Aspergillus oryzae type novel technique for producing fermented soya bean

A production process and technology of Aspergillus oryzae, applied in the field of production technology of Aspergillus oryzae type tempeh, can solve the problems of long cycle, poor molding degree and poor gloss, and achieve the effects of simple equipment, good gloss and shortened fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

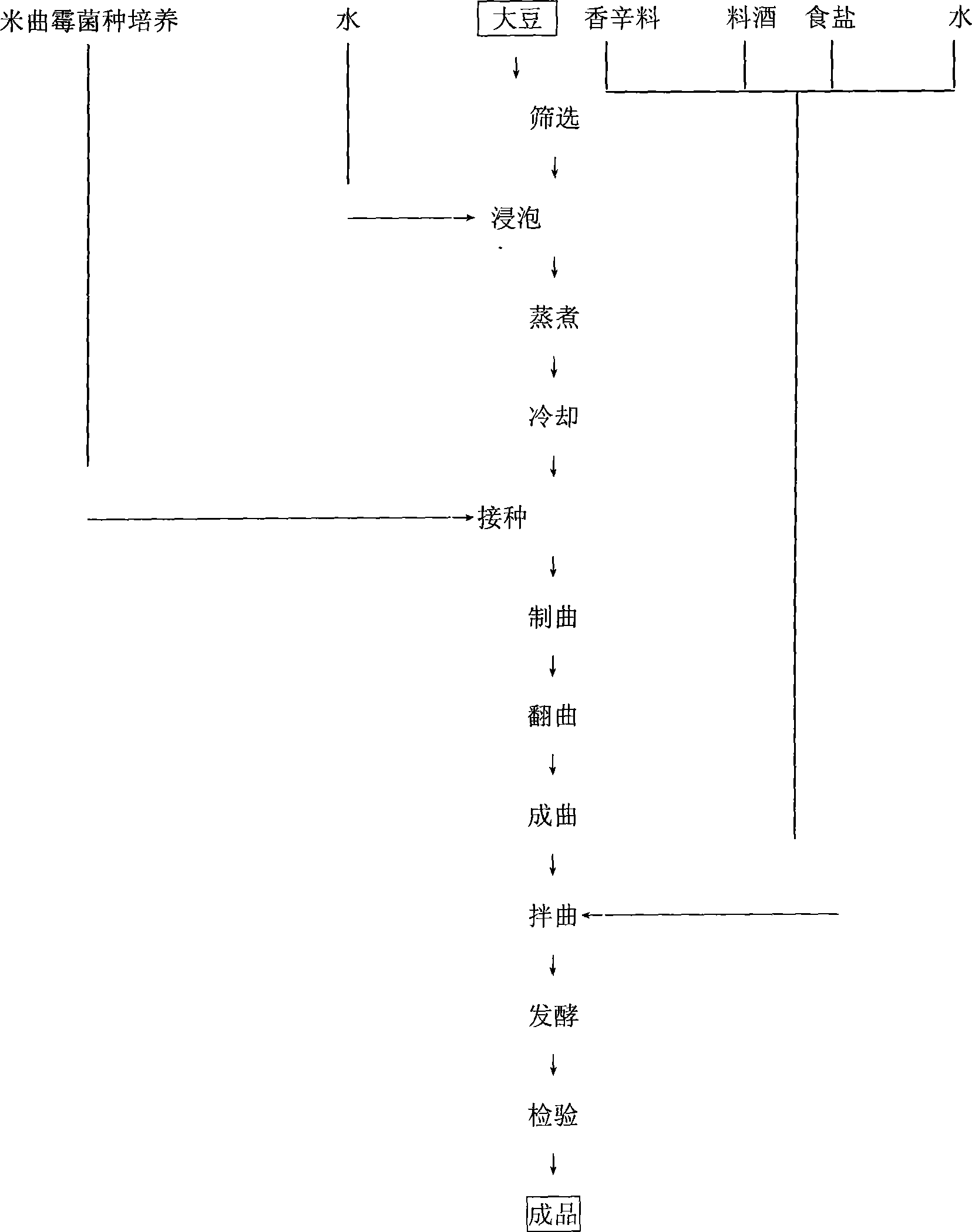

[0038] Embodiment 1 Production process of the present invention produces fermented soya bean

[0039] a. Raw material processing: Soak soybeans until about 50% of the beans have no wrinkled skin, about 50% of the beans have wrinkled skin, the water content is 42% ± 2%, steam for 3.5 hours under normal pressure, stew in a steamer for 45 minutes, and steam until it has a bean aroma , The finger can be pinched into a cake shape without a hard core, and the clinker moisture content is 46% ± 2%.

[0040] b. Koji making: the clinker is cooled to 40°C to 42°C, added 0.25% of 3.042 Aspergillus oryzae third-grade species according to the weight of soybean dry raw materials, mixed well and put into the pool, the thickness of the material layer is 25cm to 28cm, and the room temperature is kept at 28 to 32 ℃, product temperature 30 ℃ ~ 32 ℃, 16 hours ± 1 hour or so beans agglomerated, the surface is covered with white hyphae, with the aroma of koji and cooked soybeans, and the koji can be...

Embodiment 2

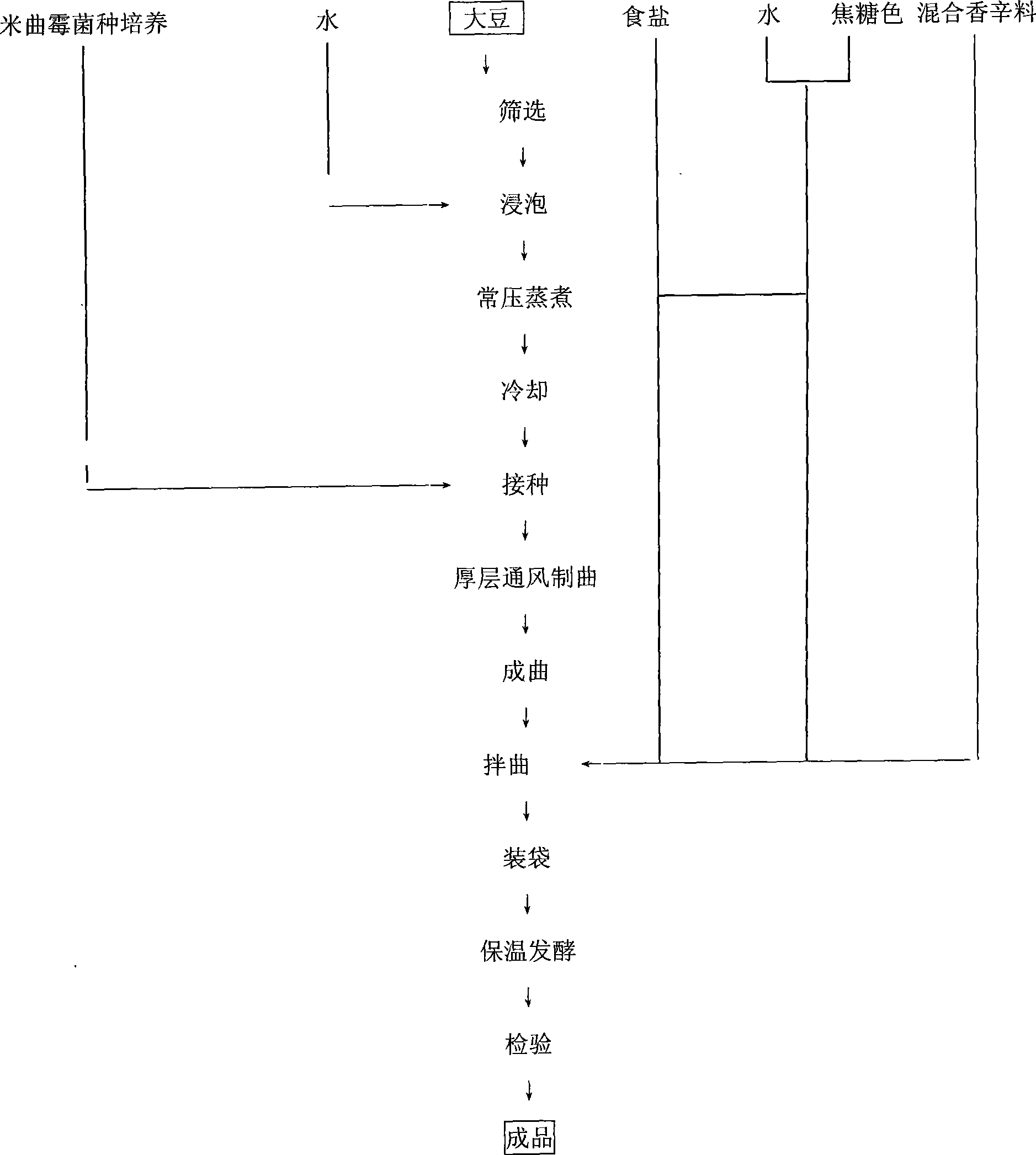

[0046] Embodiment 2 Production process of the present invention produces fermented soya bean

[0047] a. Raw material processing: Soak soybeans until about 53% of the beans have no wrinkled skin, about 47% of the beans have wrinkled skin, and the water content is 44% ± 2%. Steam for 4.5 hours under normal pressure, stew in a steamer for 20 minutes, and steam until it has a bean aroma , The finger can be pinched into a cake shape without a hard core, and the clinker moisture content is 46% ± 2%.

[0048]b. Koji making: the clinker is cooled to 42°C to 44°C, added 0.28% of 3.042 Aspergillus oryzae third-grade species according to the weight of soybean dry raw materials, mixed well and put into the pool, the thickness of the material layer is 28cm to 30cm, and the room temperature is kept at 30 to 35 ℃, product temperature 30 ℃ ~ 35 ℃, 18 hours ± 1 hour or so beans agglomerated, the surface is covered with white hyphae, with the aroma of koji and cooked soybeans, the koji can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com