Combined technological process for producing lube oil base stock

A technology of lubricating base oil and combined process, which is applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems of increasing energy consumption and operating costs, increasing equipment investment, reducing reaction efficiency, etc., and reducing construction costs. Investment and operating costs, low operating costs, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

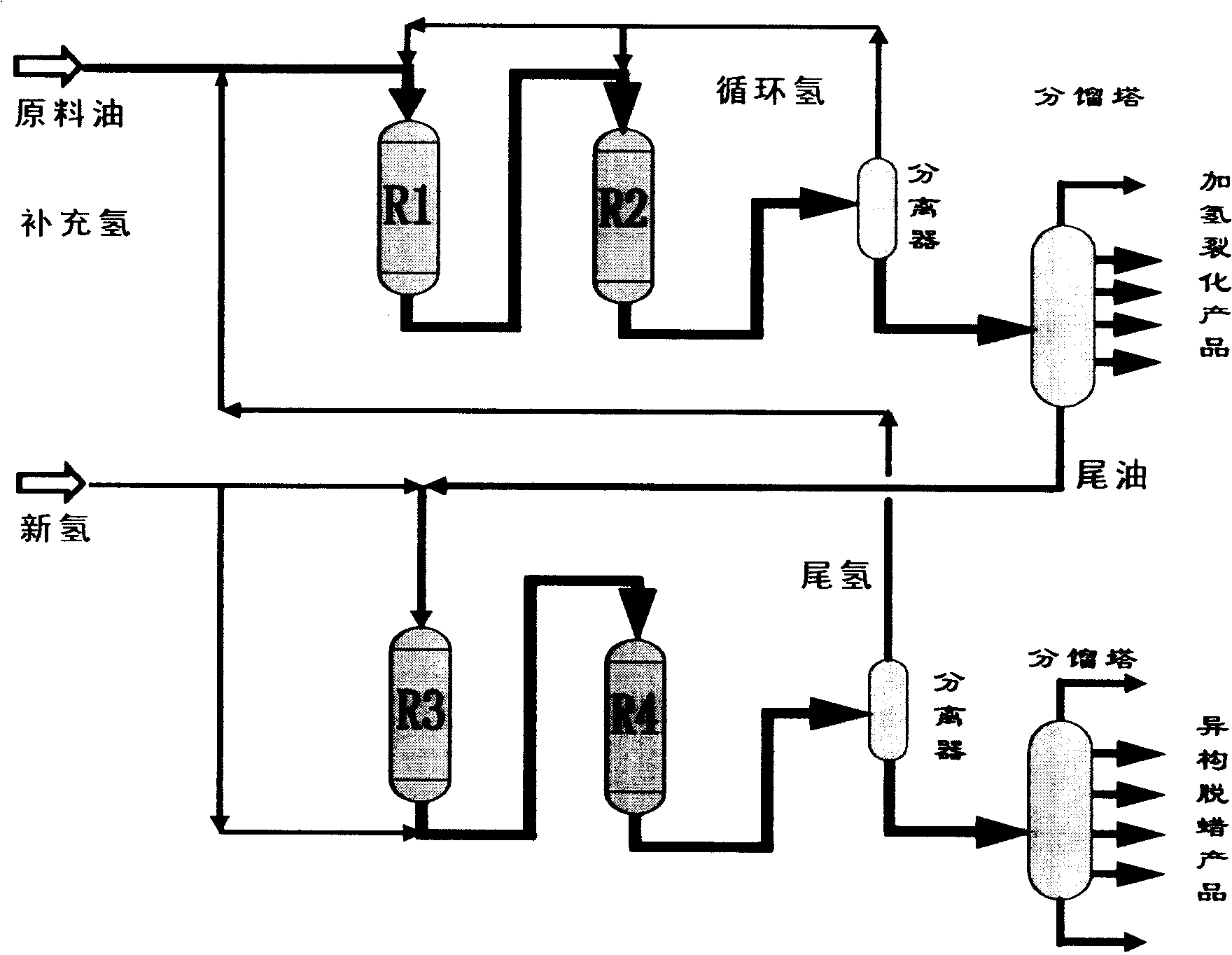

[0033] The catalysts in Table 2 were used in the hydrocracking reaction zone of Examples 1-3, and the FC-26 hydrocracking catalyst was used as the hydrocracking catalyst in Example 4. The hydroisomerization catalysts listed in Table 2 were used in the hydroisomerization reaction zones of Examples 1-4. The materials listed in Table 1 were processed. The hydrogen in the hydroisomerization dewaxing unit passes through once, and the tail hydrogen is used as supplementary hydrogen for hydrocracking. The results obtained are shown in Table 3. The hydrocracking and hydrorefining catalysts are vulcanized by conventional methods, followed by hydrocracking reactions, and the hydroisomerization and supplementary refining catalysts are reduced by conventional methods, followed by isomerization or refining reactions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com