Patents

Literature

111 results about "Wrinkled skin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antioxidant composition for topical/transdermal prevention and treatment of wrinkles

InactiveUS6180133B1Significant free radical protectionHead bandagesCosmetic preparationsWrinkle skinVitamin C

An anti-wrinkle skin treating composition comprises a pressure sensitive matrix patch having dissolved in the adhesive a mixture of antioxidants in the form of a Vitamins C ester and Vitamin E. Also preferably dissolved in the adhesive are glycerine and a polydiorganosiloxane adhesion-adjusting agent. Optionally dissolved in the adhesive is also one or more members selected from the group consisting of moisturizing agents, skin collagen synthesis promoting agents and exfoliating agents. When applied to a wrinkled skin area the composition acts to diminish fine wrinkles and improves the overall thickness, elasticity, firmness and smoothness of the skin. The modified adhesive properties of the patch are sufficient to maintain the patch in place on the skin for the recommended treatment period while allowing the patch to be readily removed without causing skin irritation or leaving adhesive residue on the skin.

Owner:ACTAVIS HOLDCO US INC

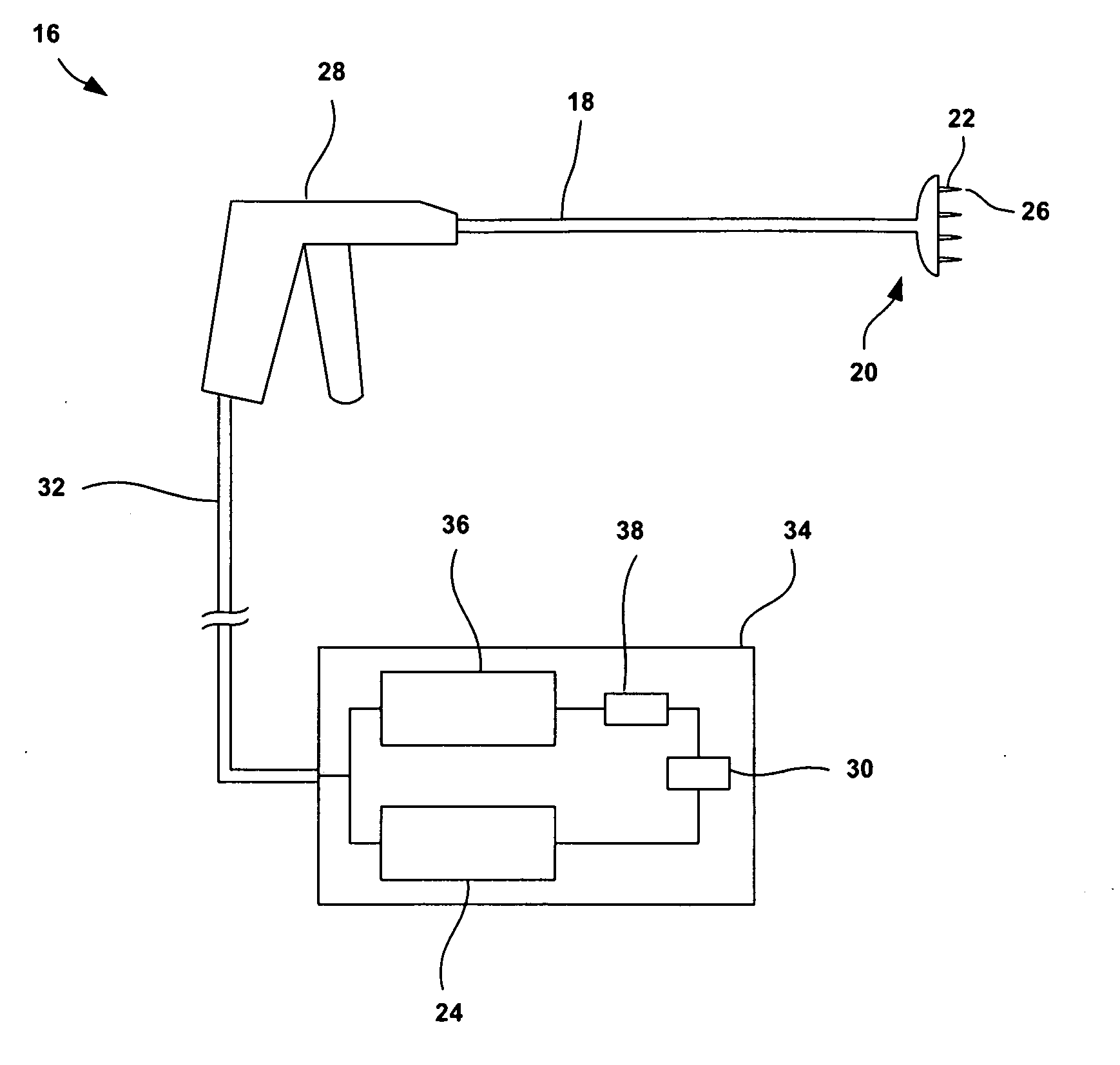

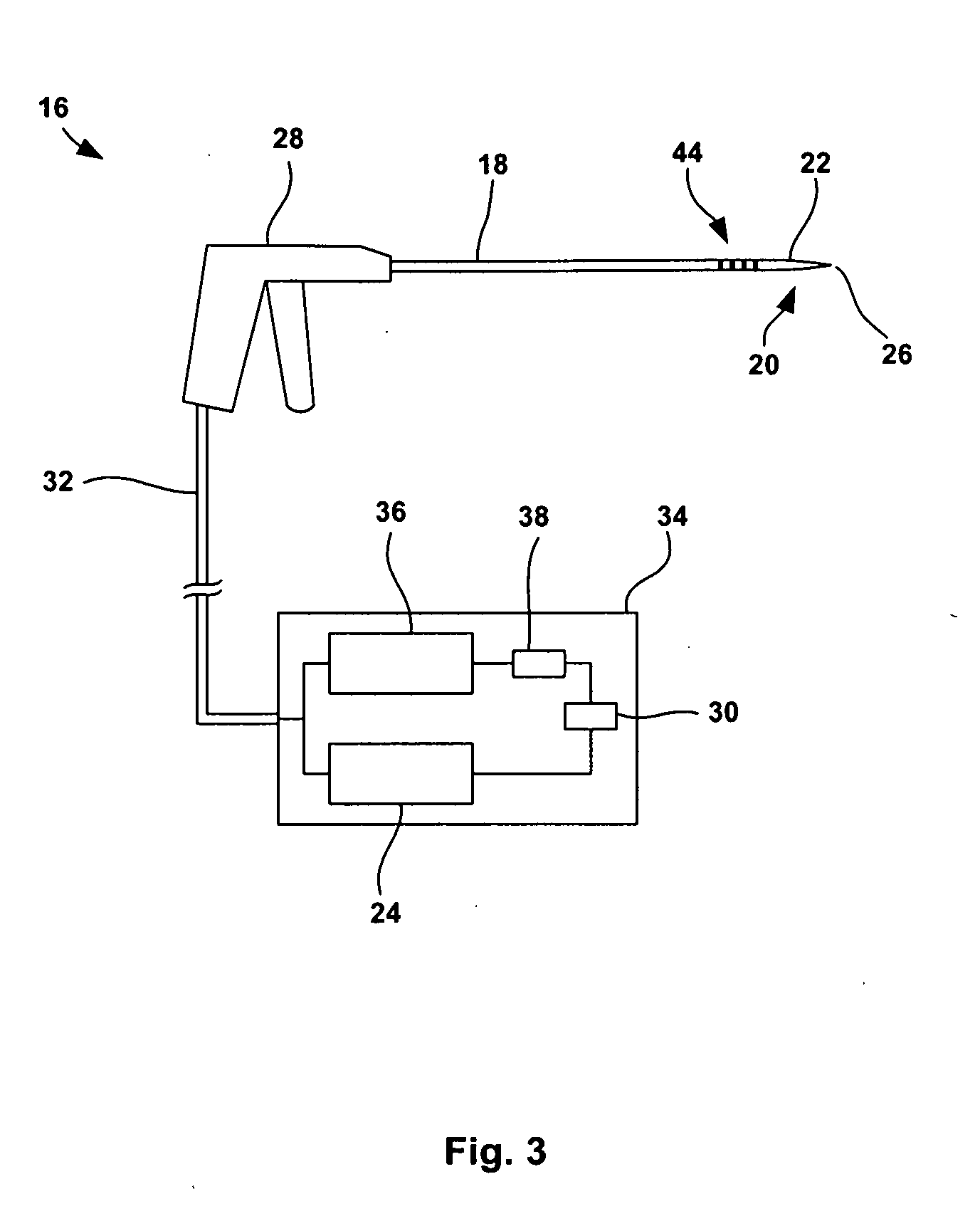

Device and methods for treatment of tissue

InactiveUS20090124958A1Reduce appearance problemsIncrease stiffnessElectrotherapySurgical needlesWrinkly skinMedicine

A device and methods for treating tissue via laser energy to induce tissue reduction and / or necrosis are described herein. Laser energy may be applied to a tissue region via an optical fiber advanced through a lumen of at least one needle. Fluid may also be infused or injected into the tissue region through at least one needle. Tissue reduction and / or necrosis of a target tissue region in turn reduces the appearance of droopy, baggy and / or wrinkled skin.

Owner:LI KASEY K +1

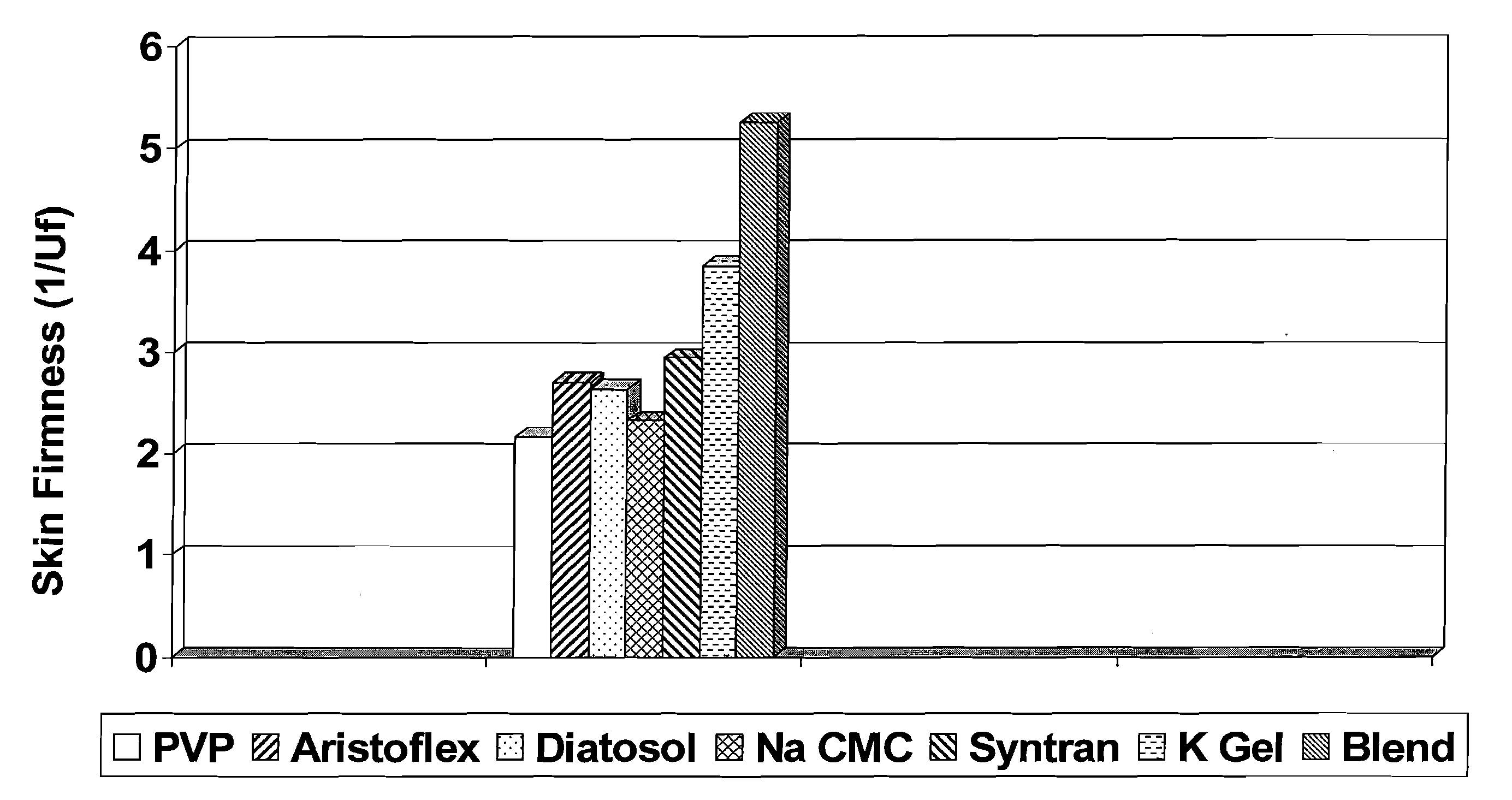

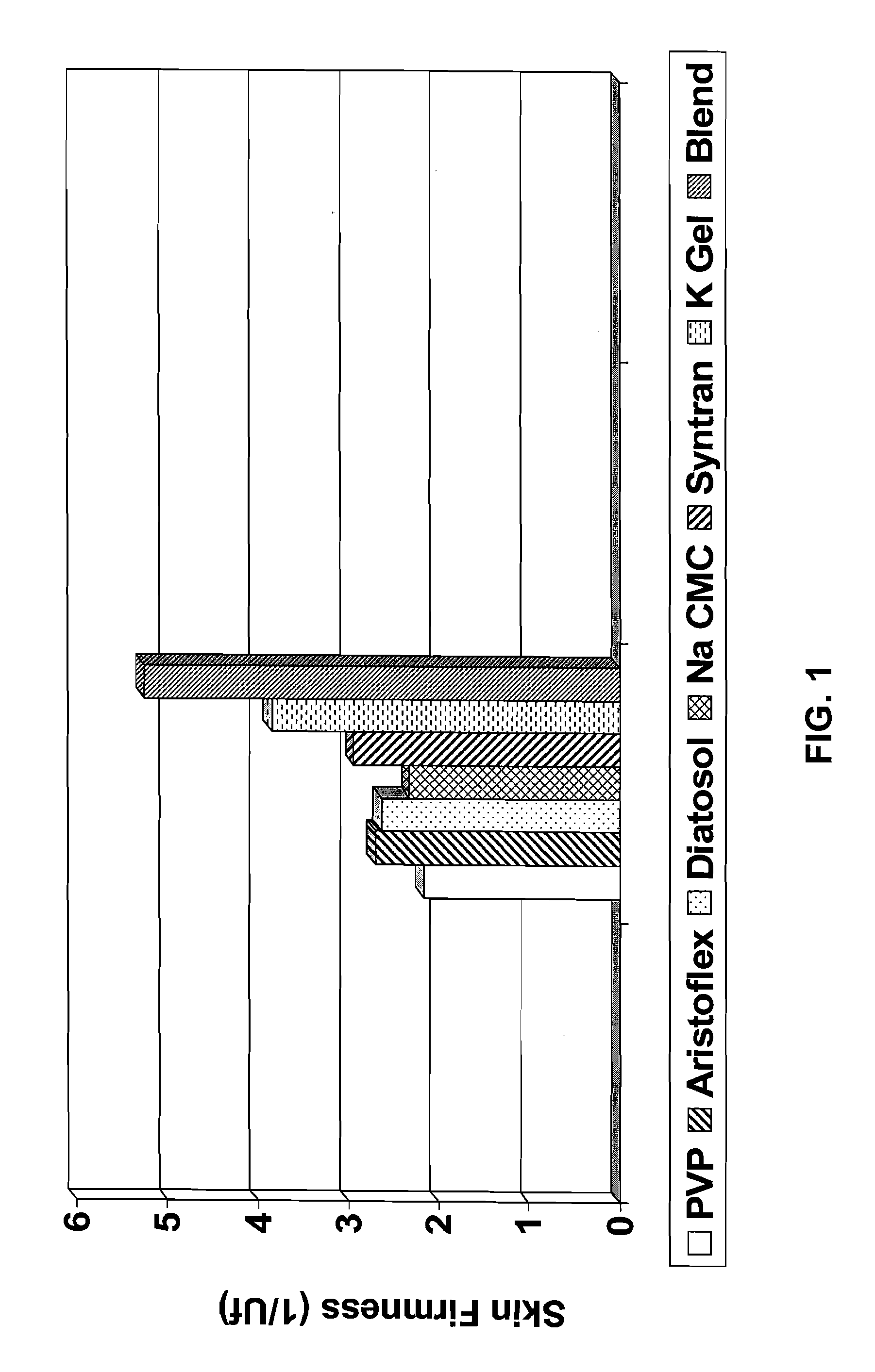

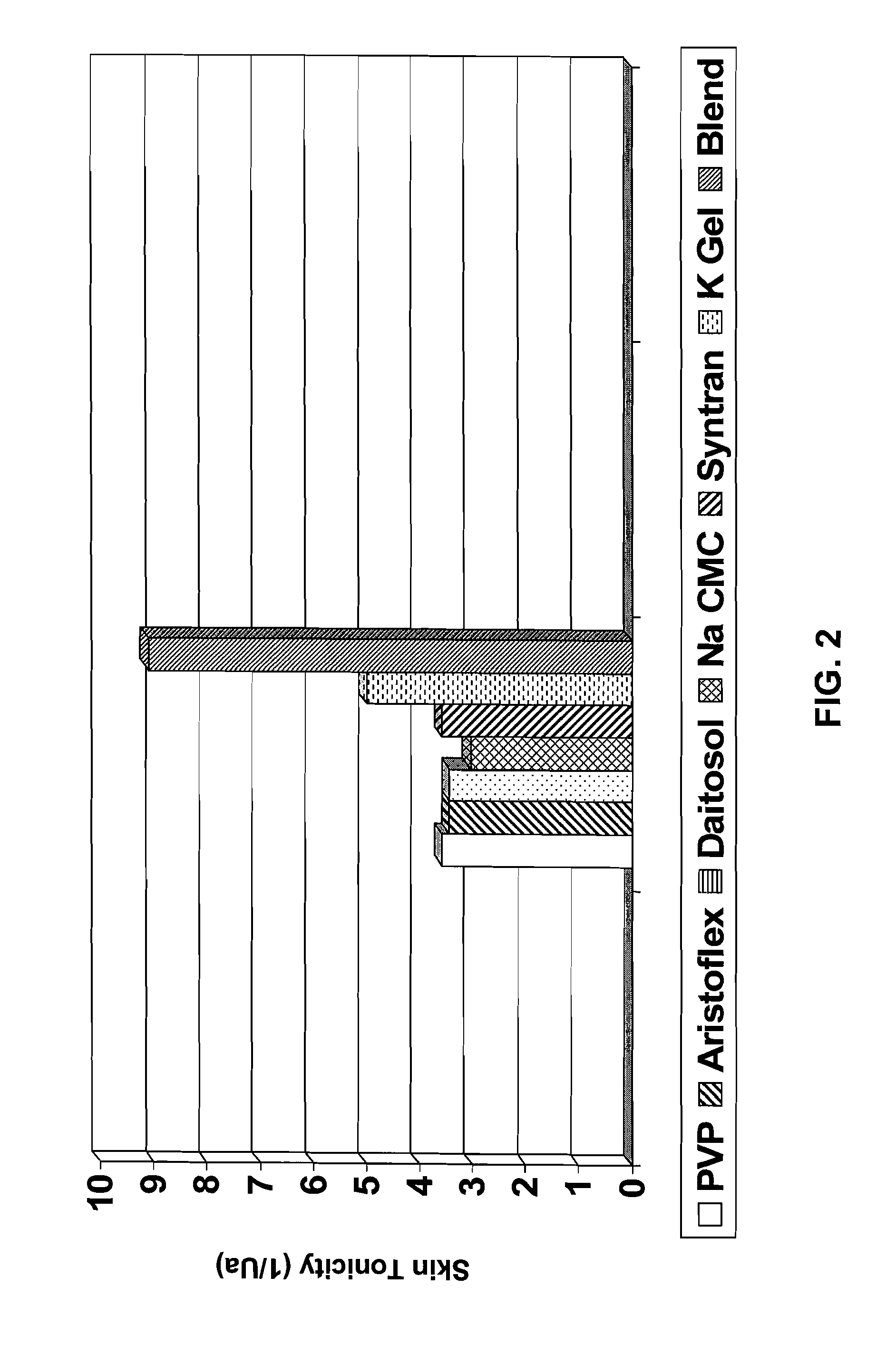

Cosmetic composition for skin tightening

InactiveUS20080233075A1Improve skin firmnessCosmetic preparationsToilet preparationsWrinkle skinBiopolymer

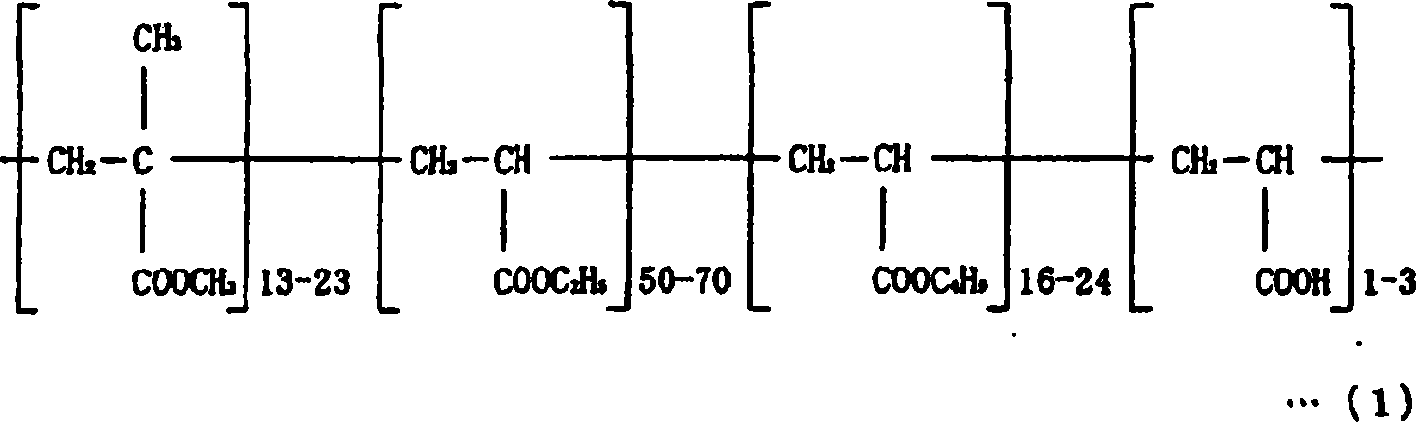

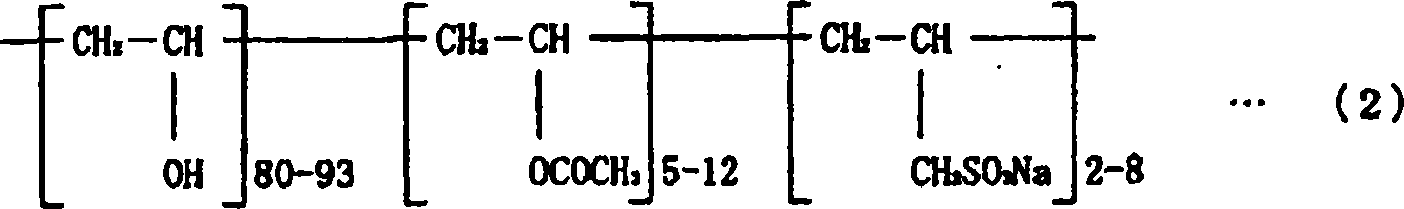

The present invention provides a topical composition that contains a water-soluble film-forming polymer, a bimodal copolymer comprising a first polymeric component with anionic functional groups and a second polymeric component with cationic functional groups, and one or more biological polymers that are derived from a source selected from the group consisting of animals, plants, algae, fungi, and bacteria or are biotechnologically synthesized. The first and second polymeric components of the bimodal copolymer form an interpenetrating polymeric network that interacts with the water-soluble film-forming polymer and the biological polymers to form a polymeric film with superior skin-firming and skin-toning effects. Such a topical composition can be applied to saggy or wrinkled skin for enhancing the appearance of the skin.

Owner:ELC MANAGEMENT LLC

Anti-wrinkle cosmetic composition

ActiveUS20090136595A1Improving dermal fibroblast regulationEasy to superviseHeavy metal active ingredientsCosmetic preparationsWrinkle skinAdditive ingredient

The present invention relates to a composition for treating skin comprising an acylated short chain bioactive peptide and fulvic acid, and optionally colloidal gold. The invention further relates to a method for topically administering the composition in an amount therapeutically effective to reduce wrinkles by building the dermal fibroblast matrix. The invention further relates to a method of treating wrinkled skin by topically administering the composition to an individual in need of such treatment.

Owner:GRANT INDS

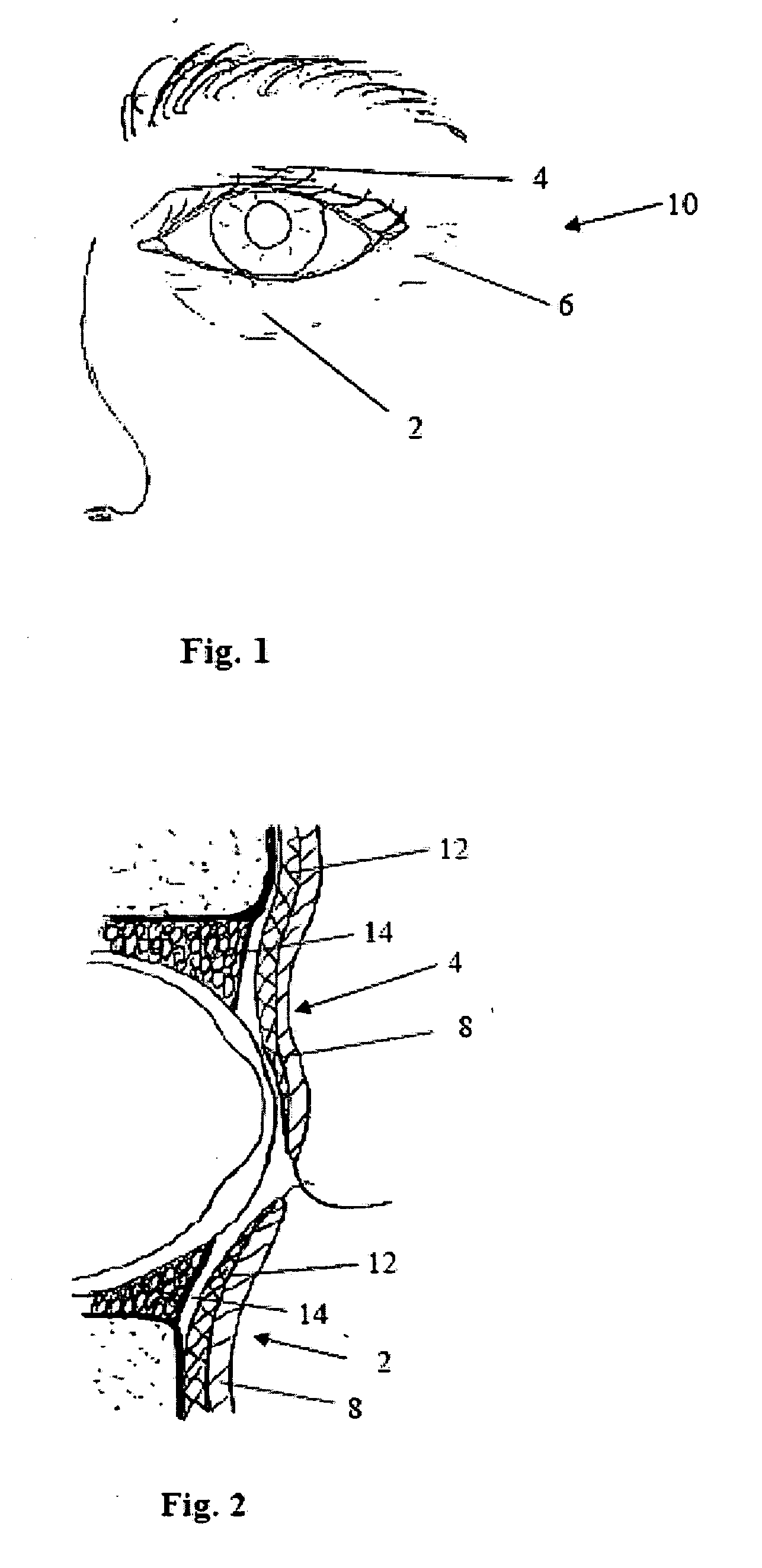

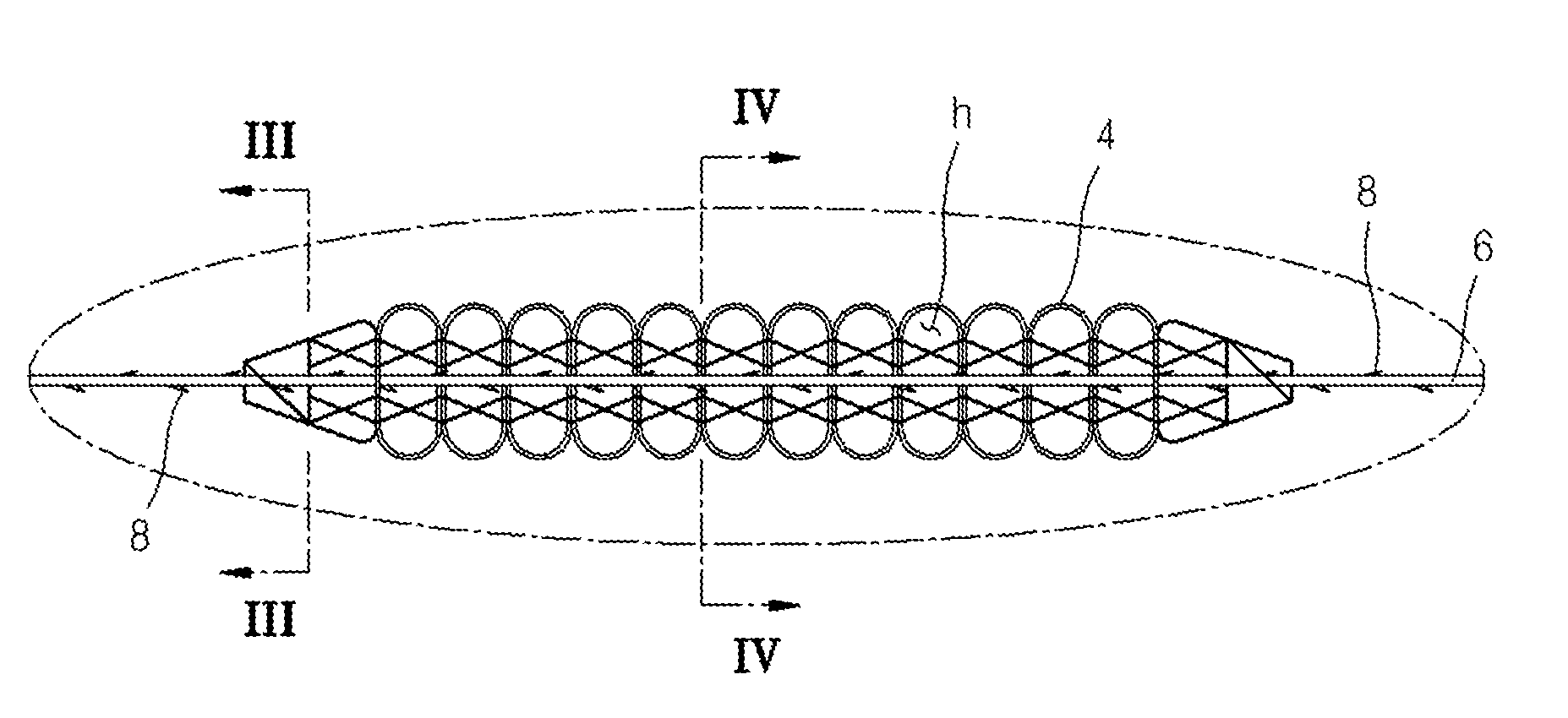

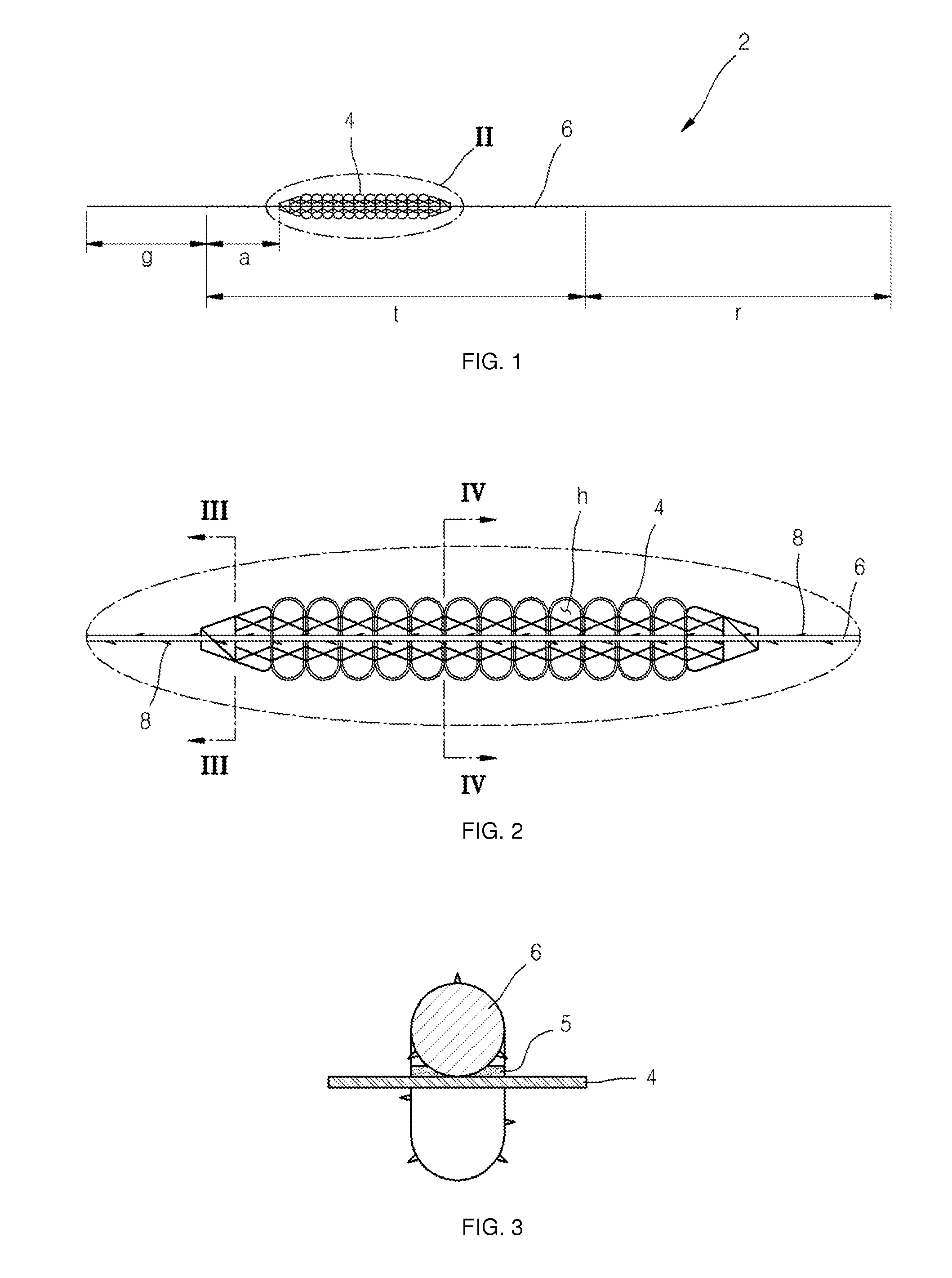

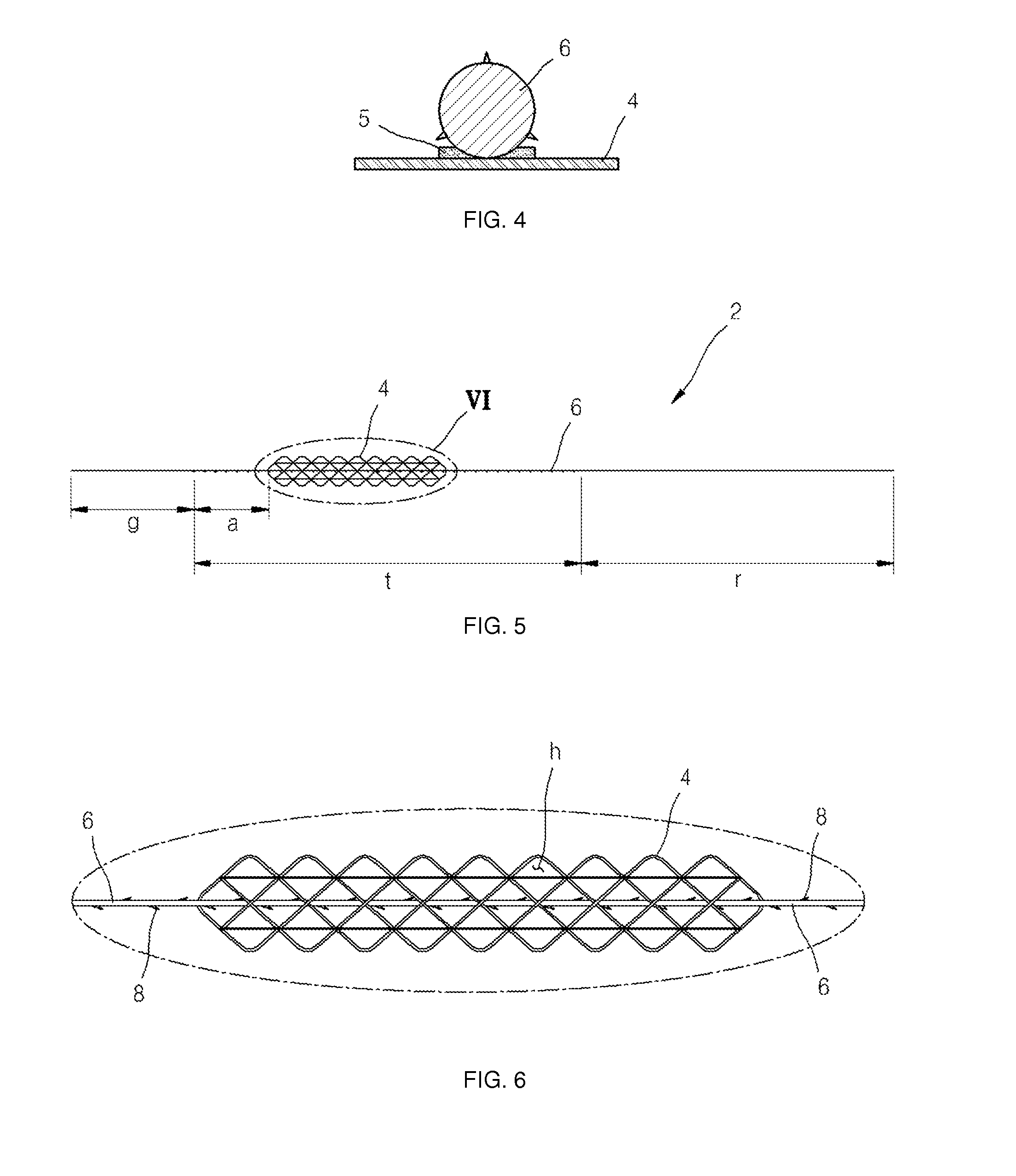

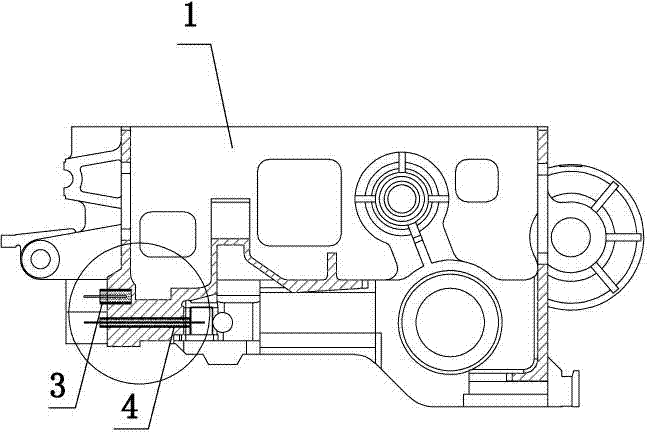

Graft for tissue lifting

ActiveUS20140228971A1Improve adhesionEasy to disassembleSuture equipmentsSkin implantsWrinkle skinDistal portion

Provided is an graft for a tissue lifting that is inserted between sagged or wrinkled skin and subcutaneous muscle to enable pulling and smoothing tissue, wherein the graft for tissue lifting can be inserted between skin and subcutaneous muscle, includes the bioimplantable thread having a distal portion where pulling is required and a proximal portion where the bioimplantable thread is pulled, and the mesh member that is fixedly coupled to the distal portion of the bioimplantable thread and has numerous pores wherein bodily tissues grow and fill the pores.

Owner:KIM JONG WOO

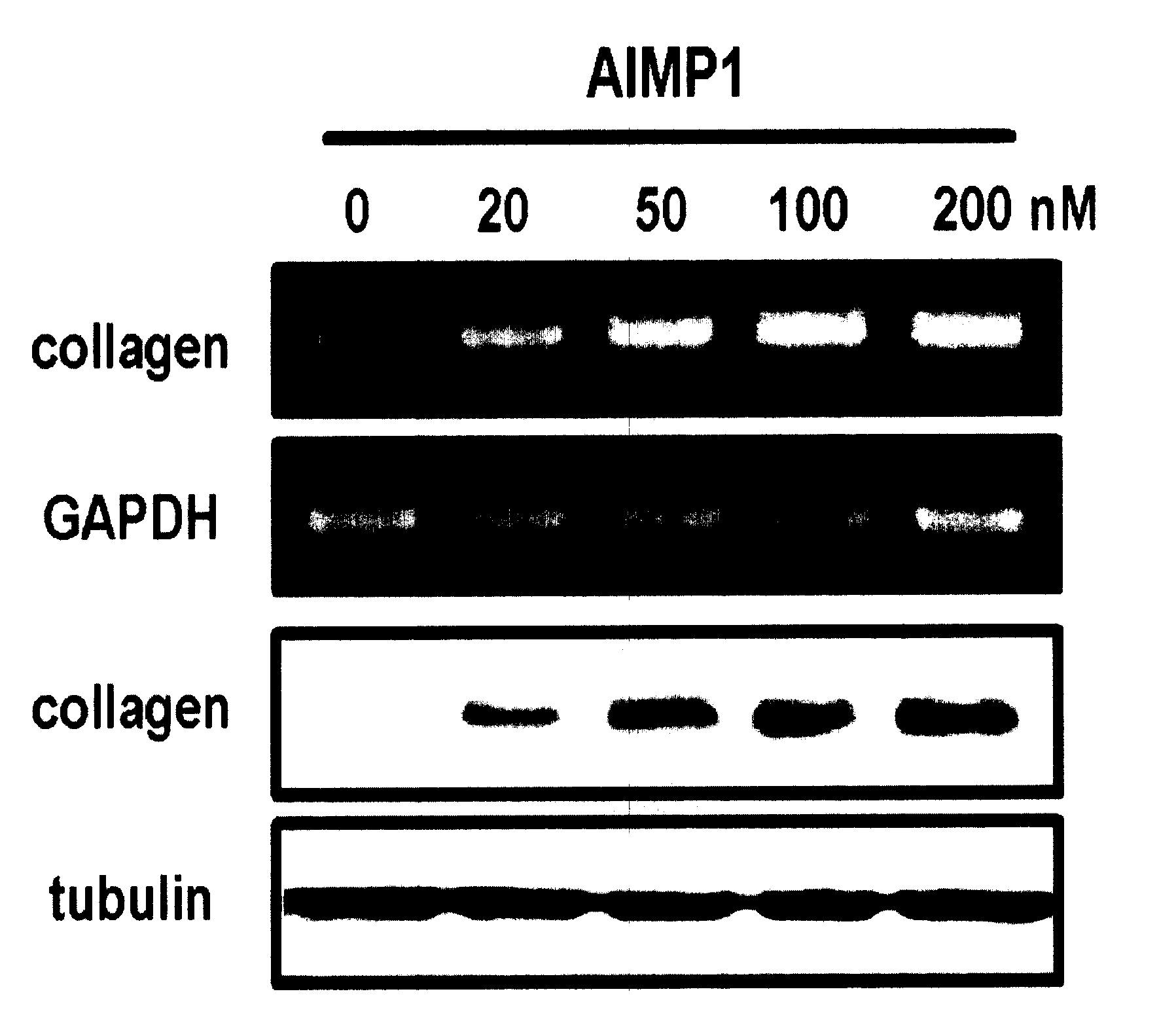

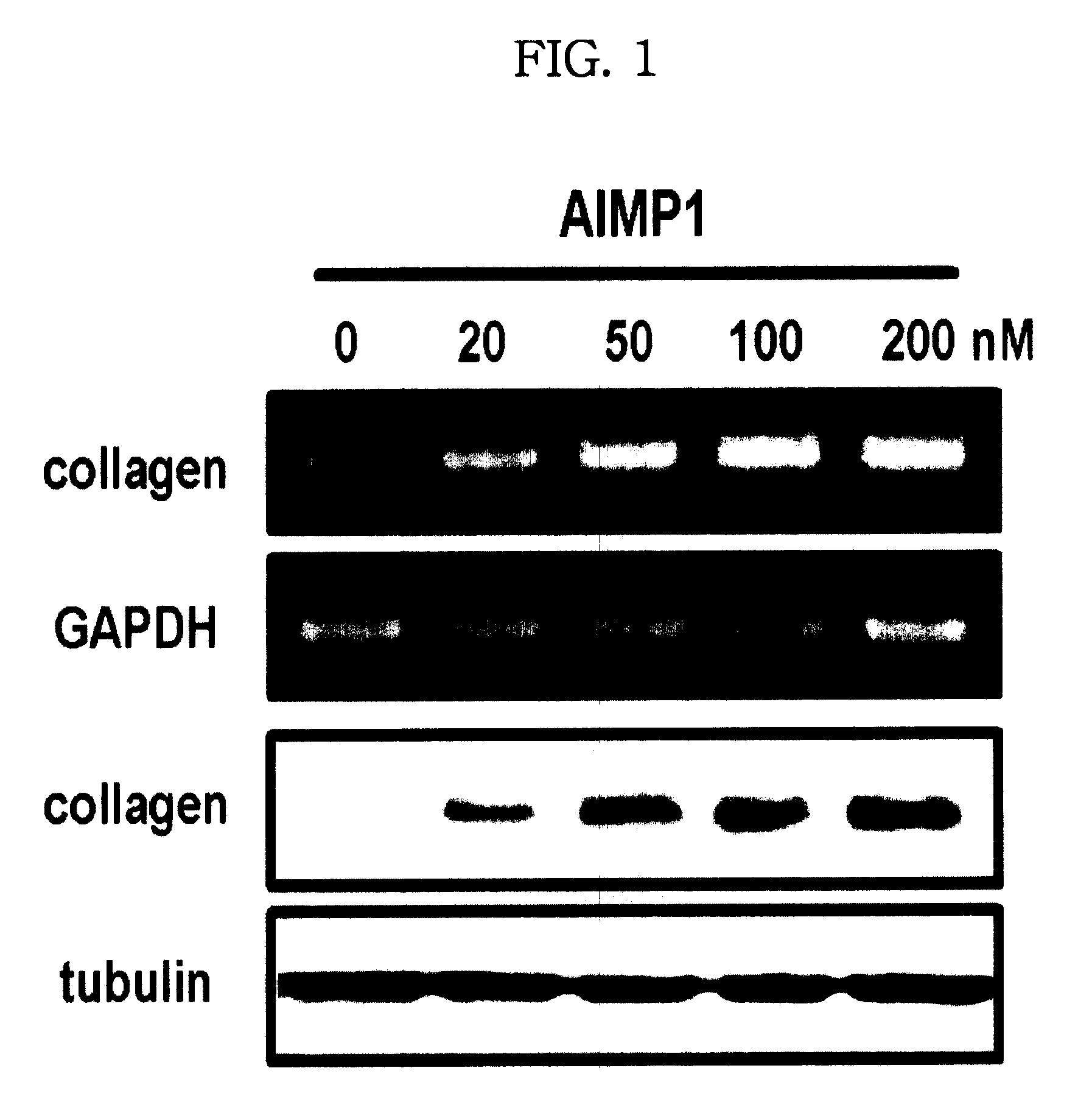

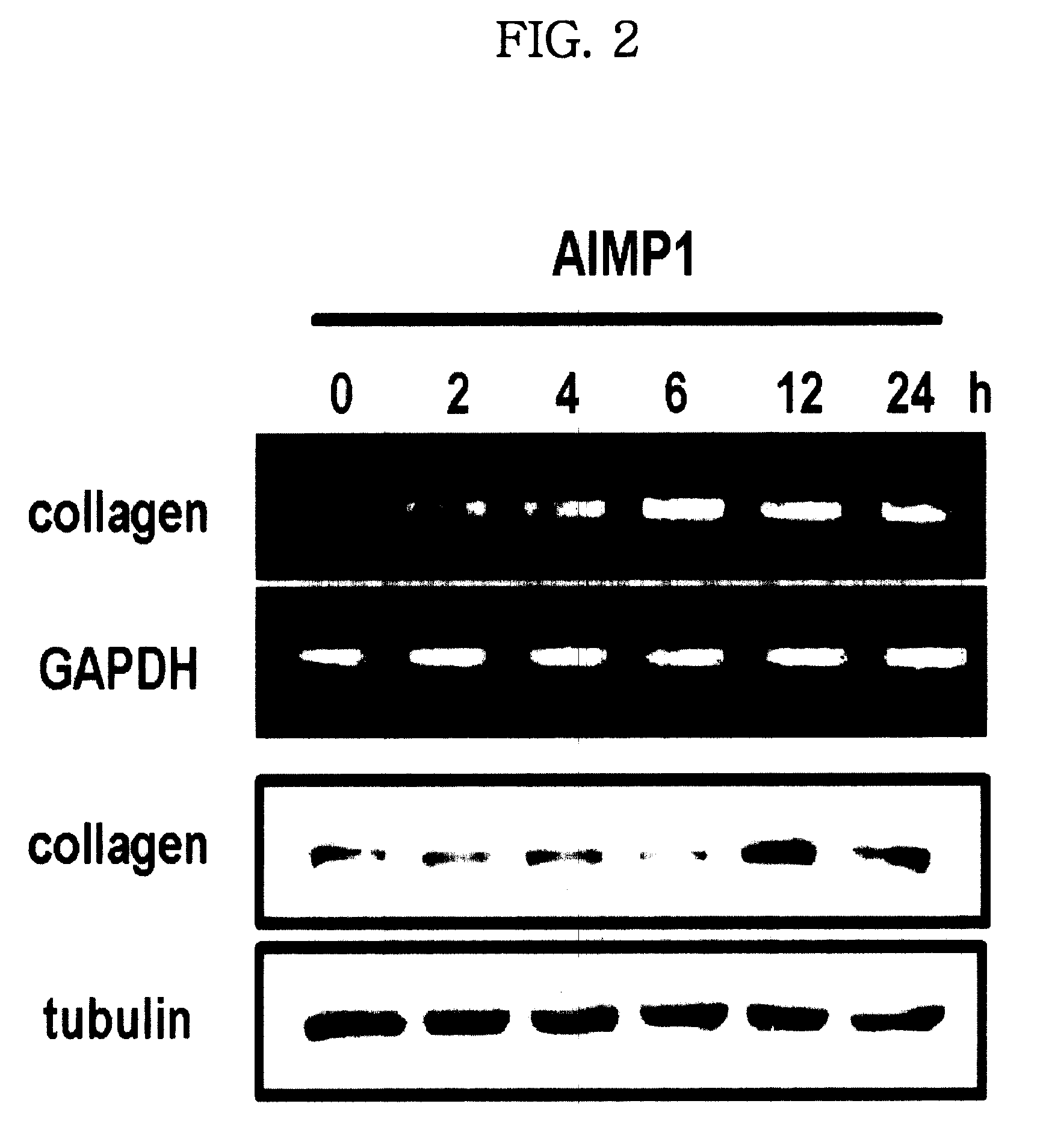

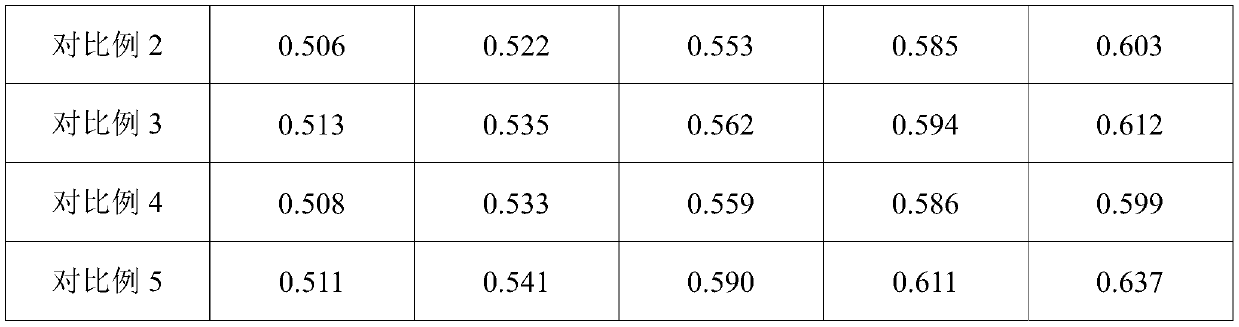

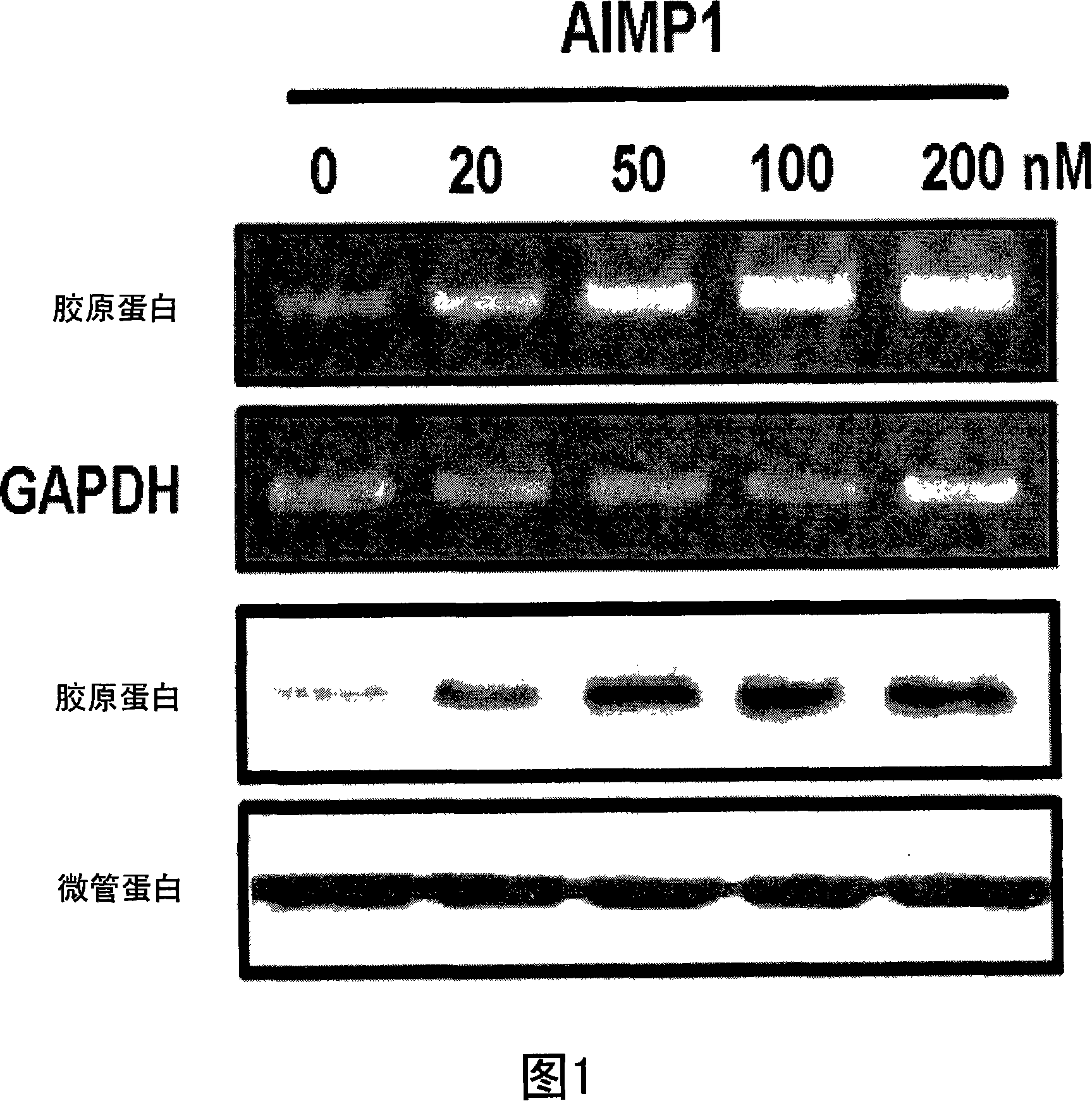

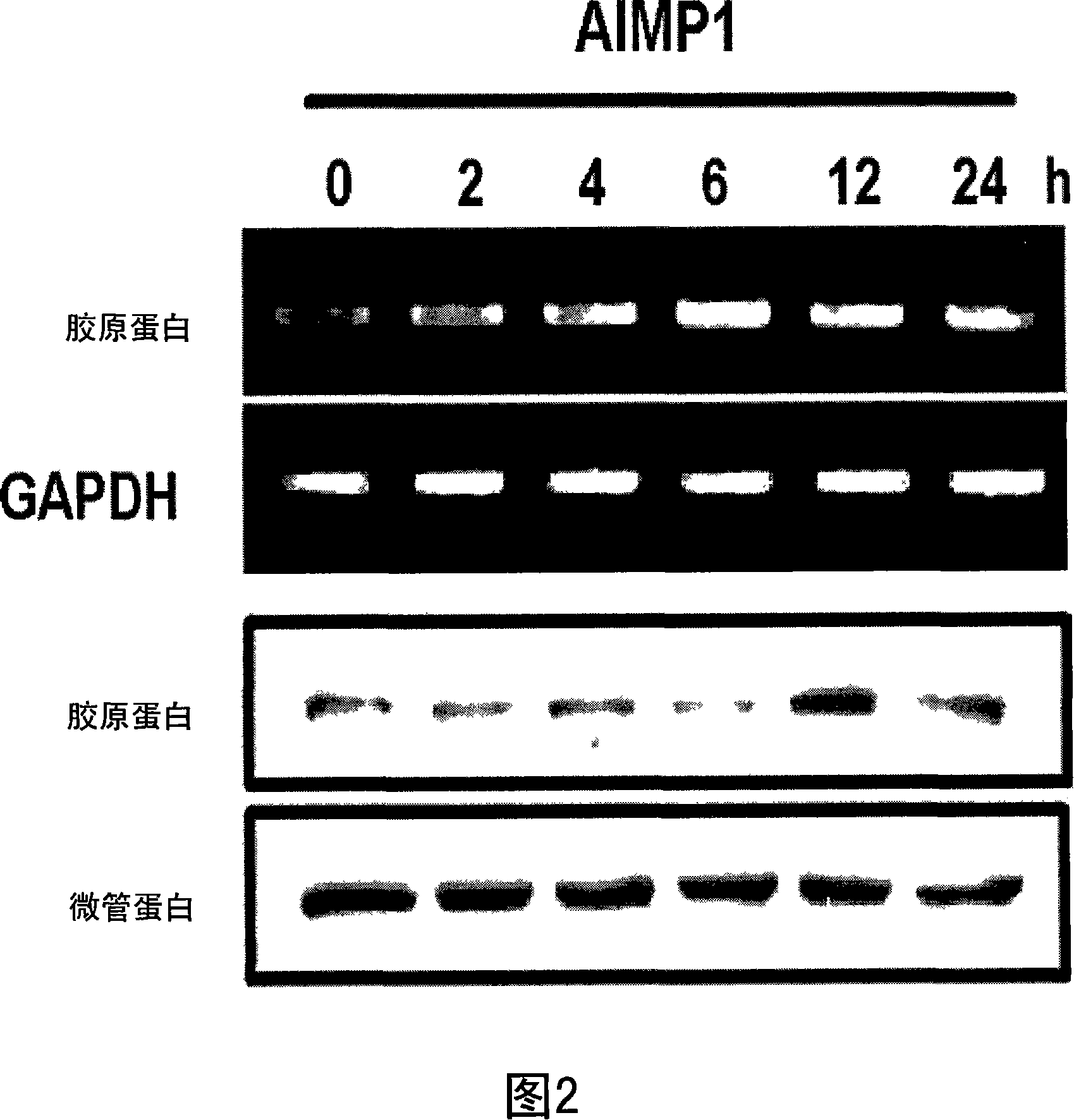

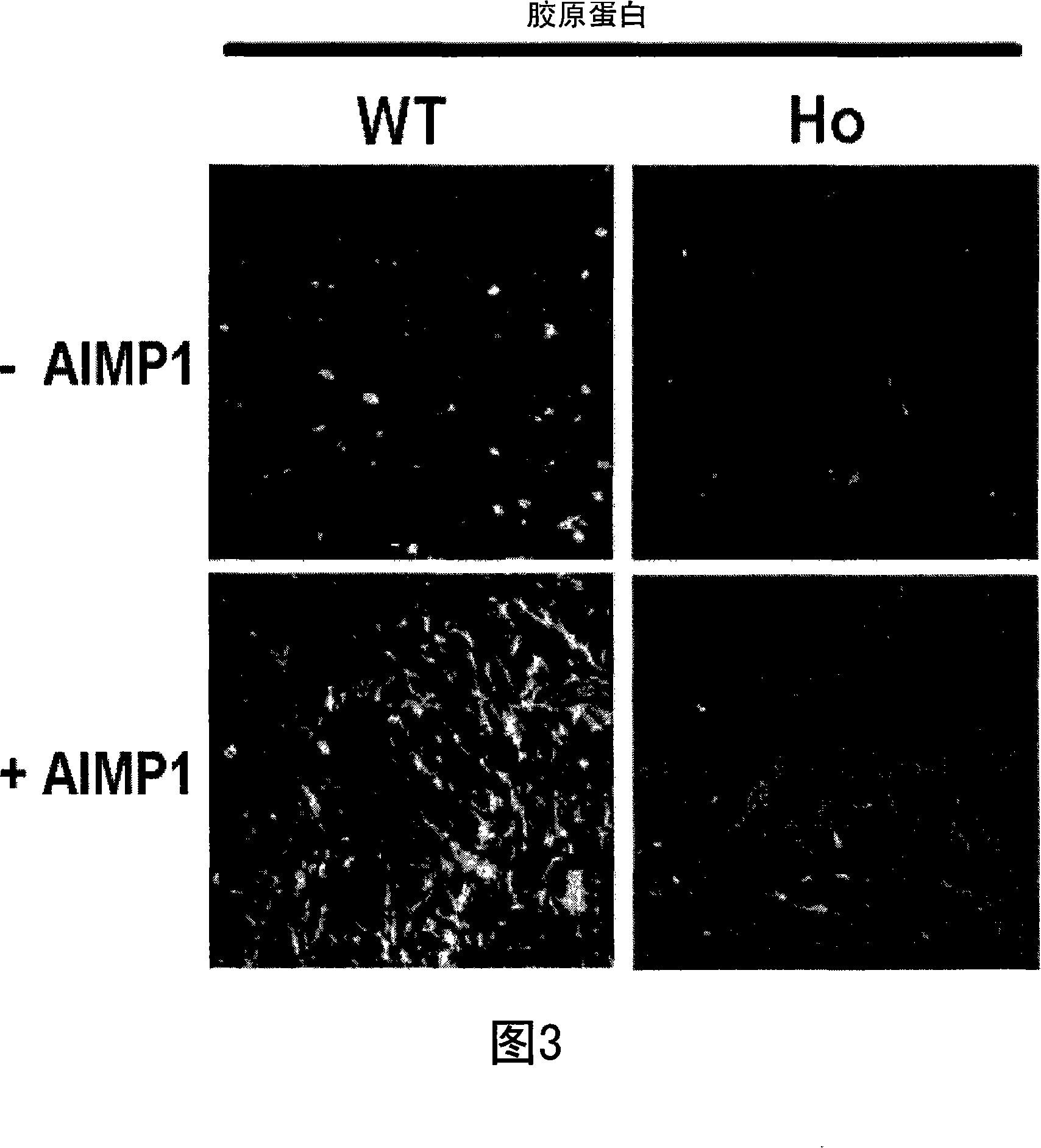

Method for stimulation collagen synthesis and/or kgf expression

InactiveUS20100167997A1Prevent agingPrevent skinBiocideCosmetic preparationsWrinkle skinMenopause present

The present invention relates to a method for stimulating collagen synthesis and / or KGF expression, and more particularly, to a method for stimulating collagen synthesis and / or KGF expression using the AIMP1 or its fragment. The AIMP1 or its fragment can be effectively used for the stimulation of collagen synthesis and / or KGF expression in a subject in need thereof, the treatment of skin aging in the subject, the treatment of the flaccid and / or wrinkled skin in the subject, the promoting the smoothing and / or firming of the skin in the subject, the treatment of adverse cutaneous effects of menopause in the subject, and the treatment of adverse effects of menopause on the collagen.

Owner:ATYR PHARM INC

Aqueous dispersion of colloidal particles of mineral filler and fibres

InactiveUS20070141095A1Good effectImprove mechanical propertiesCosmetic preparationsHair cosmeticsFiberWrinkle skin

The invention relates to a composition containing an aqueous dispersion of colloidal particles of at least one mineral filler, and fibres. The invention also relates to a process for treating the skin, especially wrinkled skin, via the application of the described composition to the skin.

Owner:LOREAL SA

Method of using lectins for prevention and treatment of skin diseases and disorders

InactiveUS20020001600A1Prevent intrusionEliminate wrinklesAntibacterial agentsCosmetic preparationsWrinkle skinDisease

Diseases and disorders of dermal tissue such as the skin, hair and nails are treated or prevented by administering one or more lectins, capable of binding to the surface of pathogenic microorganisms inhabiting the hair, skin, and nails, or of binding to the superficial tissues that comprise hair, skin, and nails. The lectins may be administered topically or subcutaneously to a patient infected with pathogenic microorganisms or in danger of being exposed to such pathogens. Lectins that stimulate cell mitosis may also be administered to accelerate wound healing and restore the appearance of age-wrinkled skin. Lectins that coagulate blood can be administered to assist in stopping bleeding from skin lesions. The lectins may be applied to the skin in a pharmceutically acceptable vehicle.

Owner:LECTIN BIOPHARMA INC

Insulated impregnating process for high-frequency transformers

ActiveCN101699586ANot easy to penetrateSufficient heat resistancePlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsEpoxyLacquer

The invention discloses an insulated impregnating process for high-frequency transformers. The method can significantly improve the surface quality of high-frequency transformers and ensure that the surface of a transformer is completely covered; gaps between iron cores and windings are completely filled; and paint layers are glossy and free from paint protrusions, wrinkled skin and large-area flowing paint. The process is implemented through a technical scheme comprising the following: a) a step of impregnating with paint, which is to impregnate an iron core component with high-temperature epoxy glue, put the iron core component into a sealed container and bake for 2 hours; b) a step of winding, which is to wrap the iron core component in a glass cloth belt for insulation, wind primary and secondary windings and tie the glass cloth belt for insulation; c) a step of impregnating with paint, which is to bake the obtained product at 70+ / -10 DEG C for 0.5 hour; d) a step of baking, whichis to put the obtained product into a vacuum tank, vacuumize the vacuum tank, maintain pressure for 10 minutes, raise pressure to normal pressure, pressurize to between 0.3 and 0.4 MPa, maintain pressure for 20 minutes and bake for 2 hours; and e) a step of packaging, which is to pour high-temperature epoxy glue and put the obtained product into the same sealed container for baking. The high-frequency transformers manufactured by the process have the advantages of good thermal stability, excellent insulation performance and capability of completing the boost output of high-energy pulses.

Owner:四川泛华航空仪表电器有限公司

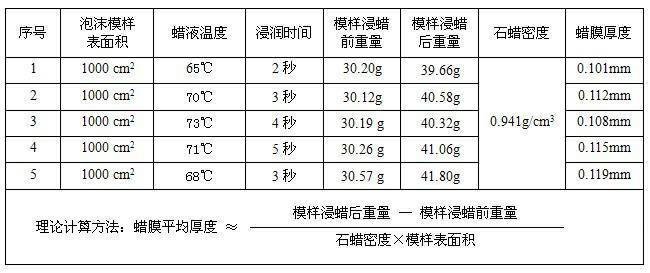

Precision casting method for pouring evanescent mold through high-performance coating foam and mold laminating paraffin

The invention discloses a precision casting method for pouring an evanescent mold through high-performance coating foam and mold laminating paraffin. The method includes the following steps: manufacturing an expandable polystyrene (EPS) foam mold; covering a paraffin mask on the foam mold; preparing high-performance coating; coating and drying the coating; filling sands for shaping; and burning out the foam and the paraffin mask in a casting mold and pouring metal liquid. The high-performance coating is prepared by mixing Guilin No.5 additive special for evanescent mold coating, 180-220 meshes of refractory aggregate powder and water with stirring and adding silicon solution into the mixture with stirring. Dimension accuracy and surface smoothness of a cast member poured by the method can achieve the level equivalent to that of investment precision casting small members, the shortcomings of carbon adding, slag inclusion, pores, wrinkled skin, carbon black, uneven composition, deviation of mechanical property and the like of the casting member do not exist, and large casting members, small casting members and medium casting members all can be manufactured.

Owner:刘翔 +1

Composition containing a tensioning polymer and hybrid particles, methods of use

InactiveUS20080181953A1Improve mechanical propertiesImprove remanencePowder deliveryCosmetic preparationsFacial skinMedicine

Composition containing, in a physiologically acceptable medium, a tensioning polymer and organic-mineral hybrid particles. Process, particularly for facial skin, in particular wrinkled skin, involving the application of the invention composition to the skin.

Owner:LOREAL SA

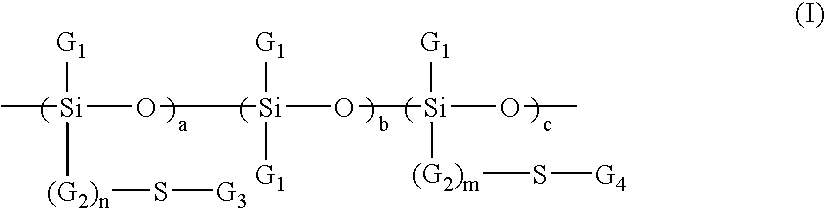

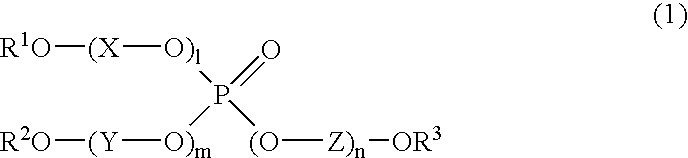

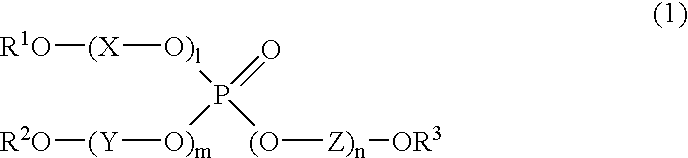

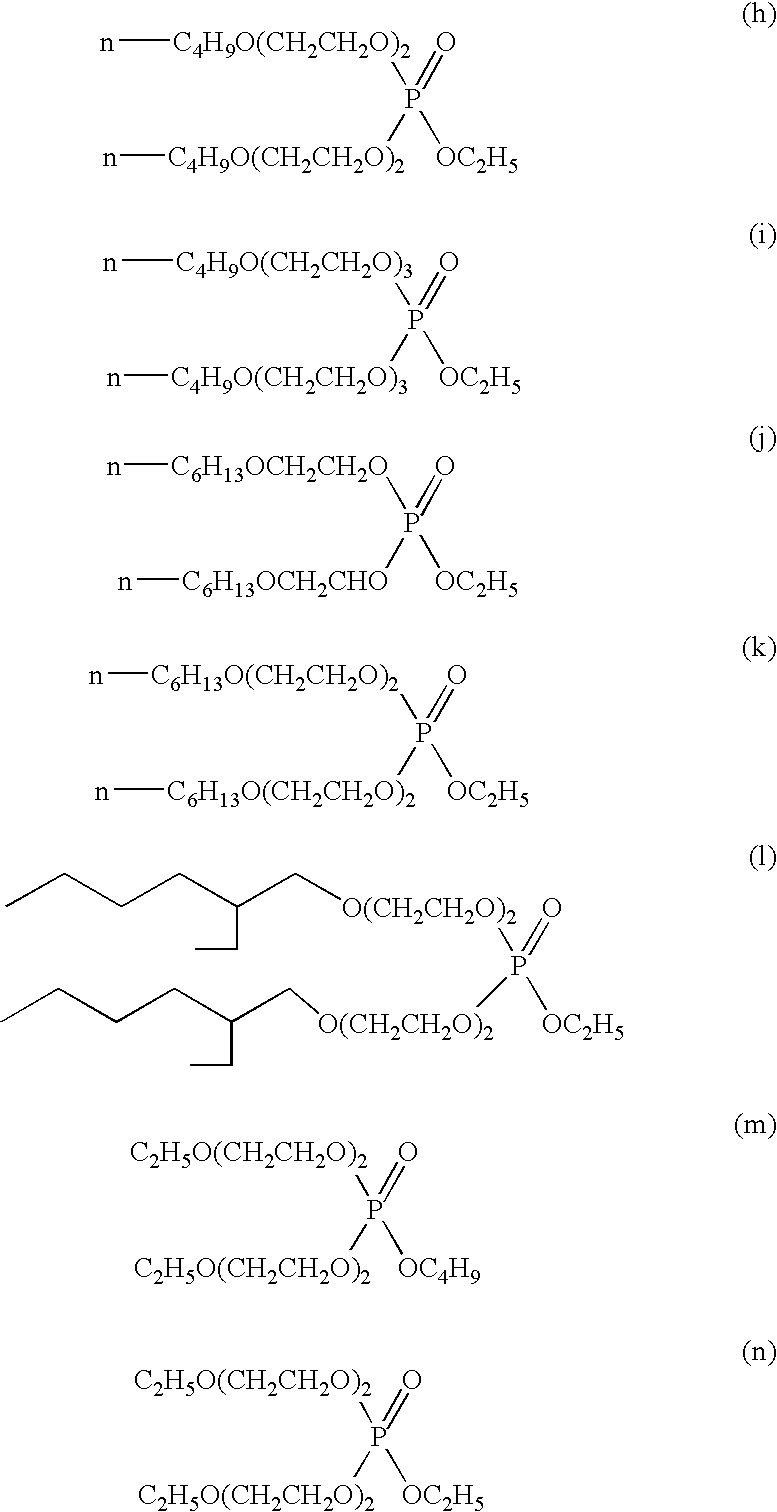

Method of treating skin with a composition comprising a phosphoric triester and a skin activating component

InactiveUS20050123578A1Improve permeabilityGood effectCosmetic preparationsToilet preparationsWrinkle skinSkin complexion

The invention relates to a cosmetic comprising (A) a phosphoric triester represented by the general formula (1): wherein R1 and R2 are independently an alkyl group having 1 to 8 carbon atoms, R3 is an alkyl group having 1 to 4 carbon atoms, X, Y and Z are independently an alkylene group having 2 or 3 carbon atoms, l and m are independently a number of 1 to 10, and n is a number of 0 to 10, and (B) a skin activating component. The cosmetic is excellent in moisturizing effect; the effects of preventing and remedying skin roughness; the effects of preventing the firm and resilient skin from declining and remedying the declined skin; the effects of preventing a complexion from dulling and remedying a dull looking face; the effects of preventing and remedying the conspicuousness of pores of the skin and pimples caused by excess sebum, microorganisms or keratonosis; the effects of preventing development of wrinkles and remedying the wrinkled skin; and the effects of preventing and remedying spots and freckles, and moreover gives users a pleasant feeling upon use.

Owner:KAO CORP

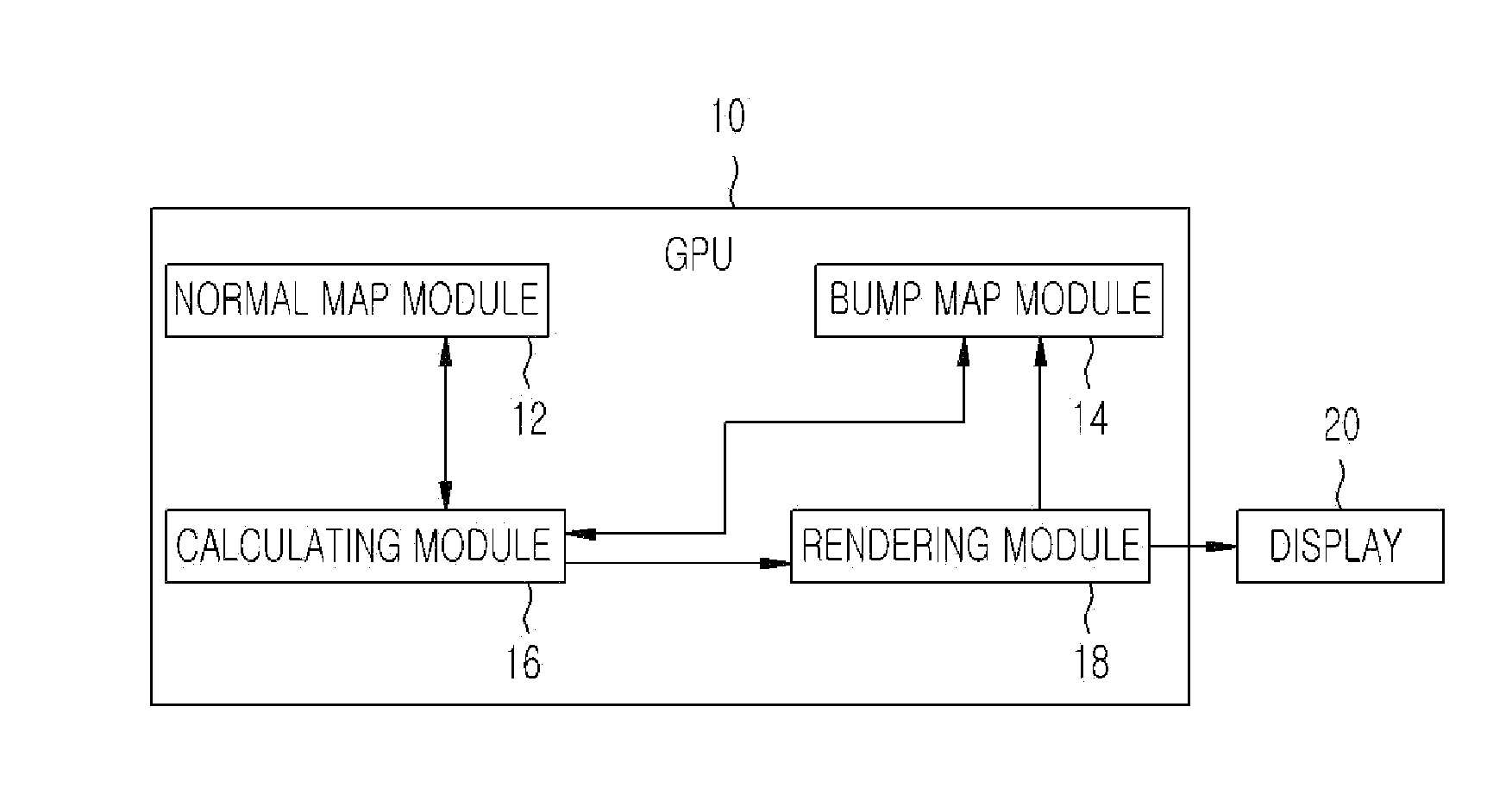

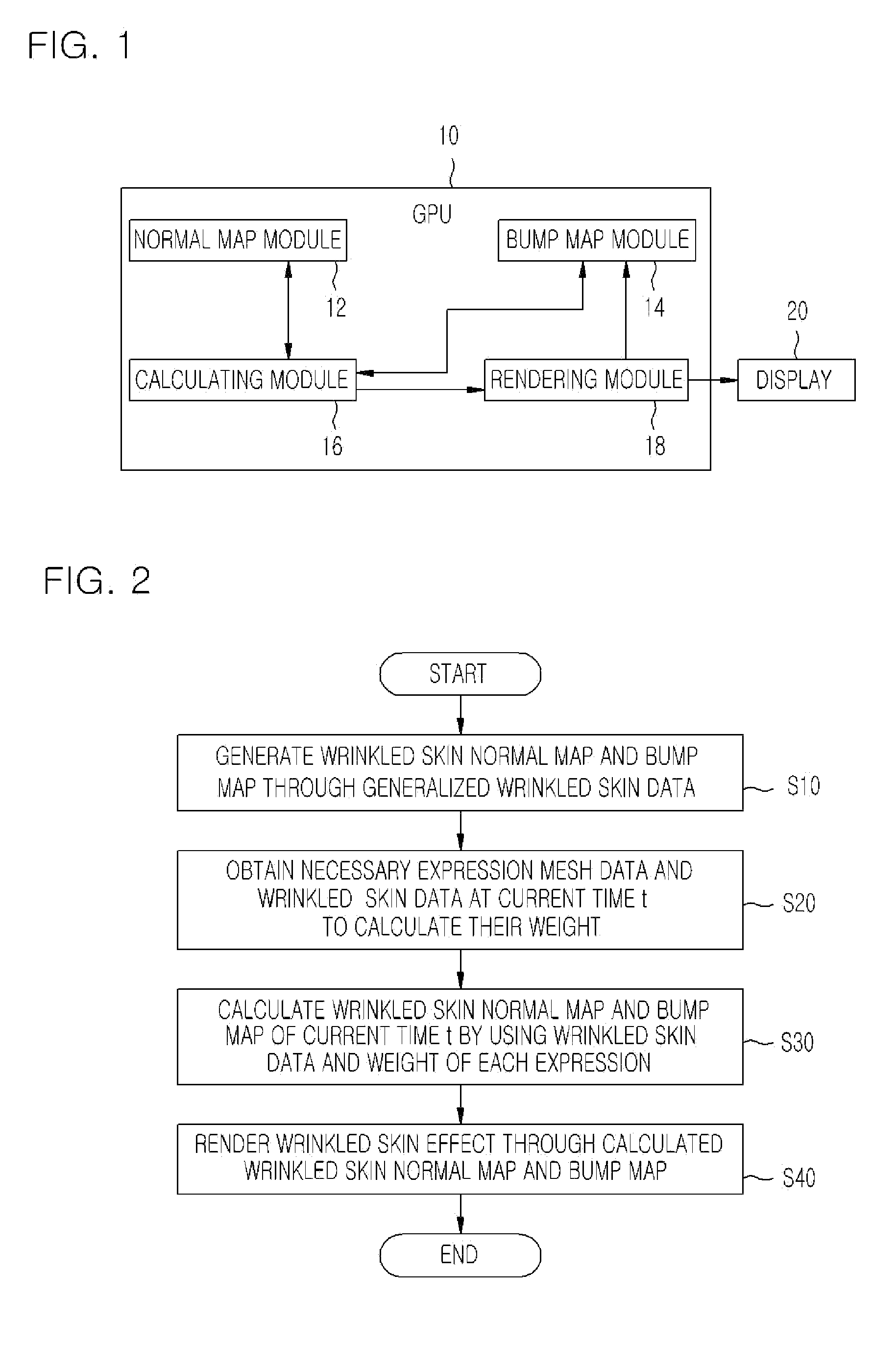

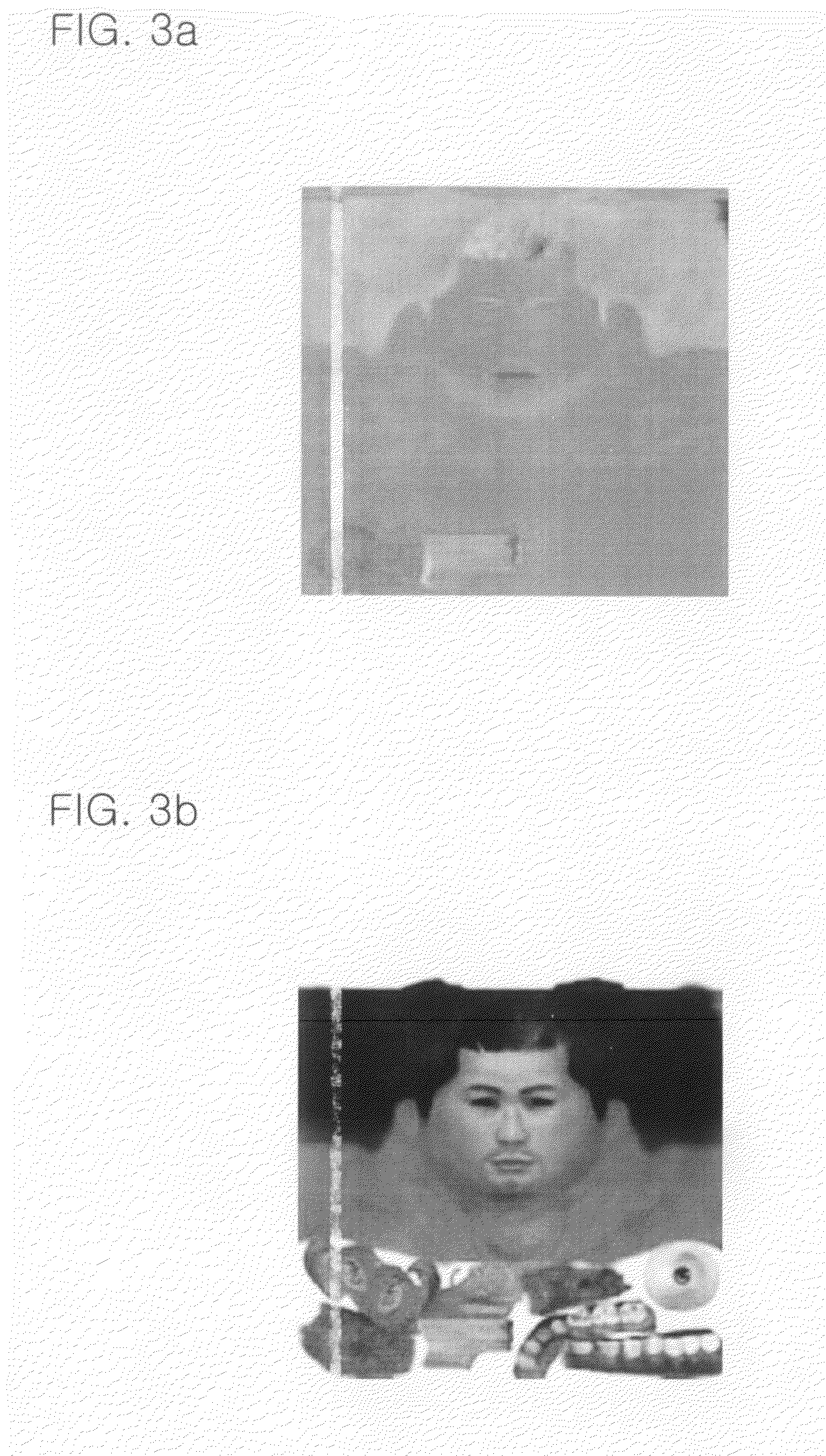

Method and apparatus for rendering efficient real-time wrinkled skin in character animation

Provided are an apparatus and method for providing the optimized speed and realistic expressions in real time while rendering wrinkled skin during character animation. The wrinkled skin at each expression is rendered using a normal map and a bump map. Generalized wrinkled skin data and weight data are generated by calculating a difference of the normal and bump maps and other normal and bump maps without expressions. Then, the wrinkled skin data of a desirable character is generated using the generalized wrinkle skin data at each expression, and then the normal and bump maps expressing a final wrinkled skin are calculated using the weight at each expression in a current animation time t. Therefore, the wrinkled skin in animation is displayed.

Owner:ELECTRONICS & TELECOMM RES INST

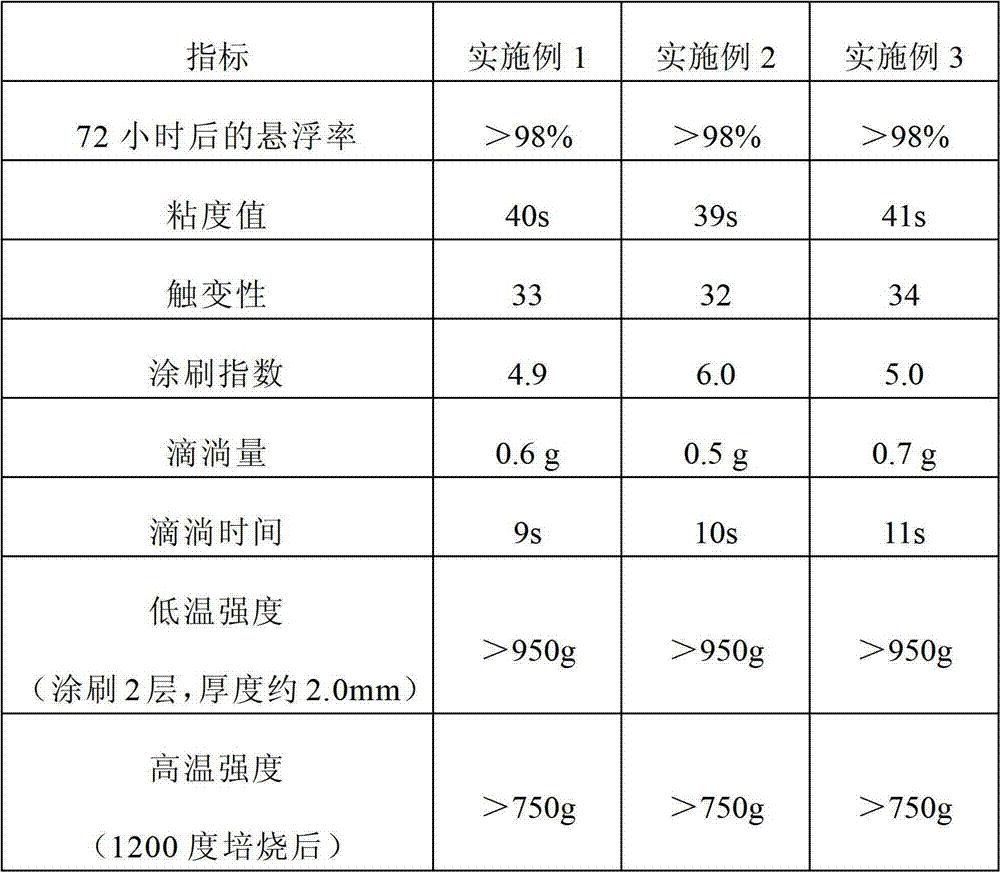

Lost foam paint and preparation method thereof

InactiveCN102847871AImprove breathabilityStrong adhesionFoundry mouldsFoundry coresWrinkle skinSodium Bentonite

The invention relates to a lost foam paint and a preparation method thereof. The paint comprises, by weight, 45 to 55 parts of bauxite chamotte, 25 to 35 parts of quartz powder, 1 to 3 parts of sodium-based bentonite, 0.5 to 1.5 parts of CMC, 1 to 2.5 parts of polyvinyl alcohol, 1 to 3 parts of silica sol, 0.5 to 1.5 parts of soluble glass, 4 to 6 parts of BR resin, 0.1 to 0.3 part of T-80 and 1 to 3 parts of iron oxide red powder. The lost foam paint provided by the invention has good high temperature permeability, excellent brushability, good permeability, strong adhesion and no wrinkled skin on a casting surface; and after a template is dried, the template has high strength, can satisfy transport requirements for heavy castings and has strong capacity in resisting sticky sand.

Owner:TAICANG KEBOER PRECISION CASTING

Method of using lectins for prevention and treatment of skin diseases and disorders

InactiveUS20020183248A1Prevent intrusionSimple methodAntibacterial agentsCosmetic preparationsWrinkle skinDisease

Diseases and disorders of dermal tissue such as the skin, hair and nails are treated or prevented by administering one or more lectins, capable of binding to the surface of pathogenic microorganisms inhabiting the hair, skin, and nails, or of binding to the superficial tissues that comprise hair, skin, and nails. The lectins may be administered topically or subcutaneously to a patient infected with pathogenic microorganisms or in danger of being exposed to such pathogens. Lectins that stimulate cell mitosis may also be administered to accelerate wound healing and restore the appearance of age-wrinkled skin. Lectins that coagulate blood can be administered to assist in stopping bleeding from skin lesions. The lectins may be applied to the skin in a pharmceutically acceptable vehicle.

Owner:OLDHAM MICHAEL J +2

Wrinkle-improving external preparation for skin

ActiveCN1909882AWon't breakWon't peel offCosmetic preparationsToilet preparationsWrinkle skinCross-link

To provide a skin treatment composition for wrinkle reduction that is superior in terms of the wrinkle reduction effect, usability, and the sensation during use. A skin treatment composition having a water dispersion of a polymer in which a non-water soluble film-forming polymer is dispersed in water wherein the main ingredients of said film-forming polymer are polyurethane having a film shrinkage rate of 20% or less and an acrylic type polymer having a film shrinkage rate of 20% or less. Also, a skin treatment composition for wrinkle reduction comprising (a) a non-emulsification type cross-linked silicone, (b) a film forming polymer having a film shrinkage rate of 20% or less containing as a main ingredient a polyurethane having a film shrinkage rate of 20%, (c) a liquid oil component, and (d) water.

Owner:SHISEIDO CO LTD

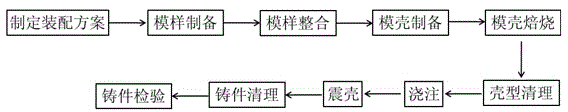

Method for preparing overall shell mold by utilizing vaporizing combustion of mold shell roasting pattern

The invention provides a method for preparing an overall shell mold by utilizing vaporizing combustion of mold shell roasting pattern. The method comprises the following steps: preparing a plastic mold by adopting an injection molding method, splicing and assembling the plastic mold to form an overall pattern, and coating, sanding, drying and hardening the overall pattern, thus obtaining a solid mold shell; roasting the obtained mold shell, wherein the pattern disappears due to vaporizing combustion, thus obtaining an overall shell mold; and finally, cleaning and pouring the obtained shell mold, thus obtaining the casting. The method is high in applicability, the complexity of the cast alloy types and casting structures is not limited, the processes of investment casting and dewaxing are reduced, the production cycle is shortened, and the production efficiency is improved. In the process of manufacturing the shell mold, a phenolic resin is not used as an adhesive, and the problems of pungent smell and subskin blowholes of castings in the process of casting and pouring the shell mold are solved. The pattern disappears before pouring due to roasting and vaporizing combustion of the mold shell, the defects of evaporative pattern casting steel casting recarburization and iron casting wrinkled skin are overcome, and the casting quality is improved.

Owner:沃尔曼科技张家港有限公司

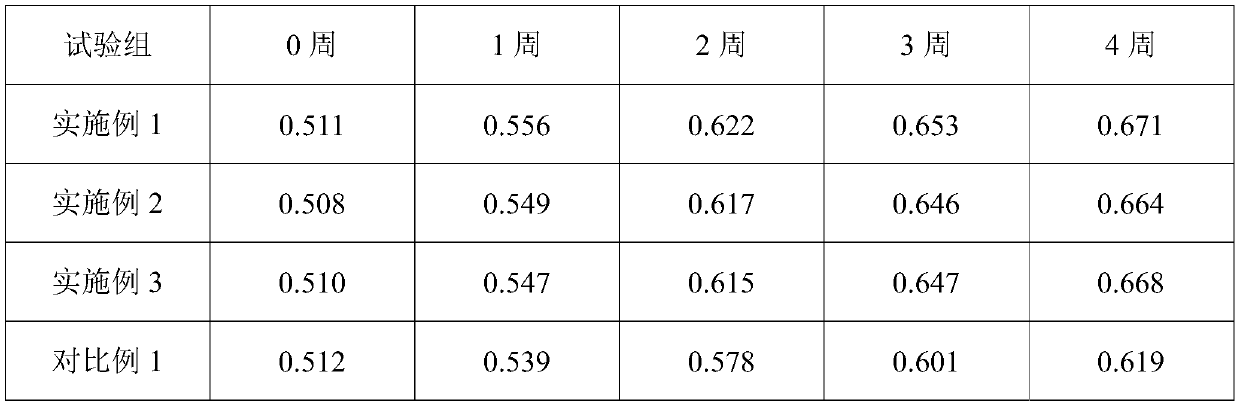

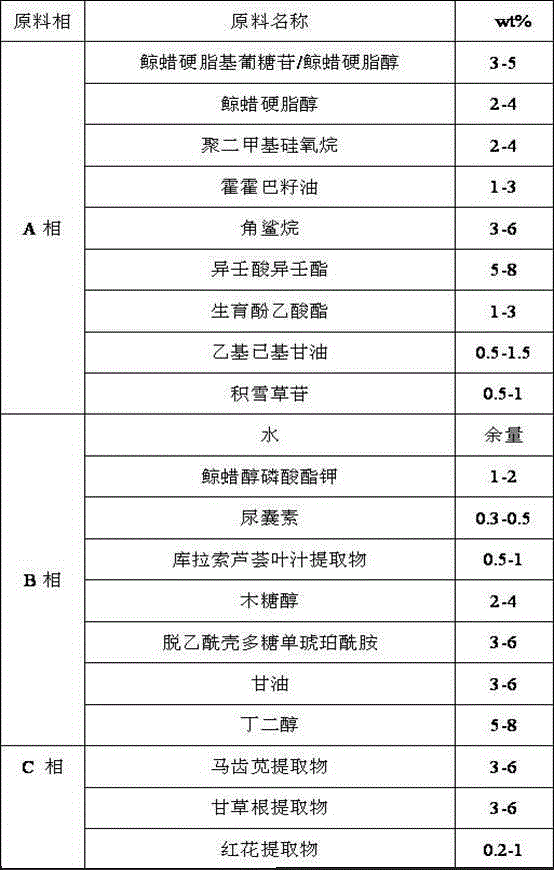

Anti-wrinkle skin-tightening composition and application thereof in cosmetics

ActiveCN110897987AGood anti-wrinkle and firming effectGood moisturizing effectCosmetic preparationsToilet preparationsWrinkle skinOligopeptide

The invention, which belongs to the technical field of cosmetics, particularly relates to an anti-wrinkle skin-tightening composition and application thereof in cosmetics. The anti-wrinkle skin-tightening composition mainly comprises the following components: borago officinalis seed oil, glycine betaine, snail secreta, bifidobacteriumlongum lysate, crithmum maritimum extract, oligopeptide-1, xanthan gum, tocopheryl acetate, fullerene and triethanolamine. The anti-wrinkle and skin-tightening composition has good anti-wrinkle and skin-tightening effects as well as whitening, anti-aging and moisturizing effects and is easy to absorb by the skin. The anti-wrinkle skin-tightening composition can be applied to cosmetics; and the preparation method is simple and is easy to implement.

Owner:广州熙然化妆品有限公司

Anti-wrinkle skin activating cream and preparation method thereof

InactiveCN111686068ASolve skin problemsAvoid accumulationCosmetic preparationsToilet preparationsWrinkle skinOligopeptide

The invention relates to an anti-wrinkle skin activating cream and a preparation method thereof, and belongs to the technical field of cosmetics. Effective components of the anti-wrinkle skin activating cream comprise anti-aging agents, and the anti-aging agents are selected from at least one of lactobacillus / roselle flower fermentation product filtrates, hydrangea leaf extracts, alchemilla vulgaris leaf extracts, lotus flower extracts, peony flower extracts, palmitoyl tripeptide-5, oligopeptide-1 and palmitoyl pentapeptide-4. The anti-wrinkle skin activating cream can effectively inhibit skinoxidation and skin wrinkle generation to effectively repair damaged epidermal cells; and through the mutual synergistic effect of the anti-aging agents, skin conditioners, humectants, antioxidants, the anti-inflammatory agents and other components, wrinkles, sagging and other aging problems can be effectively inhibited, damaged epidermis is repaired, so that the normal metabolism function of theskin is recovered, the activity of MMPs is hindered, elastin and collagen are prevented from being decomposed, and the anti-aging effect of the skin is achieved.

Owner:佐登妮丝(广州)美容化妆品有限公司

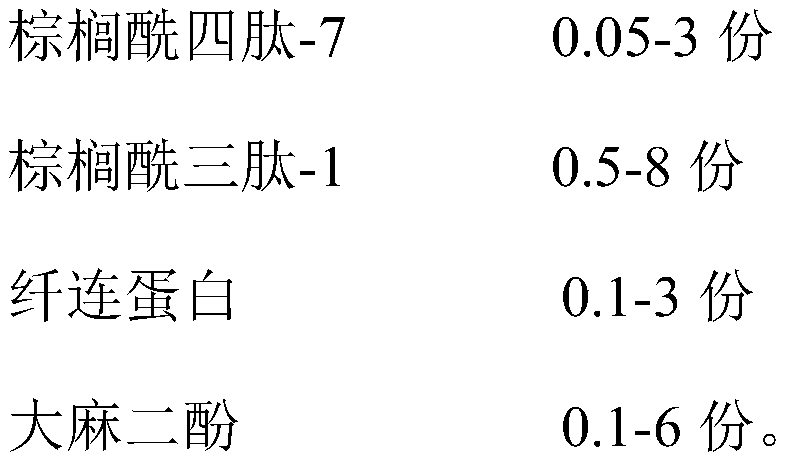

Anti-wrinkle skin-tightening composition, anti-wrinkle skin-tightening essence and preparation method thereof

InactiveCN109998939AStrong Free Radical InhibitionInhibit the inflammatory responseCosmetic preparationsToilet preparationsApoptosisFree Radical Suppression

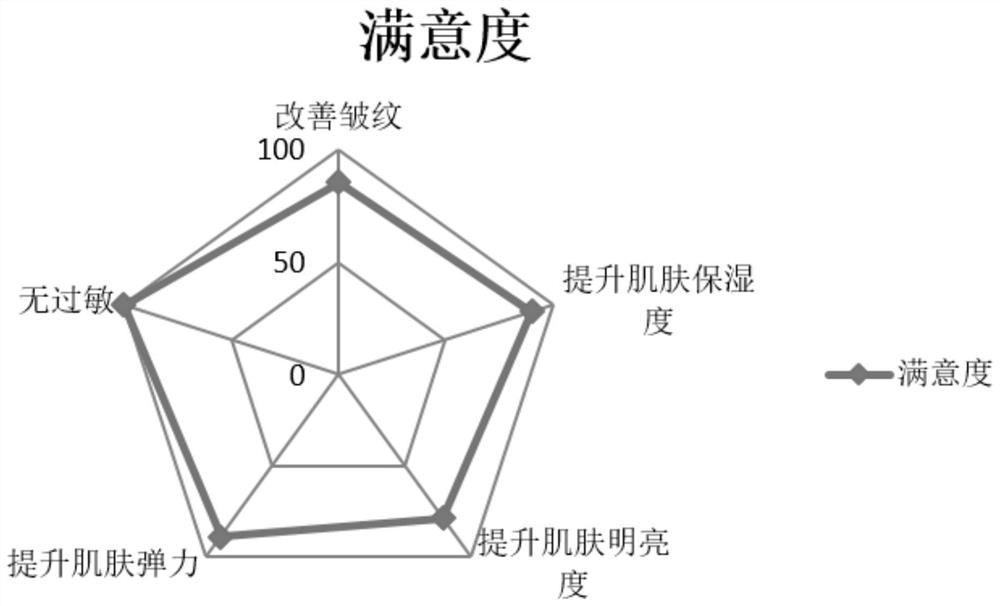

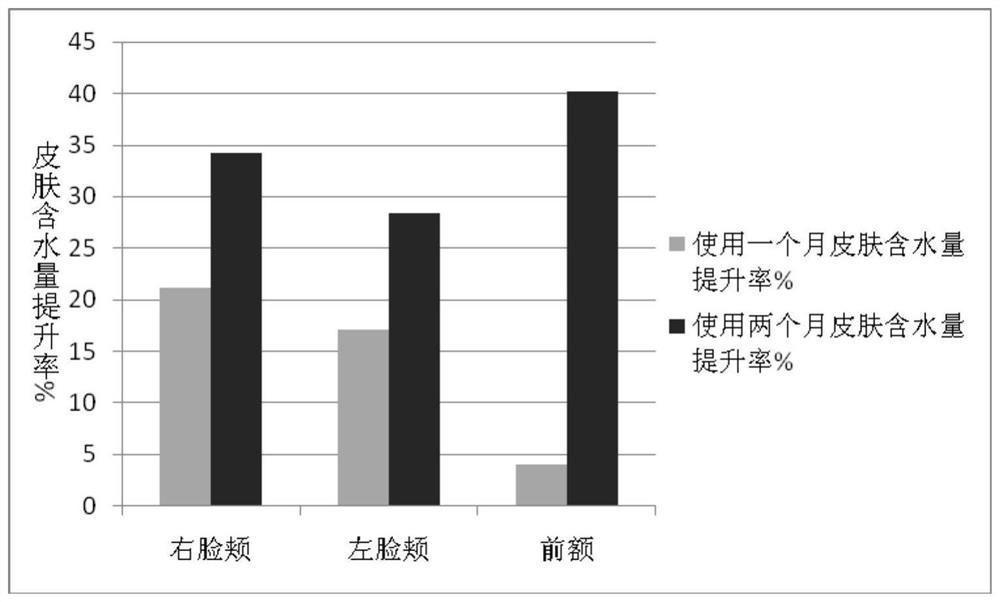

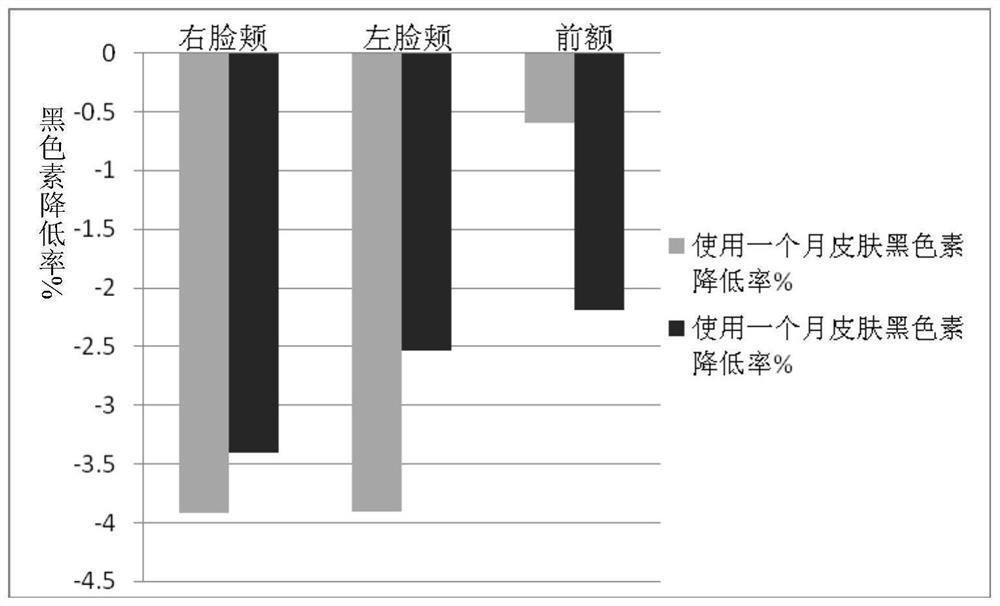

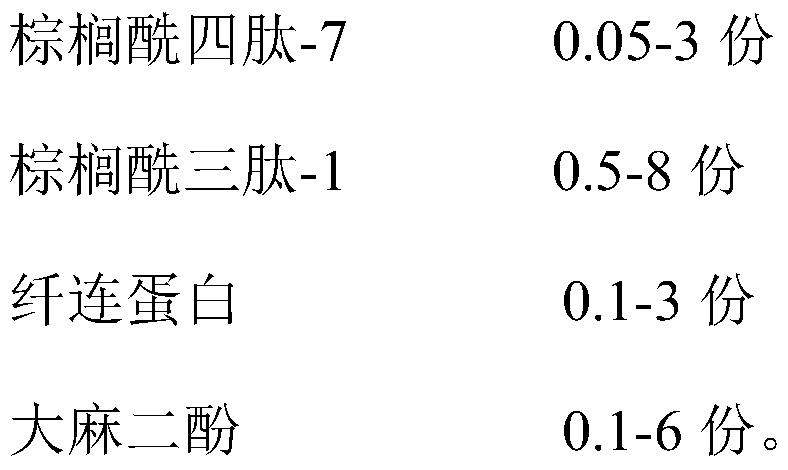

The invention relates to an anti-wrinkle skin-tightening composition, an anti-wrinkle skin-tightening essence and a preparation method thereof. The anti-wrinkle skin-tightening composition comprises 0.05-3 parts of palmitoyl tetrapeptide-7, 0.5-8 parts of palmitoyl tripeptide-1, 0.1-3 parts of fibronectin and 0.1-6 parts of cannabidiol. Due to the mutual action of the components, the anti-wrinkleskin-tightening composition inhibits an inflammation reaction of skin and then reduces the cell aging apoptosis speed, meanwhile, sufficient nutrient substances are provided for the skin, nutrition metabolism of cells is improved, the skin is moisturized, cell regeneration is promoted, the regeneration and degradation balance of the cells is maintained, and the skin is healthy and active. The anti-wrinkle skin-tightening composition has a relatively strong free radical inhibiting effect, further maintains the environmental balance in the cells, improves the cell regeneration capability and improves the anti-wrinkle skin-tightening effects.

Owner:广州恒雅生物化工有限公司

Traditional Chinese medicinal facial mask containing flowers with five colors

InactiveCN104055726ARough preventionAnti-wrinkleCosmetic preparationsToilet preparationsWrinkle skinMedicinal herbs

The invention provides a traditional Chinese medicinal facial mask containing flowers with five colors. The facial mask is characterized by being prepared from the following raw materials in percentage by weight: 10-30 percent of peach blossom, 10-30 percent of yellow chrysanthemum, 8-26 percent of red rose, 2-20 percent of jasmine, 3-20 percent of lavender, 5-16 percent of honey, 4-15 percent of egg white, 7-6 percent of tea polyphenol, 5-10 percent of L-vitamin C, 1-15 percent of pearl powder, 3-10 percent of isoimperatorin, 5-15 percent of ginsenoside, 2-10 percent of ferulic acid and 8-15 percent of asiaticoside. The facial mask can be used for removing melanin on the surface layer of a human face, enables skin to be bright, white, tender and elastic, and is prepared from flower leaves with an effective skin-nourishing effect, wherein the peach blossom can be used for promoting excretion of lipofuscin pigment causing human senescence and preventing melanin from depositing on skin; the yellow chrysanthemum can be used for strengthening the resistance of blood capillary; the red rose can be easily absorbed by skin because of enriched vegetable protein, and has a certain effect for preventing and treating dry, rough and wrinkled skin; the jasmine contains phenylcarbinol, linalool ester and other organic matters, and has a certain beautifying effect; the adopted traditional Chinese medicinal herbs generate affinity with skin, and respectively infiltrate into skin to play roles in nourishing, removing freckles and acnes, whitening and the like.

Owner:BOCALY BIO TECH

Tin alloy metal mold casting paint and preparation method thereof

InactiveCN102078914AImprove insulation effectImprove flame retardant performanceFoundry mouldsFoundry coresAlloySuspending Agents

The invention discloses a tin alloy metal mold casting paint with better heat preservation, fire resistance, cohesiveness and coating ability and a preparation method thereof. The coating comprises the following chemical components in percentage by weight: 3% to 9% of talcum powder, 1% to 5% of diatomite, 1% to 4% of cohesive agent, 0.1% to 2% of suspending agent, 2% to 10% of flame retardant and 72% to 91% of water, wherein the cohesive agent comprises water glass and silica sol, the suspending agent comprises attapulgite clay, palygorskite clay and the like, and the flame retardant comprises alkyl sodium sulfonate and boracic acid. The tin alloy metal mold casting paint has the advantages of the stronger heat preservation, the fire resistance, the cohesiveness and the coating ability as well as excellent suspension property, and is difficult to precipitate in use and beneficial to obtaining tin alloy paint with smooth surface and non-oxidation wrinkled skins.

Owner:王可新

Whitening and moisturizing emulsion and preparation method thereof

PendingCN111789804AAvoid drying and wrinklingHigh activityCosmetic preparationsToilet preparationsWrinkle skinActive agent

The invention discloses a whitening and moisturizing emulsion. The whitening and moisturizing emulsion comprises the following components in parts by weight: 15-35 parts of moisturizing grease, 5-15 parts of an emulsifier, 1-5 parts of a thickener, 2-7 parts of glycerol, 0.02-16 parts of a surfactant, 0.2-0.8 part of sodium hyaluronate, 0.1-0.5 part of a preservative, 0.5-0.8 part of trehalose, 10-25 parts of aloe extract, 5-12 parts of hydrolyzed collagen, 3-6 parts of arbutin, 0.5-1.5 parts of ginseng fruit extract, 6-10 parts of safflower extract liquid, 0.1-0.3 part of nano pearl powder and 15-80 parts of deionized water, wherein the emulsifier is composed of the following components in percentage by mass: 25 to 70 percent of poloxamer and 30 to 75 percent of a self-emulsifying compound emulsifier. The whitening and moisturizing emulsion has good moisturizing and water locking effects, keeps the skin moist and glossy, and avoids dry and wrinkled skin; and through the synergistic effects of supplementing nutritional ingredients, improving cell activity, improving qi-blood circulation and maintaining water-oil balance, the emulsion effectively improves water-oil imbalance of theskin, reduces wrinkles and improves complexion.

Owner:美丽华化妆品(上海)有限公司

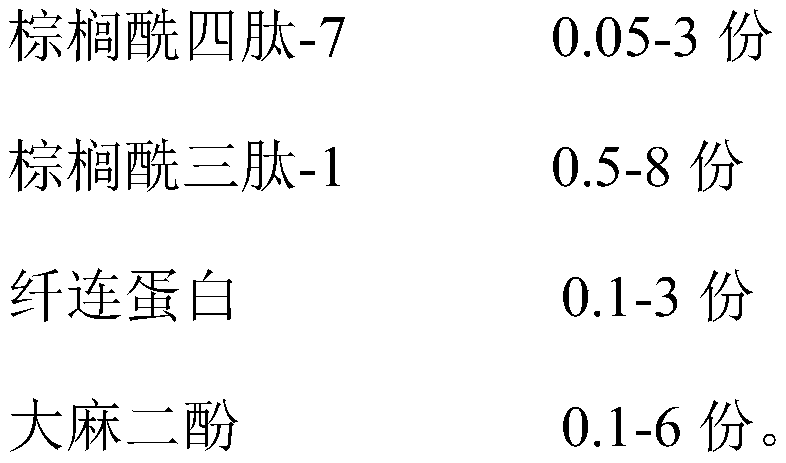

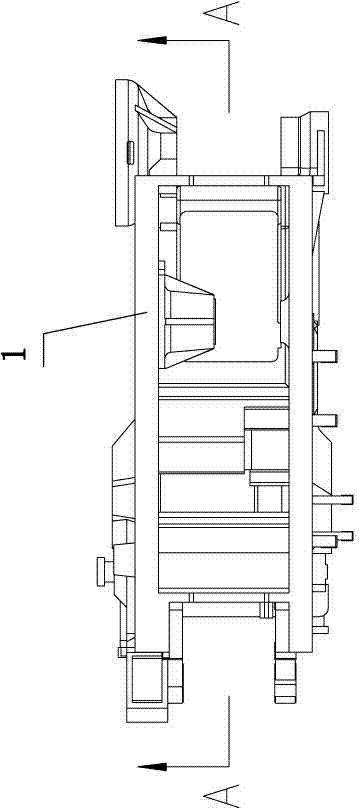

Casting technology method for compression molding machine body

ActiveCN104759591ASolve the problem of surface slag inclusionsSolve wrinkled skinFoundry mouldsFoundry coresWrinkle skinCompression molding

The invention relates to casting technology improvement techniques, in particular to a casting technology method for a compression molding machine body. The casting technology method for the compression molding machine body is characterized in that foam for a polystyrene foam sheet material with the density of 19-20 g / l is adopted to manufacture a foam model with the identical shape and structure with a casting of the compression molding machine body, the polystyrene foam sheet material with the density of 20-21 g / l is adopted to manufacture a special foam molding bed with the identical shape and structure with a lower cavity portion of the casting of the compression molding machine body, a casting gate is arranged after coating of the surface of an assembled model is dried, a specially-made pore-forming core rod is adopted to perform casting forming on baffle holes and long through holes, a stepped casting system integrating punching, exhausting, slagging and feeding is used, and finally the casting is subjected to doffing cleaning. According to the casting technology method for the compression molding machine body, the manufacturing period of the casting is short, the cost is low, and the problems that a solid type casting technology is prone to generating defects such as surface slag inclusion, wrinkled skin, shrinkage and the like are solved.

Owner:黄石新兴管业有限公司

Cosmetic for treating chapped hands and feet and preparation method thereof

InactiveCN106551856AInhibit peroxidationDelay agingCosmetic preparationsToilet preparationsWrinkle skinTraditional medicine

The invention provides a cream for treating chapped hands and feet and a preparation method thereof. Plant extracts are the main functional additives, and common matrix components in cosmetics are used as the auxiliary materials. The provided cosmetic can remove spots and old skin, has the functions of removing spots, keeping beauty, whitening and moisturizing the sin, and preventing aging and wrinkled skin, does not have any side effect, is mild, and is nonirritant to the skin. Moreover, the preparation technology is simple. Natural extracts are taken as the antiseptic, and thus the cosmetic is green and safe, and does not contain any substance that is harmful or toxic to human body.

Owner:SHENYANG KUNMEIXI BEAUTY SUPPLIES CO LTD

Alcohol-based foundry coating with strong coating property and producing method thereof

ActiveCN104084526ACoating stabilityImprove high temperature resistanceFoundry mouldsFoundry coresFoundryWrinkle skin

The present invention discloses an alcohol-based foundry coating with strong coating property, and the alcohol-based foundry coating with strong coating property is characterized by being prepared from the following raw materials by weight: 65-80 parts of bauxite curring material, 1.1-2.3 parts of aluminum dihydrogen phosphate, 1-2 parts of attapulgite clay, 0.4-0.9 part of lignin, 30-40 parts of bauxite tailings, 0.3-0.6 part of antioxidant 425, 0.5-0.8 part of zinc sulfide, 12-15 parts of canna edulis ker residue, 1-3 parts of thermosetting phenol resin, 2-4 parts of hexamethylenetetramine, 45-55 parts of ethanol and 3-5 parts of an assistant, the prepared coating has strong coating property, high temperature resistance, flame resistance, and bonding property; the suspending property of the coating prepared by using the canna edulis ker residue and the attapulgite clay as suspending agents is improved, and the coating is not easy to precipitate in the use process, is beneficial to obtain castings with smooth surfaces and no oxidation wrinkled skin.

Owner:嘉兴如运建筑科技有限公司

Hyaluronic acid injection and preparation method thereof

InactiveCN110638676AImprove water retentionSoft textureCosmetic preparationsToilet preparationsWrinkle skinHyaluronate Injection

The invention provides a hyaluronic acid injection and a preparation method thereof. The hyaluronic acid injection is prepared from the following components in percentage by mass: 0.1-1.5% of hyaluronic acid, 0.01-1% of amino acid, 0.1-2% of mannitol and 0.05-0.8% of minerals. The prepared hyaluronic acid injection can supplement the hyaluronic acid in the extracellular matrix of skin and improvethe own collagen synthesis ability of the skin, so that wrinkled skin is restored to be smooth and elastic. The hyaluronic acid injection is safe in ingredients, the preparation method is simple, thecost is low, and the hyaluronic acid injection is suitable for industrialization.

Owner:西安博和医疗科技有限公司

Blueberry anti-wrinkle skin-beautifying honey and a preparing method thereof

InactiveCN107485587AFade fine linesPromote skin metabolismCosmetic preparationsToilet preparationsNutrientAnti wrinkle

The invention relates to the technical field of skincare products, particularly blueberry anti-wrinkle skin-beautifying honey and a preparing method thereof. Through designing a ratio of a blueberry extract, hyaluronic acid, trehalose, collagen, sorbitol, butanediol, triethanolamine, glyceryl monostearate, white mineral oil, hydrogenated vegetable oil, methyl p-hydroxybenzoate, an aseptic and deionized water, the prepared anti-wrinkle skin-beautifying honey can supplement comprehensive nutrients for kin, can reduce fine wrinkles on skin, supplements water, preserves moisture, improves skin metabolism, makes skin soft, tender, smooth and more elastic, and prevents ageing. Through formula designing, nutrients can be extremely easily absorbed by skin surface layers, and skin immunity and activity are enhanced.

Owner:GUIZHOU INST OF BIOLOGY

Hub casting method

InactiveCN109304427AReduce formationAvoid defectsFoundry mouldsFoundry coresVolumetric Mass DensityDip-coating

The invention discloses a hub casting method and relates to the technical field of hub casting methods. The hub casting method comprises the following steps that a mold sample is manufactured and comprises 65-75% of EPMMA and 25-35% of EPS, and after the mold sample is manufactured, combination and drying are conducted; and coating is prepared and stirred evenly, and dip-coating of the coating anddrying are conducted. The matching ratio of the mold sample is set to be 65-75% of EPMMA and 25-35% of EPS, and can reduce formation of wrinkled skin and carbon black of nodular iron castings; by setting the density of the mold sample to be within 18-21 kg / m3, the problem of the carbon black of the castings is prevented advantageously; and by controlling the baume degree of the coating to be within 65-75 degrees and controlling the layer thickness of the coating to be within 0.6-0.8 mm, the compactness, intensity and refractoriness of the coating layer are improved advantageously, and the carbon defects and burnt-on sand problem of the castings can be prevented at the same time.

Owner:ANHUI HELI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com