Energy-absorbing method based on hybrid cross-linked network dynamic polymer

A technology of hybrid cross-linking and cross-linking network, applied in the field of energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

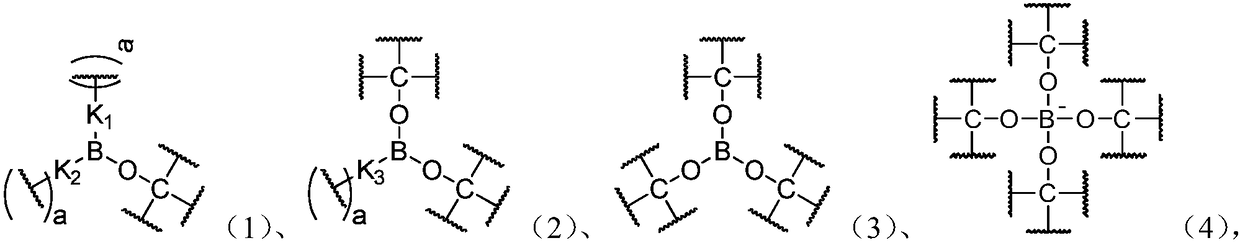

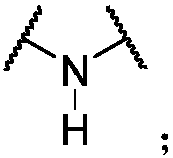

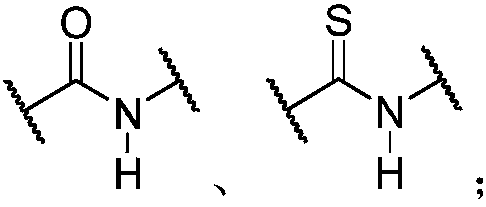

[0256] In the preparation process of the dynamic polymer, for the dynamic polymer with the first kind of network structure (containing only one cross-linked network, and this cross-linked network contains both common covalent cross-links and inorganic borate bond cross-links), It can be obtained by using at least one inorganic boron compound (I) and at least one compound (II) containing a single hydroxyl group to participate in the reaction to form an inorganic borate bond and a common covalent bond for hybrid crosslinking; or use at least one A compound (III), or it participates in the reaction with at least one inorganic boron compound (I) and / or at least one compound (II) containing a single hydroxyl group to form an inorganic borate bond and a common covalent bond for hybridization Obtained by cross-linking; or by using at least one compound (IV), or by participating in the reaction with at least one compound (V) to generate common covalent bonds for hybrid cross-linking; w...

Embodiment 1

[0359] Take by weighing 20.5g side group and contain the random copolymer of inorganic boronic acid group and succinic anhydride group (first take AIBN as initiator, vinyl chloride, (but-3-en-1-yl) succinic anhydride as monomer, by free base polymerization to obtain the random copolymer 1 of the two; then use p-toluenesulfonic acid as a catalyst to prepare N-(2-aminoethyl) boric acid and random copolymer 1 through amidation reaction), 12.5g A random copolymer containing hydroxyl and amino groups in side groups (with AIBN as the initiator, N-(3-aminopropyl) acrylamide and hydroxyethyl acrylate as monomers, prepared by free radical polymerization), 0.15g Toluenesulfonic acid, 1.5g di-n-butyltin dilaurate, 5.2g dioctyl phthalate, 0.25g stearic acid, 0.06g antioxidant 168, 0.12g antioxidant 1010 are mixed evenly, and then added to the small compact Banbury blending is carried out in the mixer, and the mixing temperature is controlled below 40°C. After the mixing is completed, tak...

Embodiment 2

[0361] Weigh a certain amount of random copolymer 1 containing amide groups and hydroxyl groups in side groups (using AIBN as the initiator, butyl acrylate, isopropyl acrylamide, and hydroxyethyl acrylate as monomers, prepared by RAFT polymerization) and dissolve Prepare a 0.25mol / L solution in tetrahydrofuran solvent. Take 60mL of the solution of random copolymer 1, add hexamethylene diisocyanate in an amount of 36% of the hydroxyl group, 7.5% by mass fraction (accounting for the total solids of the system) of organic montmorillonite dispersed in an appropriate amount of tetrahydrofuran, and stir to disperse After 5 minutes, ultrasonication was carried out for 10 minutes, and then 3 drops of dibutyltin dilaurate were added dropwise, stirred and mixed evenly, protected by nitrogen gas, heated to 85° C. for 1.5 hours; and then added a macromolecular dibasic boric acid compound ( Using triethylamine as catalyst, dichloromethane as solvent, excess 4-morpholino boronic acid and 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com