Dynamic polymer material and application thereof

A technology of polymer materials and polymer chains, used in adhesives, coatings, etc., can solve the problem that the characteristics of dynamic reversible covalent bonds are difficult to fully reflect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

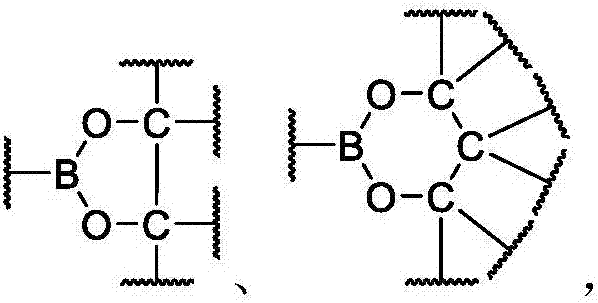

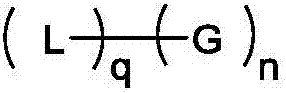

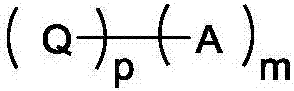

[0105] One embodiment of the present invention, a dynamic polymer material, is characterized in that, it contains the aminomethyl phenyl borate bond that diol element and aminomethyl benzene boronic acid element form on polymer chain skeleton, Wherein the following components are at least obtained after the complete hydrolysis of the aminomethylphenyl borate bond:

[0106] Component (1) is at least one polyol compound (I) containing two or more diol units, wherein the diol units are selected from 1,2-diol units and 1, 3-diol moiety;

[0107] Component (2), which is at least one phenylboronic acid compound (II) containing two or more aminomethylphenylboronic acid units;

[0108] Wherein, at least one polyol compound (I) in component (1) contains three or more diol radicals, or at least one phenylboronic acid compound (II) in component (2) contains three or three More than one aminomethylphenylboronic acid group;

[0109] And, when only containing small molecule polyol compou...

Embodiment 1

[0421] In the there-necked flask, add 10.7ml of aminomethylbenzeneboronic acid-terminated polypropylene glycol (b) (using 2-formylphenylboronic acid, polyetheramine with a molecular weight of about 2000 as a raw material, toluene as a solvent, and sodium borohydride as a reducing agent, Synthesized by Petasis reaction), heated to 120°C under stirring, weighed 4.61g of polyol compound (a) (1,3,5-triacryloylhexahydro-1,3,5-triazine and 3 -Mercapto-1,2-propanediol as raw material, with AIBN as initiator and triethylamine as catalyst, prepared by mercaptan-alkene click addition reaction) was added into a three-necked flask, and it was fully mixed with polypropylene glycol by stirring After 30-40 minutes of reaction, pour it into a suitable mold, and place the sample in a vacuum oven at 80°C for 24 hours for further reaction, then cool to room temperature for 30 minutes, and finally obtain a block of rigid polymer The material has certain surface strength and rigidity, but poor tou...

Embodiment 2

[0424] In a dry and clean flask, measure 20ml 1,2-diol-terminated polyethylene glycol (polyethylene glycol 400 and acrylic acid are used as raw materials to obtain double bond-terminated polyethylene glycol through esterification, and then and 3-mercapto-1,2-propanediol by thiol-alkene click addition reaction), heated to 80°C, and added 5.34g of aminomethylbenzeneboronic acid compound (a) under stirring (using 1,3, 6-triaminohexane, 2-formylphenylboronic acid as raw materials, toluene as solvent, sodium borohydride as reducing agent, synthesized by Petasis reaction), after stirring evenly, a small amount of triethylamine was added dropwise, and continued at 80°C Stirring reaction is carried out. After stirring for about 1-1.5h, the polymer sample with a certain viscosity is poured into a suitable mold, placed in a vacuum oven at 80°C to continue the reaction for 24h, and then cooled to room temperature for 30min. Colloidal solid samples of polymers. Make it into a dumbbell-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com