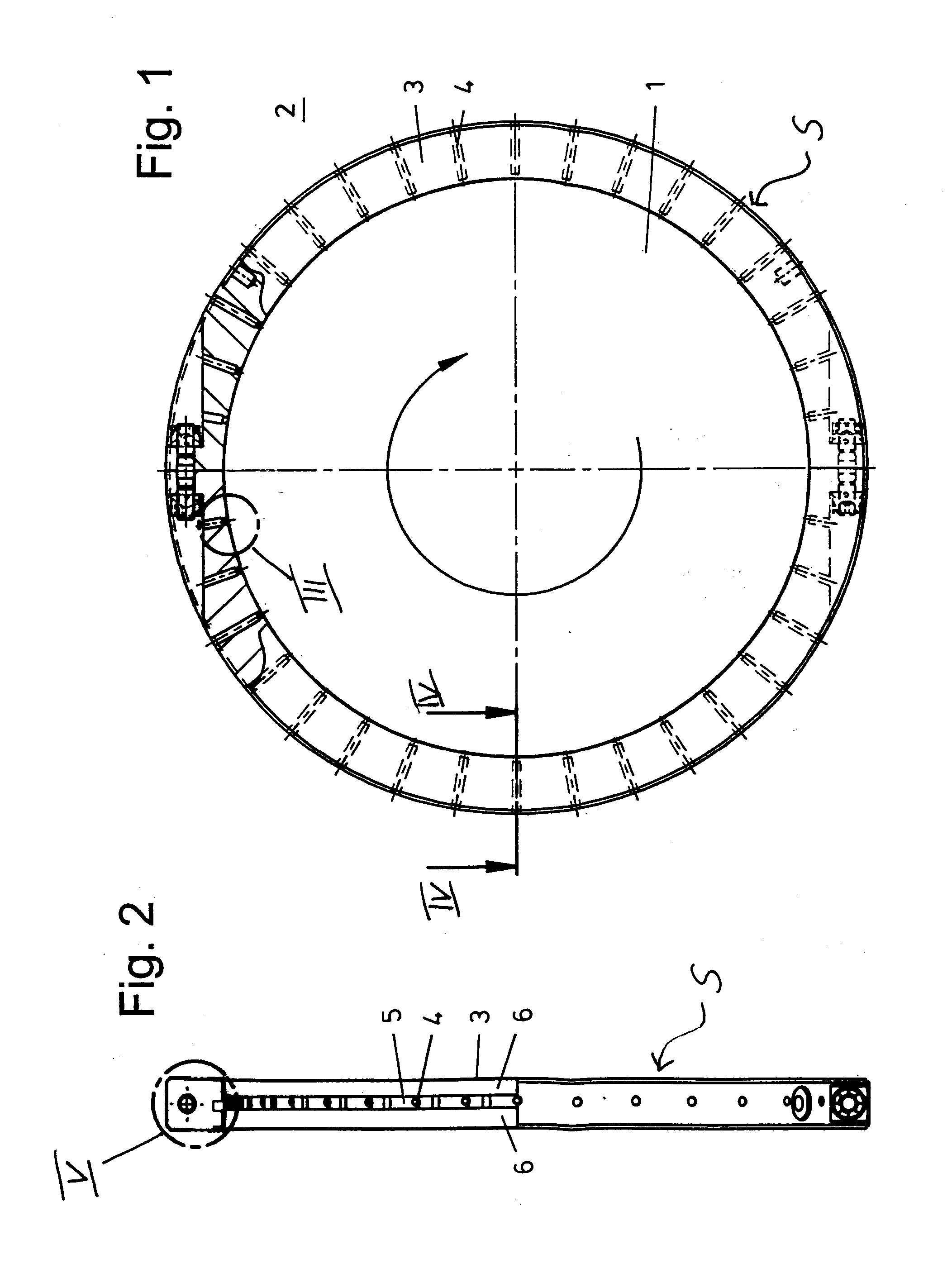

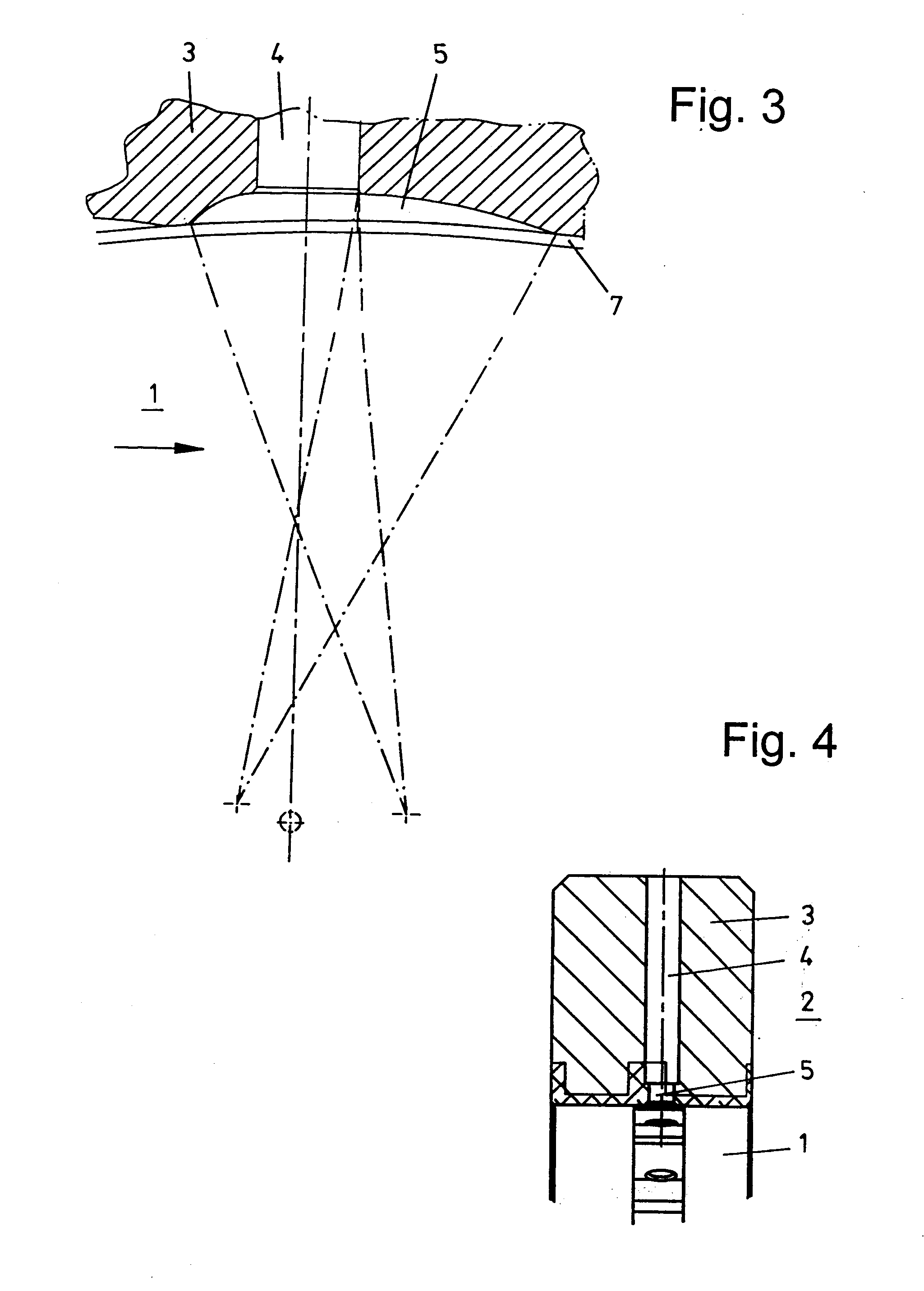

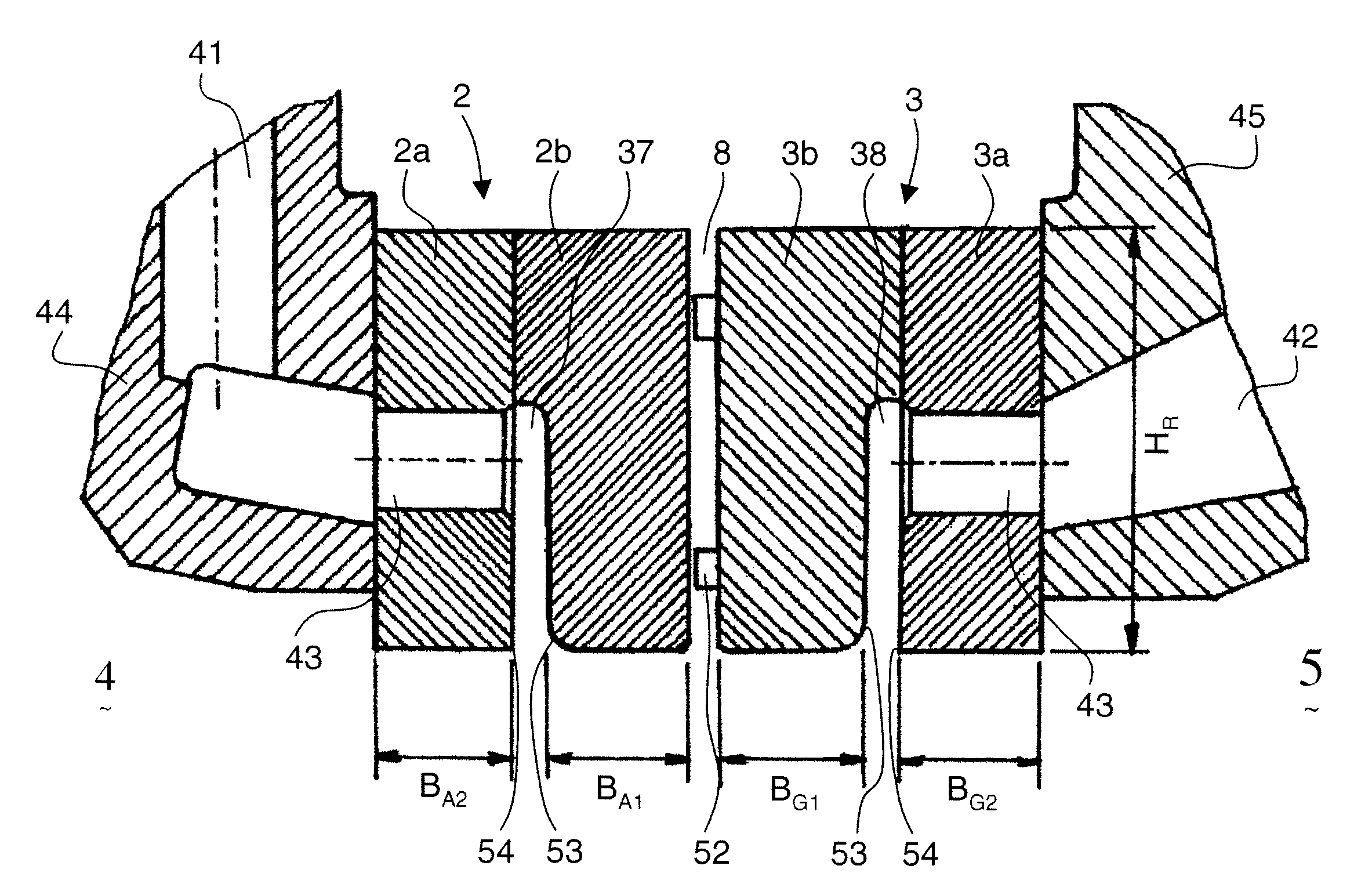

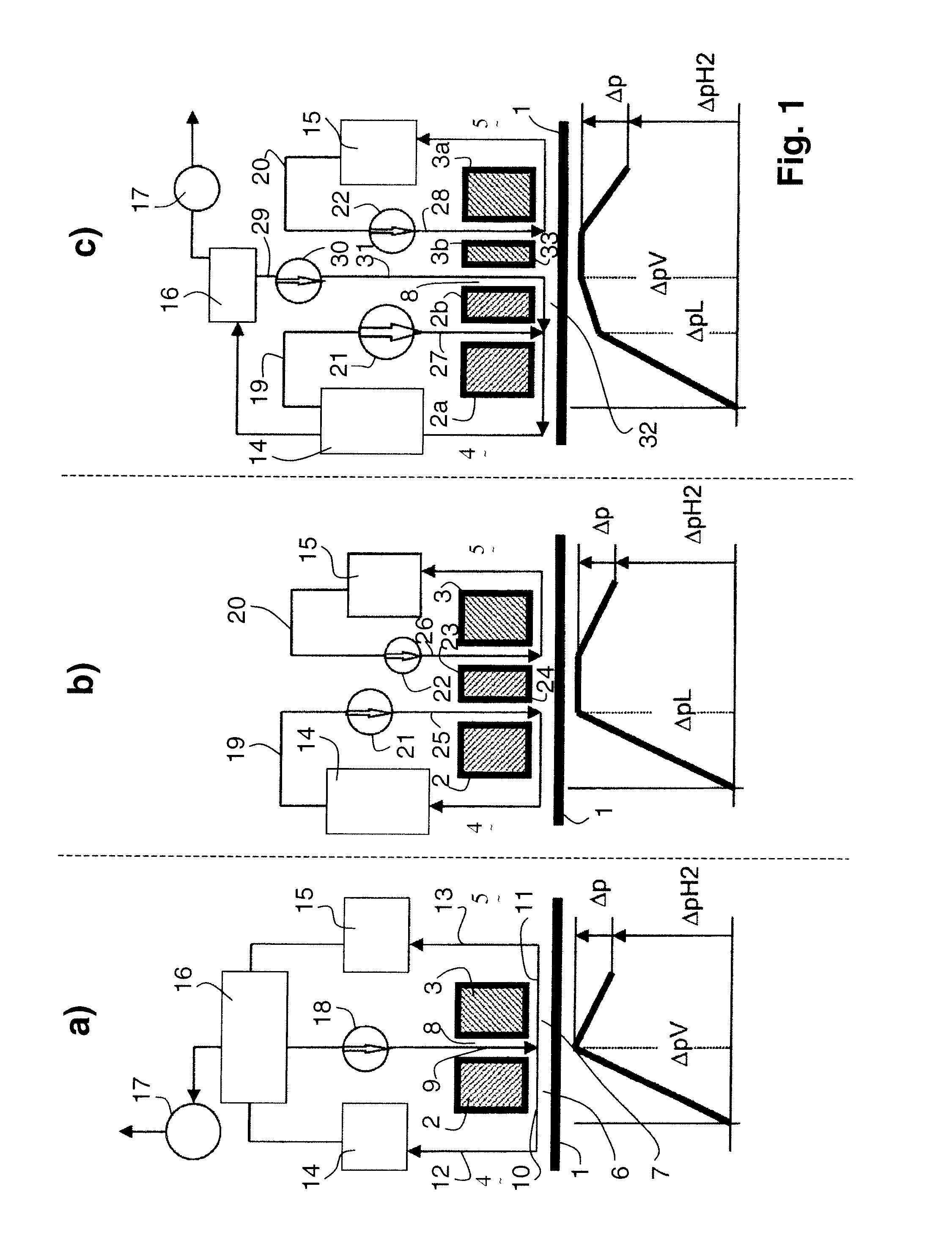

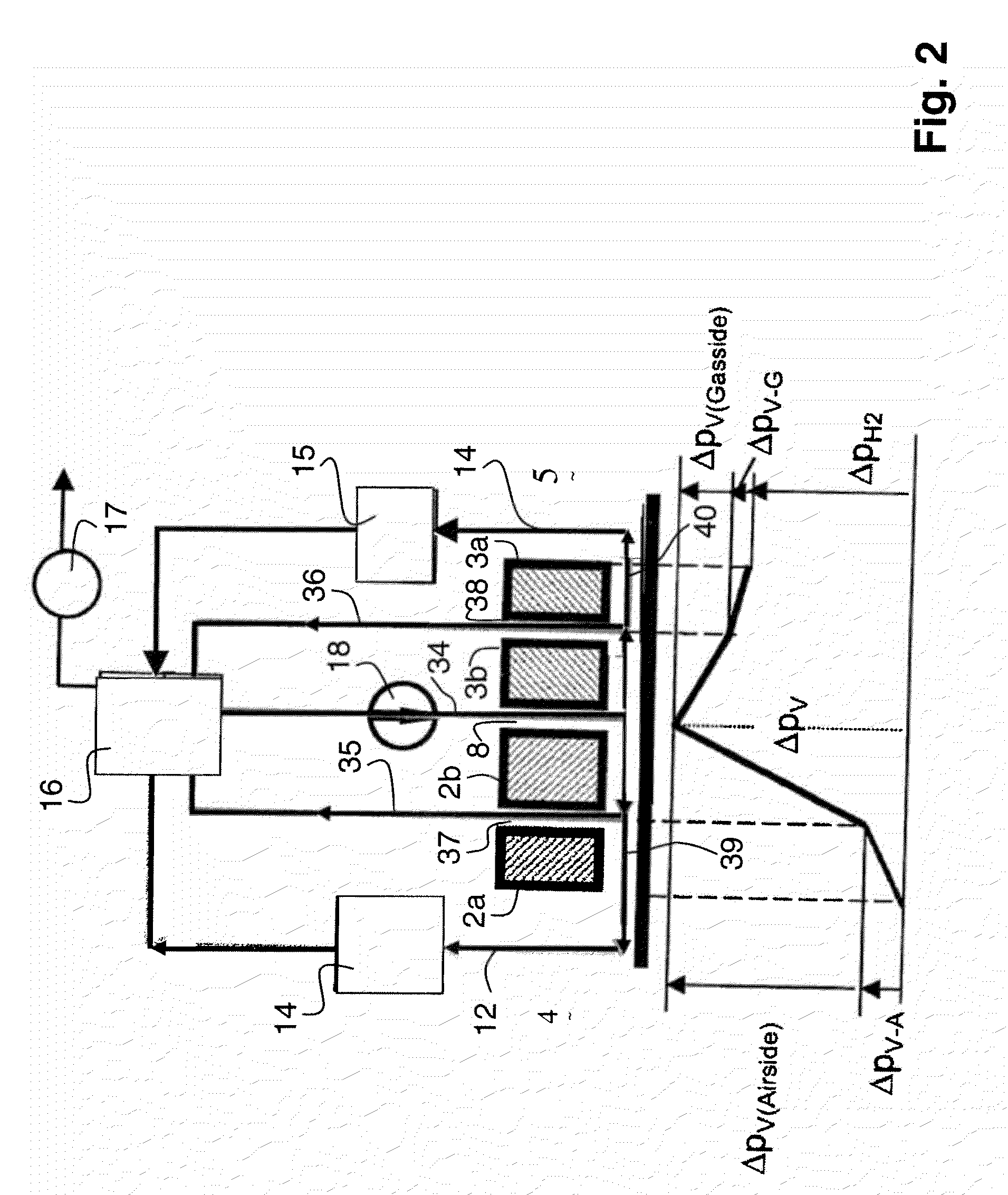

Device for Sealing a Rotating Shaft Penetrating a Housing Wall

InactiveUS20070114728A1Improve sealingIncrease capacityEngine sealsLeakage preventionEngineeringMechanical engineering

A device for sealing a rotating shaft that penetrates a stationary housing wall has a sealing ring fastened to the housing wall and arranged between the housing wall and a shaft. The sealing ring has sealing oil supply bores supplying sealing oil into a sealing gap formed between an inner wall surface of the sealing ring and an outer wall surface of the shaft. The inner wall surface has pocket-shaped recesses where the sealing oil supply bores open. The pocket-shaped recesses extend in the circumferential direction of the sealing ring. The inner wall of the sealing ring has at least one circumferential boundary stay that delimits and seals the pocket-shaped recesses in an axial direction of the sealing ring toward the first or second housing side. The inner wall surface of the sealing ring has a circumferential groove that connects the pocket-shaped recesses to one another.

Owner:GENERAL ELECTRIC TECH GMBH

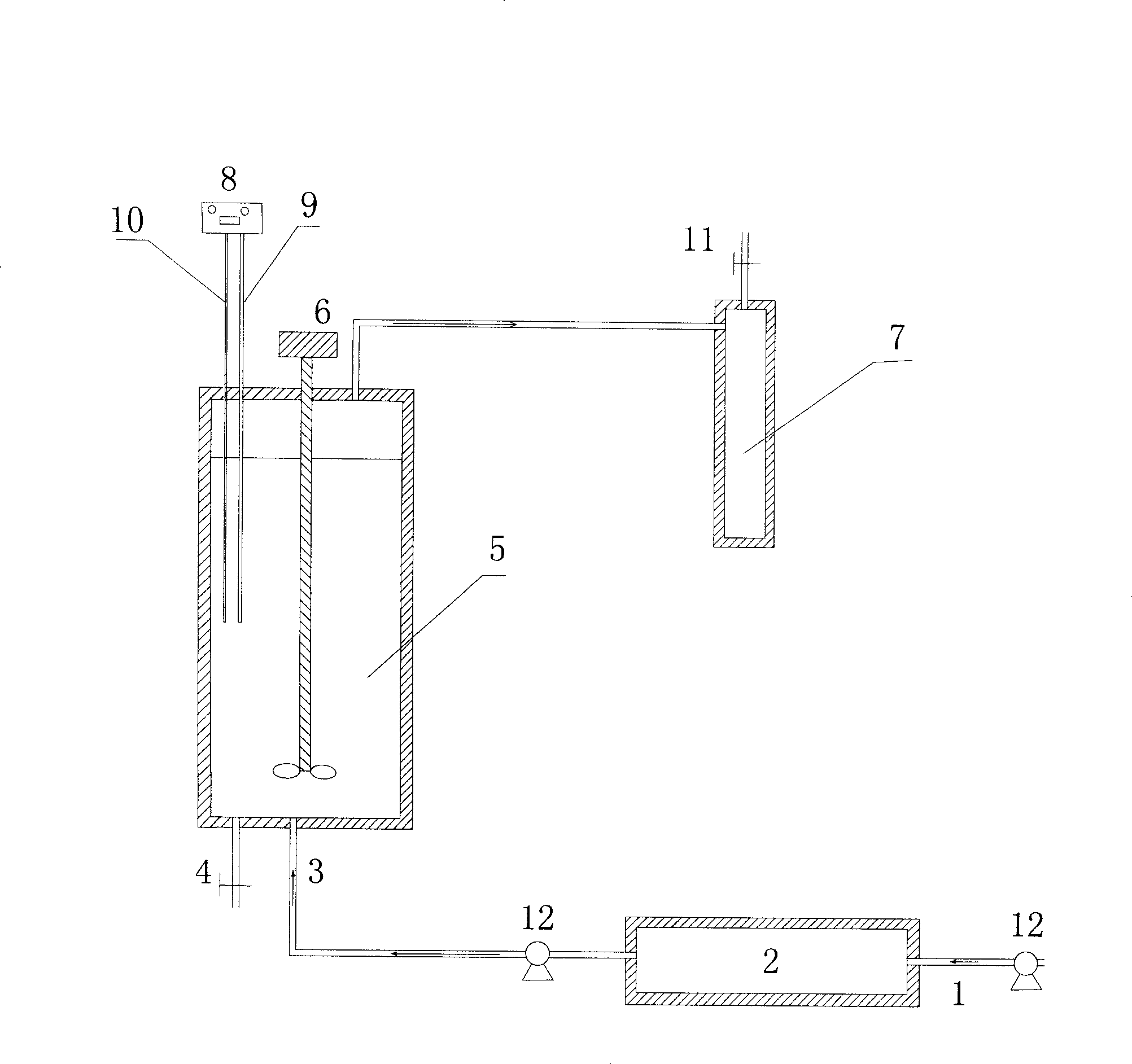

Method and apparatuses for pretreating sewage plant excess sludge by microwave method and producing hydrogen by fermentation

The invention discloses a method and a device for pretreating excess sludge of a sewage plant by a microwave method for fermentation to produce hydrogen. The method comprises the following steps: microwave is utilized to pretreat the excess sludge of the sewage plant for 2 to 20 minutes, then the sludge pretreated by the microwave is placed into a sealed fermentation hydrogen production reactor, hydrogen production seed sludge which accounts for 5 to 15 percent of the volume of the excess sludge is grafted, the temperature is controlled to between 25 and 45 DEG C for fermentation hydrogen production, and hydrogen is produced after 8 to 15 hours. The device comprises a microwave generator, the fermentation hydrogen production reactor and a hydrogen collection device, wherein the top of the fermentation hydrogen production reactor is provided with a hydrogen outlet, while the bottom is provided with a sludge inlet and a sludge discharge outlet; the microwave generator is connected with the sludge inlet of the fermentation hydrogen production reactor; the hydrogen collection device is connected with the hydrogen outlet of the fermentation hydrogen production reactor; and the fermentation hydrogen production reactor is provided with a stirrer and a heater. The method has the advantages that the method has large hydrogen yield and short delay time, can improve the biological redegradation capability of the sludge, can release heavy metals in the sludge, reduce the pollution of landfill treatment to soil, and has simple equipment, low cost and less energy consumption.

Owner:HUNAN UNIV

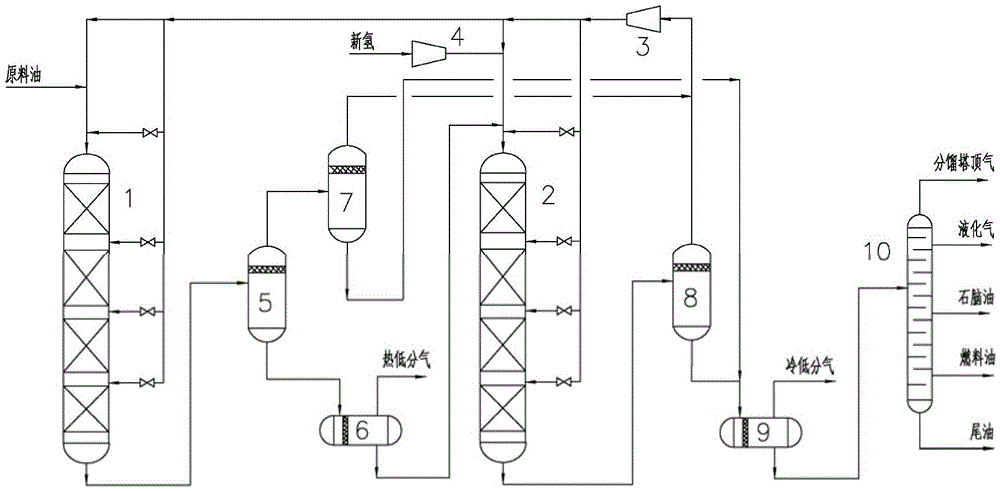

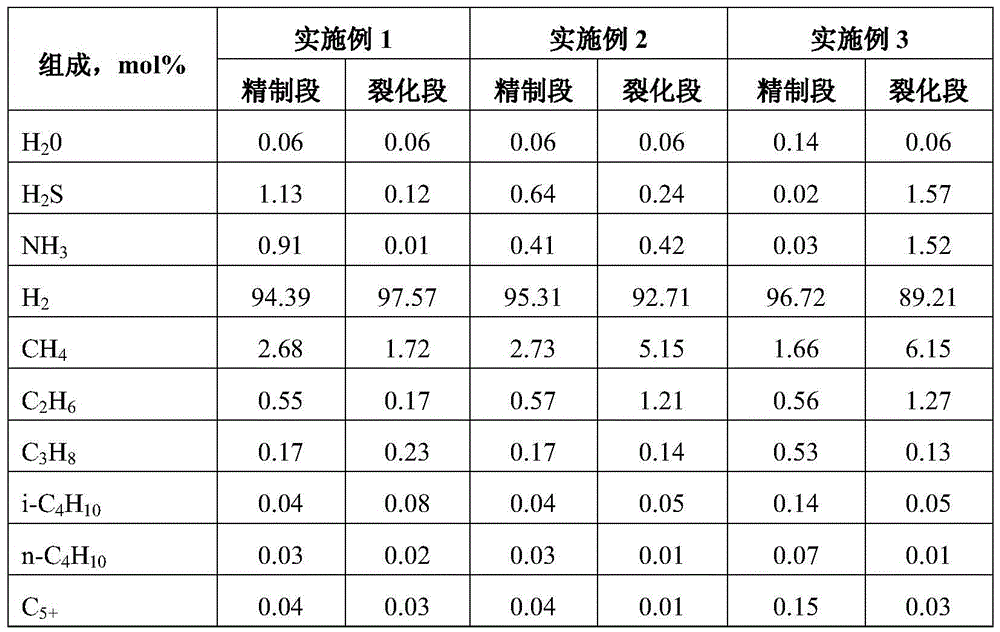

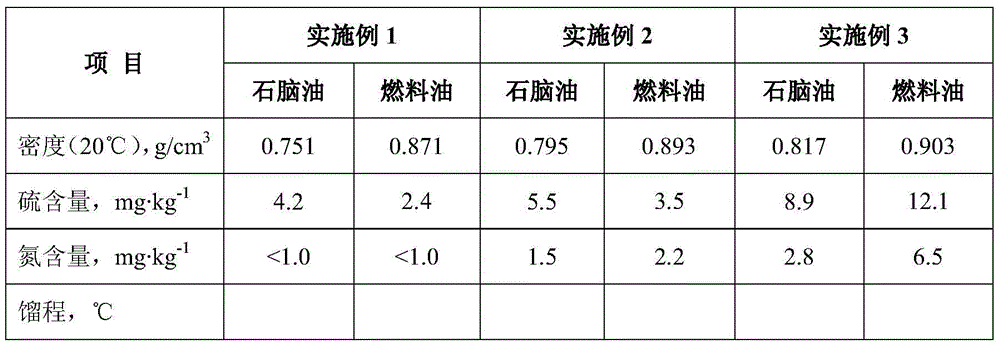

Anthracene oil hydrogenation method

ActiveCN105462610AAdd depthIncrease liquid collectionTreatment with hydrotreatment processesAnthraceneHydrogen purity

The invention discloses an anthracene oil hydrogenation method. According to the method, anthracene oil is diluted with hot low-pressure segregator oil, and then the diluted oil and inlet hydrogen are mixed to undergo hydrofining so as to obtain a hydrofining product; the hydrofining product is separated to obtain refined hot low-pressure segregator oil; part of the refined hot low-pressure segregator oil and inlet hydrogen are mixed, and new hydrogen is supplemented to carry out hydrocracking so as to obtain a hydrocracking product; the hydrocracking product is separated to obtain cracked cold high-pressure segregator oil; the cracked cold high-pressure segregator oil and refined cold high-pressure segregator oil are mixed and separation is then carried out to obtain cold low-pressure segregator oil; and the cold low-pressure segregator oil undergoes fractionation so as to obtain a product. by the method of introducing inlet hydrogen in the hydrofining stage and supplementing new hydrogen in the hydrocracking stage, the hydrogen circulatory system and new hydrogen joint point are adjusted, hydrogen purity and hydrogen partial pressure in the hydrogen circulatory system are guaranteed, hydrofining and hydrocracking depth is enhanced, liquid yield of the product is raised, and tail oil quantity is reduced. The method has advantages of simple technological flow, high conversion rate and stable plant operation.

Owner:HUADIAN HEAVY IND CO LTD

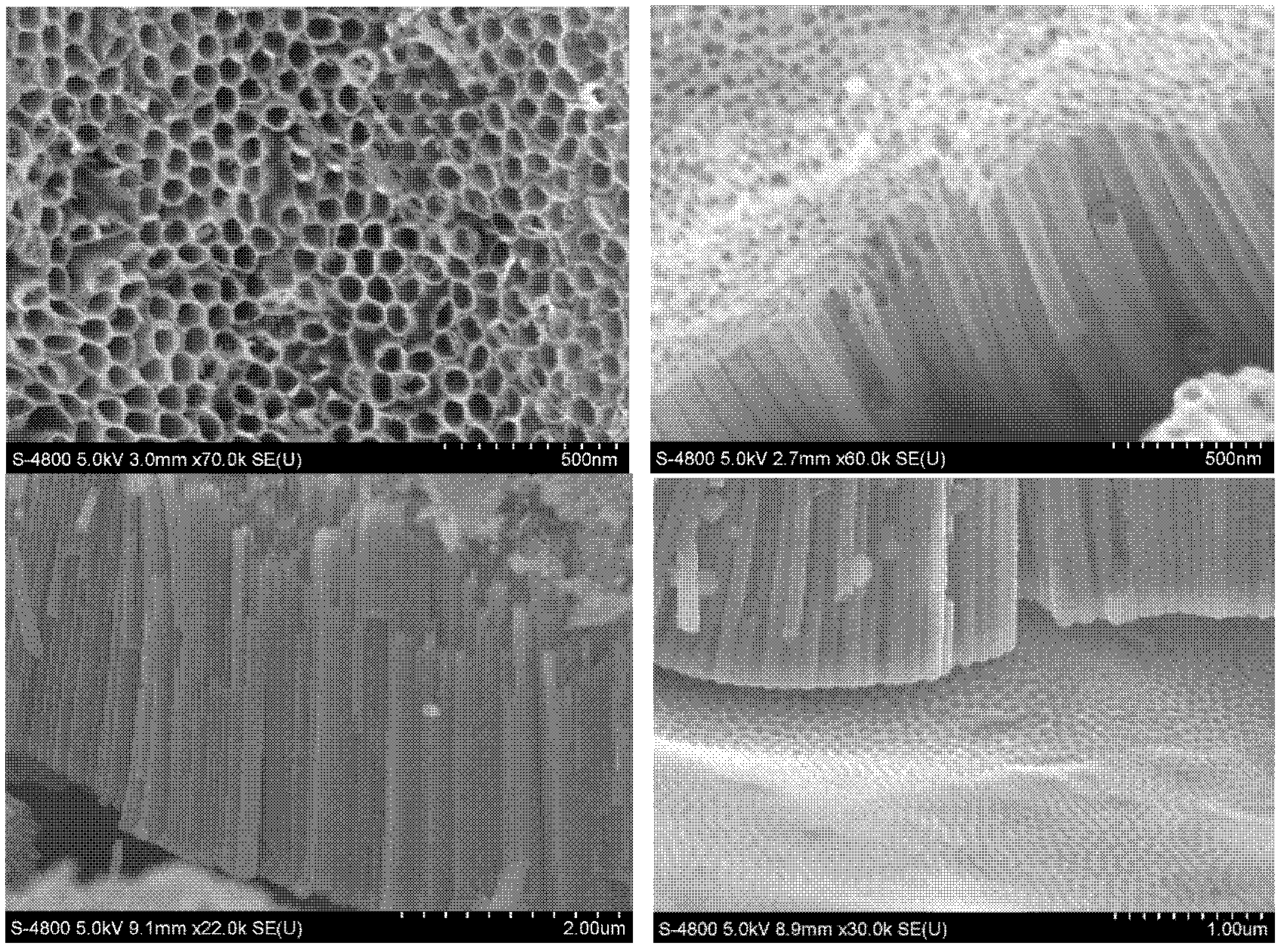

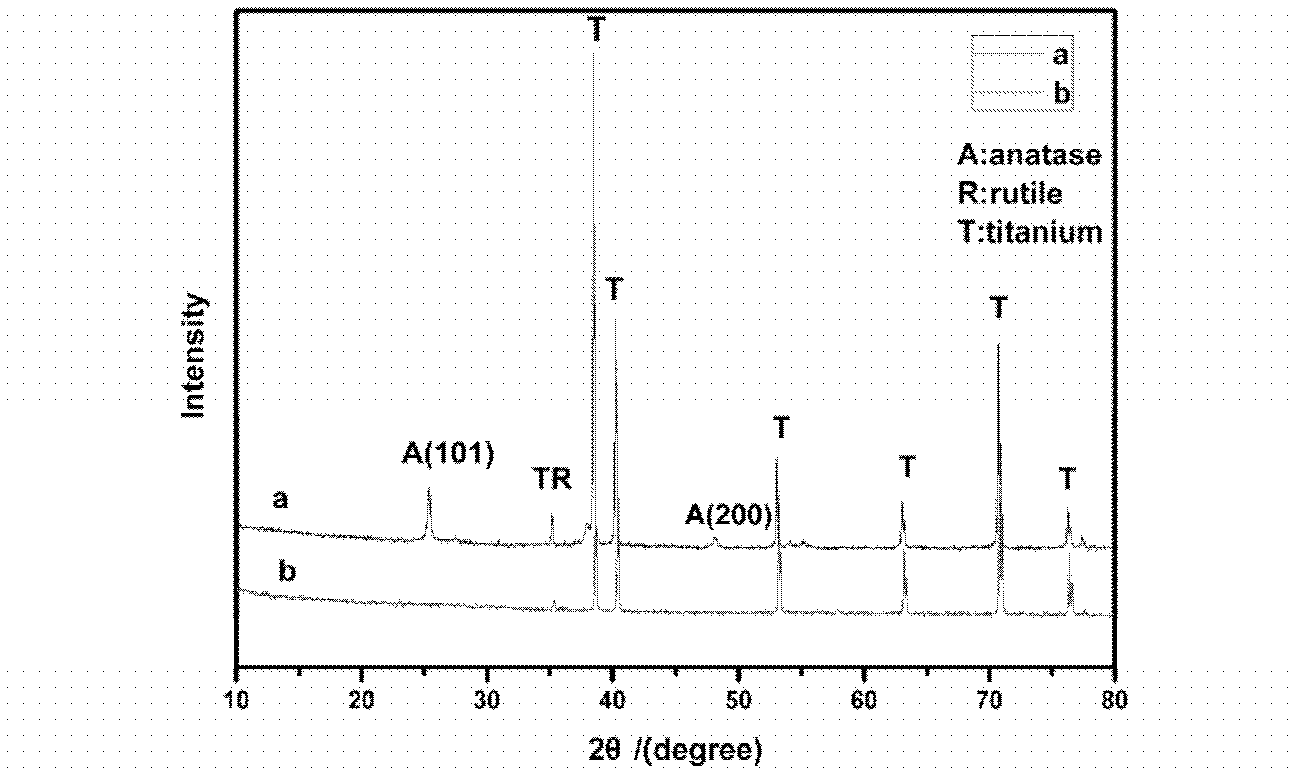

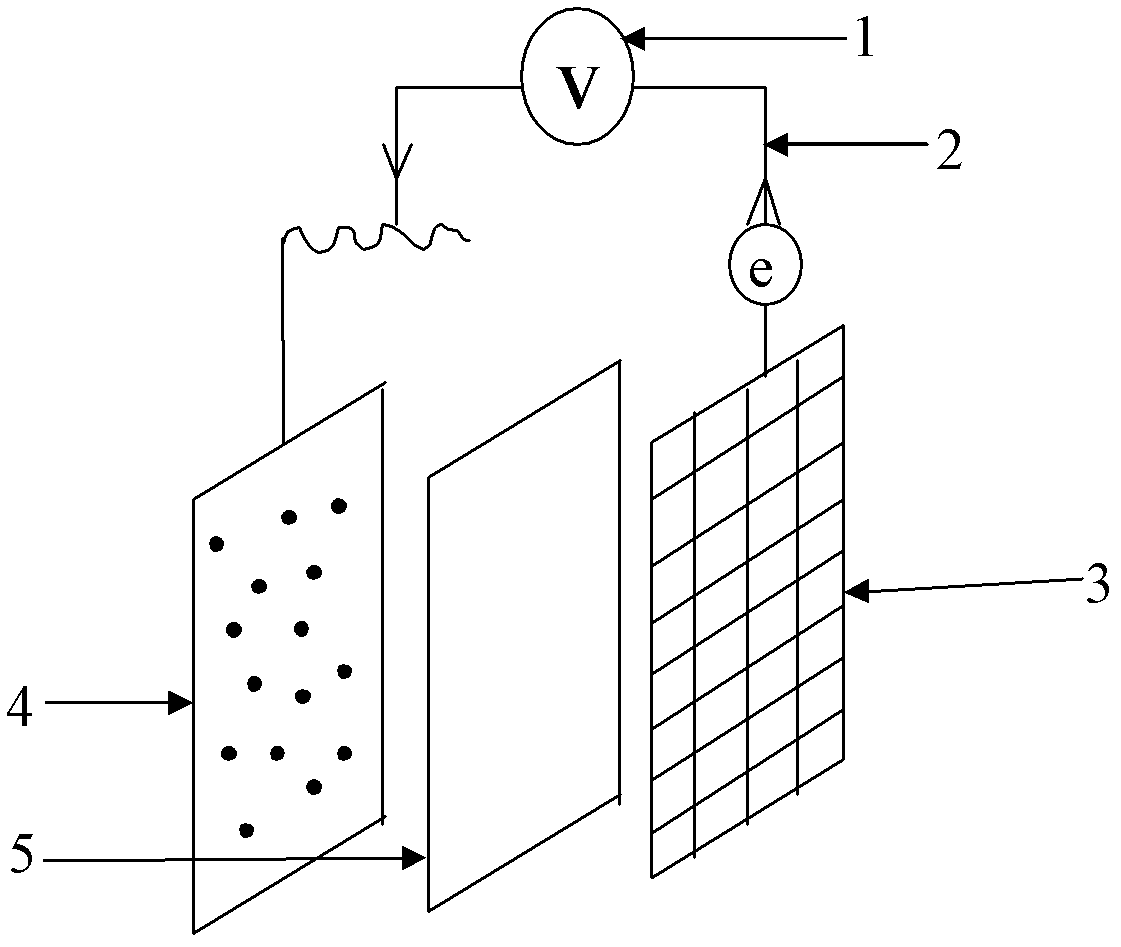

Hydrogen-production and on-line separation device for decomposing water by optical electrolytic cell

ActiveCN103159297AAvoid corrosionReduce ohmic impedance lossElectrolysis componentsWater/sewage treatment by irradiationAfter treatmentHydrogen production

The invention relates to a novel optical electrolytic cell structure, and particularly relates to an improvement on the basis of a three-electrode system, with a membrane electrode assembly being applied therein and an intermediate membrane layer being a solid polymer alkaline membranes. The device can directly perform on-line separation on hydrogen and oxygen produced by photoelectrocatalysis of water, prevents after-treatment processes of a conventional separation device for the hydrogen and oxygen, increases security of a system and greatly saves energy consumption. Besides, the structure has good stability. The novel optical electrolytic cell structure is compact in structure and compared with the three-electrode system, size is greatly reduced under the same illumination area.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Shaft sealing system, preferably for a hydrogen cooled generator

InactiveUS20100127458A1Improve sealingReduce hydrogen consumptionEngine sealsLeakage preventionHydrogenEngineering

A shaft sealing arrangement includes at least two seal rings radially enclosing a rotating shaft so as to define a clearance between the shaft and the at least two seal rings. A sealing oil supply channel is disposed between the at least two seal rings and a pump is configured for pumping a sealing oil through the sealing oil supply channel in a radial direction towards the shaft so that the sealing oil subsequently flows through the clearance in a first axial direction toward a first side of the sealing arrangement and in a second opposite axial direction toward a second side of the sealing arrangement. The sealing oil is collected on the first and second sides and at least partially reintroduced into the sealing oil supply channel. At least one seal ring includes a sealing oil return channel and at least a portion of the sealing oil flowing through the clearance exits the clearance in a radial direction through the sealing oil return channel and is at least partially collected and reintroduced into the sealing oil supply channel.

Owner:ALSTOM TECH LTD

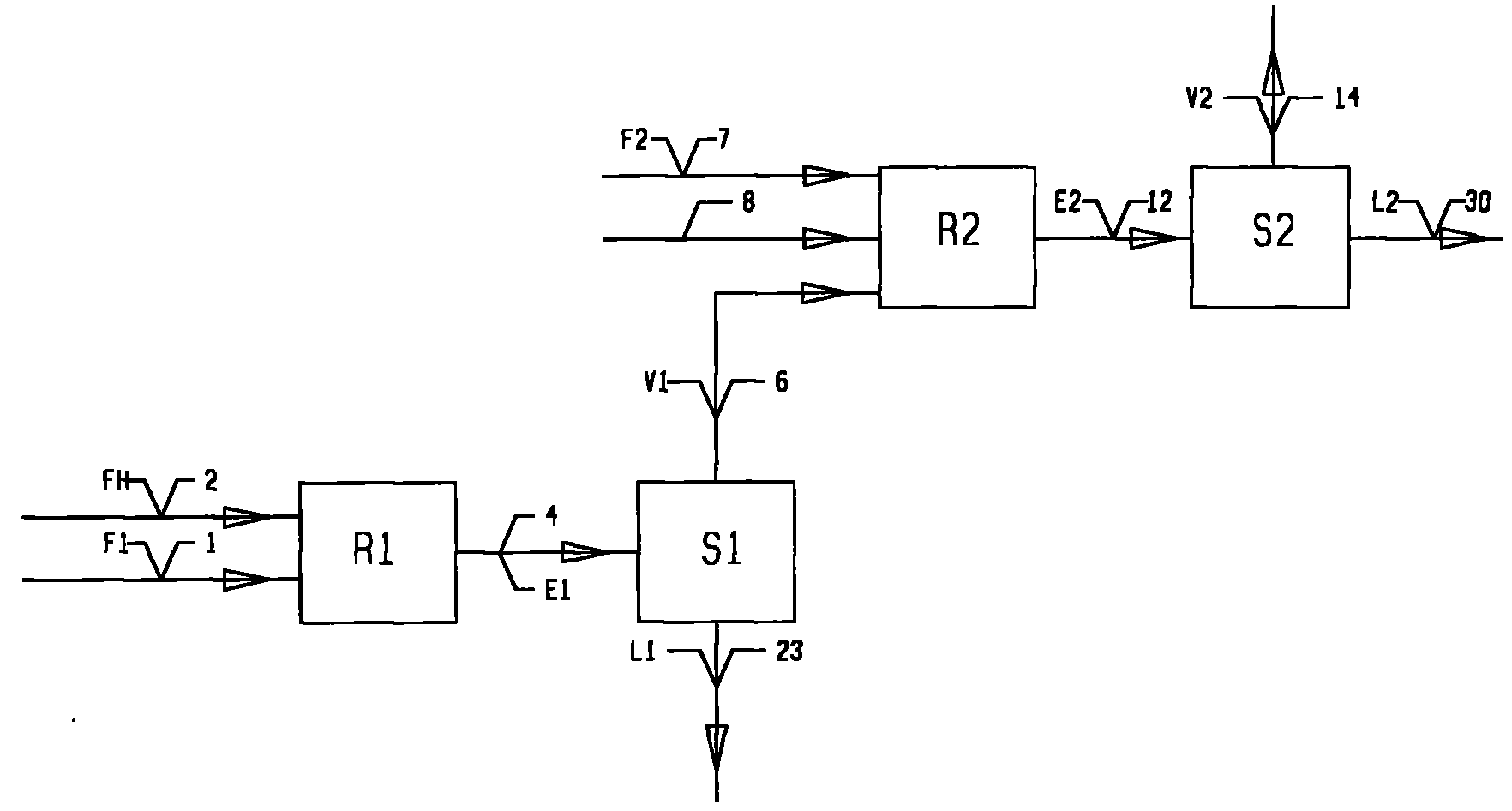

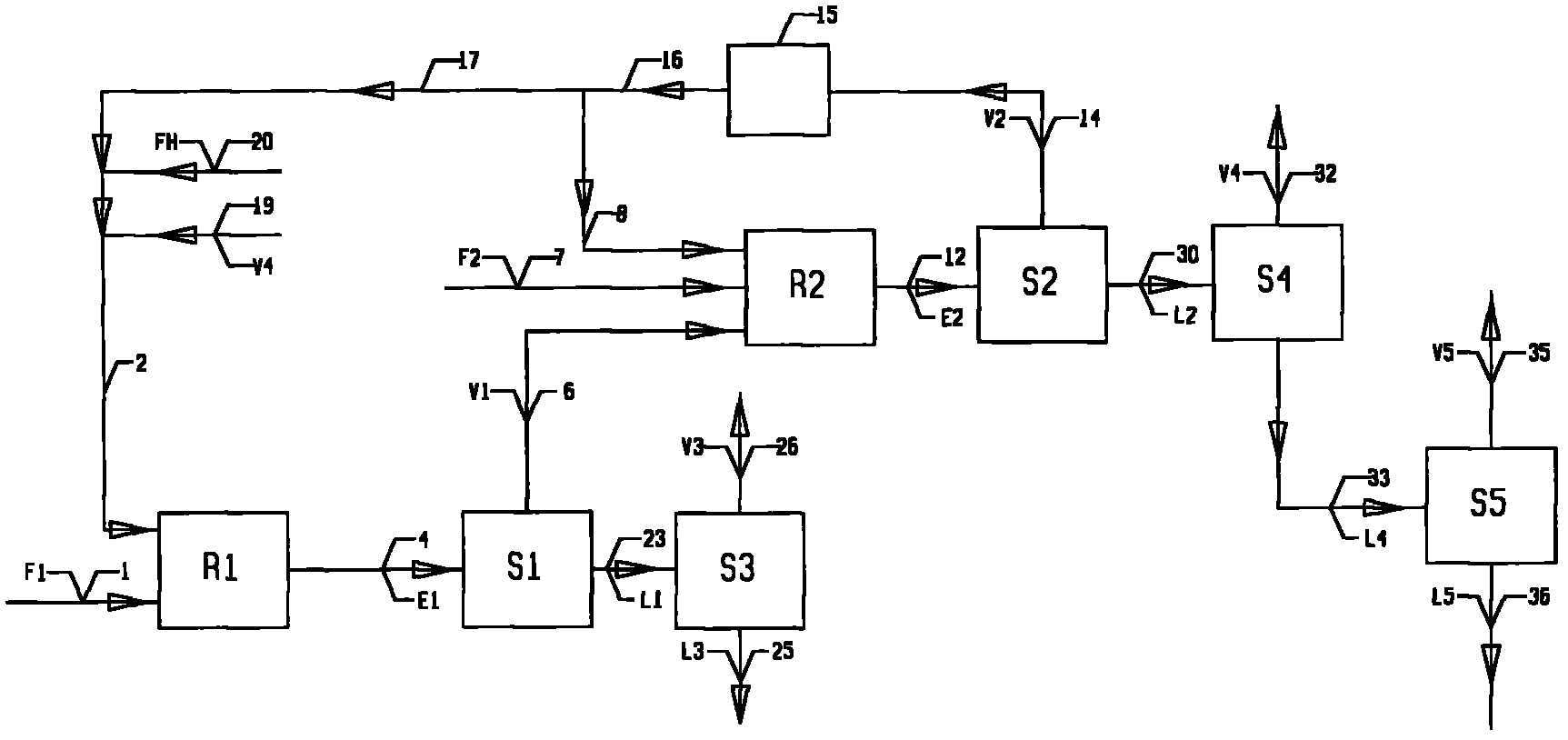

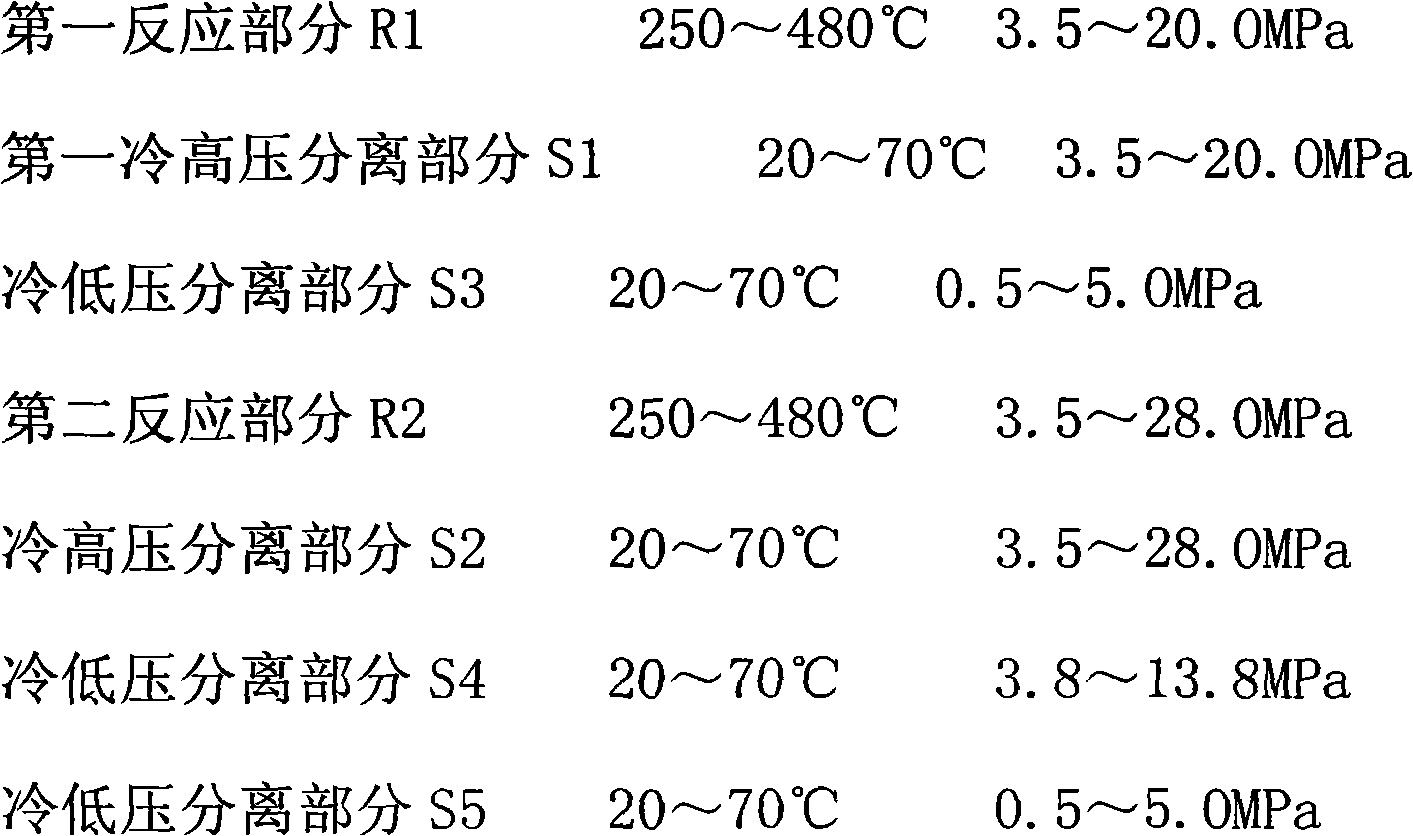

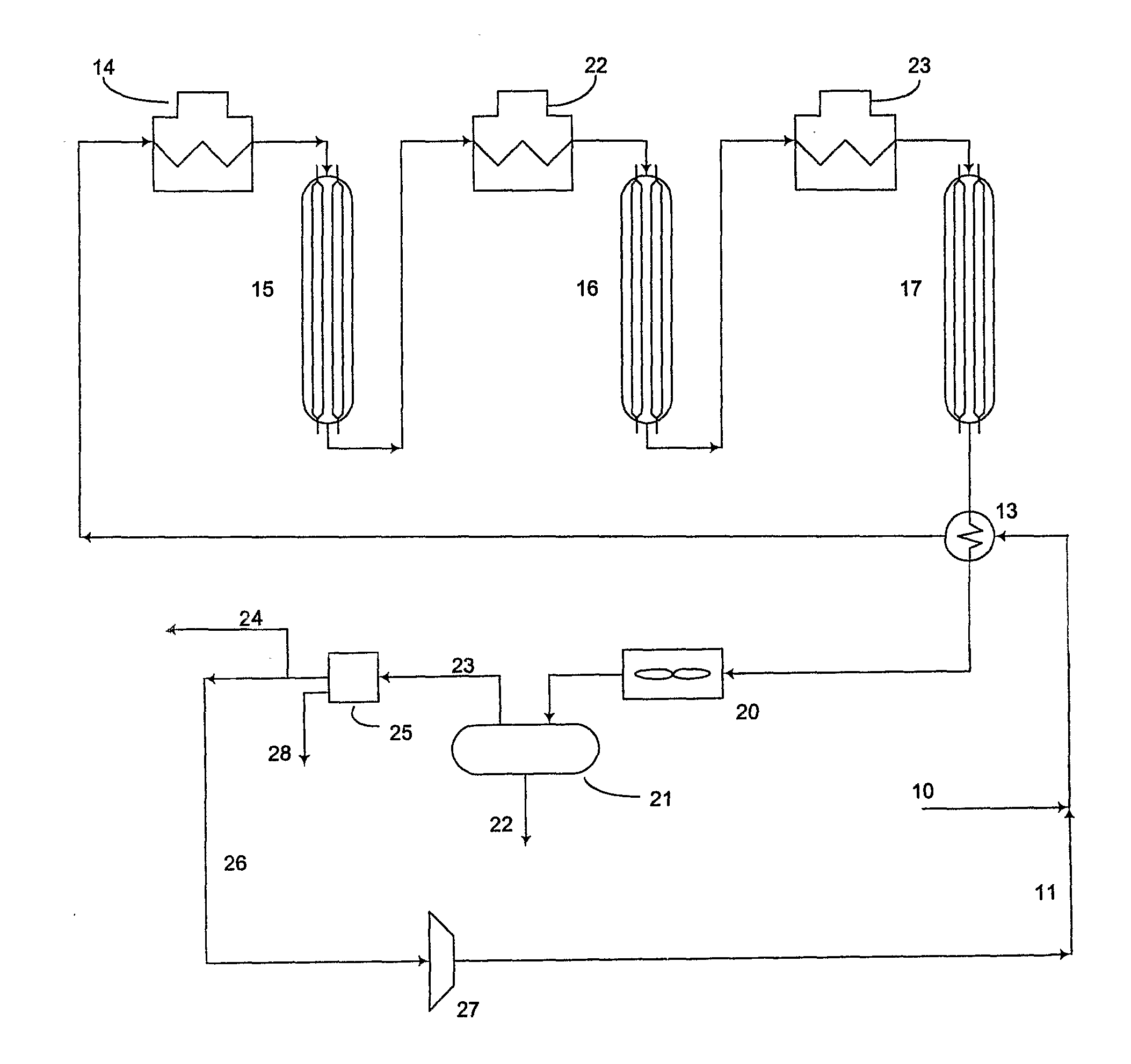

Hydrocarbon hydrogenation conversion process combined method

InactiveCN102146298AReduced dedicated cycle hydrogen volumeLess investmentTreatment with hydrotreatment processesHydrodesulfurizationCombined method

The invention relates to a hydrocarbon hydrogenation conversion process combined method which comprises steps as follows: a first reaction effluent E1 obtained by new hydrogen FH and a first hydrocarbon raw material F1 at a first reaction part R1 is separated into a first cold high-pressure hydrogen-rich gas V1 and a first cold high-pressure hydrocarbon liquid L1 at a first cold high-pressure separation part S1; at least part of V1 enters a second reaction part R2 for treating a second hydrocarbon raw material F2; and a second reaction effluent E2 is separated into a second cold high-pressure hydrogen-rich gas V2 and a second cold high-pressure hydrocarbon liquid L2 at a second cold high-pressure separation part S2. The invention also comprises the step of recovering dissolved hydrogen in the L2. The invention has obvious effects of saving the step of high-pressure operation, reducing the hydrogen consumption and the like, is suitable for the combination of a medium / low-pressure low-hydrogen-consumption hydrocarbon hydrogenation process (such as petroleum-based gasoline / diesel hydrofining, wax oil hydrodesulfurization or low-sulfur diesel hydrogenation and aroma removal process) and a high-pressure high-hydrogen-consumption hydrocarbon hydrogenation process (such as coal tar hydrogenation process).

Owner:何巨堂

Catalytic Reformer Unit and Unit Operation

ActiveUS20110147270A1High purity hydrogenLower overall pressure dropGas treatmentHydrogen separation using solid contactCatalytic reformingPetroleum naphtha

An improved process for catalytic reformers and their use for the catalytic reforming of petroleum naphthas. More particularly, the invention relates to an improved reformer unit which can be operated at higher throughput relative to compressor size. The invention utilizes pressure swing adsorption to improve the hydrogen content of hydrogen containing streams generated by and utilized in catalytic reforming processes. The invention also has the capability of enabling compressor-limited catalytic reforming units to be operated at increased capacities.

Owner:EXXON RES & ENG CO

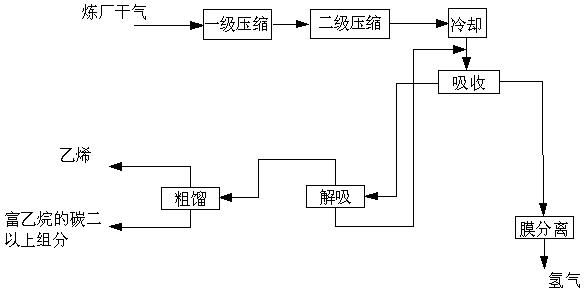

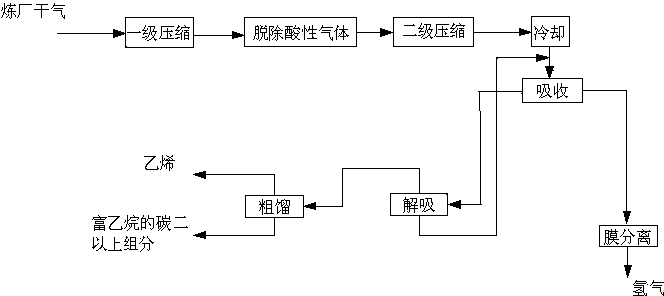

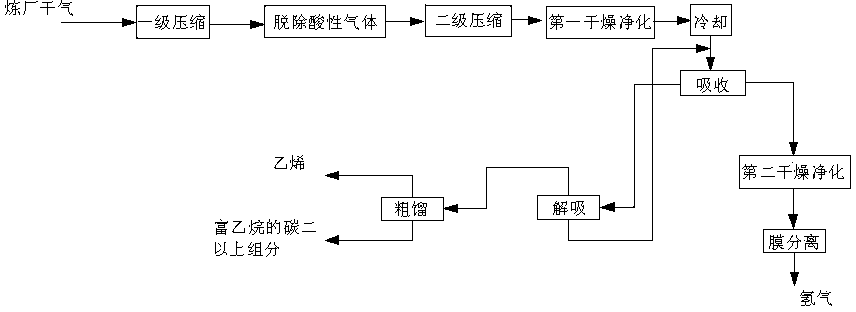

Method for recovering ethylene and hydrogen from refinery dry gases by combining cold oil absorption and membrane separation

ActiveCN104031684AHigh purityHigh yieldHydrogen separation using solid contactDistillation purification/separationHydrogenDesorption

The invention discloses a method for recovering ethylene and hydrogen from refinery dry gases by combining membrane separation and cold oil absorption. The method has the advantages and beneficial effects that main components such as hydrogen, ethylene and the like are obtained from the refinery dry gases through the steps of compression and pressure increase, cold oil absorption, membrane separation, desorption, normal coarse distillation and the like; the main components are clearly separated; meanwhile, under the actions of cold oil absorption and membrane separation, the purity of various components can be more than 99%, the yield of hydrogen can reach 90-95%, and the yield of ethylene is 92-98%; the whole recovery flow is reasonable; the method has the characteristics of high yield, high purity, low operating cost and relatively low energy consumption.

Owner:SICHUAN TECHAIRS

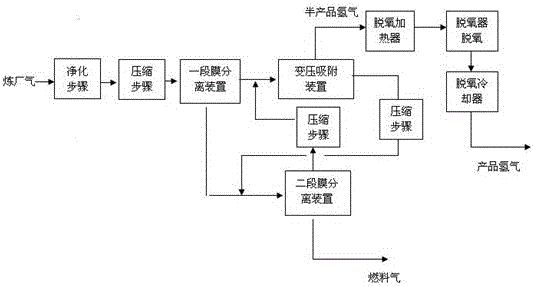

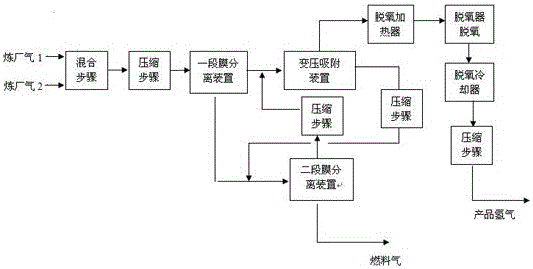

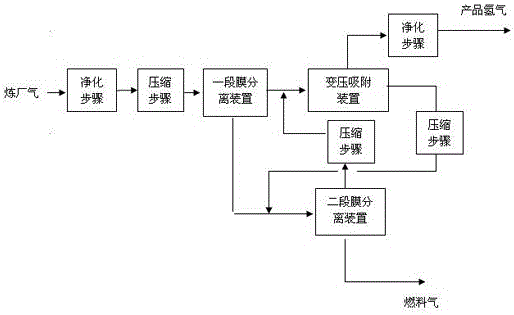

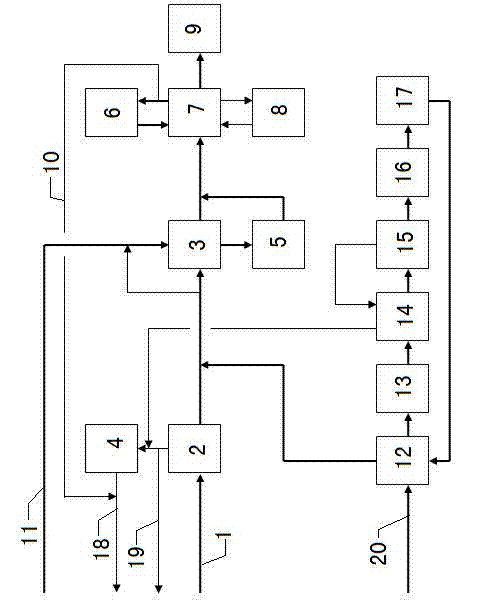

Method for improving hydrogen recovery rate

ActiveCN104986735AHigh purity hydrogenImprove separation efficiencyHydrogen separation using solid contactChemical industryEnergy consumption

The invention belongs to the field of chemical industry and relates to a hydrogen extraction technology in the field of chemical industry, particularly a method for improving the hydrogen recovery rate by combining a refinery gas pressure swing adsorption method and a membrane separation method. The method comprises the following steps: carrying out first-section membrane separation; carrying out pressure swing adsorption; carrying out second-section membrane separation; returning osmotic gas in membrane separation devices in the two sections to a pressure swing adsorption device; and discharging osmotic residual gas as fuel gas. The technology provided by the invention has the advantages that by combining the technical characteristics of pressure swing adsorption and membrane separation, the advantages of the individual single technology are fully exerted, and moreover, the purity and recovery rate of hydrogen are improved, and the energy consumption is reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

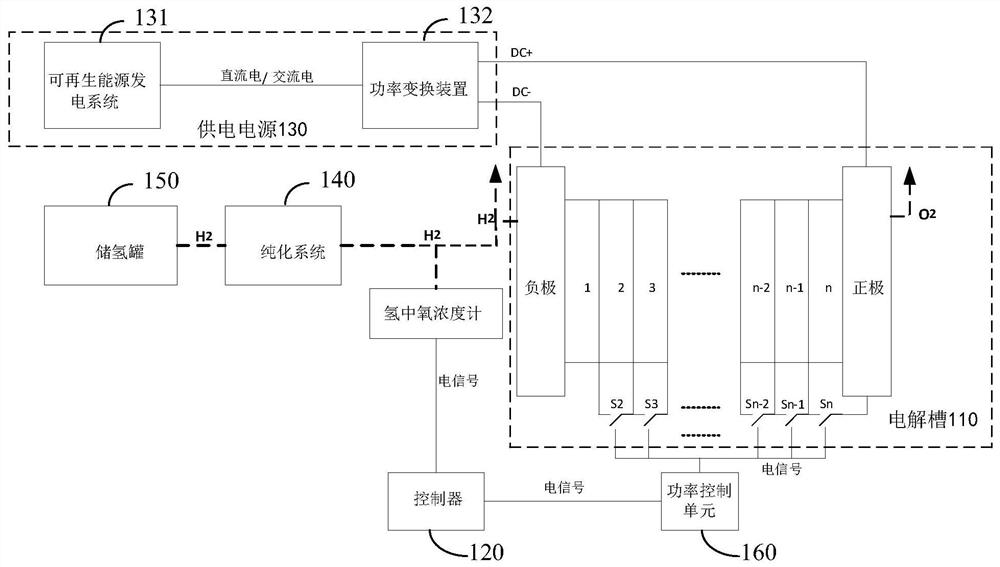

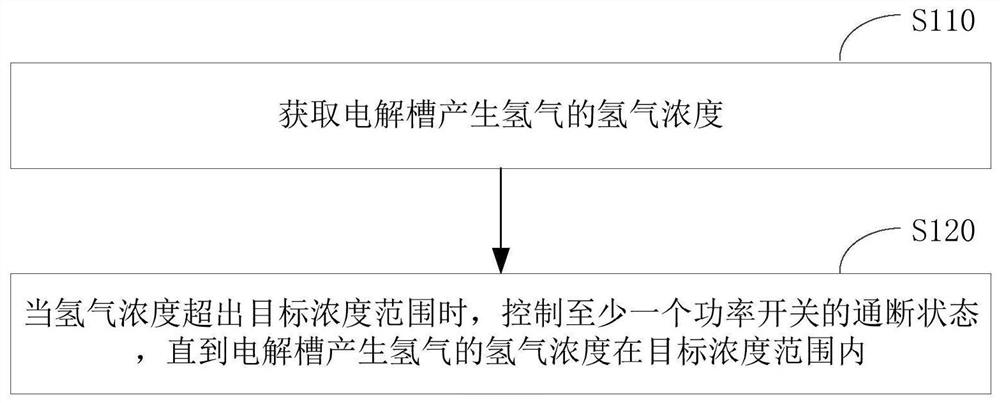

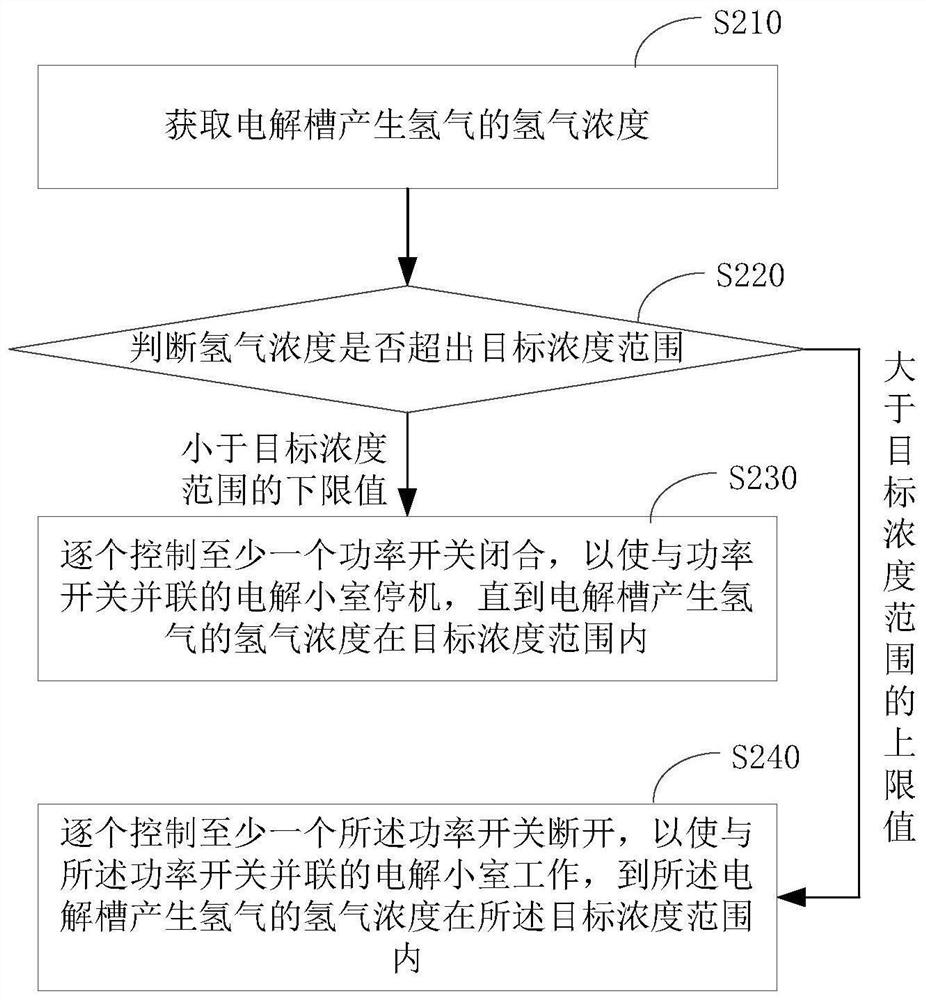

Water electrolysis hydrogen production control method and system and controller

PendingCN112725832AChange concentrationIncrease productionCellsEnergy inputHydrogen yieldRenewable energy

The invention provides a water electrolysis hydrogen production control method and system and a controller. According to the scheme, the method comprises the steps: controlling the working state of an electrolytic cell according to the concentration of hydrogen generated by the electrolytic cell, and controlling the on-off state of at least one power switch when the concentration of hydrogen exceeds a target concentration range so as to adjust the number of electrolysis cells participating in hydrogen production in the electrolytic cell; equivalently, the power required by the electrolytic cell is adjusted so that the hydrogen concentration generated by the electrolytic cell is changed, and finally, the hydrogen production concentration of the electrolytic cell is stabilized within a target concentration range. According to the scheme, the working state of the electrolytic cell is dynamically adjusted according to the hydrogen production concentration of the electrolytic cell, electric energy generated by a renewable energy power generation system in a weak power generation area is fully utilized, and hydrogen yield and hydrogen purity are improved.

Owner:阳光氢能科技有限公司

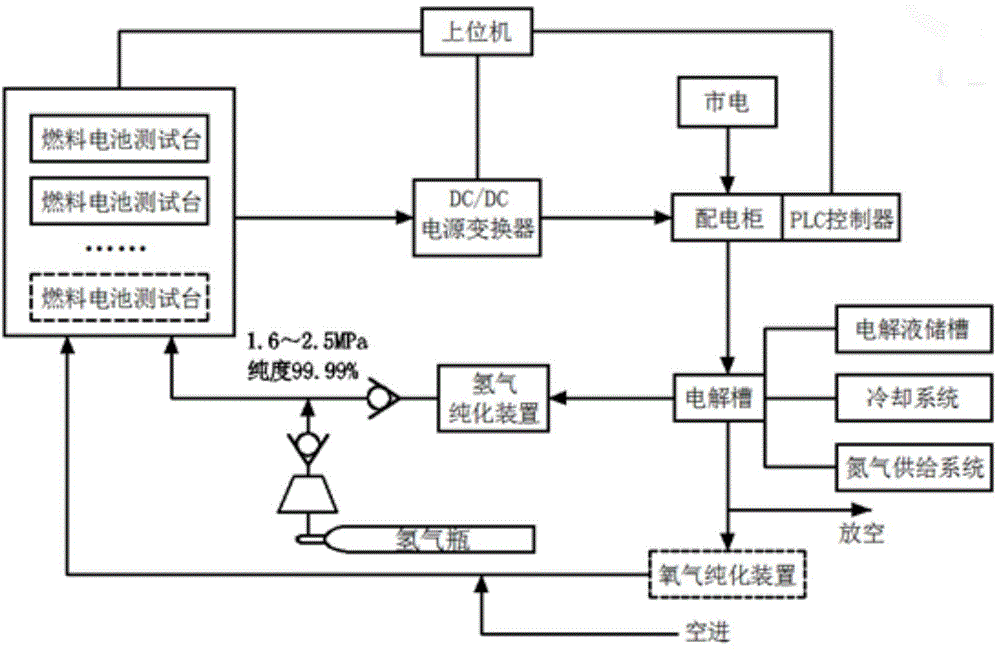

Fuel cell testing system capable of performing circular electrolytic hydrogen production

ActiveCN104597409AGuaranteed uptimeOperational controlFuel cell auxillariesElectrical testingElectrolysisEngineering

The invention discloses a fuel cell testing system capable of performing circular electrolytic hydrogen production. The fuel cell testing system comprises a DC / DC power converter, an electrolytic hydrogen production mechanism, a power distribution mechanism, a hydrogen purification device, a hydrogen cylinder and an upper computer, wherein the power distribution mechanism comprises a power distribution cabinet with a PLC, one input end of the power distribution cabinet is connected with the output end of the DC / DC power converter, and the other input end of the power distribution cabinet is connected with a mains supply. The output end of the power distribution mechanism is connected with the input end of the electrolytic hydrogen production mechanism. A hydrogen inlet of the hydrogen purification device is communicated with a hydrogen outlet of the power distribution mechanism. The hydrogen outlet of the power distribution mechanism is in pipe communication with a fuel cell hydrogen supply system in a fuel cell testing table through a first one-way valve. The output port of the hydrogen cylinder is in pipe communication with the fuel cell hydrogen supply system in the fuel cell testing table through a second one-way valve. The upper computer is respectively connected with the fuel cell testing table, the DC / DC power converter and the PLC. The outlet pressure of the first one-way valve is higher than the outlet pressure of the second one-way valve. The hydrogen electrolyzed by the fuel cell testing system is high in purity and stable in quality.

Owner:上海新源动力有限公司

Catalyst and device for preparing high-purity hydrogen through electrocatalytic water-vapor shift reaction

ActiveCN110835765ALower starting voltageMild reaction conditionsCellsElectrodesPtru catalystCo carbon monoxide

The invention relates to applications of a catalyst and a device in a reaction for preparing high-purity hydrogen through an electrocatalytic water-vapor shift reaction. According to the invention, based on the application, a process for converting carbon monoxide and water into hydrogen and carbon dioxide at a normal temperature under a normal pressure is achieved, the purity of the cathode product hydrogen is up to 99.99%, and the separation is not required; and the method is mild in reaction conditions, the cathode product and the anode product are completely separated, the obtained hydrogen is high in purity and is not required to be further separated, and the energy efficiency of the whole reaction is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multifunctional device capable of generating oxygen, hyperpure activated water and hydrogen-rich water at same time and application method of multifunctional device

ActiveCN105803477AImprove electrolysis efficiencyReduce energy consumptionCellsWater/sewage treatment with mechanical oscillationsHydrogenWater storage tank

The invention discloses a multifunctional device capable of generating oxygen, hyperpure activated water and hydrogen-rich water at the same time and an application method of the multifunctional device. The multifunctional device comprises an electrolytic tank, a hydrogen-rich water generator, an air pump, an activated water generator, an oxygen humidity adjuster, an activated water storage tank, a hydrogen guide-out pipe, a hydrogen guide-in pipe and a catalytic bed layer. An oxygen outlet of the electrolytic tank is connected with the oxygen humidity adjuster. A hydrogen outlet of the electrolytic tank is connected with the hydrogen-rich water generator through the hydrogen guide-in pipe. The hydrogen-rich water generator is sequentially connected with the activated water generator and the activated water storage tank. The activated water generator is further connected with the air pump. The hydrogen guide-in pipe stretches into hydrogen-rich water in the hydrogen-rich water generator. The hydrogen-rich water generator is connected with the activated water generator through the hydrogen guide-out pipe. The catalytic bed layer is arranged in the activated water generator. The multifunctional device can be widely applied to medical and family healthcare and other places needing high-purity oxygen, high-purity hydrogen, high-purity activated water and hydrogen-rich water.

Owner:廖若琛

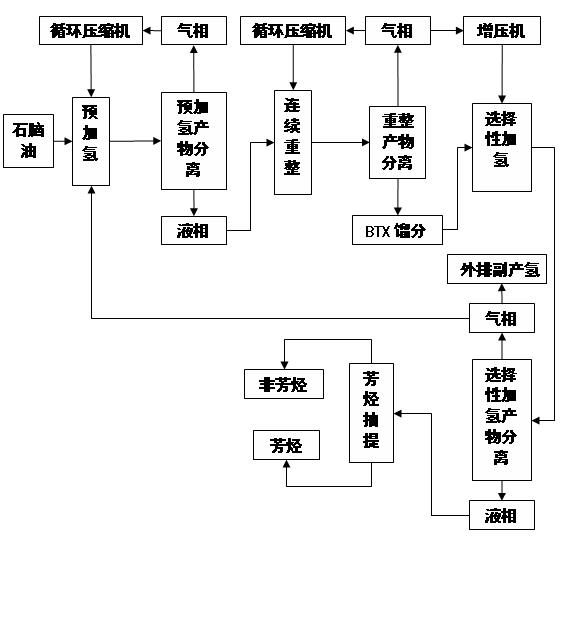

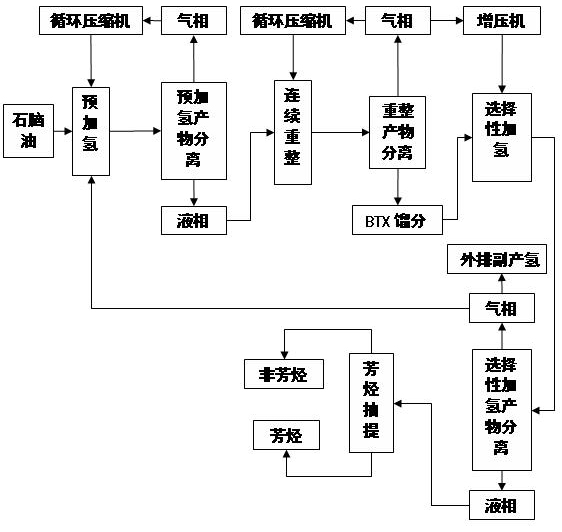

Process for producing arene through continuous reforming

InactiveCN102051231AExtensive sources of raw materialsExpand production scaleTreatment with hydrotreatment processesCycloalkaneChemistry

The invention discloses a process for producing arene through continuous reforming. The process comprises the following steps: pre-hydrogenation treatment is performed on a naphtha raw material, catalytic reforming is performed on the oil generated through pre-hydrogenation treatment so that at least a part of paraffin and a part of cycloparaffin are converted to arene, selective hydrodealkylation is performed on the oil generated through catalytic reforming, the oil generated through selective hydrogenation is separated to obtain arene; a part of the gas with rich hydrogen, generated by catalytic reforming device is circulated to the catalytic reforming device and the residual gas is pressurized to perform selective hydrogenation reaction with the oil generated through catalytic reforming to remove the olefin in the oil, wherein the selective hydrogenation of the oil generated through catalytic reforming adopts hydrogen single-pass flow, the effluent of the selective hydrogenation reaction is separated to gaseous phase and liquid phase; a part of gaseous phase is used as the hydrogen make-up of the naphtha raw material pre-hydrogenation device, the rest part is discharged out of the device; and the liquid phase is used for the separation of the arene product. Compared with the prior art, the method disclosed by the invention has the advantages that the raw material adaptability is high, the byproduct discharged to the outside has high hydrogen content and the economy of the catalytic reforming device is high and the like.

Owner:赵丽

Method for separation and purification of hydrogen gas

InactiveCN108147365AGood hydrogen purification effectHigh purity hydrogenHydrogen separation using solid contactRare-earth elementDesorption

The invention relates to a hydrogen gas separation and purification material. The material is prepared from rare-earth elements and other metal elements and can be prepared by adopting vacuum induction melting, and the preparation process is simple. The purification material can selectively adsorb hydrogen gas and repel other impurities, so that the purification of the hydrogen gas can be achievedin a hydrogen gas adsorption and desorption manner and can be carried out at room temperature; and the purity of the hydrogen gas can be improved to 99.999% or more in one time, so that the materialis suitable for providing high-purity hydrogen gas for industries of electronic information, semiconductors, LED, photovoltaic power generation, fuel cells and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

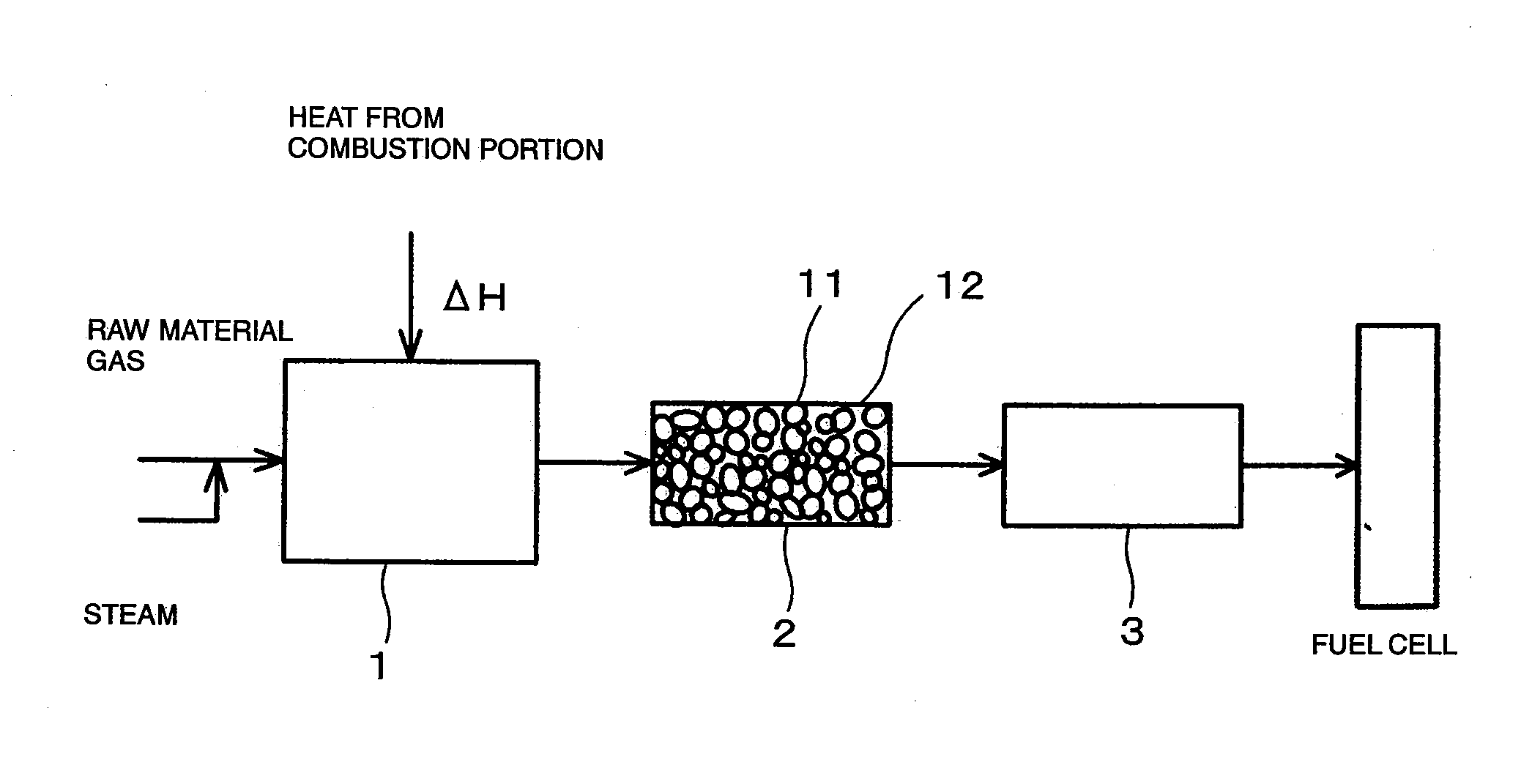

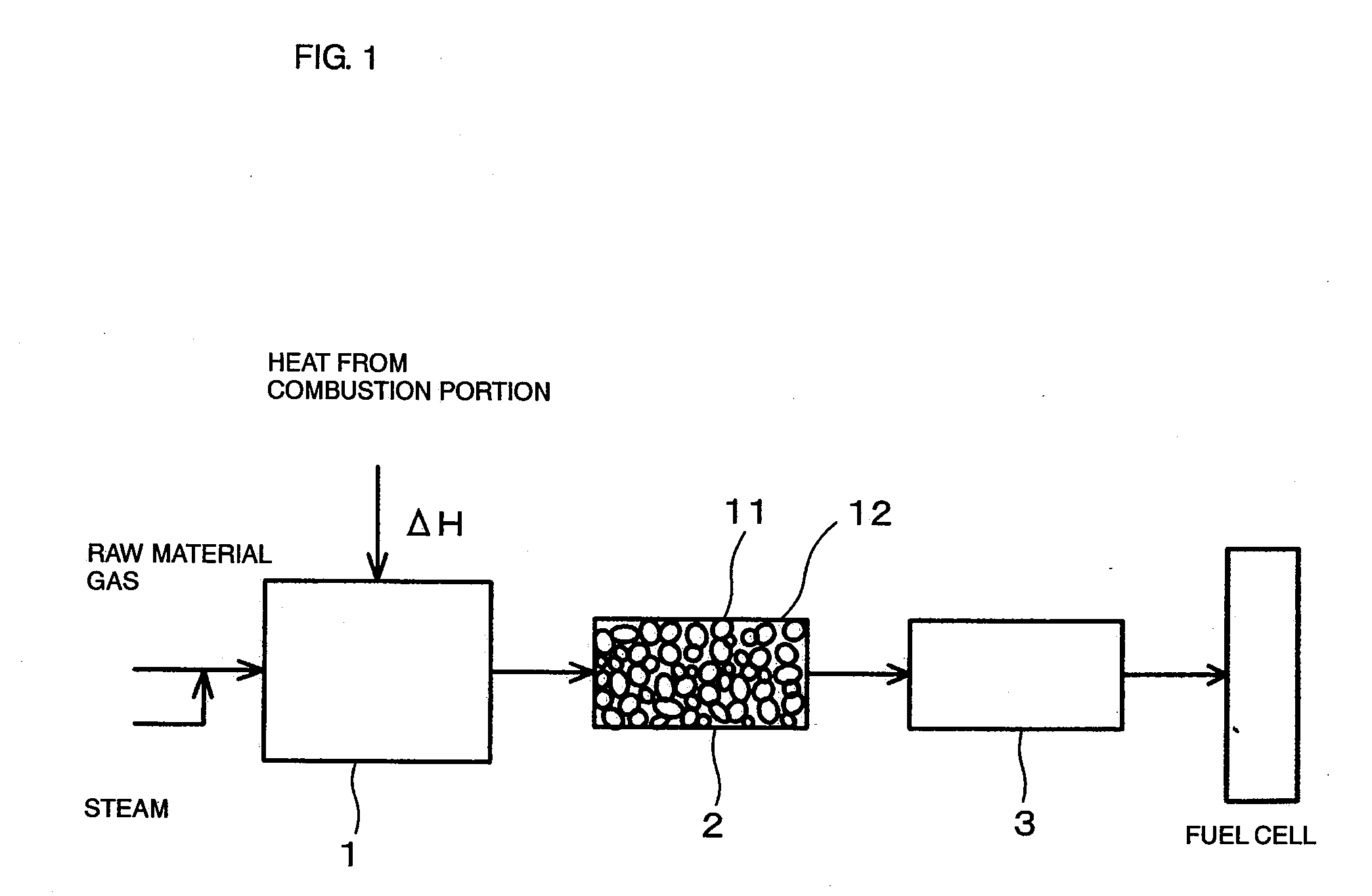

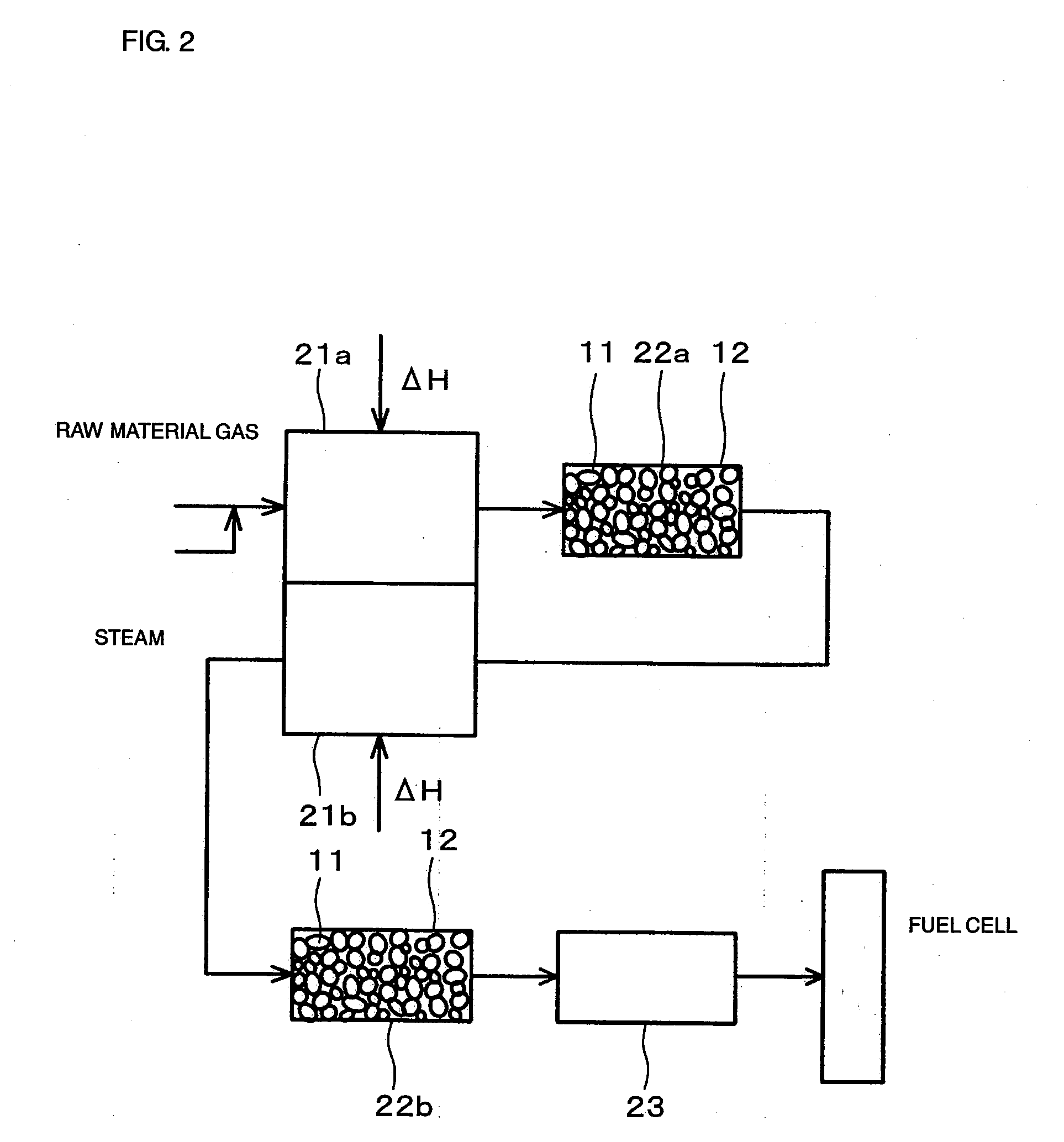

Reforming apparatus for fuel cells

InactiveUS20080102023A1Improving hydrogen conversion rateEasy to removeHydrogen productionHydrogen/synthetic gas productionSteam reformingFuel cells

A reforming apparatus for fuel cells capable of effectively removing carbon dioxide at a high temperature from a reformed gas which is produced by a steam reforming method, and of producing high-purity hydrogen gas with a high hydrogen conversion rate. A reforming apparatus for fuel cells includes a reformer for steam-reforming a raw material to produce hydrogen, and carbon dioxide removing apparatus for removing carbon dioxide gas by absorbing carbon dioxide from a reformed gas, which is produced by steam reforming in the reformer, using a material containing Ba2TiO4 as a main component as a carbon dioxide absorbent. The reforming apparatus for fuel cells may further include a second reformer for steam-reforming again the reformed gas from which carbon dioxide gas has been removed by the carbon dioxide gas removing means. Alternatively, the reformer for steam reforming may enclose the carbon dioxide removing apparatus which uses the carbon dioxide absorbent containing Ba2TiO4 as a main component so that carbon dioxide produced by steam reforming is removed by absorption within the reformer.

Owner:MURATA MFG CO LTD

Catalyst sulfurization method of diesel hydrotreating technique

ActiveCN103357449AImprove vulcanization effectReduce concentrated heat releaseCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenReaction temperature

The invention discloses a catalyst sulfurization method of a diesel hydrotreating technique, which comprises the following steps: normally operating a high-sulfur diesel hydrotreating device; (2) filling an oxidation-state diesel hydrogenation catalyst into the diesel hydrotreating reactor; (3) regulating the desulfurization rate of a recycle-hydrogen hydrogen sulfide remover in the high-sulfur diesel hydrotreating device; (4) introducing the hydrogen-sulfide-containing gas discharged from the recycle-hydrogen hydrogen sulfide remover of the high-sulfur diesel hydrotreating device into the hydrotreating device, and sulfurizing the catalyst of the diesel hydrotreating device; (5) sulfurizing according to the normal sulfurization conditions of the diesel hydrotreating device; and (6) after the sulfurization is finished, carrying out recycle hydrogen recycling operation of the diesel hydrotreating device, regulating the reaction temperature, and switching to raw oil to carry out the diesel hydrotreating reaction. The method disclosed by the invention can enhance the sulfurization efficiency and reduce the consumption of the sulfurizing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

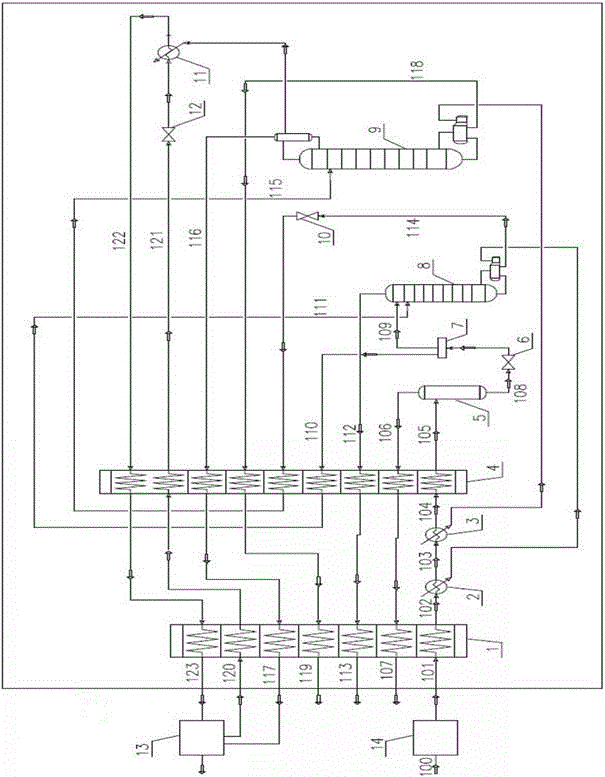

Device and technique of producing liquid ammonia by coke oven gas and methanol relief gas

ActiveCN102765733AImprove energy consumptionEnergy saving in the adsorption processAmmonia preparation/separationDesorptionGas compressor

The invention relates to a device and a technique of producing liquid ammonia by coke oven gas and methanol relief gas. A methanol relief gas material pipe is connected with a relief gas hydrogen extraction system; the relief gas hydrogen extraction system is connected with a desorption gas compressor and a hydrogen-nitrogen combination compressor; the hydrogen-nitrogen combination compressor is connected with a deoxidizing drying device, a nitrogen material pipe and an ammonia synthesis system; the ammonia synthesis system is respectively connected with an ammonia synthesis circulator, an ice machine system and a liquid ammonia spherical-tank; the coke oven gas material pipe is connected with the combination compressor; the combination compressor is connected with an active carbon rough-distillate device; the active carbon rough-distillate device is connected with a temperature change absorption system; the temperature change absorption system is connected with the coke oven gas hydrogen extraction system; the coke oven gas hydrogen extraction system is connected with a hydrolysis fine-desulfurization system; the hydrolysis fine-desulfurization system is connected with the deoxidizing drying device; the deoxidizing drying device is further connected with the combination compressor; and the combination compressor is further connected with the hydrogen-nitrogen combination compressor.

Owner:HENAN ZHONGHONG GRP COAL

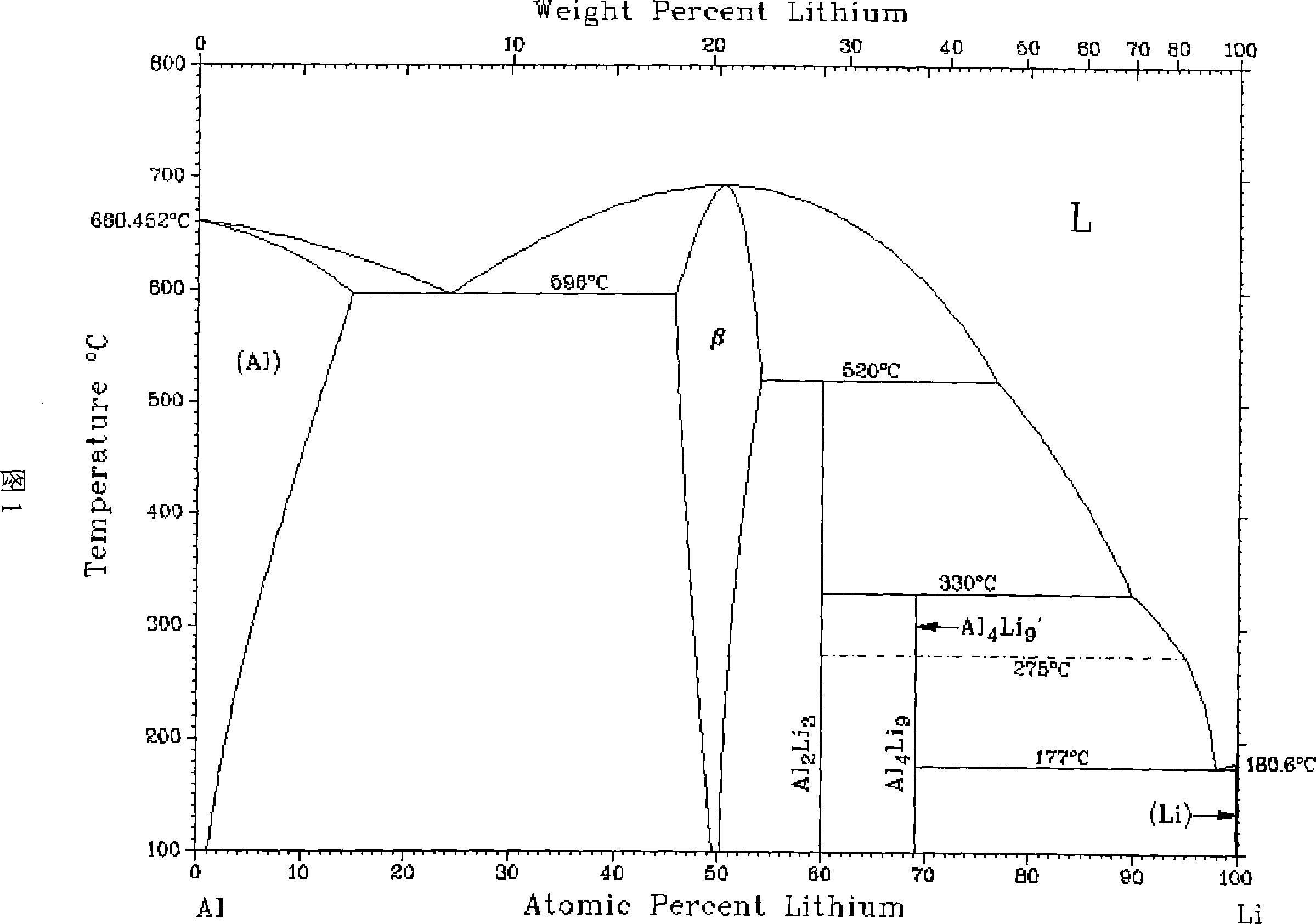

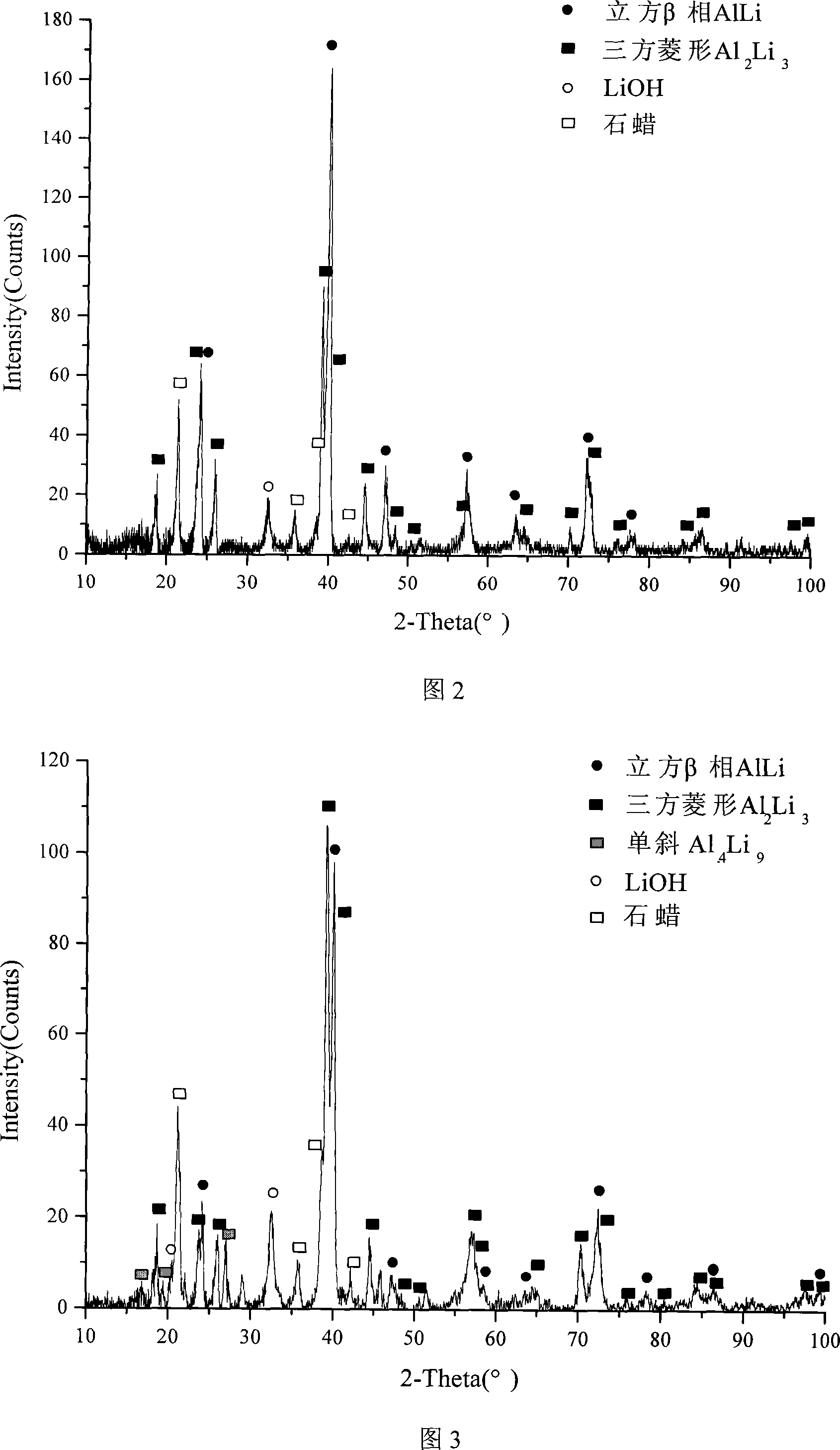

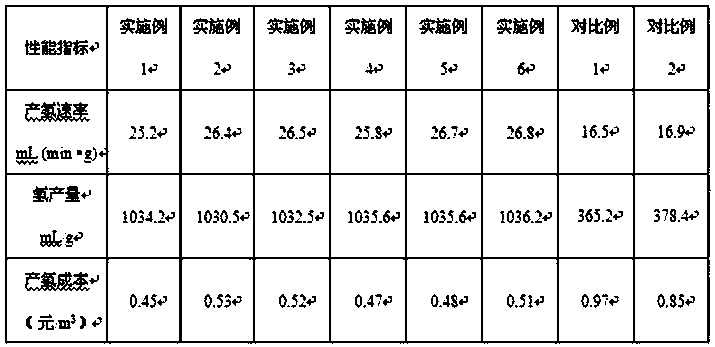

Alloy used for preparing hydrogen gas and method of producing the same

InactiveCN101182612ARich reservesExtensive sources of raw materialsHydrogen productionHydrogen internal combustion engine vehicleHydrogen fuel

The invention discloses an alloy which is used for preparing hydrogen and a preparation method hereof. The alloy consists of cubic beta phase AlLi, cubic beta phase AlLi and Al<2>Li<3> of three-square rhombus structure or cubic beta phase AlLi and Al<2>Li<3> of three-square rhombus structure and a single inclined Al<4>Li<9>. Lithium and aluminum are proportioned and mixed according to quality percent content and then the mixture is melted in a vacuum melting device; the melting temperature is higher than that of the melting point of pure aluminum and after the mixture is melted totally, the temperature is reduced to one which is higher than the melting point of the mixed alloy for heat preservation in a fusant state; and then the fusant is cooled until the normal temperature. The mixed alloy and water contact and react to produce high-purity hydrogen. The process for preparing alloy with the invention is simple and convenient and the process of preparing hydrogen through the reaction of alloy and water is fast and safe; the prepared hydrogen is provided with high purity and the hydrogen can be used for various application fields of hydrogen, in particular for hydrogen supply of fuel battery, hydrogen fuel battery used for portable tools and hydrogen gas engine automobile.

Owner:CHINA JILIANG UNIV

Method of producing hydrogen energy through physical ball milling of metal powder

InactiveCN108751128AIncrease manufacturing costHigh cost of preparationHydrogen productionMetal chlorideReaction rate

The invention provides a method of producing hydrogen energy through physical ball milling of metal powder. The method comprises: putting metal powder into a vacuum ball mill, adding a small amount ofa metal chloride aqueous solution and an aid into the powder and carrying out wet ball milling in a hydrogen protective atmosphere so that the oxide layers or hydroxide formed by the reaction is peeled from the metal powder under the action of ball milling. Through use of the aid in the metal powder-based hydrogen production and physical ball milling, the oxide / hydroxide film formed in the hydrolysis hydrogen production reaction is peeled from the metal powder so that the hydrogen production yield and the reaction rate are effectively ensured. The whole process is simple, the reaction processis neutral, the equipment requirements are low and the production cost is low.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

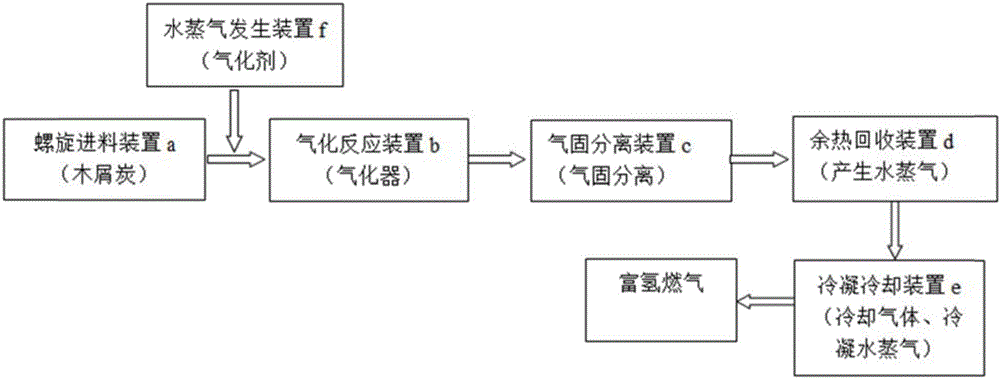

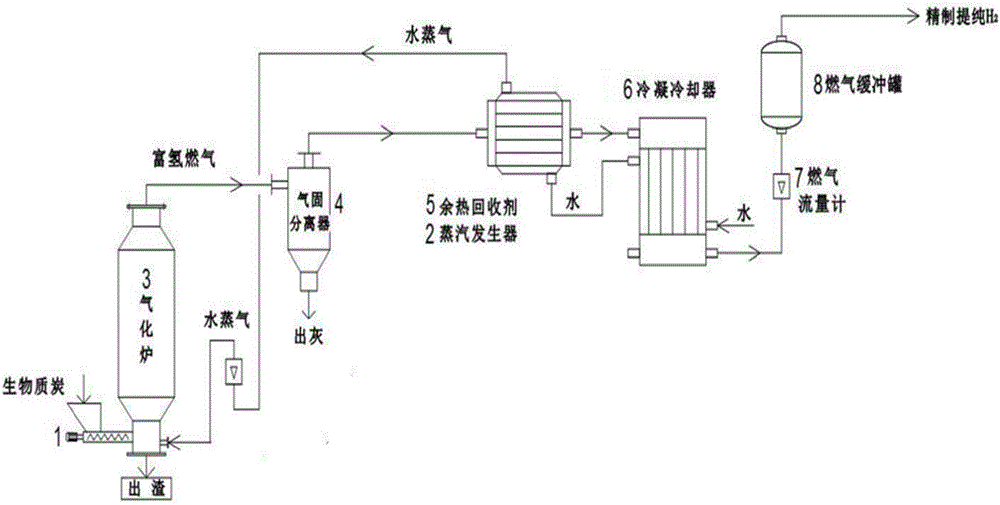

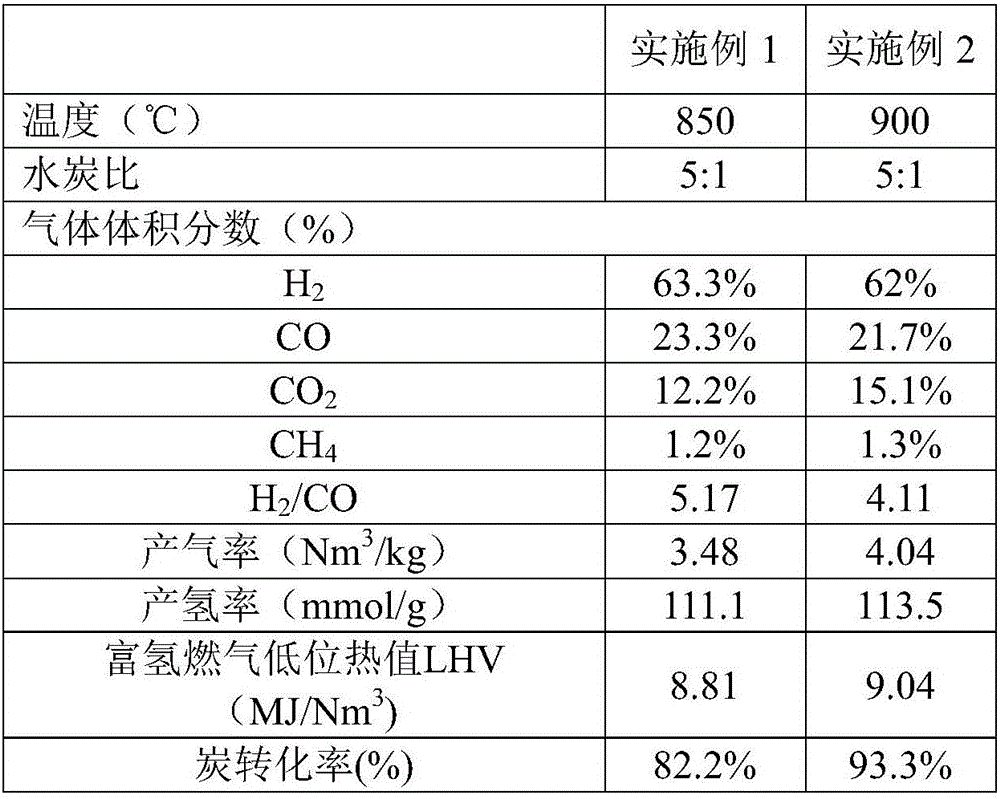

Method and device for preparing hydrogen-enriched fuel gas through sawdust charcoal gasification by high-temperature water vapor

InactiveCN106544057AIncrease useLow volatile contentEnergy inputGasification processes detailsWater vaporReaction temperature

The invention discloses a method and a device for preparing hydrogen-enriched fuel gas through sawdust charcoal gasification by high-temperature water vapor. Sawdust charcoal is used as a raw material, and water vapor is used as a gasification medium, so as to prepare the hydrogen-enriched fuel gas. The method mainly comprises the following steps: helical feeding of sawdust charcoal, generation of water vapor, gasification of sawdust charcoal and cooling of hydrogen-enriched fuel gas. The water vapor is supplied by a water vapor generator in the early stage; after the system is stabilized, the water vapor is supplied by a waste heat recycling device; the temperature of a reactor is 800 to 950 DEG C; and the hydrogen-enriched fuel gas is prepared under technological conditions of proper reaction temperature, flow of the water vapor, particle size of the raw material, reaction time and the like. According to the method, the hydrogen-enriched fuel gas with the hydrogen volume percentage of 61.2 to 65.8 percent and the maximum hydrogen yield of 113.5 mmol / g can be prepared. The method has the advantages that the hydrogen volume percentage of the fuel gas is high, no tar is generated, and the gasification device is simple in structure; and the hydrogen-enriched fuel gas can be applied to preparation of high-purity hydrogen, synthesized natural gas, liquid fuel including methyl alcohol and dimethyl ether, and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com