Patents

Literature

162results about How to "Improve the reaction environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

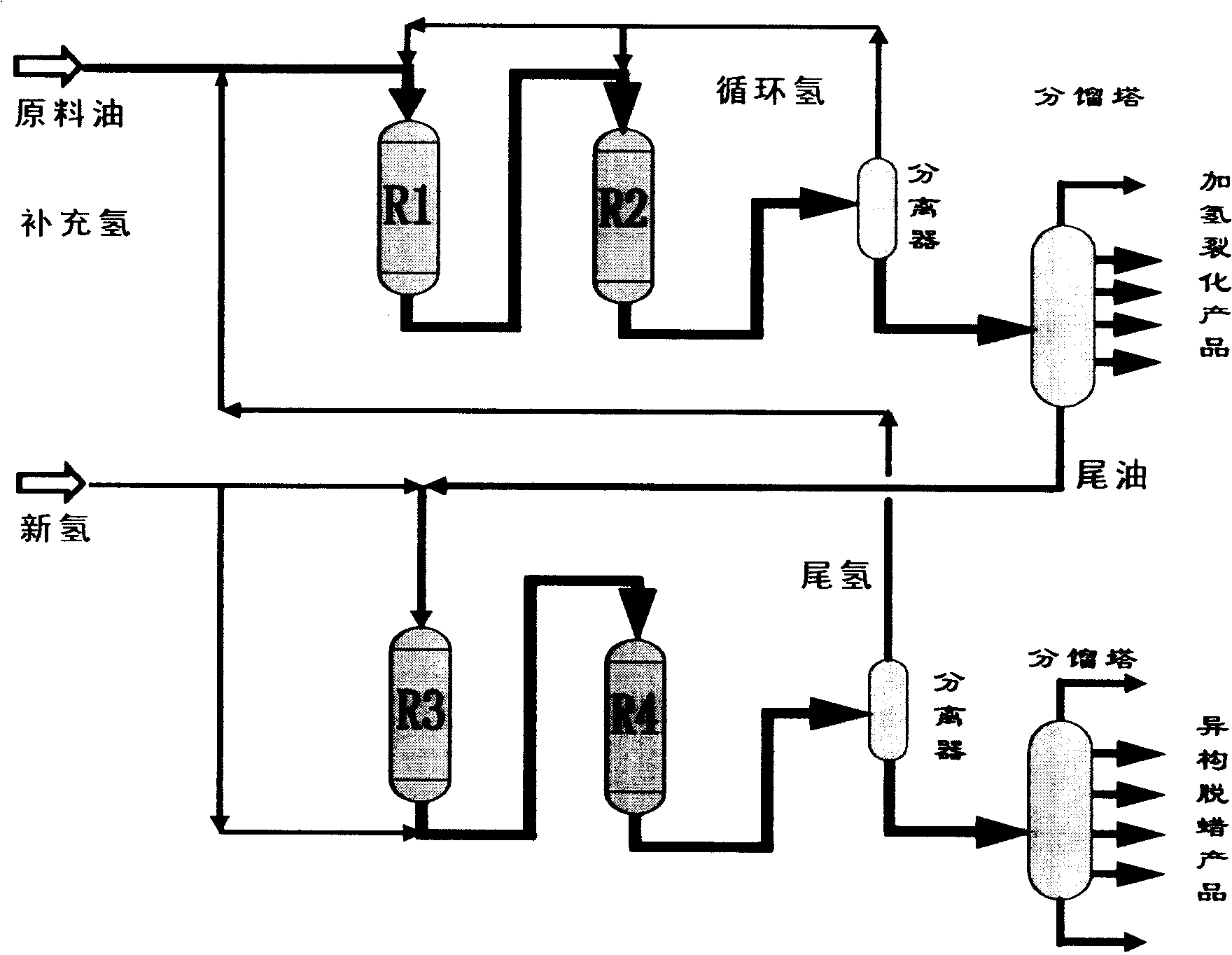

Combined technological process for producing lube oil base stock

ActiveCN101333460ASimple processLow operating costTreatment with hydrotreatment processesPetroleum wax recoveryHydrogenIsomerization

The invention discloses a production method of lubricating oil basic oil. The method takes distillate oil or refined oil, etc. as raw materials, and adopts the combined process of hydrogen cracking-isomerization dewaxing to produce the lubricating oil basic oil. The tail oil of a hydrogen cracking unit is directly supplied to a tail oil isomerization dewaxing unit for serving as a raw material, the new hydrogen passes through the tail oil isomerization dewaxing unit at a time, and the tail hydrogen directly returns to the hydrogen cracking unit for serving as compensation hydrogen. Only one hydrogen circulation system is arranged due to the deep combination of the two units, the construction investment of apparatus and the operating cost are obviously reduced, and the product quality is somewhat improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

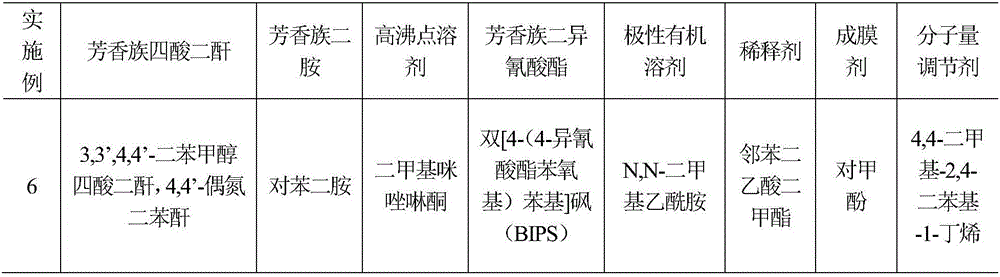

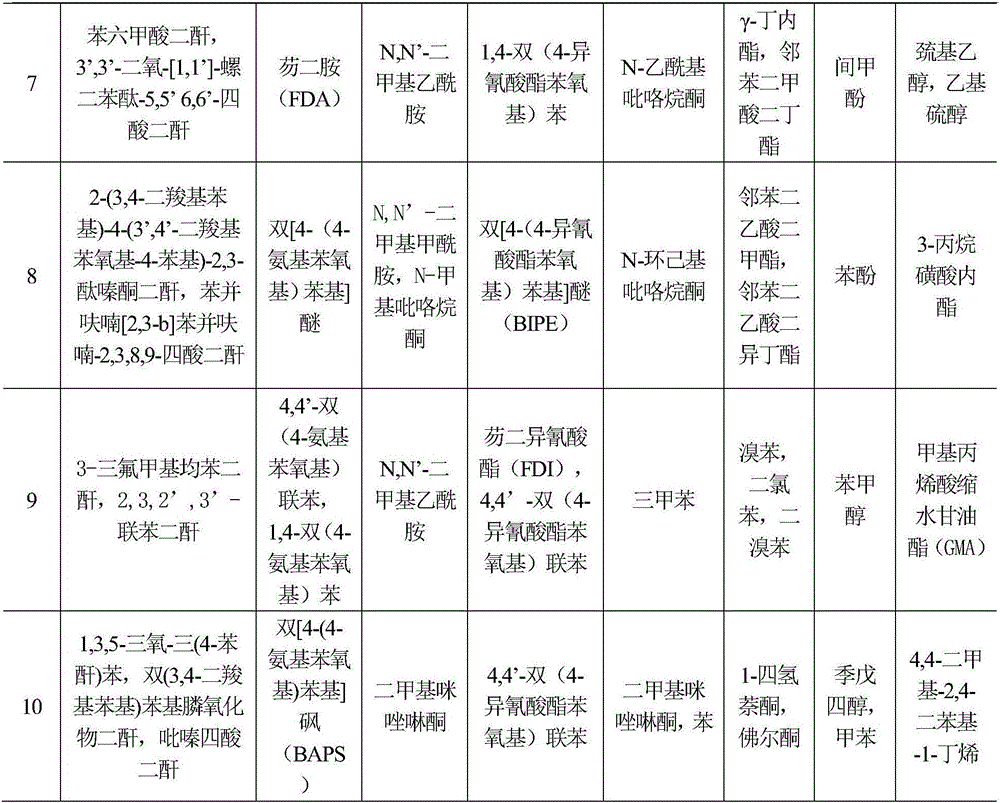

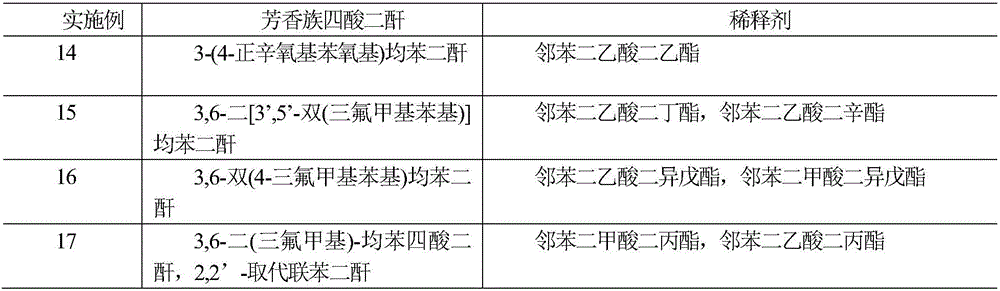

Method for preparing polyimide nano-film

The invention provides a method for preparing a polyimide nano-film. The method comprises the steps: firstly, synthesizing polyimide resin from aromatic tetracid dihydride, aromatic diamine and aromatic diisocyanate; and then, mixing the polyimide resin, a polar organic solvent, a diluent, a film forming agent and a molecular weight regulator so as to obtain a polyimide solution system, then, carrying out nano-scale uniform spreading on a clean substrate by dint of the action of a mechanical external force of 0.5N to 30N, and then, carrying out an imidization method, thereby preparing the polyimide nano-film. According to the film, the high-temperature resistance is 10 seconds at the high temperature of 400 DEG C to 750 DEG C, and the electrical insulation property is that the dielectric constant is 1.5 to 4.5 at the frequency of 103Hz. Compared with the prior art, the polyimide nano-film prepared by the method has the advantages of excellent surface physical properties and stable chemical properties, high-temperature resistance, electrical insulation properties and chemical corrosion resistance.

Owner:SHAANXI UNIV OF SCI & TECH

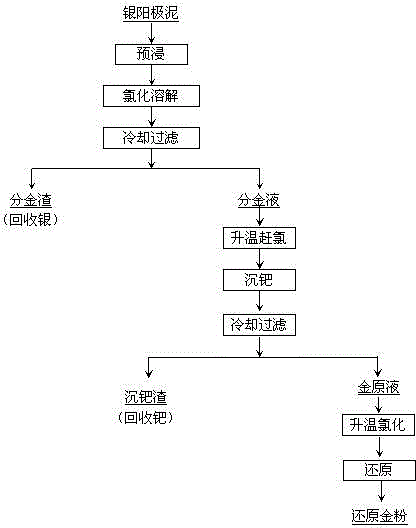

Method for extracting refined gold from palladium-silver-containing anode mud

InactiveCN104451186AEfficient separationShort process structureProcess efficiency improvementSodium bisulfateImpurity

The invention provides a method for extracting refined gold from palladium-silver-containing anode mud, relates to the field of noble metal wet metallurgy, and particularly relates to a method for purifying the gold from the palladium-silver-containing anode mud. The method mainly comprises the following steps: adding the palladium-silver-containing anode mud into hydrochloric acid and carrying out chlorination dissolving; carrying out temperature rising type chlorine removing on filtered parting liquid; then adding dimethylglyoxime to carry out palladium sedimentation and impurity removal; after reaction is finished, carrying out precision filtering, wherein filtrate is gold raw liquid; introducing choline into the gold raw liquid and increasing electric potential; when the electric potential is up to more than 1000mV, stopping the introducing of the choline; adding a saturated sodium hydrogen sulfite solution into the gold raw liquid and reducing; when the electric potential is up to 620mV-630mV, stopping the reducing; and filtering after cooling, and further recycling valuable metal from the filtrate, wherein a filter cake is reduced gold powder. According to the process, the impurity palladium removing rate is high, the valuable metal can be comprehensively recycled, a flow structure is simple and the cost is low. When dimethylglyoxime is used for carrying out palladium sedimentation operation, the reaction is environmentally-friendly; and toxic and harmful gas is not generated and the reaction is rapid and efficient.

Owner:JINCHUAN GROUP LIMITED

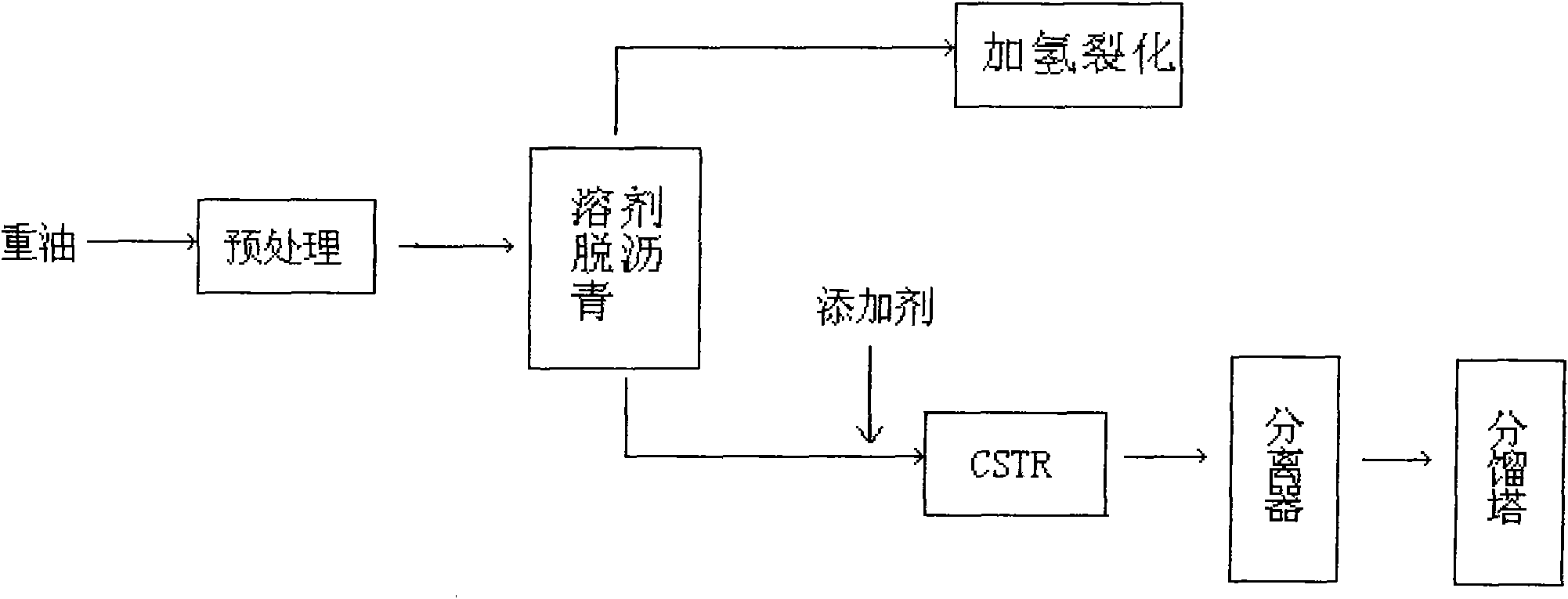

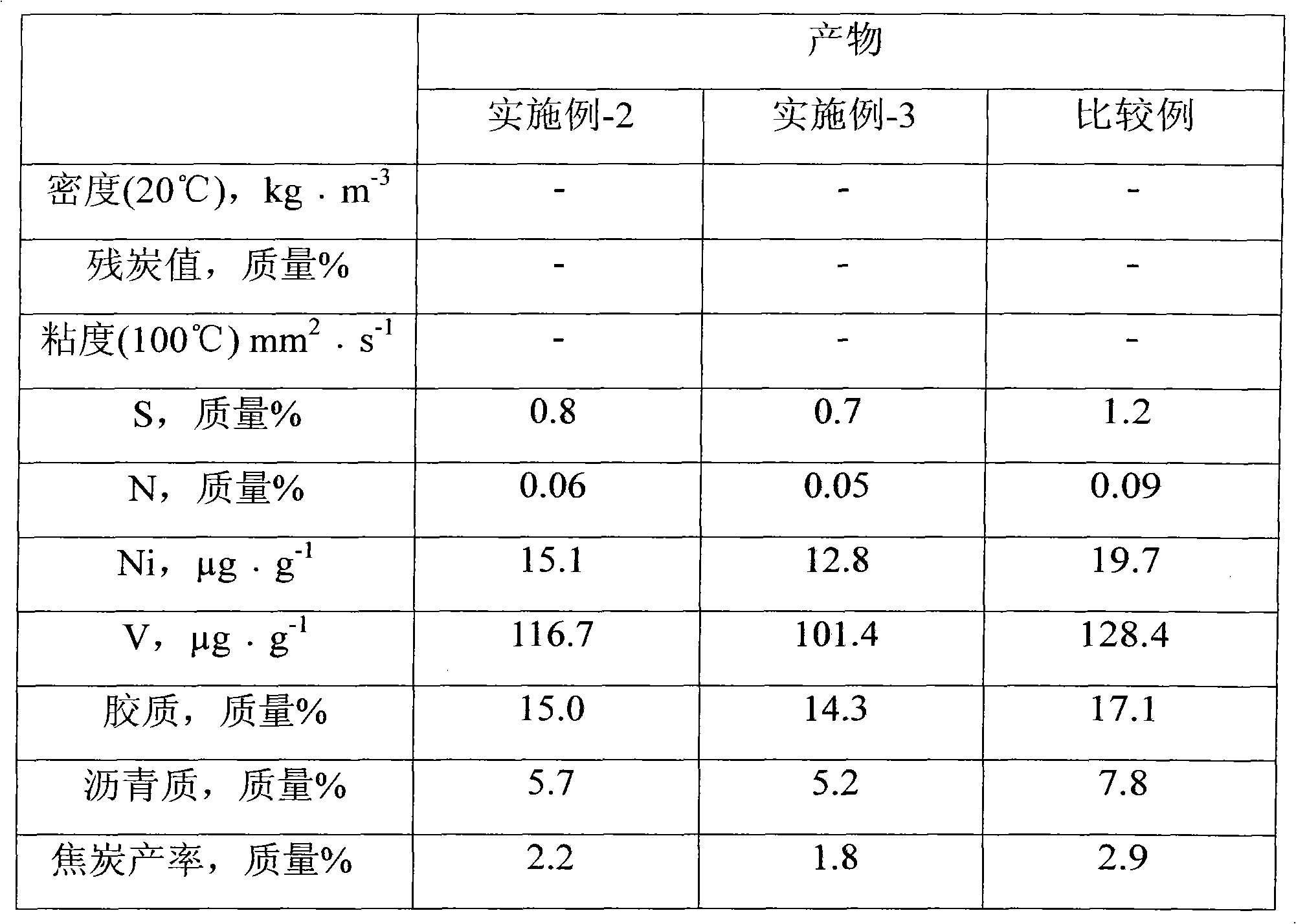

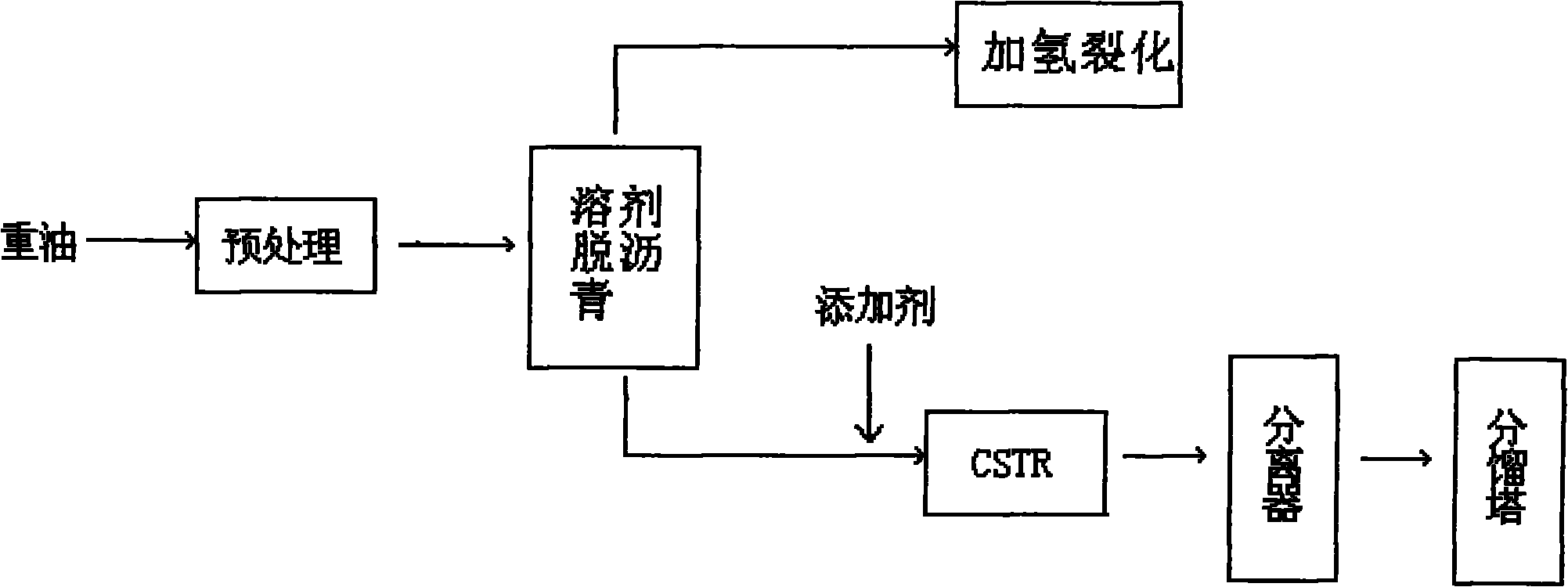

Combined process for heavy oil modification

ActiveCN101942337AImprove fusion effectImprove responseTreatment with hydrotreatment processesLight treatmentFuel oil

The invention discloses a combined process for heavy oil modification. A heavy oil raw material is first subjected to solvent de-asphalting treatment, the de-asphalted oil obtained by the solvent de-asphalting is subjected to catalytic cracking or hydro-cracking treatment, and the de-oiled asphalt obtained by the solvent de-asphalting is subjected to supercritical treatment, wherein the supercritical treatment method for the de-oiled asphalt comprises supercritical treatment of mixture of de-oiled asphalt and hydrogen supply solvent, the hydrogen supply solvent comprises tetrahydronaphthaleneor decahydronaphthalene, the mixing weight ratio of the heavy oil raw material to the hydrogen supply solvent is 1:0.5-1:10, and the supercritical treatment is performed for 0.2 to 5 hours under the pressure of 15 to 40MPa at the temperature of between 300 and 500 DEG C. The method can effectively improve the utilization rate of poor-quality heavy oil, has low coking rate and stable production process, and can be used for light treatment of various heavy and poor raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

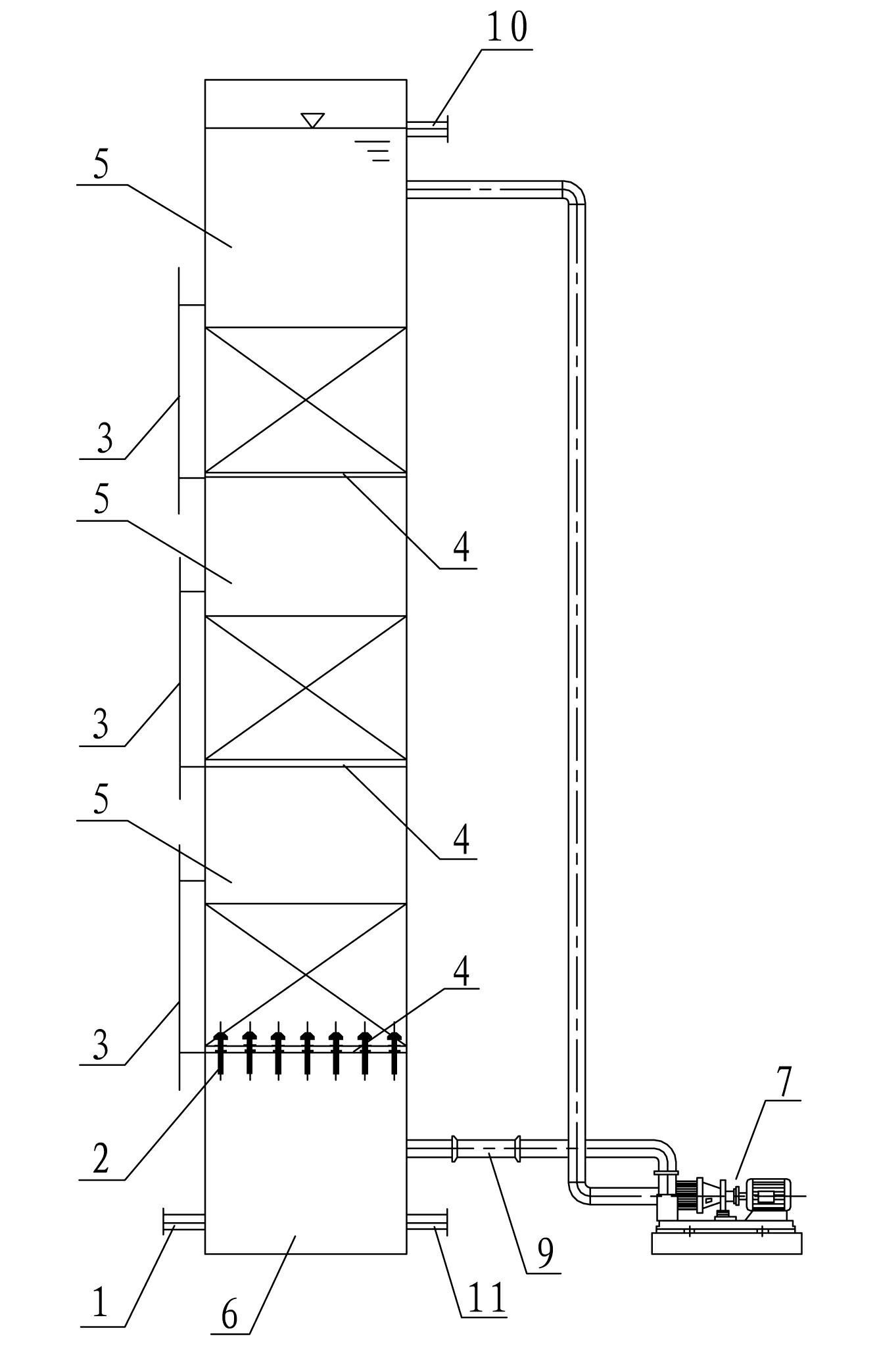

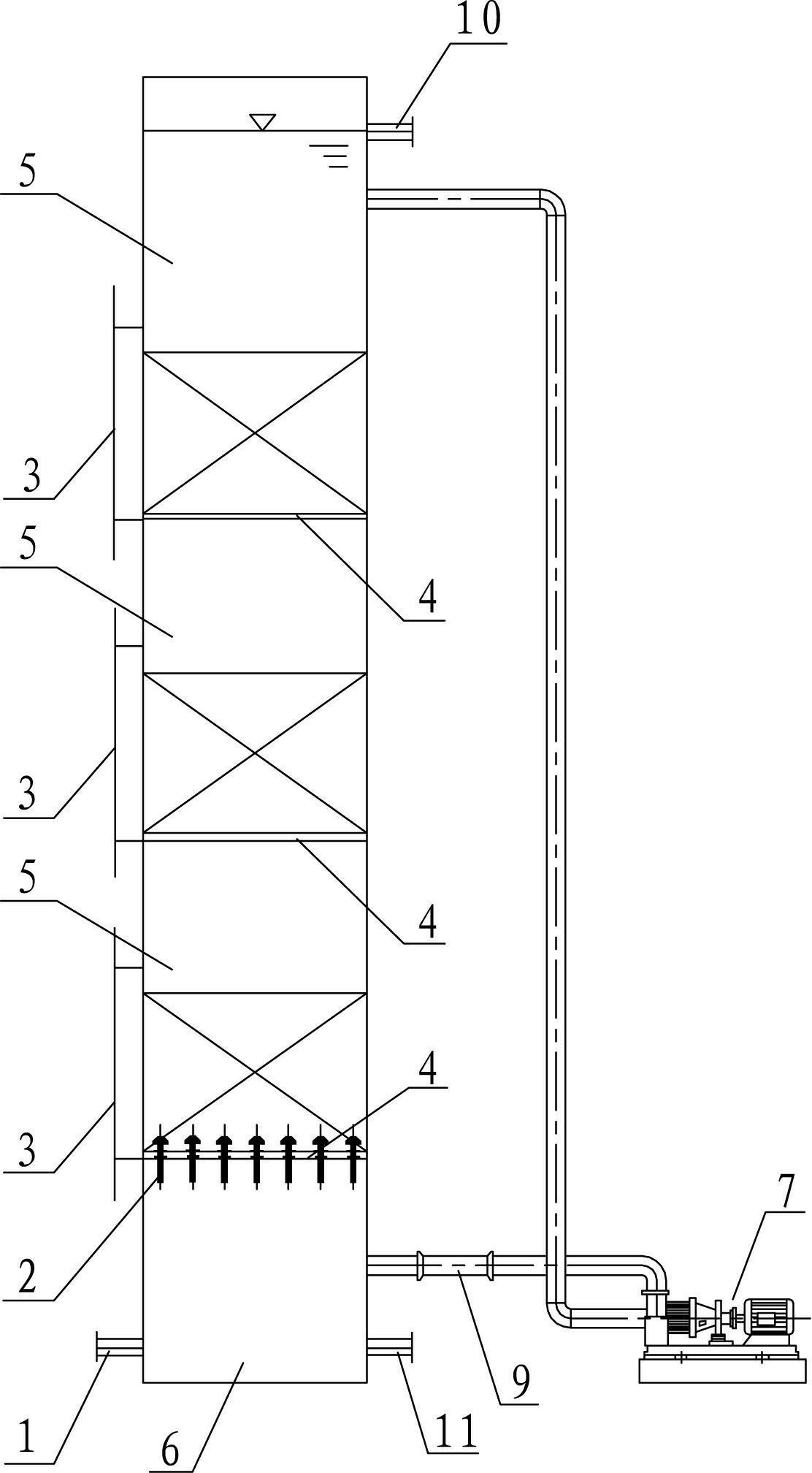

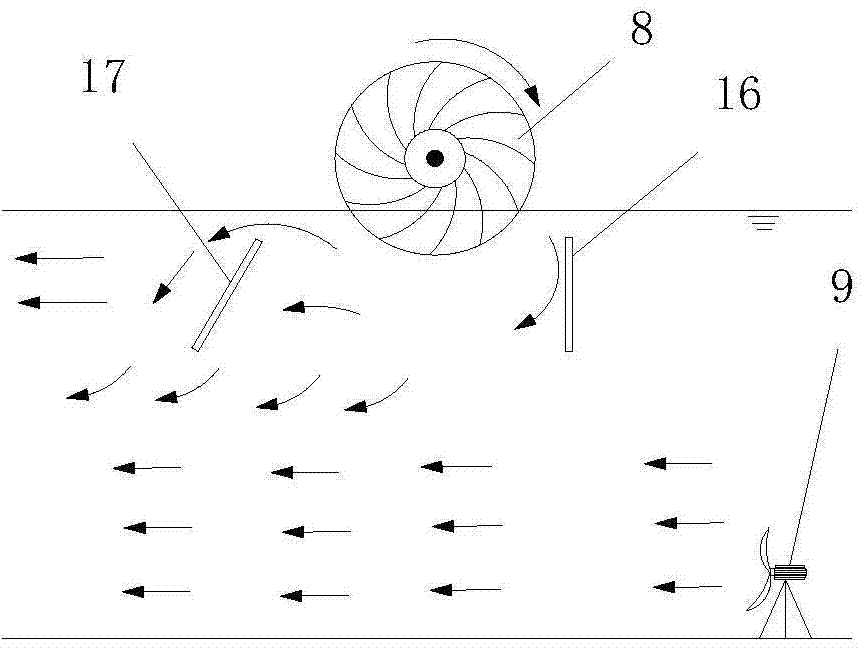

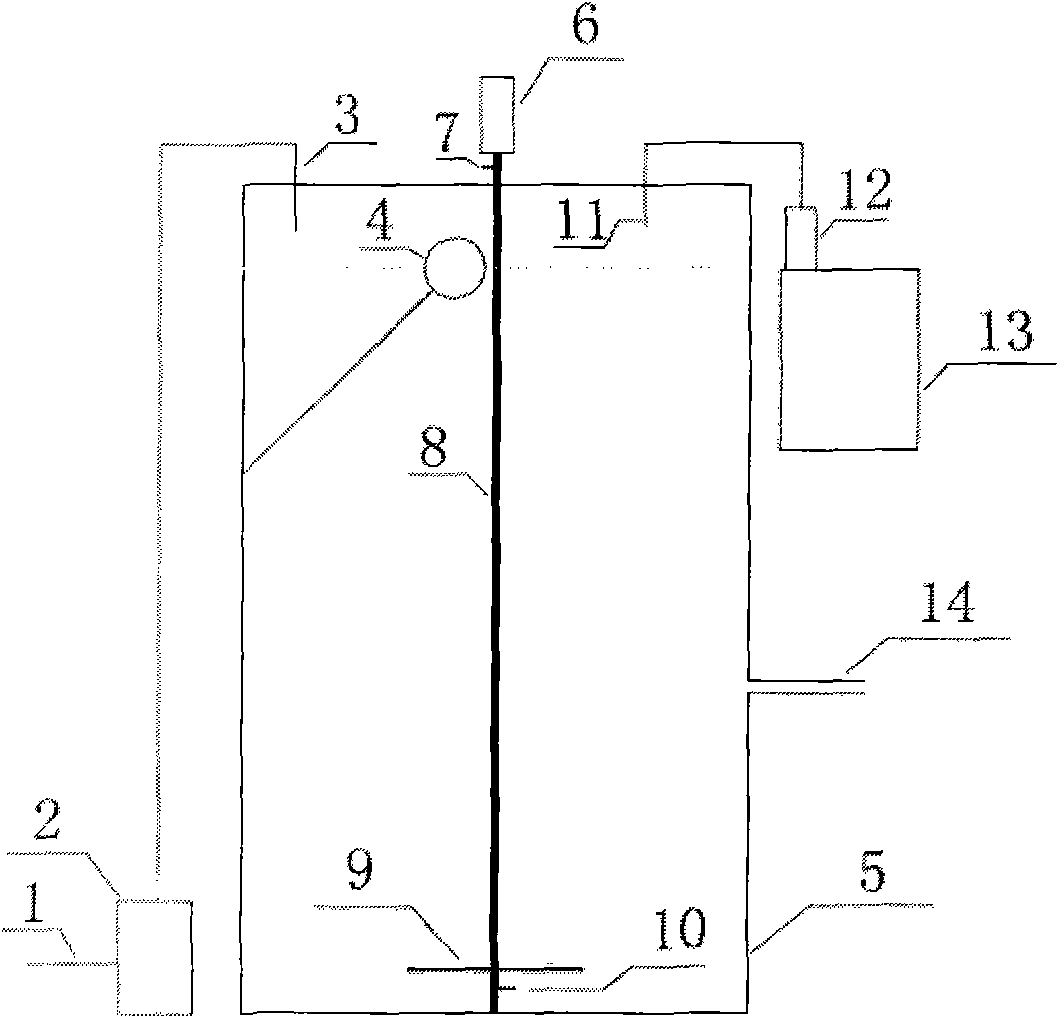

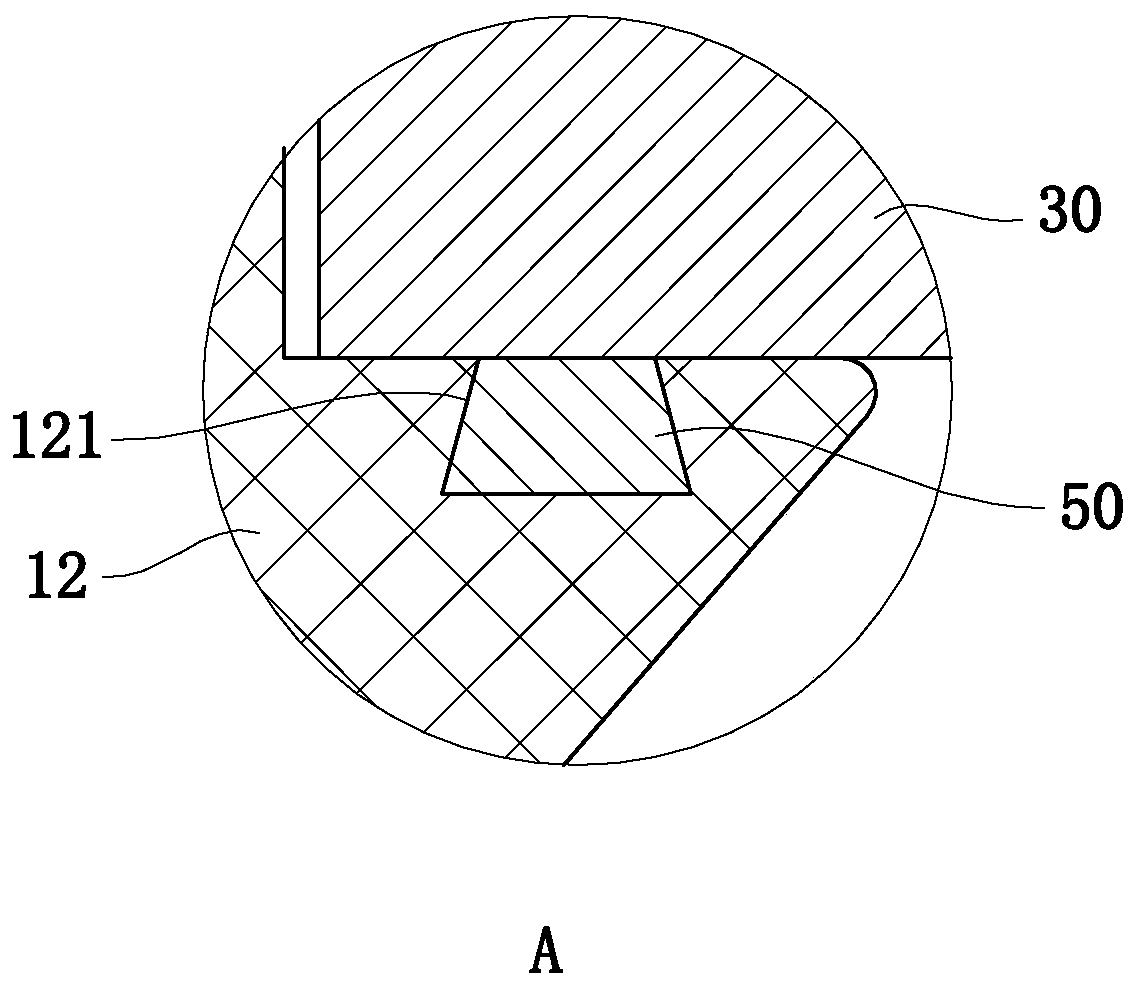

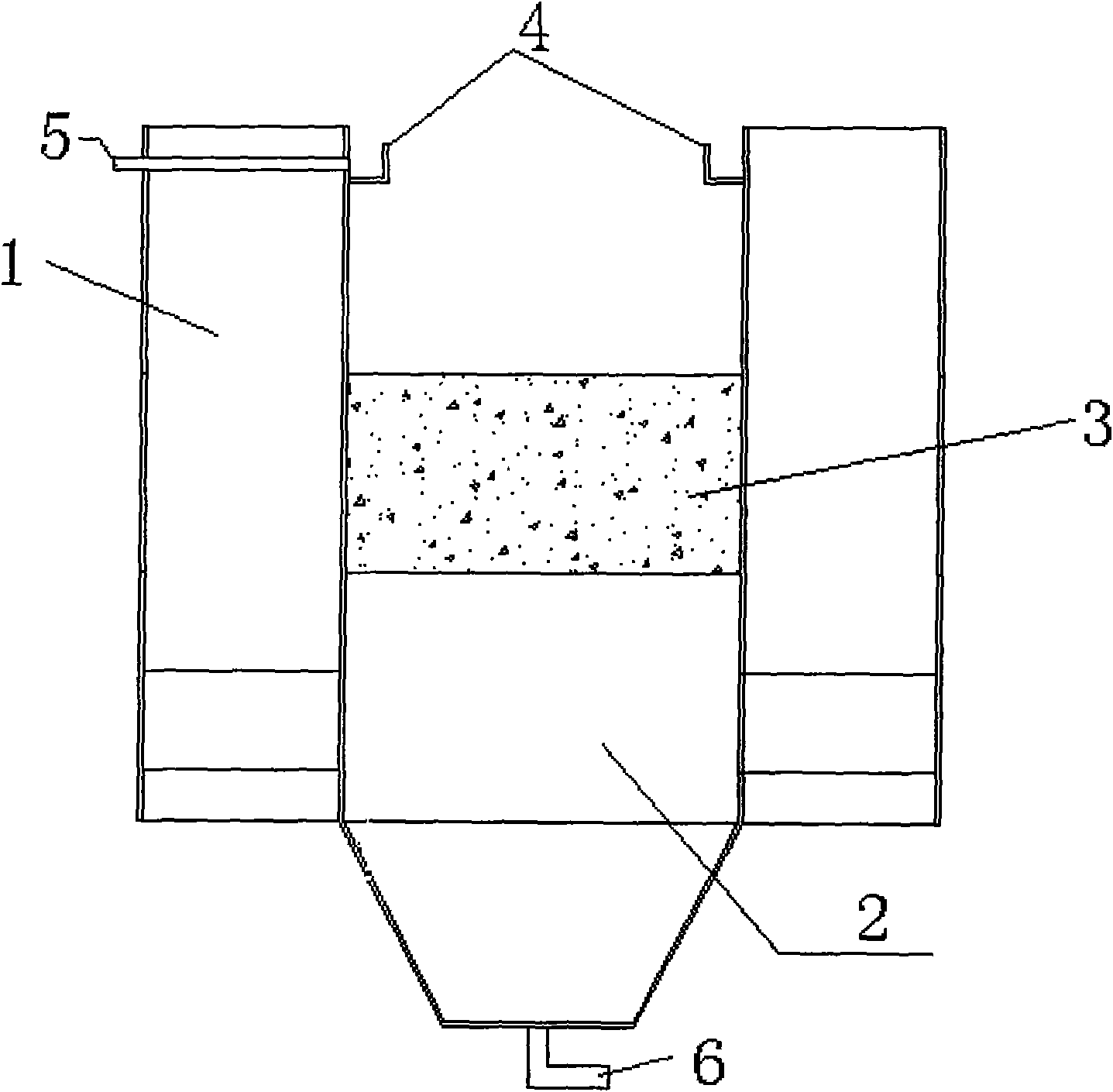

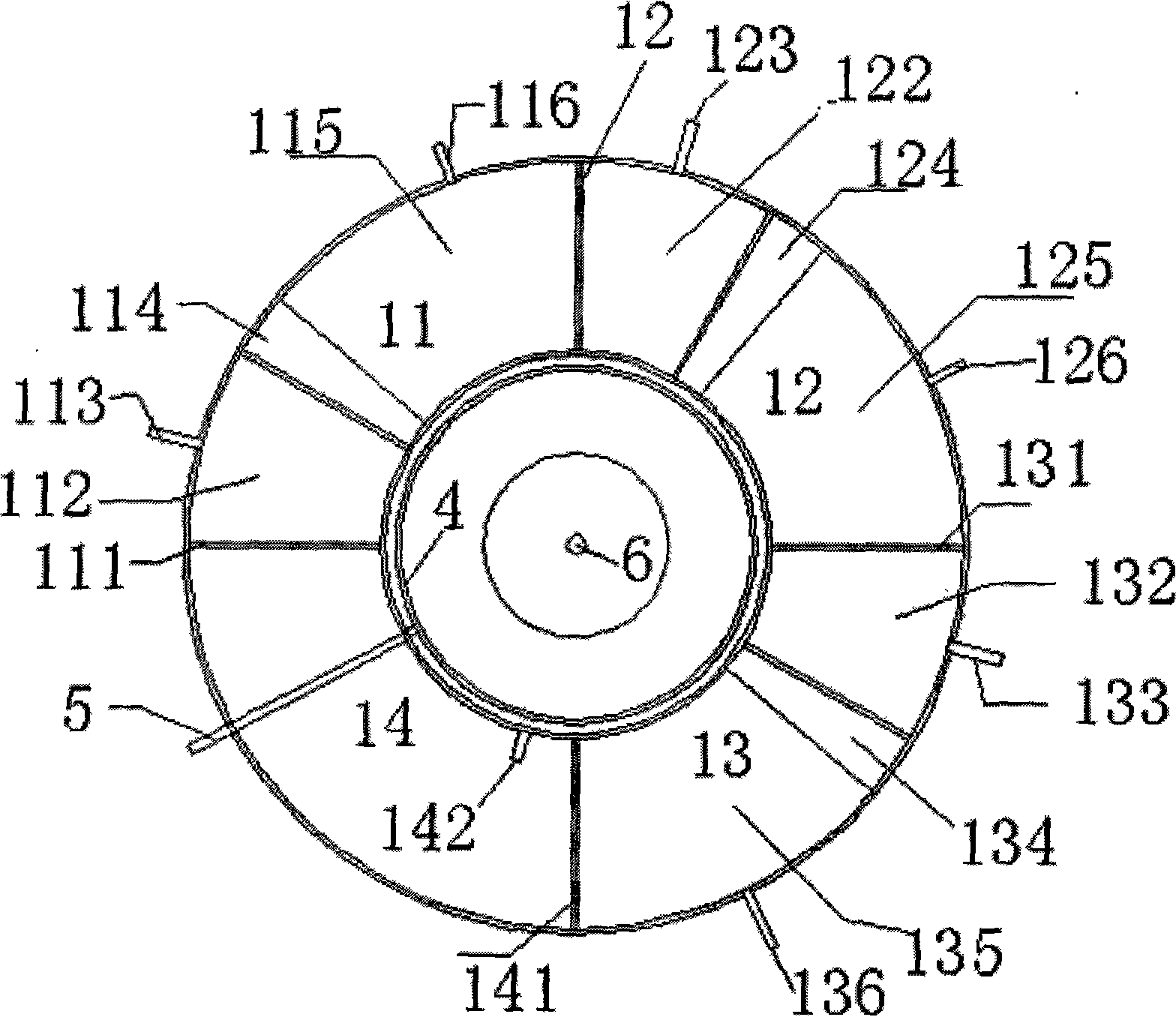

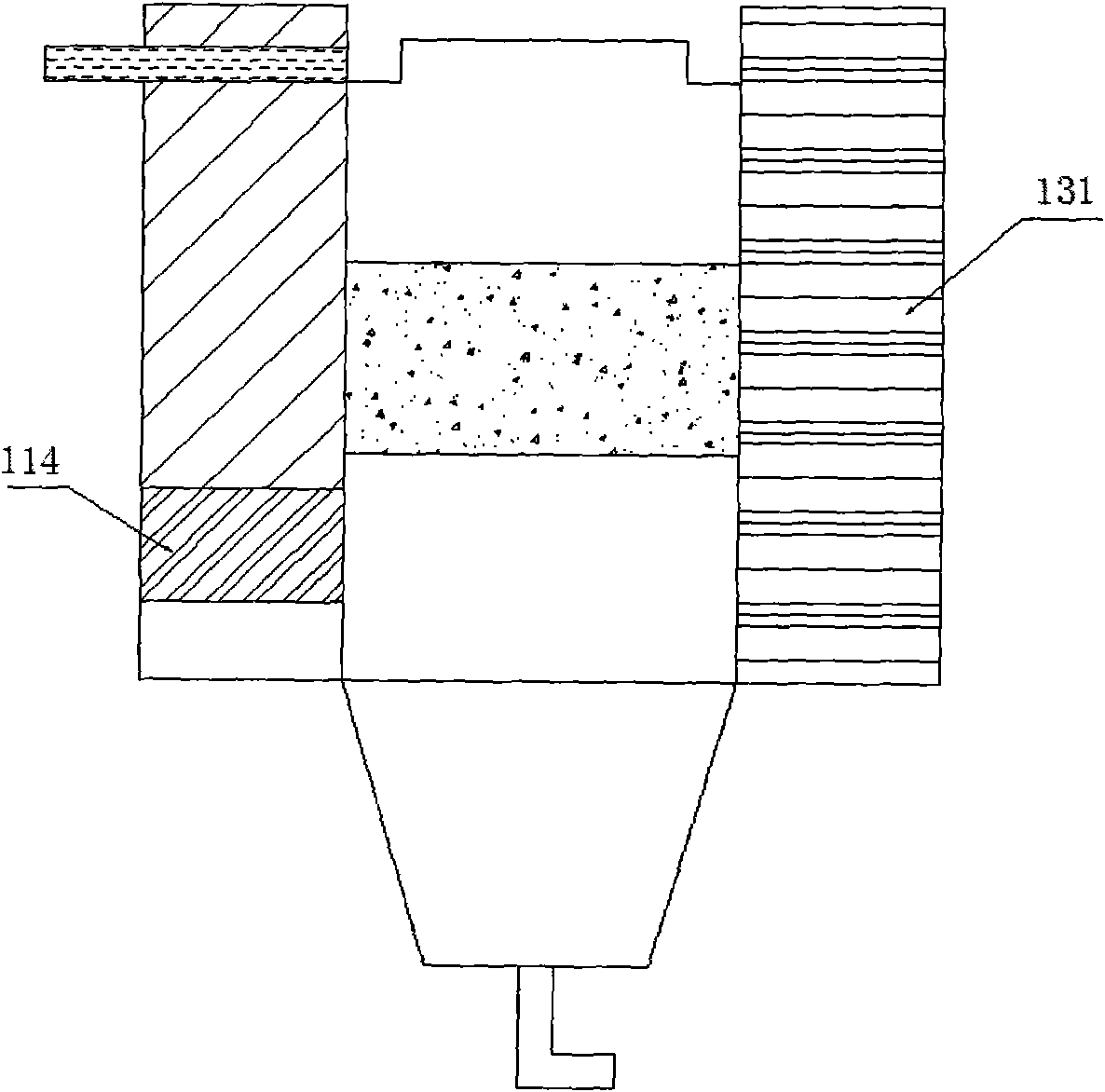

Iron-carbon micro-electrolysis reaction system of multistage fluidized bed

ActiveCN102583658AImprove the reaction environmentAvoid hardeningWater/sewage treatmentEngineeringFluidized bed

The invention discloses an iron-carbon micro-electrolysis reaction system of a multistage fluidized bed. The iron-carbon micro-electrolysis reaction system comprises a reactor, wherein a water distribution chamber which is provided with a lower circulating water gap is arranged on the lower part of the reactor; an upper circulating water gap is formed on the upper part of the reactor; the lower circulating water gap is communicated with the upper circulating water gap through a pipeline; an internal circulating pump is arranged on the pipeline; the upper space in the reactor is divided into aplurality of reaction chambers laminated from top to bottom by a plurality of screen mesh clapboards; and the reaction chambers are positioned above the water distribution chamber. According to the iron-carbon micro-electrolysis reaction system, the reactor is divided into a plurality of stages of reaction chambers by the screen mesh clapboards, so that an iron-carbon filler can be placed in the reaction chambers stage by stage, the reaction environment of the filler is improved, a condition that the filler can be hardened because a plurality of layers of filler is stacked is avoided, and themicro-electrolysis effect is optimized. The iron-carbon micro-electrolysis reaction system can be used as an iron-carbon micro-electrolysis reaction device in the waste water treatment industry.

Owner:中国人民解放军广州军区空军勘察设计院 +1

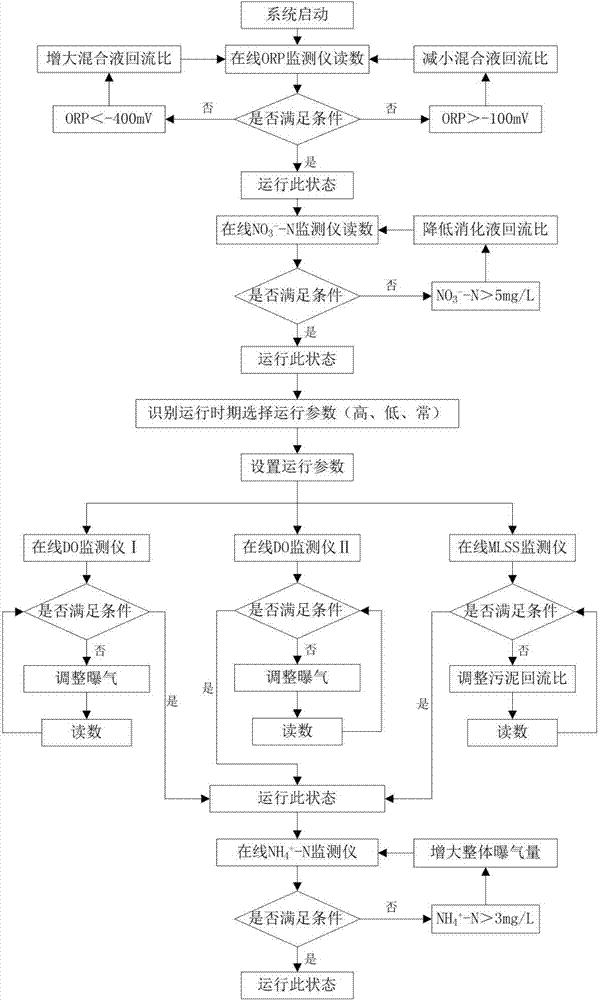

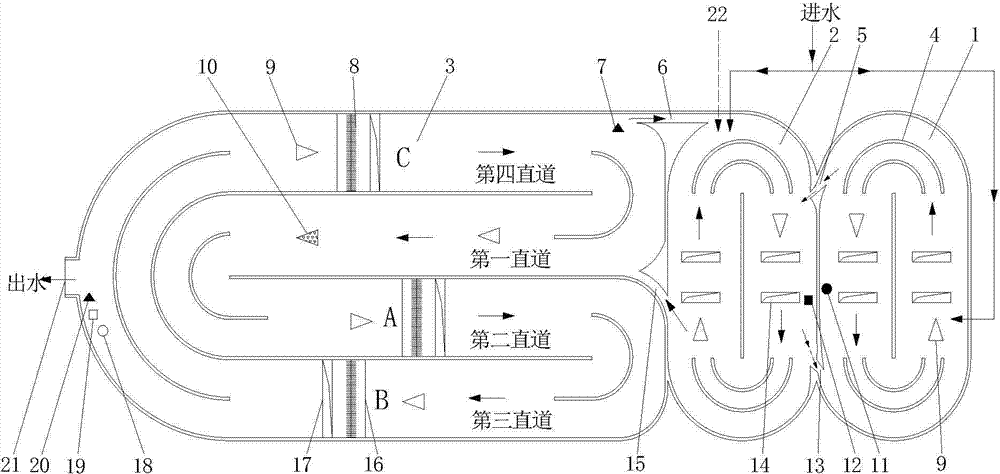

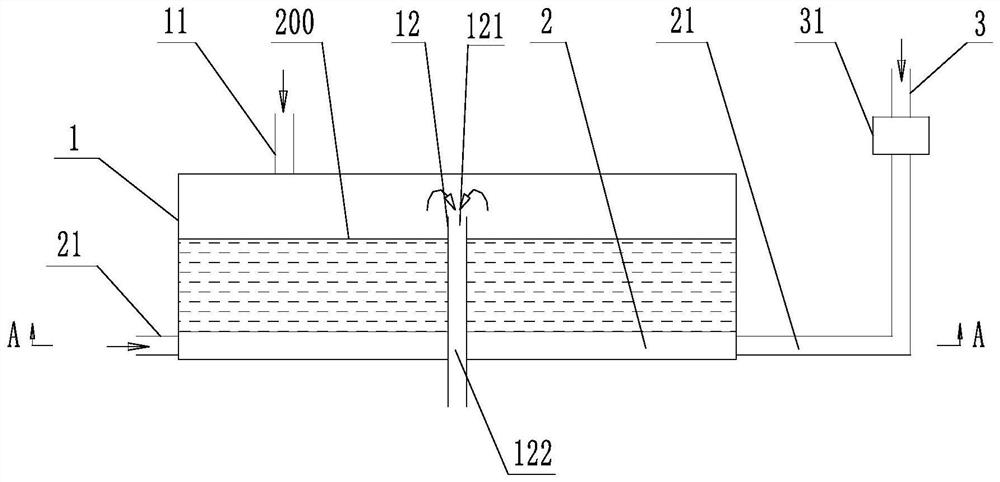

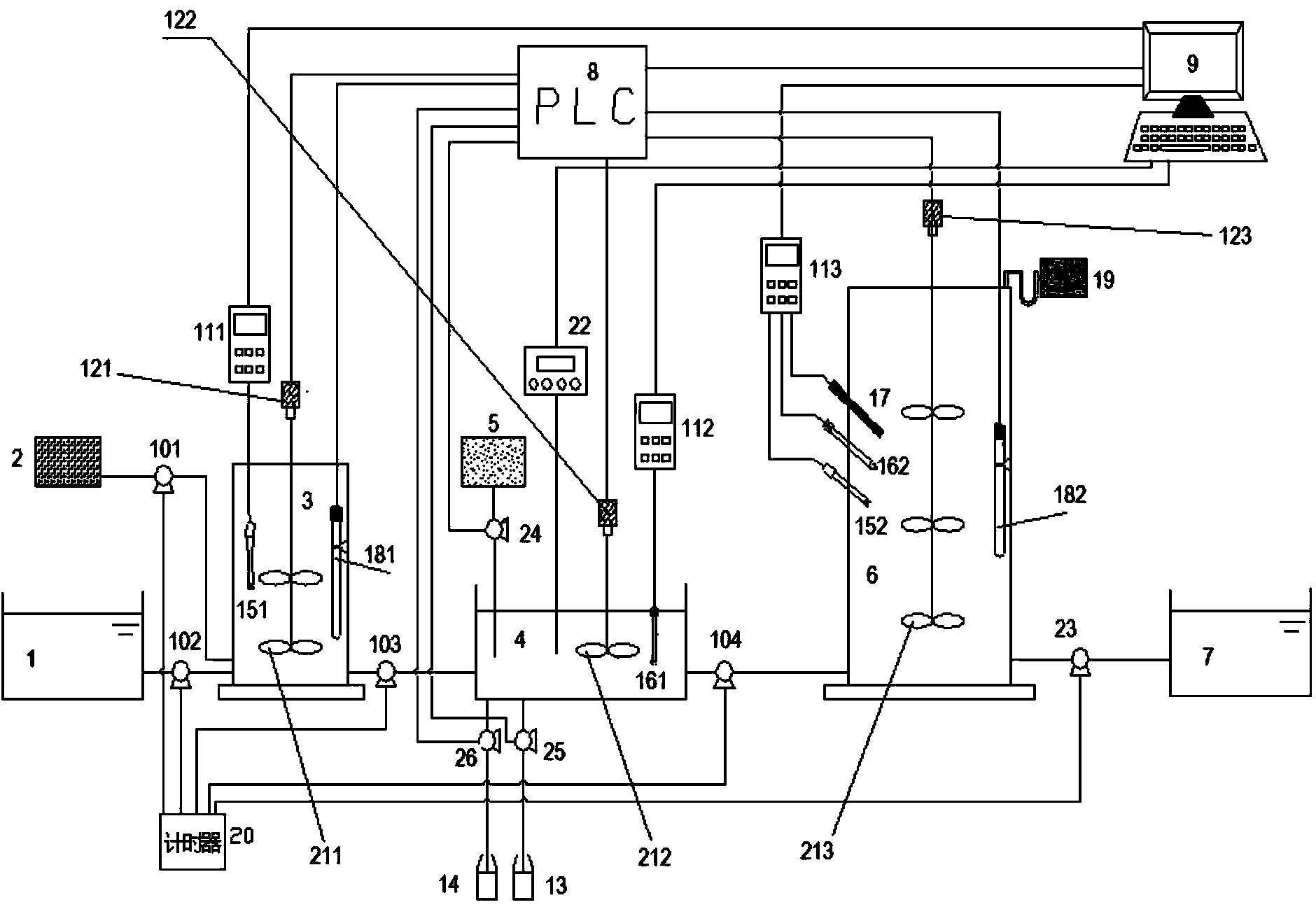

Real-time AAO oxidation ditch regulation system and sewage treatment method thereof

ActiveCN104710010AAvoid the effects of anaerobic phosphorus releaseImprove the reaction environmentWater treatment parameter controlBiological treatment regulationPhosphateHigh energy

The invention discloses a real-time AAO oxidation ditch regulation system and a sewage treatment method thereof. The method comprises the following steps: denitrifying mixed solution in an anoxic pond and refluxing the denitrified mixed solution into an anaerobic tank to perform anaerobic phosphate release with raw water, so that the influence of nitrate on the anaerobic phosphate release in the traditional AAO process is overcome; entering the mixed solution in the anoxic pond, the returned sludge in a secondary sedimentation tank and return nitrification liquor in the oxidation ditch into the anoxic pond together, and performing nitrogen removal by denitrification; entering the mixed solution in the anoxic pond into the oxidation ditch, and creating an aerobic-anoxic alternative environment by virtue of regulation, so that simultaneous nitrification and denitrification are performed in the ditch, and a denitrification effect is enhanced; and regulating the aeration mode, reflux ratio and the like in real time according to signals acquired by each online monitor by using a PLC control system. The traditional AAO oxidation ditch is subjected to structure and equipment transformation and operating mode regulation, a set of real-time regulation system based on water inflow change is established, the problems such as sludge deposition, poor nitrogen and phosphorus removal effect and high energy consumption existing in the AAO oxidation ditch are solved, and the aims of allowing the effluent to stably reach the standard, saving the energy and reducing the consumption are achieved.

Owner:WUHAN UNIV OF TECH

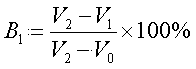

Degradation method for acquiring dalteparin

ActiveCN107236057AReduce the proportion of useless molecular weight fragmentsImprove production yieldChemistryWeight distribution

The invention discloses a degradation method for acquiring dalteparin and belongs to the field of dalteparin production. The method comprises the following steps: dissolving heparin sodium in water and then using hydrochloric acid for regulating pH to be acidic and adding sodium nitrite for performing degradation reaction; adjusting the pH of the degradation reaction solution to be alkali, adding sodium borohydride for reacting, and then using the hydrochloric acid for regulating pH and performing ultra-filtration; diluting and then using the hydrochloric acid for regulating pH to be acidic, performing the secondary degradation reaction, regulating the pH of the degradation reaction solution to be alkali after the reaction and then adding sodium borohydride for reacting; filtering, and then using the hydrochloric acid for regulating pH, using an ultraviolet lamp for irradiating the solution and adding ethyl alcohol for precipitating; performing column chromatography on the acquired precipitate and using ethyl alcohol for precipitating the acquired eluant; and dewatering the wet solid and drying, thereby acquiring the end product of dalteparin. According to the method disclosed by the invention, the degradation process is effectively utilized to adjust the self-molecular weight distribution, the loss of the molecular weight modification step is reduced and the yield is increased.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD +1

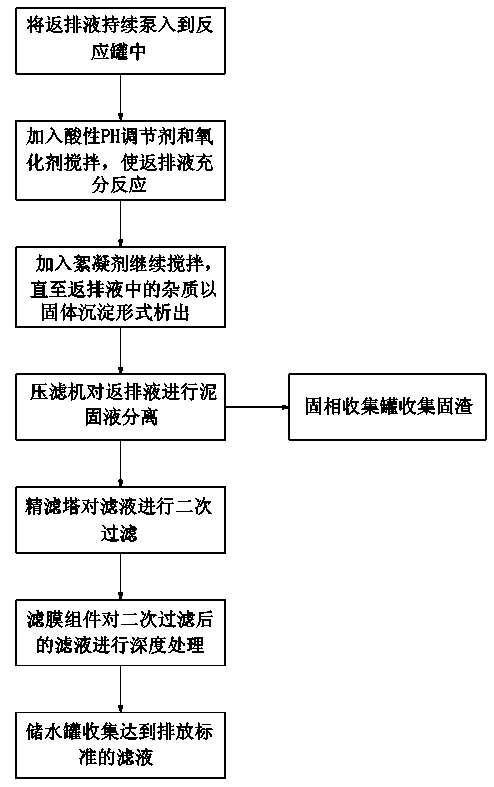

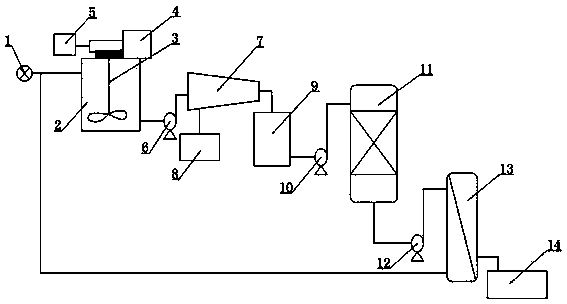

Fracturing flow-back fluid treatment system and treatment technology

ActiveCN104261592AHigh recycling valueAvoid risk of leakageWaste water treatment from quariesTreatment involving filtrationWater storage tankFilter press

The invention discloses a fracturing flow-back fluid treatment system and a treatment technology and aims to solve the problems that the existing fracturing flow-back fluid treatment technology pollutes the environment, waste the resources and is high in fracturing construction cost. The fracturing flow-back fluid treatment system comprises a flow-back fluid reaction device, a first screw pump, a press filter, a filtrate fine filter, a third screw pump, a filter membrane assembly and a water storage tank, which are sequentially connected, and a solid phase collecting tank connected with the press filter. The fracturing flow-back fluid treatment system is reasonable in structure, simple in process and convenient to operate, and can greatly reduce environment pollution, improve the recycling utilization value of fracturing flow-back fluid and reduce treatment cost and later fracturing construction cost, thereby having high application value.

Owner:SICHUAN WELDON CHEM

Preparation method of hydrogenation catalyst composition

ActiveCN103801364AEasy to useAvoid cloggingMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveOrganic acid

The invention discloses a preparation method of a hydrogenation catalyst composition. The method comprises the following steps: adding a mixture of molecular sieves and organic amines as well as organic alcohols and / or organic acids before or in the process of preparing an alumina-hydrogenation active metal oxide composite oxide by a coprecipitation method; carrying out aging after gel forming is completed and then carrying out filtration, washing and drying; then carrying out forming, drying and roasting, thus obtaining the hydrogenation catalyst composition. A catalyst prepared by the method can organically combine the molecular sieves and alumina together with good combination degree and dispersion degree, thereby avoiding agglomeration and even blockage of the molecular sieves and alumina, simultaneously controlling the distribution of the hydrogenation components on various acidic components effectively and improving the usability of the catalyst. The hydrogenation catalyst composition prepared by the method is especially suitable for hydrogenation catalysts with relatively high requirements for acidity and relatively low requirements for hydrogenation properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

N-methylol acrylamide and preparation thereof

InactiveCN101462978ANo emissionsNo pollution in the processOrganic compound preparationCarboxylic acid amides preparationHydroquinone CompoundSolvent

The invention relates to a N-methylolacrylamide and a preparation method thereof, belonging to the fine chemistry industry field. Acrylamide and paraformaldehyde are used as raw materials, and the N-methylolacrylamide is prepared by reaction in the presence of a catalyst and solvent; wherein, one or several of parahydroxyben-zaldehyde, hydroquinone and phenothiazine are added in a reaction system. The invention optimizes the reaction environment required by the production, has fewer byproducts and improves the product quality and the yield correspondingly, and the invention has simple technology and convenient use and is safe and environment-friendly.

Owner:TIANJIN CHEM REAGENT RES INST

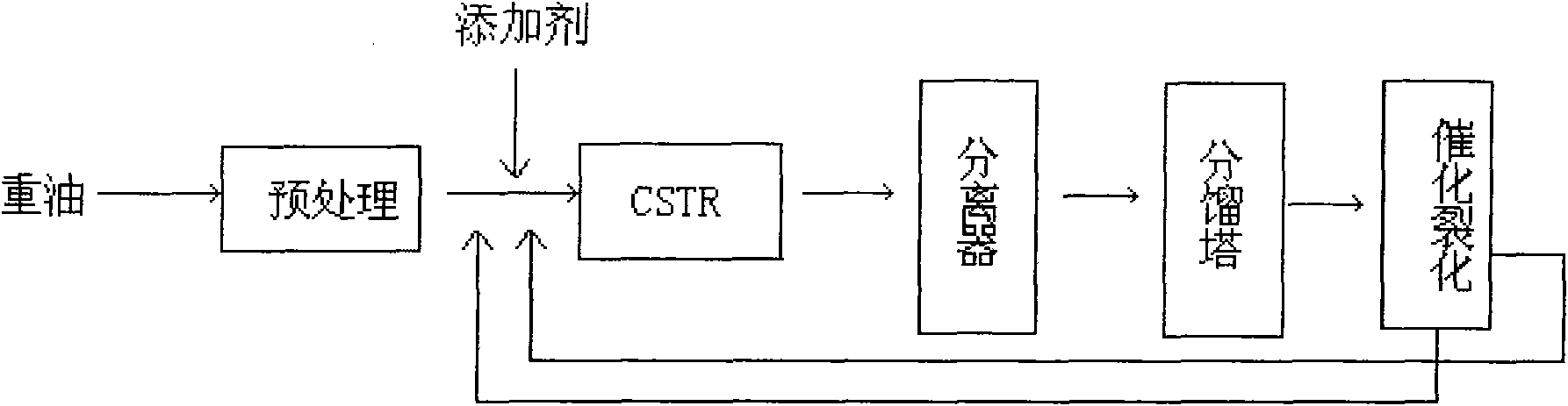

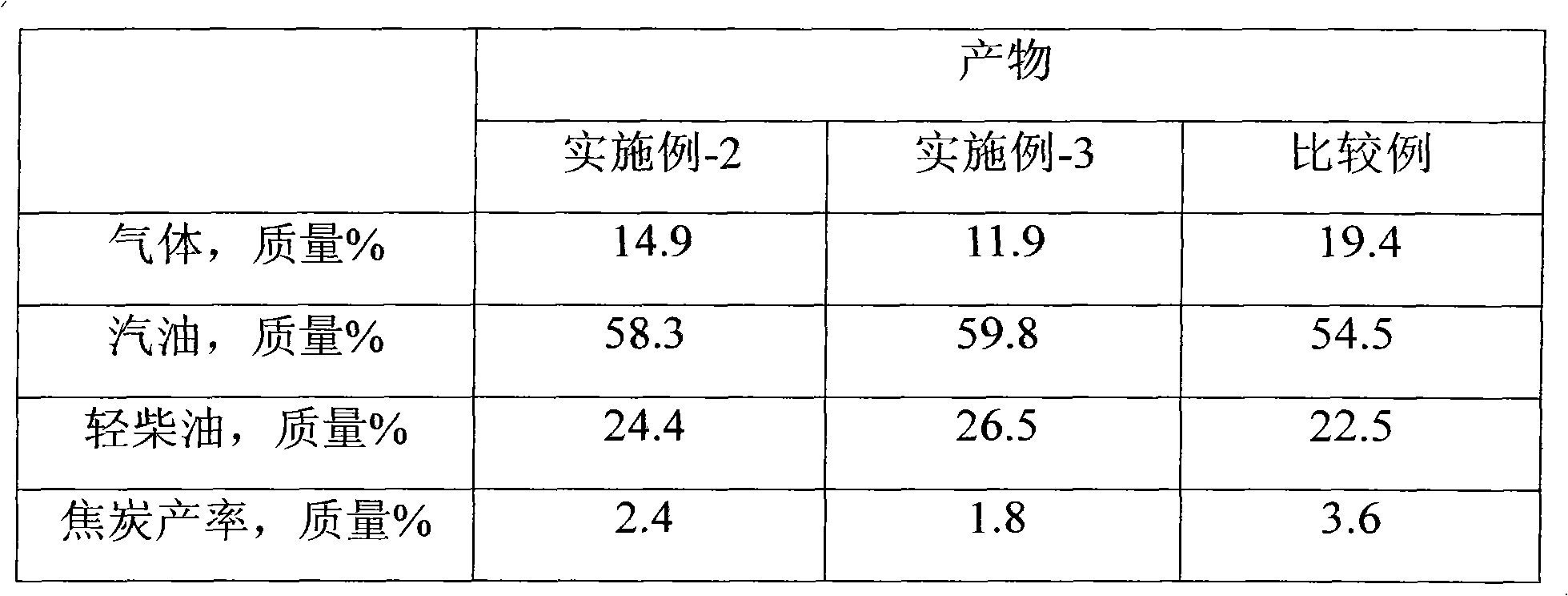

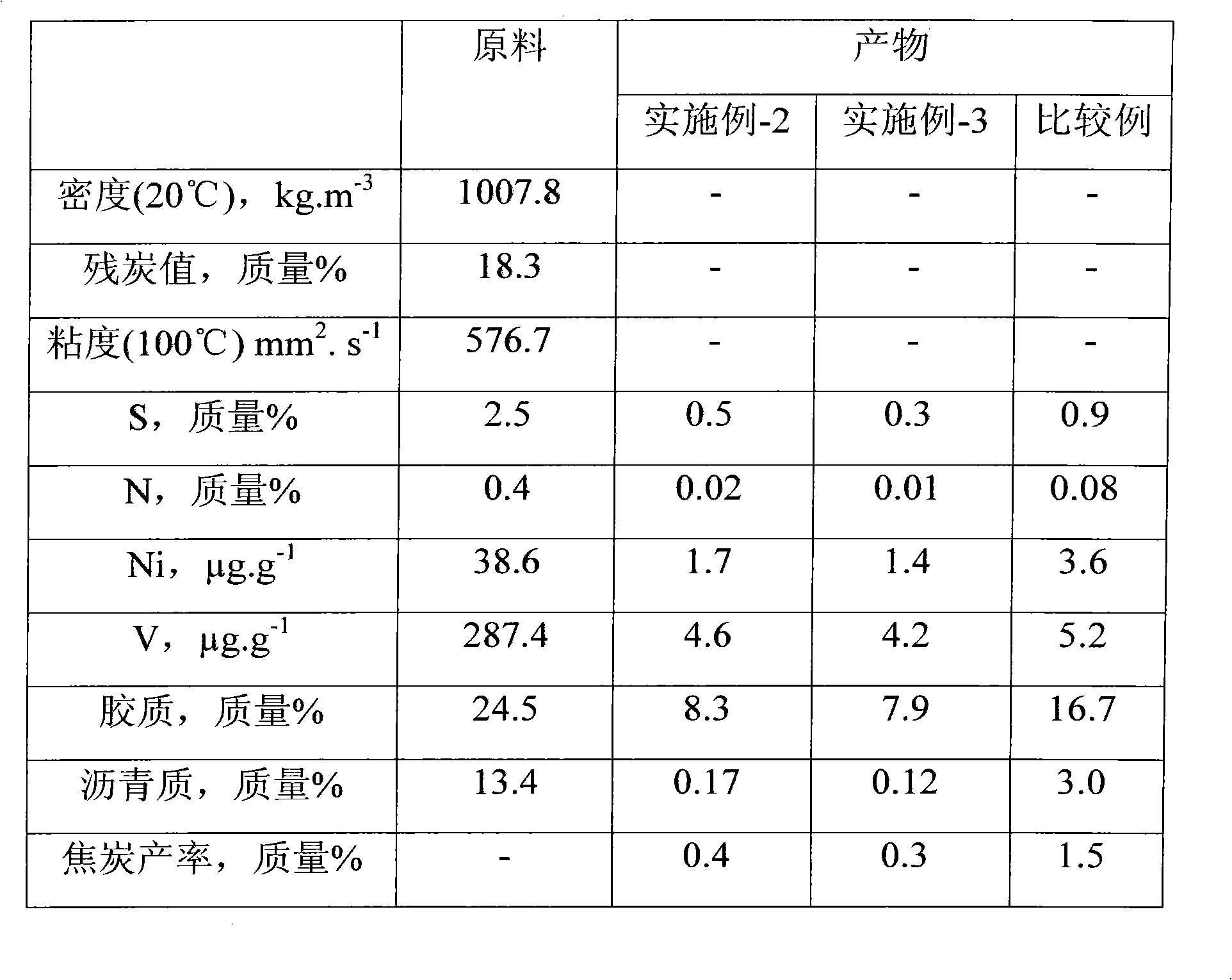

Combined process method for heavy oil modification

ActiveCN101942338AImprove fusion effectImprove responseTreatment with hydrotreatment processesFuel oilSlurry

The invention discloses a combined process method for heavy oil modification, which comprises the following steps of: mixing heavy oil raw materials and a hydrogen supply solvent for supercritical treatment, and making the heavy oil subjected to the supercritical treatment enter a catalytic cracking unit for treatment; and performing a cracking reaction in the presence of a cracking catalyst, and separating reaction products to obtain dry gas, liquefied gas, gasoline, diesel oil, heavy cycle oil and slurry oil, wherein the heavy cycle oil partially or totally cycles for the supercritical treatment, and the slurry oil partially or totally cycles for the supercritical treatment. The supercritical treatment method for the heavy oil raw materials comprises the step of mixing the heavy oil raw materials and the hydrogen supply solvent for the supercritical treatment, wherein the hydrogen supply solvent comprises tetrahydronaphthalene or decahydronaphthalene. The method has the advantages of capacity of effectively improving the utilization rate of poor-quality heavy oil, low coking rate, stable production process, and suitability for light treatment of various heavy and poor-quality raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrogenation catalyst containing molecular sieves

ActiveCN103801368AImprove bindingImprove performanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveOrganic acid

The invention discloses a preparation method of a hydrogenation catalyst containing molecular sieves. The method comprises the following steps: adding a mixture of the molecular sieves containing hydrogenation active metal components and organic amines as well as organic alcohols and / or organic acids in the amorphous alumina gel forming process; carrying out aging after amorphous alumina gel forming is completed and then carrying out hydrothermal treatment, filtration, washing and drying; then carrying out forming, drying and roasting, thus obtaining the hydrogenation catalyst. By adopting the method, the molecular sieves and alumina can be organically combined together with good combination degree and dispersion degree, agglomeration and even blockage of the molecular sieves and amorphous alumina can be avoided, and meanwhile, the hydrogenation and cracking functions of the catalyst can be effectively adjusted and the usability of the catalyst can be improved. The catalyst prepared by the method is suitable for the shallow cracking and deep hydrogenation processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for culturing biological flocculating constituent by use of solid waste of aquaculture

The invention discloses a device for culturing a biological flocculating constituent by use of the solid waste of aquaculture. The device consists of a culture barrel, a feed pump, a floating ball liquid-level switch, a stirrer and a dosing pump, and is characterized in that: a feed port and a dosing port are arranged at the top of the culture barrel; the feed port is connected with the feed pump; the dosing port is connected with the dosing pump; a discharge port is arranged at the 0.8m-deep position of the side wall of the culture barrel; the stirrer is mounted at the top of the culture barrel; the opening of the feed pump is controlled by the floating ball liquid-level switch; the dosing pump is connected with a plastic barrel; an organic carbon source is reserved in the plastic barrel; the opening of the dosing pump is controlled by the floating ball liquid-level switch; a transmission shaft of the stirrer is a hollow shaft; an air leading-in hole vertical to the central axis of the transmission shaft is drilled below the joint between the transmission shaft of the stirrer and a motor, and the hole is communicated with a central axis hole; an air leading-out hole vertical to the central axis of the transmission shaft is drilled below the joint between the transmission shaft and a stirring impeller, and the hole is communicated with the central axis hole; and the motor of the stirrer is a variable-speed motor which can adjust the mixing strength.

Owner:SHANGHAI OCEAN UNIV

Preparation method of hydrocarbon hydrogenation catalyst

ActiveCN103801375AAdjustment functionEasy to useMolecular sieve catalystsMolecular sieveOrganic acid

The invention discloses a preparation method of a hydrocarbon hydrogenation catalyst. The method comprises the following steps: adding a mixture of group VIII metal cation modified molecular sieves and organic amines as well as organic alcohols and / or organic acids before or in the process of preparing an alumina-group VIB metal oxide composite oxide by a coprecipitation method; carrying out aging after gel forming is completed and then obtaining a catalyst intermediate through filtration, washing and drying; then carrying out forming, drying and roasting, thus obtaining the hydrogenation catalyst. The catalyst prepared by the method can organically combine the molecular sieves and alumina together with good combination degree and dispersion degree, thereby avoiding agglomeration and even blockage of the molecular sieves and amorphous alumina, simultaneously controlling the distribution of hydrogenation components on various acidic components effectively and improving the usability of the catalyst; and the catalyst is especially suitable for the hydrocarbon hydro-upgrading process with moderate requirements for acidity and the hydrogenation function.

Owner:CHINA PETROLEUM & CHEM CORP +1

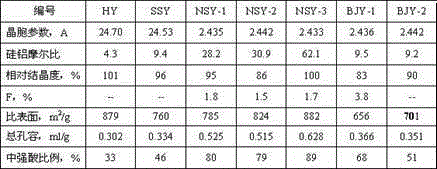

Modified Y type molecular sieve and preparation method thereof

ActiveCN105712373AImprove the reaction environmentReduce consumptionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAqueous solution

The invention discloses a preparation method for a modified Y type molecular sieve. The preparation method comprises the following steps: (1) preparing an aqueous solution containing fluorine and silicon; (2) weighing a low-sodium Y type molecular sieve, spraying and soaking the low-sodium Y type molecular sieve with the aqueous solution containing fluorine and silicon prepared in the step (1), carrying out maintenance for 30 to 240 min, then carrying out drying and subjecting the dried Y type molecular sieve to hydro-thermal treatment; and (3) treating the molecular sieve having undergone hydro-thermal treatment with a weak acid solution with a concentration of 0.2 to 2.0 mol / L, carrying out solid-liquid separation, washing a filter cake until a pH value is neutral and then carrying out drying so as to prepare the modified Y type molecular sieve. The method can prepare the modified Y type molecular sieve with a high silica-alumina ratio, abundant macroporous structures and an appropriately high crystallization degree; and the modified Y type molecular sieve has high macro-molecular hydrocarbon conversion capability and is simple to prepare.

Owner:CHINA PETROLEUM & CHEM CORP +1

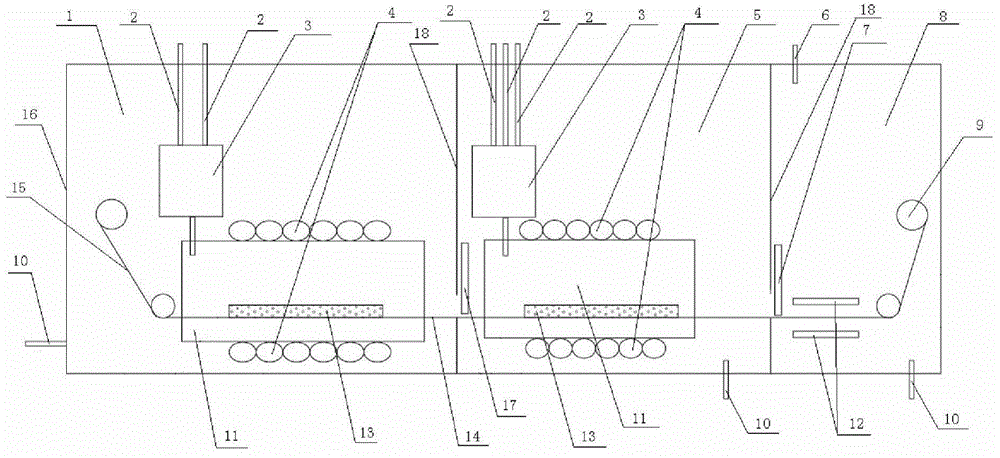

Equipment and method of continuously and rapidly preparing graphene under normal pressure

The invention relates to equipment and a method of continuously and rapidly preparing graphene under a normal pressure. The equipment comprises a box, a constant-temperature annealing cavity, a cooling growth cavity and a cooling cavity, wherein the box is separated into the constant-temperature annealing cavity, the cooling growth cavity and the cooling cavity; a gas intake tube, a gas mixing chamber and a reaction cavity are arranged in the constant-temperature annealing cavity and the cooling growth cavity respectively; the gas intake tube stretches in the gas mixing chamber; the gas mixing chamber is communicated with the reaction cavity; a cooling device is arranged in the cooling cavity; a feeding device and a cold gas tube are further arranged in the box; the feeding device penetrates through the reaction cavities and the cooling devices of the constant-temperature annealing cavity and the cooling growth cavity; the constant-temperature annealing cavity, the cooling growth cavity and the cooling cavity are provided with pressure release tubes. The method comprises the following steps: conveying a metal substrate in the constant-temperature annealing cavity and annealing at first; then conveying the metal substrate in the cooling growth cavity and reacting to grow graphene; finally conveying graphene in the cooling cavity and cooling. The equipment and method have the beneficial effects that preparation cycle is short, the equipment is simple in structure and convenient in operation, production efficiency is increased, and high economic benefits are achieved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

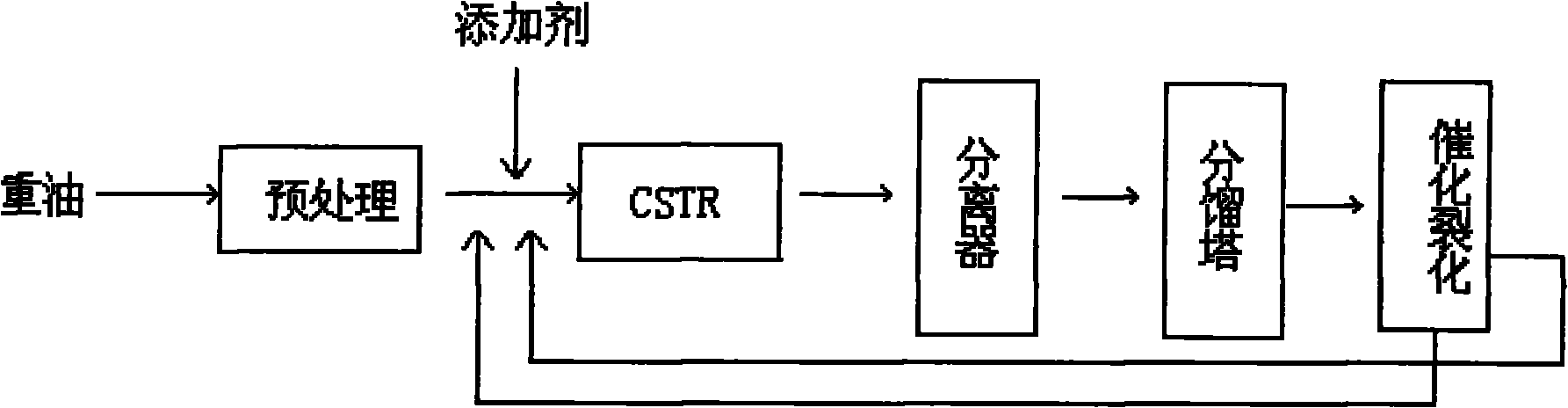

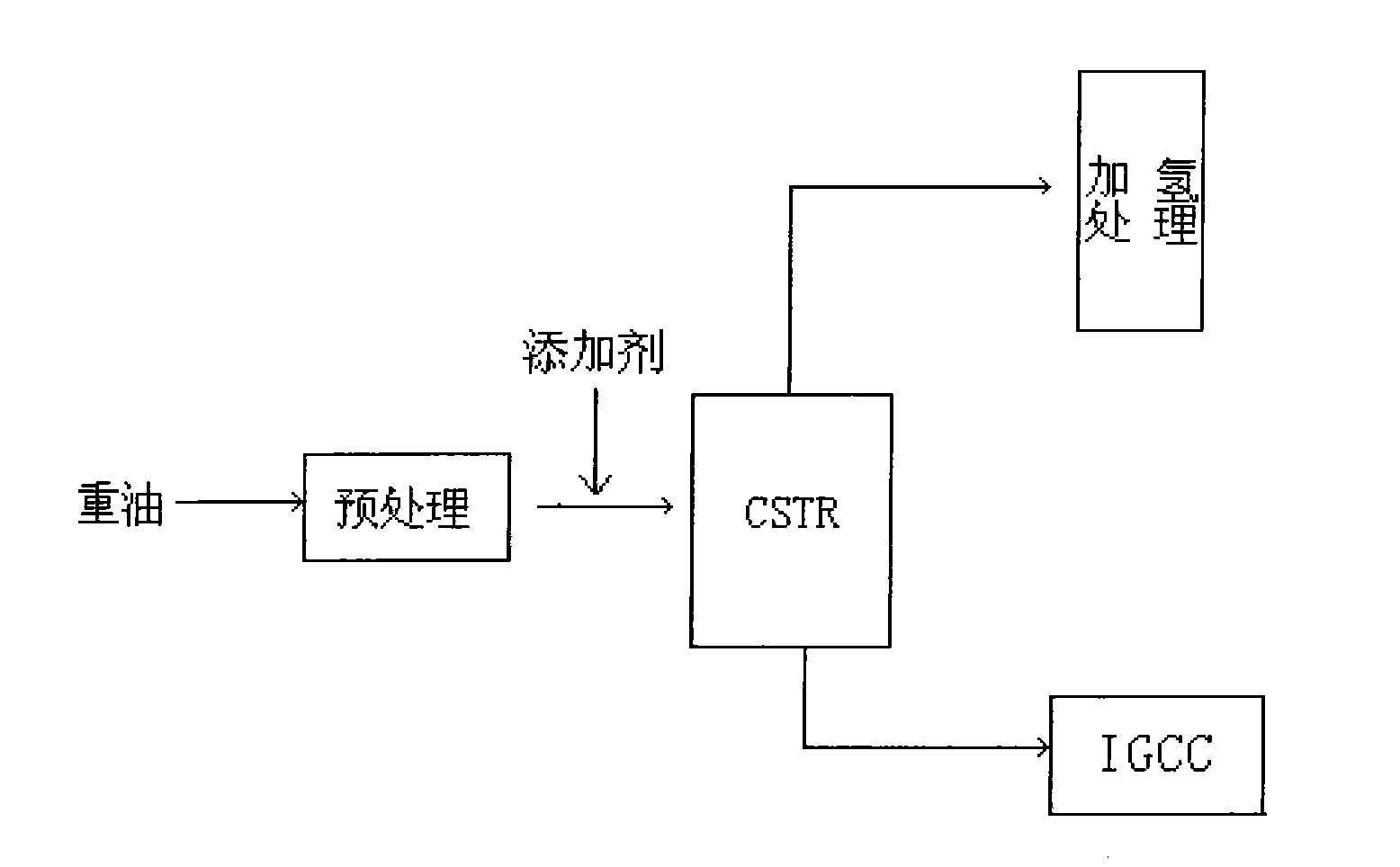

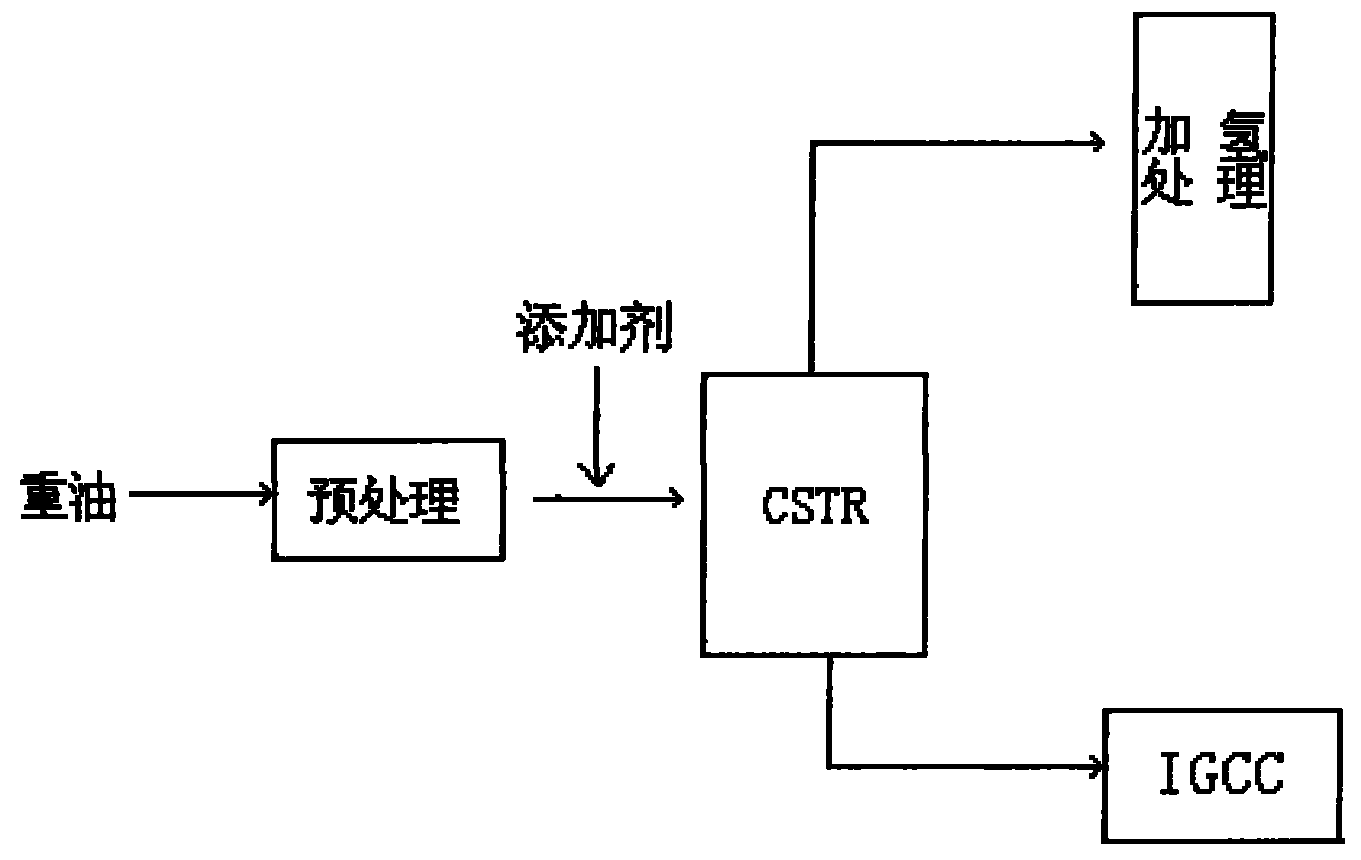

Combined process method for modifying heavy oil

InactiveCN102311797AImprove fusion effectImprove responseHydrocarbon oil crackingTreatment with hydrotreatment processesFuel oilSolvent

The invention discloses a combined process method for modifying heavy oil, which comprises the following contents: a heavy oil raw material is pretreated first to remove water and mechanical impurities; then supercritical treatment is performed in the presence of a hydrogendonating solvent and in a supercritical or subcritical state; and light oil obtained after supercritical treatment is subjected to hydrogenation treatment or catalytic cracking treatment, and a heavy component obtained after supercritical treatment is treated by an integrated gasification combined cycle (IGCC) technique. When the method is used, the impurities in low-quality heavy oil can be removed effectively, and the utilization rate of a heavy oil raw material can be improved effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

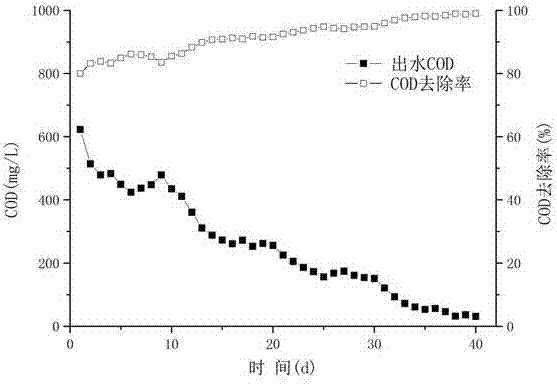

Method for promoting anaerobism and efficiently producing methane through denitrification at same time

InactiveCN107540085AEnsure anaerobic environmentImprove the reaction environmentWater contaminantsTreatment with anaerobic digestion processesSodium acetateChemical oxygen demand

The invention discloses a method for promoting anaerobism and efficiently producing methane through denitrification at the same time. The method comprises the following steps: inoculating anaerobic granule sludge in an anaerobic reactor, guiding waste water taking sodium acetate and sodium propionate as a mixed carbon source, taking nitrate nitrogen in the waste water as a nitrogen source, controlling inflow COD (chemical oxygen demand) of the waste water to be consistent, gradually reducing the C / N specific value and operating the anaerobic reactor, so as to promote the waste water to be anaerobic and produce the methane through denitrification at the same time. According to the method, by controlling the type of the carbon source and the C / N specific value, a reaction environment of anaerobism and production of the methane through denitrification at the same time is improved, the anaerobism and the production of the methane through denitrification are achieved in the single reactor at the same time, the system adaptation time and the hydraulic retention time are shortened, the pollutant removal efficiency is high, the water quality of effluent is table, and the clean energy methane is produced.

Owner:SOUTH CHINA UNIV OF TECH

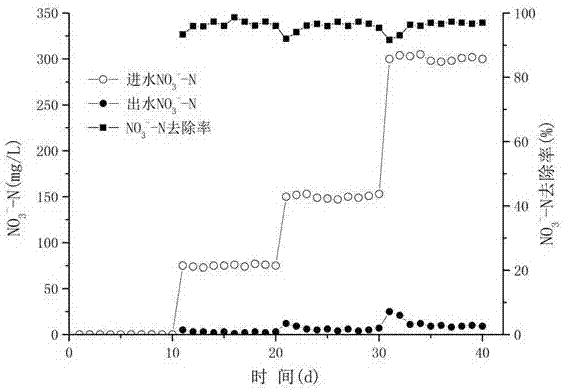

Preparation method of pregabalin

ActiveCN103073443ARaw materials are easy to getSimple and efficient operationOrganic compound preparationAmino-carboxyl compound preparationCarbonyl groupGlutaric anhydride

The invention provides a synthetic method of pregabalin. The method comprises the following steps that (R)-3-(2-(benzyl sulfydryl)-2-ethyl)-5-methylhexanoic acid is synthesized from 3-isobutyl glutaric anhydride in carbinol; then, through base catalysis, (S)-S-phenyl 3-((benzyloxycarbonylamino group) methyl)-5-methylhexanol thioester is synthesized; next, hydrolysis is carried out, (S)-S-phenyl 3-((benzyloxycarbonylamino group) methyl)-5-methylhexanol is synthesized; and finally, hydrogenation is carried out, and the pregabalin is prepared. The material has the advantages that raw materials are easy to obtain, the operation is simple and convenient, the reaction condition is mild, and the industrial production is easy.

Owner:FUDAN UNIV

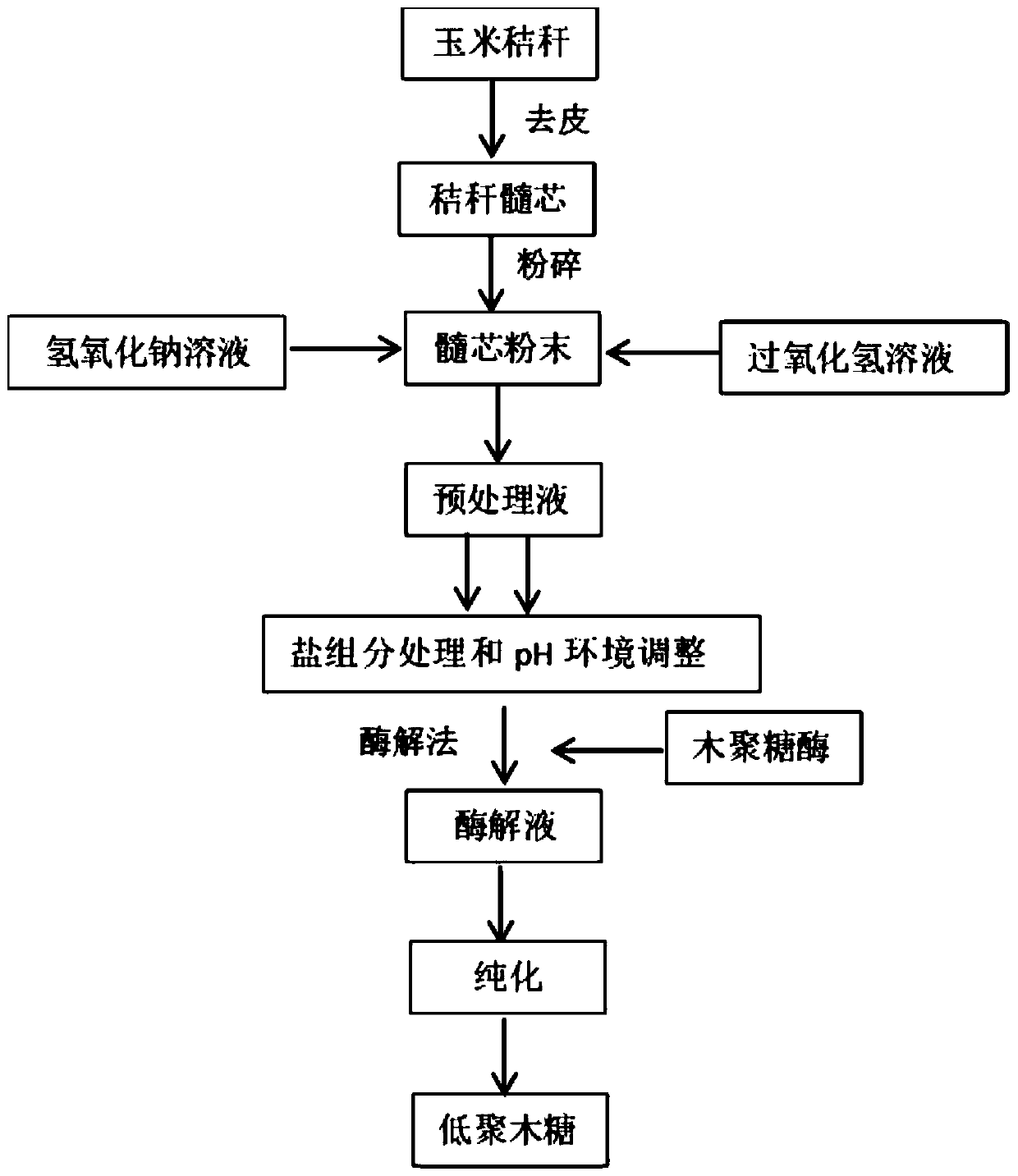

Method for preparing xylooligosaccharide by using corn straw cores

ActiveCN111334542AWide variety of sourcesSuitable for productionFermentationActivated carbonEnzymatic hydrolysis

The invention relates to the field of xylooligosaccharide, in particular to a method for preparing xylooligosaccharide by using corn straw cores. The raw materials used in the method are corn straw cores, alkaline hydrogen peroxide is used to carry out prehydrolysis to remove lignin, then hydrolysate is subjected to desalting and pH environment adjustment, and finally hydrolyzation is further carried out by an enzymatic hydrolysis method to obtain a xylooligosaccharide solution. In order to further improve the purity of xylooligosaccharide, purification treatment is carried out by adopting activated carbon combined with decolorization resin. The method is simple in preparation process, mild in reaction and environmentally friendly, the obtained xylooligosaccharide is high in purity and high in yield, the use amount of enzyme is small in a subsequent enzymatic hydrolysis method, and the cost is saved.

Owner:BEIHUA UNIV

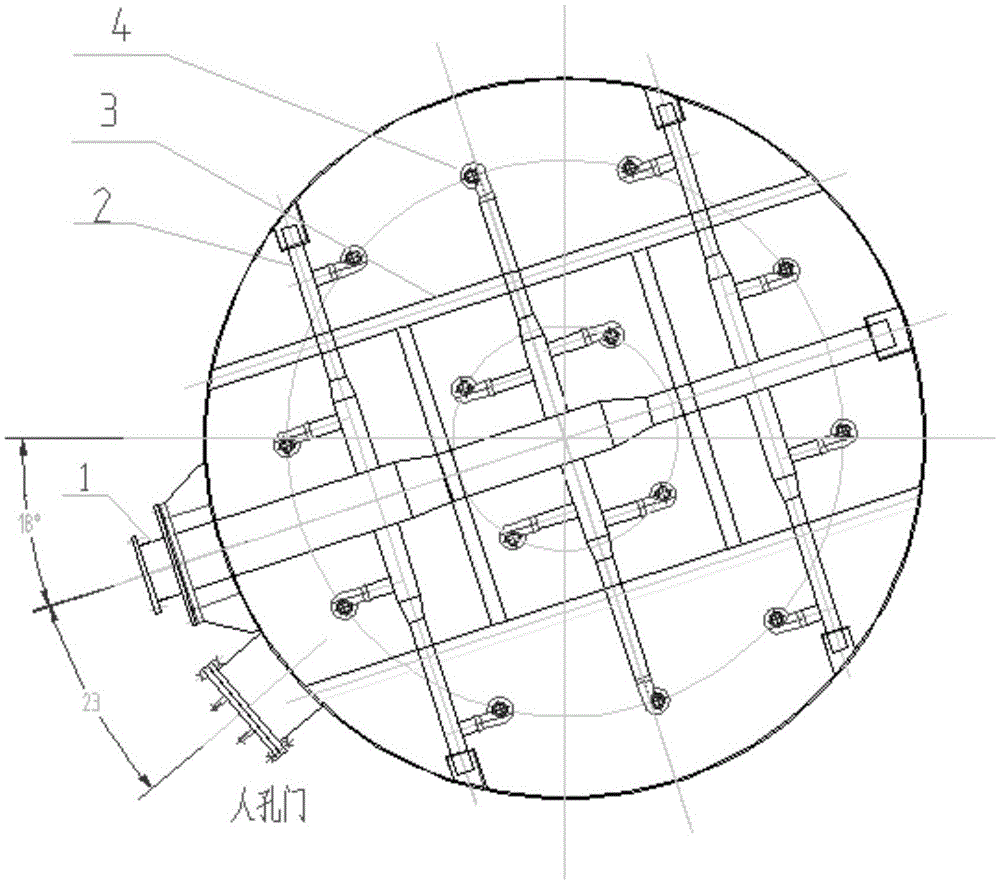

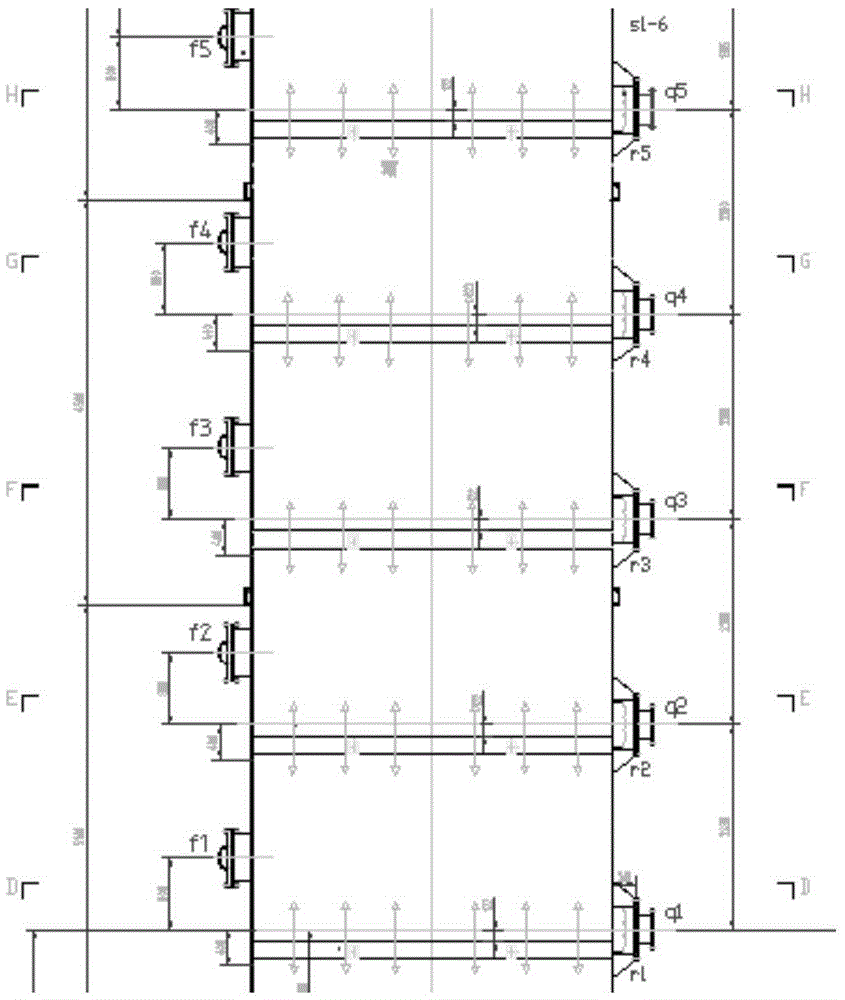

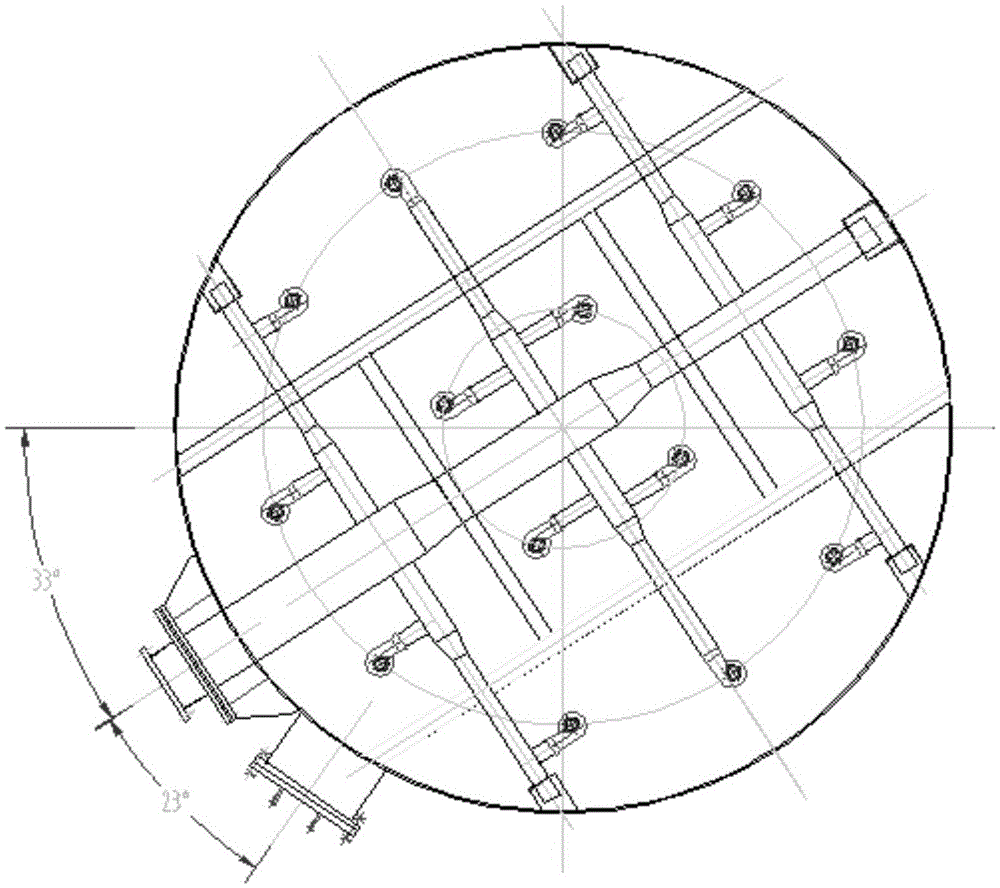

Spray device capable of meeting desulfurization towers under different working conditions of CFB (circulating fluidized bed) boiler

The invention relates to a spray device capable of meeting desulfurization towers under different working conditions of a CFB (circulating fluidized bed) boiler and belongs to the environmental protection field. Each spray layer contains a main water inlet pipe, a plurality of branch pipes and a bearing beam for fixation, wherein each main water inlet pipe is a pipe adopting reducing type change, the branch pipes are arranged on pipes with different diameters, and spray heads arranged on the branch pipes; the bearing beams are fixedly connected with the wall of a spray tower; multiple spray layers are fixed in the spray tower, and the vertical positions of the main water inlet pipes of all the spray layers are not overlapped. Through combination of forward-flow spray with reverse-flow spray, angle arrangement of the spray heads and arrangement of directions of the spray layers, the conditions that the desulfurization tower scales, is blocked and has spray dead corners are eliminated fundamentally, so that the desulfurization efficiency of the desulfurization tower is improved, and the spray device has characteristics of reliability in operation, convenience in operation and high adaptability to flue gas change in engineering practice. The reaction environment is optimized, the size of the tower body is narrowed, and the design principle of simplicity and reliability is embodied. Conciseness, high efficiency and reliability are realized indeed.

Owner:CHINA NORTH ENERGY CONSERVATION & ENVIRONMENT PROTECTION

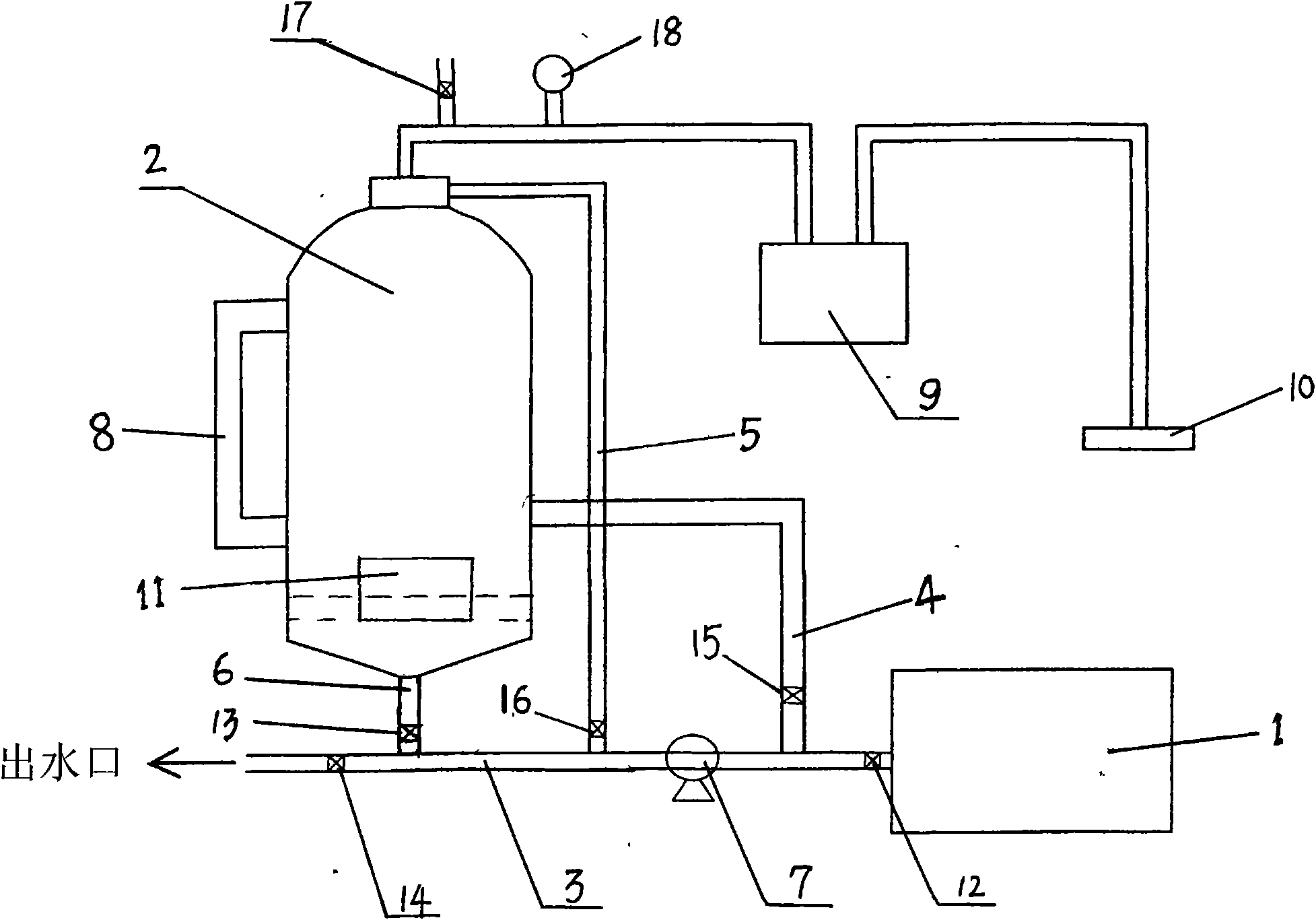

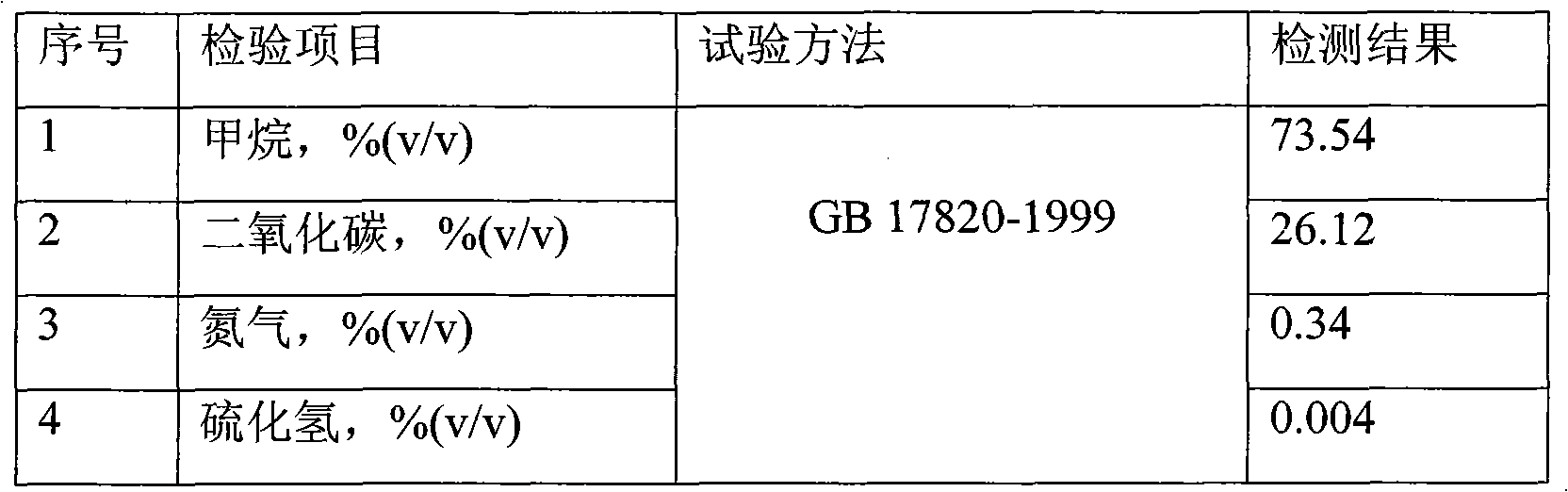

Method for efficiently producing marsh gas and device thereof

InactiveCN101654688AShorten fermentation timeHigh Organic Loading RateBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAnaerobic reactor

The invention relates to a method for efficiently producing marsh gas and a device thereof. The method comprises the following steps: mainly using urban domestic garbage and rural waste as raw materials; putting the domestic garbage in a fermentation vat for primary corruption; then, conveying pretreated fermented liquid to an anaerobic reactor to ferment and generate the marsh gas; conveying devulcanized marsh gas to a cooker for combustion and use; and conveying liquid in the anaerobic reactor to the fermentation vat again. The device is characterized in pipeline design; an outlet pipeline of the fermentation vat is respectively communicated with a middle pipeline, a top pipeline and a bottom pipeline of the anaerobic reactor; and each pipeline is provided with a pipeline switch which can be opened or closed as required to achieve the functions of the reactor, such as automatically flushing, returning the liquid of the reactor to the fermentation vat, automatically discharging sewageand pollution, and the like. The invention improves the organic load rate and the processing efficiency of the reactor and has the advantages of easy cleaning, convenient pollution discharge and highmarsh gas production efficiency; and the produced marsh gas has high methane concentration and extremely low sulfureted hydrogen concentration, thereby being a favorable clean power source.

Owner:陈志明 +3

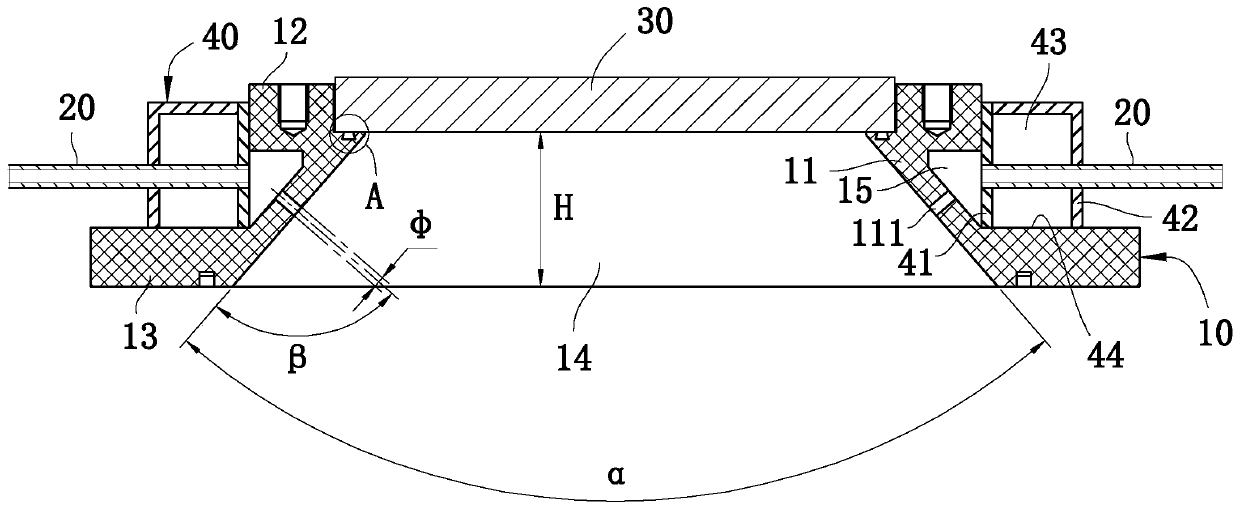

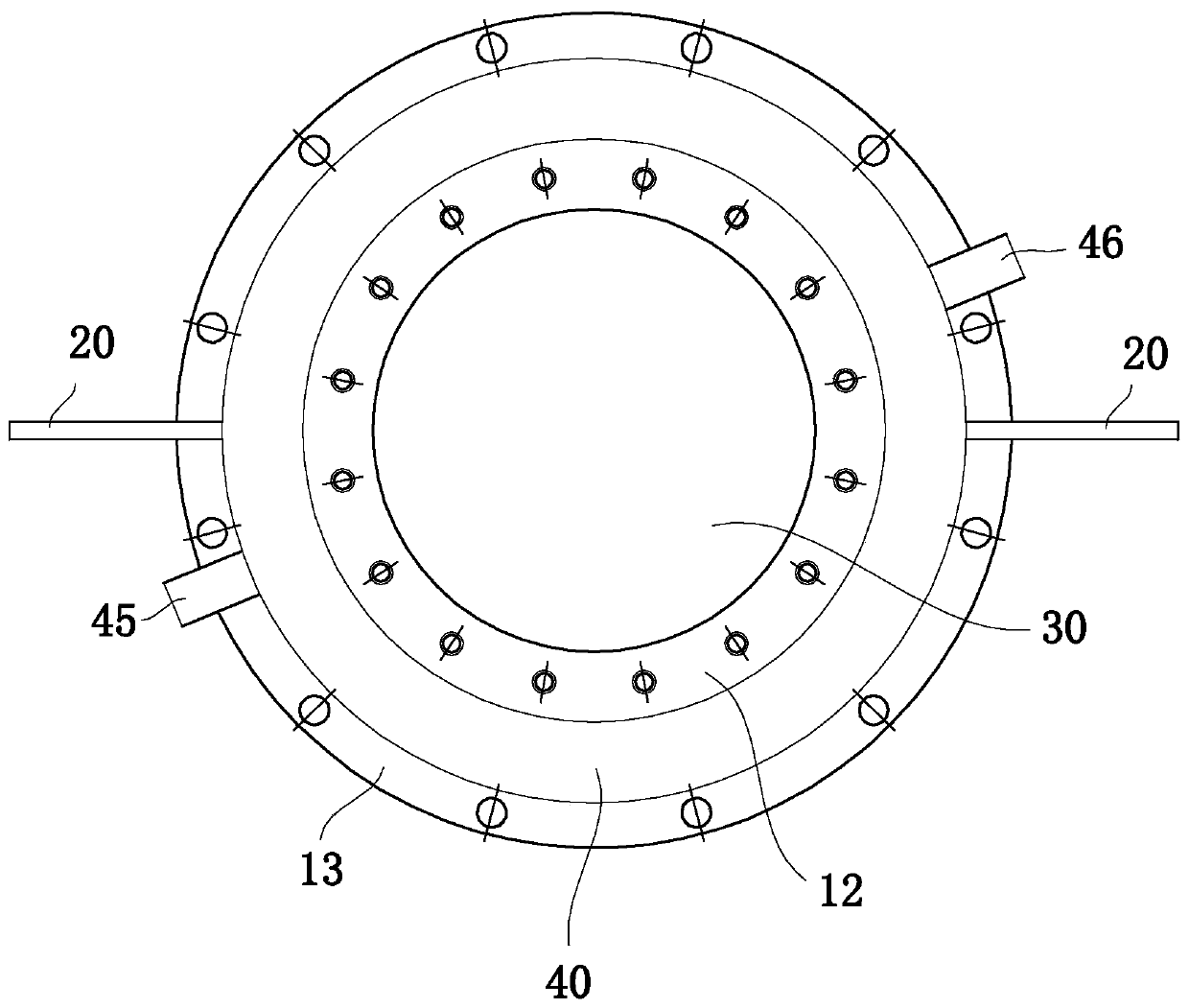

Microwave plasma reactor used for manufacturing monocrystal diamond and diffusion device thereof

ActiveCN110468449AQuality improvementEvenly distributedPolycrystalline material growthFrom chemically reactive gasesEquipotential surfaceMicrowave

The invention discloses a microwave plasma reactor used for manufacturing a monocrystal diamond and a diffusion device thereof. The diffusion device comprises a diffusion base, a gas inlet pipe groupand medium glass, wherein the diffusion base is provided with a conical wall body; the upper edge of the wall body is provided with a first round flange; the lower edge of the wall body is provided with a second round flange which is parallel to the first round flange; the enclosure of the wall body defines a diffusion opening therein; the area of the cross section of the diffusion opening is gradually increased in a direction from the first round flange to the second round flange; the gas inlet pipe group comprises at least two gas inlet pipes which are circumferentially and uniformly distributed around the axis of the diffusion base; the medium glass is clamped in the first round flange and seals the upper part of the diffusion opening; a plurality of gas holes are also circumferentiallyand uniformly arranged in the wall body along an axis; and gas brought in by the gas inlet pipes is introduced into the diffusion opening through the gas holes. According to the invention, through arrangement of the conical diffusion base, microwave is guided to be distributed around a seed crystal in a uniform and stable ellipsoid equipotential surface manner, so a good environment is provided for growth of the seed crystal, and the growth quality of the seed crystal is improved.

Owner:宁波晨鑫维克工业科技有限公司 +1

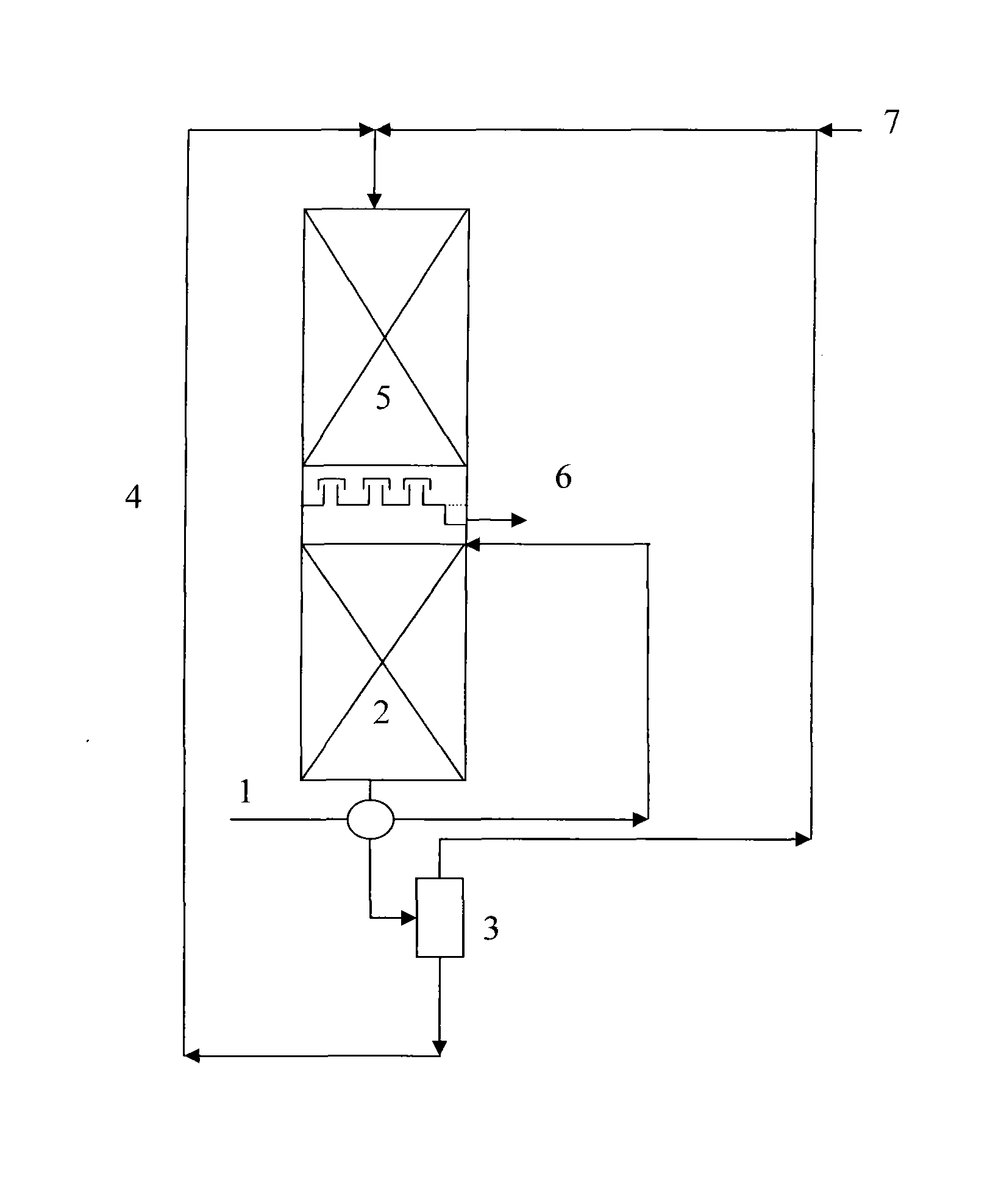

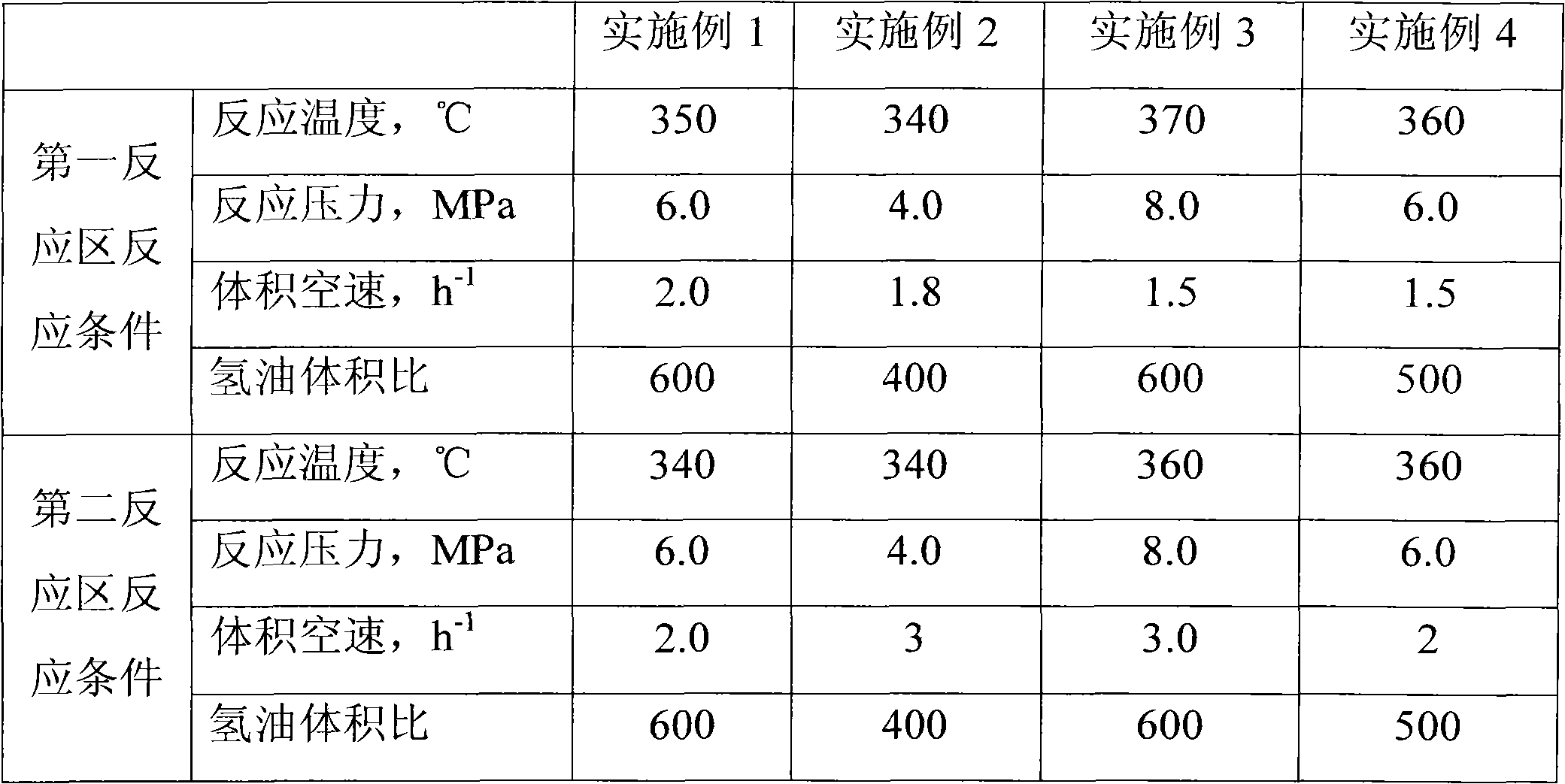

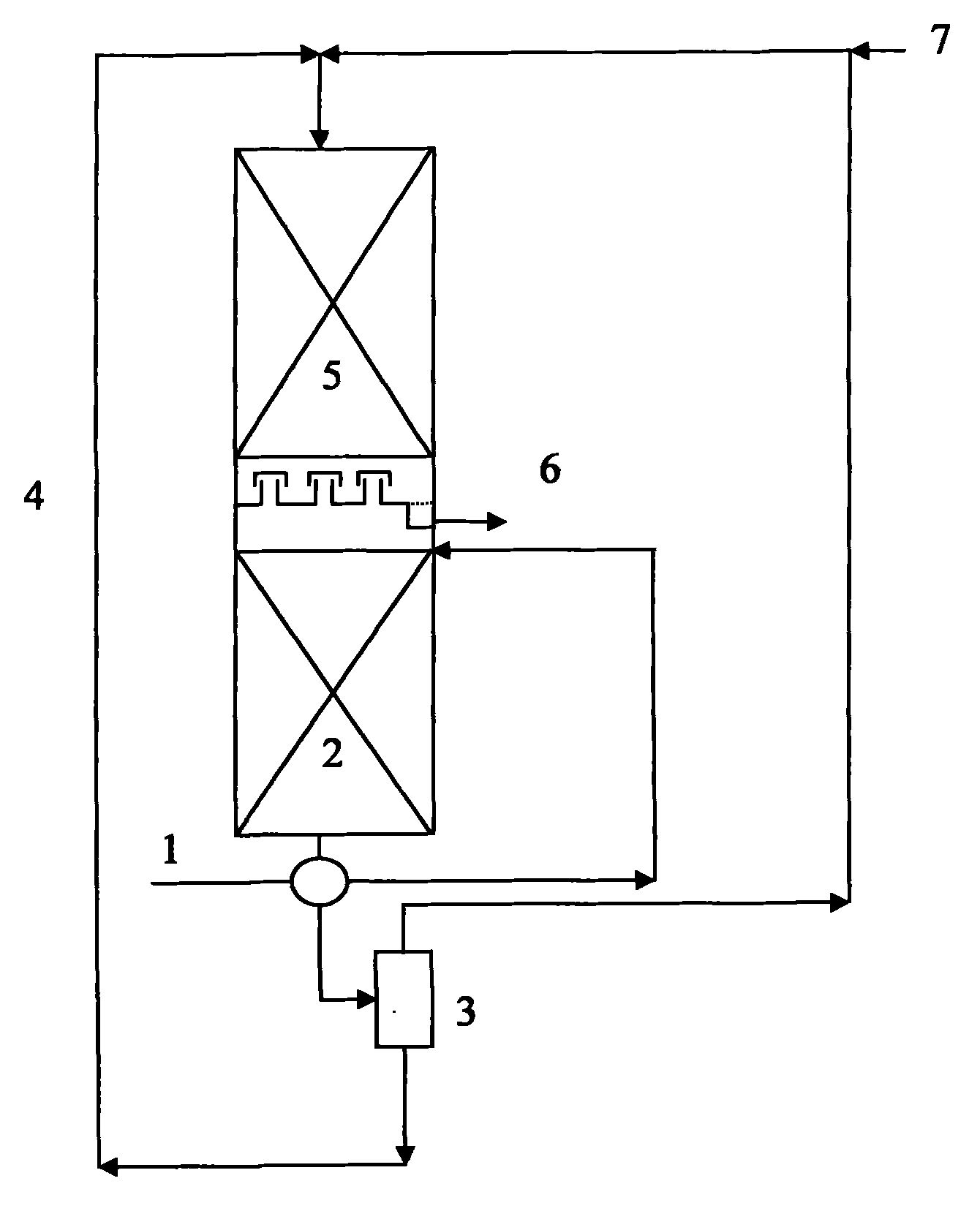

Diesel hydrogenation process method

ActiveCN102041072AUniform temperature distributionImprove the reaction environmentTreatment with hydrotreatment processesGas phaseHydrogenation reaction

The invention discloses a diesel hydrogenation process method. The upper part in a hydrofining reactor is provided with a first reaction zone, and the lower part in the hydrofining reactor is provided with a second reaction zone; a liquid collecting and discharging part is arranged between the two reaction zones and is used for collecting liquid of reaction effluent in the first reaction zone and discharging the liquid out of the reactor; a gas phase of the reaction effluent in the first reaction zone enters the second reaction zone through a bubble cap of the liquid collecting and discharging part; a diesel raw material enters the second reaction zone and is mixed with the gas phase inflowing from the first reaction zone to be subjected to hydrofining reaction under the hydrofining condition; reaction effluent in the second reaction zone is subjected to gas-liquid separation to form a gas phase; the gas phase from which hydrogen sulfide is removed is mixed with a liquid phase to enter the first reaction zone so as to be subjected to hydrogenation reaction; and the hydrogenated product is obtained after the liquid phase of the reaction effluent in the first reaction zone is discharged by the liquid collecting and discharging part. Compared with the prior art, the method has the advantages that: reaction heat is fully utilized; a large amount of cold hydrogen is not needed; meanwhile, the reaction environments of different reaction zones are optimized, and the whole reaction performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sectional type anaerobic baffled reactor

InactiveCN101560036ASmall volumeIncrease oxygen contentTreatment with anaerobic digestion processesMultistage water/sewage treatmentWater districtSmall footprint

The invention belongs to sewage treatment device, in particular to waste water anaerobe treatment device with principal character of sectional water inlet operation. An anaerobic reaction chamber surrounds the main part of a reactor, the middle of the main part of the reactor is provided with a denitrification dephosphorization zone, the bottom is provided with a sludge settling zone which is externally connected with a sludge outlet pipe; the top is provided with an overflow groove which is externally connected with a water outlet pipe; the anaerobic reaction chamber is divided into a plurality of anaerobic reaction chambers by baffles, baffle plate positioned between two adjacent baffles divide each chamber into a lower water district and an upper water district, the top of the lower water district is provided with a water inlet pipe, the bottom of the upper water district is thrown in granular anaerobic sludge, the top is provided with a sewage sample port; a row of water discharging ports are arranged between the bottom of the anaerobic reaction chamber with the lowest height of the baffle and the sludge settling zone. The invention has the characteristics of very low energy consumption, high load resistance, small amount of excess sludge, good water conservancy mixing condition, easy devices, small floor area, low running cost and the like.

Owner:JIANGSU UNIV

Hydride vapor phase epitaxy gallium boat structure

ActiveCN112126976AExtended pathImprove conversion ratePolycrystalline material growthFrom chemically reactive gasesVapour phase epitaxyEngineering

The invention relates to the technical field of semiconductors, and discloses a hydride vapor phase epitaxy gallium boat structure which comprises a boat body, and further comprises a gallium source inlet formed in the top of the boat body. A liquid gallium source is contained in the boat body. A reactant outlet pipeline arranged in the boat body, the top end of thereactant outlet pipeline is higher than the liquid level of theliquid gallium source, the bottom end of the reactant outlet pipeline penetrates out of the bottom wall of the boat body; a gas distribution disc is also arranged on thebottom wall in the boat body, a hydrogen chloride inlet is formed in the side face of the gas distribution disc, at least one hydrogen chloride outlet is formed in the top end of a pipeline of the gas distribution disc, and each hydrogen chloride outlet is located below the liquid level of the liquid gallium source. The gallium boat structure has the advantages that the hydrogen chloride conversion rate is high, the contact area of hydrogen chloride and a liquid gallium source is large, and the hydrogen chloride path is effectively prolonged.

Owner:紫石能源有限公司

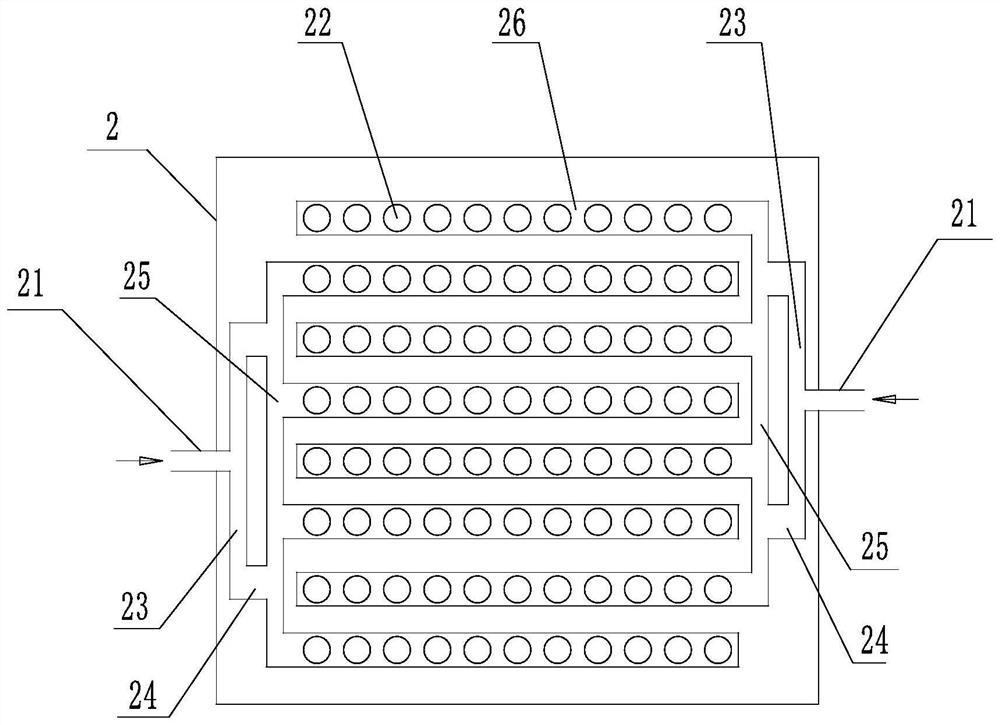

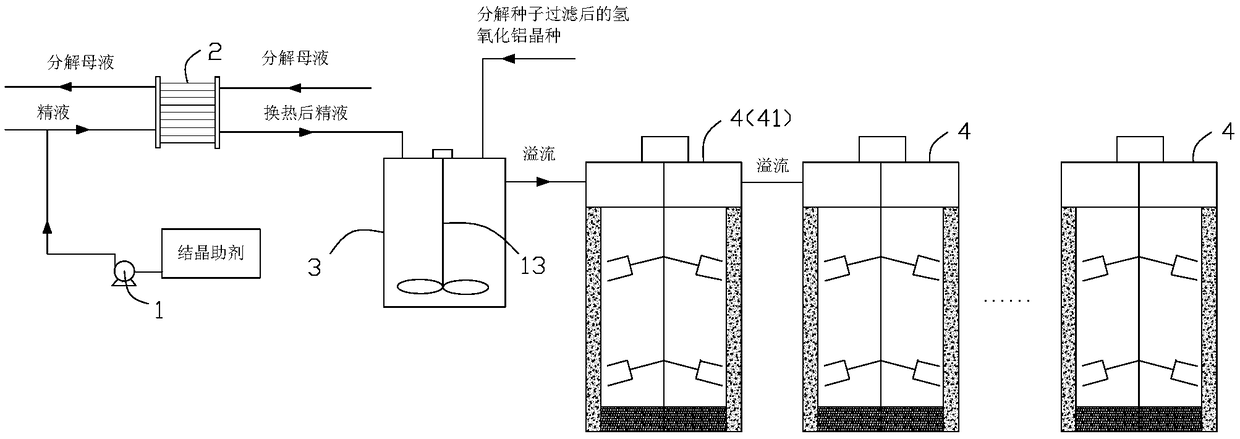

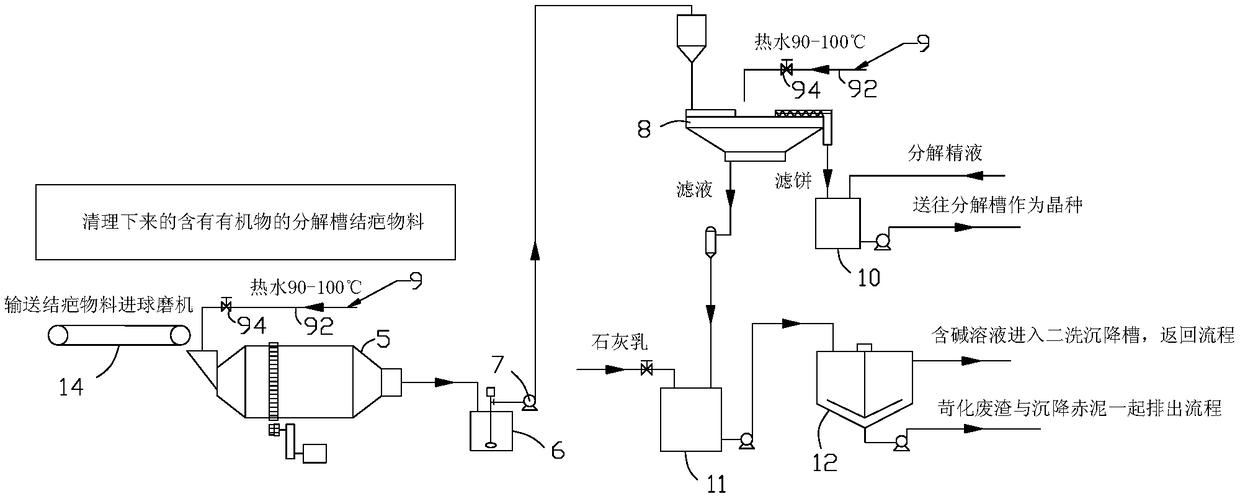

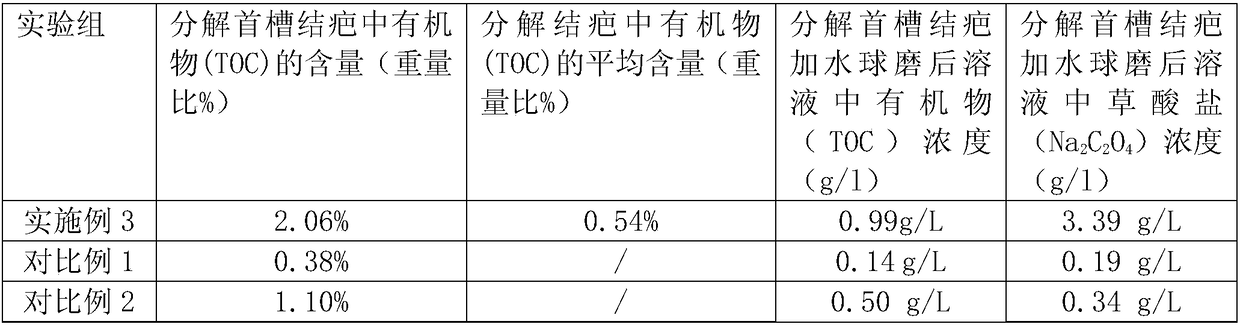

Method and system for eliminating organic matters in aluminium oxide production process

ActiveCN109052441ANo wasteAvoid accumulationAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium hydroxideDecomposition

The invention provides a method for eliminating organic matters in an aluminium oxide production process. The method comprises the following steps that a crystallization auxiliary is added into undecomposed aluminium hydroxide refined liquor; the undecomposed aluminium hydroxide refined liquor containing the crystallization auxiliary and decomposed mother liquor are subjected to heat exchange; theundecomposed aluminium hydroxide refined liquor subjected to heat exchange and aluminum hydroxide crystal seeds subjected to decomposed seed filtering are mixed and stirred in a mixing tank to obtainmixed liquid, wherein the stirring speed is 70-90 r / min; the stirred mixed liquid enters a decomposition tank for decomposition; washing and causticizing treatment is conducted on scabs attached to the decomposition tank. According to the method, an organic matter crystal precipitation process is adjusted to be conducted in a seed decomposition working section, a better reaction environment is provided for organic matter precipitation, then the mixing tank is added between a heat exchanger and the decomposition tank, through the crystallization auxiliary and action of stirring, crystal seed particles which are evener and uniform in size are generated, increase of the particle size of aluminium hydroxide particles is promoted, organic matter form and critical concentration change is caused, large organic matter druses are induced, and the purpose of improving the organic matter precipitation amount is achieved.

Owner:广西田东锦鑫化工有限公司

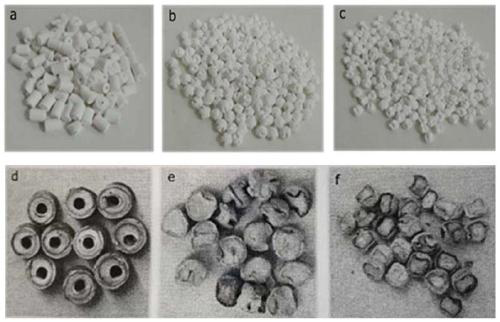

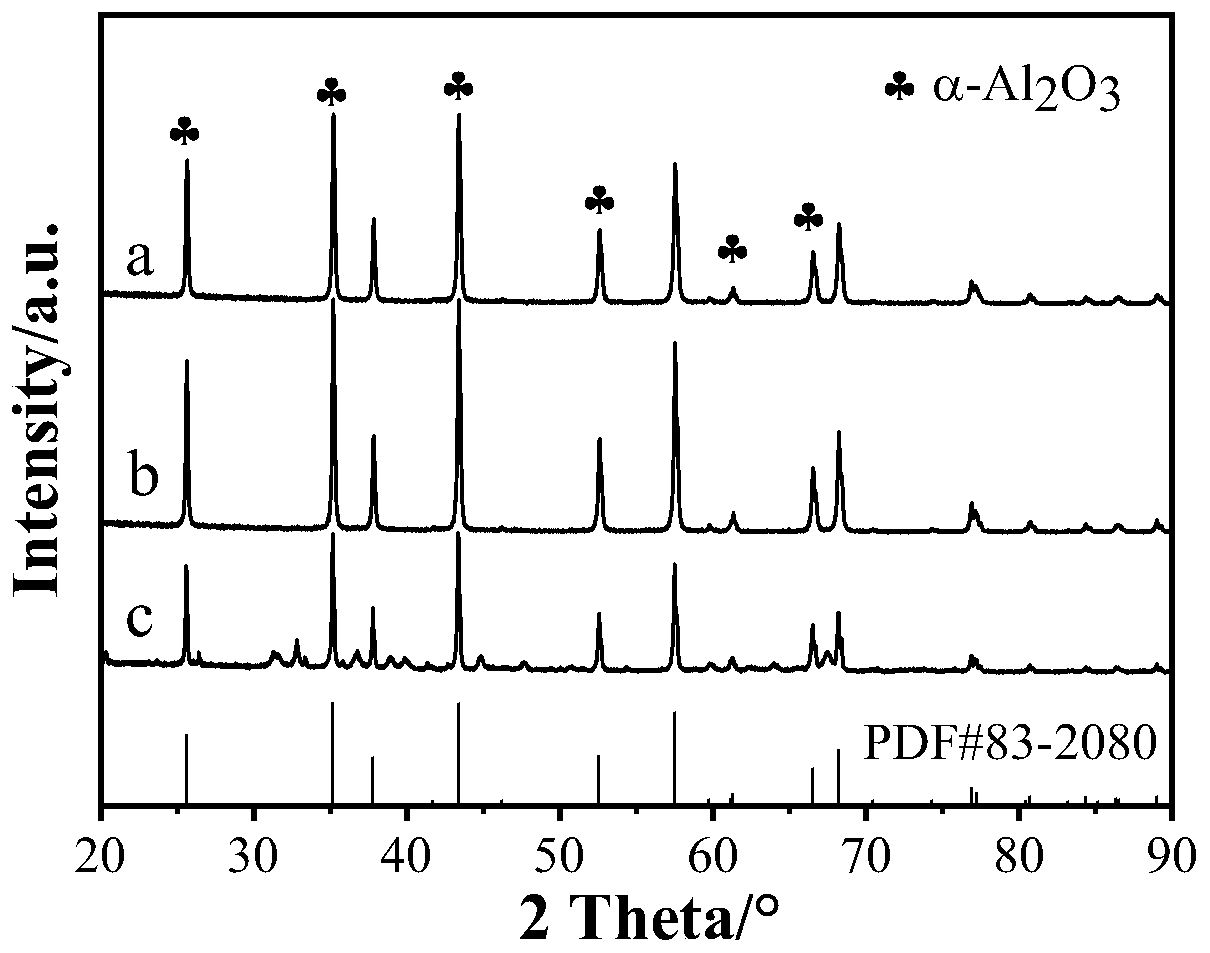

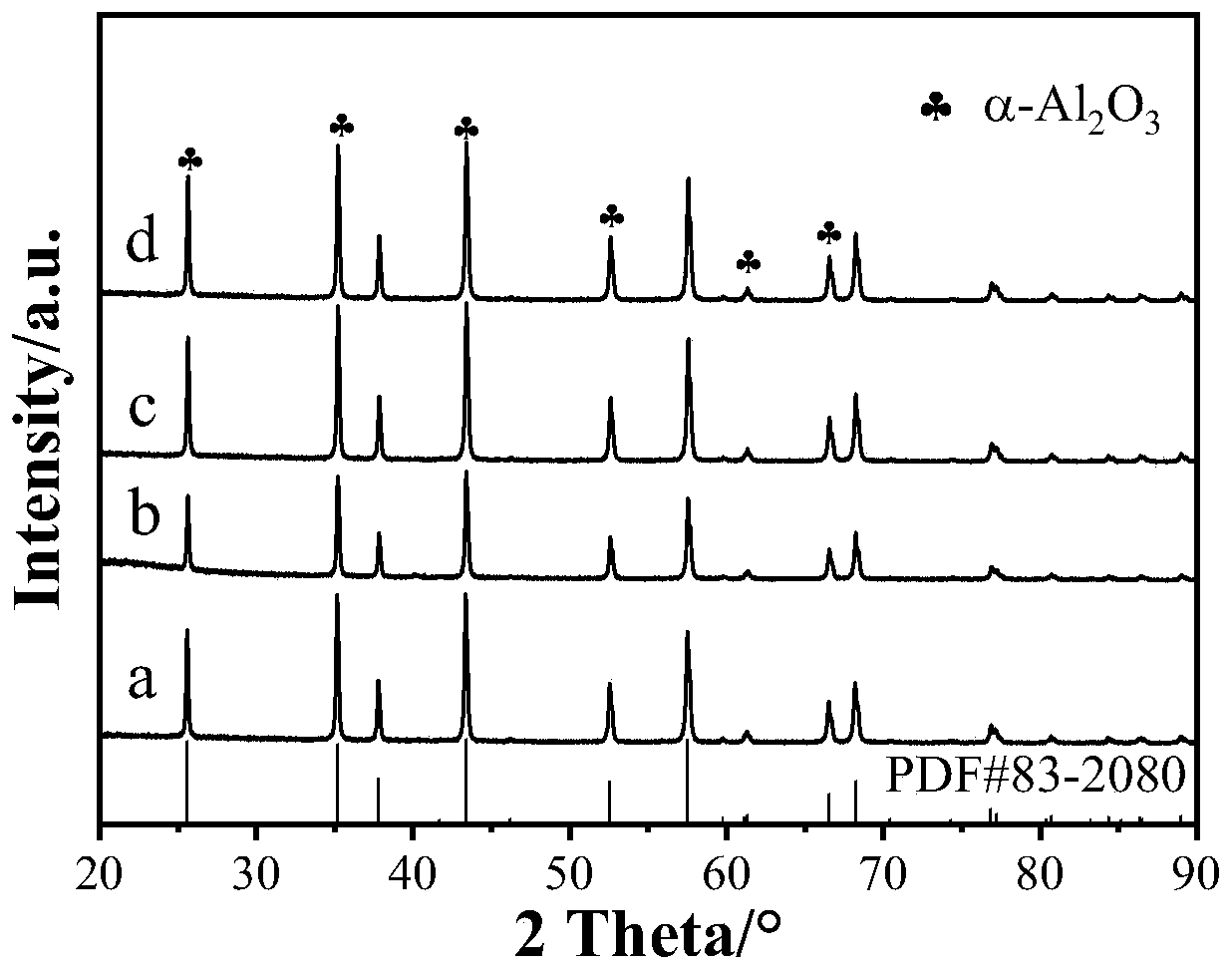

Catalyst for synthesizing diethyl oxalate by CO gas-phase coupling of ethyl nitrite and preparation method thereof

ActiveCN111495388AReduce loadInhibition of agglomerationCatalyst activation/preparationPreparation by carbon monoxide or formate reactionPtru catalystFixed bed

The invention relates to a catalyst for synthesizing diethyl oxalate by CO gas-phase coupling of ethyl nitrite and a preparation method thereof. The catalyst comprises a carrier, an active component palladium and a metal auxiliary agent iron, wherein the carrier is commercial hollow columnar [alpha]-Al2O3, the content of the active component palladium accounts for 0.1-1.0 wt% of the weight of thecarrier, and the content of the metal auxiliary agent iron accounts for 0.1-1.0 wt% of the weight of the carrier. According to the preparation method, a commercial hollow columnar carrier is adopted,and vegetable tannin and / or anhydrous dextrose and / or polyvinylpyrrolidone are / is added, so that palladium metal nanoparticles in the catalyst are smaller, the dispersity is higher, and the palladiumloading capacity is lower. The catalytic activity of the catalyst is basically improved by more than two times, the cost of the catalyst is reduced by more than four times, the prepared catalyst carrier is suitable for filling of a fixed bed with high space velocity by taking industrialization as a reference, and more precious experience is provided for industrialization of diethyl oxalate production.

Owner:TIANJIN UNIV

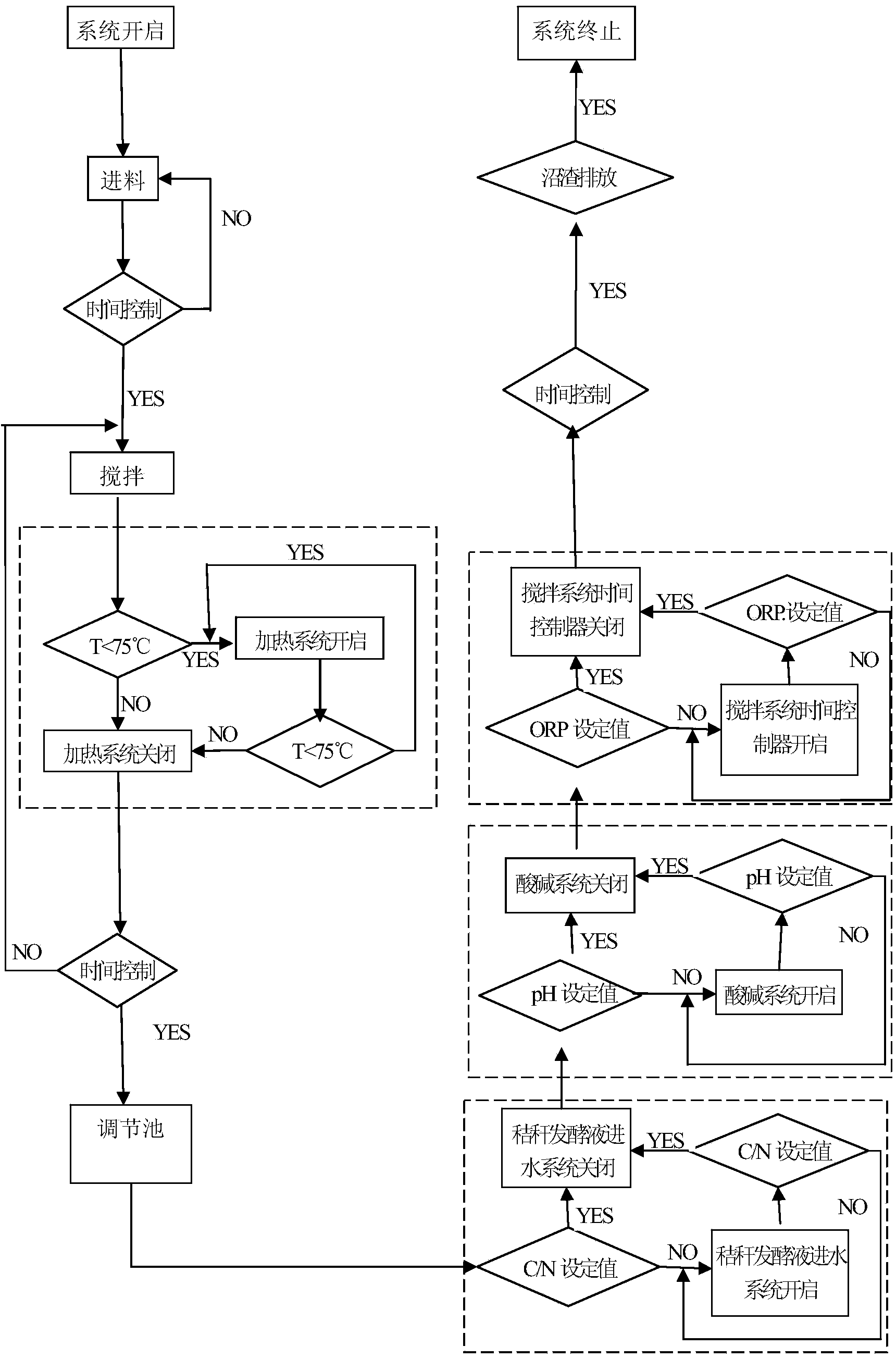

Treating device and treating method for streptomycin dregs

ActiveCN103865791AHarmlessImplement resourcesBioreactor/fermenter combinationsBiological substance pretreatmentsSequencing batch reactorWater quality

The invention belongs to the technical field of anaerobic biological treatment, and in particular relates to a treating device and a treating method for streptomycin dregs. The device comprises a streptomycin dreg storage reservoir, an alkali liquor tank, a pre-reaction reservoir, a regulating reservoir, a straw fermentation reservoir, an ASBR (anaerobic sequencing batch reactor), a biogas residue colleting tank, a PLC (programmable logic controller) auto-control system and an online water quality monitoring system. The method is automatically finished by using the computer PLC auto-control system and comprises the following steps: firstly injecting streptomycin dregs and alkali liquor in the pre-reaction reservoir, heating to pre-heat the alkali, placing the pre-treated mixed liquor in the regulating reservoir, regulating the C / N ratio and pH by using the straw fermenting liquor, placing in the ASBR, recycling the biogas produced after anaerobic digestion as the cleaning fuel, discharging dregs which are identified as harmless into a biogas residue colleting tank as the raw material for manufacturing an organic fertilizer. The device and method provided by the invention are capable of improving the utilization rate of the organic matter of the streptomycin dregs, and realizing the harmless and reutilization of the streptomycin dregs.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-humic-acid multi-solid-waste coupling soft soil curing agent in cold region

The invention discloses a high-humic-acid multi-solid-waste coupling soft soil curing agent in a cold region. The curing agent is prepared from the following raw materials in parts by weight: 16-18 parts of Portland cement, 20-22 parts of quicklime powder, 35-38 parts of waste glass powder, 8-10 parts of fly ash, 6-10 parts of an exciting agent, 2-3 parts of an ion replacement agent, 0.9-2 parts of a humic acid degradation agent, 1-2 parts of a water reducing agent, 0.54-1.1 parts of a grinding aid, 0.9-1.9 parts of an early strength agent and 0.5-1 part of an air entraining agent. The curing agent provided by the invention mainly solves the adverse effect of humic acid in high-humic-acid clay soil in northern China on soil curing, and can effectively improve the strength, durability and the like of the cured soil. The curing agent utilizes solid waste to replace part of Portland cement, so that waste utilization is realized.

Owner:吉林建筑科技学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com