Method for efficiently producing marsh gas and device thereof

A biogas and high-efficiency technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of high hydrogen sulfide concentration, difficult biogas sewage discharge, low biogas pressure, etc., to avoid floating. The effect of slag crusting, shortening fermentation time and convenient sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

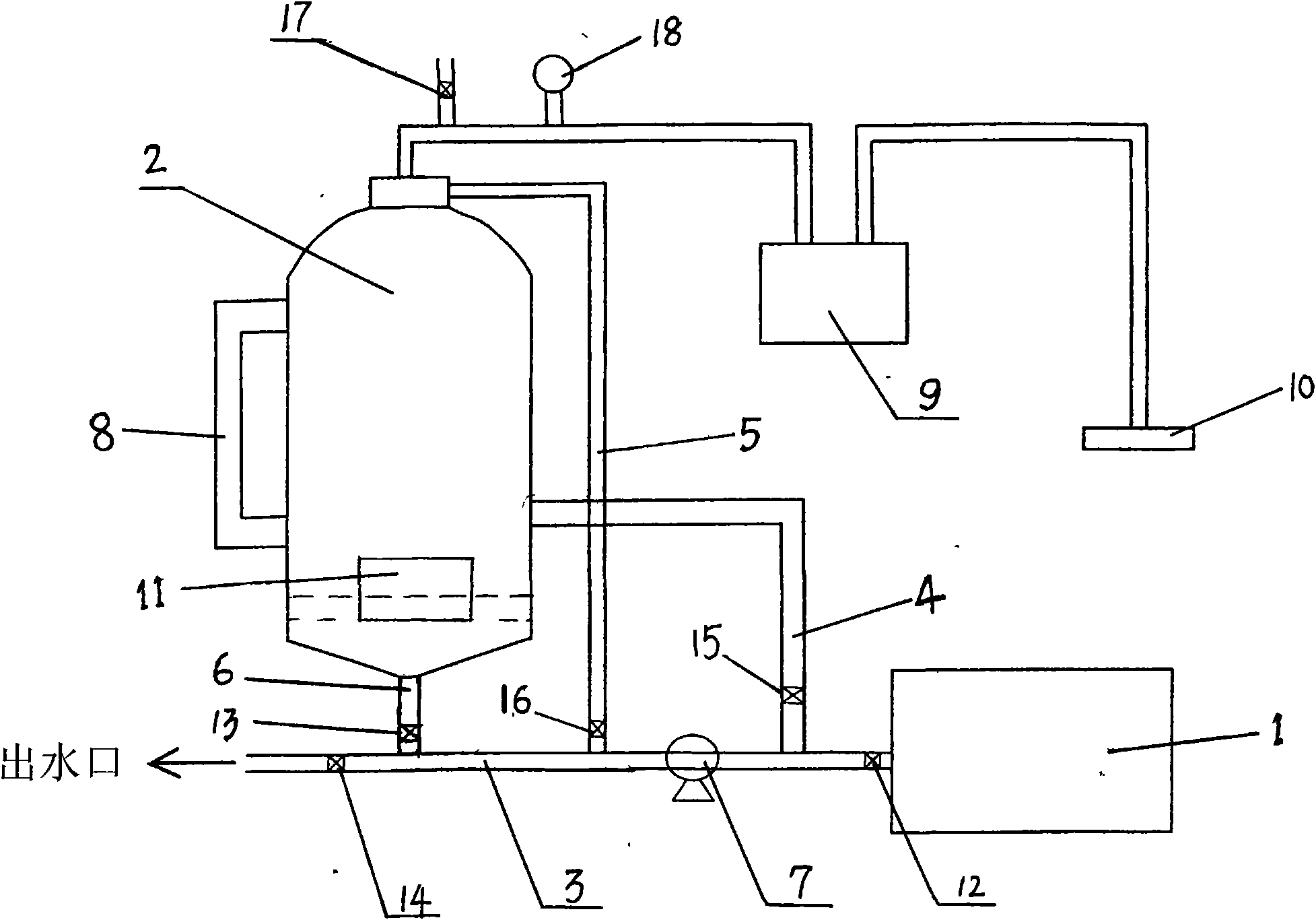

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the volume of the fermentation tank is 0.5 cubic meters, the anaerobic reactor is 3.3 cubic meters, and the temperature is 15 to 50 degrees Celsius. Put into domestic waste, cattle, horses, pigs, human urine and stool, and the minimum biogas pressure is 3.3 * 4 = 13kpa, the highest is 3.3×20=66kPa.

Embodiment 2

[0035] Embodiment 2: The fermentation tank is 0.036 cubic meters, and the reactor is a stainless steel plate water tower with a diameter of 0.8 meters, a height of 1.3 meters, and a volume of 0.65 cubic meters. After 18 days of fermentation, the biogas can be used, and the volumetric gas production rate is 2 times, which is 16kpa during the day , 12kpa at night, 28kpa pressure gauge in 24 hours, with a volume of 0.65 cubic meters. 1-16kpa biogas pressure can be produced every day.

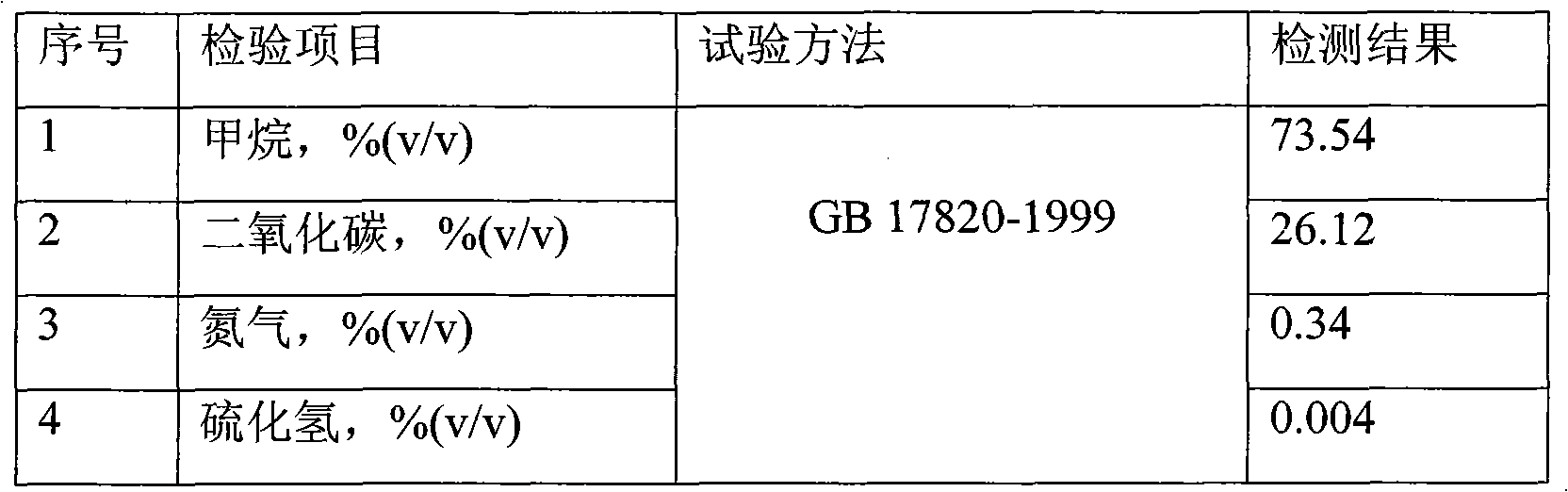

[0036] Send the biogas generated above to Guangxi Civil Fuel and Gas Products Quality Supervision and Inspection Station for inspection, and produce the inspection report (No. H2009-070) showing the main biogas indicators as follows:

[0037]

[0038] Generally, the content of biogas methane is 55% to 70%, the content of carbon dioxide is 28% to 44%, and the average content of hydrogen sulfide is 0.034%, while the methane concentration (73.54%) produced by the present invention is higher than it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com