Dynamic polymer with hybrid cross-linked network and application thereof

A technology of hybrid cross-linking and cross-linking network, applied in the field of smart polymers, which can solve the problems of limitation and limited dynamics of dynamic covalent bonds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

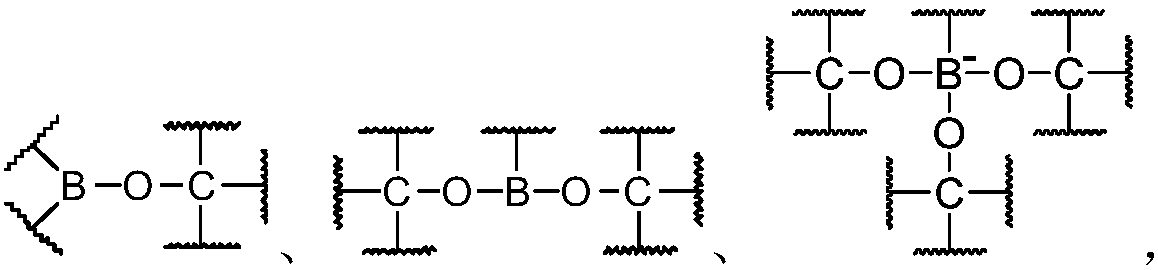

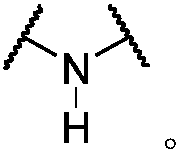

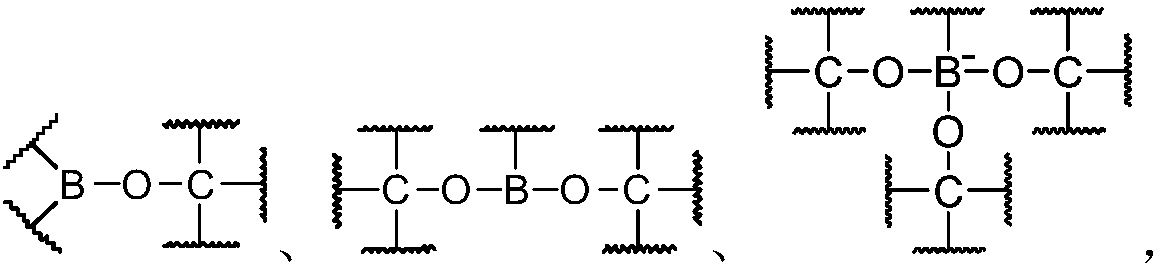

[0276] In the preparation process of the dynamic polymer, for the dynamic polymer with the first network structure (containing only one cross-linked network, and this cross-linked network contains both common covalent cross-links and organic borate bond cross-links), It can be obtained by using at least one organoboron compound (I) and at least one compound (II) containing a single hydroxyl group to participate in the reaction to form an organic borate bond and a common covalent bond for hybrid crosslinking; or by using at least one A compound (III), or it participates in the reaction with at least one organoboron compound (I) and / or at least one compound (II) containing a single hydroxyl group to form an organic borate bond and a common covalent bond for hybridization Obtained by cross-linking; or by using at least one compound (IV), or by participating in the reaction with at least one compound (V) to form a common covalent bond for hybrid cross-linking; wherein, at least one...

Embodiment 1

[0384] Take by weighing 12.5g phenylboronic acid graft modified nitrile rubber (with polybutadiene-acrylonitrile random copolymer, 4-mercaptophenylboronic acid as raw material, with DMPA as photoinitiator, under ultraviolet light irradiation condition, by Mercaptan-alkene click addition reaction makes), 22.5g hydroxyl graft modified nitrile rubber (with polybutadiene-acrylonitrile random copolymer, 2-(2-mercaptoethoxy) ethanol as raw material, Using DMPA as a photoinitiator, under the condition of ultraviolet light irradiation, through mercaptan-alkene click addition reaction) and 1.2g trihexylamine, after adding in a small internal mixer and kneading for 30min, take out the kneaded The material was cooled, placed in a twin-roller, pressed into thin sheets, cooled at room temperature, cut into pieces, and placed in an oven at 120°C for 2 hours for cross-linking to obtain nitrile rubber with a dynamic cross-linked structure. Then take by weighing 20.5g nitrile rubber, 2.25g dic...

Embodiment 2

[0386] In a dry and clean flask, take by weighing 10.8g side groups polyether polyols containing carbamate groups (first add 150g polyoxypropylene triols, catalyst KOH 1.25g in the BUSS formula external circulation reactor, and carry out nitrogen gas Replacement, after heating to 120°C, add 250g of (S)-(oxiranemethyl)carbamate tert-butyl ester to react, and the reaction temperature is controlled at 140-150°C. Under constant temperature conditions, the aging reaction is carried out for 40min, and the reactor When the pressure no longer drops, start to lower the temperature of the reactor material. When the temperature drops to 70°C, add acetic acid for neutralization reaction until the pH of the reaction system is 6.8 to obtain a polyether with a side group containing a carbamate group polyol), add 150mL DMF solvent, heat up to 50°C and stir to dissolve; then add 4.6g of random copolymers containing organic boron chloride groups and isocyanate groups in side groups (using AIBN a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com