Patents

Literature

262results about How to "Tough enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

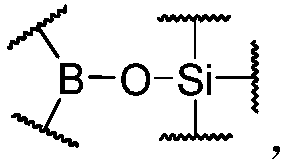

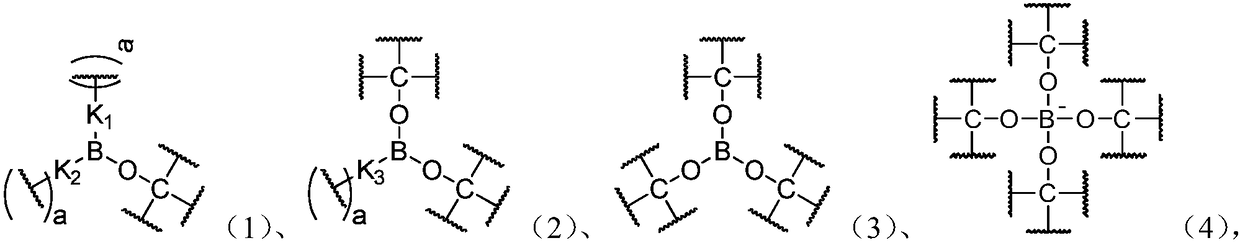

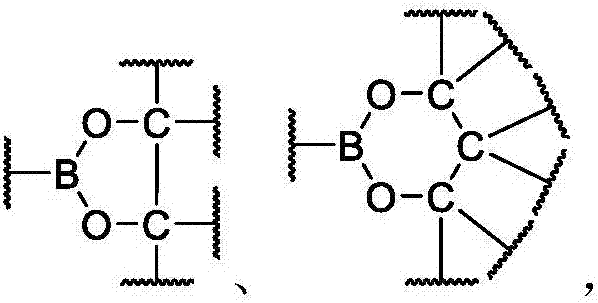

Dynamic polymer having hybrid cross-linked network and application thereof

The invention discloses a dynamic polymer having a hybrid cross-linked network, and contains common covalent crosslinking and dynamic covalent crosslinking; and the dynamic covalent crosslinking is realized by organic boric acid silicon ester bonds. The dynamic polymer combines the advantages of dynamic covalent organic boric acid silicon ester bonds and a common covalent bond, and by regulation and control of a reactant structure, a dynamic polymer having abundant structure and various properties can be prepared. The dynamic covalent crosslinking in the dynamic polymer has strong dynamic reversibility, the polymer can present function characteristics of stimulation responsiveness and self-repair performance, and the common covalent crosslinking endows certain intensity and stability to the polymer; in addition, the dynamic nature of the organic organic boric acid silicon ester bonds can generate good energy dissipation and energy-absorbing effect, and is capable of toughening, dampingand resisting impact on a material in a specific structure. The dynamic polymer can be used for preparing a shock-absorption material, a shock-resistant protection material, a self-repair material, and a toughness material.

Owner:厦门天策材料科技有限公司

Multiplex composite bone tissue engineering bracket material capable of degrading gradiently and preparation method thereof

The invention discloses a multiplex composite engineering scaffold material capable of gradually decomposing bone tissue and a preparation method thereof. The composite scaffold material consists of calcium phosphate bone cement, biological compatible degradable synthetic high polymer and biological compatible degradable natural high polymer, has better mechanical property and gradient degradation characteristic, and can achieve the aim of regenerating and repairing bone tissue defect by implanting a bone growth factor to induce in-vivo stem cells to be differentiated into bone cells, thereby obviously improving initial strength and toughness of the scaffold material, and ensuring enough strength and toughness of the scaffold material during operating and implanting. After compounded with the high polymer material, the scaffold has excellent flexibility, so that the scaffold can be subjected to certain machining, such as cutting and the like.

Owner:SOUTH CHINA UNIV OF TECH

Plastic packaging bag

The invention discloses a plastic packaging bag, and relates to the technical field of plastic products. The plastic packaging bag is made of 15-18 parts of linear low-density polyethylene, 15-25 parts of heavy calcium carbonate powder, 15-20 parts of corn straw fibers, 2-3 parts of chitosan, 10-15 parts of corn starch, 15-18 parts of polyethylene and 0.1-1 part of toner. The linear low-density polyethylene, the heavy calcium carbonate powder and the corn starch serve as raw materials and can be biologically degraded, and the corn straw fibers are added into the polyethylene to modify the polyethylene, so that the plastic packaging bag has enough strength and toughness.

Owner:柳州蔚园塑料彩印包装有限责任公司

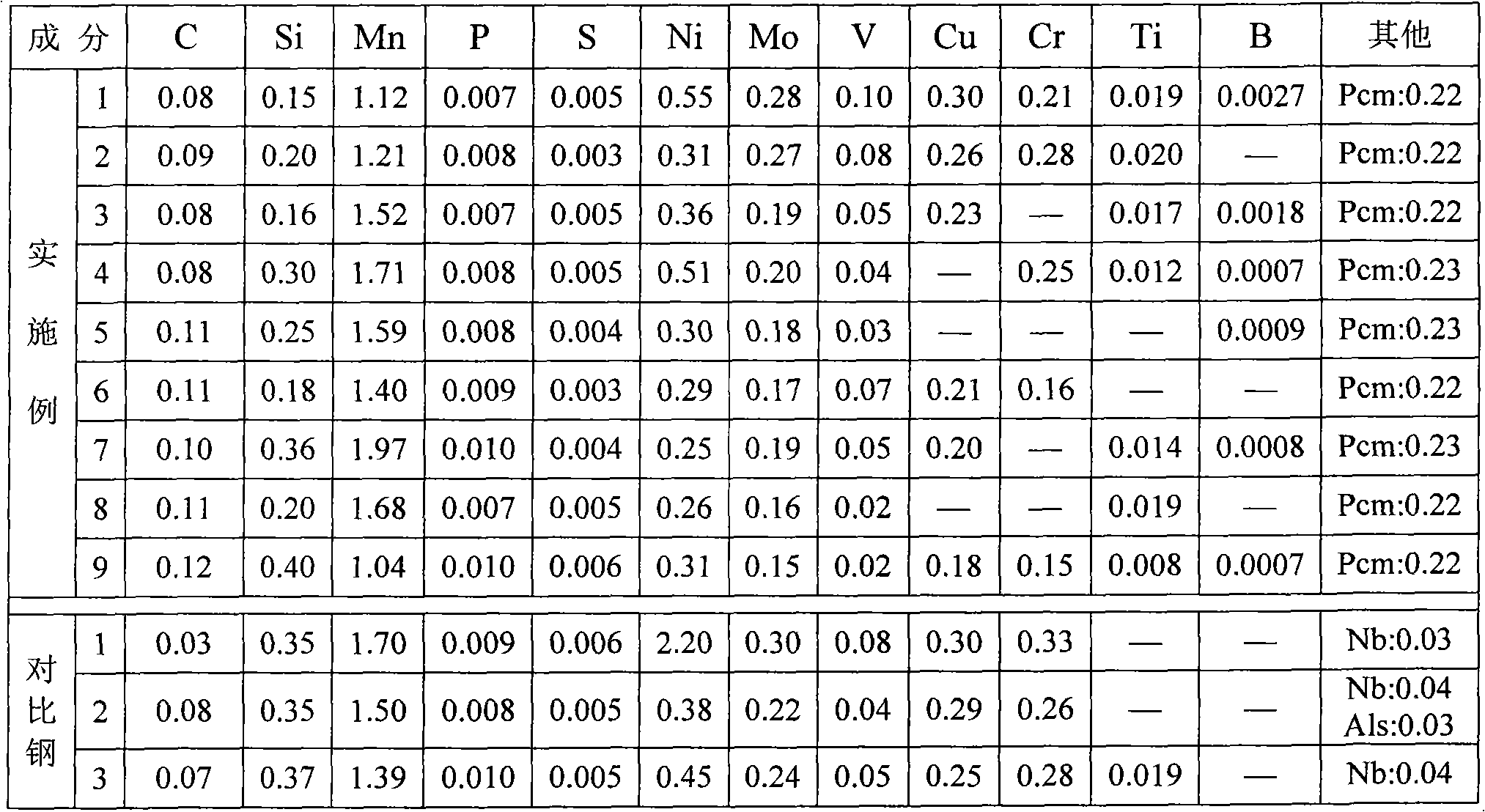

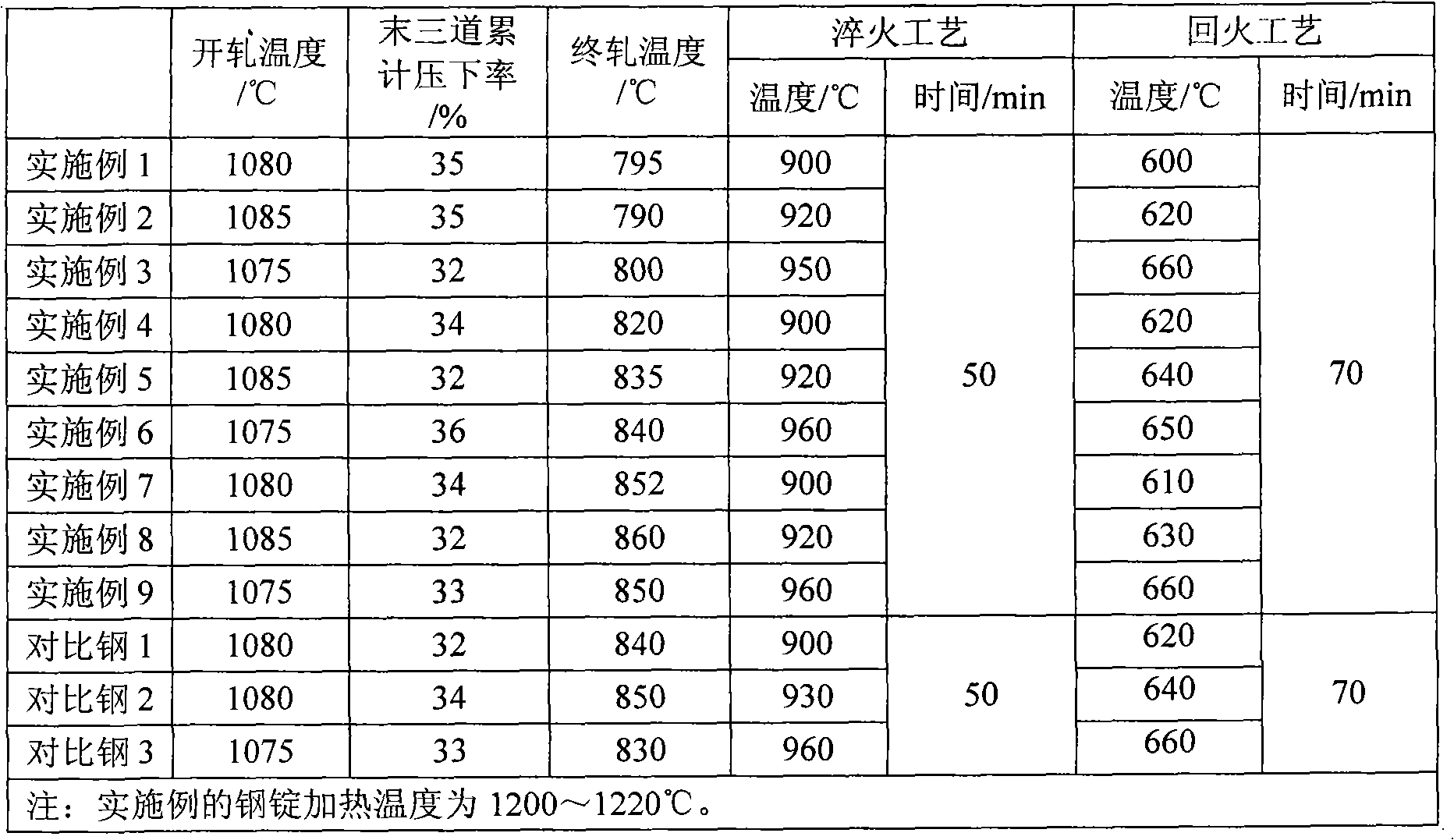

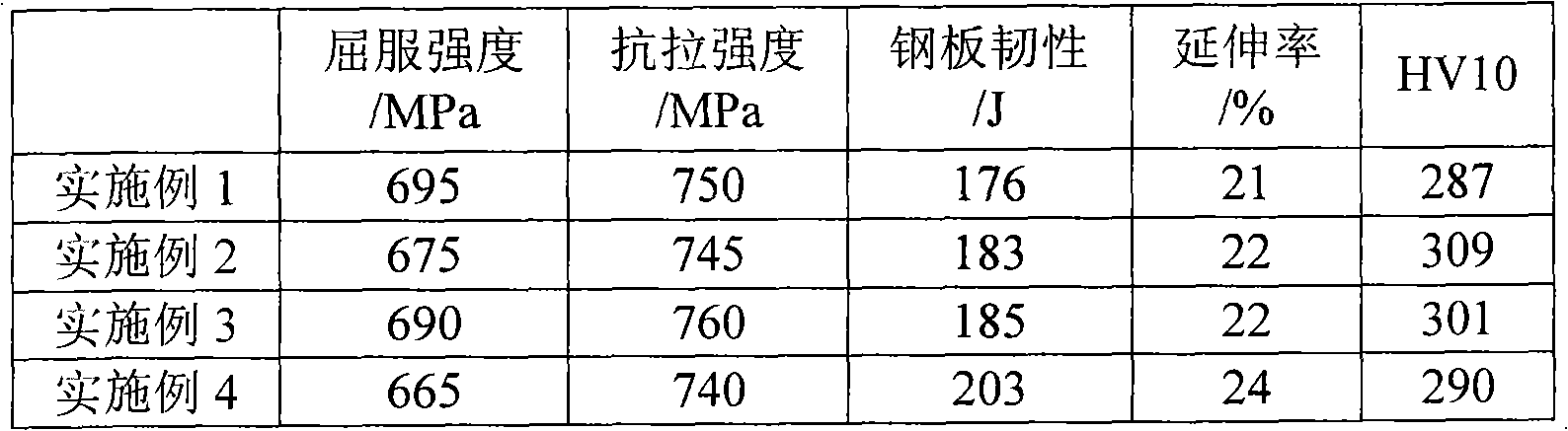

Low welding crack sensitivity steel with tensile strength at 700MPa level and production method thereof

ActiveCN101643888ATough enoughStrong enoughTemperature control deviceManufacturing convertersChemical compositionMetallurgy

The invention provides low welding crack sensitivity steel with tensile strength at a 700MPa level and a production method thereof. The steel comprises the following two or more chemical components inpercentage by weight: C: 0.08-0.12, Si: 0.15-0.40, Mn: 1.00-2.00, P: smaller than or equal to 0.015, S: smaller than or equal to 0.006, Ni: 0.25-0.55, Mo: 0.15-0.28, V: 0.02-0.10, Cu: 0.18-0.30, Cr:0.15-0.30, Ti: 0.008-0.020 and B: 0.0007-0.0027 as well as the balance of Fe and inevitable impurities and also satisfies that Pcm is smaller than or equal to 0.24 percent and satisfies an equation: Pcm=C+Si / 30+Mn / 20+Cu / 20+Cr / 20+Ni / 60+Mo / 15+V / 10+5B (percent). The invention adopts a deep molten iron desulphurization technology, a converter top and bottom converting, vacuum treatment and continuouscasting processes and carries out rolling and hardening, tempering and thermal treatment production according to a general clean steel process.

Owner:武汉钢铁有限公司

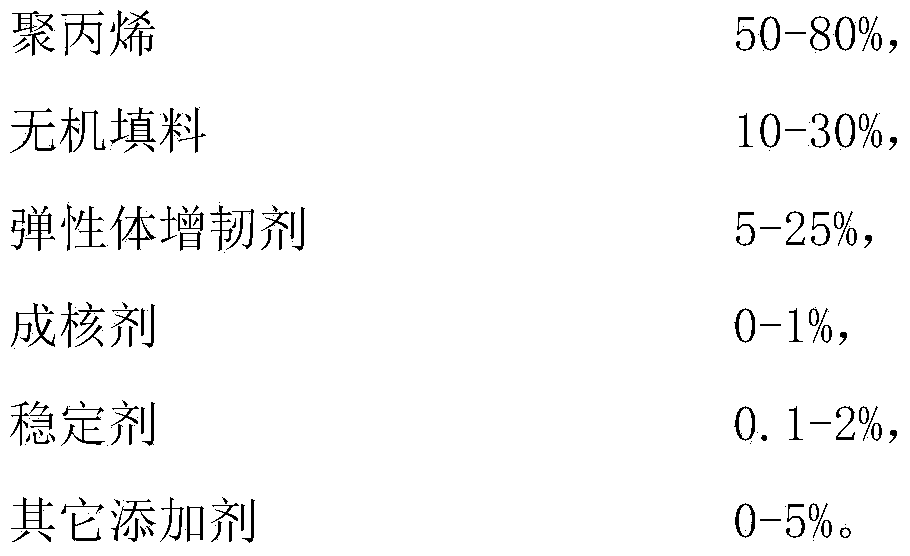

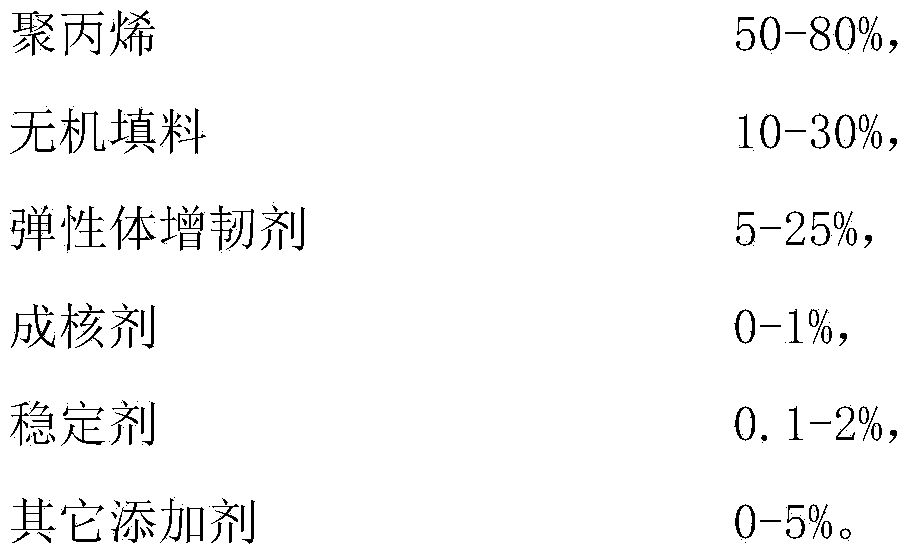

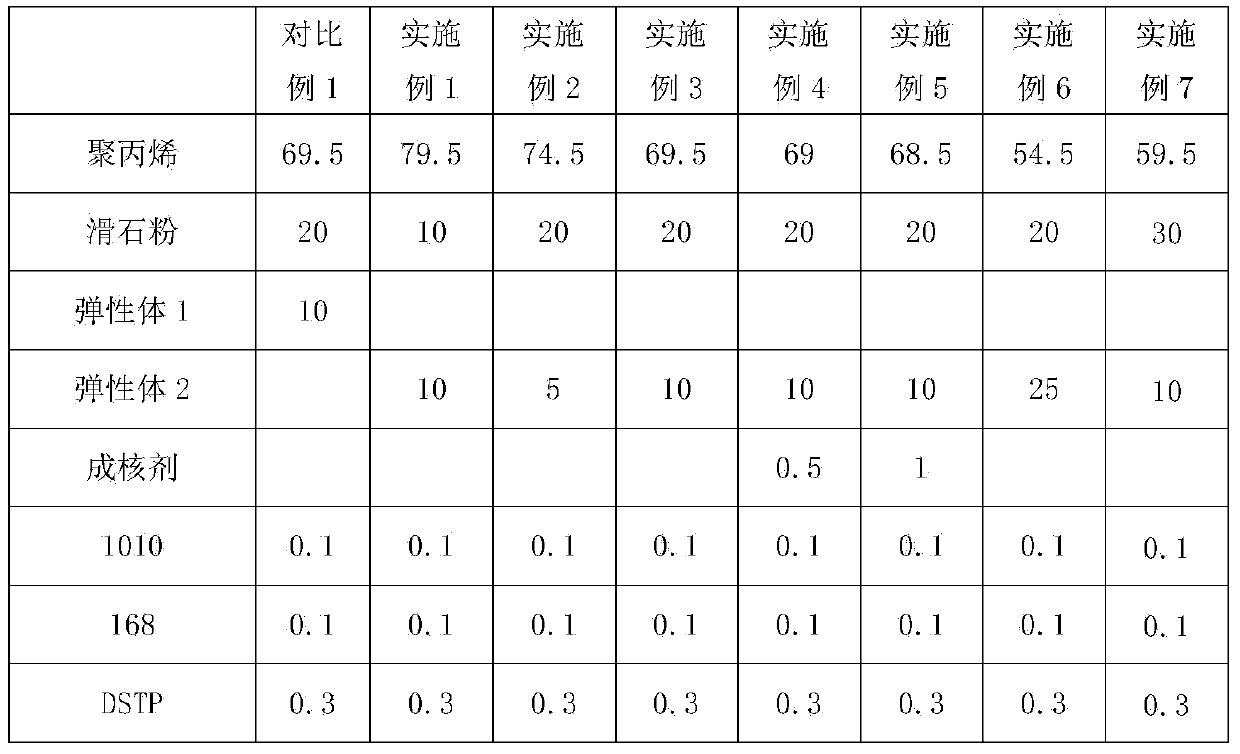

Polypropylene composite material with low after shrinkage, high modulus and high impact resistance and preparation method thereof

The invention discloses a polypropylene composite material with low after shrinkage, a high modulus and high impact resistance, which consists of the following raw materials in percentage by weight: 50 to 80 percent of polypropylene, 10 to 30 percent of inorganic filler, 5 to 25 percent of an elastomer toughening agent, 0 to 1 percent of a nucleating agent, 0.1 to 2 percent of a stabilizer and 0 to 5 percent of other additives. The polypropylene composite material has the advantages as follows: 1, an ethylene-butylene copolymer is used as the elastomer toughening agent, so that compared with conventional toughened and modified polypropylene, the polypropylene composite material has obviously reduced after shrinkage and has higher size stability; 2, the nucleating agent is used as a crystallization promoter agent of the material, so that after shrinkage of the polypropylene material can be further reduced and size stability can be further improved; 3, the ethylene-butylene copolymer is used as the elastomer toughening agent, so that compared with the conventional toughened and modified polypropylen, the polypropylene composite material has higher low-temperature toughness.

Owner:ZHEJIANG PRET NEW MATERIALS +2

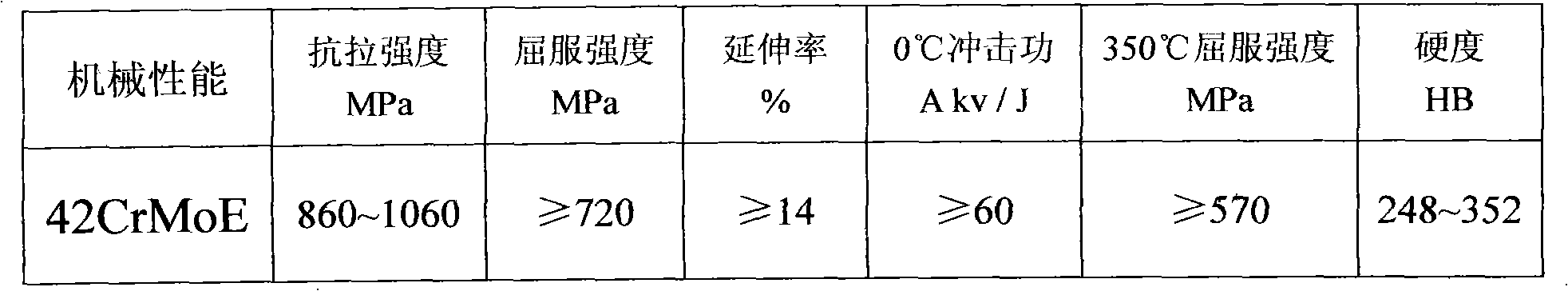

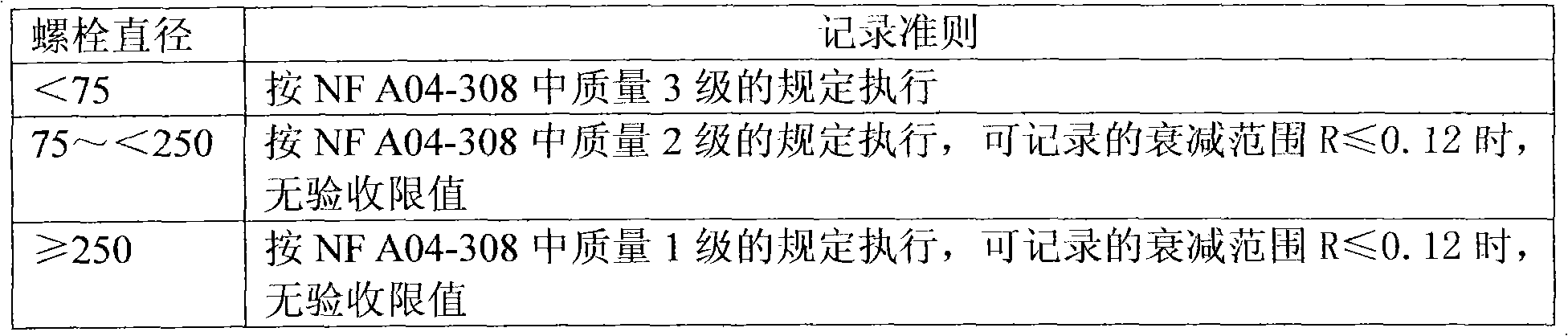

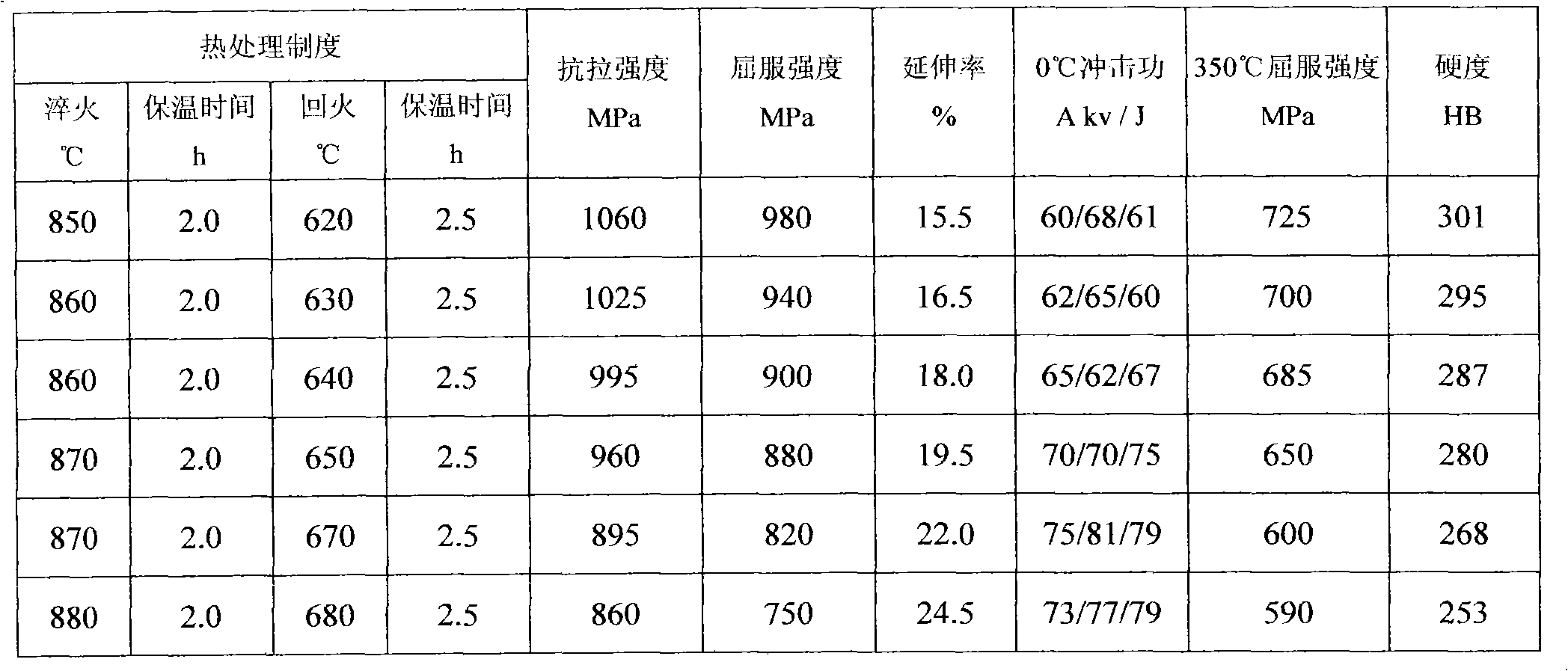

Production process of nuclear bolt

The invention mainly discloses a production process of a nuclear bolt. A 42CrMoE steel material is adopted as a raw material, and the nuclear bolt is produced by blank preparation, heat treatment, surface treatment and flaw detection, wherein the raw material of 42CrMoE comprises the following chemical components by mass percent: 0.38 to 0.48 of C, 0.10 to 0.40 of Si, 0.75 to 1.00 of Mn, no more than 0.025 of P, no more than 0.015 of S, 0.80 to 1.15 of Cr, 0.15 to 0.30 of Mo and the balance of Fe. The product obtained by production in the invention meets the requirements of nuclear 1-stage equipment, nuclear 2-stage equipment and nuclear 3-stage equipment, and the strength, the hardness and the impact resistance all reach standards.

Owner:浙江高强度紧固件有限公司

Low-alloy heat-resistant steel plate and manufacturing method thereof

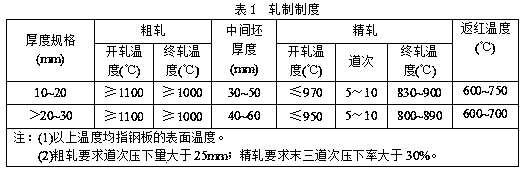

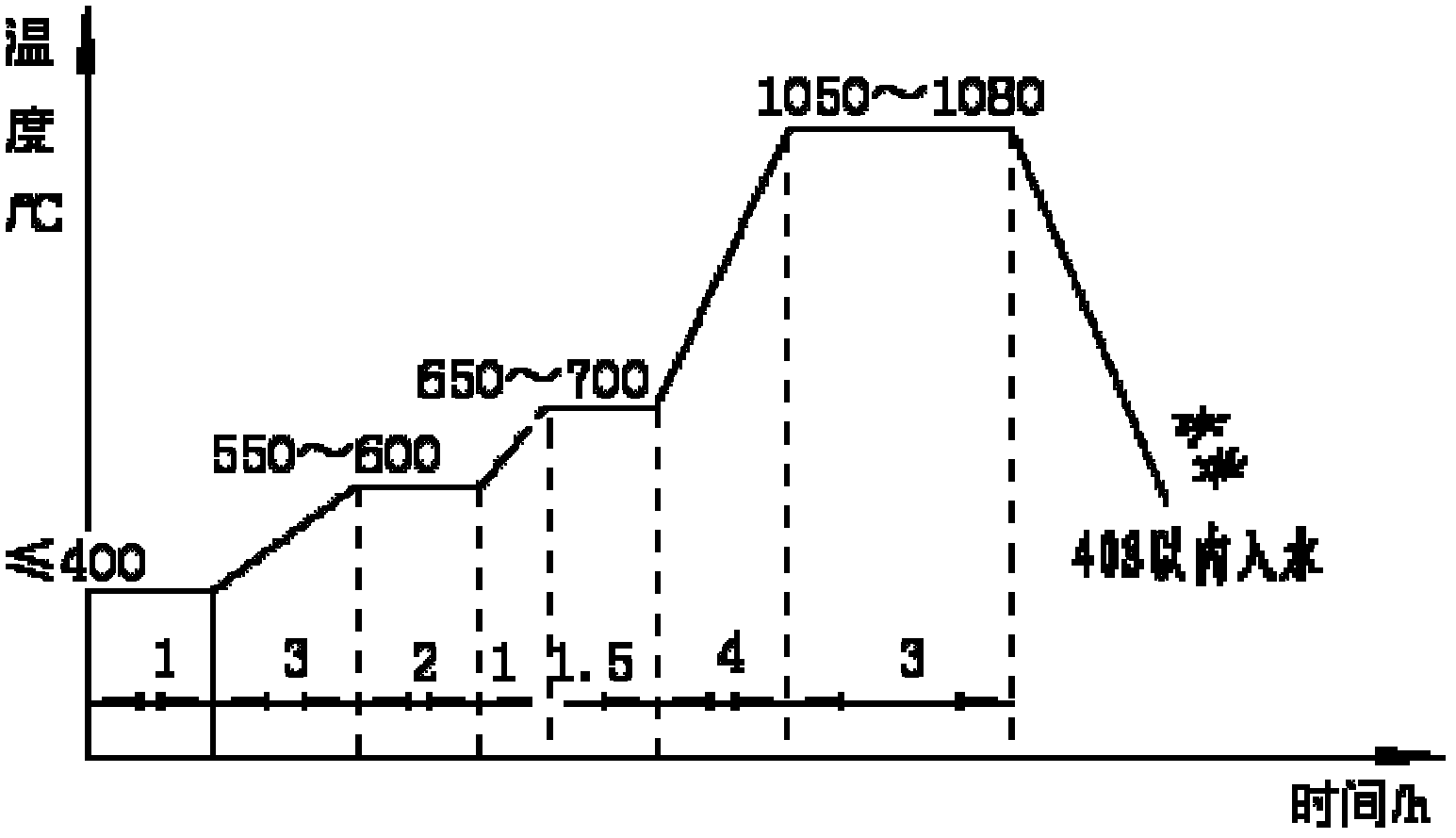

InactiveCN103320696AGood tensile properties at room temperatureOrganization performance is stableManufacturing convertersManganeseWorking temperature

The invention belongs to the technical field of alloy material manufacturing, and especially relates to a manufacturing method of a low-alloy heat-resistant steel plate and a manufacturing method thereof. According to the low-alloy heat-resistant steel plate and the manufacturing method thereof, the steel plate comprises the following components, by weight, 0.08-0.16% of carbon, 0.15-0.40% of silicon, 0.40-0.70% of manganese, no more than 0.015% phosphorus, no more than 0.010% of sulfur, 0.90-1.20% of chromium, 0.20-0.35% of molybdenum, 0.15-0.30% of vanadium, and balance of iron and unavoidable impurities. The steel plate is produced through the processes of converter smelting, LF+VD or RH out-furnace refining, slab continuous casting, slab stacking and slow cooling, re-heating, high pressure water phosphorus removing, slab rolling, steel plate stacking and slow cooling, normalizing+ tempering, and the like. The steel plate provided by the invention has good normal temperature and high-temperature properties, and the like, such that steel plate application safety under high-temperature environment is ensured. The steel plate is mainly used for manufacturing steel structural parts with a working temperature of 540-640 DEG C in a power plant boiler, such as end cap, lug, header, gas-saving device beam, steam pipe, superheater, reheater tube, and the like.

Owner:JIGANG GRP

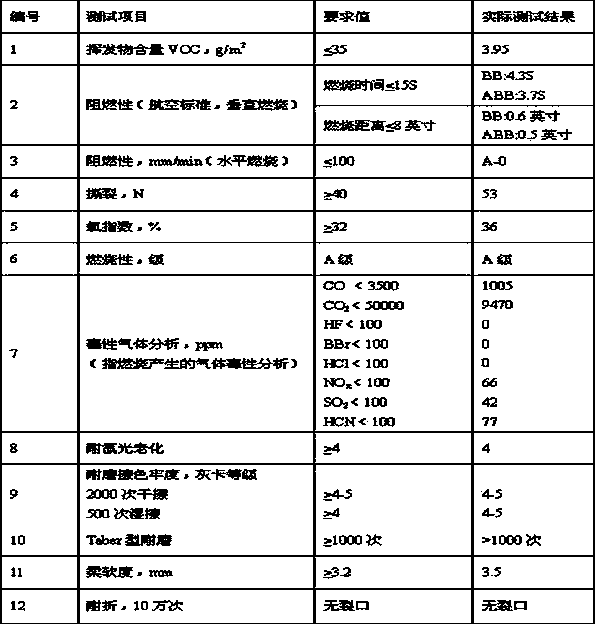

Production process of flame retardant trim cow leather

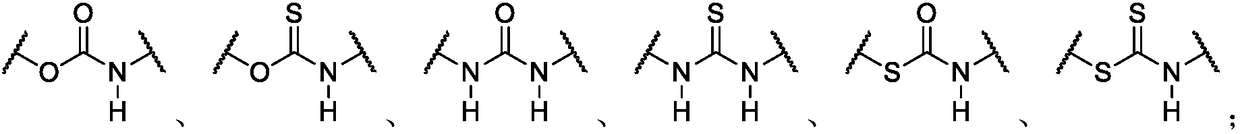

ActiveCN104032048AProper firmnessImprove uniformityTanning treatmentPolyurea/polyurethane coatingsEngineeringWear resistance

The invention relates to a production process of flame retardant trim cow leather. The production process comprises the steps of fleshing, deliming, softening, tanning, shaving, retanning, dyeing, stuffing, drying, milling and finishing, wherein the step of tanning comprises the successive procedures of salting, pickling and chrome powder tanning; and the retanning, the dyeing, the stuffing, the low-temperature airing drying and the finishing adopt characteristic processes. The flame retardant trim cow leather is compact and uniform in body, is excellent in toughness, is good in resilience and is excellent in flame retardance, and the quality can be controlled easily in the production process; after the leather is stretched in a seat or is used, the seat can be kept in an optimal form and comfort because of excellent resilience of the leather; and under the precondition of guaranteeing the softness and flame retardance, the water resistance, the sweat resistance, the color fastness to rubbing and the wear resistance of a coating layer are effectively improved.

Owner:浙江富邦汽车内饰科技有限公司

Method for processing dried sweet potatoes

The invention discloses a method for processing dried sweet potatoes. The method comprises the following steps of: airing the sweet potatoes naturally indoors until the surfaces of the sweet potatoes feel soft; cleaning the surfaces of the aired sweet potatoes with clear water; peeling the cleaned sweet potatoes, and removing peel fiber, diseased spots, dark spots and bitter shreds; soaking the peeled sweet potatoes in clear water at room temperature in time for 8 hours at most; taking the peeled sweet potatoes out of the clear water, putting into a sealed steaming pot in time, steaming with sharp fire for 2-2.5 hours by keeping the pressure in the sealed steaming pot at 0.02-0.04Mpa, and steaming with soft fire for 1.5-2 hours by keeping the pressure in the sealed steaming pot at 0.01Mpa; cutting the steamed sweet potatoes into pieces with widths of 150-200mm and thicknesses of 100-150mm; baking the sweet potatoes pieces in a steam baking room in four phases; and moisturizing the sweet potatoes pieces for more than 10 hours in the steam baking room.

Owner:湖南省永吉农业开发有限公司

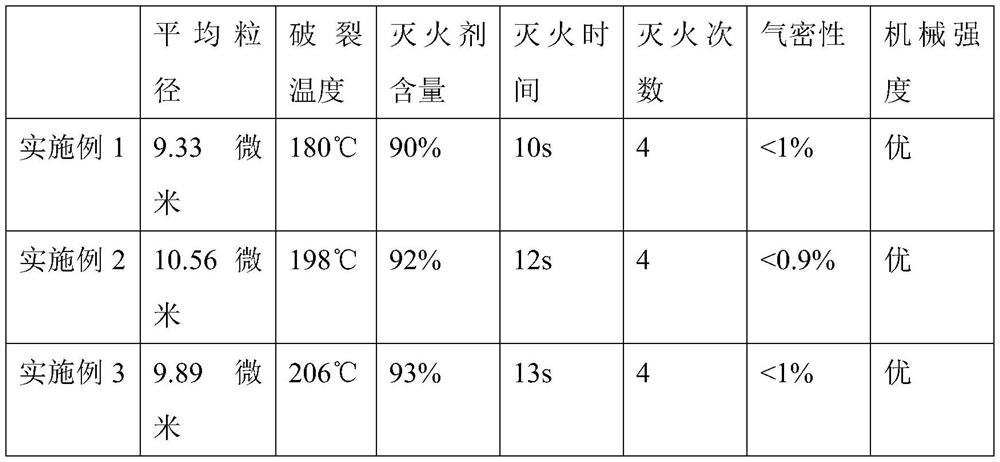

High-stability fire extinguishing microcapsule and preparation method thereof

ActiveCN113476778AHigh strengthImprove thermal stabilityMicroballoon preparationFire extinguisherPolymer scienceMelamine formaldehyde resin

The invention relates to a high-stability fire extinguishing microcapsule and a preparation method thereof. The fire extinguishing microcapsule comprises a shell and a core material, the core material comprises a fire extinguishing agent, the shell comprises an inner layer, an outer layer and an airtight promoter, the inner layer comprises modified melamine-formaldehyde resin generated by reaction of melamine, m-phenylenediamine, urea and a formaldehyde solution, the outer layer is made of modified polyurethane resin generated by reaction of a trimethyloldodecane-diisocyanate addition product and a gelatin solution, and the trimethyloldodecane-diisocyanate addition product is generated by reaction of trimethyloldodecane and a diisocyanate compound. The shell of the fire extinguishing microcapsule has the characteristics of high stability, high toughness and high air tightness, leakage of the core material can be effectively reduced, and the service life of the fire extinguishing microcapsule is prolonged.

Owner:广州十克拉投资有限公司

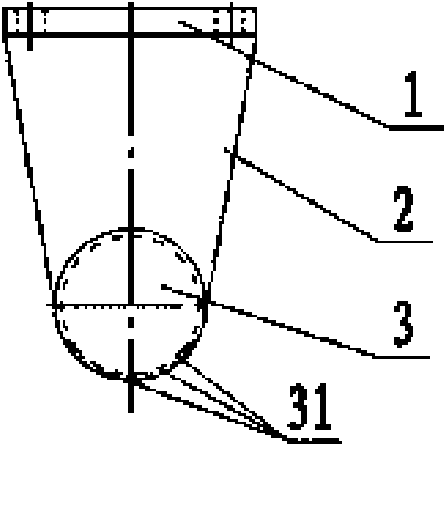

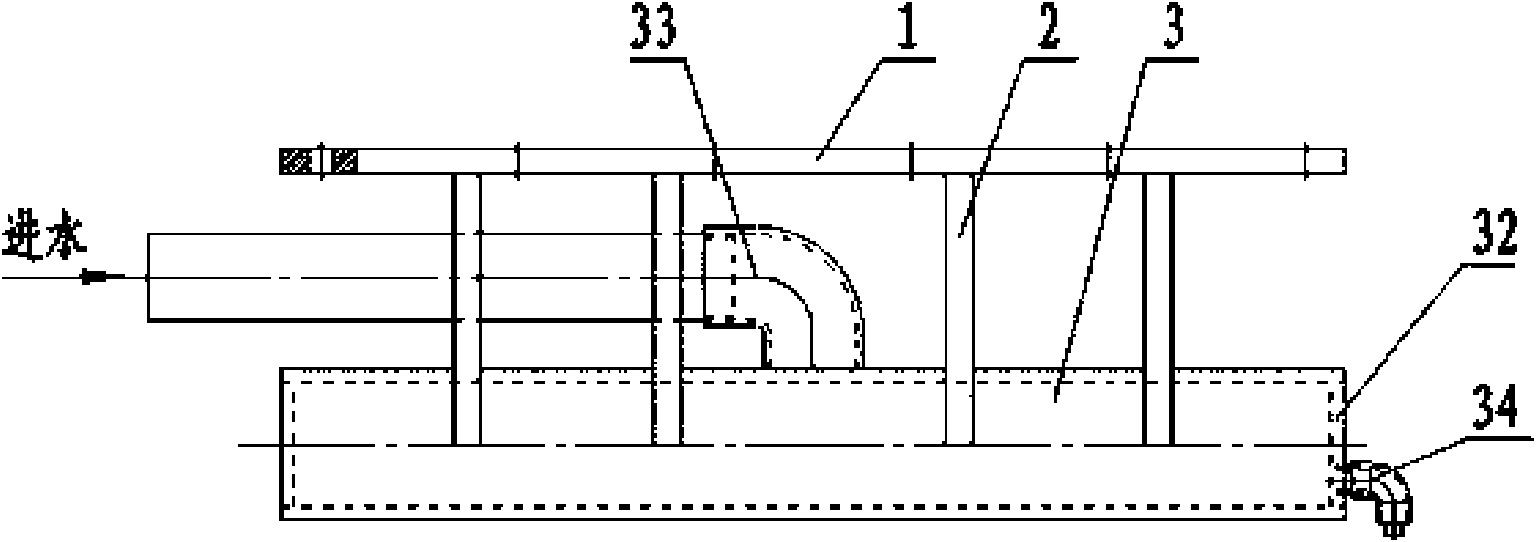

Centrifugal ceramic composite vertical mill roller sleeve and manufacturing method thereof

The invention discloses a centrifugal ceramic composite vertical mill roller sleeve and a manufacturing method thereof. The centrifugal ceramic composite vertical mill roller sleeve comprises an inner layer and an outer layer. The outer layer is high-chromium cast iron, and ceramic particles are embedded in the outer layer. The high-chromium cast iron is prepared from, by weight, 2.3-3.3% of C, 0.3-1.0% of Si, 0.6-1.2% of Mn, 18-22% of Cr, 0.7-1.7% of Ni, 1.5-3.0% of Mo, 0-0.03% of P, 0-0.03% of S and the balance Fe and inevitable impurities. According to the vertical mill roller sleeve, the material proportion of the inner layer and the outer layer is optimized; high-alloy elements are adopted by the outer layer, the matrix can be effectively reinforced by increasing the content of alloy such as C, Cr, Mo and V, the total amount of carbide is increased, and therefore the smoothness of a friction surface can be effectively improved; the outer layer of the roller sleeve is made to be high in abrasion resistance, high in strength and enough in toughness, and the service life of the roller sleeve is effectively prolonged. According to the manufacturing method, a heat treatment technique of annealing, quenching and tempering is adopted, the purposes of improving the carbide form, promoting structural transformation and refining structures are achieved, so that the abrasion resistance and fracture toughness of the roller sleeve are improved.

Owner:河北津西钢铁集团重工科技有限公司

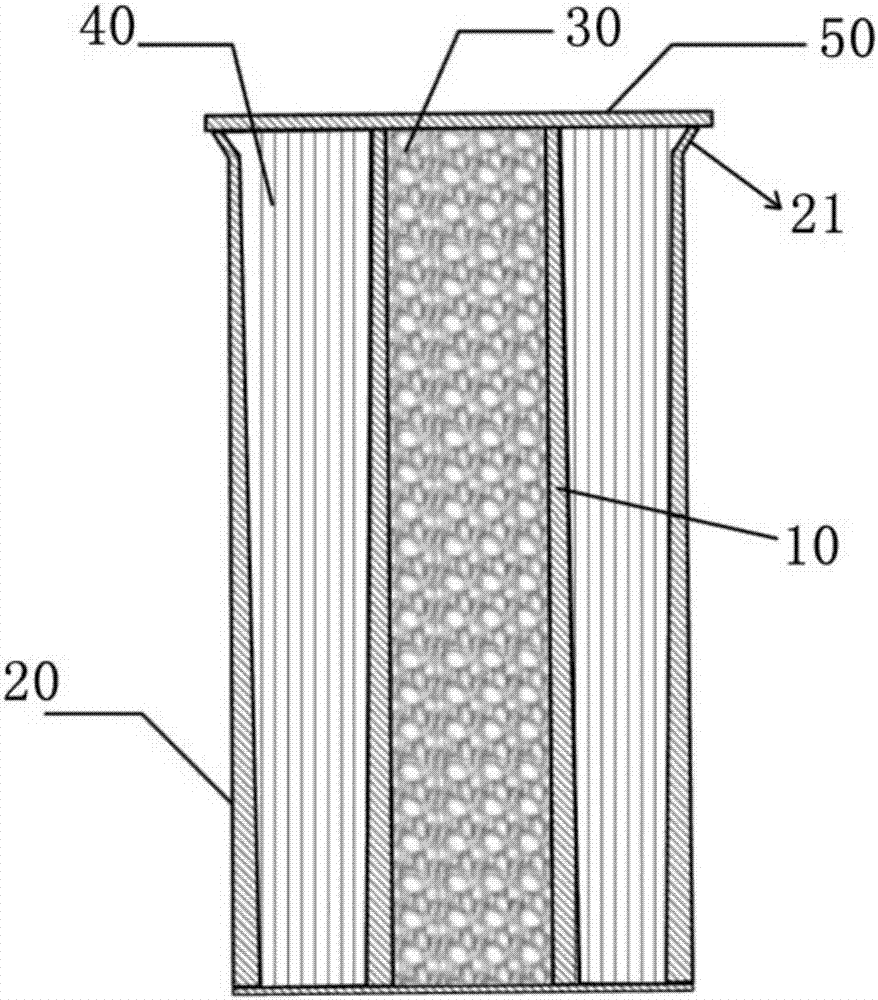

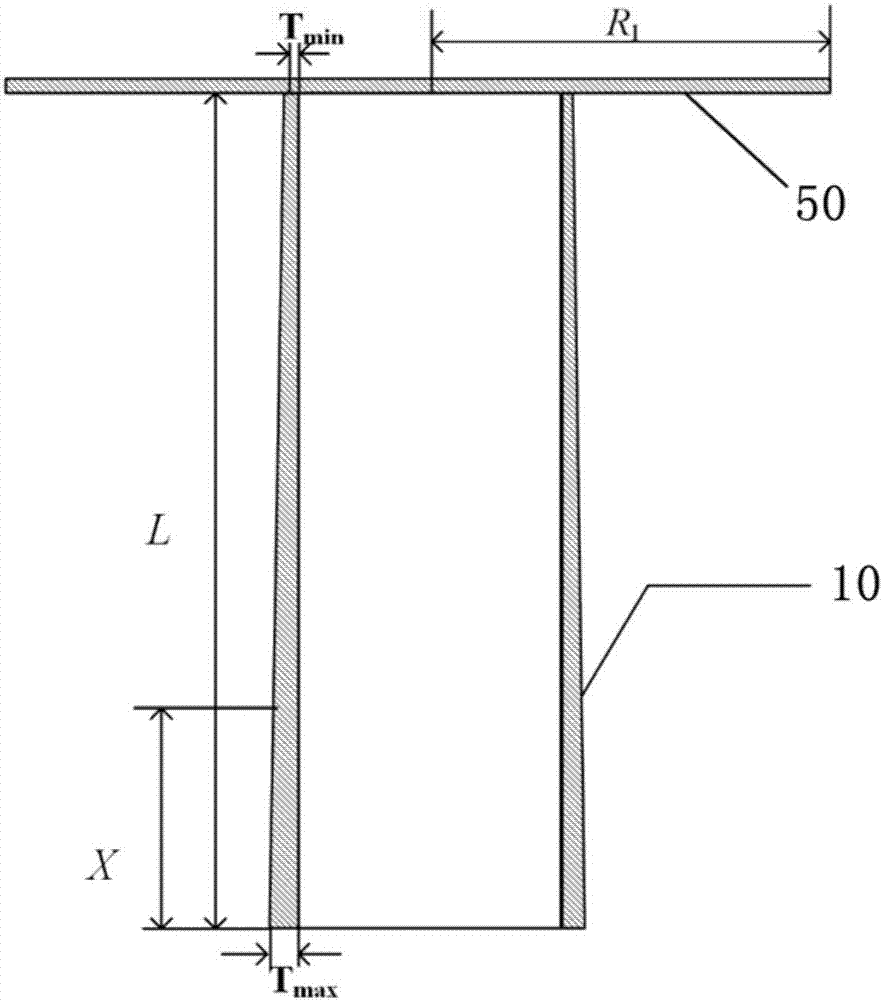

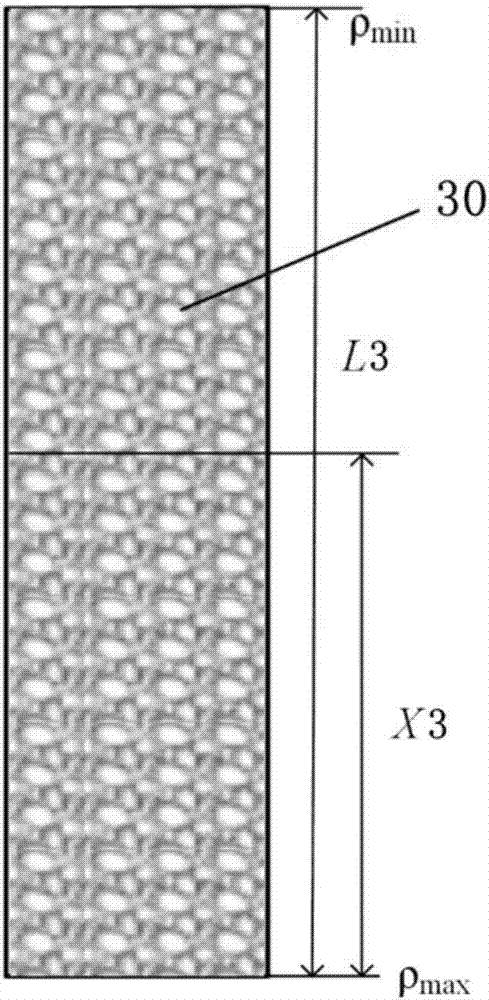

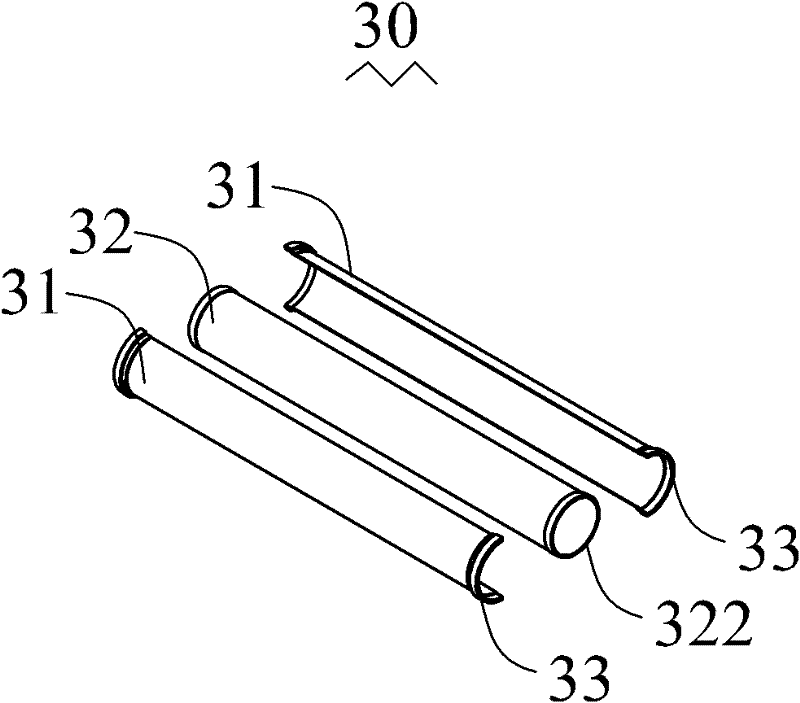

Gradient composite impacting energy absorption pipe fitting

ActiveCN107097741AProtect lifeProtection securityBumpersClimate change adaptationPipe fittingEnergy conversion efficiency

The invention discloses a gradient composite impacting energy absorption pipe fitting. The pipe fitting comprises a gradient inner pipe, a gradient outer pipe, an aluminum foam filling layer and a fiber reinforced cloth filling layer; the gradient inner pipe is sleeved with the gradient outer pipe, the gradient inner pipe is filled with the aluminum foam filling layer, and the portion between the gradient inner pipe and the gradient outer pipe is filled with fiber reinforced cloth. The gradient composite impacting energy absorption pipe fitting has the following advantages that the energy absorption efficiency can be improved in the modes of axial crumple, radial extrusion, expansion energy absorption, tearing energy absorption and the like, when the pipe fitting is applied to an automobile, when collision occurs, the life safety and property safety of automobile occupants can be protected to the maximum extent.

Owner:HUAQIAO UNIVERSITY

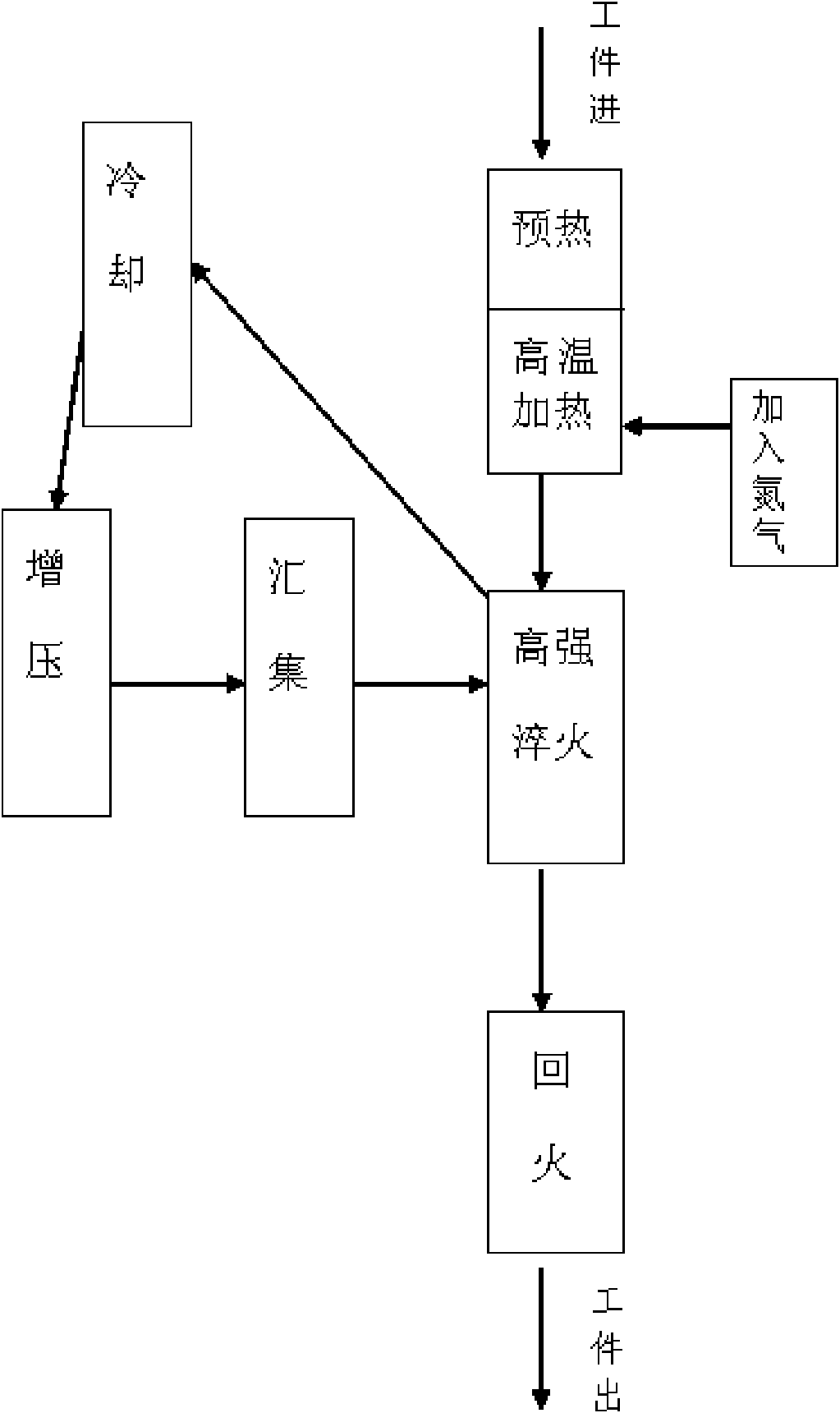

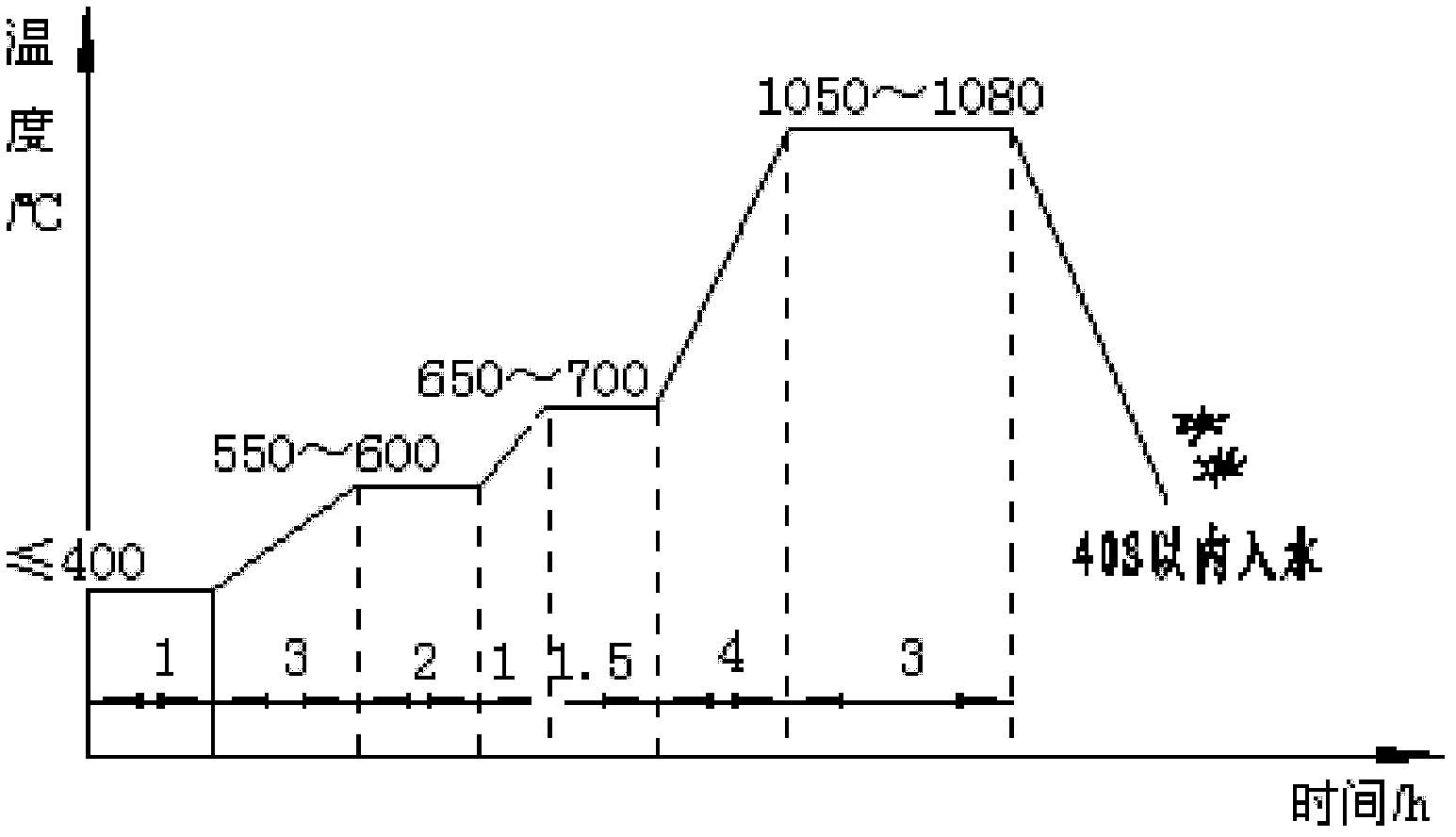

Heating processing technology for wear-resistant cutting board

ActiveCN101570819AHigh strengthIncrease productivityFurnace typesQuenching agentsQuenchingWear resistant

The invention relates to a heating processing technology of a wear-resistant cutting board, in which a shaped wear-resistant cutting board workpiece is preheated, heated under high temperature, and then is subjected to high-strength quenching and tempering. The technology comprises the following steps: A. preheating: the preheating temperature is 450-550 DEG C, and the preheating time is 0.5-1.125min / mm; B. high temperature heating: the temperature is 870-890 DEG C, and the holding time is 0.5-1.125min / mm; C. high-strength quenching: whole spray water time of high-strength quenching is 70-700 seconds, and time in intensified spray is 15-20 seconds; D. tempering: low temperature tempering is carried out, followed by air cooling to room temperature; high pressure cooling water used in the invention is recyclable. The invention has the advantages of making full use of reasonable heating processing technology under the premise of ensuring fine property of the wear-resistant cutting board, improving production efficiency and saving energy consumption, thus lowering production cost of the wear-resistant cutting board.

Owner:LIUZHOU JINMAO MACHINERY

Novel pumping rod

InactiveCN102839332AReasonable formulation of ingredientsStrong enoughDrilling rodsDrilling casingsUltimate tensile strengthThermal treatment

The invention discloses a novel pumping rod which is made of a high-performance alloy steel material. The high-performance alloy steel material comprises the following main components: 0.12-0.18% of C, 0.45-0.85% of Si, 2.2-3.2% of Mn, 1.0-1.4% of Cr, 0.1-0.3% of Ni, 0.12-0.3% of Al, 0.06-0.12% of Co, 0.001-0.004% of B and the balance of Fe. The novel pumping rod disclosed by the invention is reasonable in the preparation of the components; the prepared pumping rod has sufficient strength, rigidity, toughness and cutting performance and excellent corrosion resistance and oxidation resistance; the service performance of the material can be improved and increased through thermal treatment.

Owner:常熟市石油固井工具有限公司

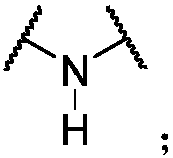

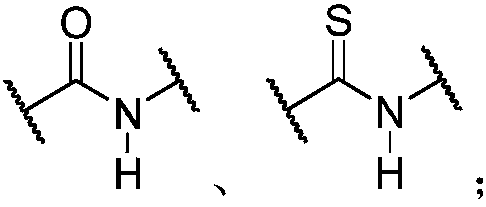

Energy-absorbing method based on hybrid cross-linked network dynamic polymer

The invention discloses an energy-absorbing method based on a hybrid cross-linked network dynamic polymer. The method is characterized in that the hybrid cross-linked network dynamic polymer containing common covalent cross-linking, a dynamic covalent bond and an optional supramolecular hydrogen bond is used as an energy-absorbing material for energy-absorbing protection, wherein the dynamic covalent bond is an inorganic borate bond. The dynamic polymer provided by the invention integrates the respective advantages of the common covalent cross-linking and the dynamic covalent bond; the commoncovalent cross-linking endows the dynamic polymer with certain strength and stability; the dynamic covalent bond in the dynamic polymer has good dynamic reversibility, so the dynamic polymer has the characteristics of energy dissipation and energy absorption and can provide the functions of damping, shock absorption, sound insulation, impact resistance, noise abatement, impact resistance, high toughness and the like as an energy-absorbing material; and the dynamic polymer is especially applicable to the body protection of people during exercises, daily life and working, the body protection ofthe military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

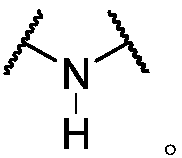

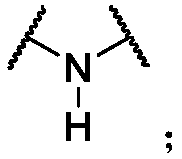

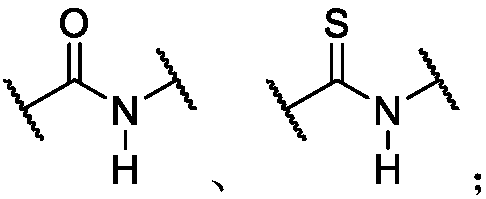

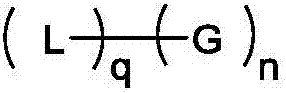

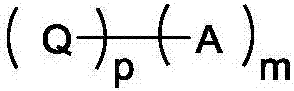

Hybrid crosslinked dynamic polymer

InactiveCN109206576ASimple structureImprove performanceEster polymer adhesivesIonCation–pi interaction

The invention relates to a hybrid crosslinked dynamic polymer, which contains host-guest interaction, covalent bond formed covalent crosslinking and optional other supramolecular interactions. Specifically, covalent crosslinking reaches the gel point of covalent crosslinking or above in at least one crosslinked network, and the other supramolecular interactions are at least selected from ion interaction, metallophilic interaction, dipole-dipole interaction, hydrogen bond interaction, cation-pi interaction, anion-pi interaction, benzene-fluorobenzene interaction, pi-pi stacking interaction, ionhydrogen bond interaction, hydrogen bond interaction, metal-ligand interaction, and radical cation dimerization. As host-guest interaction has the advantages of molecular recognition, stable action effect and the like, the dynamic polymer has self-repairability and good toughness, and covalent crosslinking endows the polymer with certain strength and stability. The dynamic polymer can be used formaking self-repair materials, sealing materials, tough materials, adhesives, shape memory materials and force sensor materials.

Owner:厦门天策材料科技有限公司

Connecting rod material for engines in powder metallurgy and preparation method thereof

The invention discloses a connecting rod material for engines in powder metallurgy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 0.5-1.5% of Mo, 0.5-1.5% of Cr, 0.5-1.0% of Mn, 0.5-1.0% of Si, 1.5-2.0% of Ni, 1.0-2.0% of Cu, 0.4-0.8% of C and the balance of Fe. The preparation method comprises the following steps: mixing, rolling, sintering, carrying out fine die forging, quenching and tempering. The forging density of the material is greater than 7.6g / cm<3>, the tensile strength is greater than 1060 MPa, the yield strength is greater than 600 MPa, the symmetrical cyclic tensile fatigue strength is greater than 350 MPa, and the fatigue life is stably 5 million revolutions.

Owner:CENT SOUTH UNIV

Machining method of peppery chili chicken feet

InactiveCN105639469AReasonable processing technologyLess tastyFood scienceBiotechnologyChicken-claws

The invention discloses a machining method of peppery chili chicken feet. The peppery chili chicken feet is prepared from 60 to 100 kg of chicken feet, 2.0 to 3.2 kg of pepper, 0.8 to 1 kg of fresh chili, 8 to 10 g of lllicium verum, 3 to 5 g of amomum tsaoko, 0.5 to 1 kg of lemon, 30 to 50 g of garlic, 40 to 50 kg of water, 4.7 to 5.7 kg of peppery chili, 1 to 1.5 kg of monosidum glutamate and 2.0 to 3.0 kg of white sugar. The peppery chili chicken feet are prepared through the steps of selecting chicken feet, washing the chicken feet, decocting by brine, boiling by the brine, mixing materials and curing. The peppery chili chicken feet prepared by the invention are deep in taste, strong in chilly taste of the peppery chili, spicy and delicious, delicious in taste and enough in toughness and have an endless aftertaste, the delicious taste and the nutritional ingredients of the chicken feet are also kept, the product quality of the peppery chili chicken feet can be effectively ensured, and the peppery chili chicken feet have the characteristics of reasonable machining technology, cleanliness and sanitation, no pollution, long shelf life, convenience in eating, normal-temperature preservation and low manufacturing cost, are snack food for a business trip, a trip and the like and have better popularization value.

Owner:YUNNAN HENONG FOOD DEV CO LTD

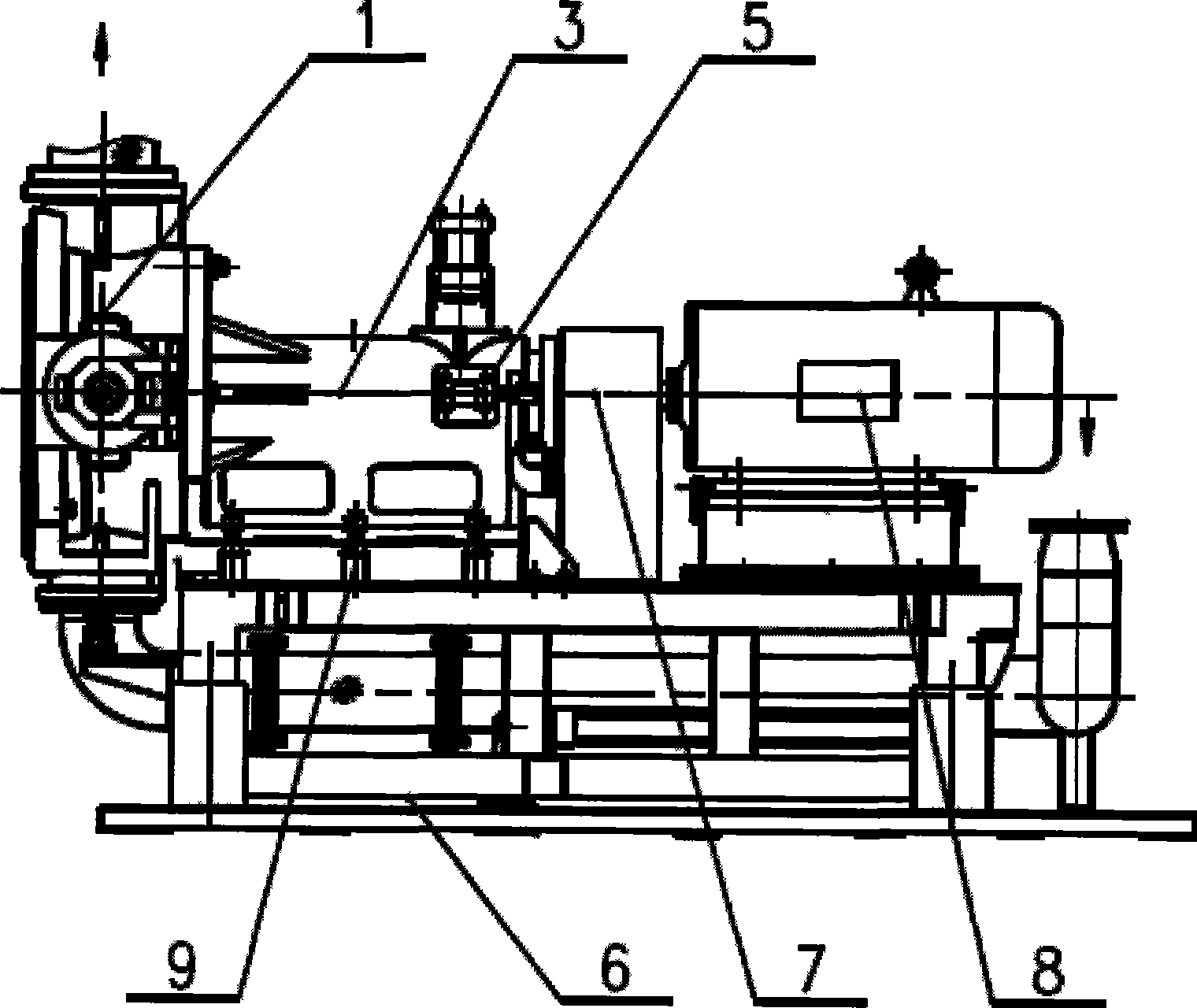

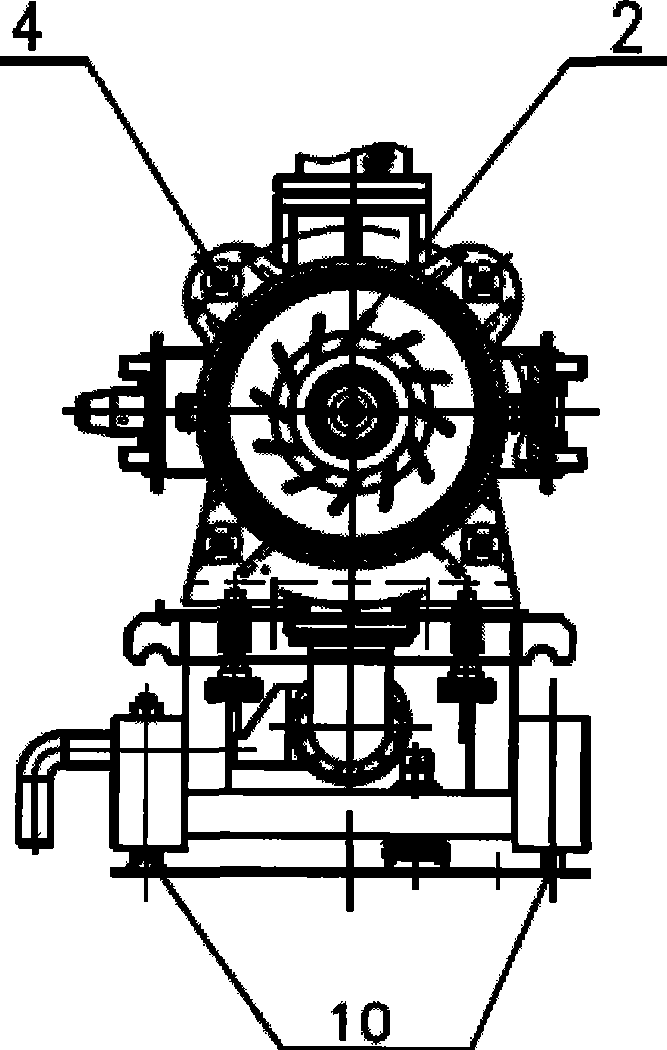

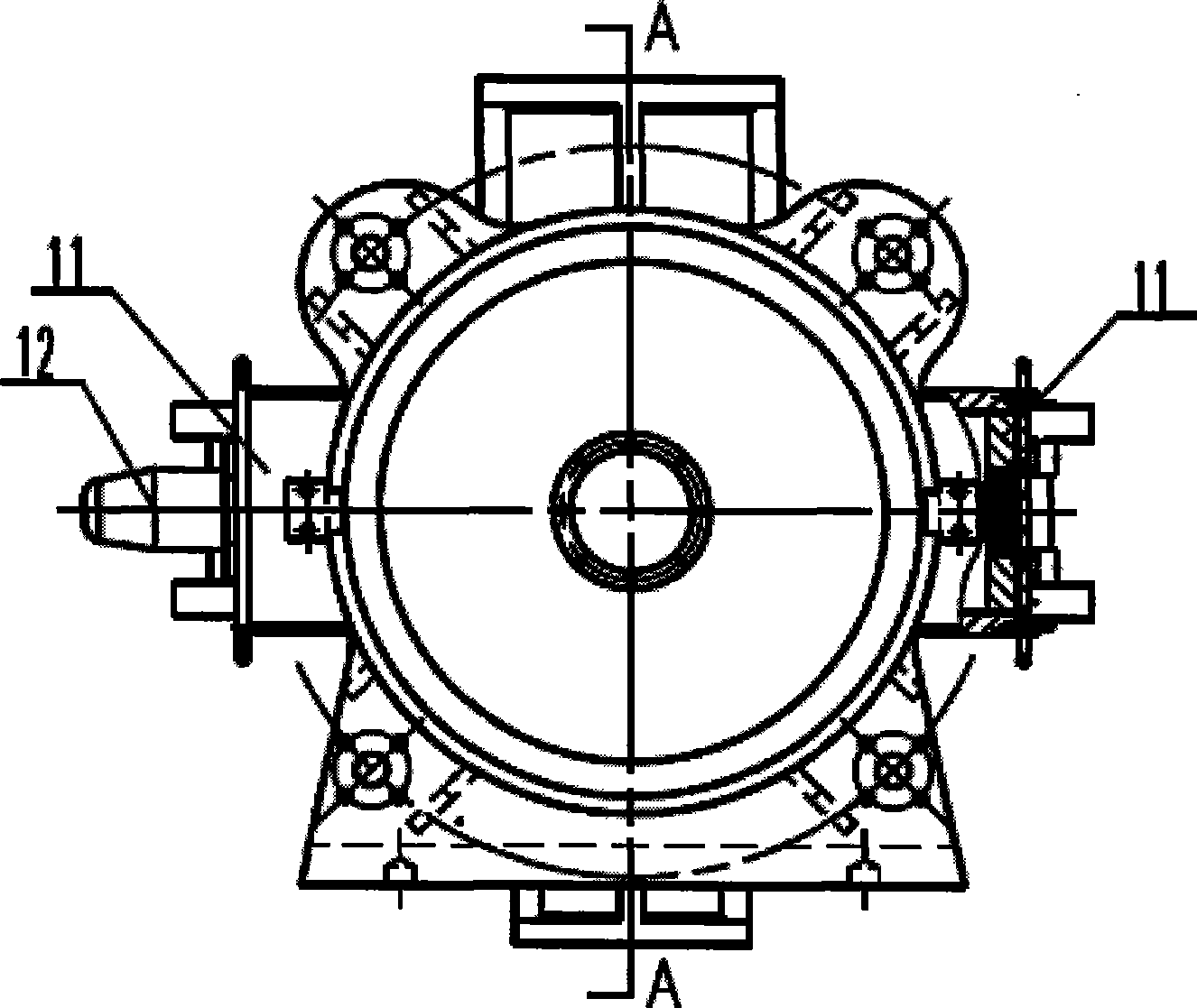

Underwater pelleting device of machine unit for compounding, squeezing and prilling

The invention relates to a mixing extrusion pelleting machine set. An underwater pelleting device of the mixing extrusion pelleting machine set is provided with a machine head template and a pelleting cutter head, wherein the machine head template is arranged on the wall surface of a hot water chamber and sealed, the cutter head is arranged in the hot water chamber through the end of a cutter shaft, a driving motor is in driving connection with the cutter shaft through a coupling, the cutter shaft is arranged in a bearing box and driven by a piston rod of a cylinder, the bearing box is arranged on a trolley bracket, trolley wheels are placed on a guide rail, and the cylinder drives a trolley to move along the guide rail so as to combine and separate the pelleting cutter head and the temperate. The mixing extrusion pelleting machine set rotates at high speed close to a discharge template in the water chamber filled with deionized water during operation, so as to finish pelleting. Cut particles are conveyed to a downstream device along with cooling water. The machine set is safe, is favorable for prolonging service life of the template and a pelleting cutter, and controls a system with simple and easy operation.

Owner:大连橡胶塑料机械有限公司

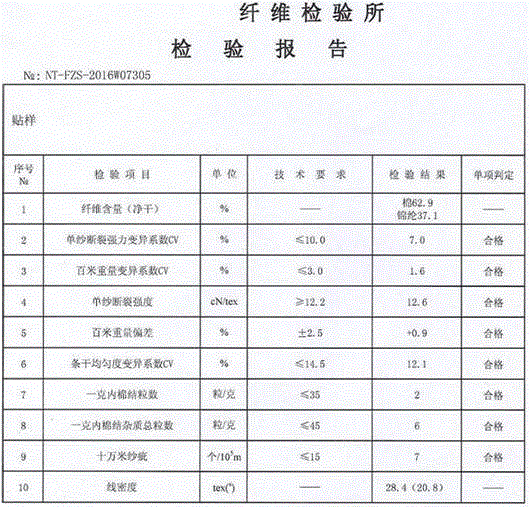

Processing method of polyamide fiber and cotton fiber blended yarns

The invention discloses a processing method of polyamide fiber and cotton fiber blended yarns. The processing method comprises the process steps of polyamide strip processing, combed cotton strip processing and blending processing. The polyamide strip processing steps includes polyamide fiber raw material preprocessing, polyamideblowing, polyamide combing and polyamide pre-drawing, the glossiness, strength and anti-static capability of the fibers are improved by conducting activation treatment and anti-statictreatment on the surfaces of the fibers, the influence of end breakage and static electricity on the spinning process in the post spinning and processing process is avoided, and finally spinning quality is improved. The processing method has the advantages that blended yarns produced by polyamide fibers and cotton fibers contain less fluff, are good in evenness, high in strength and sufficient in toughness.

Owner:NANTONG HUAQIANG CLOTH IND

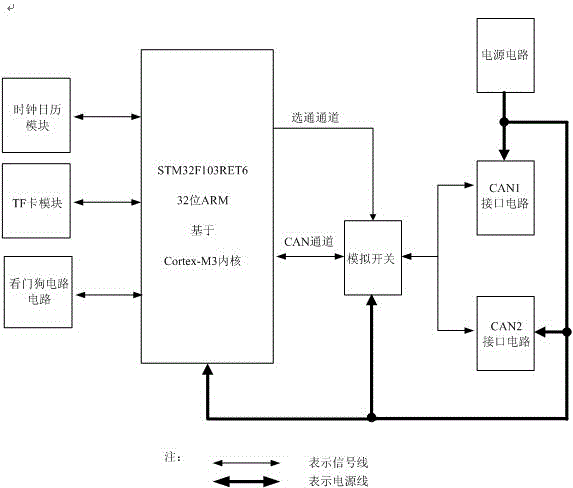

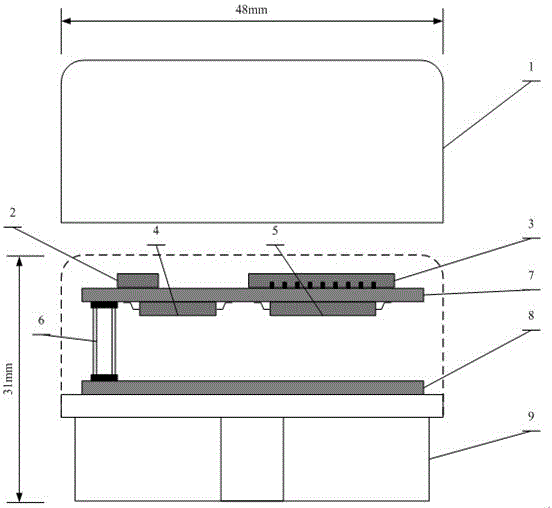

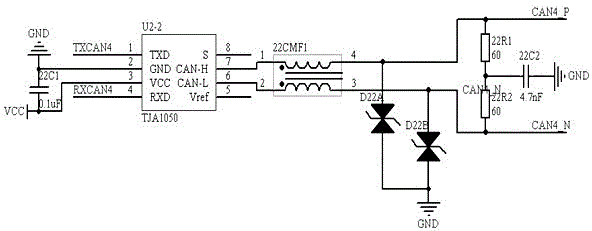

J1939 bus data recorder, component layout method and technological process

ActiveCN104318638ARealize reading and writingRealize editing functions such as reading and writingRegistering/indicating working of vehiclesOperational systemData file

The invention discloses a J1939 bus data recorder. The J1939 bus data recorder comprises a master controller MCU, wherein the master controller MCU respectively reads data of a J1939 data bus and CAN bus diagnosis data of a vehicle bases on a UDS protocol through two CAN interface circuits, and reads and writes a TF card through a TF card interface circuit, and a clock signal is provided for the master controller MCU through an RTC module. The master controller MCU is an STM32 chip, and adopts a uCos-iii operation system. The invention further discloses a component layout method and a technological process of the J1939 bus data recorder; the J1939 bus data recorder can be widely applied to J1939 bus data recording aiming at commercial passenger cars and trucks so as to carry out the off-line analysis on vehicle bus data. The J1939 bus data recorder is very convenient and rapid to use, realizes the immediate recording after insertion, and recorded data files can be opened by using specific software to be used for carrying out data analysis.

Owner:SINO TRUK JINAN POWER

Method for manufacturing degradable plastic packaging bags

InactiveCN105924764AStrong enoughTough enoughFlexible coversWrappersFiberLinear low-density polyethylene

The invention discloses a method for manufacturing degradable plastic packaging bags. The packaging bags are prepared from the following ingredients in parts by weight: 45-50 parts of linear low-density polyethylene, 10-15 parts of calcium carbonate powder, 10-15 parts of corn stalk fibers, 2-3 parts of chitosan, 5-8 parts of corn starch, 2-5 parts of plasticizer, 1-2 parts of toughening agent and 2-8 parts of degradation accelerant. According to the method, the linear low-density polyethylene, the calcium carbonate powder and the corn starch serve as raw materials and can be biologically degraded, and the corn stalk fibers are added to modify the polyethylene, so that the plastic packaging bags have sufficient strength and toughness.

Owner:ANHUI HUILONG PACKAGING CO LTD

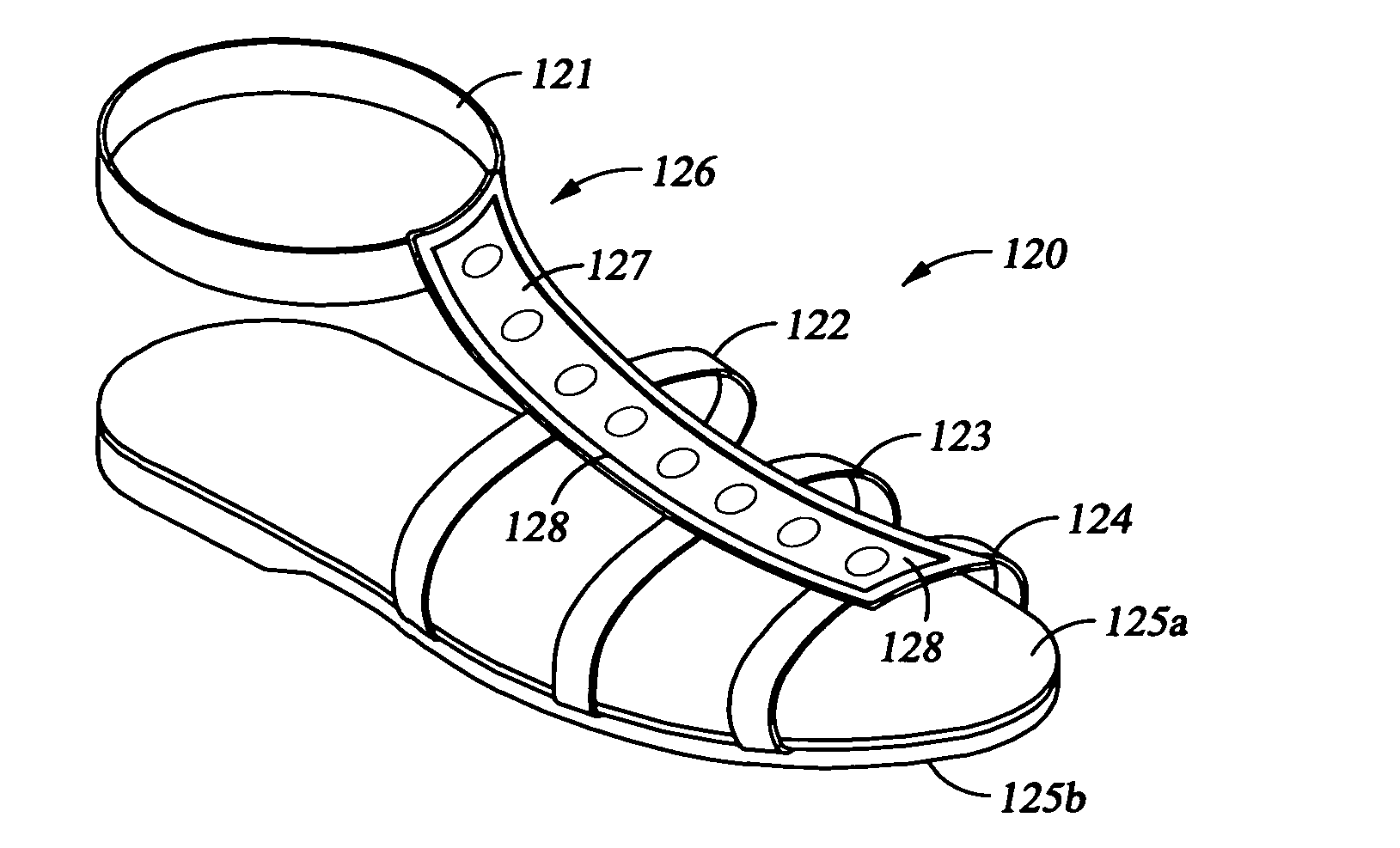

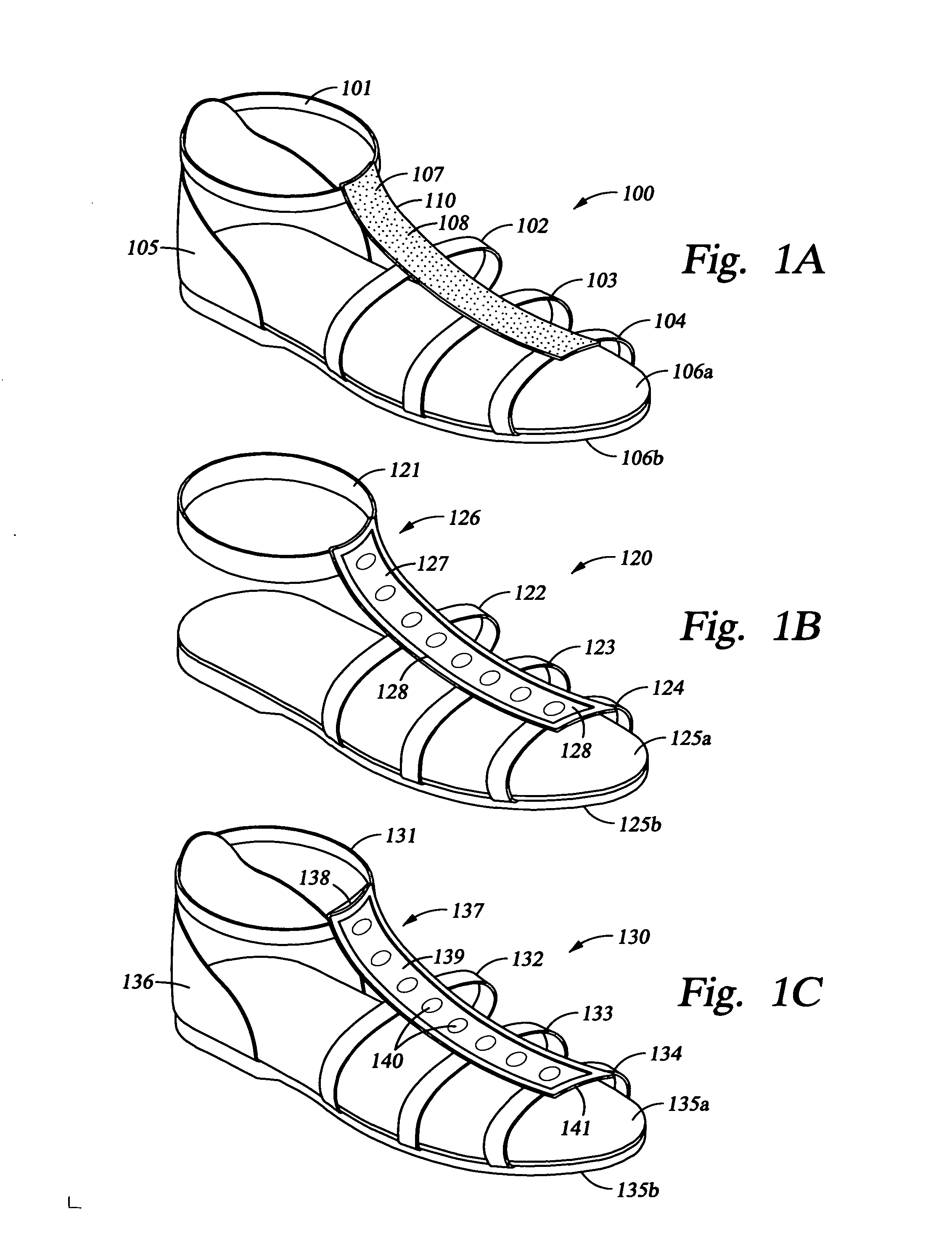

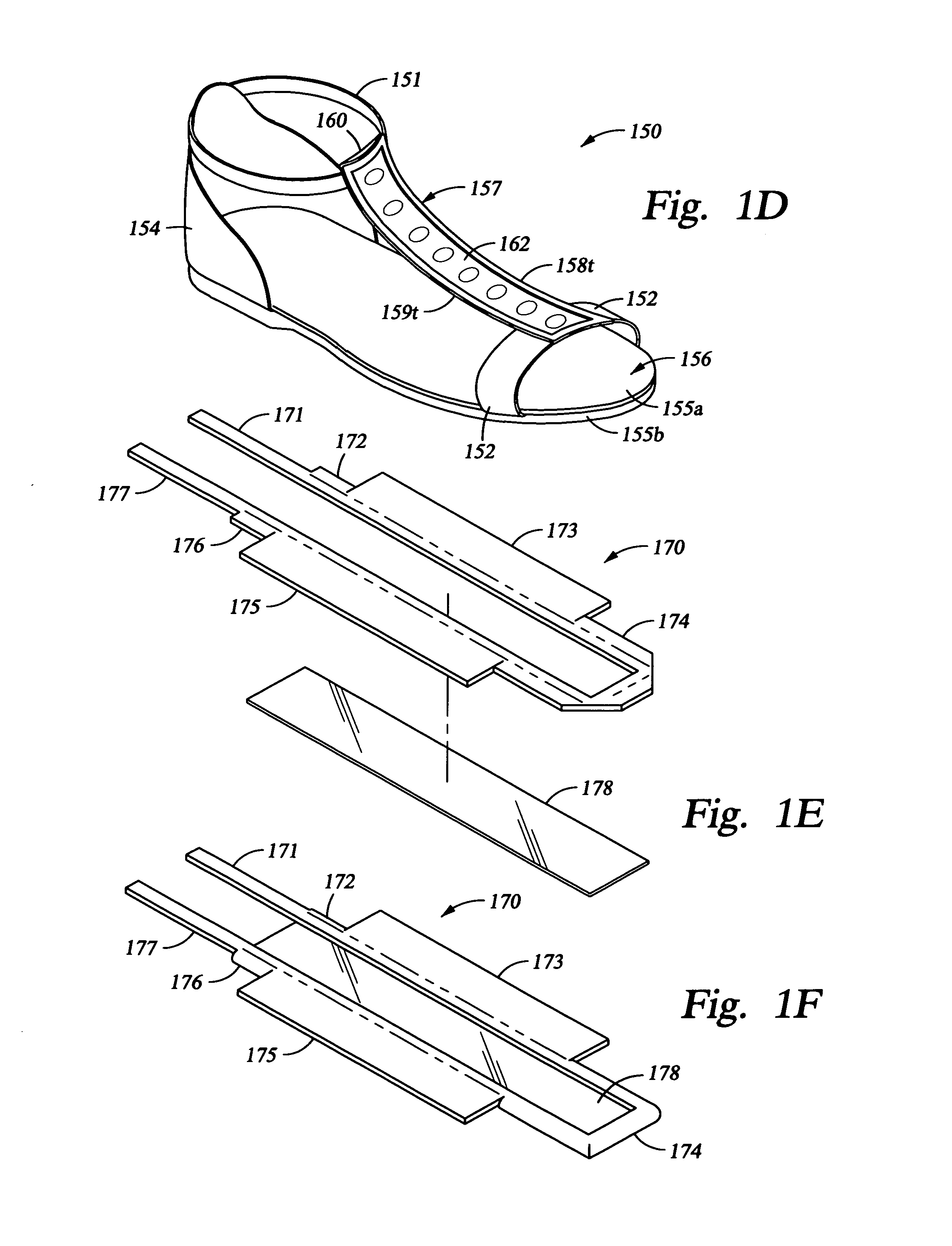

Shoes with a fashion design mounting base material for use with interchangeable fashion design attachments

InactiveUS20140331521A1Easy repositioningEasy to replaceUpperBootlegsMechanical engineeringCombined use

The present invention relates to a shoe, including sandals, for men, women, and children, wherein the shoe includes a shoe display strip which traverses from an ankle strap of the shoe to a forefoot area of the shoe, along a centerline of a sole of the shoe, and wherein a top-facing surface of the shoe display strip includes a fashion design mounting base material which enables the attachment of at least one fashion design attachment. The fashion design attachment may be present in a pouch of showcase which is attached to the fashion design mounting base material, or may be attached directly to the fashion design mounting base material. In addition, the invention relates to a shoe fashion modification kit which is used in combination with a strip of material which travels from an ankle strap of said shoe to a foot retaining strap in a forefoot area of said shoe.

Owner:IN EDEN PROPERTIES LLC

Hybrid crosslinked dynamic polymer

The invention discloses a hybrid crosslinked dynamic polymer, which contains metal-ligand interaction and covalent bond formed covalent crosslinking. Specifically, covalent crosslinking reaches the gel point of covalent crosslinking or above in at least one crosslinked network. The dynamic polymer combines the respective advantages of metal-ligand interaction and covalent crosslinking, and throughregulation of the reactant structure, polymer materials with abundant structures and diverse properties can be prepared. The dynamic reversibility of the metal-ligand interaction in the dynamic polymer enables the polymer to show stimulus response and other functional properties, and has self-repair, shape memory, toughening and other effects on the material in a specific structure. And covalentcrosslinking endows the polymer with certain strength and stability. The dynamic polymer can be widely applied as a self-repair material, ductile material, sealing material, shape memory material, force sensor material and the like.

Owner:厦门天策材料科技有限公司

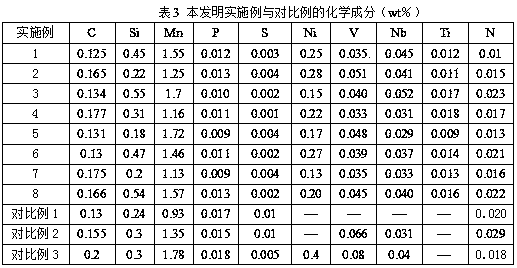

Steel plate for high-performance and corrosion-resisting movable pressure container and manufacturing method thereof

ActiveCN108977731AImprove low temperature toughnessGood welding performanceMetallurgyUltimate tensile strength

The invention relates to the technical field of alloy steel manufacturing and in particular relates to a steel plate for a high-performance and corrosion-resisting movable pressure container and a manufacturing method thereof. The steel plate is prepared from the following chemical components in percentage by mass: 0.12 to 0.18 percent of C, 0.10 to 0.60 percent of Si, 1.10 to 1.74 percent of Mn,less than or equal to 0.013 percent of P, less than or equal to 0.004 percent of S, 0.10 to 0.30 percent of Ni, 0.032 to 0.055 percent of V, less than or equal to 0.06 percent of Nb, 0.008 to 0.020 percent of Ti, 0.009 to 0.025 percent of N and the balance of Fe and unavoidable impurities, wherein the content of the components meets the following relations: Ti / N is less than or equal to 4.0, and the sum of the Nb, the V and the Ti is less than or equal to 0.11 percent; the yield strength of the steel plate is greater than or equal to 430MPa, the tensile strength is 600 to 720MPa, the elongation percentage is greater than or equal to 20 percent and the transverse-50 DEG C KV2 of the steel plate is greater than or equal to 60J; meanwhile, the steel plate has relatively high corrosion performance and is especially suitable for manufacturing movable pressure containers with relatively high requirements.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Wear-resistant hammer head for crusher and production method thereof

InactiveCN102634734AHigh hardnessTough enoughFoundry mouldsFurnace typesWear resistantEvanescent mode

The invention relates to a wear-resistant hammer head for a crusher, and a production method of the wear-resistant hammer head, and belongs to a wear-resistant hammer head for a crusher, and a production method of the wear-resistant hammer head. The invention aims at mainly solving the technical problems of that the wear resistance is poor and the service life is short in the prior art. According to the technical scheme, the wear-resistant hammer head for the crusher comprises the following raw materials by weight percent: 0.9-1.2% of C, 11.0-14.0% of Mn, 0.3-0.7% Si, 0.1-0.5% Cr, less than or equal to 0.3% of Mo, less than 0.1% of V, less than or equal to 0.1% of Ti, less than or equal to 0.04% of P and S, 0.1-0.4% of Re, 0.3-0.6% of No.1 Tieshen, and the balance of Fe. The production method comprises the steps of: manufacturing an evanescent mode-manufacturing a sand mould-smelting alloy-conducting modification-pouring-cleaning-conducting thermal treatment. According to the wear-resistant hammer head and the production method, the rigidity is high, the toughness is enough, the wear resistance is improved greatly, the service life is prolonged by one time compared with the original service life, and the wear-resistant hammer head is especially applicable to non-strong-impaction working conditions.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

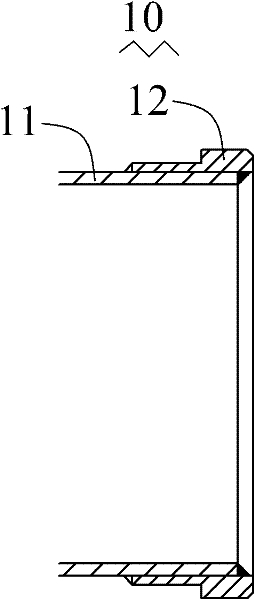

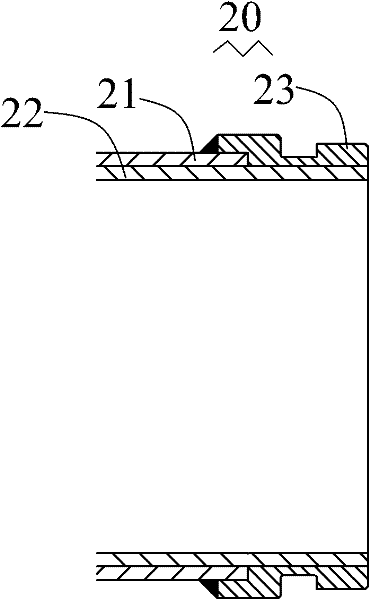

Material conveying machine, composite structure conveying pipe and manufacture method thereof

ActiveCN102537533AHigh strengthReduce toughnessFlanged jointsBulk conveyorsWear resistantShear capacity

The invention discloses a composite structure conveying pipe and a manufacture method of the conveying pipe. The composite structure conveying pipe comprises an outer pipe and an inner pipe, wherein the outer pipe is made of a light alloy material; the inner pipe is made of a light wear-resistant material; and the inner pipe is arranged in the outer pipe. In addition, the invention also discloses a material conveying machine including the composite structure conveying pipe. According to the invention, the outer pipe of the composite structure conveying pipe made of the low-density, high-strength and high-toughness material can provide enough strength and toughness at a lighter weight so as to prevent deformation and burst of the conveying pipe, and has higher shear resistance, less possibility of damages caused by bumping or dropping and lower cost in comparison with the composite material; and the inner pipe made of the light wear-resistant material can provided enough wear resistance at a lighter weight. Therefore, the overall weight of the product is reduced by more than 50% in comparison with that of a steel conveying pipe so as to facilitate assembly and disassembly, greatly improve efficiency and safety and simplify the process, and subsequent heat treatment for the inner layer is obviated.

Owner:ZOOMLION HEAVY IND CO LTD

Production technology of rice-flour noodles

The invention discloses a production technology of rice-flour noodles. The production technology comprises the following steps of (1) selecting raw materials; (2) washing rice, and performing soaking;(3) performing grinding to obtain pulp; (4) performing pressure filtration and crushing; (5) steaming flour; (6) performing squeezing to obtain slices and threads; (7) performing ageing for the firsttime; (8) performing thread loosening; (9) performing re-steaming; (10) performing ageing for the second time; (11) washing vermicelli, and performing baking; (12) performing sorting, measuring and packaging; and (13) performing warehousing for storage. Through the adoption of the production technology disclosed by the invention, the quality and the appearance of rice-flour noodle finished products can be improved, and the rice-flour noodle finished products have the characteristics of being not liable to break, not liable to adhere, and good in toughness.

Owner:宁波米氏实业有限公司

Supporting hanger for grooved cable bridge and preparation process of supporting hanger

ActiveCN104862608AHigh elastic limitIncrease yield pointSolid state diffusion coatingCable trayElectric cables

The invention discloses a supporting hanger for a grooved cable bridge. The supporting hanger comprises the following constituents: C, Cr, B, Ni, N, Mo, Cu, Al, V, W, Si, Mn, Nb, Ti, S, P, and the balance of Fe and inevitable impurities. The invention further provides a preparation process of the supporting hanger for the grooved cable bridge. The preparation process is simple and feasible, low in manufacture cost and pollution-free in the manufacture process, and the prepared supporting hanger is abrasion-proof, corrosion resistant, high in strength and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com