Hybrid crosslinked dynamic polymer

A hybrid cross-linking and polymer technology, applied in the field of intelligent polymers, can solve the problems of inability to combine structural and dynamic properties, limited dynamic regulation ability, singleness, etc., and achieve excellent recycling, high usability, and high value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

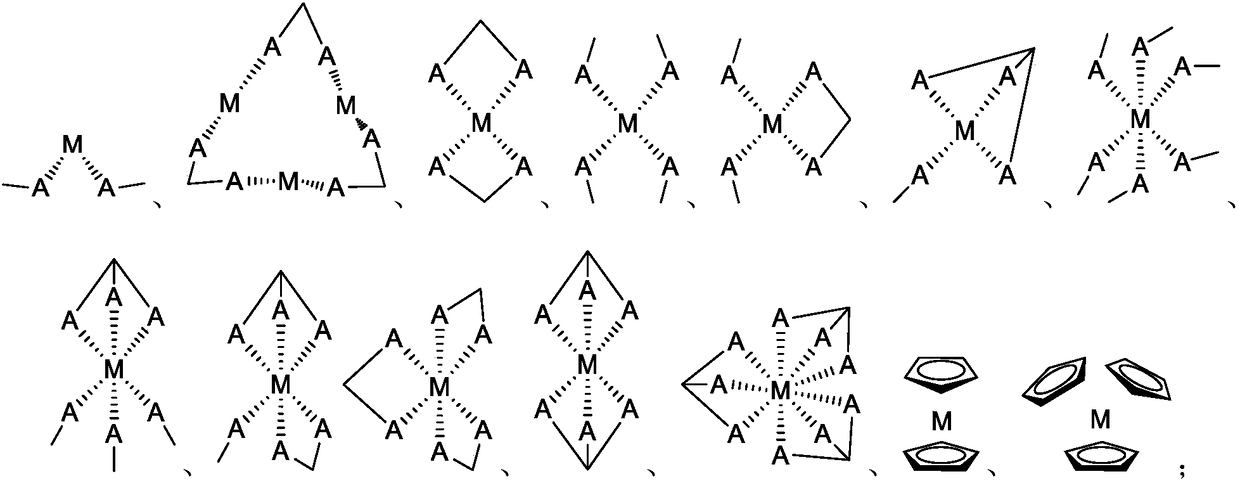

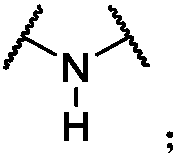

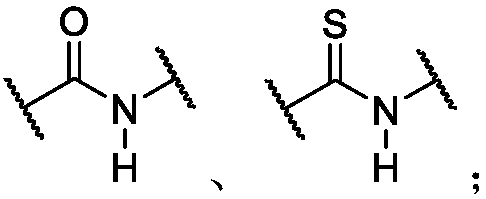

Method used

Image

Examples

preparation example Construction

[0152] In the preparation process of dynamic polymer, three methods of mechanical foaming method, physical foaming method and chemical foaming method are mainly used to foam dynamic polymer.

[0153] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0154] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under ...

Embodiment 1

[0213] Add 10.9g 2,6-diaminopyridine, 100mL N,N-dimethylformamide, 2mL condensing agent 1-hydroxybenzotriazole (HOBT) and 3mL activator 1-(3- Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), after stirring and mixing evenly, add 13g of 2-propene-1,1-dicarboxylic acid, continue to stir and react at room temperature for 12h , add 5.5g of 4-mercaptopyridine and 0.5g of antioxidant 168, after mixing evenly, put the reactant under a 300W ultraviolet lamp for 30min, remove the solvent, put the reactant, 2.4g of 1,2-ethanedithiol , 100mL dioctyl phthalate, 2mL 0.2mol / L copper chloride solution, and 3mL 0.2mol / L zinc chloride solution were mixed and stirred evenly, placed in a suitable mold, irradiated with a 300W ultraviolet lamp for 30min, and immediately after cooling A dynamic polymer plasticizer swelled gel is obtained. Make it into a dumbbell-shaped sample with a size of 80.0×10.0×2mm, and use a tensile testing machine to perform a tensile test. The tensile rate is...

Embodiment 2

[0215] Add 100mL of toluene, 16g of tetrahydrofuran-2,5-dicarboxylic acid, 11.4g of 1,2:5,6-diepoxy-hexane, 0.5g of chromium naphthenate into reactor No. 1, and stir evenly. Raise the temperature to 100°C, after 6 hours of reaction, add 18.9g of 4-isocyanato-2,6-dichloropyridine, continue to stir and react for 2 hours, remove the solvent and transfer the reactant to the wide-mouthed No. 2 reactor. Add 100mL N-butyl-N-methylpiperidinium bromide ionic liquid, 3mL 0.2mol / L ferric chloride solution, 2mL0.2 mol / L silver nitrate solution, 3g graphene, 8.4g 1,6-diisocyanate hexane, 0.3g triethylamine, 3g gallium indium tin liquid alloy, continue to stir for 5 minutes, ultrasonic for 30 minutes, after mixing evenly, stop stirring, put it in an oven at 80°C, and maintain this state for 6 hours, then A dynamic polymer ionic liquid-swellable gel was obtained. It was made into a dumbbell-shaped sample with a size of 80.0×10.0×2.0mm, and a tensile test was carried out using a tensile test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com