Patents

Literature

39results about How to "Sufficient heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

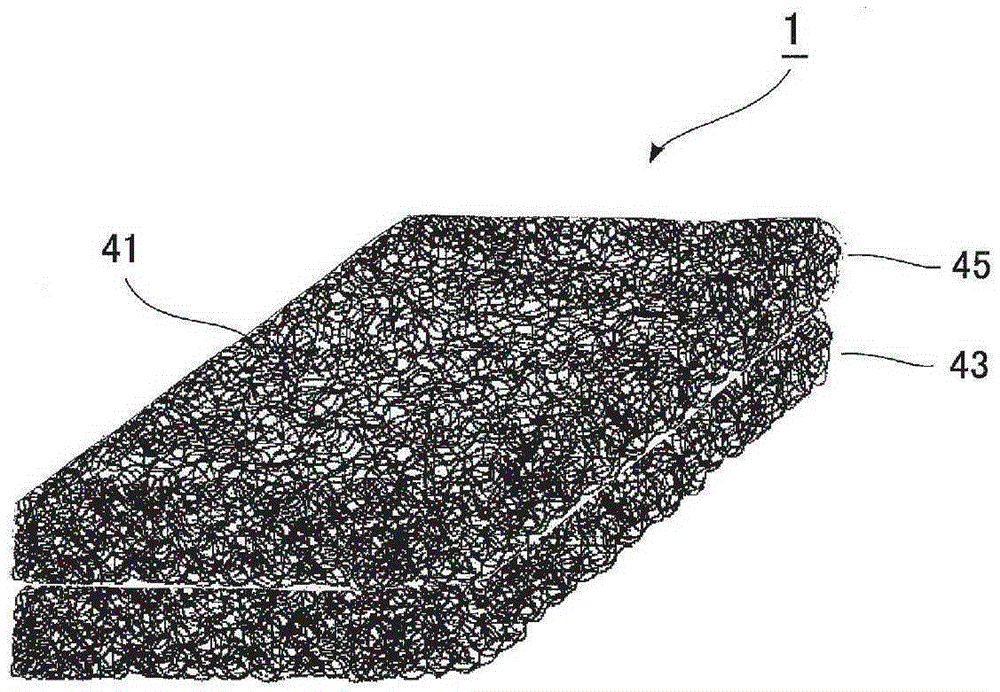

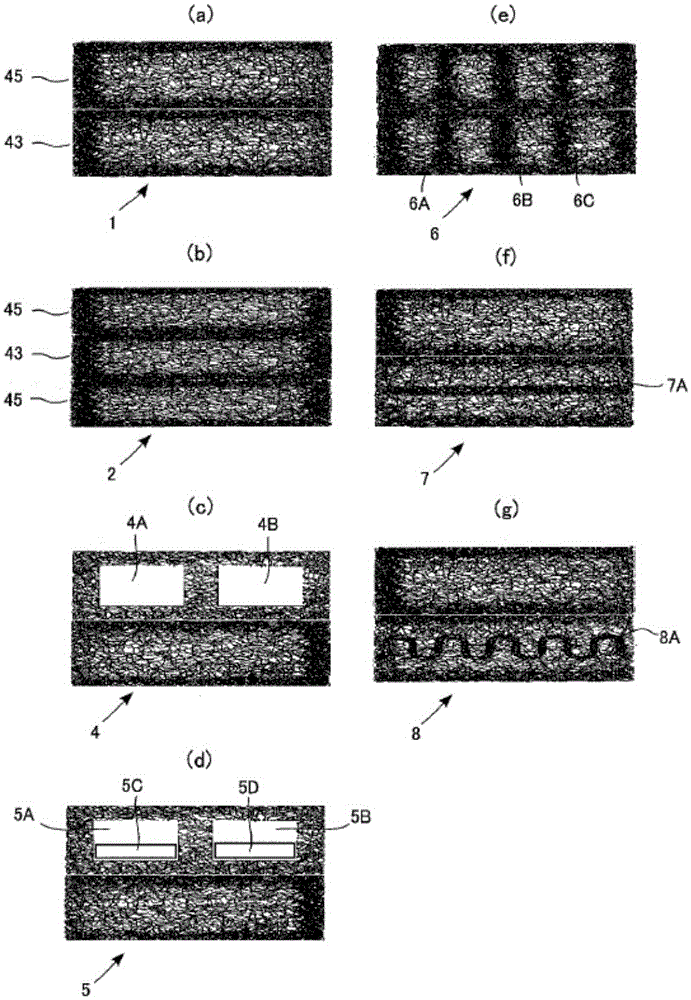

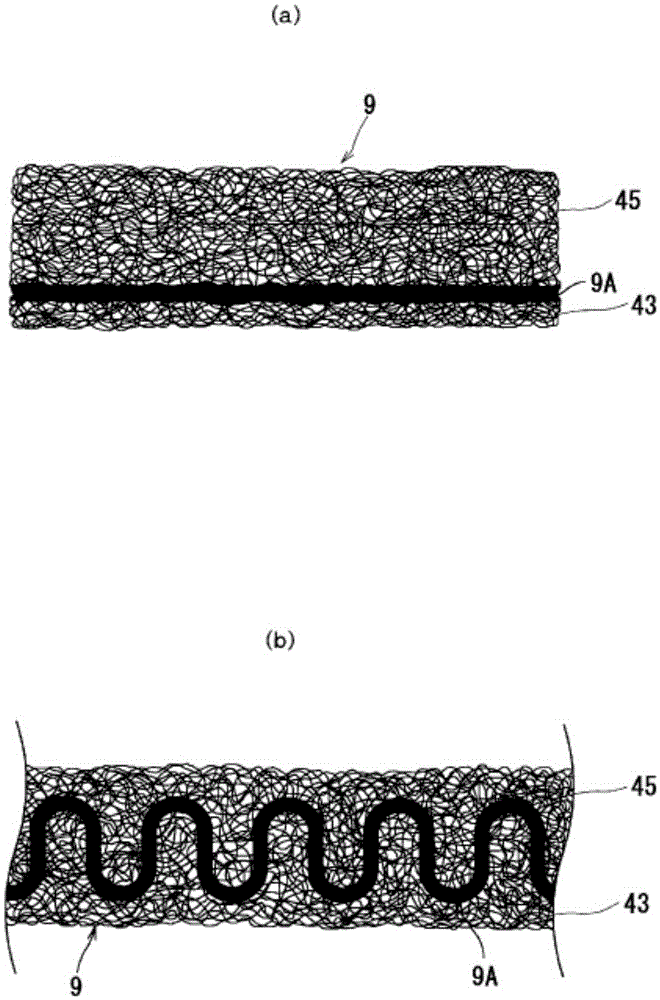

Core material for cushion, and cushion

ActiveCN105377083AInhibition of contractionHigh Thermal Expansion PropertiesStuffed mattressesDomestic upholsteryHysteresisPolyester

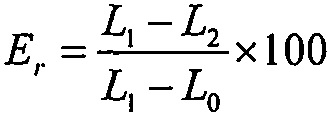

The present invention provides a hygienic cushion which can be washed in water, exhibits excellent air permeability, and is light while exhibiting body-shape retention and exerting a resiliency force no less than a given standard at an appropriate thickness. A core material (1) for a cushion, wherein: one surface or both surfaces of a first layer in a three-dimensional mesh structure, said first layer being formed from a polyethylene-based thermoplastic resin, a polyester-based thermoplastic elastomer, or a mixture of a polyethylene-based thermoplastic resin and a polyethylene-based thermoplastic elastomer, is / are laminated with a second layer containing a thermoplastic resin that is different from that of the first layer; the three-dimensional mesh structure has an impact resilience of 13cm or greater and a hysteresis loss of 13-34%; and the thermal elongation rate of the three-dimensional mesh structure in the lengthwise direction before and after a hot-air drying test is 0-8% after 30 minutes at 90 DEG C in the case of a polyethylene-based thermoplastic resin, after 30 minutes at 130 DEG C in the case of a polyester-based thermoplastic elastomer, or after 30 minutes at 90 DEG C in the case of a mixture of a polyethylene-based thermoplastic resin and a polyethylene-based thermoplastic elastomer.

Owner:C ENG CO LTD

Insulated impregnating process for high-frequency transformers

ActiveCN101699586ANot easy to penetrateSufficient heat resistancePlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsEpoxyLacquer

The invention discloses an insulated impregnating process for high-frequency transformers. The method can significantly improve the surface quality of high-frequency transformers and ensure that the surface of a transformer is completely covered; gaps between iron cores and windings are completely filled; and paint layers are glossy and free from paint protrusions, wrinkled skin and large-area flowing paint. The process is implemented through a technical scheme comprising the following: a) a step of impregnating with paint, which is to impregnate an iron core component with high-temperature epoxy glue, put the iron core component into a sealed container and bake for 2 hours; b) a step of winding, which is to wrap the iron core component in a glass cloth belt for insulation, wind primary and secondary windings and tie the glass cloth belt for insulation; c) a step of impregnating with paint, which is to bake the obtained product at 70+ / -10 DEG C for 0.5 hour; d) a step of baking, whichis to put the obtained product into a vacuum tank, vacuumize the vacuum tank, maintain pressure for 10 minutes, raise pressure to normal pressure, pressurize to between 0.3 and 0.4 MPa, maintain pressure for 20 minutes and bake for 2 hours; and e) a step of packaging, which is to pour high-temperature epoxy glue and put the obtained product into the same sealed container for baking. The high-frequency transformers manufactured by the process have the advantages of good thermal stability, excellent insulation performance and capability of completing the boost output of high-energy pulses.

Owner:四川泛华航空仪表电器有限公司

Resin composition for sealing solar cell element, and solar cell module

InactiveCN102884097ALow hygroscopicityLow non-hydrolyzabilityGlass/slag layered productsAdhesivesPolymer scienceChain type

Provided are: a resin composition for sealing a solar cell element which comprises a hydrogenated block copolymer and has a tensile elasticity (at 23oC) of 1.0-500 MPa, said hydrogenated block copolymer being obtained by hydrogenating 90% or more of total unsaturated bonds present in a block copolymer, which comprises at least two polymer blocks [A] having an aromatic vinyl compound-origin repeating unit as the main component and at least one polymer block [B] comprising a chain-type conjugated diene compound-origin repeating unit as the main component and in which the ratio (wA:wB) of the weight fraction (wA) of the total polymer blocks [A], relative to the total block copolymer, to the weight fraction (wB) of the total polymer block [B] is 20:80 to 60:40; and a solar cell module.

Owner:ZEON CORP

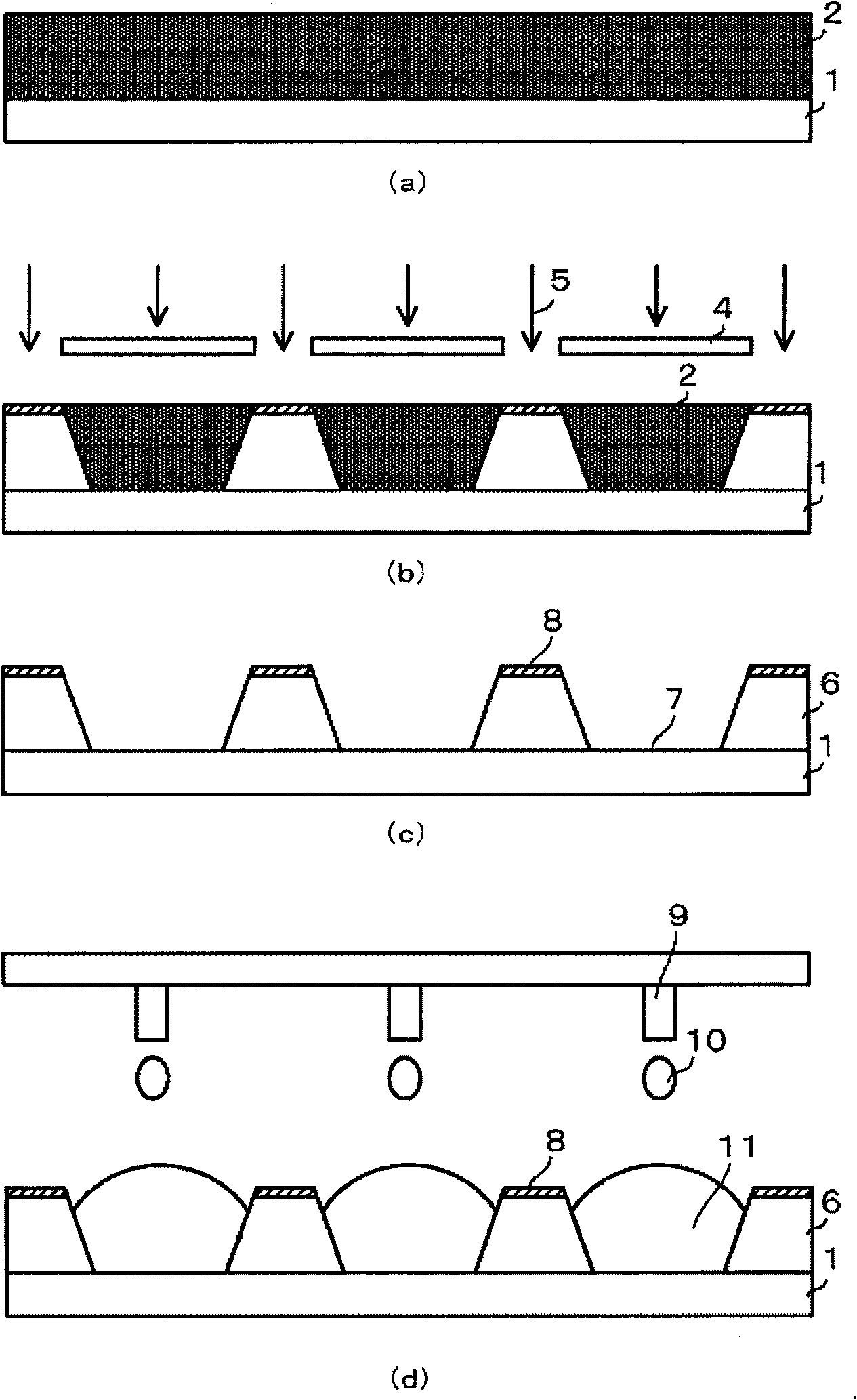

Method For Manufacturing Optical Elements

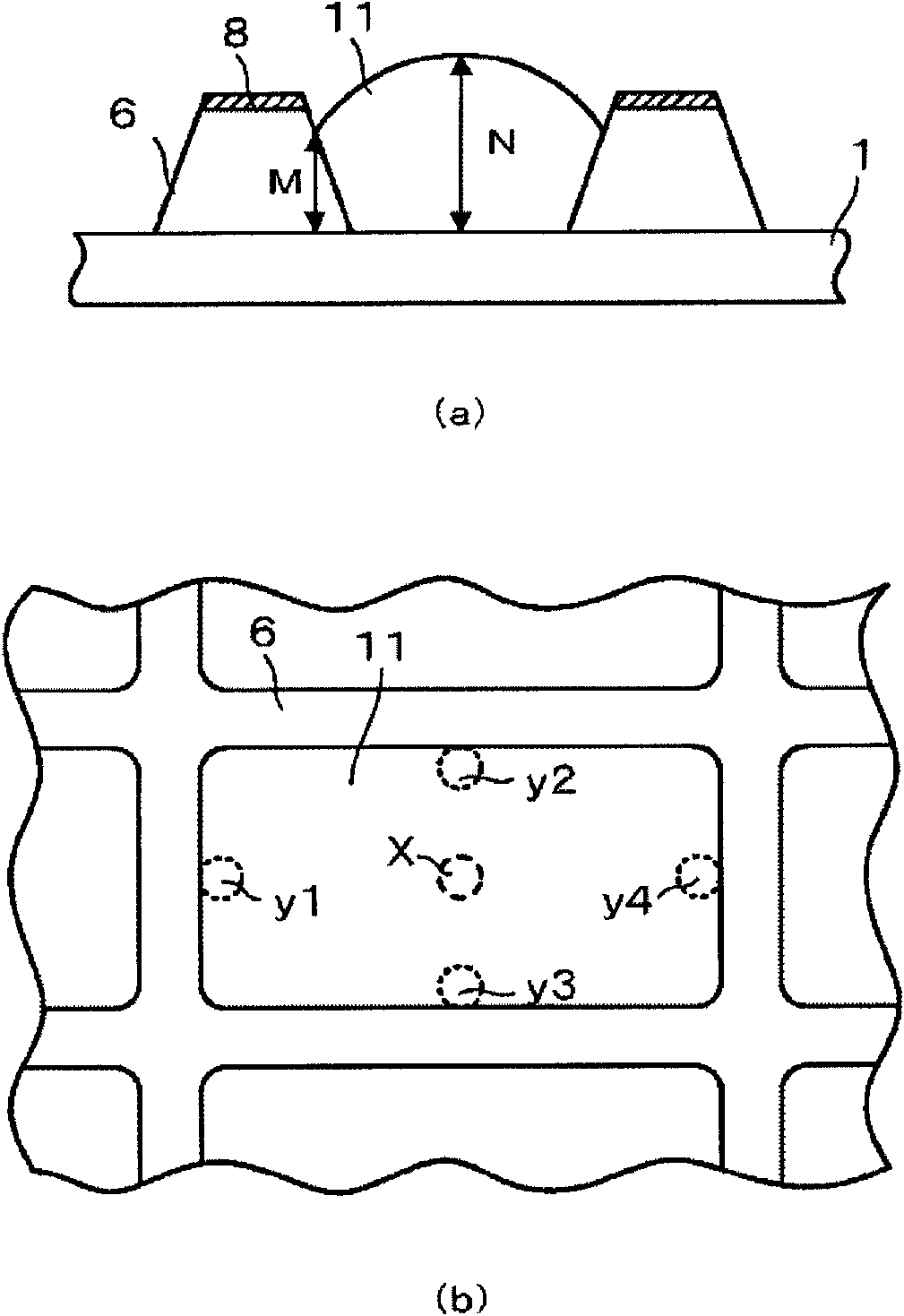

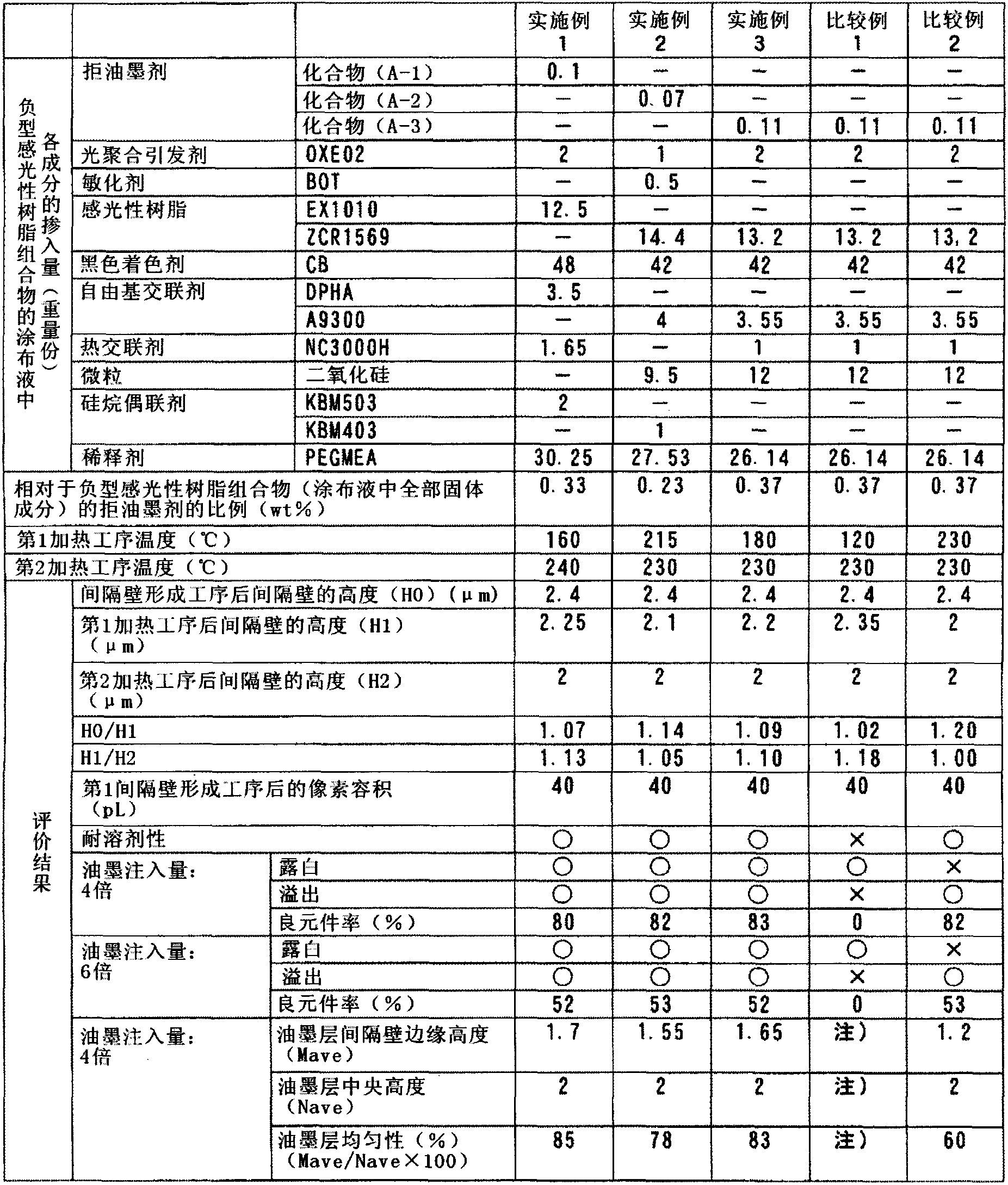

InactiveCN102428395ASufficient heat resistanceAvoid mixing colorsInking apparatusElectroluminescent light sourcesHeat resistanceEngineering

Provided is a method for manufacturing optical elements, said method being capable of: preventing mixing of ink colors when injecting ink as part of the inkjet method, without decreasing the solvent resistance of partition walls; forming even ink layers by ensuring that pixels have a good degree of wettability with respect to the ink; maintaining sufficient heat tolerance in obtained optical elements; and being performed in a simplified and economically advantageous process. After forming, on top of a support substrate, partition walls that comprise a resin composite having an ink-repellent surface, an inkjet is used to inject ink between said partition walls, thereby manufacturing an optical element. After forming the partition walls, before and after the inkjet step, heat treatment is performed such that the thickness of the partition walls decreases by a prescribed fraction, thereby curing the resin composite that constitutes the partition walls.

Owner:ASAHI GLASS CO LTD

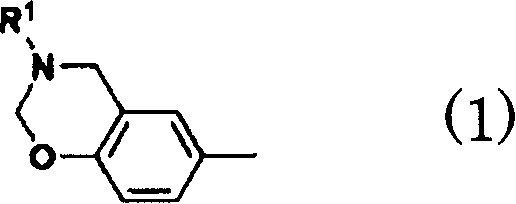

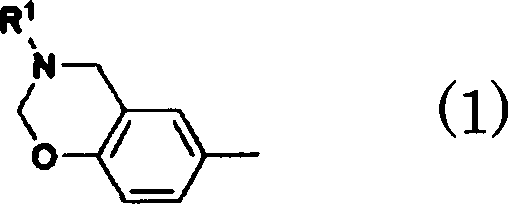

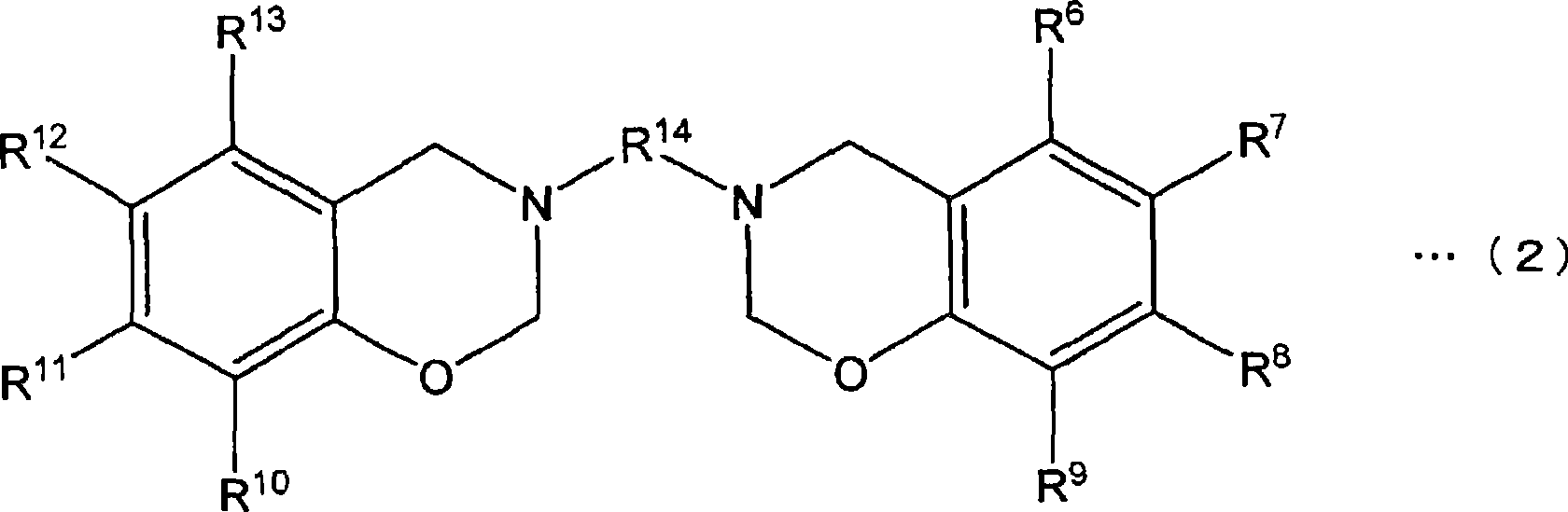

Photosensitive resin composition, its condensate and display panel used interval element formed therewith

ActiveCN1818780AHigh compressive strengthSolve the lack of hardnessSludge treatmentSoil-shifting machines/dredgersHeat resistanceHardness

To provide a photosensitive resin composition capable of being used for forming a spacer which has high hardness, little plastic deformation amount when it is compressed, heat resistance required as a permanent film, and chemical durability; and the spacer formed by using the same. The photosensitive resin composition for the display panel contains, which has the characteristics of (A) an alkali-soluble, carboxyl group-containing photosensitive resin, (B) a polymerizable compound having an ethylenic unsaturated bond, (C) a photopolymerization initiator, and (D) a compound having a oxazin ring.

Owner:TAIYO HLDG CO LTD

Biodegradable layered sheet

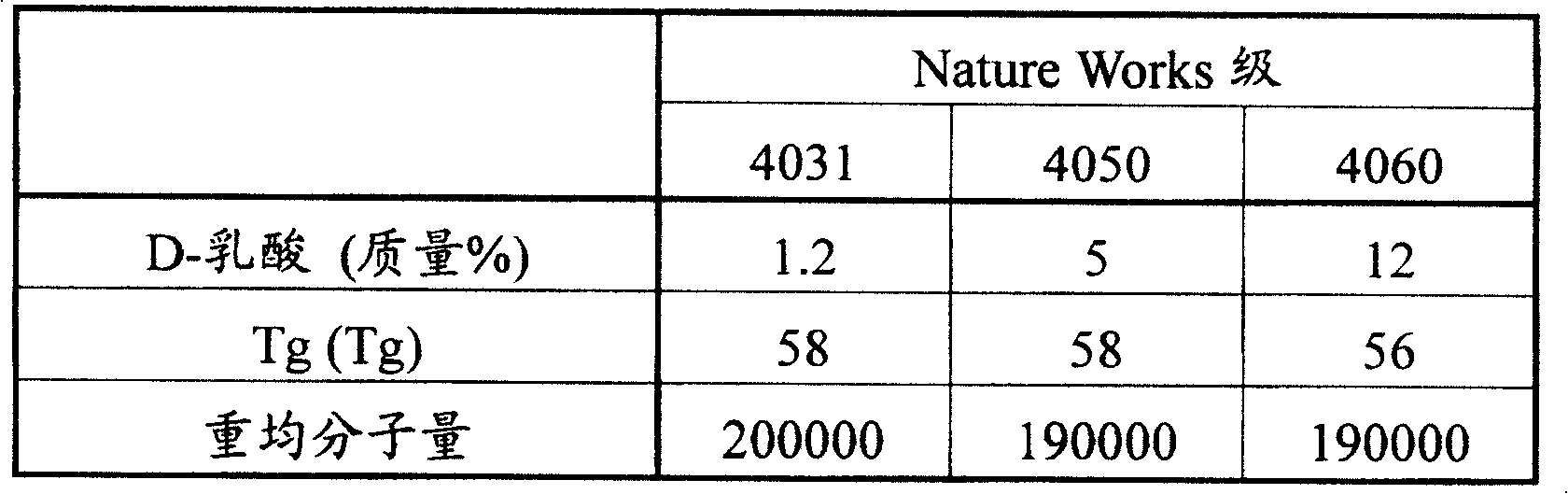

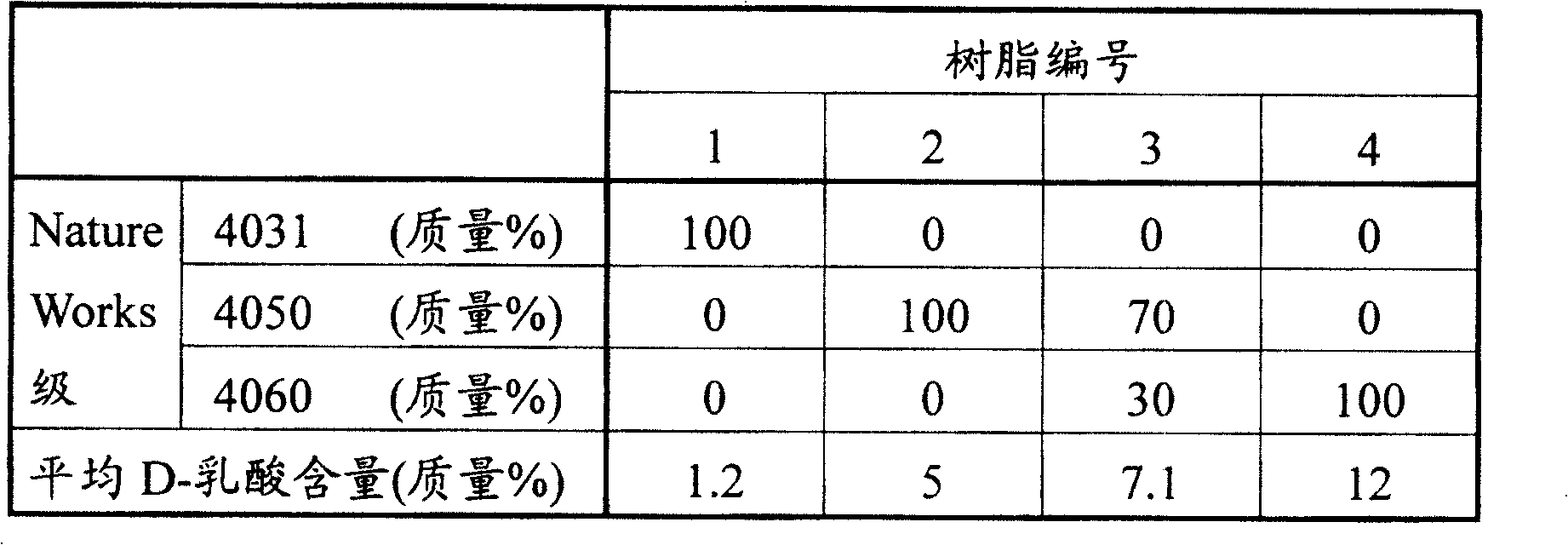

ActiveCN1860026ADoes not cause environmental problemsThe need to promote crystallizationSynthetic resin layered productsGlass transitionPolymer chemistry

It is an object to provide a biodegradable laminated sheet which is high in heat resistance, impact resistance and strength when subjected to loads at high temperature, does not develop wrinkles called 'bridges', which can be easily deep-drawn or formed into blister articles, which are typically complicated in shape. The biodegradable sheet is a laminated sheet comprising at least two layers. Each of the layers forming the laminated sheet is a resin composition comprising 75 to 25% by mass of a polylactic acid resin, and 25 to 75% by mass of a polyester resin having a glass transition temperature not exceeding 0 degrees C and a melting point higher than the glass transition temperature of the polylactic acid resin, and not exceeding the melting point of the polylactic acid resin, based on 100 mass percent of the total amount of the polylactic acid resin and the polyester resin. The D-lactic acid content of the polylactic acid resin contained in one layer, and the D-lactic acid content of the polylactic acid resin in the other layer are determined to satisfy a predetermined relationship. The laminated sheet is subjected to crystallization treatment.

Owner:MITSUBISHI CHEM CORP

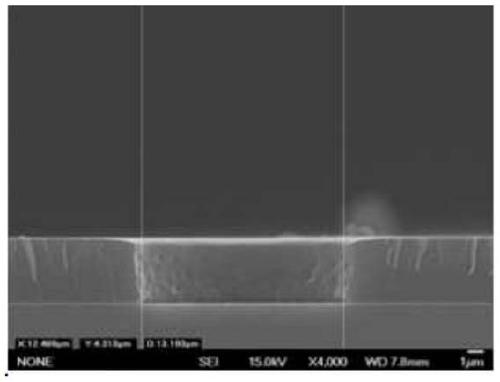

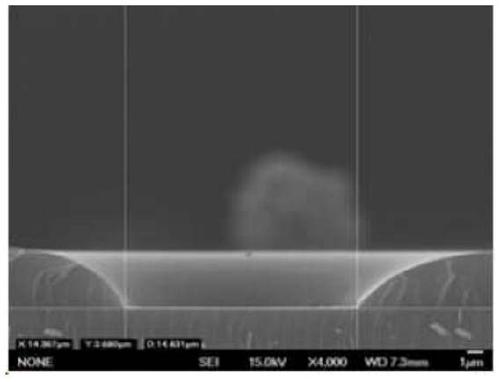

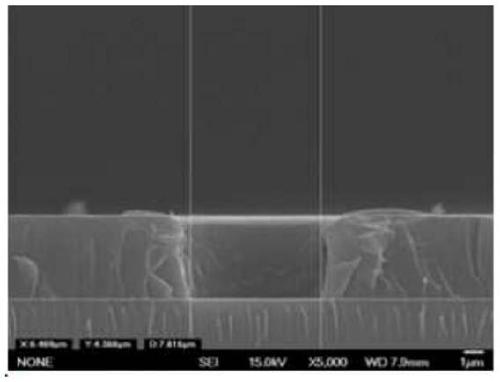

MEMS microphone with a built-in textile material protecting screen

ActiveUS20130058509A1Sufficient heat resistancePrevent be damageTransducer detailsSemiconductor electrostatic transducersMems microphoneEngineering

A MEMS microphone with a built-in textile material protecting screen comprises a microphone body having an opening thereat is arranged a textile material protecting screen which is built-in in the microphone body, during the production phase of the MEMS device called “packaging”.

Owner:SAATI

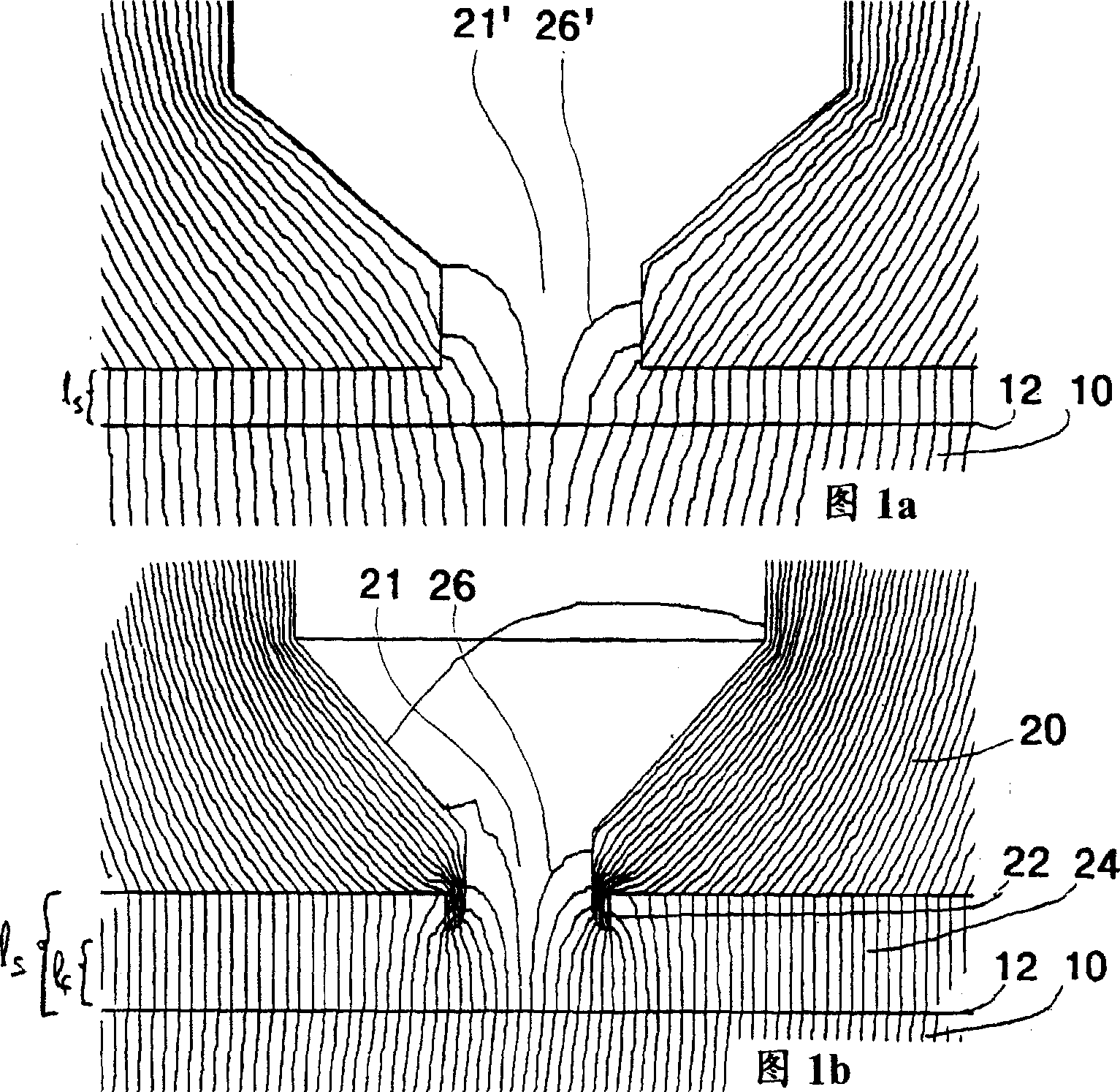

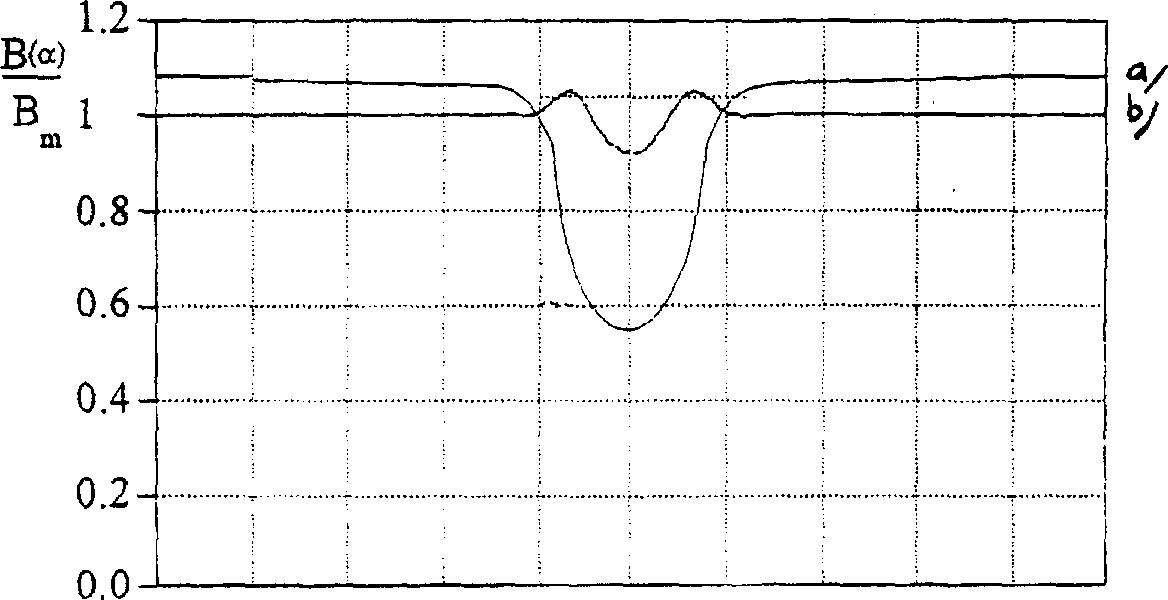

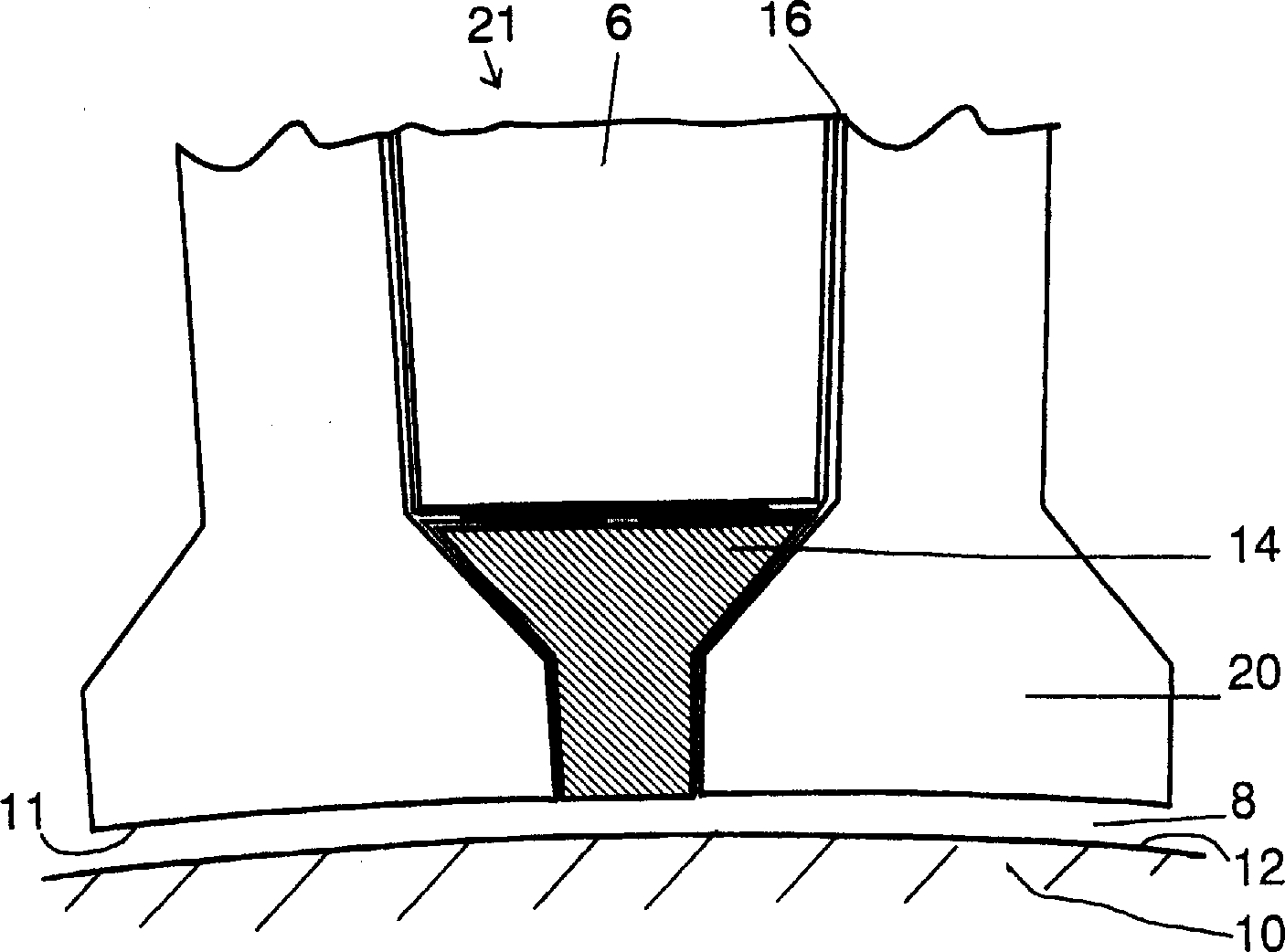

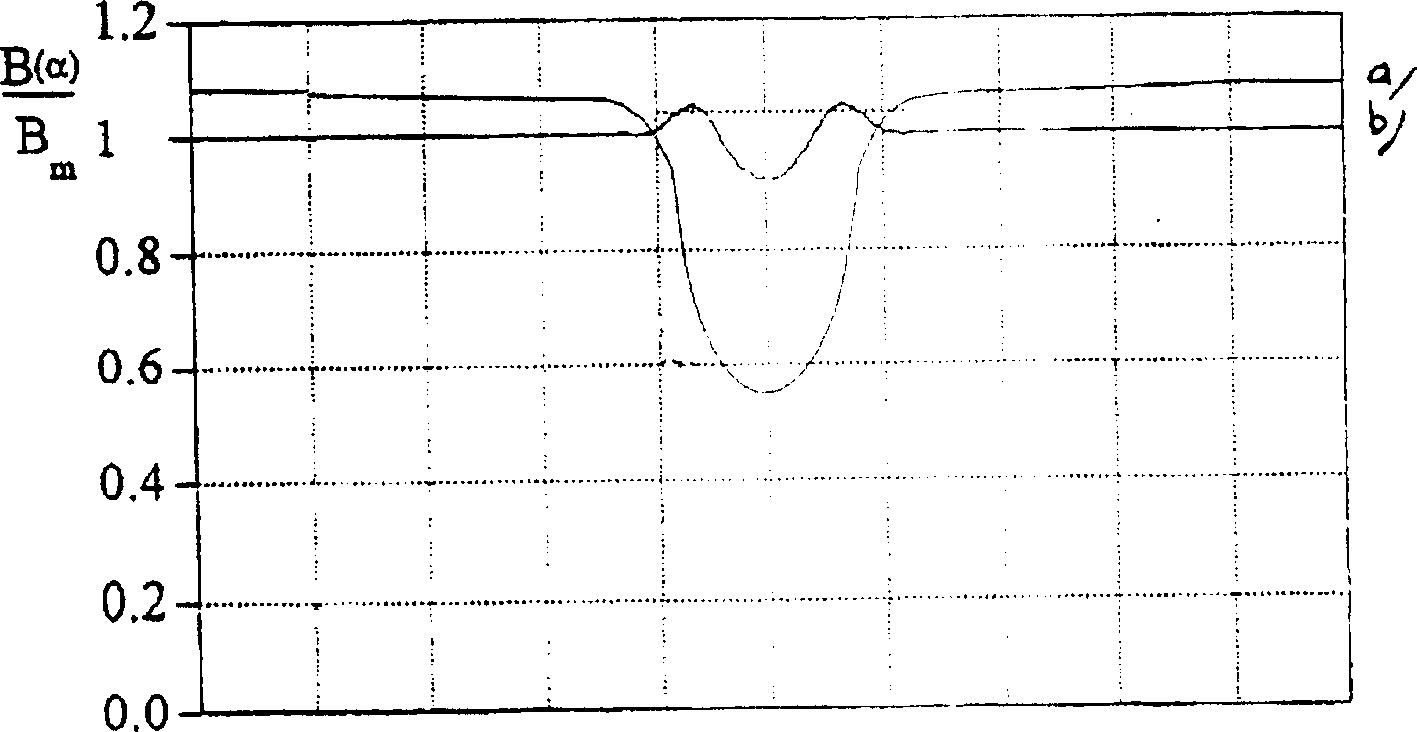

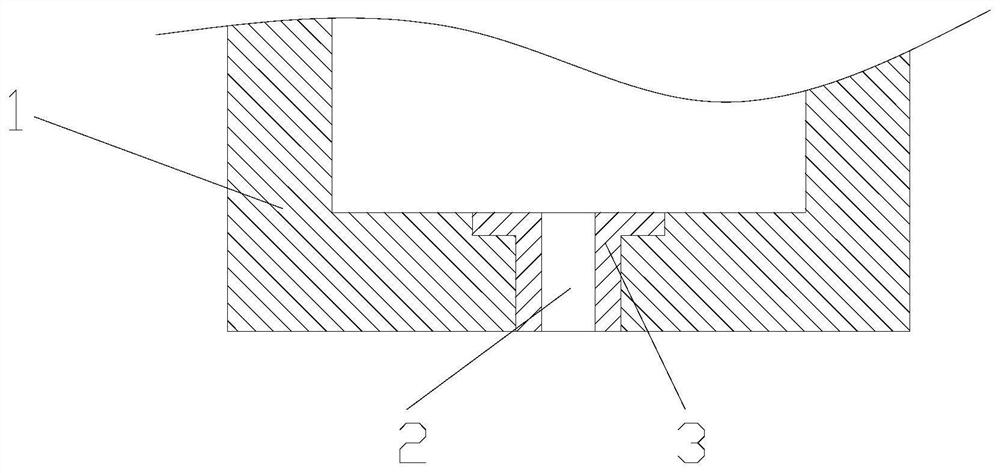

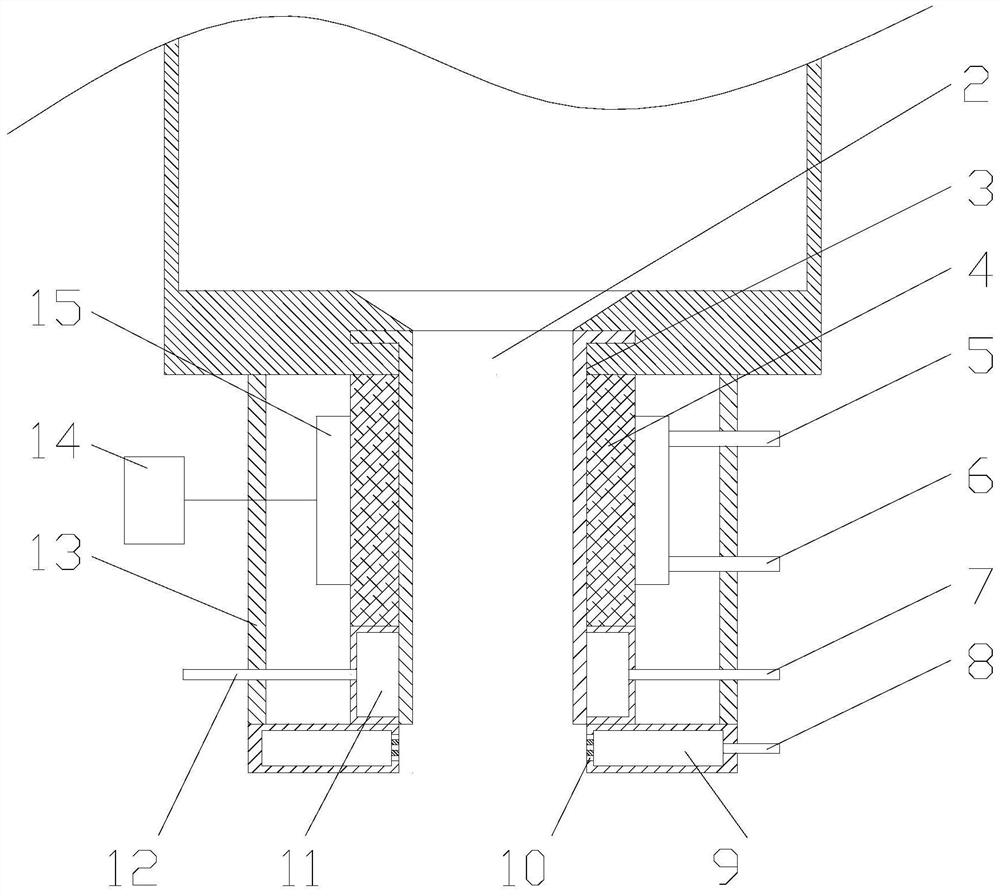

Method and instrument for profiling magnetic flux

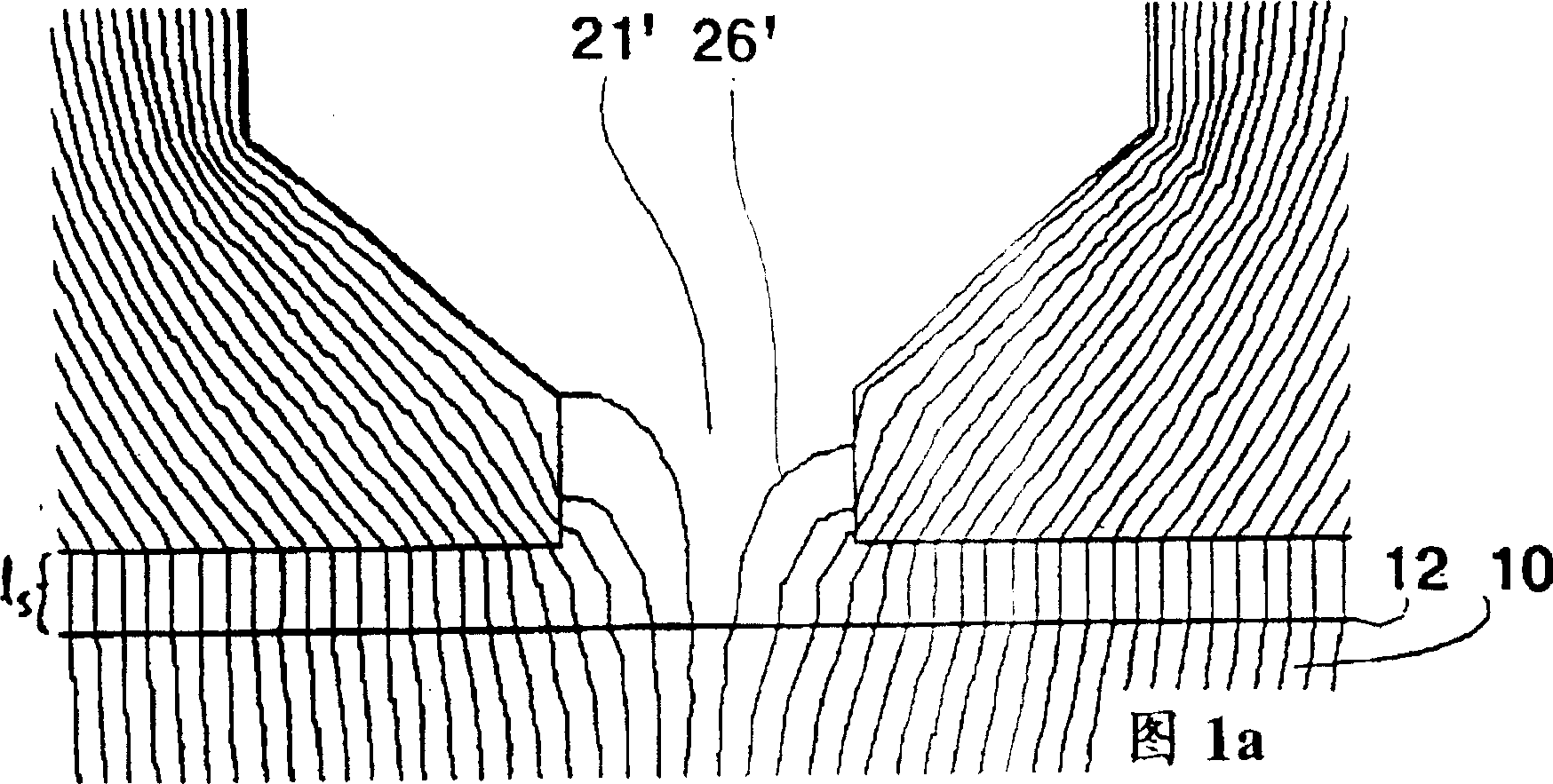

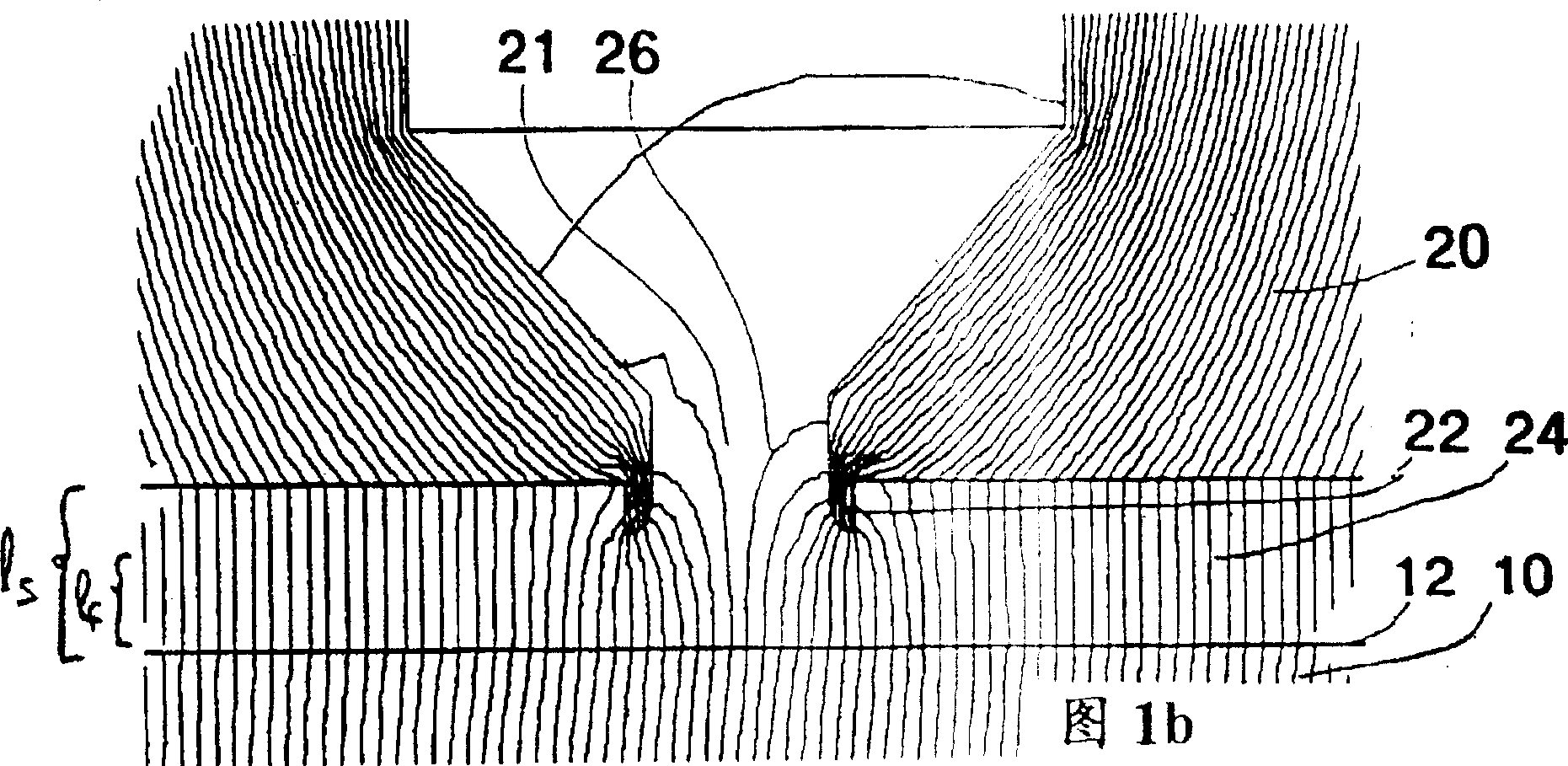

An electric machine according to the invention comprises a rotor means (10) and a stator means (20) surrounding the rotor means having radially extending slots (21). Slot lock components (14) are provided in at least some of said slots. The slot lock extends in said slot essentially to the periphery of the rotor bore of the stator means. The relative permeability ( u r) and the saturated flux density of the slot lock means is essentially good. In the inventive method the density of magnetic flux effecting on the rotor means surface is made more uniform by slot lock components described above.

Owner:贾默・阿拉梅基

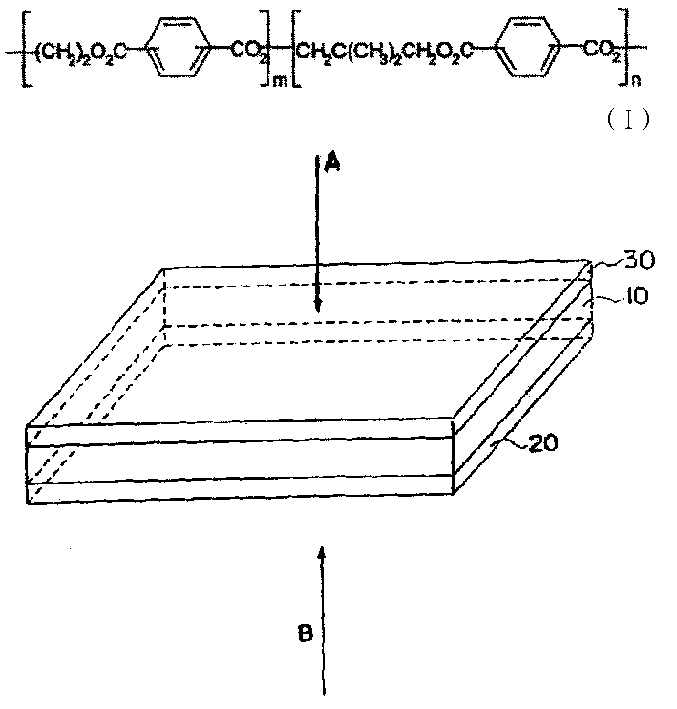

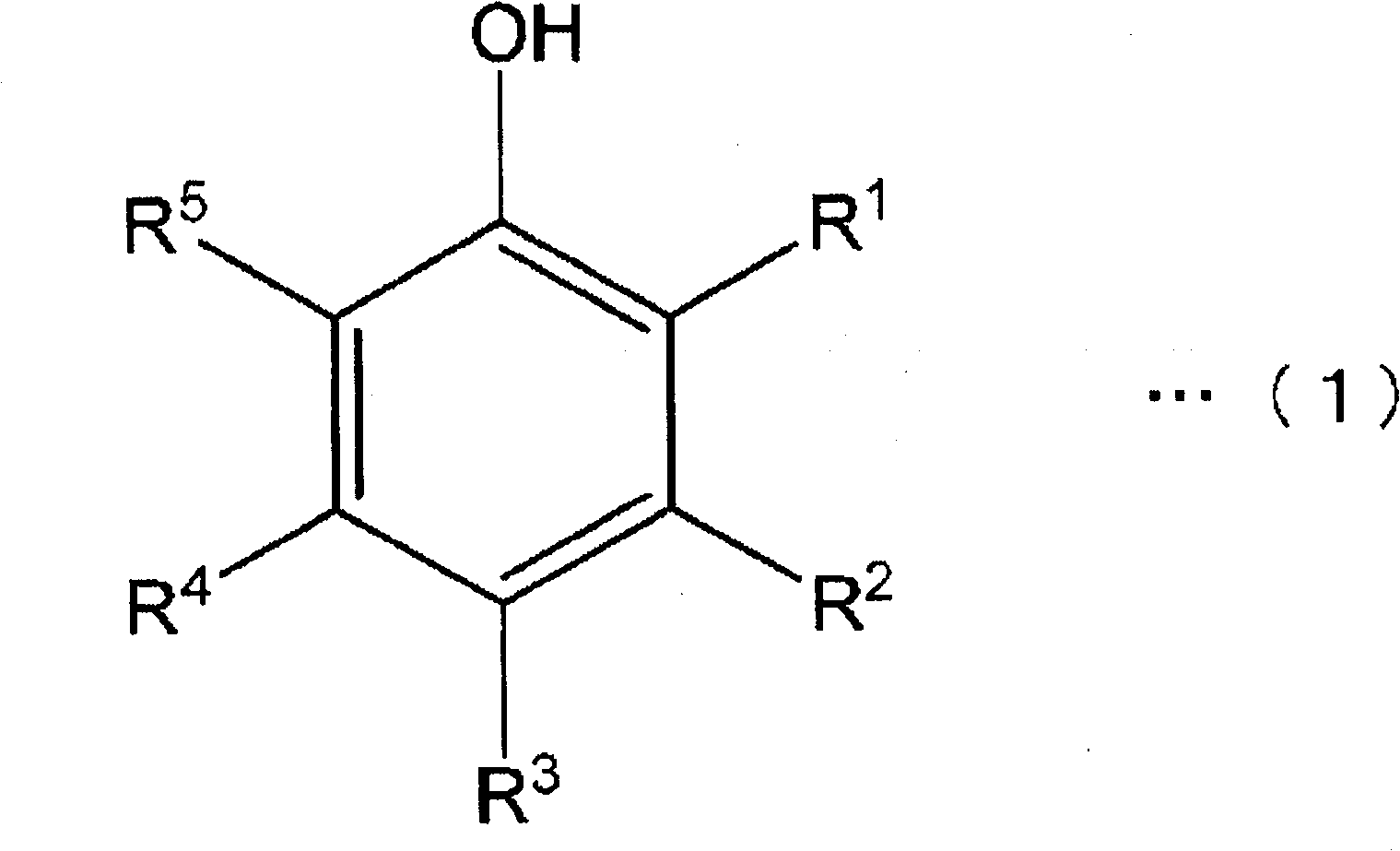

Image recording material and image display material using the same

InactiveCN1467573AImprove visibilitySufficient heat resistanceElectrography/magnetographyThin material handlingImage recordingStructural unit

The present invention provides an image recording material as well as a protective film and an image display material using the same, the image recording material comprising at least: a transparent substrate; an image-receiving layer for forming an image by an electrophotographic system and disposed on one side of the substrate; and a function controlling means disposed on the other side of the substrate; wherein the image-receiving layer include a polyester resin which comprises a structural unit represented by the structural formula (I) and which has a number average molecular weight of 12,000 to 45,000: Structural formula (I) wherein n and m represent integers such that a molar ratio n / m is from 1 to 9.

Owner:FUJIFILM BUSINESS INNOVATION CORP

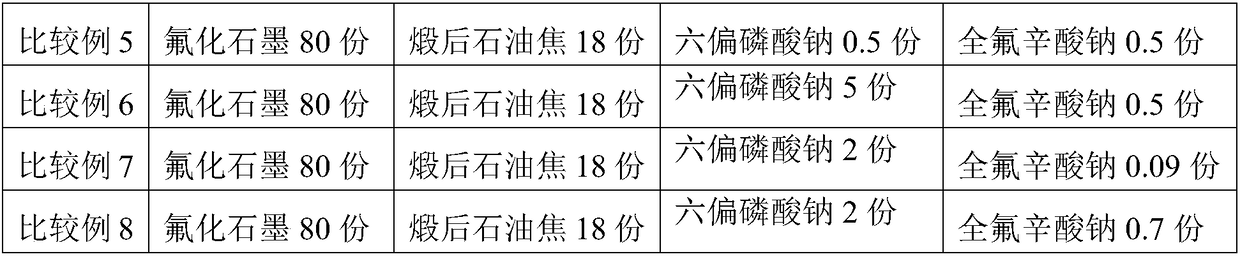

Metal demolding agent

The invention discloses a metal demolding agent which comprises the following raw materials in parts by weight: 70-90 parts of fluoride graphite, 5-25 parts of graphite, 1-3 parts of a dispersing agent and 0.1-0.5 part of a fluorinated surfactant. The metal demolding agent disclosed by the invention has the main components of fluoride graphite and graphite, the two substances are high in melting point and high in lubrication property, then a dense lubricating membrane can be formed on the surface of a mold, the flowability of a metal in the mold can be improved, and the smoothness and the flatness of the surface of a cast part can be maintained; due to addition of the dispersing agent, not only is the aggregation phenomenon of a powder demolding agent solved, but also the demolding capability of a metal cast part can be improved; due to addition of the fluorinated surfactant, not only is the viscosity of the metal cast part reduced, but also effective spreading of the fluoride graphiteand the graphite can be ensured; through the coordinated use of the substances in a certain ratio, the thermal resistance of the demolding agent can be improved, high chemical stability and excellentlubricating properties can be maintained, and both the cast part and the mold are free of residue.

Owner:HUBEI ZHUOXI FLUOROCHEM

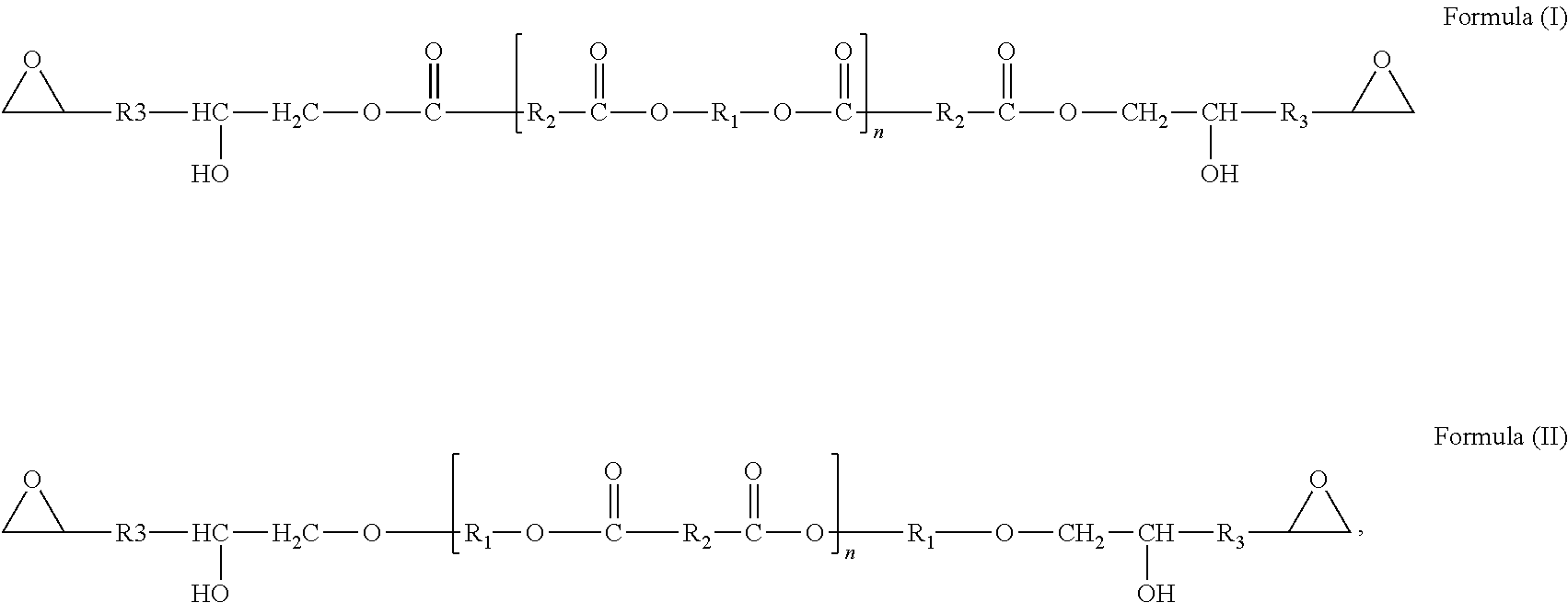

Thermally curable solder resist composition

ActiveUS20110306703A1Sufficient flexibilitySufficient heat resistancePrinted circuit aspectsPrinted circuit manufactureFlexible electronicsPolyester

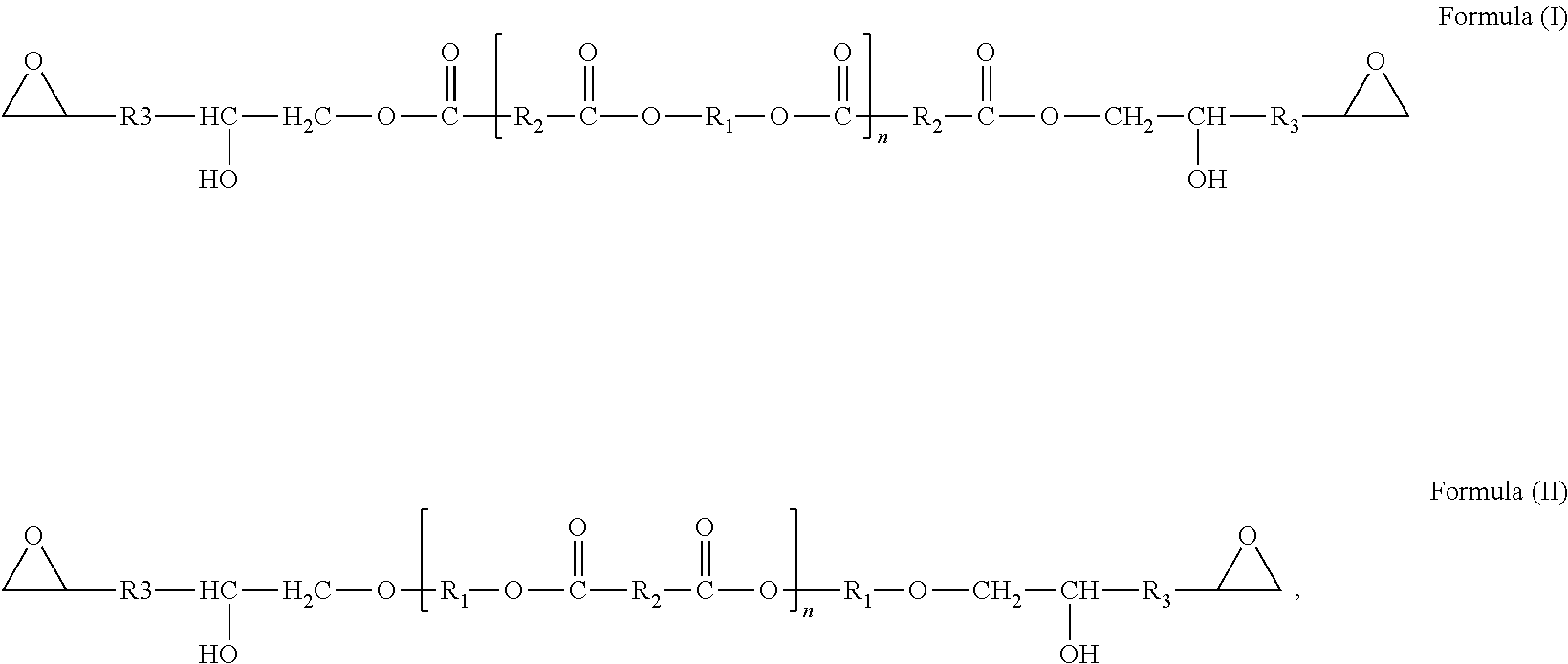

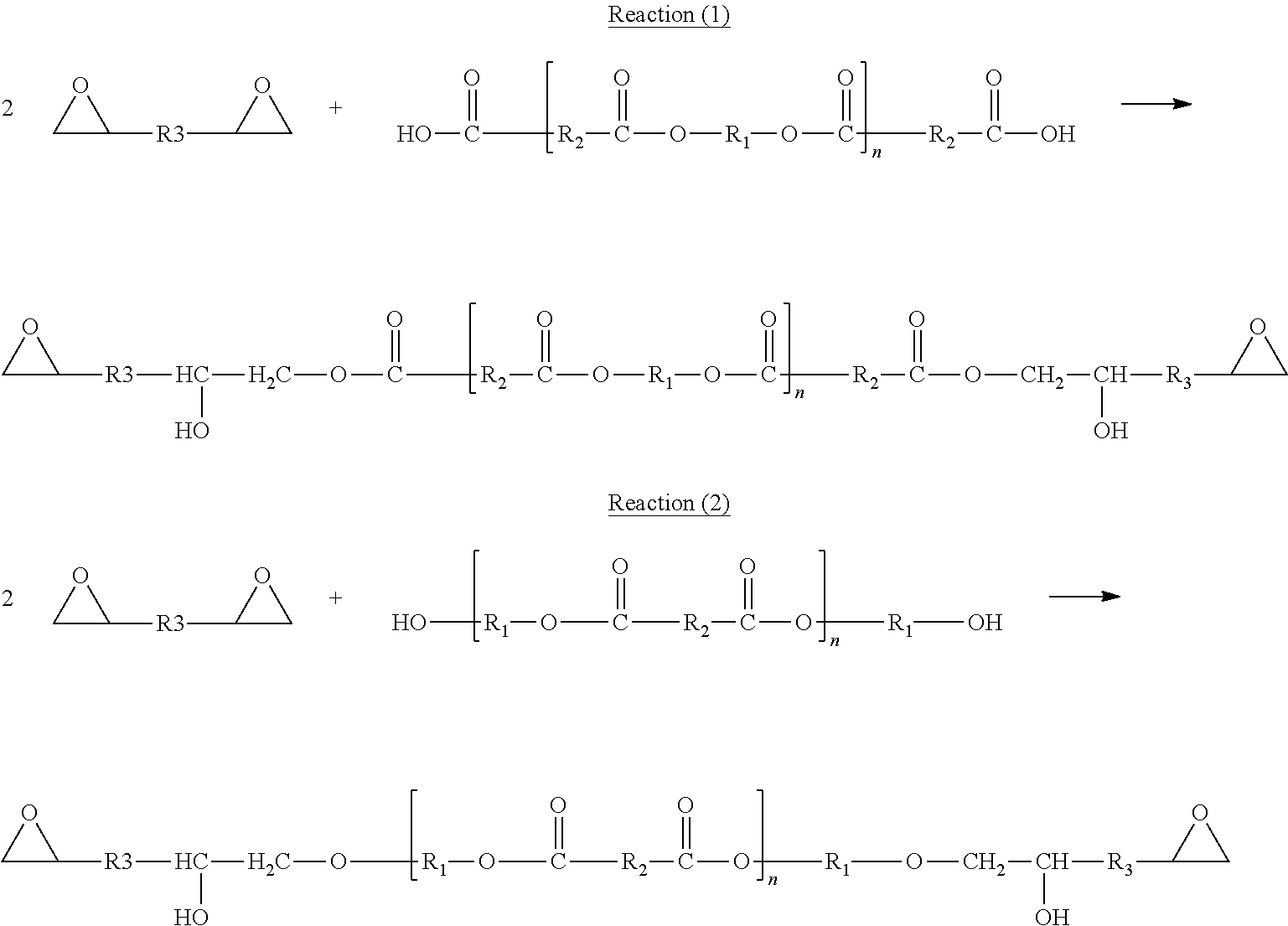

A thermally curable solder resist composition for a flexible printed circuit board is provided. The solder resist composition includes (a) 50-100 parts by weight of an epoxy resin, wherein the epoxy resin includes at least an aliphatic polyester modified epoxy resin having formula (I) or (II), in which, each of R1 and R2, independently, is a C6-38 saturated or an unsaturated carbon chain, R3 is ether, phenyl, a C6-38 heterocyclic or C6-38 saturated carbon chain, n is an integer of 1-10 and the aliphatic polyester modified epoxy resin had a molecular weight of 1000-5000; (b) 1-10 parts by weight of a curing agent; and (c) 1-10 parts by weight of a catalyst.

Owner:IND TECH RES INST

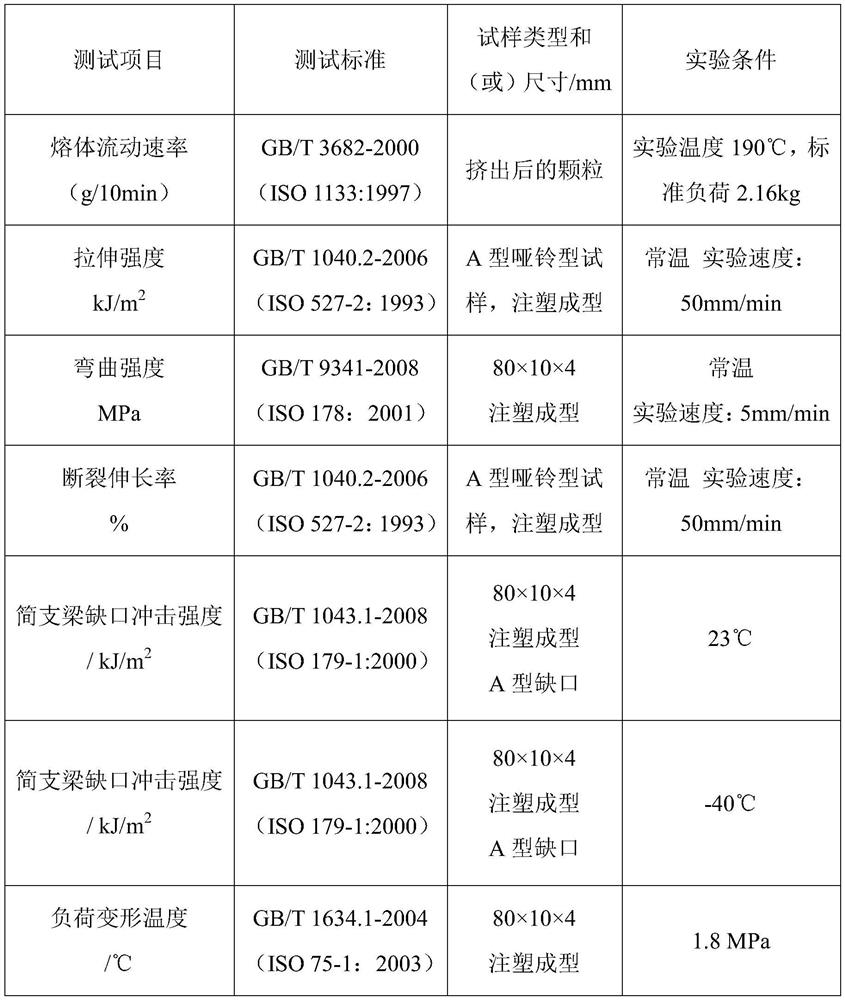

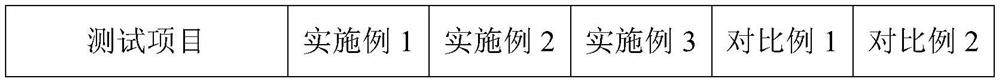

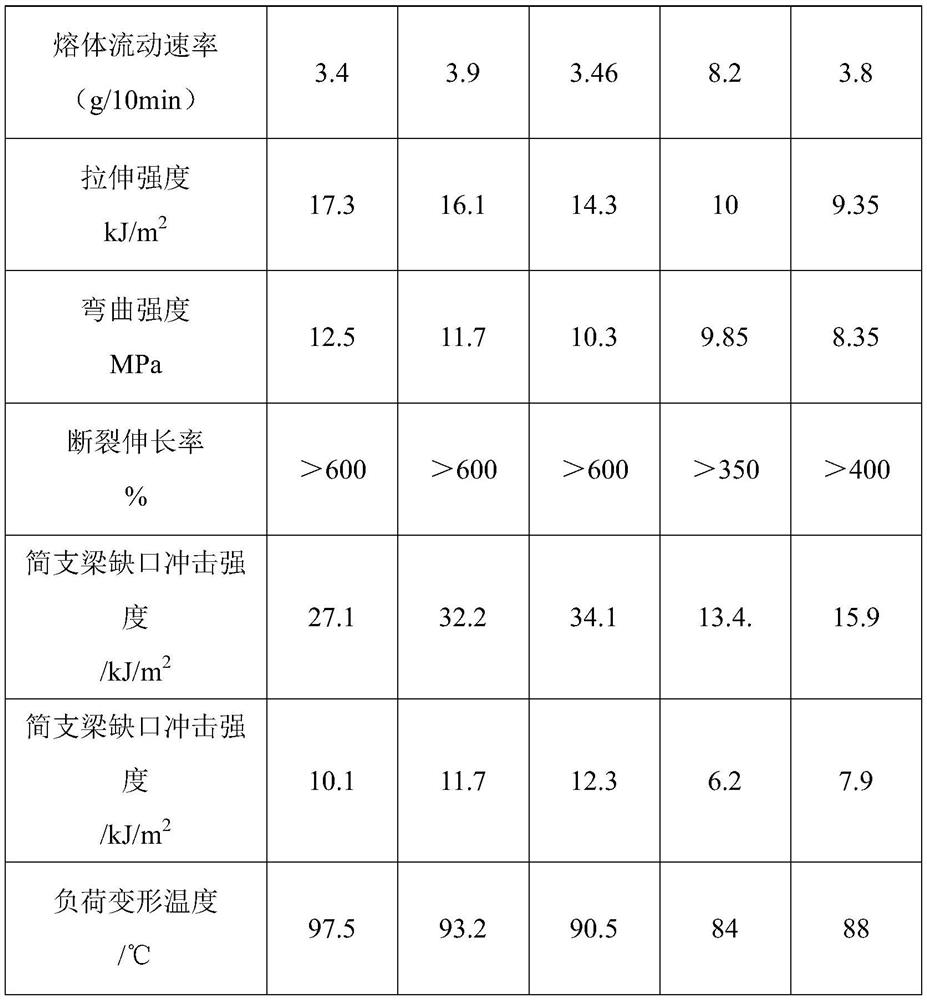

Polyethylene composite material for injection molding and preparation method thereof

The invention relates to a polyethylene composite material for injection molding and a preparation method thereof, and belongs to the technical field of high polymer materials. The polyethylene composite material for injection molding is mainly prepared from auxiliaries and the following raw materials in parts by weight: 20-30 parts of coupling agent modified calcium carbonate, 50-70 parts of high-density polyethylene, 20-40 parts of linear low-density polyethylene and 10-20 parts of a toughening agent, wherein the melt index of the HDPE is 6-10 g / 10 min, and the melt index of the LLDPE is 1-3g / 10min. The material realizes the balance of rigidity and toughness and is suitable for injection processing because of fluidity, the toughness and environmental cracking resistance are improved by the LLDPE, the normal-temperature toughness and low-temperature toughness are improved by the toughening agent, and the coupling agent modified calcium carbonate and the polymer have good compatibility, so that the polyethylene composite material for injection molding has enough rigidity and heat resistance, and the material can maintain better performance in high-temperature, normal-temperature and low-temperature environments.

Owner:HENAN SENYUAN ELECTRIC CO LTD

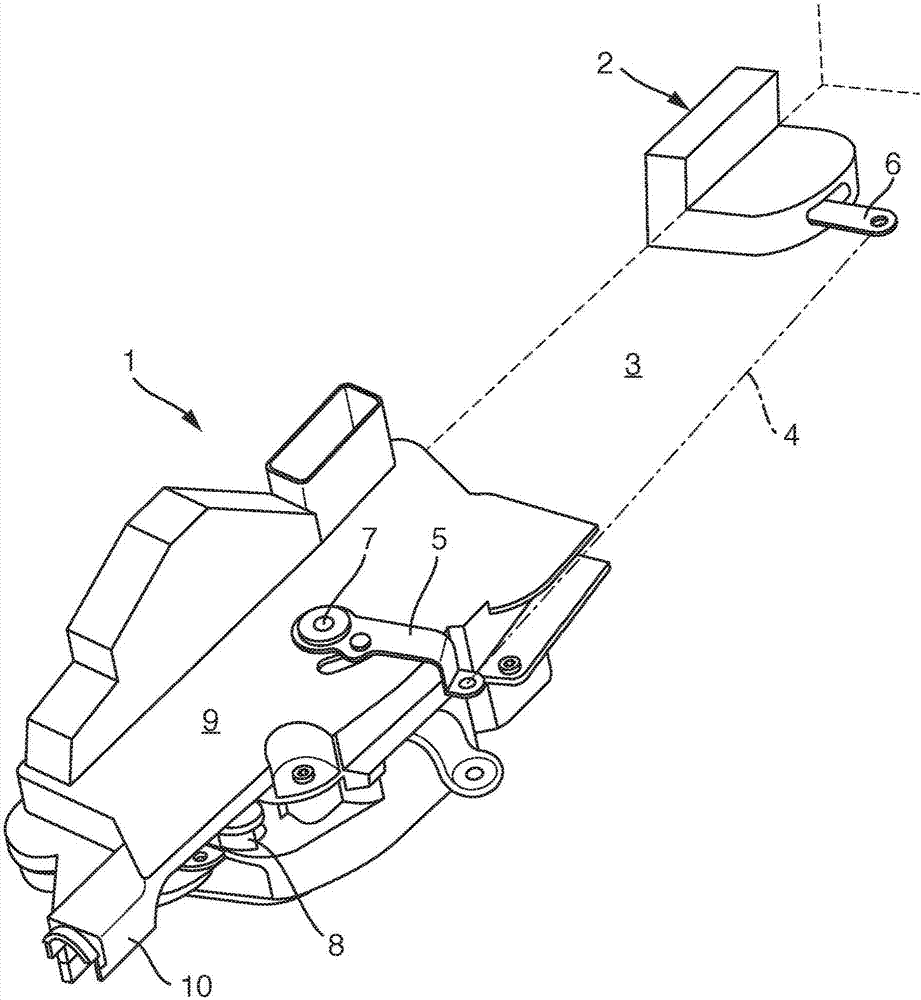

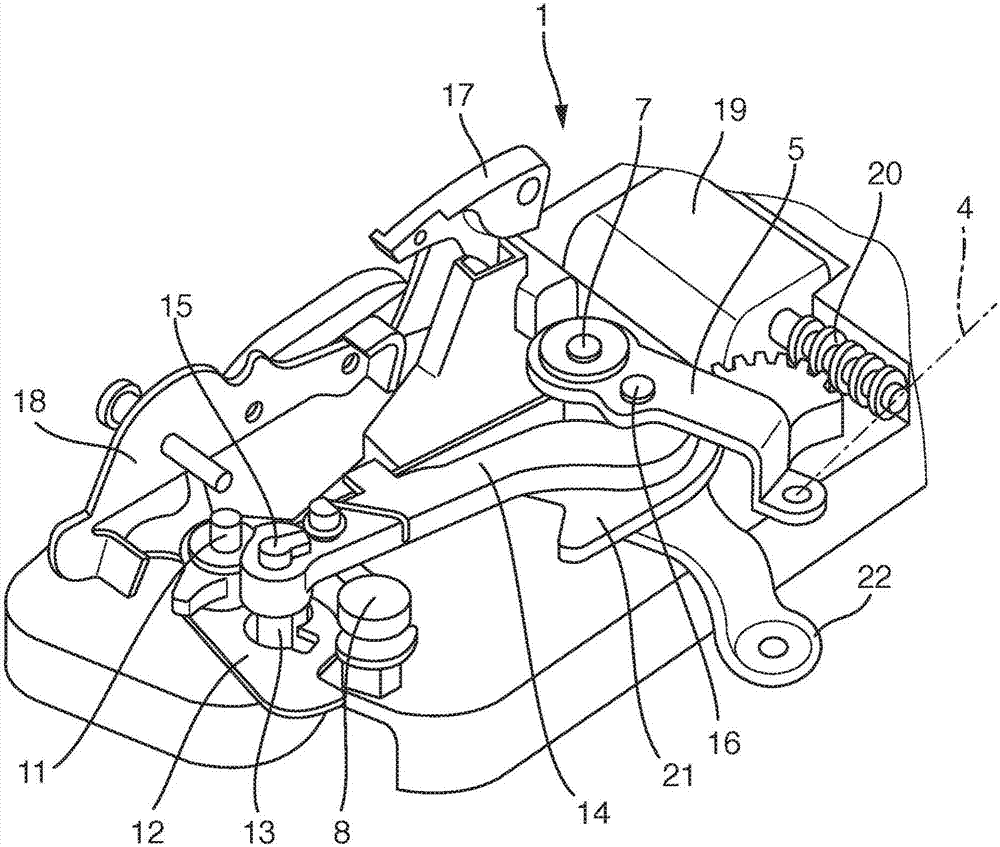

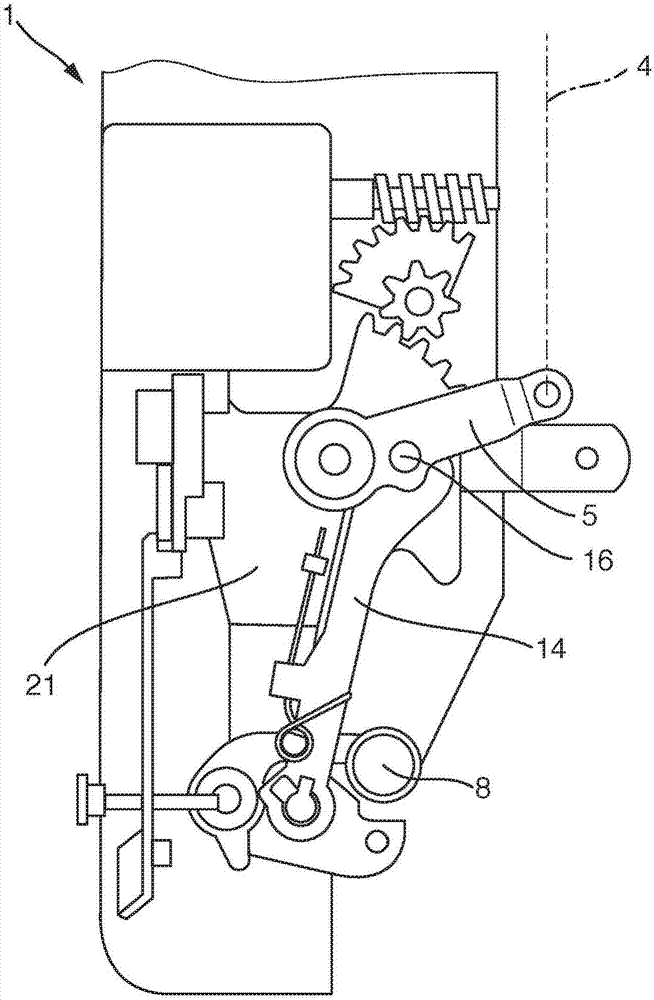

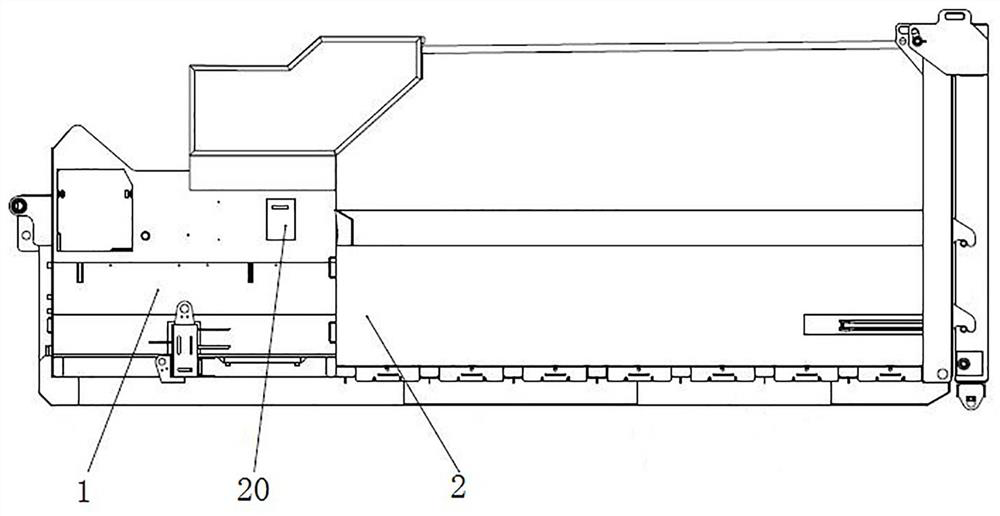

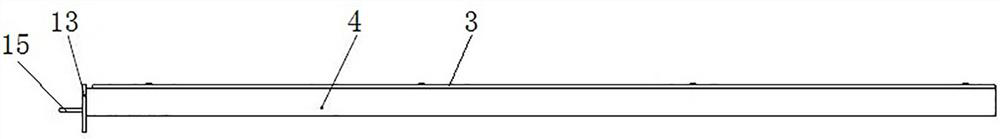

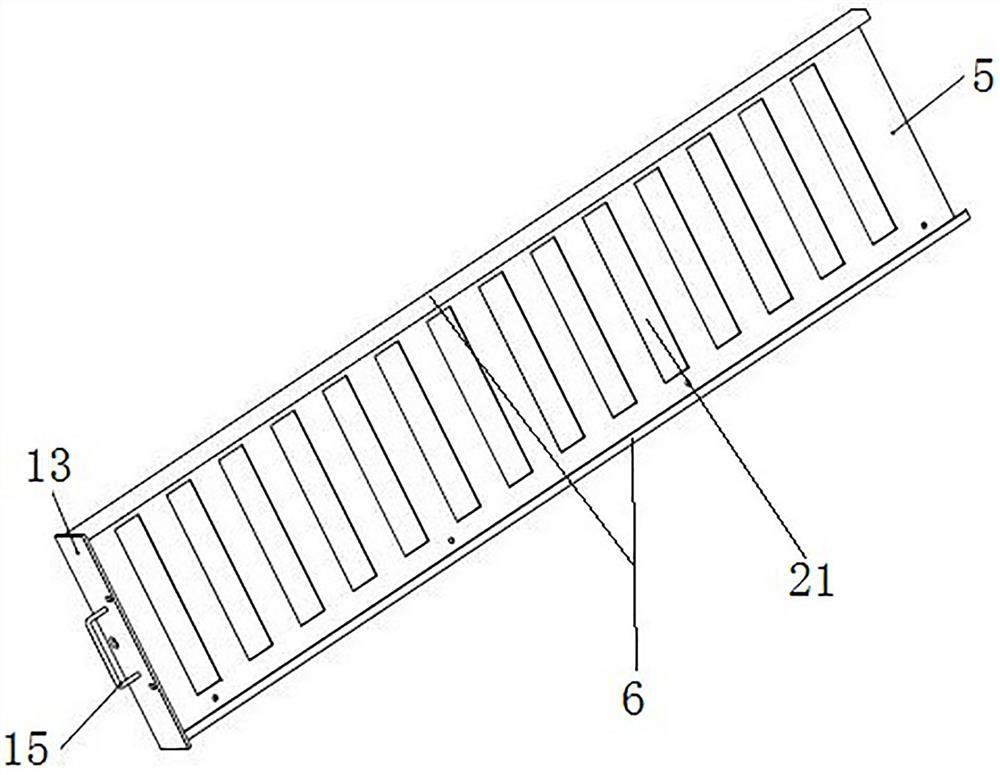

Motor vehicle door lock

ActiveCN107257877AReliable unlockSimple structurePower transmission/actuator featuresElectrical locking actuatorsCouplingLocking mechanism

The invention relates to a motor vehicle door lock (1) which comprises a locking mechanism having: a rotary latch and at least one pawl; a release lever (12); a locking device (21), the release lever (12) cooperating with the locking device (21) via a coupling lever (13); and an actuating lever (8), the locking mechanism being at least indirectly unlockable by means of the actuating lever (8). An additional motor vehicle door lock (2) is provided, and said vehicle door lock (2) can be actuated via a second coupling lever (14) and by means of the actuating lever (8), the first and the second coupling lever (13, 14) having a common pivot axis (15).

Owner:KIEKERT AG

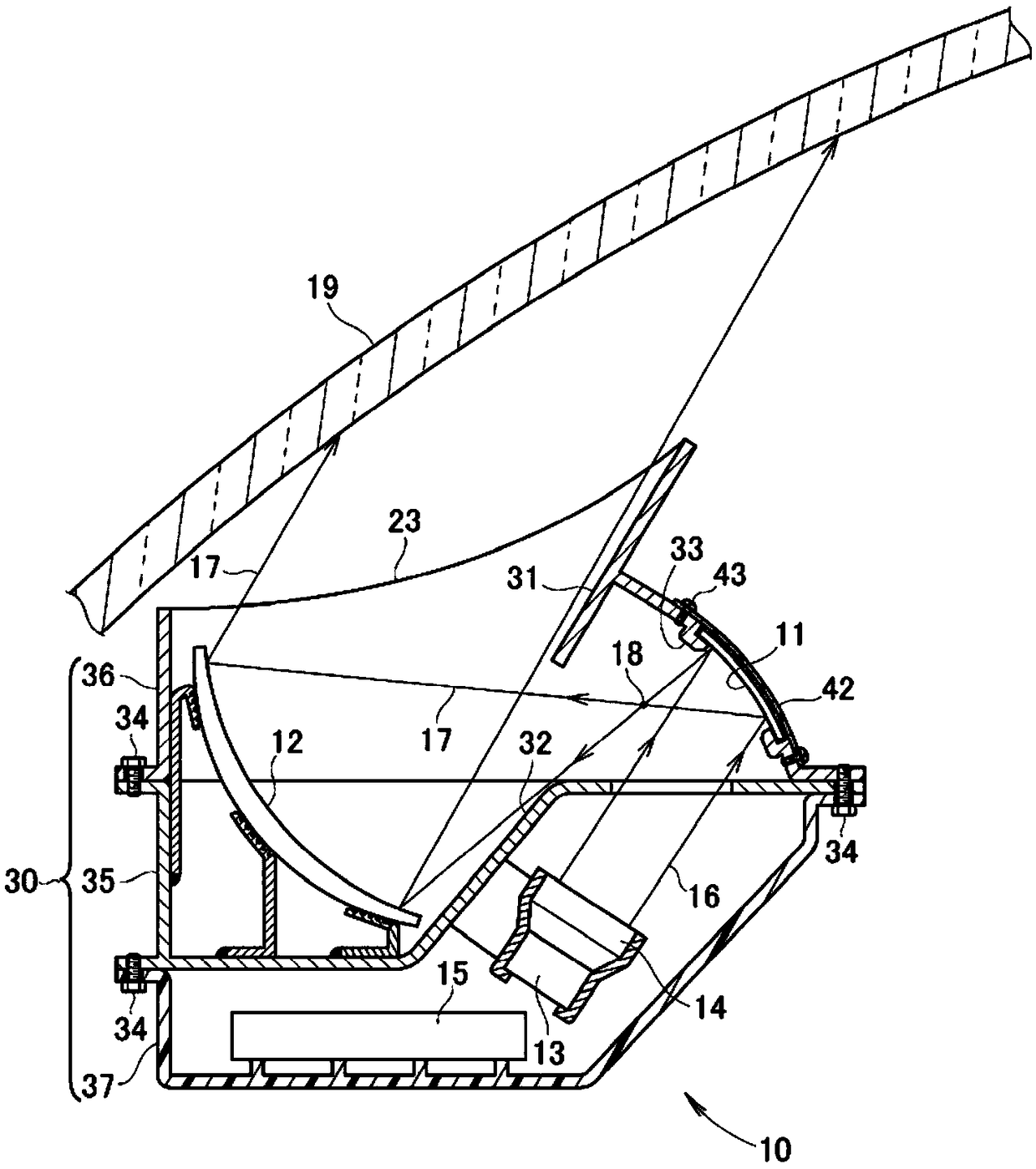

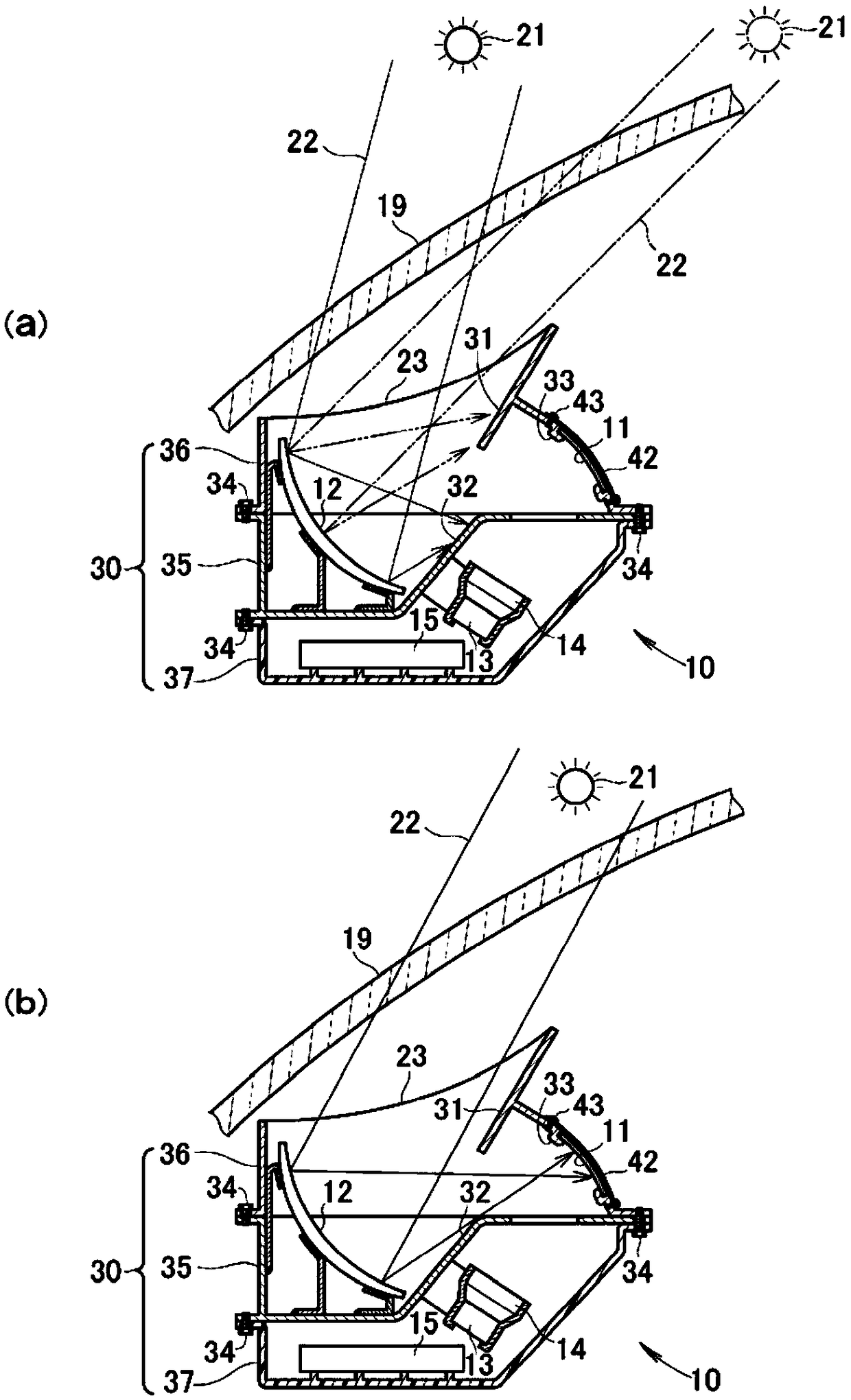

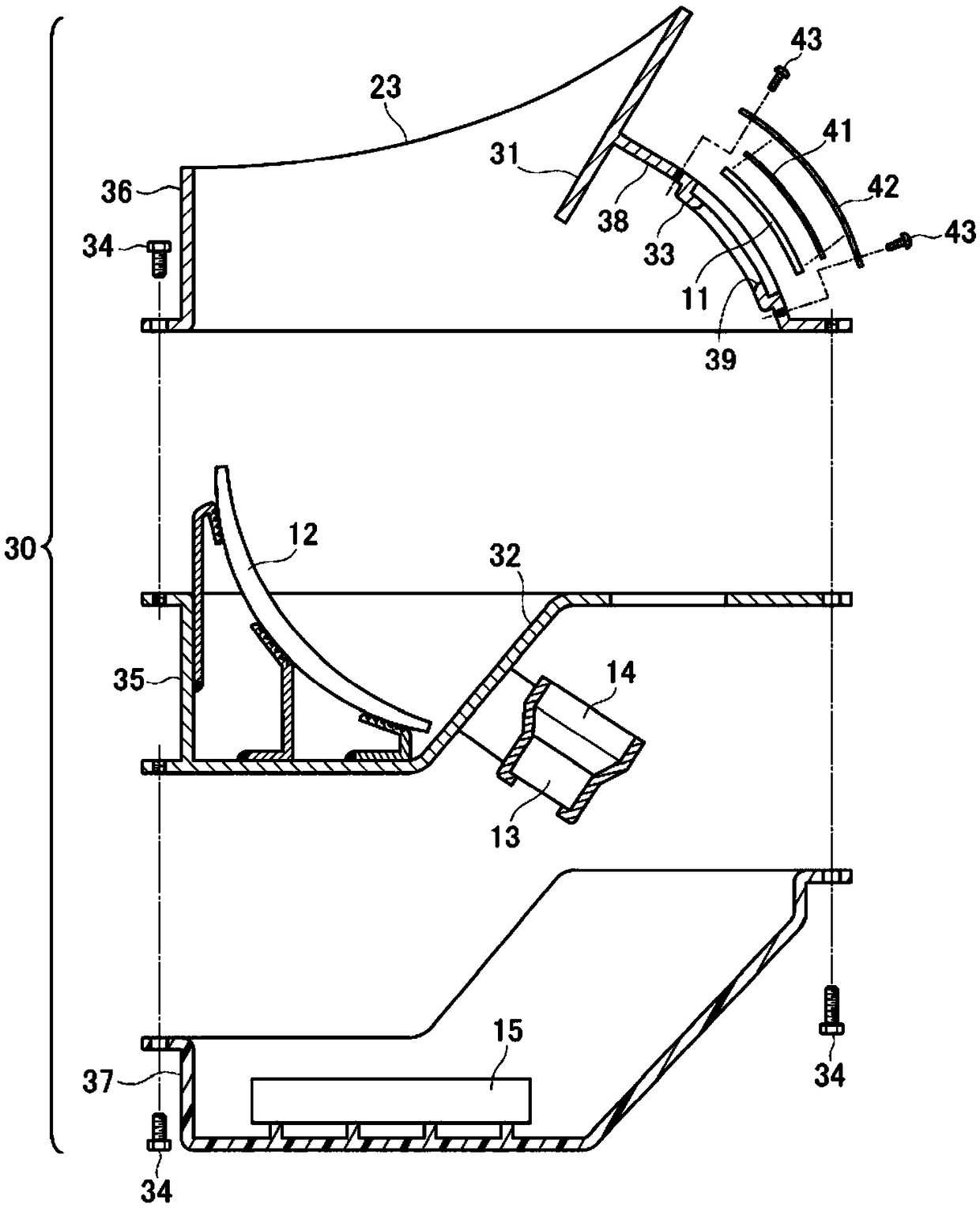

Head-up display device

ActiveCN109070747ALower supply costsCurb Supply CostsMirrorsVehicle componentsDisplay deviceMechanical engineering

The present invention addresses the problem of providing a head-up display device having a structure such that the procurement cost of a bezel can be suppressed. A bezel part (33) is integrally formedon a curved wall portion (38) of an upper cover (36). Since the upper cover (36) is a die-cast product, the curved wall part (38) can be manufactured by one-time casting (die-casting) with a through-hole (39) and the bezel part (33). Since the bezel part (33) is integral with the upper cover (36), it is possible to reduce the procurement cost of the bezel part (33) compared to when the bezel part(33) is a separate part. If the bezel is configured as a separate part having a high heatproof temperature, the procurement cost of the bezel increases. However, if the bezel part is formed integrally with the case simply by partially deforming the case, as described in the present invention, it is possible to reduce the procurement cost of the bezel part.

Owner:NIPPON SEIKI CO LTD

Paint used for casting

InactiveCN105127366ASufficient heat resistanceSufficient high temperature stabilityFoundry mouldsFoundry coresFiberCarbon fibers

The invention relates to the field of molding sand casting, in particular to paint used for casting. The paint is characterized by comprising the following ingredients in parts by mass: 10 to 20 parts of phenolic resin, 15 to 25 parts of rosin, 40 to 50 parts of carriers, 5 to 8 parts of zircon powder, 2 to 4 parts of carbon fiber, 5 to 6 parts of additives, 10 to 15 parts of ceramic powder and 2 to 5 parts of fentin hydroxide. The paint has sufficient rapid-heating-resistant performance and high-temperature stability, and can bear the thermal stress action during high-temperature intense heating; coatings do not crack or peel off; and good suspension stability and good bondability are achieved.

Owner:蚌埠冠宜型材科技有限公司

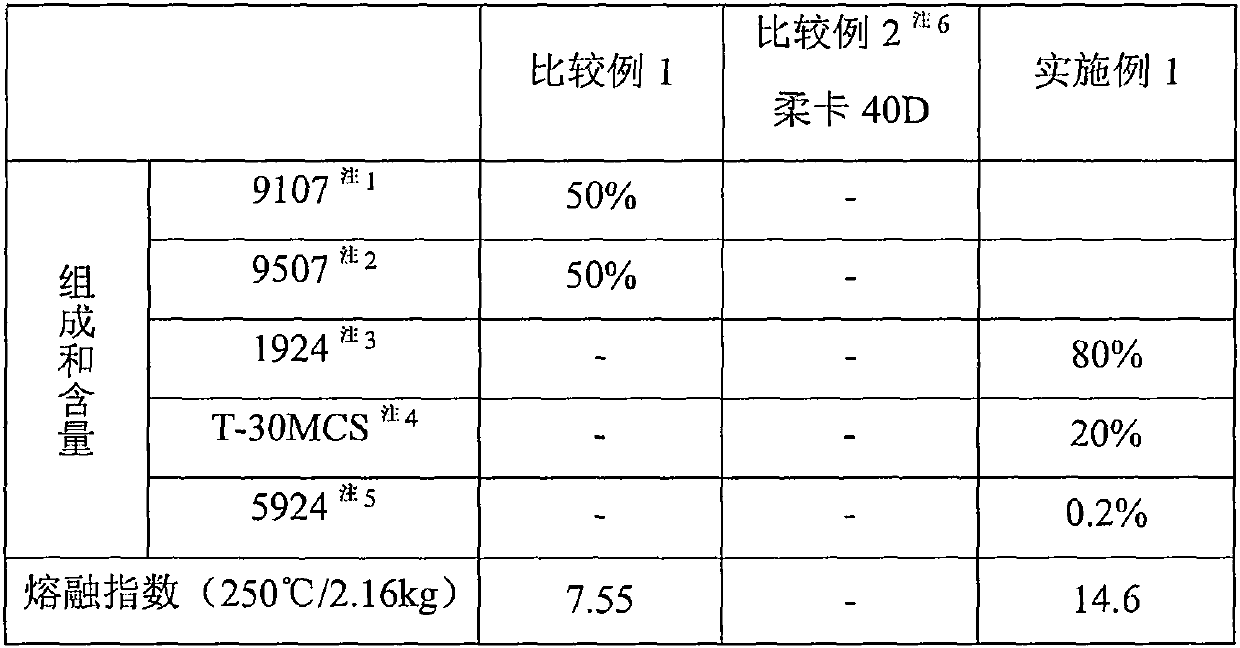

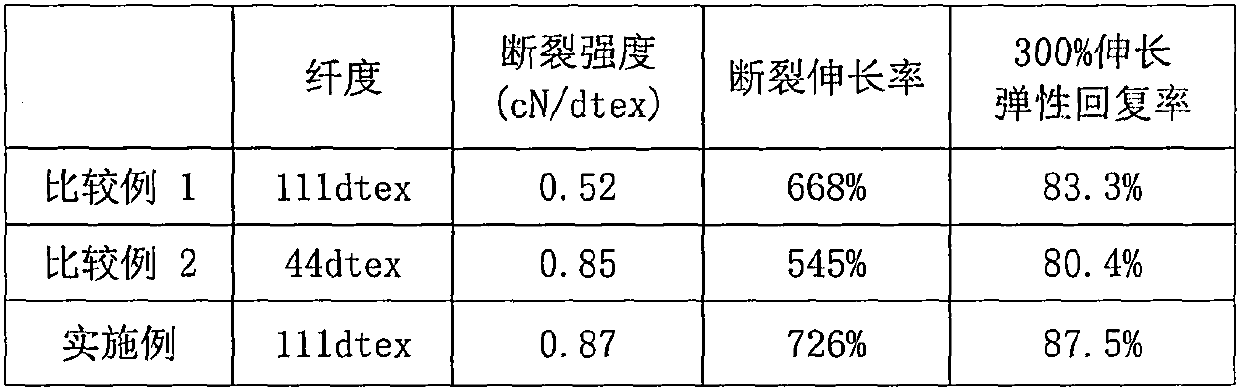

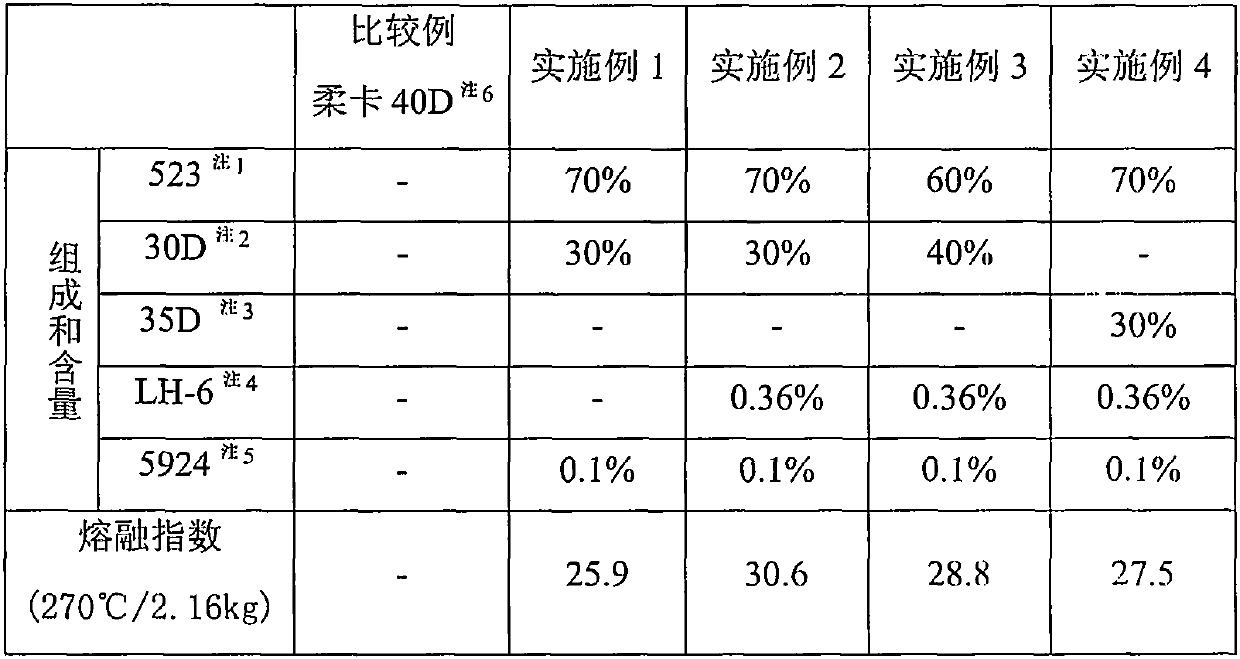

Novel styrene block copolymer mixture elastic fiber and manufacturing method thereof

ActiveCN110067039AResistant to subsequent processing temperaturesHigh breaking strengthConjugated synthetic polymer artificial filamentsArtifical filament manufactureThermoplasticPolyolefin

The object of the invention is to provide a manufacturing method of a novel styrene block copolymer mixture elastic fiber. A direct result of the invention is to provide a polyolefin elastic fiber which does not require crosslinking. The elastic fiber has sufficient elasticity and heat resistance without irradiation, can meet the temperature requirements of normal processes such as dyeing, dryingand heat setting of most textile fabrics or elastic cords, and significantly reduces the production cost and simplifies the production process. A novel styrene block copolymer mixture is mainly prepared from a grafted styrene block copolymer A and crystalline thermoplastic engineering plastic B according to a weight ratio of 90:10 to 70:30. The styrene block copolymer A is a grafted styrene blockcopolymer, and the crystalline thermoplastic engineering plastic B has a density of 0.90 to 1.40 g / cm<3> and a melting point between 160 and 260 DEG C.

Owner:上海梦丝新材料科技有限公司

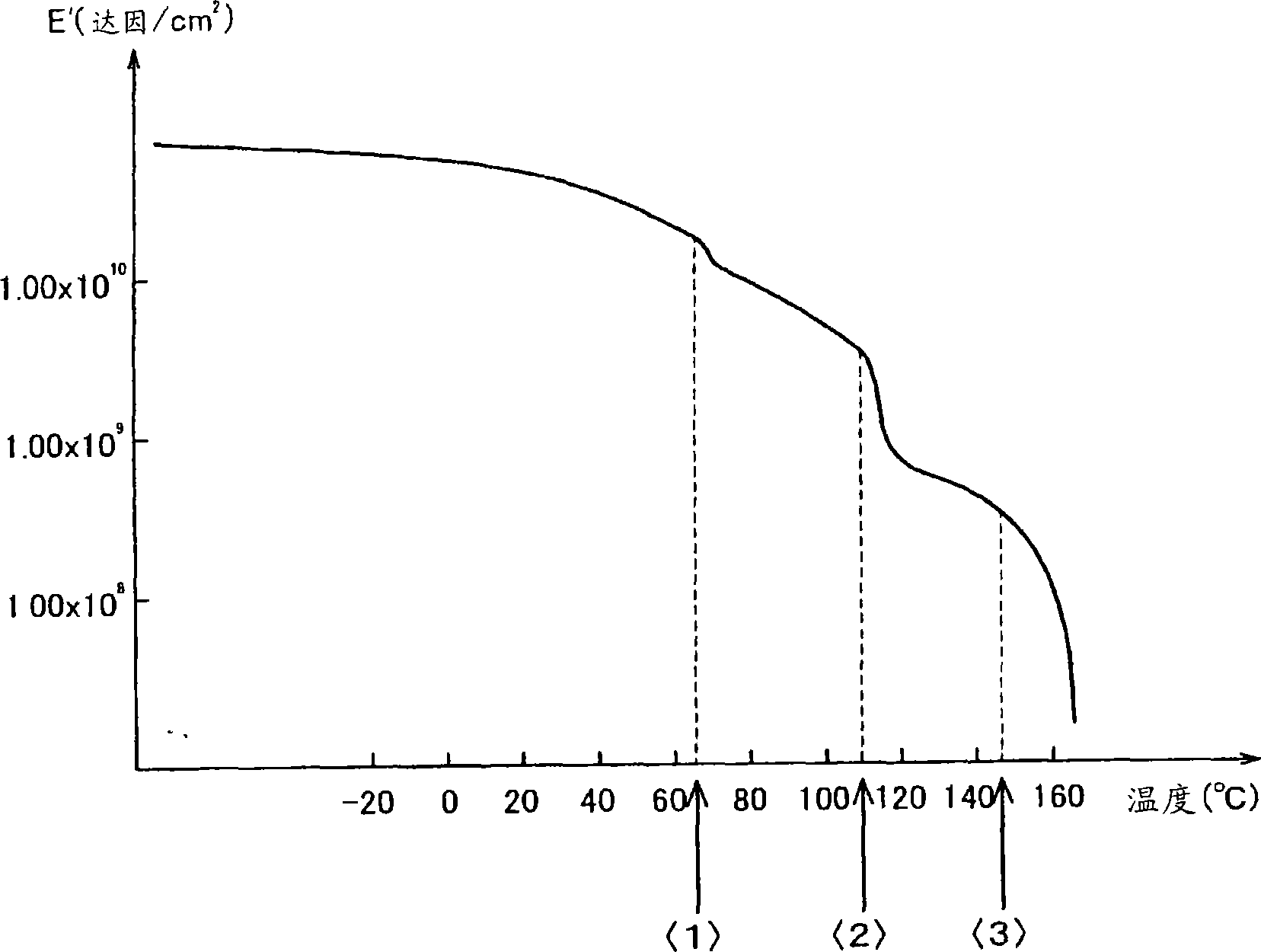

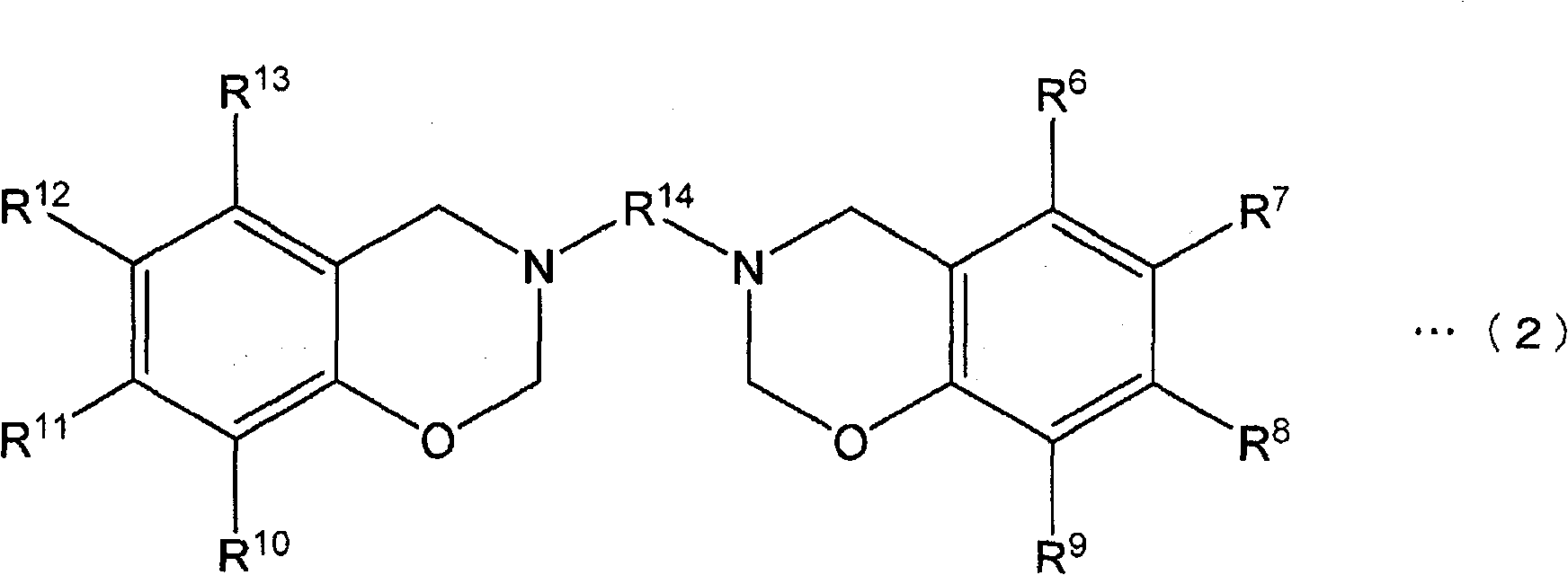

Thermosetting compound, composition containing the same, and molding

InactiveCN101228207BImprove adaptabilityLow dielectric constantOrganic chemistryHydrogen atomDielectric loss

Owner:SEKISUI CHEM CO LTD

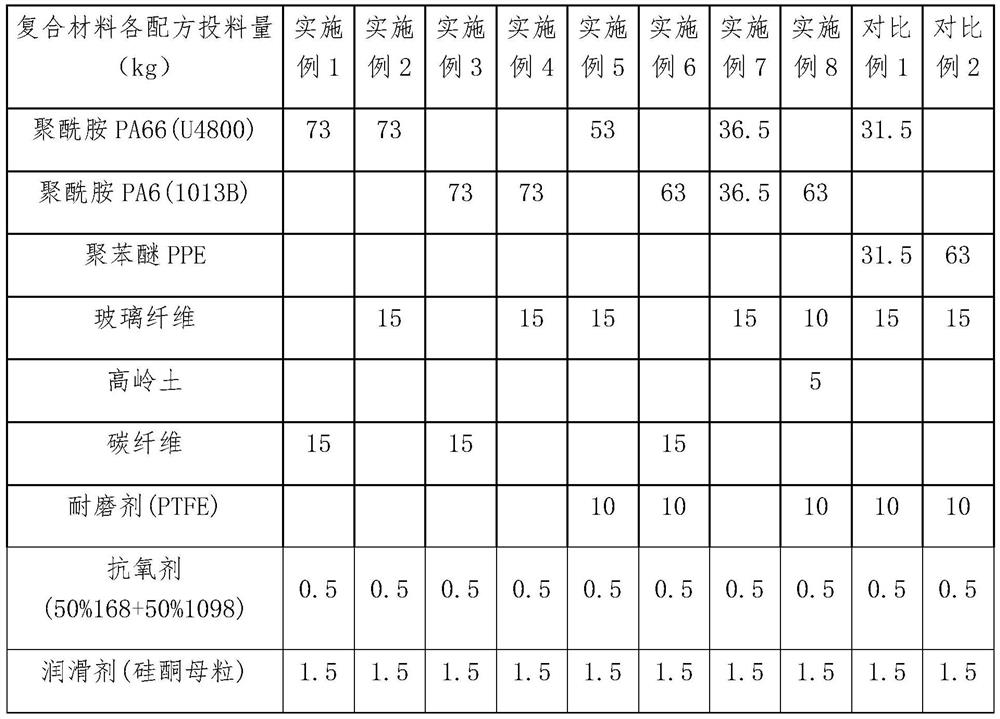

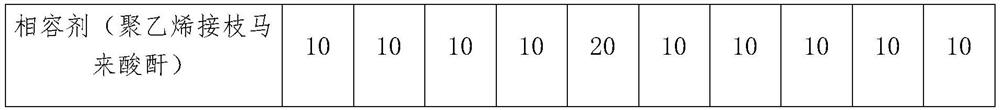

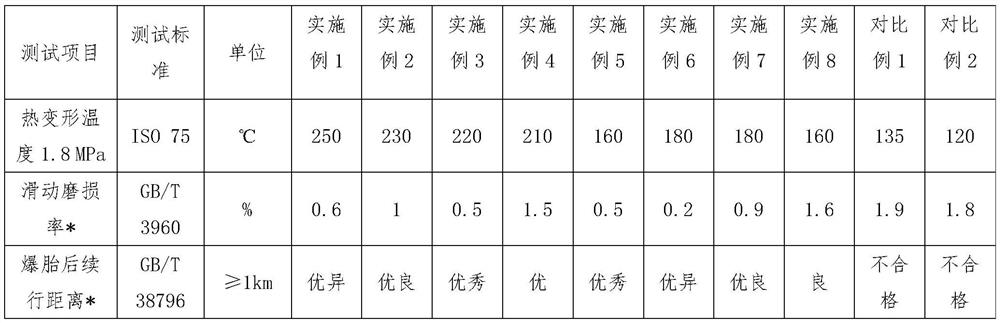

Polyamide composite material for safety device of run-flat tire inner support body and preparation method thereof

The invention relates to the technical field of tire burst prevention, in particular to a polyamide composite material for a safety device of a run-flat tire inner support body and a preparation method thereof. The material provides enough supporting strength, toughness, wear resistance, heat resistance and the like for a tire. The material is applicable to explosion-proof tires of special military police vehicles, operating passenger cars, operating trucks, urban buses and tractors. The preparation method of the polyamide composite material for the safety device of the run-flat tire inner support body thereof is simple and feasible, and is suitable for large-scale production and application.

Owner:辰东意普万新材料(广东)有限公司

A metal release agent

The invention discloses a metal demolding agent which comprises the following raw materials in parts by weight: 70-90 parts of fluoride graphite, 5-25 parts of graphite, 1-3 parts of a dispersing agent and 0.1-0.5 part of a fluorinated surfactant. The metal demolding agent disclosed by the invention has the main components of fluoride graphite and graphite, the two substances are high in melting point and high in lubrication property, then a dense lubricating membrane can be formed on the surface of a mold, the flowability of a metal in the mold can be improved, and the smoothness and the flatness of the surface of a cast part can be maintained; due to addition of the dispersing agent, not only is the aggregation phenomenon of a powder demolding agent solved, but also the demolding capability of a metal cast part can be improved; due to addition of the fluorinated surfactant, not only is the viscosity of the metal cast part reduced, but also effective spreading of the fluoride graphiteand the graphite can be ensured; through the coordinated use of the substances in a certain ratio, the thermal resistance of the demolding agent can be improved, high chemical stability and excellentlubricating properties can be maintained, and both the cast part and the mold are free of residue.

Owner:HUBEI ZHUOXI FLUOROCHEM

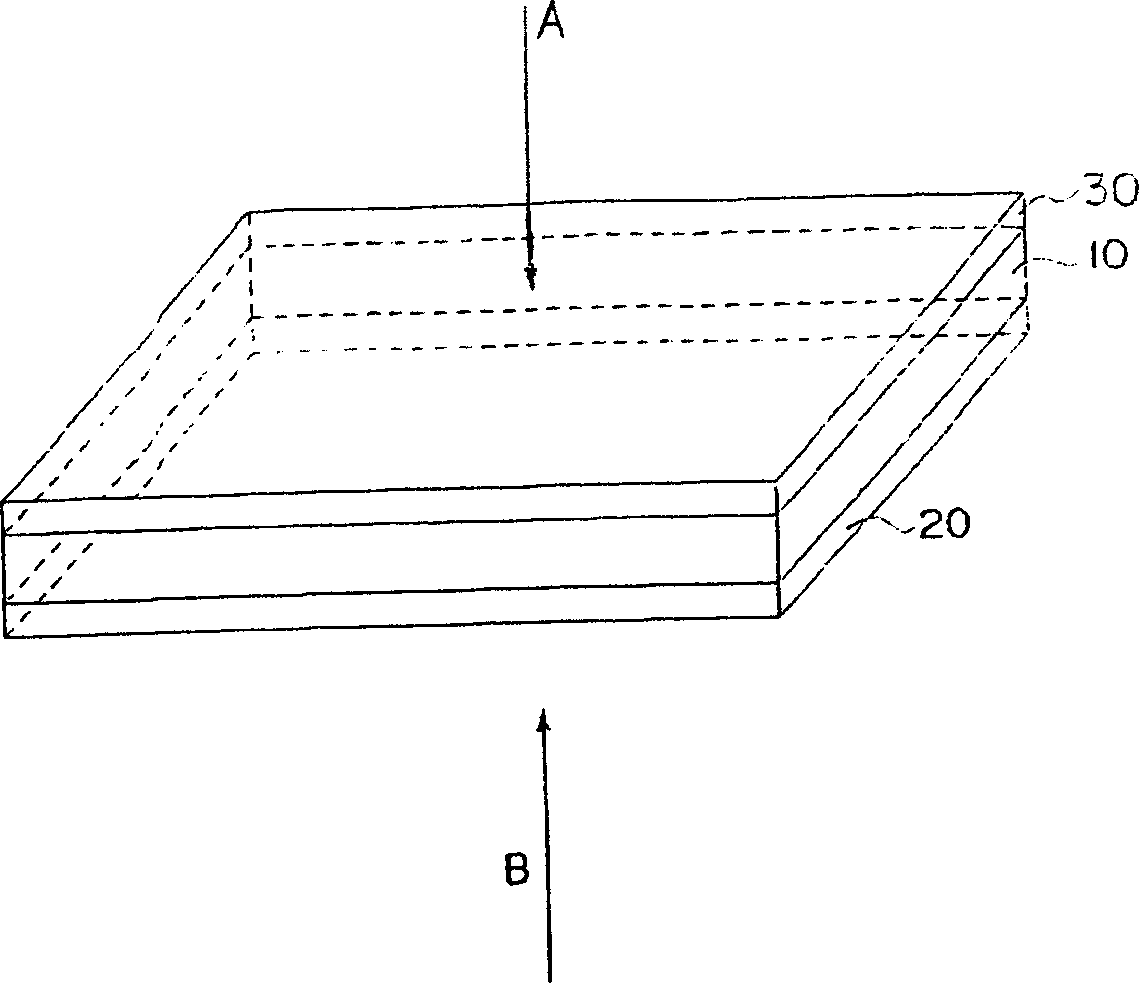

Multilayer structure

PendingCN113840724ASufficient heat resistanceImproved balanced mechanical propertiesFlexible coversWrappersPolymer scienceHeat resistance

The present invention is directed to a multilayer structure. More specifically, the present invention is directed to a polypropylene multilayer extrusion laminate structure which provides sufficient thermal resistance and mechanical properties, and which multilayer structure can be recycled. The present invention is further directed to a process for producing the multilayer structure by an extrusion lamination process.

Owner:BOREALIS AG

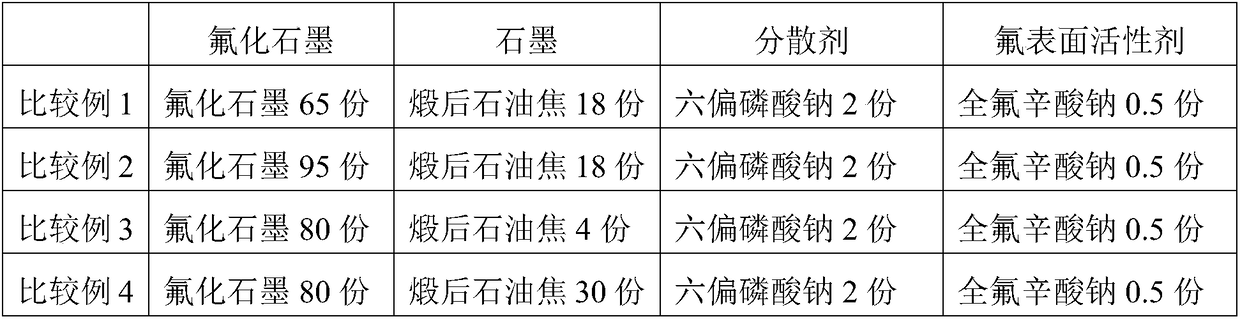

Method and instrument for profiling magnetic flux

InactiveCN1104772CRelatively good permeabilitySufficient heat resistanceWindingsElectric machineRelative permeability

An electric machine according to the invention comprises a rotor means (10) and a stator means (20) surrounding the rotor means having radially extending slots (21). Slot lock components (14) are provided in at least some of said slots. The slot lock extends in said slot essentially to the periphery of the rotor bore of the stator means. The relative permeability ( u r) and the saturated flux density of the slot lock means is essentially good. In the inventive method the density of magnetic flux effecting on the rotor means surface is made more uniform by slot lock components described above.

Owner:贾默・阿拉梅基

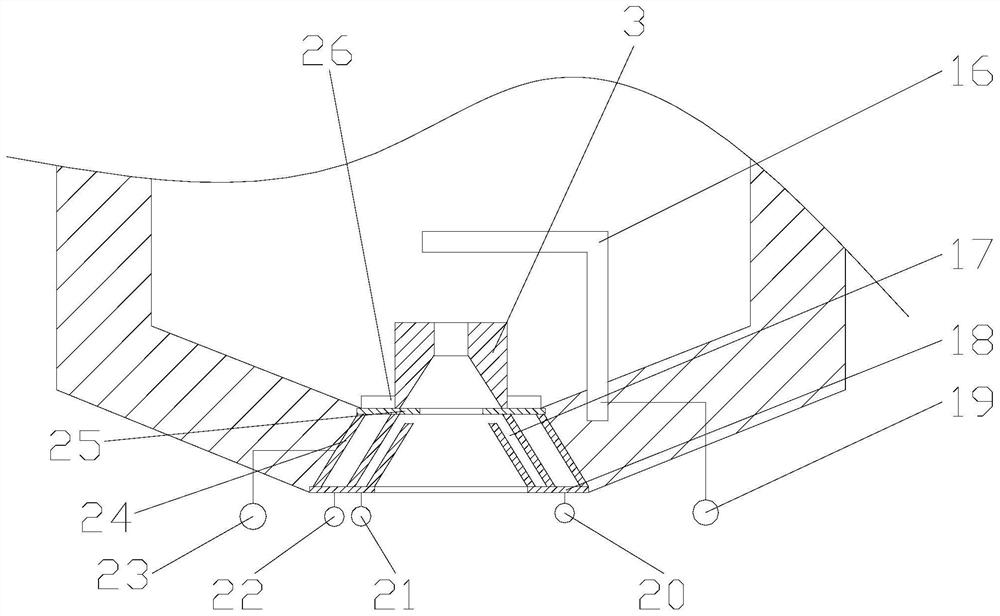

An implantable molten ceramic material outflow device

ActiveCN111692881BStable flowGuaranteed granular concentrationFoundry mouldsMaintainance of heating chambersElectric heatingCeramic materials

The invention discloses an implanted molten ceramic material outflow device, which comprises an outflow pipe, and the outflow pipe is installed at the bottom of a melting furnace. The invention can realize the opening and closing of the outlet port by means of electric heating, and at the same time, can control the flow rate of the molten ceramic material at the outlet port by controlling the magnitude of the current, thereby realizing the stable flow control of the molten ceramic material, not only ensuring the ceramic sand The particle size is concentrated, and it can also ensure the quality of ceramic sand.

Owner:JINGANG NEW MATERIALS

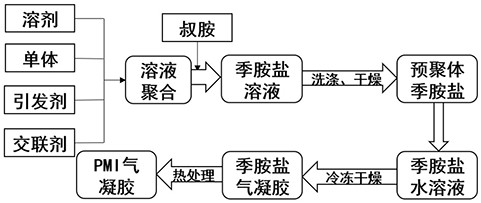

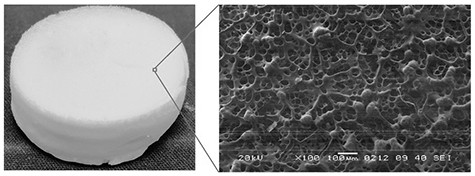

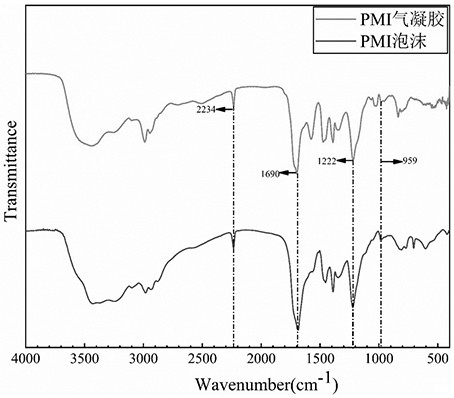

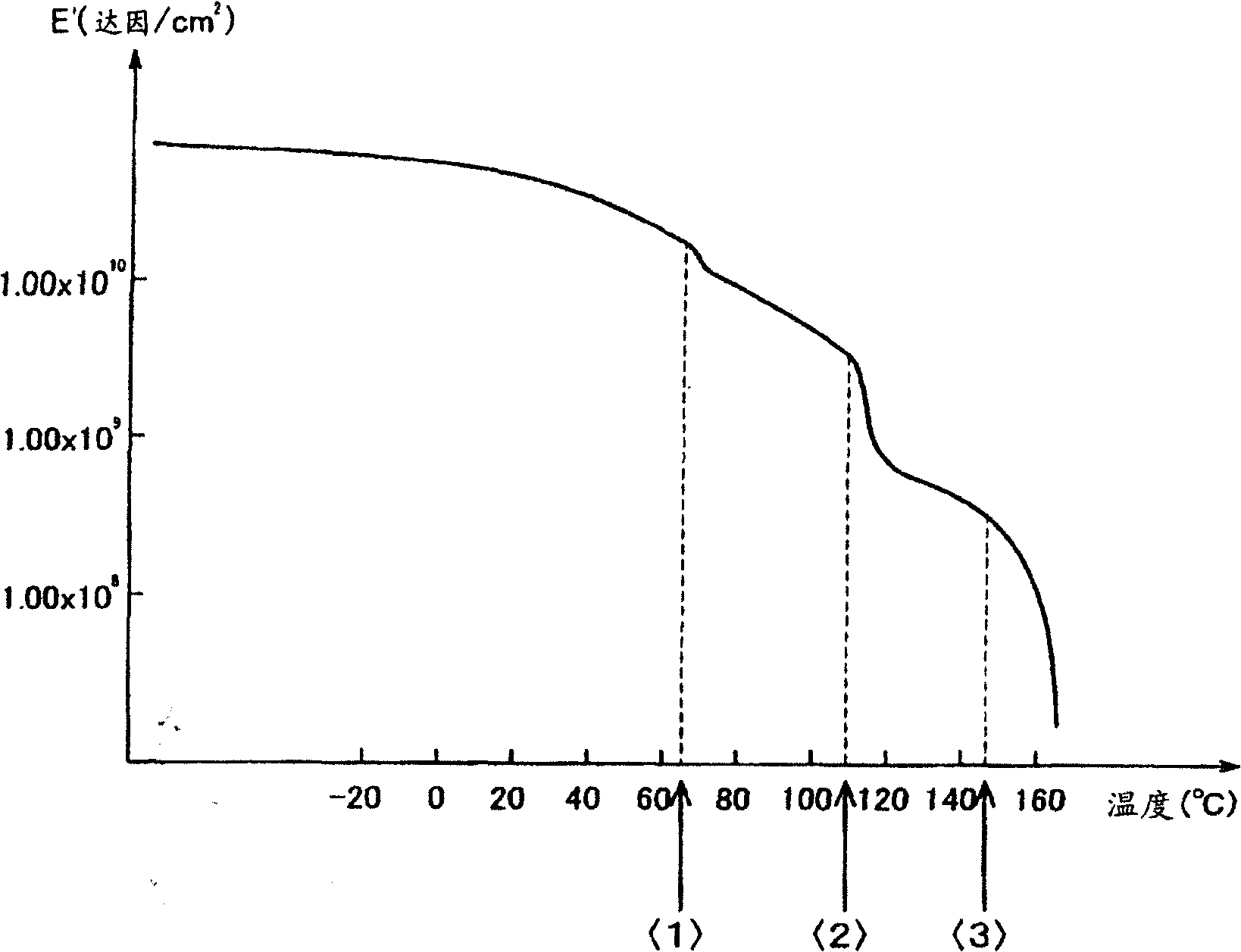

A kind of polymethacrylimide airgel and preparation method thereof

The invention relates to a polymethacrylimide airgel and a preparation method thereof, belonging to the technical field of airgel preparation. Use methacrylic acid and methacrylonitrile monomers to prepare a solution of polymethacrylimide prepolymer; the obtained PMI prepolymer solution is made into PMI prepolymer quaternary ammonium salt; after repeated washing, it turns white Agglomerated solids, followed by drying; redissolving in aqueous solution, freezing and solidifying; freeze-drying, and then obtaining PMI prepolymer quaternary ammonium salt airgel; after heat treatment, obtaining polymethacrylimide airgel. Polymethacrylimide airgel has a three-dimensional network-like open-pore structure, which expands the scope of polymethacrylimide porous materials, and also expands the application of polymethacrylimide porous materials in sound absorption, catalysis, adsorption, etc. field applications. Polymethacrylimide airgel has better mechanical properties and heat resistance. While ensuring sufficient heat resistance, it has high mechanical properties.

Owner:JIANGSU UNIV OF SCI & TECH

Polyester chip for producing automotive interior fiber and preparation method thereof

The invention discloses a polyester chip for producing automobile interior decoration fibers and a preparation method thereof. Firstly, the polyester chip that meets the technical requirements is synthesized: using a two-pot process semi-continuous polymerization reaction device, by introducing isocyanate in the esterification reaction Construct and replace carboxylic acid to reduce the melting point of the product to the target range, and then add reactive catalyst, stabilizer, auxiliary materials, etc. in the polycondensation reaction to control the reaction temperature and vacuum degree, and the final synthetic intrinsic viscosity is 0.730‑0.740dl / g The target polyester chip base material; the synthesized product is passed through the solid phase drum device water steam crystallization process to complete the pre-crystallization of the polyester chip; the pre-crystallized polyester chip is obtained by temperature control without cooling down. The continuous negative pressure processing technology completes the drying of polyester chips. After drying, the water content of polyester chips is not higher than 0.05%, and the intrinsic viscosity is not lower than 0.715dl / g. Through the above three steps, the special polyester chips for automotive interior fibers that meet the requirements of industrial production can be prepared.

Owner:TIANJIN HUAXIN YINGJU POLYESTER MATERIAL SCI & TECH

Biodegradable layered sheet

ActiveCN100439099CDoes not cause environmental problemsThe need to promote crystallizationSynthetic resin layered productsGlass transitionPolymer chemistry

It is an object to provide a biodegradable laminated sheet which is high in heat resistance, impact resistance and strength when subjected to loads at high temperature, does not develop wrinkles called 'bridges', which can be easily deep-drawn or formed into blister articles, which are typically complicated in shape. The biodegradable sheet is a laminated sheet comprising at least two layers. Each of the layers forming the laminated sheet is a resin composition comprising 75 to 25% by mass of a polylactic acid resin, and 25 to 75% by mass of a polyester resin having a glass transition temperature not exceeding 0 degrees C and a melting point higher than the glass transition temperature of the polylactic acid resin, and not exceeding the melting point of the polylactic acid resin, based on 100 mass percent of the total amount of the polylactic acid resin and the polyester resin. The D-lactic acid content of the polylactic acid resin contained in one layer, and the D-lactic acid content of the polylactic acid resin in the other layer are determined to satisfy a predetermined relationship. The laminated sheet is subjected to crystallization treatment.

Owner:MITSUBISHI CHEM CORP

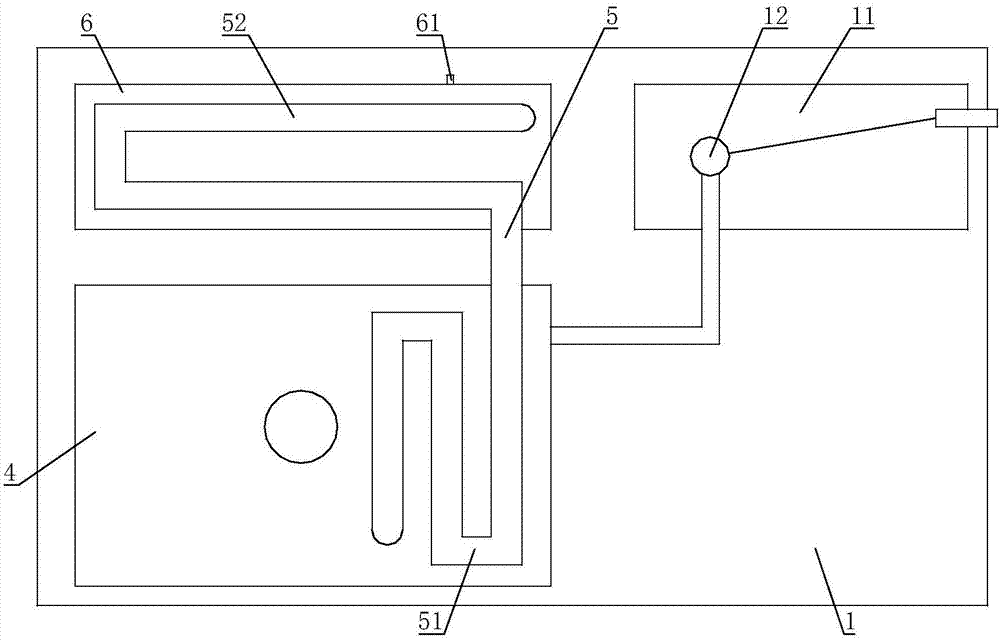

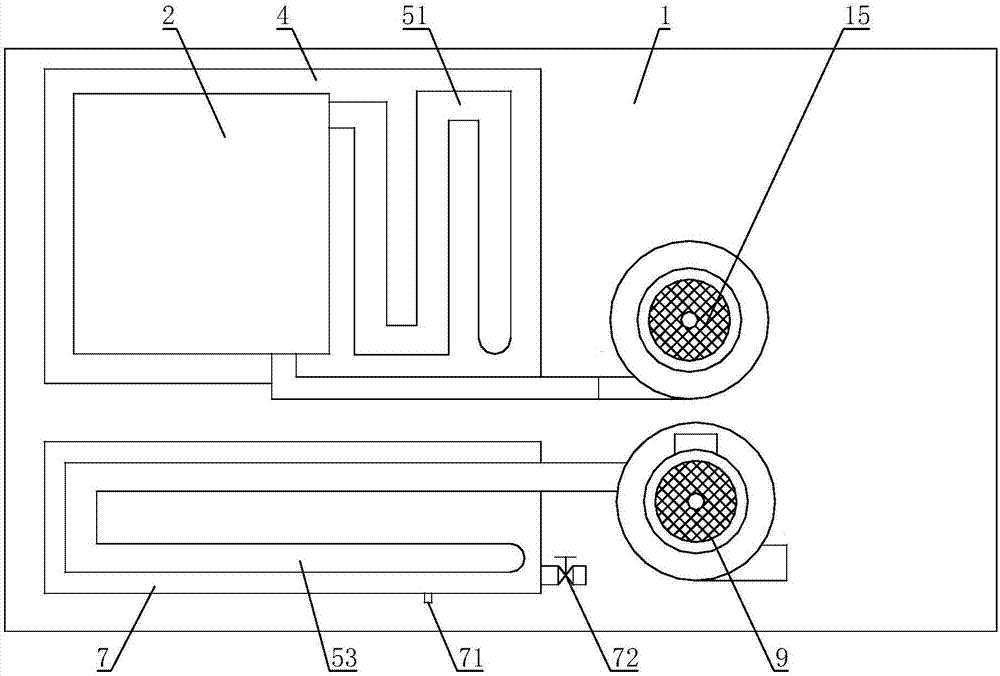

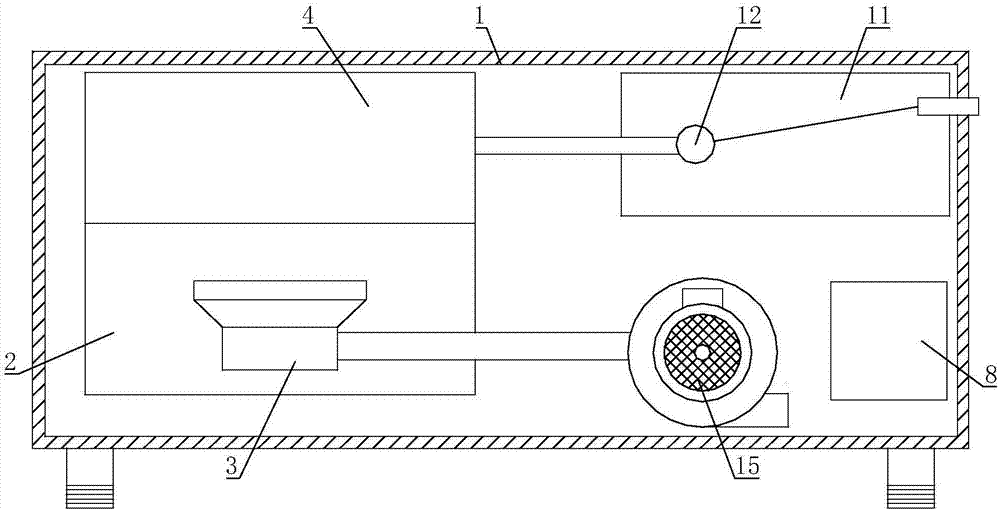

Waste heat recovery and energy conservation integrated steam oven

PendingCN107965799AIncrease profitSolve the problem of serious lossWater heating stoves/rangesCooking fumes removalCombustion chamberEngineering

The invention relates to the field of steam ovens, in particular to a waste heat recovery and energy conservation integrated steam oven. The steam oven comprises a steam oven body. A combustion chamber is formed in the steam oven body. A burner is mounted in the combustion chamber. The steam oven body is further internally provided with a steam chamber and a plurality of waste heat exchange cavities communicating in sequence. The steam chamber is provided with a steam outlet. A smoke outlet of the combustion chamber communicates with a heat guide mechanism. The heat guide mechanism penetratesthrough the steam chamber and then penetrates through the waste heat exchange cavities in sequence according to the communicating sequence of the waste heat exchange cavities. A tap water inlet pipe is connected to the final waste heat exchange cavity in the flowing direction of waste gas in the heat guide mechanism. A make-up water tank is also mounted on the steam oven body. A float ball valve is arranged on the make-up water tank. The other end of the float ball valve communicates with the steam chamber through a pipeline. The waste heat recovery and energy conservation integrated steam oven provided by the invention can recover waste gas heat in a sectional mode and improve the utilization rate of waste gas heat.

Owner:南充烽英堂厨房电器设备科技有限公司

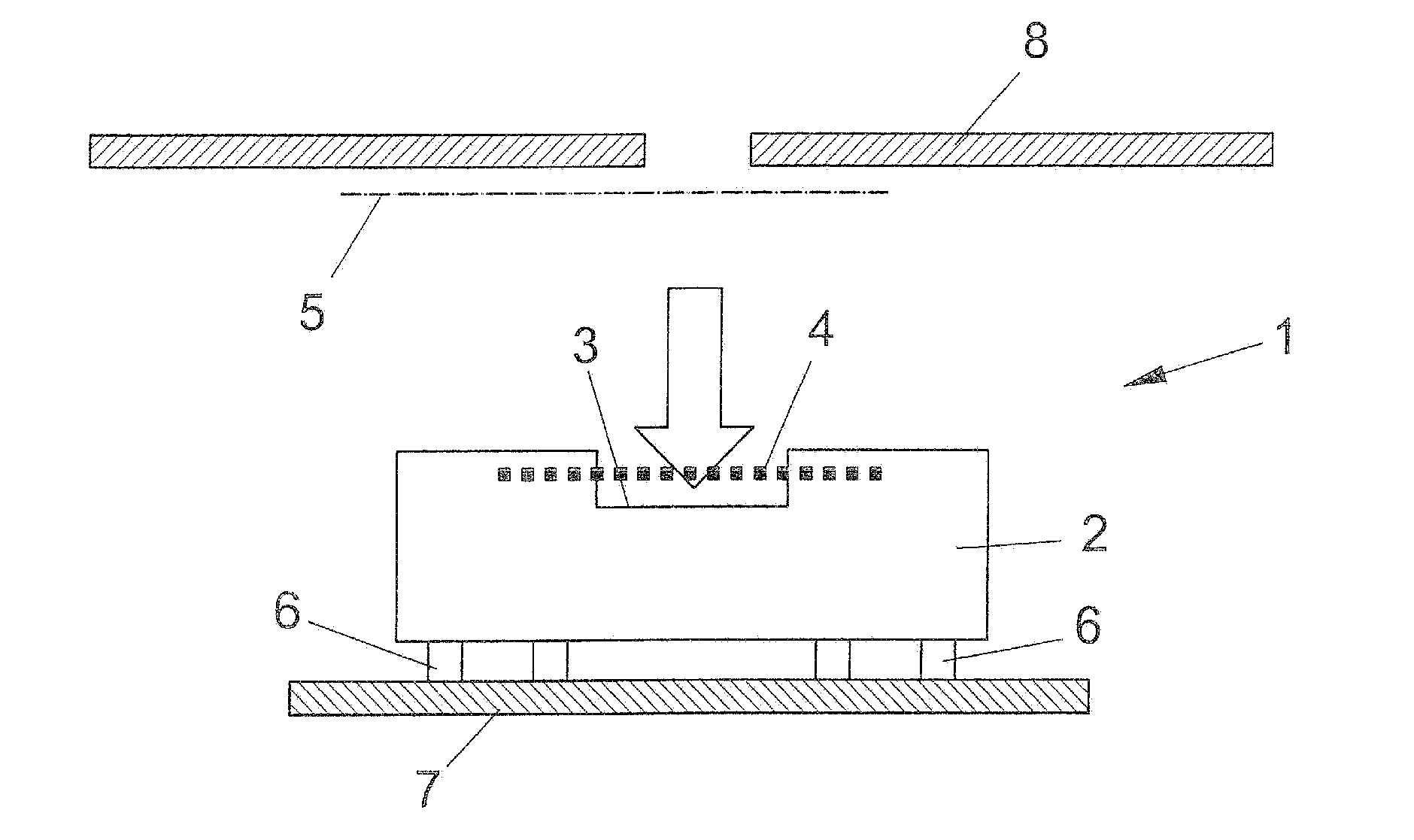

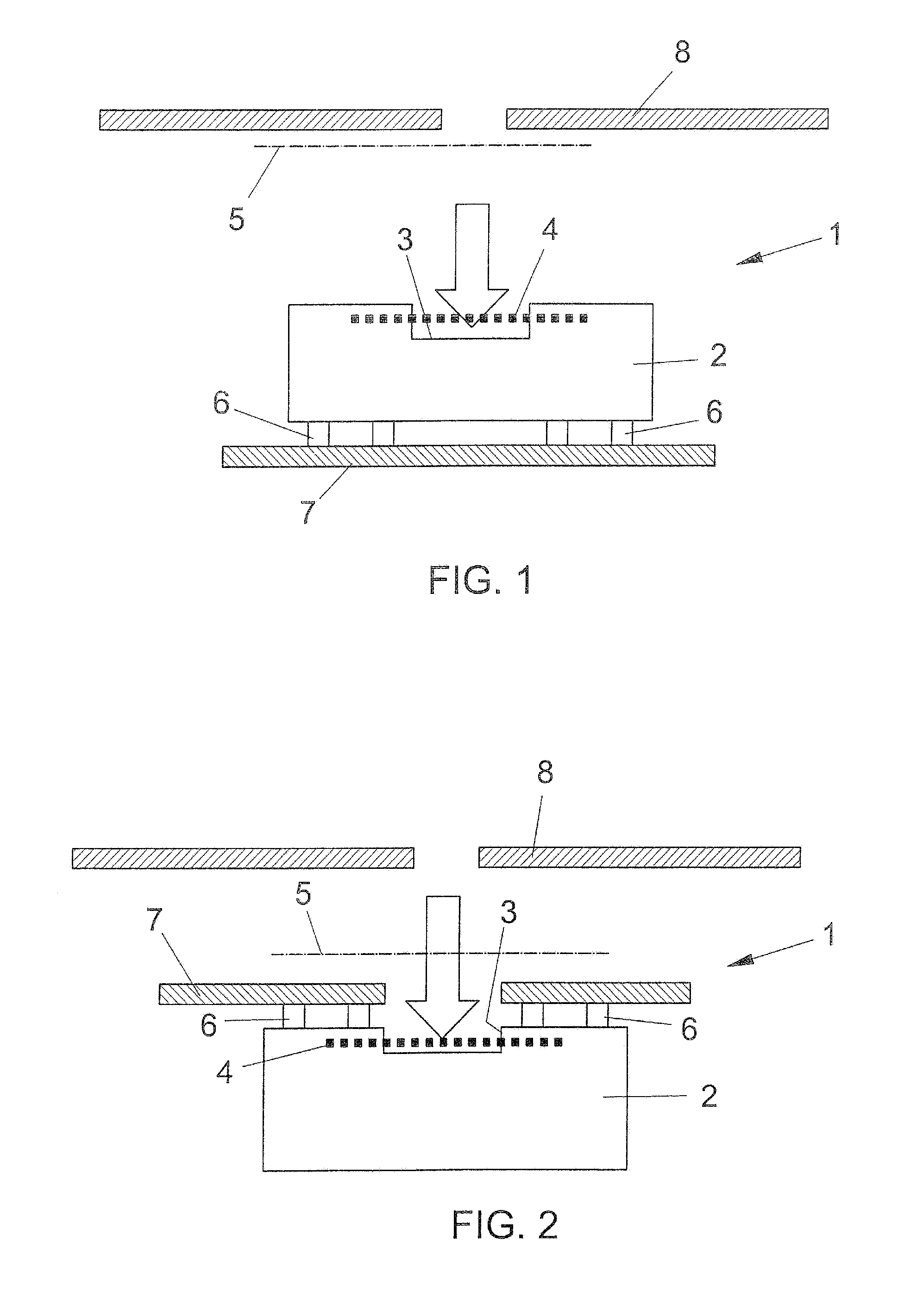

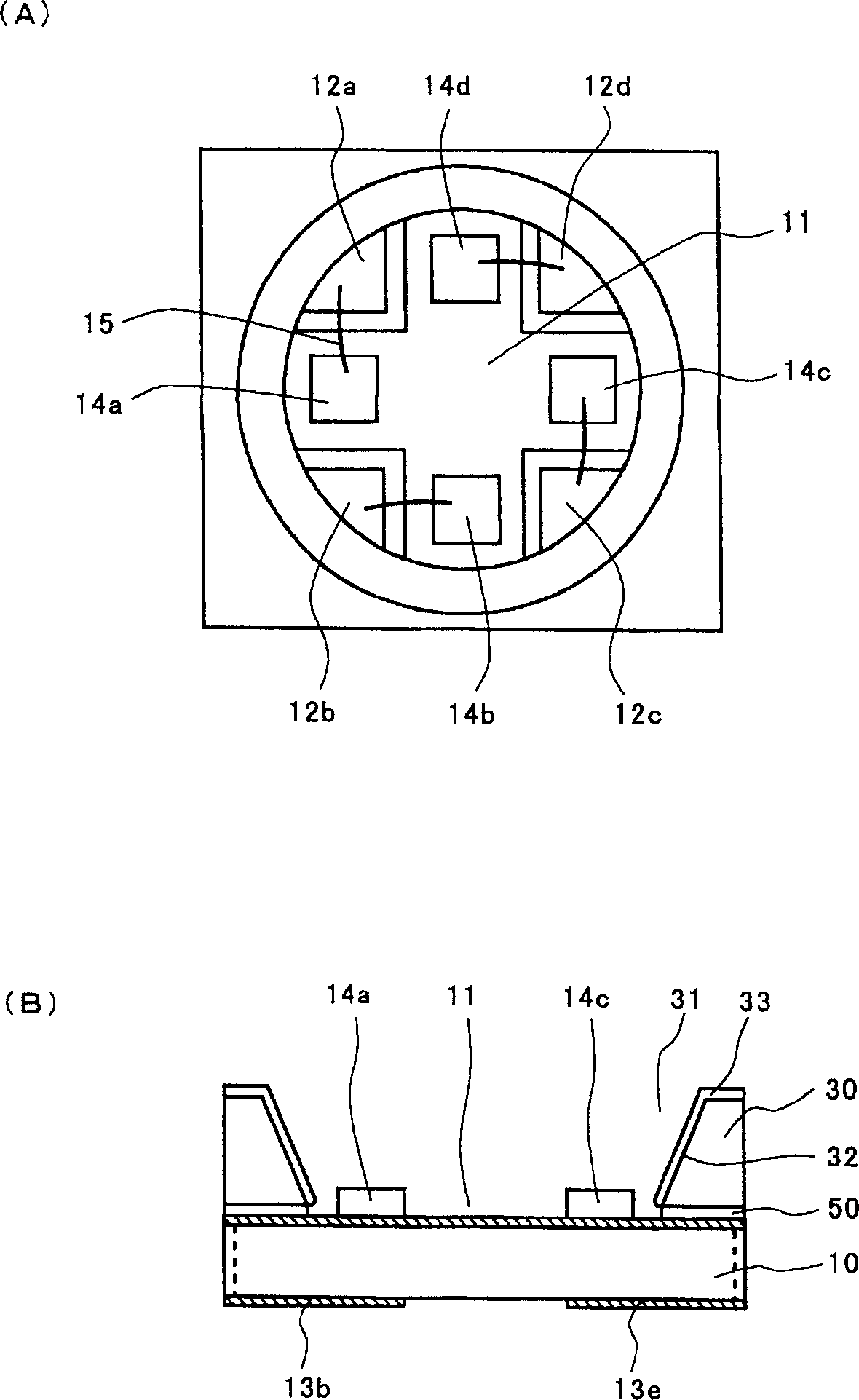

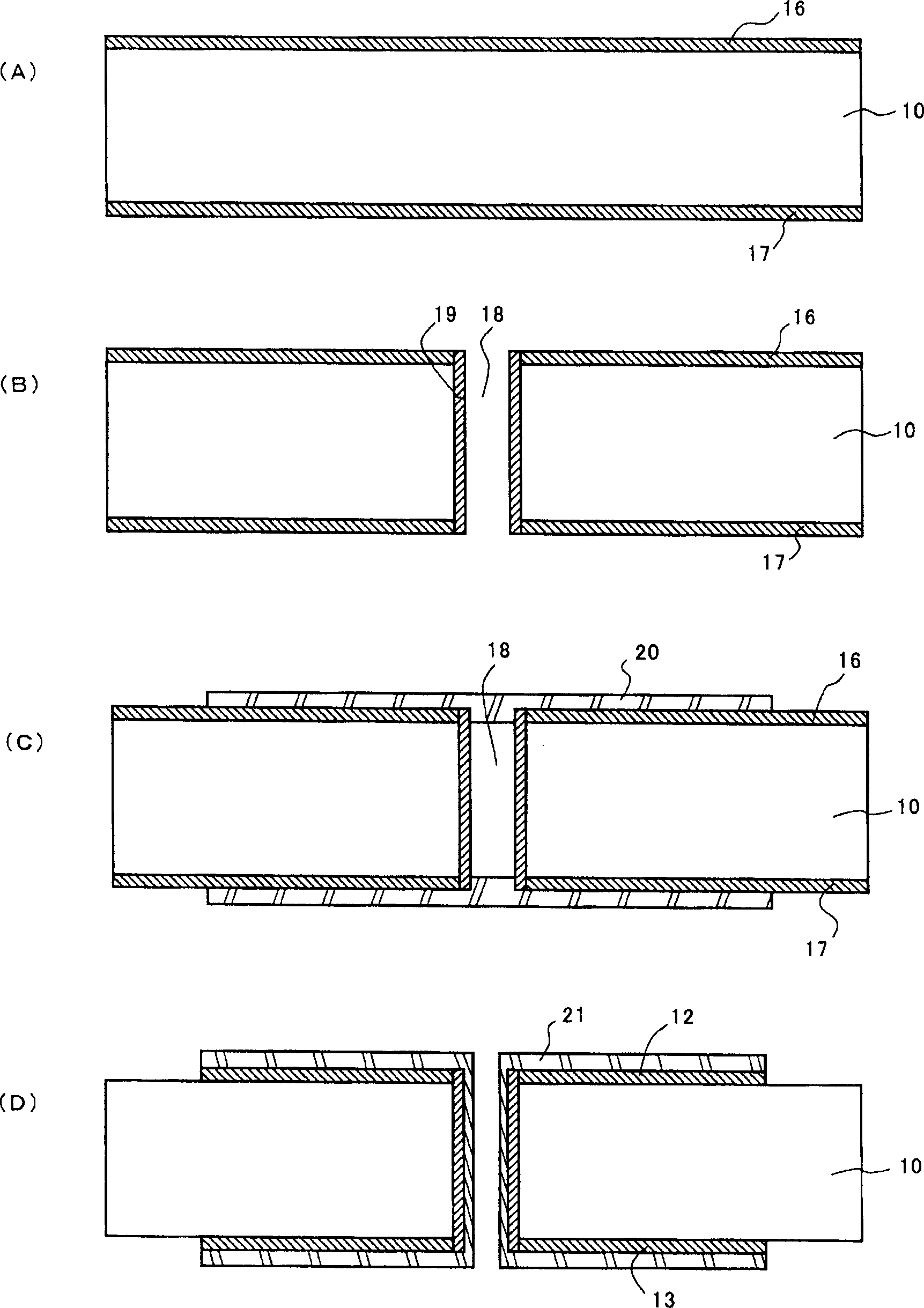

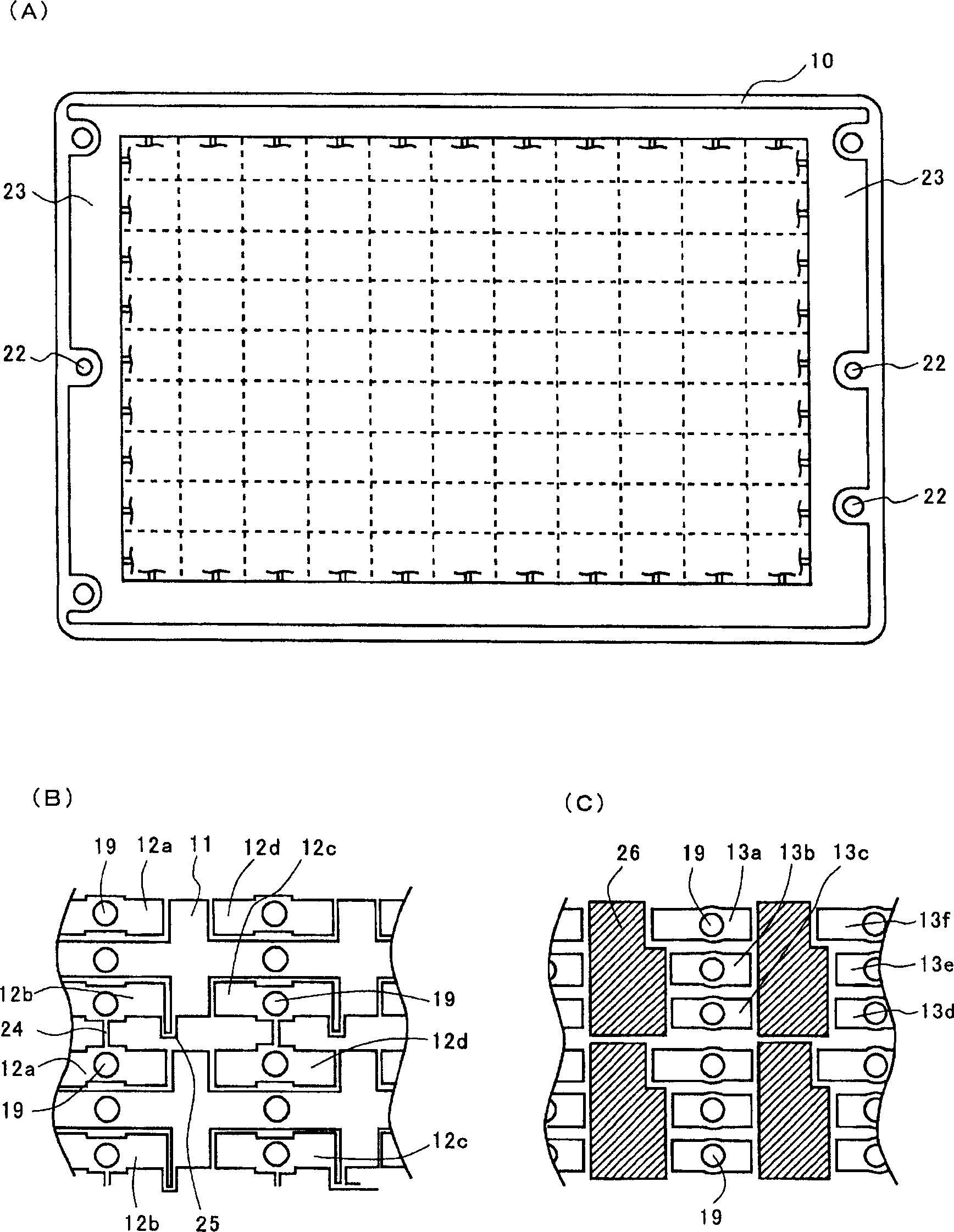

Method of manufacturing mounting board with reflector

InactiveCN1892979ANarrow intervalEasy to prepareSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveMechanical engineering

A method for fabricating a mounting board with an attached reflector is provided to embody a mounting board with a reflector by preparing a mounting board and a reflector board so that the boards are attached to each other by using adhesive. A plurality of electrodes for mounting a light emitting device are prepared. An inclined surface(32) is formed on the inner wall of a through hole(31) to surround each electrode for mounting the light emitting device, and a reflector board(34) is prepared in which a reflective plating layer is formed on the inclined surface of the through hole. The mounting board is attached to the reflector board by using an adhesive layer. The reflector board is made of a print board material capable of being mechanically processed. The through hole formed in the reflector board can be formed by mechanical processing.

Owner:ELEMENT DENSHI

Movable garbage compression station

PendingCN112537580ALoss of heatingNormal pushRefuse receptaclesRefuse transferringThermodynamicsInsulation layer

The invention belongs to the field of garbage compression devices, and particularly relates to a movable garbage compression station. The movable garbage compression station comprises a storage box, wherein the storage box is used for storing garbage, and a bottom frame is arranged at the bottom of the storage box. The movable garbage compression station further comprises electric heating devices,wherein the electric heating devices are arranged on the lower side of the storage box and attached to the bottom of the storage box or a heat conduction layer arranged at the bottom of the storage box, at least two electric heating devices are arranged, and all the electric heating devices are connected to a power source in parallel. A heat insulation layer is arranged between the storage box and the bottom frame and located on the sides, opposite to the storage box, of the electric heating devices. Heating operation is conducted by the electric heating devices, and therefore the garbage inthe storage box and the storage box are prevented from being frozen, and the situations that a push shovel can smoothly push and press the garbage, and the garbage can be smoothly discharged are ensured. In addition, at least two electric heating devices are arranged, all the electric heating devices are connected to the power source in parallel, when one of the electric heating devices has a fault and cannot normally heat a bottom plate of the garbage can, other electric heating devices can normally work, and the garbage can can still be heated by the electric heating devices.

Owner:HENAN SENYUAN HEAVY IND +1

Polysilsesquioxane copolymer and photosensitive resin composition comprising the polysilsesquioxane copolymer

ActiveCN106459415BSufficient heat resistanceHigh bonding strengthPhotosensitive materials for photomechanical apparatusCopolymerPolymer chemistry

A photosensitive resin containing (A) a polysilsesquioxane copolymer represented by chemical formula 1 is provided.

Owner:HUNET PLUS

Novel block copolymer mixture elastic fiber and manufacturing method thereof

ActiveCN110241480AResistant to subsequent processing temperaturesHigh breaking strengthConjugated synthetic polymer artificial filamentsArtifical filament manufactureElastomerElastic fiber

The invention relates to a novel block copolymer mixture elastic fiber and a manufacturing method thereof. The method includes the steps of a, providing a novel block copolymer mixture through mixing, wherein the mixture includes at least one styrene block copolymer (SBC) A and at least one thermoplastic polyether ester elastomer (TPEE) B; b, melting the novel block copolymer mixture and then granulating the mixture again through a granulator suitable for granulating copolymers so as to obtain the novel block copolymer mixture obtained after all the components are sufficiently and evenly mixed; c, conducting melt spinning the novel block copolymer mixture to obtain an elastic fiber precursor; d, conducting curing treatment on the elastic fiber precursor to obtain a novel elastic fiber, wherein the weight ratio of the styrene block copolymers A to the thermoplastic polyether ester elastomers B is 90:10 to 10:90.

Owner:上海梦丝新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com