Dynamic polymer having hybrid cross-linked network and application thereof

A technology of hybrid cross-linking and cross-linking network, applied in the field of smart polymers, which can solve the problems of limitation and limited dynamics of dynamic covalent bonds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

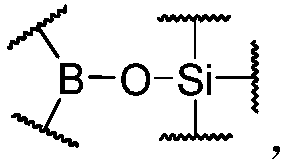

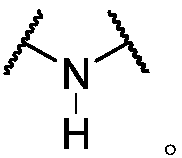

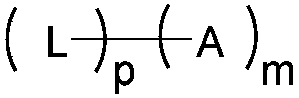

[0210]In the preparation process of the dynamic polymer, for the dynamic polymer with the first kind of network structure (containing only one cross-linked network, and this cross-linked network contains both common covalent cross-links and organoboric acid silicon ester bond cross-links), It can be obtained by using at least one organoboron compound (I) and at least one silicon-containing compound (II) to participate in the reaction to form organoborate silicon ester bonds and ordinary covalent bonds for hybrid crosslinking; or by using at least one compound (III ), or it participates in the reaction with at least one organoboron compound (I) and / or at least one silicon-containing compound (II) to generate organic borate silicon ester bonds and ordinary covalent bonds for hybrid crosslinking; or use at least one A compound (IV), or it participates in the reaction with at least one compound (V) to form a common covalent bond for hybrid crosslinking; wherein, at least one organo...

Embodiment 1

[0317] A dynamic polymer with a double cross-linked network is prepared by using a macromolecular organoboron compound (I), a small molecular silicon-containing compound (II), a macromolecular compound (V), and a small molecular compound (V), wherein the first network is a dynamic copolymer. Valence cross-linking, the second network is common covalent cross-linking.

[0318]

[0319]Add 15g acrylamide-phenylboronic acid copolymer (a) (with AIBN as initiator, acrylamide, 3-acrylamidophenylboronic acid as raw material, obtain by RAFT free radical polymerization) in the three-necked flask, 200ml deionized water, heat After stirring and dissolving at 50°C, add a little acetic acid dropwise, and slowly add 1.7g of silane compound (b) (made by reacting 3-aminopropylmethyldimethoxysilane and adipoyl chloride as raw materials), stir and mix After 30 min, 2 ml of triethylamine was added, and the stirring reaction was continued at 50° C. for 2 h to form the first network. Then add 1...

Embodiment 2

[0321] A dynamic polymer with a double cross-linked network is prepared by using a small molecular compound (V), a macromolecular compound (V), a macromolecular organoboron compound (I), and a small molecular silicon-containing compound (II), wherein the first network is a common copolymer. valence crosslinks, and the second network is dynamic covalent crosslinks.

[0322]

[0323] Add 100ml of tetrahydrofuran solvent in a dry and clean reaction flask, seal it, use argon gas bubbles to remove oxygen for 1h, then add 0.6g azide compound (a) (using pentaerythritol and 3-bromopropionic acid as raw materials) in the reaction flask , after pentaerythritol 3-bromopropionate is obtained by esterification, it is prepared by reacting it with sodium azide), 4.32g of alkyne-terminated polyamide (b) (polyamide with a molecular weight of about 5000, 5- Alkynyl hexanoic acid and propargyl alcohol as raw materials, dicyclohexylcarbodiimide and 4-dimethylaminopyridine as catalysts, prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com